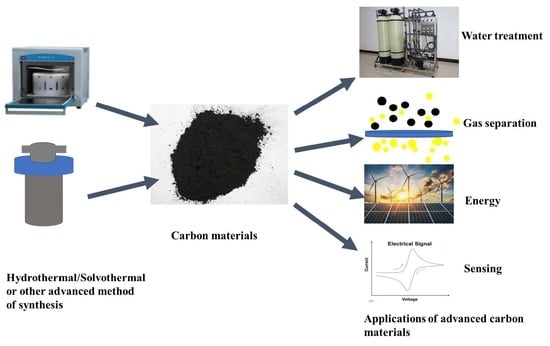

Sustainable Hydrothermal and Solvothermal Synthesis of Advanced Carbon Materials in Multidimensional Applications: A Review

Abstract

:1. Introduction

2. Short Summary of the Development of Advanced Carbon Materials Synthesis Methods and Applications

3. Advanced Synthesis Methods and the Modification of Carbon Materials

3.1. The Arc-Discharge Method

3.2. Chemical Vapour Deposition (CVD)

3.3. Other Strategic Synthesis Methods of Carbon-Based Materials

3.3.1. Sol–Gel Approaches for Water Treatment

3.3.2. Microwave-Assisted Synthesis for Advanced Carbon Materials in Energy and Sensing

4. Conventional Hydrothermal Methods for the Preparation and Modification of Carbon Materials

4.1. Microwave Chemistry for Next-Generation Green Carbon Materials

4.1.1. Hydrothermal Carbonization of Biomass and Other Sustainable Carbon Sources

4.1.2. Combinatorial MWA-HTC and MWA Exfoliation of GO

5. Sustainable Carbon Materials in Nanocomposites for Water Treatment and Gas Purification Sustainable Carbon Materials in Membrane Nanotechnology for Water Treatment

MWAS of Carbon-Based Nanocomposites for Gas Purification

6. Advances in Solvothermal Synthesis Methods for Advanced Carbon Materials in Gas Purification Technologies

7. Solvothermal and Hydrothermal Approaches to Synthesis of Carbon Nanodots for Multiple Applications

7.1. The Sustainable Synthesis of Carbon Nanodots

7.2. Solvothermal Synthesis of CDs

7.3. Hydrothermal Synthesis of CD Composites

8. An Overview of the Various Methods, Advantages, Disadvantages, Properties, and Applications

9. Outlook for Synthesis Methods and Considerations for the Future

10. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Das, J. Small molecules derived carbon dots: Synthesis and applications in sensing, catalysis, imaging, and biomedicine. J. Nanobiotechnol. 2019, 17, 1–24. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.-L.; Zhang, H.; Shao, L.-M.; Lü, F.; He, P.-J. Preparation and Application of Hierarchical Porous Carbon Materials from Waste and Biomass: A Review. Waste Biomass Valorization 2021, 12, 1699–1724. [Google Scholar] [CrossRef]

- Jastrzębski, K.; Kula, P. Emerging Technology for a Green, Sustainable Energy-Promising Materials for Hydrogen Storage, from Nanotubes to Graphene—A Review. Materials 2021, 14, 2499. [Google Scholar] [CrossRef] [PubMed]

- Speranza, G. Carbon Nanomaterials: Synthesis, Functionalization and Sensing Applications. Nanomaterials 2021, 11, 967. [Google Scholar] [CrossRef] [PubMed]

- Ye, H.; Chen, J.; Hu, Y.; Li, G.; Fu, X.-Z.; Zhu, P.; Sun, R.; Wong, C.-P. One-pot synthesis of two-dimensional multilayered graphitic carbon nanosheets by low-temperature hydrothermal carbonization using the in situ formed copper as a template and catalyst. Chem. Commun. 2020, 56, 11645–11648. [Google Scholar] [CrossRef] [PubMed]

- Bundaleska, N.; Henriques, J.; Abrashev, M.; Rego, A.; Ferraria, A.M.; Almeida, A.; Dias, F.M.; Valcheva, E.; Arnaudov, B.; Upadhyay, K.K.; et al. Large-scale synthesis of free-standing N-doped graphene using microwave plasma. Sci. Rep. 2018, 8, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mukai, S. Carbon Gels with Unique Morphologies. Carbon 2013, 55, 373. [Google Scholar] [CrossRef]

- Trovato, V.; Teblum, E.; Kostikov, Y.; Pedrana, A.; Re, V.; Nessim, G.D.; Rosace, G. Sol-gel approach to incorporate millimeter-long carbon nanotubes into fabrics for the development of electrical-conductive textiles. Mater. Chem. Phys. 2020, 240, 122218. [Google Scholar] [CrossRef]

- Manohara, H.M.; Aruchamy, K.; Chakraborty, S.; Radha, N.; Nidhi, M.R.; Ghosh, D.; Nataraj, S.K.; Mondal, D. Sustainable Water Purification Using an Engineered Solvothermal Carbon Based Membrane Derived from a Eutectic System. ACS Sustain. Chem. Eng. 2019, 7, 10143–10153. [Google Scholar] [CrossRef]

- Kurian, M.; Paul, A. Recent trends in the use of green sources for carbon dot synthesis—A short review. Carbon Trends 2021, 3, 100032. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Qureshi, S.S.; Baloch, H.A.; Siddiqui, M.T.H.; Takkalkar, P.; Mubarak, N.M.; Dumbre, D.K.; Griffin, G.J.; Madapusi, S.; Tanksale, A. Microwave Hydrothermal Carbonization of Rice Straw: Optimization of Process Parameters and Upgrading of Chemical, Fuel, Structural and Thermal Properties. Materials 2019, 12, 403. [Google Scholar] [CrossRef] [Green Version]

- Lu, T.; Liu, Y.; Xu, X.; Pan, L.; Alothman, A.A.; Shapter, J.; Wang, Y.; Yamauchi, Y. Highly efficient water desalination by capacitive deionization on biomass-derived porous carbon nanoflakes. Sep. Purif. Technol. 2021, 256, 117771. [Google Scholar] [CrossRef]

- Li, Z.; Yu, P.; Zhong, W.; Zhang, M.; Li, Z.; Cheng, A.; Liang, Y.; Miao, L.; Yang, X.; Zhang, H. Hydrothermal intercalation for the synthesis of novel three-dimensional hierarchically superstructured carbons composed of graphene-like ultrathin nanosheets. Carbon 2021, 176, 1–10. [Google Scholar] [CrossRef]

- Xu, J.-L.; Zhang, X.; Miao, Y.-X.; Wen, M.-X.; Yan, W.-J.; Lu, P.; Wang, Z.-R.; Sun, Q. In-situ plantation of Fe3O4@C nanoparticles on reduced graphene oxide nanosheet as high-performance anode for lithium/sodium-ion batteries. Appl. Surf. Sci. 2021, 546, 149163. [Google Scholar] [CrossRef]

- Ma, F.; Yuan, A.; Xu, J.; Hu, P. Porous α-MoO3/MWCNT Nanocomposite Synthesized via a Surfactant-Assisted Solvothermal Route as a Lithium-Ion-Battery High-Capacity Anode Material with Excellent Rate Capability and Cyclability. ACS Appl. Mater. Interfaces 2015, 7, 15531–15541. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.-X.; Wang, Y.-L.; Jiu, H.-F.; Zheng, W.-H.; Chang, J.-X.; He, G.-F. Controllable synthesis of spinel nano-CoMn2O4 via a solvothermal carbon templating method and its application in lithium ion batteries. Electrochim. Acta 2015, 182, 550–558. [Google Scholar] [CrossRef]

- Huan, C.; Zhao, X.; Xiao, X.; Lu, Y.; Qi, S.; Zhan, Y.; Zhang, L.; Xu, G. One-step solvothermal synthesis of V2O3@C nanoparticles as anode materials for lithium-ion battery. J. Alloy Compd. 2019, 776, 568–574. [Google Scholar] [CrossRef]

- Shandilya, M.; Rai, R.; Singh, J. Review: Hydrothermal technology for smart materials. Adv. Appl. Ceram. 2016, 115, 354–376. [Google Scholar] [CrossRef]

- Yetim, N.K. Hydrothermal synthesis of Co3O4 with different morphology: Investigation of magnetic and electrochemical properties. J. Mol. Struct. 2021, 1226, 129414. [Google Scholar] [CrossRef]

- Siddiqui, M.; Baloch, H.A.; Nizamuddin, S.; Haris, M.; Mubarak, N.; Czajka, M.; Khalid, M.; Griffin, G.; Srinivasan, M. Synthesis of novel magnetic carbon nano-composite from waste biomass: A comparative study of industrially adoptable hydro/solvothermal co-precipitation route. J. Environ. Chem. Eng. 2020, 8, 103519. [Google Scholar] [CrossRef]

- Kuang, Q.; Xie, S.-Y.; Jiang, Z.-Y.; Zhang, X.-H.; Xie, Z.-X.; Huang, R.-B.; Zheng, L.-S. Low temperature solvothermal synthesis of crumpled carbon nanosheets. Carbon 2004, 42, 1737–1741. [Google Scholar] [CrossRef]

- Zhao, Y.-C.; Zhao, L.; Mao, L.-J.; Han, B.-H. One-step solvothermal carbonization to microporous carbon materials derived from cyclodextrins. J. Mater. Chem. A 2013, 1, 9456–9461. [Google Scholar] [CrossRef]

- Liu, C.; Huang, X.; Kong, L. Efficient Low Temperature Hydrothermal Carbonization of Chinese Reed for Biochar with High Energy Density. Energies 2017, 10, 2094. [Google Scholar] [CrossRef] [Green Version]

- Sun, M.-H.; Huang, S.-Z.; Chen, L.-H.; Li, Y.; Yang, X.-Y.; Yuan, Z.-Y.; Su, B.-L. Applications of hierarchically structured porous materials from energy storage and conversion, catalysis, photocatalysis, adsorption, separation, and sensing to biomedicine. Chem. Soc. Rev. 2016, 45, 3479–3563. [Google Scholar] [CrossRef] [PubMed]

- Ndlwana, L.; Sikhwivhilu, K.; Moutloali, R.; Ngila, J.C. Microwave-assisted graft synthesis and characterization of poly(methacrylic acid)-grafted polyethersulfone towards dense hydrophilic and low-fouling membranes for water treatment. Phys. Chem. Earth Parts A/B/C 2018, 106, 107–115. [Google Scholar] [CrossRef]

- Hoang, T.T.; Pham, H.P.; Tran, Q.T. Research Article A Facile Microwave-Assisted Hydrothermal Synthesis of Graphene Quantum Dots for Organic Solar Cell Efficiency Improvement. J. Nanomater. 2020, 2020, 15–17. [Google Scholar] [CrossRef]

- Remya, N.; Lin, J.-G. Current status of microwave application in wastewater treatment—A review. Chem. Eng. J. 2011, 166, 797–813. [Google Scholar] [CrossRef]

- Li, J.; Wu, Q.; Wu, J. Synthesis of Nanoparticles via Solvothermal and Hydrothermal Methods. In Handbook of Nanoparticles; Springer Science and Business Media LLC: Cham, Germany; Berlin, Germany; Brandenburg, Germany, 2015; pp. 1–28. ISBN 978-3-319-13188-7. [Google Scholar]

- Karthik, P.; Himaja, A.; Singh, S.P. Carbon-allotropes: Synthesis methods, applications and future perspectives. Carbon Lett. 2014, 15, 219–237. [Google Scholar] [CrossRef] [Green Version]

- Iijima, S.; Ichihashi, T. Single-shell carbon nanotubes of 1-nm diameter. Nat. Cell Biol. 1993, 363, 603–605. [Google Scholar] [CrossRef]

- Zhao, D.L.; Chung, T.-S. Applications of carbon quantum dots (CQDs) in membrane technologies: A review. Water Res. 2018, 147, 43–49. [Google Scholar] [CrossRef]

- Piaskowski, K.; Zarzycki, P.K. Carbon-Based Nanomaterials as Promising Material for Wastewater Treatment Processes. Int. J. Environ. Res. Public Health 2020, 17, 5862. [Google Scholar] [CrossRef] [PubMed]

- Yi, H.; Huang, D.; Qin, L.; Zeng, G.; Lai, C.; Cheng, M.; Ye, S.; Song, B.; Ren, X.; Guo, X. Selective prepared carbon nanomaterials for advanced photocatalytic application in environmental pollutant treatment and hydrogen production. Appl. Catal. B Environ. 2018, 239, 408–424. [Google Scholar] [CrossRef]

- Xu, D.; Cheng, B.; Wang, W.; Jiang, C.; Yu, J. Ag2CrO4/g-C3N4/graphene oxide ternary nanocomposite Z-scheme photocatalyst with enhanced CO2 reduction activity. Appl. Catal. B Environ. 2018, 231, 368–380. [Google Scholar] [CrossRef]

- Xin, W.; Song, Y. Mesoporous carbons: Recent advances in synthesis and typical applications. RSC Adv. 2015, 5, 83239–83285. [Google Scholar] [CrossRef]

- Lin, L.; Wang, Y.; Xiao, Y.; Liu, W. Hydrothermal synthesis of carbon dots codoped with nitrogen and phosphorus as a turn-on fluorescent probe for cadmium(II). Microchim. Acta 2019, 186, 147. [Google Scholar] [CrossRef]

- Kratschmer, W.; Lamb, L.D.; Fostiropoulos, K.; Huffman, D.R. Solid C60: A new form of carbon. Nat. Cell Biol. 1990, 347, 354–358. [Google Scholar] [CrossRef]

- Li, N.; Wang, Z.; Zhao, K.; Shi, Z.; Gu, Z.; Xu, S. Large scale synthesis of N-doped multi-layered graphene sheets by simple arc-discharge method. Carbon 2010, 48, 255–259. [Google Scholar] [CrossRef]

- Sharma, R.; Sharma, A.K.; Sharma, V. Synthesis of carbon nanotubes by arc-discharge and chemical vapor deposition method with analysis of its morphology, dispersion and functionalization characteristics. Cogent Eng. 2015, 2, 1094017. [Google Scholar] [CrossRef]

- Pham, T.V.; Kim, J.; Jung, J.Y.; Kim, J.H.; Cho, H.; Seo, T.H.; Lee, H.; Kim, N.D.; Kim, M.J. High Areal Capacitance of N-Doped Graphene Synthesized by Arc Discharge. Adv. Funct. Mater. 2019, 29, 1905511. [Google Scholar] [CrossRef]

- Wang, C.; Lu, Z.; Ma, J.; Chen, X.; Yang, C.; Xia, W. Pressure-dependent synthesis of graphene nanoflakes using Ar/H2/CH4 non-thermal plasma based on rotating arc discharge. Diam. Relat. Mater. 2021, 111, 108176. [Google Scholar] [CrossRef]

- Sun, L.; Yuan, G.; Gao, L.; Yang, J.; Chhowalla, M.; Gharahcheshmeh, M.H.; Gleason, K.K.; Choi, Y.S.; Hong, B.H.; Liu, Z. Chemical vapour deposition. Nat. Rev. Methods Prim. 2021, 1, 1–20. [Google Scholar] [CrossRef]

- Dissanayake, D.M.N.M.; Ashraf, A.; Dwyer, D.; Kisslinger, K.; Zhang, L.; Pang, Y.; Efstathiadis, H.; Eisaman, M.D. Spontaneous and strong multi-layer graphene n-doping on soda-lime glass and its application in graphene-semiconductor junctions. Sci. Rep. 2016, 6, 21070. [Google Scholar] [CrossRef] [Green Version]

- Tan, H.; Wang, D.; Guo, Y. A Strategy to Synthesize Multilayer Graphene in Arc-Discharge Plasma in a Semi-Opened Environment. Materials 2019, 12, 2279. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hlongwa, N.W.; Ikpo, C.O.; Ndipingwi, M.M.; Nolly, C.; Raleie, N.; Dywili, N.; Iwuoha, E.I. Graphene-functionalised Olivine Lithium Manganese Phosphate Derivatives for High Performance Lithium-ion Capacitors. Electroanalysis 2020, 32, 2812–2826. [Google Scholar] [CrossRef]

- Mamba, G.; Mbianda, X.Y.; Mishra, A. Gadolinium oxide decorated multiwalled carbon nanotube/tridoped titania nanocomposites for improved dye degradation under simulated solar light irradiation. Mater. Res. Bull. 2016, 75, 59–70. [Google Scholar] [CrossRef]

- Mamba, G.; Mbianda, X.; Mishra, A. Enhanced visible light photocatalytic degradation of eriochrome black T and eosin blue shade in water using tridoped titania decorated on SWCNTs and MWCNTs: Effect of the type of carbon nanotube incorporated. Mater. Chem. Phys. 2015, 149-150, 734–742. [Google Scholar] [CrossRef]

- Escamilla, J.C.; Hidalgo-Carrillo, J.; Martín-Gómez, J.; Estévez-Toledano, R.C.; Montes, V.; Cosano, D.; Urbano, F.J.; Marinas, A. Hydrogen Production through Glycerol Photoreforming on TiO2/Mesoporous Carbon: Influence of the Synthetic Method. Materials 2020, 13, 3800. [Google Scholar] [CrossRef]

- Khavlyuk, P.D.; Stepanidenko, E.A.; Bondarenko, D.P.; Danilov, D.V.; Koroleva, A.V.; Baranov, A.V.; Maslov, V.G.; Kasak, P.; Fedorov, A.V.; Ushakova, E.V.; et al. The influence of thermal treatment conditions (solvothermal versus microwave) and solvent polarity on the morphology and emission of phloroglucinol-based nitrogen-doped carbon dots. Nanoscale 2021, 13, 3070–3078. [Google Scholar] [CrossRef]

- Chae, A.; Choi, Y.; Jo, S.; Nur’Aeni, N.; Paoprasert, P.; Park, S.Y.; In, I. Microwave-assisted synthesis of fluorescent carbon quantum dots from an A2/B3 monomer set. RSC Adv. 2017, 7, 12663–12669. [Google Scholar] [CrossRef] [Green Version]

- Vakili, R.; Xu, S.; Al-Janabi, N.; Gorgojo, P.; Holmes, S.M.; Fan, X. Microwave-assisted synthesis of zirconium-based metal organic frameworks (MOFs): Optimization and gas adsorption. Microporous Mesoporous Mater. 2018, 260, 45–53. [Google Scholar] [CrossRef]

- Glover, T.G.; Mu, B.; Mu, B. Gas Adsorption in Metal-Organic Frameworks: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2018; ISBN 978-0-429-46977-0. [Google Scholar]

- Chai, X.; He, H.; Fan, H.; Kang, X.; Song, X. A hydrothermal-carbonization process for simultaneously production of sugars, graphene quantum dots, and porous carbon from sugarcane bagasse. Bioresour. Technol. 2019, 282, 142–147. [Google Scholar] [CrossRef]

- Yuan, M.; Zhong, R.; Gao, H.; Li, W.; Yun, X.; Liu, J.; Zhao, X.; Zhao, G.; Zhang, F. One-step, green, and economic synthesis of water-soluble photoluminescent carbon dots by hydrothermal treatment of wheat straw, and their bio-applications in labeling, imaging, and sensing. Appl. Surf. Sci. 2015, 355, 1136–1144. [Google Scholar] [CrossRef]

- Zhang, J.; An, Y.; Borrion, A.; He, W.; Wang, N.; Chen, Y.; Li, G. Process characteristics for microwave assisted hydrothermal carbonization of cellulose. Bioresour. Technol. 2018, 259, 91–98. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gao, Y.; Liu, Y.; Zhu, G.; Xu, J.; Xu, H.; Yuan, Q.; Zhu, Y.; Sarma, J.; Wang, Y.; Wang, J.; et al. Microwave-assisted hydrothermal carbonization of dairy manure: Chemical and structural properties of the products. Energy 2018, 165, 662–672. [Google Scholar] [CrossRef]

- Elaigwu, S.E.; Greenway, G.M. Chemical, structural and energy properties of hydrochars from microwave-assisted hydrothermal carbonization of glucose. Int. J. Ind. Chem. 2016, 7, 449–456. [Google Scholar] [CrossRef] [Green Version]

- Adolfsson, K.H.; Lin, C.-F.; Hakkarainen, M. Microwave Assisted Hydrothermal Carbonization and Solid State Postmodification of Carbonized Polypropylene. ACS Sustain. Chem. Eng. 2018, 6, 11105–11114. [Google Scholar] [CrossRef]

- Lyu, J.; Wen, X.; Kumar, U.; You, Y.; Chen, V.; Joshi, R.K. Separation and purification using GO and r-GO membranes. RSC Adv. 2018, 8, 23130–23151. [Google Scholar] [CrossRef] [Green Version]

- Jakhar, R.; Yap, J.E.; Joshi, R. Microwave reduction of graphene oxide. Carbon 2020, 170, 277–293. [Google Scholar] [CrossRef]

- Luo, L.; Zhou, Y.; Yan, W.; Wu, X.; Wang, S.; Zhao, W. Two-step synthesis of B and N co-doped porous carbon composites by microwave-assisted hydrothermal and pyrolysis process for supercapacitor application. Electrochim. Acta 2020, 360, 137010. [Google Scholar] [CrossRef]

- Gupta, O.; Roy, S.; Mitra, S. Microwave Induced Membrane Distillation for Enhanced Ethanol–Water Separation on a Carbon Nanotube Immobilized Membrane. Ind. Eng. Chem. Res. 2019, 58, 18313–18319. [Google Scholar] [CrossRef]

- Ashfaq, M.Y.; Al-Ghouti, M.A.; Zouari, N. Functionalization of reverse osmosis membrane with graphene oxide and polyacrylic acid to control biofouling and mineral scaling. Sci. Total Environ. 2020, 736, 139500. [Google Scholar] [CrossRef]

- Kovtun, A.; Zambianchi, M.; Bettini, C.; Liscio, A.; Gazzano, M.; Corticelli, F.; Treossi, E.; Navacchia, M.L.; Palermo, V.; Melucci, M. Graphene oxide–polysulfone filters for tap water purification, obtained by fast microwave oven treatment. Nanoscale 2019, 11, 22780–22787. [Google Scholar] [CrossRef] [Green Version]

- Hossain, N.; Nizamuddin, S.; Griffin, G.; Selvakannan, P.; Mubarak, N.M.; Mahlia, T.M.I. Synthesis and characterization of rice husk biochar via hydrothermal carbonization for wastewater treatment and biofuel production. Sci. Rep. 2020, 10, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Grossman, E. Chasing Molecules: Poisonous Products, Human Health, and the Promise of Green Chemistry; Island Press/Center for Resource Economics: Washington, DC, USA, 2012. [Google Scholar]

- Jacquot, J.-P. History and Philosophy of Biology. By Robert Kretsinger. World Scientific, 2015. pp. 364. Price GBP 38.00. ISBN 9789814635042. Acta Crystallogr. Sect. D Biol. Crystallogr. 2015, 71, 2362–2363. [Google Scholar] [CrossRef] [Green Version]

- Kiat, J.H. Nanomaterials in Energy Devices; CRC Press: Boca Raton, FL, USA, 2017; ISBN 978-1-315-15344-5. [Google Scholar]

- Hunt, C. The construction of gas-works. (Including plate at back of volume). In Minutes of the Proceedings of the Institution of Civil Engineers; ICE Virtual Library: London, UK, 1894; Volume 117, pp. 208–229. [Google Scholar]

- Kumar, A.; Kuang, Y.; Liang, Z.; Sun, X. Microwave chemistry, recent advancements, and eco-friendly microwave-assisted synthesis of nanoarchitectures and their applications: A review. Mater. Today Nano 2020, 11, 100076. [Google Scholar] [CrossRef]

- Sharma, R.K.; Yadav, S.; Gupta, R.; Arora, G. Synthesis of Magnetic Nanoparticles Using Potato Extract for Dye Degradation: A Green Chemistry Experiment. J. Chem. Educ. 2019, 96, 3038–3044. [Google Scholar] [CrossRef]

- Hauser, A.W.; Schwerdtfeger, P. Methane-selective nanoporous graphene membranes for gas purification. Phys. Chem. Chem. Phys. 2012, 14, 13292. [Google Scholar] [CrossRef] [PubMed]

- Goh, P.S.; Wong, K.C.; Yogarathinam, L.T.; Ismail, A.F.; Abdullah, M.S.; Ng, B.C. Surface Modifications of Nanofillers for Carbon Dioxide Separation Nanocomposite Membrane. Symmetry 2020, 12, 1102. [Google Scholar] [CrossRef]

- Sazali, N. A review of the application of carbon-based membranes to hydrogen separation. J. Mater. Sci. 2020, 55, 11052–11070. [Google Scholar] [CrossRef]

- Ding, J.; Li, X.; Wang, X.; Zhang, J.; Yu, D.-G.; Qiu, B. Fabrication of Vertical Array CNTs/Polyaniline Composite Membranes by Microwave-Assisted In Situ Polymerization. Nanoscale Res. Lett. 2015, 10, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Kaygusuz, K. Energy and environmental issues relating to greenhouse gas emissions for sustainable development in Turkey. Renew. Sustain. Energy Rev. 2009, 13, 253–270. [Google Scholar] [CrossRef]

- Huaman, R.N.E.; Jun, T.X. Energy related CO2 emissions and the progress on CCS projects: A review. Renew. Sustain. Energy Rev. 2014, 31, 368–385. [Google Scholar] [CrossRef]

- Yeo, Z.Y.; Chew, T.L.; Zhu, P.W.; Mohamed, A.R.; Chai, S.-P. Conventional processes and membrane technology for carbon dioxide removal from natural gas: A review. J. Nat. Gas Chem. 2012, 21, 282–298. [Google Scholar] [CrossRef]

- Kazmi, B.; Haider, J.; Qyyum, M.A.; Saeed, S.; Kazmi, M.R.; Lee, M. Heating load depreciation in the solvent-regeneration step of absorption-based acid gas removal using an ionic liquid with an imidazolium-based cation. Int. J. Greenh. Gas Control. 2019, 87, 89–99. [Google Scholar] [CrossRef]

- Demazeau, G. Solvothermal reactions: An original route for the synthesis of novel materials. J. Mater. Sci. 2008, 43, 2104–2114. [Google Scholar] [CrossRef] [Green Version]

- Kalam, A.; Al-Sehemi, A.; Assiri, M.; Du, G.; Ahmad, T.; Ahmad, I.; Pannipara, M. Modified solvothermal synthesis of cobalt ferrite (CoFe2O4) magnetic nanoparticles photocatalysts for degradation of methylene blue with H2O2/visible light. Results Phys. 2018, 8, 1046–1053. [Google Scholar] [CrossRef]

- Pahinkar, D.G.; Garimella, S. A novel temperature swing adsorption process for natural gas purification: Part I, model development. Sep. Purif. Technol. 2018, 203, 124–142. [Google Scholar] [CrossRef]

- Choudhury, P.; Uday, U.S.P.; Mahata, N.; Tiwari, O.N.; Ray, R.N.; Bandyopadhyay, T.K.; Bhunia, B. Performance improvement of microbial fuel cells for waste water treatment along with value addition: A review on past achievements and recent perspectives. Renew. Sustain. Energy Rev. 2017, 79, 372–389. [Google Scholar] [CrossRef]

- Wiheeb, A.D.; Shamsudin, I.K.; Ahmad, M.A.; Murat, M.N.; Kim, J.; Othman, M.R. Present technologies for hydrogen sulfide removal from gaseous mixtures. Rev. Chem. Eng. 2013, 29, 449. [Google Scholar] [CrossRef]

- Zhao, D.; Liu, X.; Zhang, R.; Liao, L.; Xiao, X.; Cheng, H.; Zhang, Z.; Zhang, R. Synthesis of Multicolor Carbon Dots Based on Solvent Control and Its Application in the Detection of Crystal Violet. Nanomaterials 2019, 9, 1556. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, G.-Q.; Wan, M.-X.; Huang, Z.-H.; Kang, F.-Y. Preparation of graphene/metal-organic composites and their adsorption performance for benzene and ethanol. New Carbon Mater. 2015, 30, 566–571. [Google Scholar] [CrossRef]

- Zhao, P.; Li, X.; Baryshnikov, G.; Wu, B.; Ågren, H.; Zhang, J.; Zhu, L. One-step solvothermal synthesis of high-emissive amphiphilic carbon dots via rigidity derivation. Chem. Sci. 2018, 9, 1323–1329. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jin, Z.; Dong, Y.; Dong, N.; Yang, Z.; Wang, Q.; Lei, Z.; Su, B. One-step synthesis of magnetic nanocomposite Fe3O4/C based on the waste chicken feathers by a green solvothermal method. Mater. Lett. 2017, 186, 322–325. [Google Scholar] [CrossRef]

- Han, X.; Qu, Y.; Wu, J.; Li, D.; Ren, N.; Feng, Y. Nitric oxide reduction by microbial fuel cell with carbon based gas diffusion cathode for power generation and gas purification. J. Hazard. Mater. 2020, 399, 122878. [Google Scholar] [CrossRef]

- Liu, Y.; Xiang, M.; Hong, L. Three-dimensional nitrogen and boron codoped graphene for carbon dioxide and oils adsorption. RSC Adv. 2017, 7, 6467–6473. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Wang, B.; Yu, X.; Li, J.; Shang, J.; Yu, J. Carbon Dots in Porous Materials: Host–Guest Synergy for Enhanced Performance. Angew. Chem. Int. Ed. 2020, 59, 19390–19402. [Google Scholar] [CrossRef]

- Zheng, L.; Chi, Y.; Dong, Y.; Lin, J.; Wang, B. Electrochemiluminescence of Water-Soluble Carbon Nanocrystals Released Electrochemically from Graphite. J. Am. Chem. Soc. 2009, 131, 4564–4565. [Google Scholar] [CrossRef]

- Li, J.; Wang, B.; Zhang, H.; Yu, J. Carbon Dots-in-Matrix Boosting Intriguing Luminescence Properties and Applications. Small 2019, 15, e1805504. [Google Scholar] [CrossRef]

- Liu, H.; Ye, T.; Mao, C. Fluorescent Carbon Nanoparticles Derived from Candle Soot. Angew. Chem. Int. Ed. 2007, 46, 6473–6475. [Google Scholar] [CrossRef]

- Long, C.; Jiang, Z.; Shangguan, J.; Qing, T.; Zhang, P.; Feng, B. Applications of carbon dots in environmental pollution control: A review. Chem. Eng. J. 2021, 406, 126848. [Google Scholar] [CrossRef]

- Liu, R.; Wu, D.; Liu, S.; Koynov, K.; Knoll, W.; Li, Q. An Aqueous Route to Multicolor Photoluminescent Carbon Dots Using Silica Spheres as Carriers. Angew. Chem. Int. Ed. 2009, 48, 4598–4601. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Li, Y. Colloidal Carbon Spheres and Their Core/Shell Structures with Noble-Metal Nanoparticles. Angew. Chem. Int. Ed. 2004, 43, 597–601. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Kang, Z.; Liu, Y.; Lee, S.-T. Carbon nanodots: Synthesis, properties and applications. J. Mater. Chem. 2012, 22, 24230–24253. [Google Scholar] [CrossRef]

- Ming, H.; Ma, Z.; Liu, Y.; Pan, K.; Yu, H.; Wang, F.; Kang, Z. Large scale electrochemical synthesis of high quality carbon nanodots and their photocatalytic property. Dalton Trans. 2012, 41, 9526–9531. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Wang, N.; Yu, Y.; Yan, Y.; Zhang, H.; Li, J.; Yu, J. Carbon dots in zeolites: A new class of thermally activated delayed fluorescence materials with ultralong lifetimes. Sci. Adv. 2017, 3, e1603171. [Google Scholar] [CrossRef] [Green Version]

- Yao, C.; Xu, Y.; Xia, Z. A carbon dot-encapsulated UiO-type metal organic framework as a multifunctional fluorescent sensor for temperature, metal ion and pH detection. J. Mater. Chem. C 2018, 6, 4396–4399. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, X.; Li, Y.; Wang, Z.; Yang, F.; Yang, X. Microwave synthesis of fluorescent carbon nanoparticles with electrochemiluminescence properties. Chem. Commun. 2009, 5118–5120. [Google Scholar] [CrossRef] [PubMed]

- Zhai, X.; Zhang, P.; Liu, C.; Bai, T.; Li, W.; Dai, L.; Liu, W. Highly luminescent carbon nanodots by microwave-assisted pyrolysis. Chem. Commun. 2012, 48, 7955–7957. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Zhao, D.; Chen, X.; Wang, F.; Song, H.; Shen, D. Long lifetime pure organic phosphorescence based on water soluble carbon dots. Chem. Commun. 2013, 49, 5751–5753. [Google Scholar] [CrossRef]

- Green, D.C.; Holden, M.A.; Levenstein, M.A.; Zhang, S.; Johnson, B.R.G.; de Pablo, J.G.; Ward, A.; Botchway, S.W.; Meldrum, F.C. Controlling the fluorescence and room-temperature phosphorescence behaviour of carbon nanodots with inorganic crystalline nanocomposites. Nat. Commun. 2019, 10, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Kong, B.; Tang, J.; Zhang, Y.; Jiang, T.; Gong, X.; Peng, C.; Wei, J.; Yang, J.; Wang, Y.; Wang, X.; et al. Incorporation of well-dispersed sub-5-nm graphitic pencil nanodots into ordered mesoporous frameworks. Nat. Chem. 2016, 8, 171–178. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Mu, Y.; Zhang, H.; Shi, H.; Chen, G.; Yu, Y.; Yang, Z.; Li, J.; Yu, J. Red Room-Temperature Phosphorescence of CDs@Zeolite Composites Triggered by Heteroatoms in Zeolite Frameworks. ACS Central Sci. 2019, 5, 349–356. [Google Scholar] [CrossRef] [PubMed]

- Zuo, J.; Jiang, T.; Zhao, X.; Xiong, X.; Xiao, S.; Zhu, Z. Preparation and Application of Fluorescent Carbon Dots. J. Nanomater. 2015, 2015, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Chen, R.; Zhai, S.; Lu, W.; Wei, J.; Xu, J.; Lu, A.; Jiang, H. Facile one-pot solvothermal synthesis of magnetic mesoporous carbon for the efficient adsorption of methyl orange. Environ. Sci. Pollut. Res. 2020, 27, 8248–8259. [Google Scholar] [CrossRef] [PubMed]

- Xiong, C.; Li, B.; Duan, C.; Dai, L.; Nie, S.; Qin, C.; Xu, Y.; Ni, Y. Carbonized wood cell chamber-reduced graphene oxide@PVA flexible conductive material for supercapacitor, strain sensing and moisture-electric generation applications. Chem. Eng. J. 2021, 418, 129518. [Google Scholar] [CrossRef]

- Xu, H.; Xie, L.; Hakkarainen, M. Coffee-Ground-Derived Quantum Dots for Aqueous Processable Nanoporous Graphene Membranes. ACS Sustain. Chem. Eng. 2017, 5, 5360–5367. [Google Scholar] [CrossRef]

- Voiry, D.; Yang, J.; Kupferberg, J.; Fullon, R.R.; Lee, C.; Jeong, H.Y.; Shin, H.S.; Chhowalla, M. High-quality graphene via microwave reduction of solution-exfoliated graphene oxide. Science 2016, 353, 1413–1416. [Google Scholar] [CrossRef] [Green Version]

- Xiong, C.; Li, B.; Liu, H.; Zhao, W.; Duan, C.; Wu, H.; Ni, Y. A smart porous wood-supported flower-like NiS/Ni conjunction with vitrimer co-effect as a multifunctional material with reshaping, shape-memory, and self-healing properties for applications in high-performance supercapacitors, catalysts, and sensors. J. Mater. Chem. A 2020, 8, 10898–10908. [Google Scholar] [CrossRef]

| Method | Precursors | Conditions | Product | Properties | Advantages (A)/Disadvantages (D) | Application/s |

|---|---|---|---|---|---|---|

| MWA-HTC [50] | Succinic acid (SA), tris(2-aminoethyl)amine (TAEA) | 700 W, 3–5 min in water | CQDs | Spherical, photoluminescent | D: Household MW–caution against chemical fume exposure. A: Easy, fast. Small, uniform QD size, high sensitivity, selectivity | Drug delivery, bioimaging, photo/electrocatalysis |

| Freeze-drying and thermal treatment [110] | GO, wood, polyvinyl acrylate (PVA) 1400 | Various followed by carbonisation (400 °C, 30 min; 300 °C, 2 h) | Carbonised wood cell chamber (CWCC)-rGO@PVA | Flexibility, 3D porous structure, layered, high surface areas, capacitive, adsorptive | A: Simple method; stable nanocomposite; enhanced textural properties; high energy densities; high specific capacitance; good electrochemical performance D: Multiple treatment steps | Supercapacitors, batteries, sensors |

| PECVD [43] | SiO2, graphene | Various temperatures (140–160 °C) | Graphene/soda lime glass. | Semiconducting | D: complicated process-many steps/conditions. A: Scalable, cheap. | Electronics, batteries, sensors, photovoltaics, etc. |

| Solvothermal synthesis [110] | Pluronic P123 template, Fe salt, chitosan | Calcination, 700–900 °C, 12 h | Fe3O4/C (magnetic mesoporous carbon (M MC) | Spherical particles, magnetic, adsorptive. | D: High calcination temperatures. A: Efficient dye adsorption. A: Highly adsorptive material | Adsorbent for environmental remediation |

| MWA-HTC [58] | SiC, waste PP | 210–250 °C, 20–80 min | Amorphous C and SiC/C | Semi-crystalline particles | D: Use of harsh chemicals. A: Upcycling; easy and fast methods | Potential applications in agriculture, catalysis, adsorption, electrochemistry, etc. |

| MWA-HTC [111] | Coffee grounds, | 180 °C, 40 bar in water | QDs | Particles 6 nm in size, spherical, crystalline | A: Scalable, fast; small and uniform particle size | Removal of dyes in water using nanoporous graphene membranes |

| Sol–gel with thermal treatment [48] | MC, TiO2, Ti(OC3H7)4, | Calcination at 400 °C, 2 h | TiO2/MC | Crystalline; homogeneous dispersion of TiO2 on MC; photocatalytic | A: Improved speeds; lower temperatures; enhanced textural properties | Hydrogen production |

| Non-thermal plasma arc-discharge [41] | CH4 | Ar/H2 plasma, ambient temperature, 20–200 kPa, 200 W, 30 min | Graphene nanoflakes | High surface areas, high crystallinity, small particle size; high thermal stability | A: Rapid, low energy consumption; ambient operating temperatures, | A wide window of potential applications |

| MWA-HTC vs. HTS [56] | Dairy manure | 240 °C, 4 h in water | Biochar | Graphene-like lamellar structure; microspheres | A: Improved structures over HTC; high yields, green method; value-added by-products | Possible applications in supercapacitors and adsorption of dyes in water |

| HTC [54] | Wheat straw | 250 °C, 10 h in water, | CDs | Amorphous structure, nanospheres, photoluminescence | A: Water soluble CDs, D: Long reactions | Sensing, bio-imaging, imaging of inorganic ions; fluorescent inks, etc. |

| Solvothermal [87] | 1-[bis(dimethylamino)methylene]- 1H-1,2,3-triazolo [4,5-b]pyridinium 3-oxide hexafluorophosphate (HATU), 1-benzylimidazole, 1 mL diisopropylamine, AlCl3·6H2O | 150 °C, 8 h | Amphiphilic CDs (ACDs) | Small (2–5 nm), monodisperse, spherical, crystalline nanoparticles; photoluminescence | A: One-step reaction; facile method; high quantum yields (QY); low toxicity | Bioimaging, optoelectronics |

| MWA-LTH vs. oven heating [64] | Polysulfone (PSU) scraps, GO | 70 °C, 45 min, dry conditions | PSU-GO-OV (oven); PSU-GO-MW (MW) | Layered GO on PSU | A: Low temperatures, green, fast, upcycling, stable, adsorptive, reusable, recovery of adsorbent. PSU-GO-MW—better properties than PSU-GO-OV. | Adsorption of dyes from water |

| Solvothermal [86] | GO, ZnNO3·6H2O, 1,4-benzene-dicarboxylate, | 120 °C, 25 h in DMF, CHCl3 | GO/MOF | Microporous to mesoporous, high surface areas, adsorptive | A: High adsorption capacities. D: Long reactions; use of toxic chemicals | Adsorption of volatile organic compounds (VOCs) |

| Solvothermal [88] | Waste chicken feathers (CF), Fe(NO3)3·9H2O | 200 °C, 30 h in EtOh | Fe3O4/CF | Magnetic, adsorptive | A: Simple, green reactions, D: Long reactions | Potential adsorbent for environmental pollutants from water |

| MWA dry reduction and annealing [112] | GO, CaCl2, | 1. Mild reduction: 300 °C, 1 h under Ar 2. Annealing: 1–2 s under Ar | rGO | Single layer rGO | A: Highly ordered structures; | Oxygen evolution reactions |

| STC [113] | Wood (lignin-free), NiCl2·9H2O, TAEA, Bis-cyclic carbonate | Polymerisation, and vitrimization (25 °C, DMSO) | Carbonised wood/Ni/Nis | Structurally improved wood; flower-like morphology of Ni/Nis | A: Sustainable biomass; good dispersion of the nanoNi/NiS; high power densities; Enhanced conductivity; cycling stability; high energy densities; self-healing; etc. | CO2 reduction to Ch3OH; supercapacitors, etc. |

| Solvothermal vs. MWA-STC [49] | Phloroglucinol, DMF, EDA, FA | S: 160 °C, 6 h; M: 700 W, 6 min | N-CDs | Amorphous, carbonised, to onion-like structures depending on solvent. | (S) D: Time-consuming. (M) A: highly rapid synthesis speeds | Potential is catalysis, optoelectronics, etc. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ndlwana, L.; Raleie, N.; Dimpe, K.M.; Ogutu, H.F.; Oseghe, E.O.; Motsa, M.M.; Msagati, T.A.M.; Mamba, B.B. Sustainable Hydrothermal and Solvothermal Synthesis of Advanced Carbon Materials in Multidimensional Applications: A Review. Materials 2021, 14, 5094. https://doi.org/10.3390/ma14175094

Ndlwana L, Raleie N, Dimpe KM, Ogutu HF, Oseghe EO, Motsa MM, Msagati TAM, Mamba BB. Sustainable Hydrothermal and Solvothermal Synthesis of Advanced Carbon Materials in Multidimensional Applications: A Review. Materials. 2021; 14(17):5094. https://doi.org/10.3390/ma14175094

Chicago/Turabian StyleNdlwana, Lwazi, Naledi Raleie, Kgogobi M. Dimpe, Hezron F. Ogutu, Ekemena O. Oseghe, Mxolisi M. Motsa, Titus A.M. Msagati, and Bhekie B. Mamba. 2021. "Sustainable Hydrothermal and Solvothermal Synthesis of Advanced Carbon Materials in Multidimensional Applications: A Review" Materials 14, no. 17: 5094. https://doi.org/10.3390/ma14175094