Types of Component Interfaces in Metal Matrix Composites on the Example of Magnesium Matrix Composites

Abstract

:1. Introduction

2. Materials and Methods

- Technically pure magnesium matrix composite with SiC particles and Ti particles,

- AM50 magnesium matrix alloy with SiC particles,

- AME505 magnesium matrix alloy with Ti particles,

- ME3 magnesium matrix alloy with SiC particles,

- AZ91 magnesium matrix alloy with as-received (uncoated) aluminosilicate cenospheres,

- AZ91 magnesium matrix alloy with Ni–P-coated aluminosilicate cenospheres and initially heated at 773 K,

- AZ91 magnesium matrix alloy with Ni–P-coated aluminosilicate cenospheres.

3. Results and Discussion

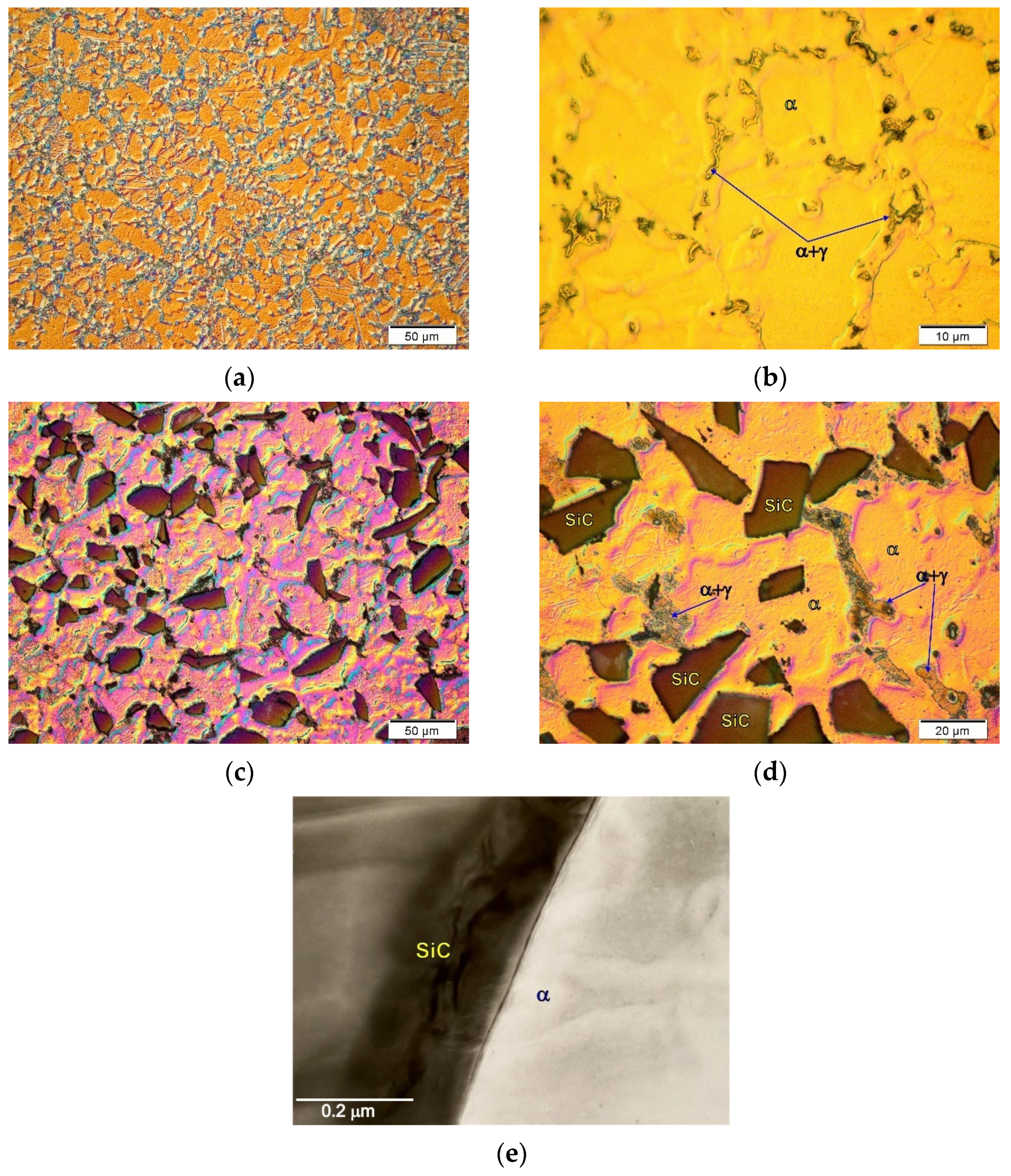

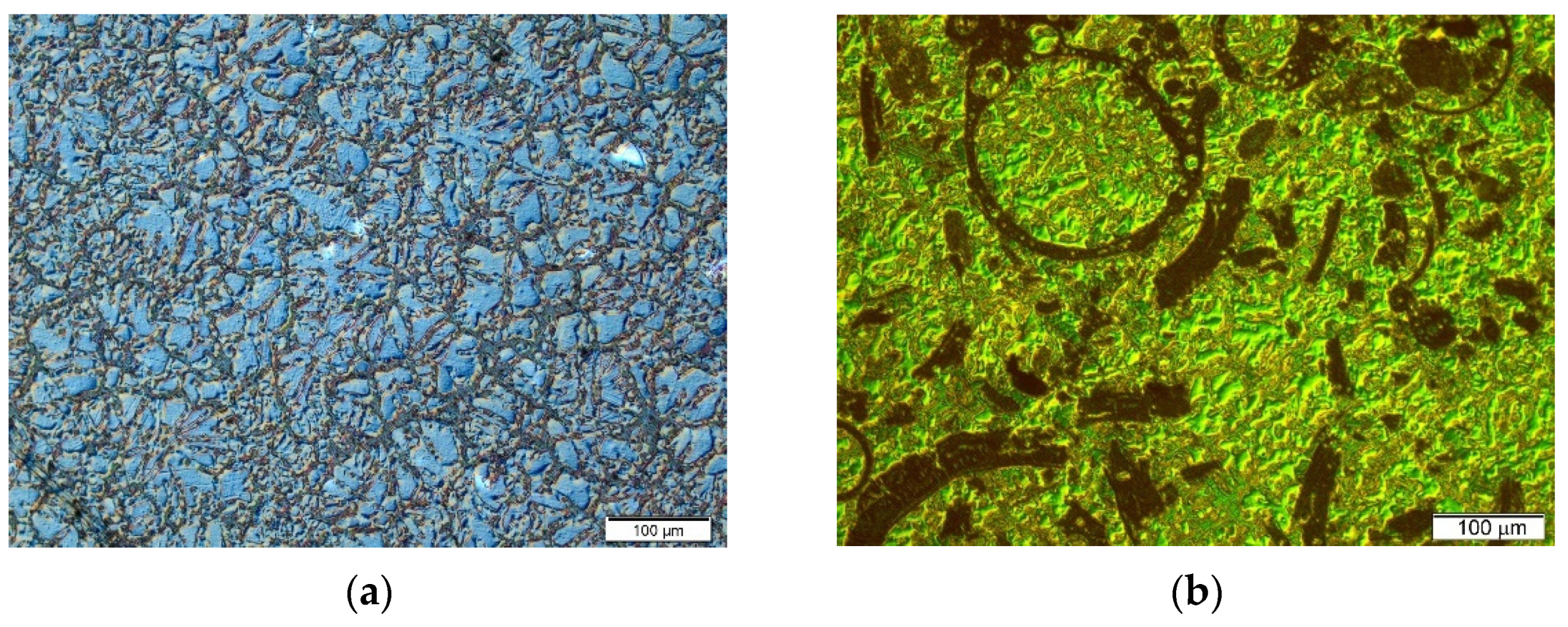

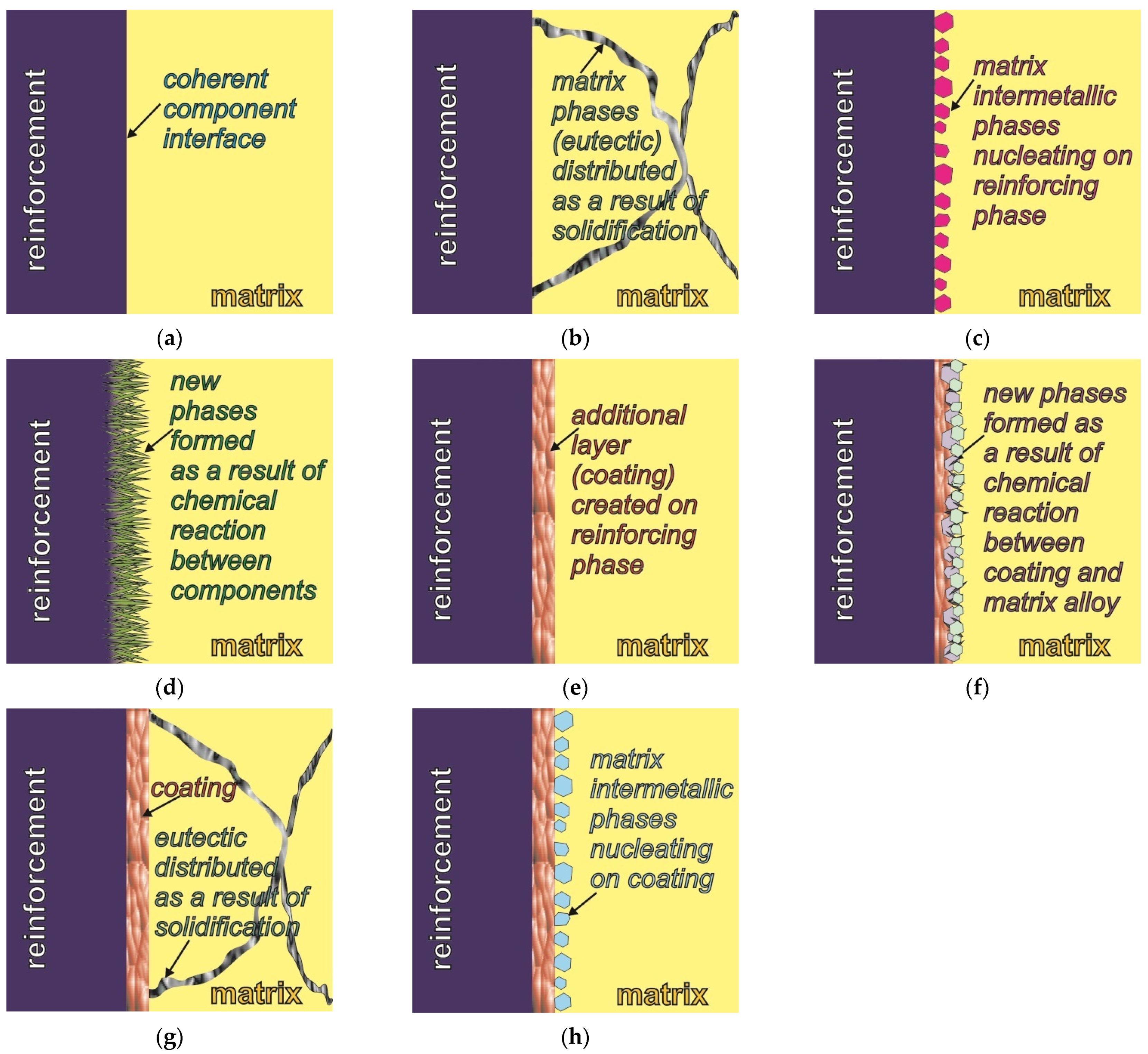

3.1. Coherent Interfaces between Components

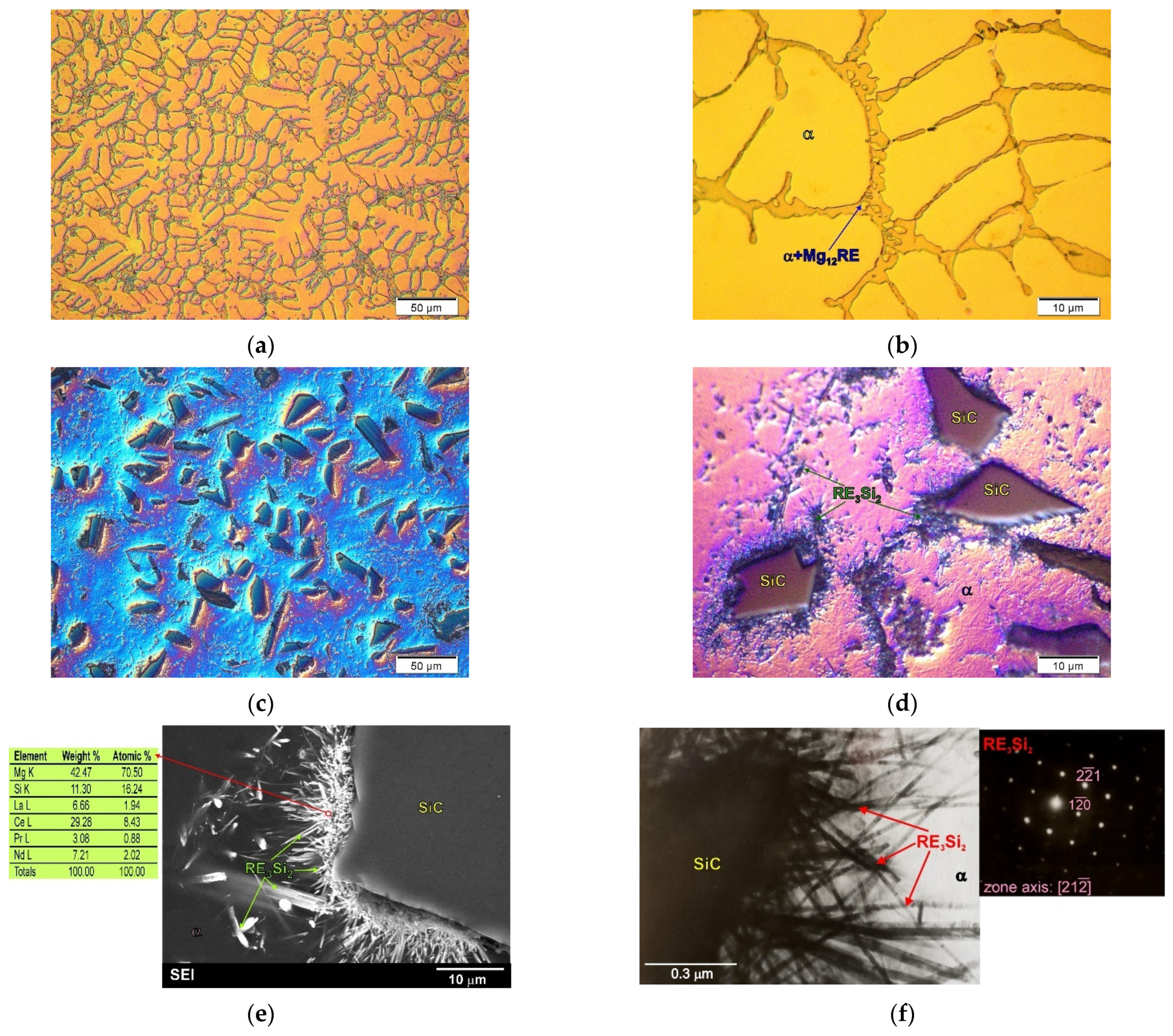

Eutectics Distributed During Solidification

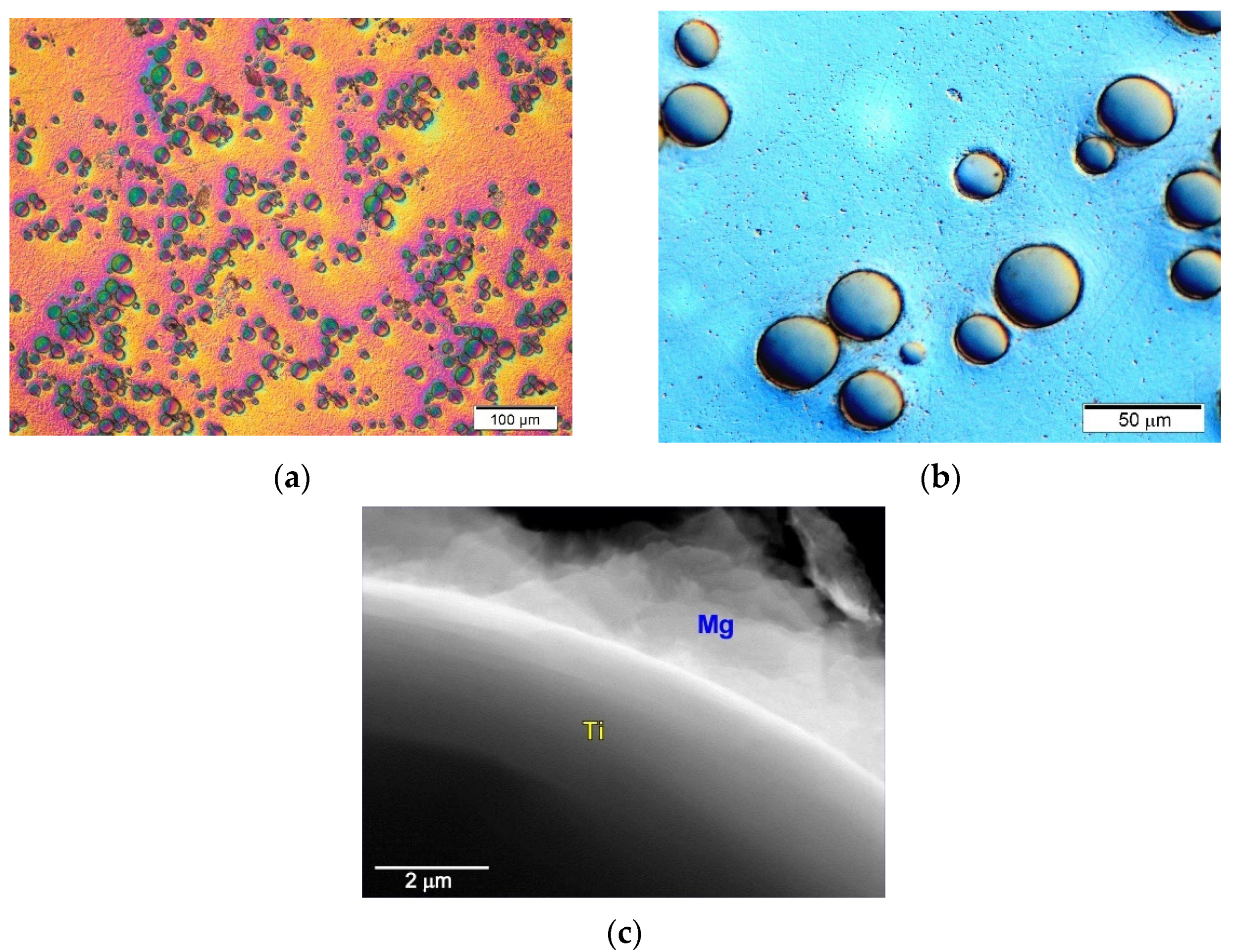

3.2. Nucleation of Matrix Phases on Reinforcement

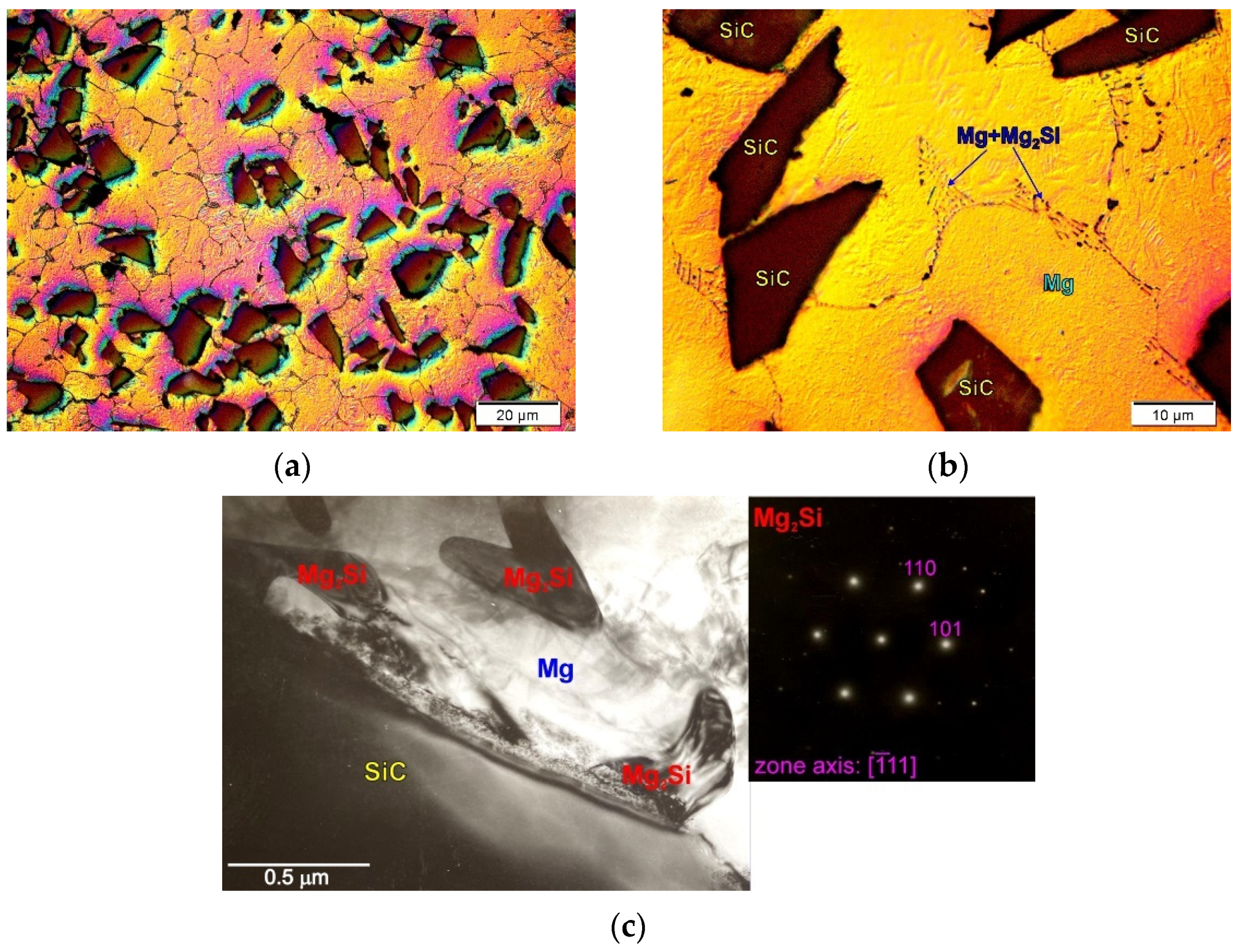

3.3. Reactions between Reinforcement and Matrix Alloy

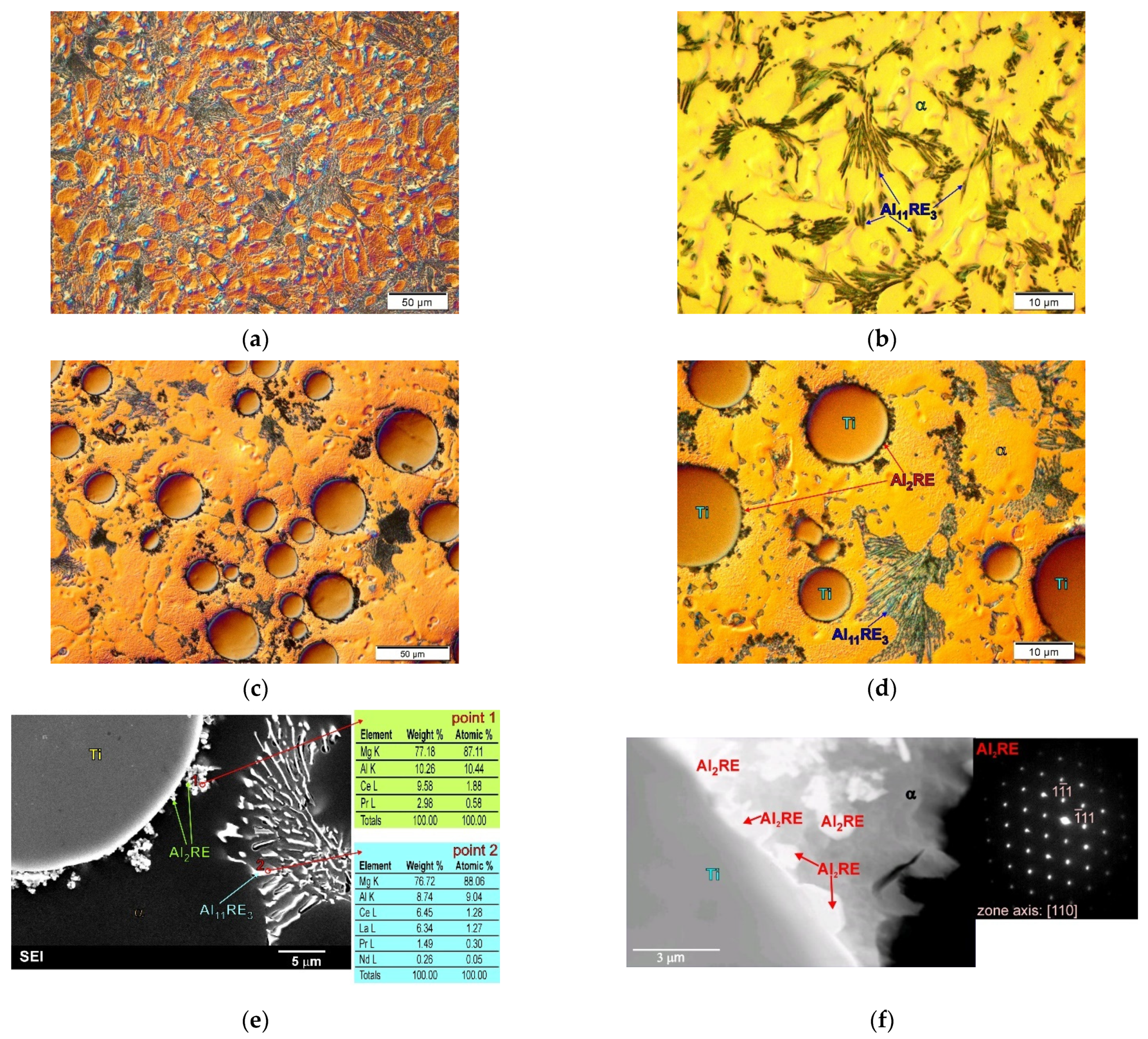

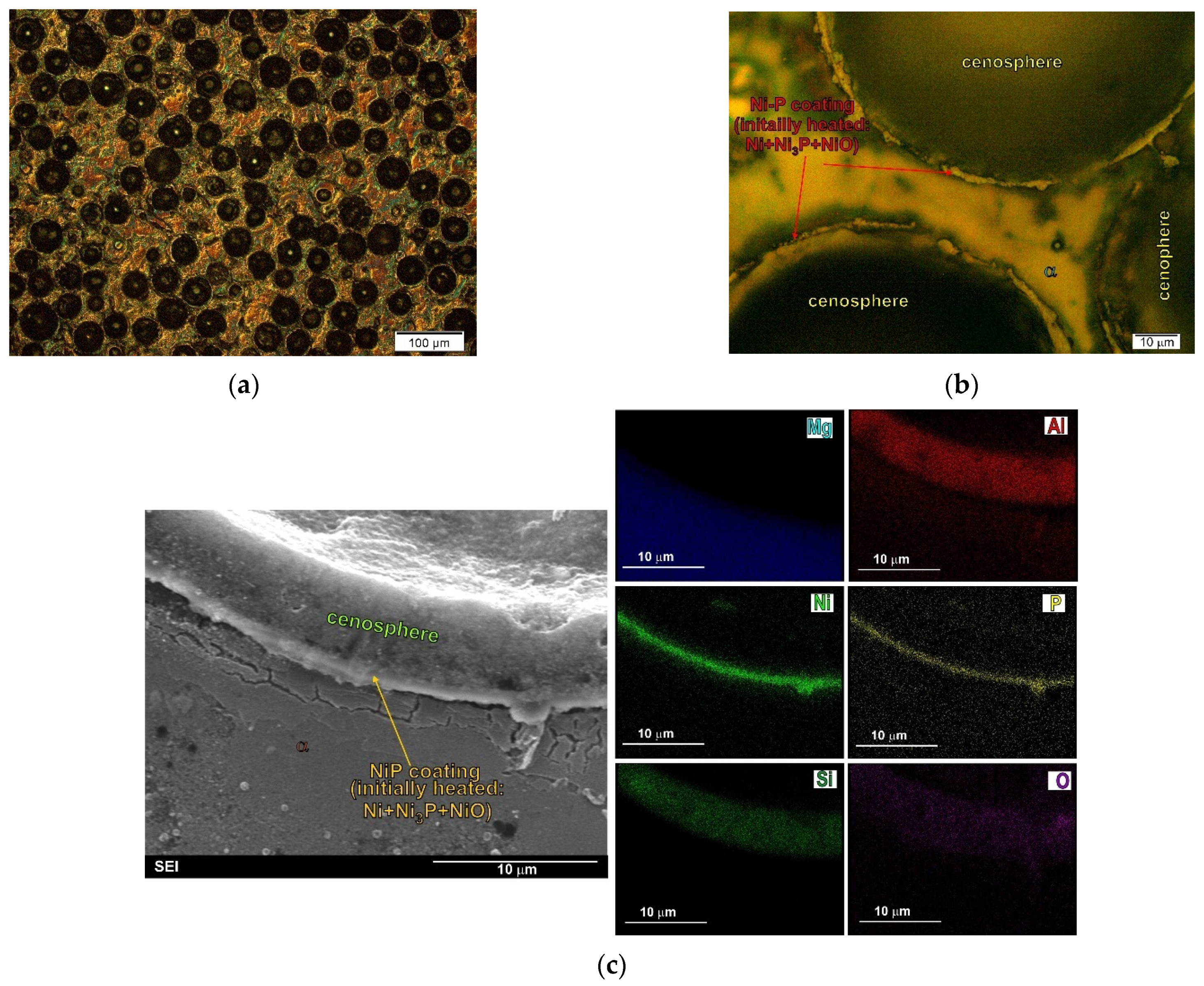

3.4. Additional Layer (Coating) on Reinforcement

3.5. Reactions between Additional Layer (Coating) on Reinforcement and Matrix Alloy

4. Summary

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Lelito, J.; Zak, P.; Shirzadi, A.A.; Greer, A.L.; Krajewski, W.K.; Suchy, J.J.; Haberl, K.; Schumacher, P. Effect of SiC reinforcement particles on the grain density in a magnesium-based metal-matrix composite: Modeling and experiment. Acta Mater. 2012, 60, 2950–2958. [Google Scholar] [CrossRef] [Green Version]

- Umeda, J.; Kawakami, M.; Kondoh, K.; Ayman, E.-S.; Imai, H. Microstructural and mechanical properties of titanium particulate magnesium composite materials. Mater. Chem. Phys. 2010, 123, 649–657. [Google Scholar] [CrossRef]

- Pérez, P.; Garcés, G.; Adeva, P. Mechanical properties of a Mg-10 (vol. %)Ti composite. Compos. Sci. Technol. 2004, 64, 145–151. [Google Scholar] [CrossRef]

- Kamieniak, J.; Braszczyńska-Malik, K.N. Problems fabricating cast magnesium matrix composites with aluminosilicate cenospheres. Compos. Theory Pract. 2014, 14, 214–218. [Google Scholar]

- Orbulov, I.N.; Ginsztler, J. Compressive characteristics of metal matrix syntactic foams. Compos. Part. A 2012, 43, 553–561. [Google Scholar] [CrossRef] [Green Version]

- Kucharczyk, A.; Naplocha, K.; Tomanik, M. Processing in porous NiTi preforms for NiTi/Mg composites. Arch. Metal Mater. 2019, 64, 747–752. [Google Scholar]

- Dolata, A.J.; Dyzia, M.; Boczkal, S. Influence of the Sr and Mg alloying additions on the bonding between matrix and reinforcing particles in the AlSi7Mg/SiC-Cgr hybrid composites. Arch. Metal Mater. 2016, 61, 651–656. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.A.; Yu, S.R.; Huang, Z.Q.; Ma, G.; Liu, Y. Microstructure and compressive property of in situ Mg2Si reinforced Mg-microballoon composites. J. Alloys Compd. 2012, 537, 12–18. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N.; Kamieniak, J. AZ91 magnesium matrix foam composites with fly ash cenospheres fabricated by negative pressure infiltration technique. Mater. Charact. 2017, 128, 209–216. [Google Scholar] [CrossRef]

- Deng, K.K.; Wu, K.; Wu, Y.W.; Nie, K.B.; Zheng, M.Y. Effect of submicron size SiC particulates on microstructure and mechanical properties of AZ91 magnesium matrix composites. J. Alloys Compd. 2010, 504, 542–547. [Google Scholar] [CrossRef]

- Sasaki, G.; Yoshida, M.; Fuyama, N.; Furii, T. Modeling of compocasting process and fabrication of AZ91D magnesium alloy matrix composites. J. Mater. Process. Technol. 2002, 130–131, 151–155. [Google Scholar] [CrossRef]

- Trojanová, Z.; Gärtnerová, V.; Jäger, A.; Námešný, A.; Chalupová, M.; Palček, P.; Lukáč, P. Mechanical and fracture properties of an AZ91 Magnesium alloy reinforced by Si and SiC particles. Compos. Sci. Technol. 2009, 69, 2256–2264. [Google Scholar] [CrossRef]

- Bochenek, A.; Braszczyńska, K.N. Structural analysis of the MgAl5 Matrix—SiC particles cast composites. Mater. Sci. Eng. A 2000, 290, 122–127. [Google Scholar] [CrossRef]

- Rohatgi, P.K.; Daoud, A.; Schultz, B.F.; Puri, T. Microstructure and mechanical behavior of die casting AZ91D-Fly ash cenosphere composite. Compos. Part. A 2009, 40, 883–896. [Google Scholar] [CrossRef]

- Braszczyński, J.; Zyska, A. Analysis of the influence of ceramic particles on solidification process of metal matrix composites. Mater. Sci. Eng. A 2000, 278, 195–203. [Google Scholar] [CrossRef]

- Sree Manu, K.M.; Ajay Raag, L.; Rajan, T.P.D.; Gupta, M.; Paj, B.C. Liquid metal infiltration processing of metallic composites: A critical review. Metall. Mater. Trans. B 2016, 47, 2799–2819. [Google Scholar] [CrossRef]

- Dezellus, O.; Eustathopoulos, N. Fundamental issues of reactive wetting by liquid metals. J. Mater. Sci. 2010, 45, 4256–4264. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.J.; Hu, X.S.; Wu, K.; Zheng, M.Y.; Zheng, L.; Zhai, Q.J. The interfacial characteristic of SiCp/AZ91 magnesium matrix composites fabricated by stir casting. J. Mater. Sci. 2009, 44, 2759–2764. [Google Scholar] [CrossRef]

- Nishida, Y. Introduction to Metal Matrix Composites—Fabrication and Recycling, 1st ed.; Springer: Tokyo, Japan, 2013; pp. 165–179. [Google Scholar]

- Clyne, T.W.; Withers, P.J. An Introduction to Metal Matrix Composites, 1st ed.; Cambridge University Press: Cambridge, UK, 1993; pp. 370–398. [Google Scholar]

- Hull, D.; Clyne, T.W. An Introduction to Composite Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 1996; pp. 133–157. [Google Scholar]

- Braszczyńska-Malik, K.N. Magnesium Alloys and Composites on Their Matrix (oryg. Title: Stopy Magnezu i Kompozyty na Ich Osnowie), 1st ed.; Czestochowa University Publisher: Częstochowa, Poland, 2017; pp. 82–133. ISBN 978-83-7193-674-6. (in Polish) [Google Scholar]

- Chawla, N.; Chawla, K.K. Metal Matrix Composites, 2nd ed.; Springer Science + Business Media: New York, NY, USA, 2013; pp. 97–119. [Google Scholar]

- Metcalfe, A.G. Interfaces in Metal Matrix Composites, 1st ed.; Academic Press: New York, NY, USA; London, UK, 1974; pp. 2–28. [Google Scholar]

- Petrasek, D.W.; Weeton, J.W. Effects of alloying on room-temperature tensile properties of tungsten-fiber-reinforced copper-alloy composites. AIME Trans. 1964, 230, 977–990. [Google Scholar]

- Ríos, A.; Martín-Meizoso, A. Micromechanical model of interface between fibre and matrix of metal matrix composite reinforced with continuous fibre. Adv. Mater. Res. 2009, 59, 158–163. [Google Scholar] [CrossRef]

- Mitra, R.; Mahayan, Y.R. Interfaces in discontinuously reinforced metal matrix composites—An overview. Bull. Mater. Sci. 1995, 18, 405–434. [Google Scholar] [CrossRef]

- Rajan, T.P.D.; Pillai, R.M.; Pai, B.C. Reinforcement coatings and interfaces in aluminium metal matrix composites. J. Mater. Sci. 1998, 33, 3491–3503. [Google Scholar] [CrossRef]

- Baumli, P. Interfacial aspects of metal matrix composites prepared from liquid metals and aqueous solutions: A review. Metals 2020, 10, 1400. [Google Scholar] [CrossRef]

- Lloyd, D.J.; Jin, I. A method of assessing the reactivity between SiC and molten Al. Metall. Trans. A 1998, 19, 3107–3109. [Google Scholar] [CrossRef]

- Srinivasa Rao, H.; Pai, B.C.; Vinod, P.L.; Manoj, R. Remelting studies on cast aluminium graphite composites. Pract. Metall. 1994, 31, 190. [Google Scholar] [CrossRef]

- Munitz, A.; Metzger, M.; Mehrabian, R. The interface phase in Al−Mg/Al2O3 composites. Metall. Trans. A 1979, 10, 1491–1497. [Google Scholar] [CrossRef]

- Dey, D.; Pandey, K.M. Magnesium metal matrix composites—A review. Rev. Adv. Mater. Sci. 2015, 42, 58–67. [Google Scholar]

- Braszczyńska, K.N.; Bochenek, A. Contribution of the silicon particles to the process of forming the structure of magnesium cast composites. Rev. Met. 2000, 97, 1455–1462. [Google Scholar] [CrossRef]

- Saravanan, R.A.; Surappa, M.K. Fabrication and characterisation of pure magnesium-30 vol.% SiCp particle composite. Mater. Sci. Eng. A 2000, 276, 108–116. [Google Scholar] [CrossRef]

- Rauber, C.; Lohmüller, A.; Opel, S.; Singer, R.F. Microstructure and mechanical properties of SiC particle reinforced magnesium composites processed by injection molding. Mater. Sci. Eng. A 2011, 528, 6313–6323. [Google Scholar] [CrossRef]

- Kumar, S.M.; Dhindaw, B.K. Magnesium alloy-SiCp reinforced infiltrated cast composites. Mater. Manuf. Process. 2007, 22, 429–432. [Google Scholar] [CrossRef]

- Braszczyńska, K.N. Contribution of SiC particles to the formation of the structure of Mg-3wt%RE cast composites. Z. Metallkd. 2003, 94, 144–148. [Google Scholar] [CrossRef]

- Dybowski, B.; Rzychoń, T.; Chmiela, B.; Gryc, A. The microstructure of WE43 MMC reinforced with SiC particles. Arch. Metall. Mater. 2016, 61, 393–398. [Google Scholar] [CrossRef] [Green Version]

- Nie, K.B.; Wang, X.J.; Hu, X.S.; Xu, L.; Wu, K.; Zheng, M.Y. Microstructure and mechanical properties of SiC nanoparticles reinforced magnesium matrix composites fabricated by ultrasonic vibration. Mater. Sci. Eng. A 2011, 528, 5278–5282. [Google Scholar] [CrossRef]

- Yang, X.; Wang, F.; Fan, Z. Crystallographic study of nucleation in SiC particulate reinforced magnesium matrix composites. J. Alloys Compd. 2017, 706, 430–437. [Google Scholar] [CrossRef]

- Wu, K.; Zheng, M.; Yao, C.; Sato, T.; Tezuka, H.; Kamio, A.; Li, D.X. Crystallographic orientation relationship between SiC and Mg in squeeze-cast SiC/Mg composites. J. Mater. Sci. Lett. 1999, 18, 1301–1303. [Google Scholar] [CrossRef]

- Braszczyńska, K.N.; Lityńska, L.; Zyska, A.; Baliga, W. TEM analyses of the interfaces between components in magnesium matrix composites reinforced with SiC particles. Mater. Chem. Phys. 2003, 81, 326–328. [Google Scholar] [CrossRef]

- Shen, M.J.; Wang, X.J.; Zhang, M.F.; Hu, X.S.; Zheng, M.Y.; Wu, K. Fabrication of biomodal size SiCp reinforcement AZ31 magnesium matrix composites. Mater. Sci. Eng. A 2014, 601, 58–64. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N.; Malik, M.A. Microstructure and mechanical properties of hypo- and hypereutectic cast Mg/Mg2Si composites. Materials 2020, 13, 3591. [Google Scholar] [CrossRef] [PubMed]

- Mirashahi, F.; Mertian, M. High temperature tensile properties of modified Mg/Mg2Si in situ composite. Mater. Des. 2012, 33, 557–562. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N. Structure analyses of Mg-Zn-Zr matrix alloy composites reinforced with SiC particles. Kompozyty (Composites) 2007, 7, 51–55. [Google Scholar]

- Zhang, C.; Fan, T.; Cao, W.; Ding, J.; Hang, D. Size control of in situ formed reinforcement in metal melts-theoretical treatment and application to in situ (AlN+Mg2Si)/Mg composites. Compos. Sci. Technol. 2009, 69, 2688–2694. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N.; Kamieniak, J. Role of Ni-P coating structure on fly ash cenospheres in formation of magnesium matrix composites. Metall. Mater. Trans. A 2017, 48, 5649–5657. [Google Scholar] [CrossRef] [Green Version]

- Braszczyńska-Malik, K.N.; Kamieniak, J. Analyses of interface between components in AZ91 magnesium matrix alloy foam composite with Ni-P coated fly ash cenospheres. J. Alloys Compd. 2017, 720, 352–359. [Google Scholar] [CrossRef]

- Peng, L.; Chen, G.; Zhao, Y.T.; Huang, K.; Shao, Y. Influence of solution treatment on microstructure and properties of in-situ Mg2Si/AZ91D composites. Trans. Nonferr. Met. Soc. 2011, 21, 2365–2371. [Google Scholar] [CrossRef]

- Malik, M.A.; Braszczyńska-Malik, K.; Majchrzak, K. Microstructural characterization of cast magnesium matrix composites by Raman microscopy. Arch. Foundry Eng. 2013, 13, 95–98. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.; Jayalakshmi, S.; Gupta, M.; Abdelmagid, S.H. Influence of micron-Ti and nano-Cu additions on the microstructure and mechanical properties of pure magnesium. Metals 2012, 2, 274–291. [Google Scholar]

- Hassan, S.F.; Gupta, M. Development of ductile magnesium composite materials using titanium as reinforcement. J. Alloys Compd. 2002, 345, 246–251. [Google Scholar] [CrossRef]

- Meenashisundaram, G.K.; Gupta, M. Low volume fraction nano-titanium particulates for improving the mechanical response of pure magnesium. J. Alloys Compd. 2014, 593, 176–183. [Google Scholar] [CrossRef]

- Raghunath, B.K.; Karthikeyan, R.; Ganesan, G.; Gupta, M. An investigation of hot deformation response of particulate-reinforced magnesium + 9% titanium composite. Mater. Des. 2008, 29, 622–627. [Google Scholar] [CrossRef] [Green Version]

- Braszczyńska-Malik, K.N.; Przełożyńska, E. Microstructure of AZ91-Ti6Al4V metal-metal composite in as-cast conditions and after heat treatment. Compos. Theory Pract. 2014, 14, 224–228. [Google Scholar]

- Kondoh, K.; Kawakami, M.; Imai, H.; Umeda, J.; Fujii, H. Wettability of pure Ti by molten pure Mg droplets. Acta Mater. 2010, 58, 606–614. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N.; Przełożyńska, E. Analyses of AM50-Tip metal-metal composite microstructure. J. Alloys Compd. 2018, 731, 1181–1187. [Google Scholar] [CrossRef]

- Xi, Y.L.; Chai, D.L.; Zhang, W.X.; Zhou, J.E. Titanium alloy reinforced magnesium matrix composite with improved mechanical properties. Scr. Mater. 2006, 54, 19–23. [Google Scholar] [CrossRef]

- Sankaranarayanan, S.; Sabat, R.K.; Jayalakshmi, S.; Suwas, S.; Gupta, M. Effect of hybridizing micron-sized Ti with nano-sized SiC on the microstructural evolution and mechanical response of Mg-5.6Ti composite. J. Alloys Compd. 2013, 575, 207–217. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N.; Przełożyńska, E. The influence of Ti particles on microstructure and properties of Mg-5Al-5RE matrix alloy composite. J. Alloys Compd. 2017, 728, 600–606. [Google Scholar] [CrossRef]

- Huang, Z.; Yu, S. Microstructure characterization on the formation of in situ Mg2Si and MgO reinforcements in AZ91D/Fly ash composites. J. Alloys Compd. 2011, 509, 311–315. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N.; Grzybowska, A. Microstructure of Mg-5Al-0.4Mn-xRE (x = 3 and 5 wt.%) alloys in as-cast conditions and after annealing. J. Alloys Compd. 2016, 663, 172–179. [Google Scholar] [CrossRef]

| Alloy | Chemical Composition wt% | ||||

|---|---|---|---|---|---|

| Al | Zn | Mn | RE | Mg | |

| AM50 | 4.9 | - | 0.26 | - | rest |

| AZ91 | 8.7 | 0.13 | 0.7 | - | rest |

| AME505 | 5.0 | - | 0.26 | 5.0 | rest |

| ME3 | - | - | - | 3.0 | rest |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Braszczyńska-Malik, K.N. Types of Component Interfaces in Metal Matrix Composites on the Example of Magnesium Matrix Composites. Materials 2021, 14, 5182. https://doi.org/10.3390/ma14185182

Braszczyńska-Malik KN. Types of Component Interfaces in Metal Matrix Composites on the Example of Magnesium Matrix Composites. Materials. 2021; 14(18):5182. https://doi.org/10.3390/ma14185182

Chicago/Turabian StyleBraszczyńska-Malik, Katarzyna N. 2021. "Types of Component Interfaces in Metal Matrix Composites on the Example of Magnesium Matrix Composites" Materials 14, no. 18: 5182. https://doi.org/10.3390/ma14185182

APA StyleBraszczyńska-Malik, K. N. (2021). Types of Component Interfaces in Metal Matrix Composites on the Example of Magnesium Matrix Composites. Materials, 14(18), 5182. https://doi.org/10.3390/ma14185182