Application of a Thermo-Hydrodynamic Model of a Viscous Torsional Vibration Damper to Determining Its Operating Temperature in a Steady State

Abstract

:1. Introduction

- Engine designs;

- Types of ignition;

- Power supply and cooling system designs;

- Piston and crank systems;

- Materials used in the production of engine parts;

- General methodology of designing selected engine parts, etc.

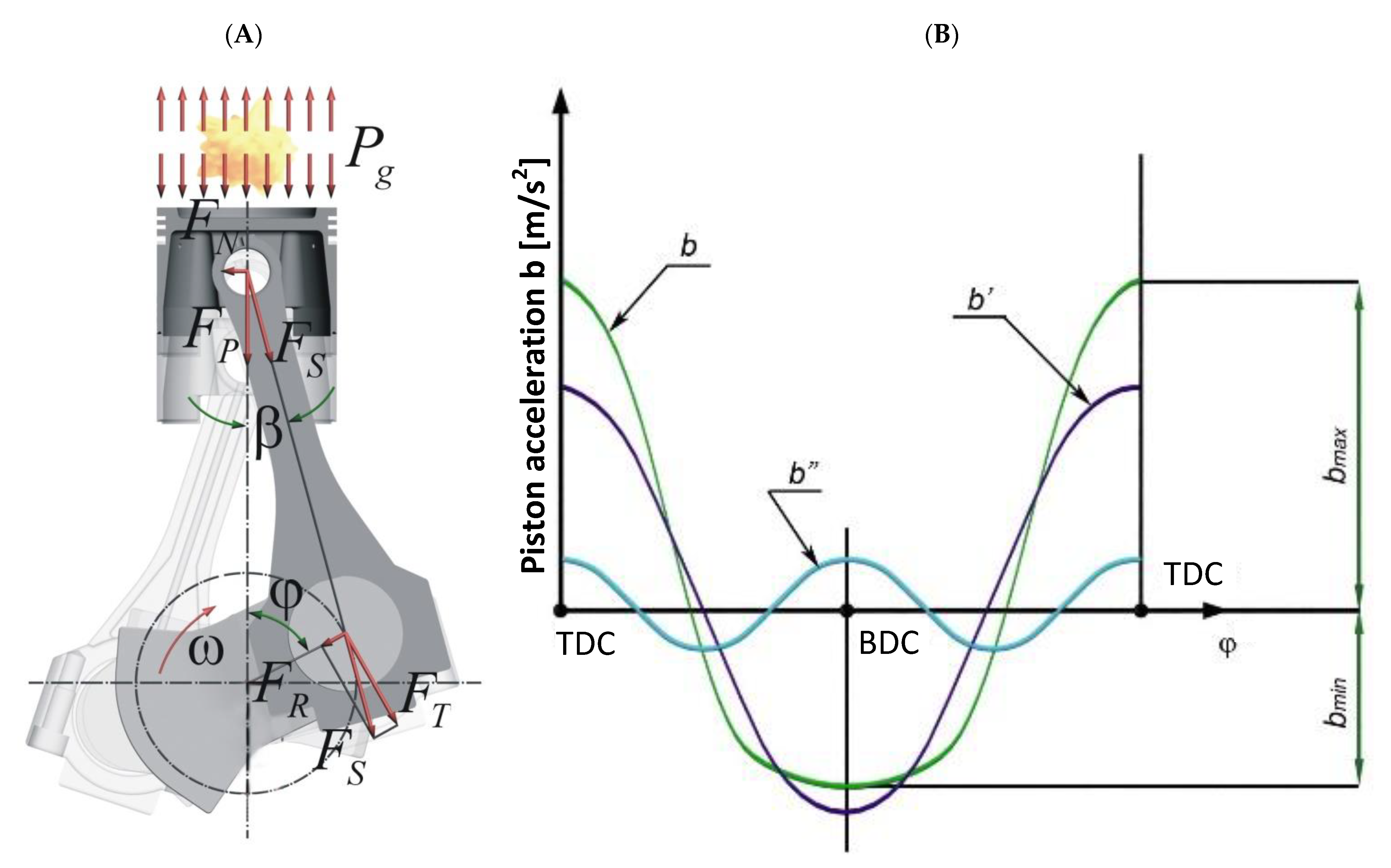

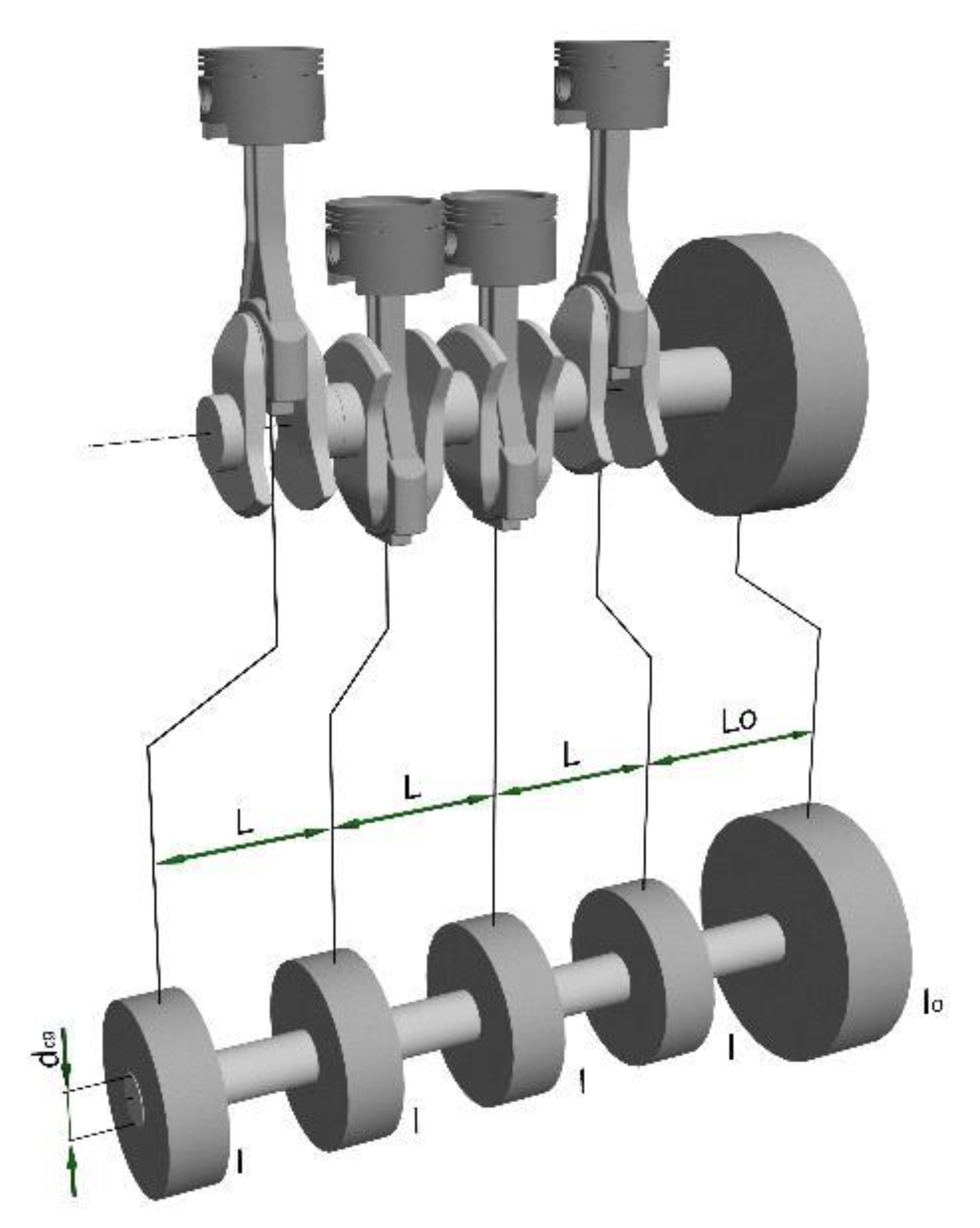

2. Torsional Vibrations of the Crankshaft and Methods of Their Elimination

- Change of rotational speeds of the engine (change of the operating speed range of the engine);

- Change of the natural frequency of vibrations of the entire system;

- Change in the course of exciting forces;

- Use of vibration dampers.

- Create a substitute vibrating model of an actual drive system (Figure 6);

- Determine the course of the tangential forces FT as a function of the shaft rotation angle φ and carry out their harmonic analysis, if the data were not supplied by the engine manufacturer;

- Determine the basic geometrical parameters of the damper;

- Calculate the mass moment of inertia of the inertia ring and the damper housing;

- Determines the size of clearances in the damper;

- Determine the viscosity of the damping fluid;

- Calculate the amplitude of resonant vibrations of the free end of the shaft with and without a damper and check the damper thermally in the end phase.

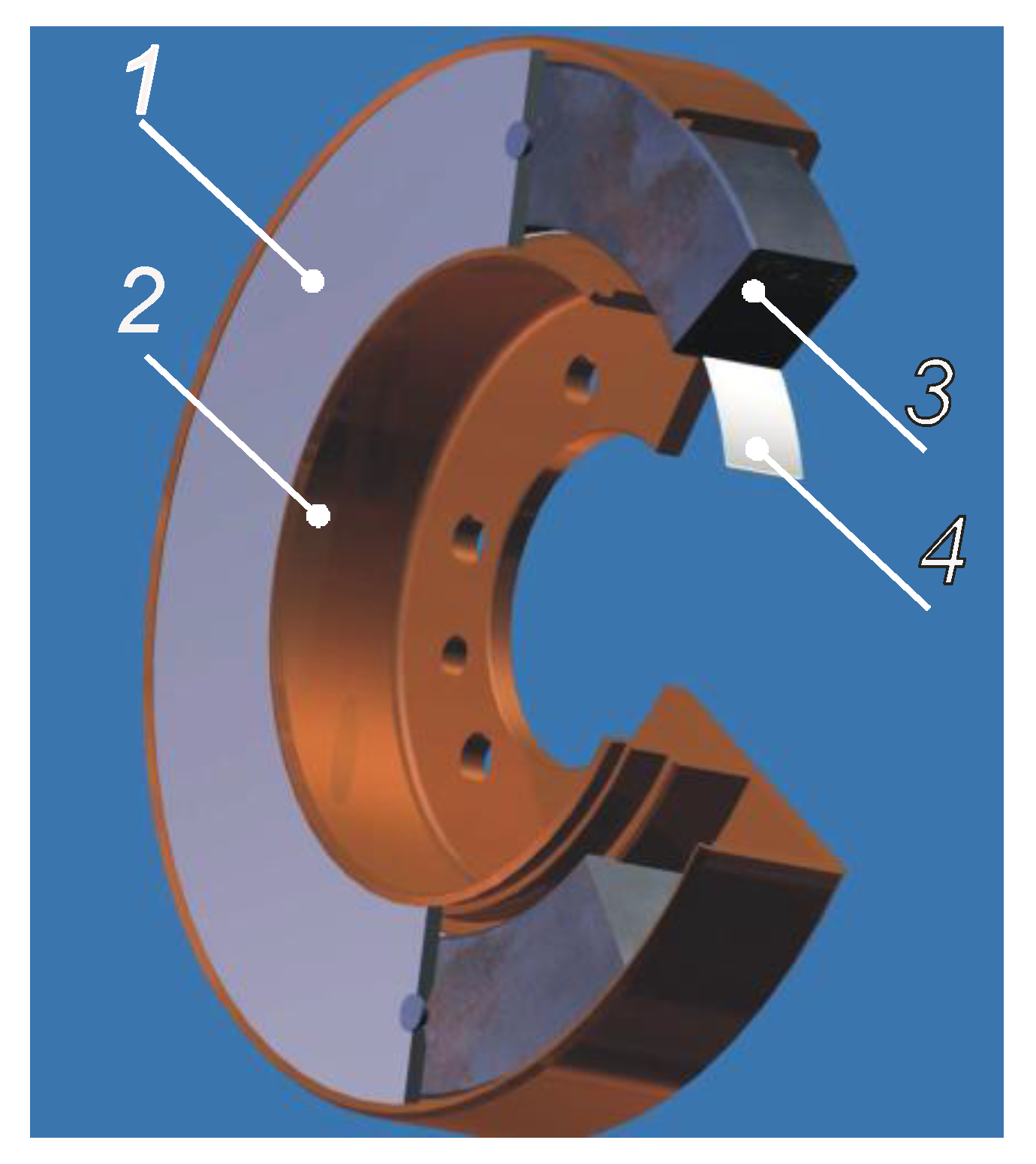

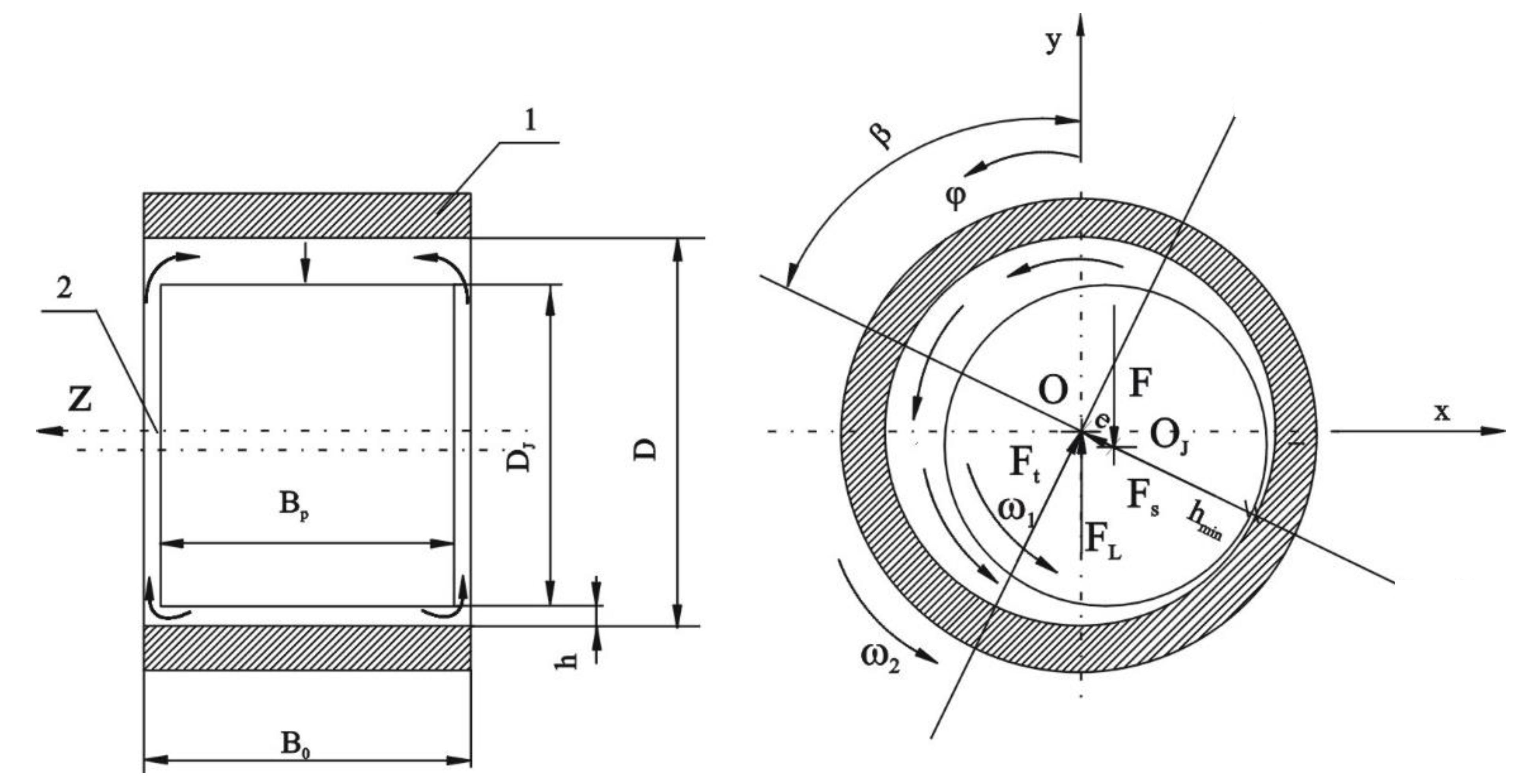

3. The Concept of a Thermo-Hydrodynamic Model of a Torsional Vibration Damper

- The value describing the intensity of heat flow through the damper housing to the environment is the heat transfer coefficient α (W/m2 °C) (in the first stage of calculations it was assumed that α = const [18]);

- The model presented in Figure 12 is described by equations taking into account:

- Geometric parameters (height) of the oil film h as a function of relative eccentricity ε:

- CR = 0.5 (D − DJ)—radial clearance between housing and ring;

- D—internal diameter of the housing;

- DJ—outer diameter of the ring;

- φ—angular coordinate;

- β—inclination angle of the center line of the inertia ring and the housing;

- e—ring and housing position eccentricity;

- ε—relative eccentricity.

- Pressure distribution in the damper oil film (the equation was derived from the Navier–Stokes equations):

- p—oil film pressure;

- η(T)—dynamic viscosity of the oil;

- T—oil temperature;

- ωw = ω2 − ω1—relative angular velocity.

- Damper housing temperature TB:

- T0—T0—ambient temperature;

- ff—fluid friction coefficient;

- F—ring weight;

- α—heat transfer coefficient;

- B0—width of the housing;

- Thermophysical properties of silicone oil M30000 taking into account viscosity changes as a function of temperature according to Clearco Products Co., Inc. (Willow Grove, PA, USA).

- —kinematic viscosity;

- ρ(T)—oil density.

4. Calculation of the Working Temperature of a Viscous Torsional Vibration Damper

5. Analysis of Research Results and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| D = 2R | internal diameter of the housing (m) |

| DJ = 2RJ | outer inertia ring diameter (m) |

| CR = R − RJ | radial clearance (m) |

| B0 | width of the housing (m) |

| Bp | width of the inertia ring (m) |

| h | oil film height (m) |

| hmin | minimum oil film height (m)) |

| x = j × R, y, z | Cartesian coordinate system |

| φ | angular coordinate (rad) |

| ω1 | angular velocity of the inertia ring (rad/s) |

| ω2 | angular velocity of the housing (rad/s) |

| ωw = ω2 − ω1 | relative angular velocity of the housing and inertia ring (rad/s) |

| O | center position of the housing |

| OJ | center position of the ring |

| F | inertia ring weight (N) |

| FL | hydrodynamic buoyancy force (N) |

| e = | ring and housing position eccentricity (m) |

| ε = e/CR | relative eccentricity (–) |

| β | angle of the center line of the inertia ring (OJ) and the housing (O) (rad) |

| p | oil film pressure (N/m2) |

| T | oil temperature (°C) |

| T0 | ambient temperature (°C) |

| TB | damper housing temperature (°C) |

| η(T) | dynamic viscosity of the oil (Pas) |

| ρ(T) | oil density (kg/m3) |

| α(T) | heat transfer coefficient (W/m2 °C) |

References

- Wróblewski, P. Technology for Obtaining Asymmetries of Stereometric Shapes of the Sealing Rings Sliding Surfaces for Selected Anti-Wear Coatings; SAE Technical Paper 2020-01-2229; Event: SAE Powertrains, Fuels & Lubricants Meeting; SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Dziubak, T.; Dziubak, S.D. Experimental Study of Filtration Materials Used in the Car Air Intake. Materials 2020, 13, 3498. [Google Scholar] [CrossRef] [PubMed]

- Dziubak, T. Material Properties Analysis with Addition of Nanofibres for Air Intake Filtration in Internal Combustion Engines. Int. J. Automot. Mech. Eng. IJAME 2021, 18, 8621–8636. [Google Scholar] [CrossRef]

- Bernhardt, M.; Dobrzyński, S.; Loth, E. Silniki Samochodowe, 4th ed.; WkiŁ: Warszawa, Poland, 1988. [Google Scholar]

- Brun, R. Szybkobieżne Silniki Wysokoprężne; WkiŁ: Warszawa, Poland, 1973. [Google Scholar]

- Ciesielski, S.; Lus, T. Okrętowe Tłokowe Silniki Spalinowe—Budowa i Zasada Działani; Wydawnictwo Akademickie AMW: Gdynia, Poland, 2009. [Google Scholar]

- Homik, W. Wiskotyczne Tłumiki Drgań Skrętnych, Studia i rozprawy; Wydawnictwo Naukowe Instytutu Technologii Eksploatacji-PIB: Radom, Poland, 2015; ISBN 978-83-7789-377-7. [Google Scholar]

- Homik, W. Szerokopasmowe Tłumiki Drgań Skrętnych, Biblioteka Problemów Eksploatacji; Wydawnictwo Naukowe Instytutu Technologii Eksploatacji—PIB: Radom, Poland, 2012; ISBN 978-83-7789-140-7. [Google Scholar]

- Song, M.-H.; Pham, X.D.; Vuong, Q.D. Torsional Vibration Stress and Fatigue Strength Analysis of Marine Propulsion Shafting System Based on Engine Operation Patterns. J. Mar. Sci. Eng. 2020, 8, 613. [Google Scholar] [CrossRef]

- Chen, M.; Ouyang, H.; Li, W.; Wang, D.; Liu, S. Partial Frequency Assignment for Torsional Vibration Control of Complex Marine Propulsion Shafting Systems. Appl. Sci. 2020, 10, 147. [Google Scholar] [CrossRef] [Green Version]

- Huang, Q.; Liu, H.; Cao, J. Investigation of Lumped-Mass Method on Coupled Torsional-longitudinal Vibrations for a Marine Propulsion Shaft with Impact Factors. J. Mar. Sci. Eng. 2019, 7, 95. [Google Scholar] [CrossRef] [Green Version]

- Jee, J.; Kim, C.; Kim, Y. Design Improvement of a Viscous-Spring Damper for Controlling Torsional Vibration in a Propulsion Shafting System with an Engine Acceleration Problem. J. Mar. Sci. Eng. 2020, 8, 428. [Google Scholar] [CrossRef]

- Drewing, S.; Witkowski, K. Spectral Analysis of Torsional Vibrations Measured by Optical Sensors, as a Method for Diagnosing Injector Nozzle Coking in Marine Diesel Engines. Sensors 2021, 21, 775. [Google Scholar] [CrossRef] [PubMed]

- Mahdisoozani, H.; Mohsenizadeh, M.; Bahiraei, M.; Kasaeian, A.; Daneshvar, A.; Goodarzi, M.; Safaei, M.R. Performance Enhancement of Internal Combustion Engines through Vibration Control: State of the Art and Challenges. Appl. Sci. 2019, 9, 406. [Google Scholar] [CrossRef] [Green Version]

- Zhong, B.; Deng, B.; Zhao, H. Simulation Model and Method for Active Torsional Vibration Control of an HEV. Appl. Sci. 2019, 9, 34. [Google Scholar] [CrossRef] [Green Version]

- Homik, W. Zmiany lepkości cieczy w czasie eksploatacji wiskotycznego tłumika drgań. Przegląd Mech. 2009, 3, 20–23. [Google Scholar]

- Homik, W.; Markowski, T. Temperature as a source of information about the technical condition viscous torsion damper. In Solid State Phenomena; Trans Tech Publications: Freienbach, Switzerland, 2015; Volume 236, pp. 78–84. [Google Scholar] [CrossRef]

- DIN 31652, Teil 1, 2, 3: Hydrodynamische Radial—Gleitlager im stationärem Betrieb; DIN: Berlin, Germany, 2017.

- Barwell, F.T. Bearing System. Principles and Practice; Oxford University Press: Oxford, UK, 1979. [Google Scholar]

- Kaniewski, W. Warunki brzegowe diatermicznego filmu smarnego. Zesz. Nauk. Politech. Łódzkiej. Zesz. Spec. 1997, z.14, 7–22. [Google Scholar]

- Mazurkow, A. Teoria Smarowania Łożysk Ślizgowych; Oficyna Wydawnicza Politechniki Rzeszowskiej: Rzeszów, Poland, 2019. [Google Scholar]

| Geometric, Physical and Kinematic Parameters. | |

|---|---|

| 1. Outer diameter of the ring | DJ = 2RJ = 207.925 mm |

| 2. Internal diameter of the housing | D = 2R = 208.109 mm |

| 3. Radial clearance | CR = R − Rj = 0.092 mm |

| 4. Inertia ring width | Bp = 33.00 mm |

| 5. Inertia ring weight | F = 89.6 N |

| 6. Relative angular velocity | ωw = ω2 − ω1 = 0.4–2.0 1/s |

| 7. Kinematic viscosity of silicone oil | ν = 30,000 cSt |

| 8. Oil density | ρ = 970 kg/m3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Homik, W.; Mazurkow, A.; Woś, P. Application of a Thermo-Hydrodynamic Model of a Viscous Torsional Vibration Damper to Determining Its Operating Temperature in a Steady State. Materials 2021, 14, 5234. https://doi.org/10.3390/ma14185234

Homik W, Mazurkow A, Woś P. Application of a Thermo-Hydrodynamic Model of a Viscous Torsional Vibration Damper to Determining Its Operating Temperature in a Steady State. Materials. 2021; 14(18):5234. https://doi.org/10.3390/ma14185234

Chicago/Turabian StyleHomik, Wojciech, Aleksander Mazurkow, and Paweł Woś. 2021. "Application of a Thermo-Hydrodynamic Model of a Viscous Torsional Vibration Damper to Determining Its Operating Temperature in a Steady State" Materials 14, no. 18: 5234. https://doi.org/10.3390/ma14185234