Influence of Embedded Gap and Overlap Fiber Placement Defects on Interlaminar Properties of High Performance Composites

Abstract

:1. Introduction

2. Material and Methods

2.1. Material

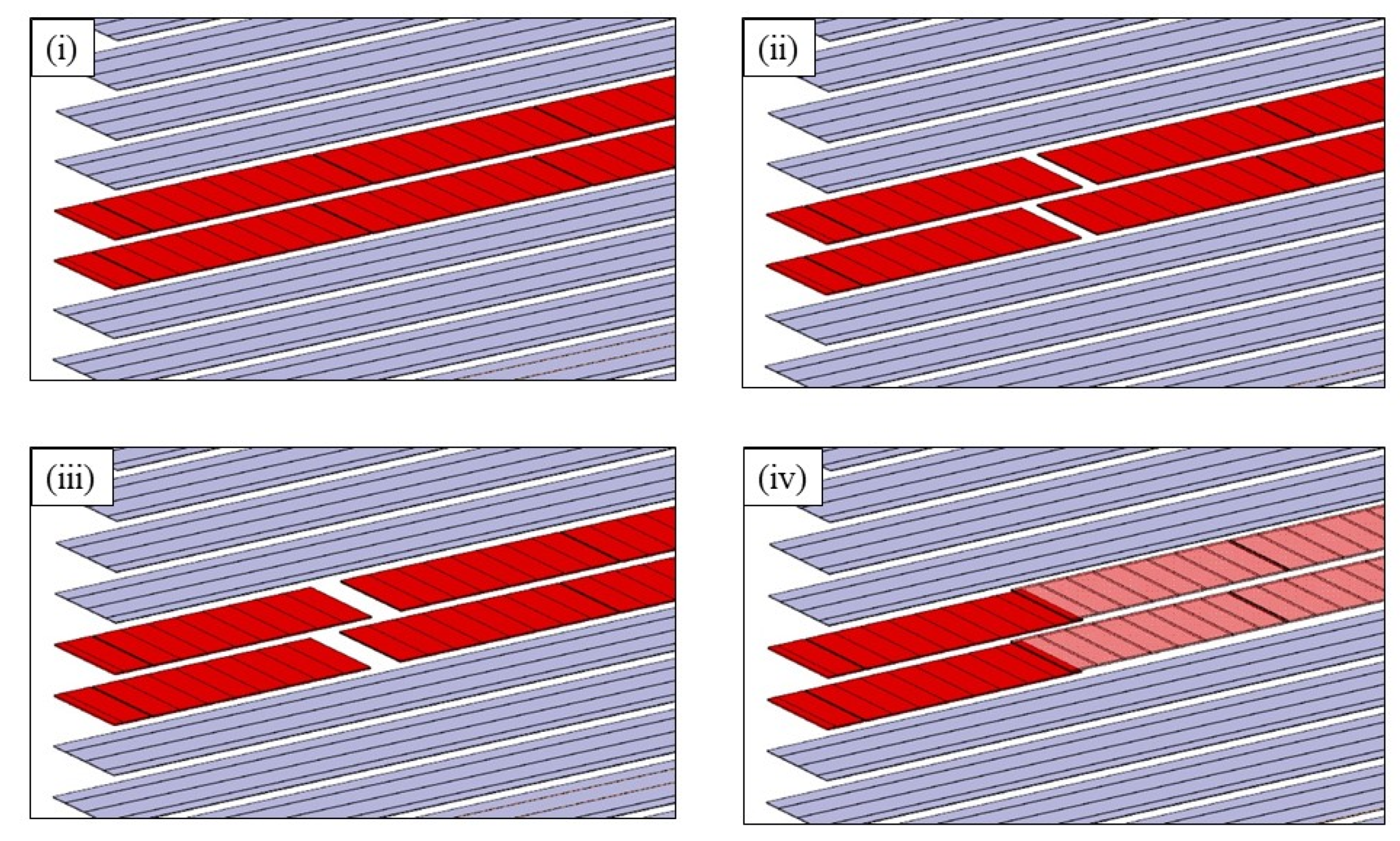

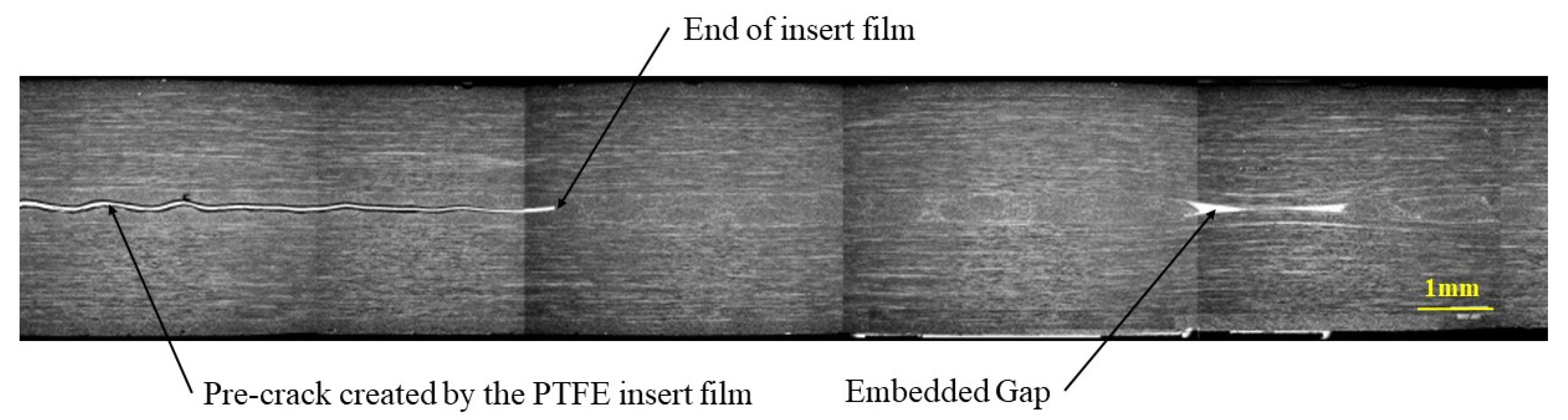

2.2. Configuration of Samples

2.3. Material Quality Control

2.4. Short Beam Shear Tests

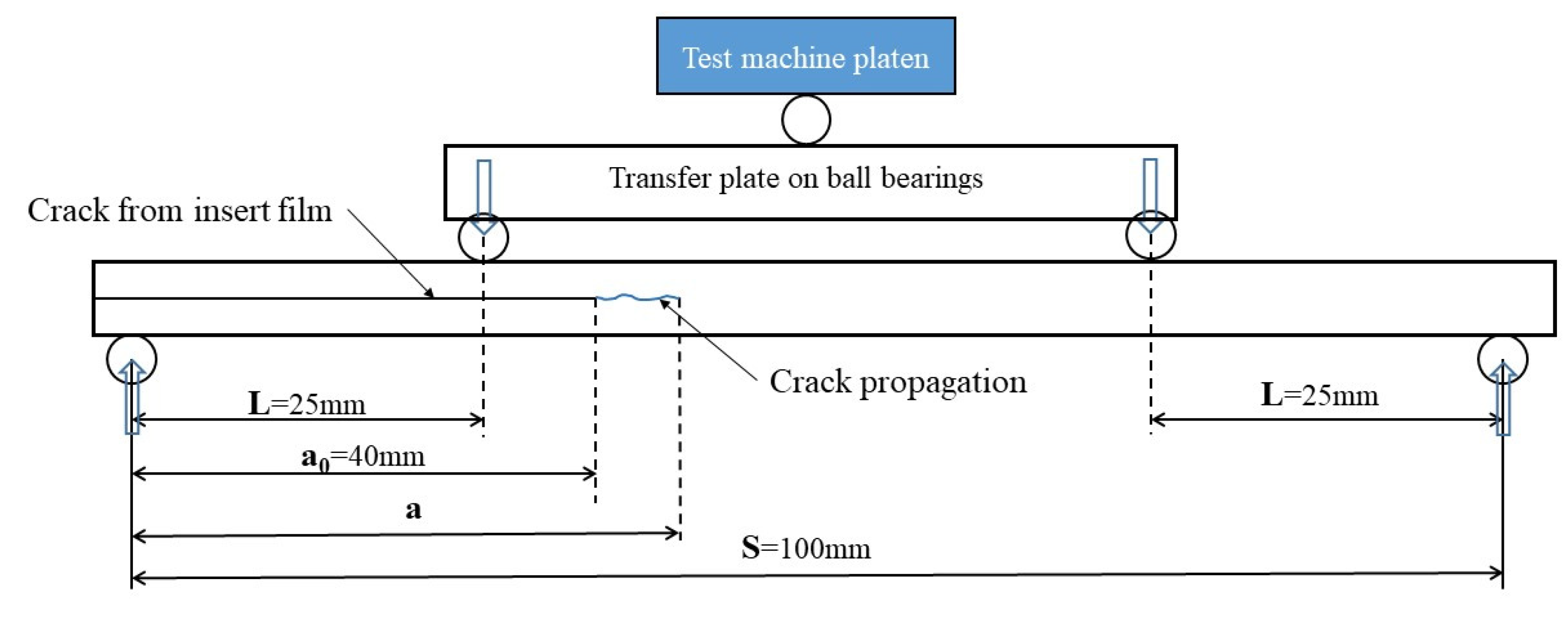

2.5. Interlaminar Fracture Toughness Tests

2.6. Data Analysis

3. Results

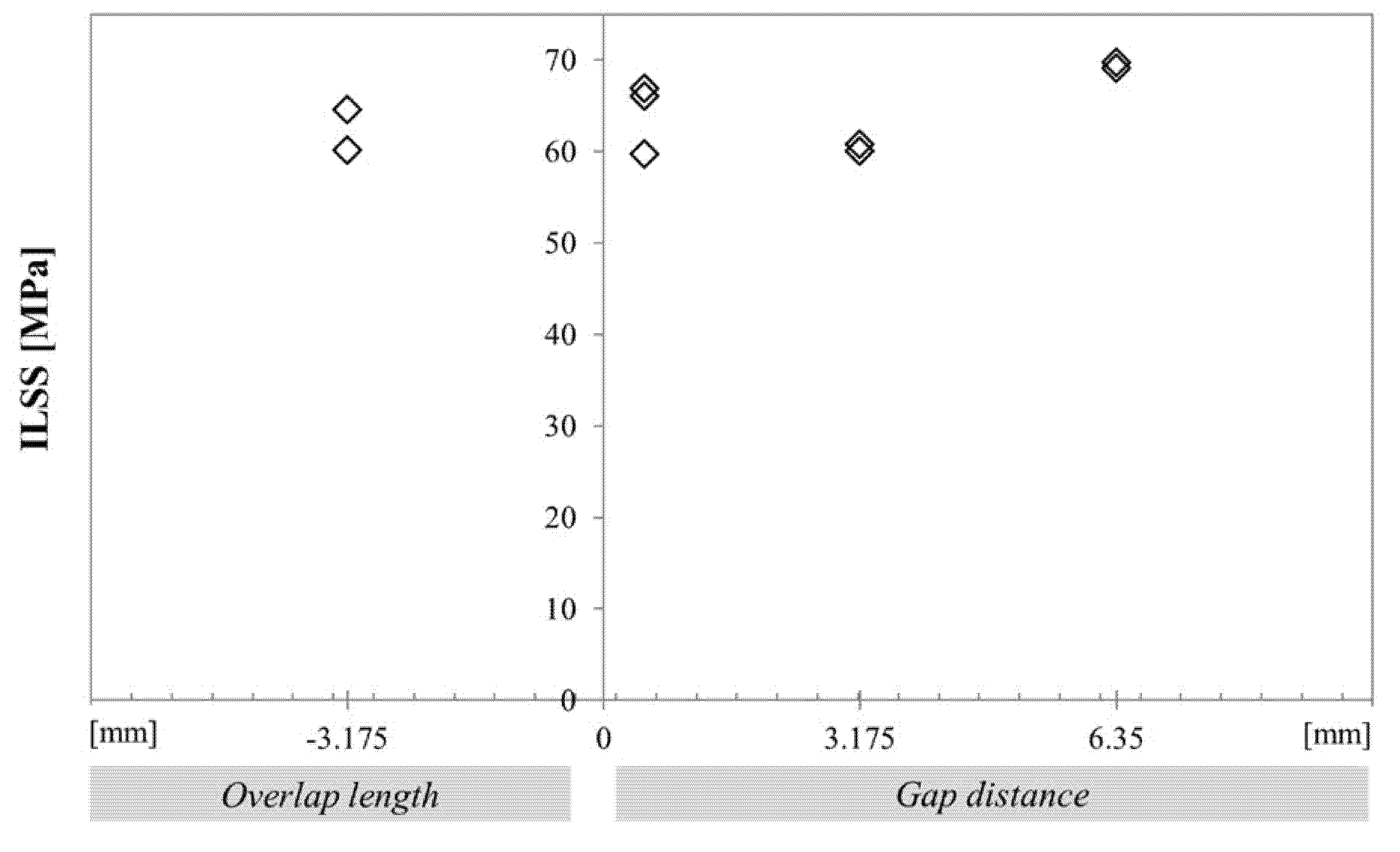

3.1. Influence of Singularities on Interlaminar Shear Strength

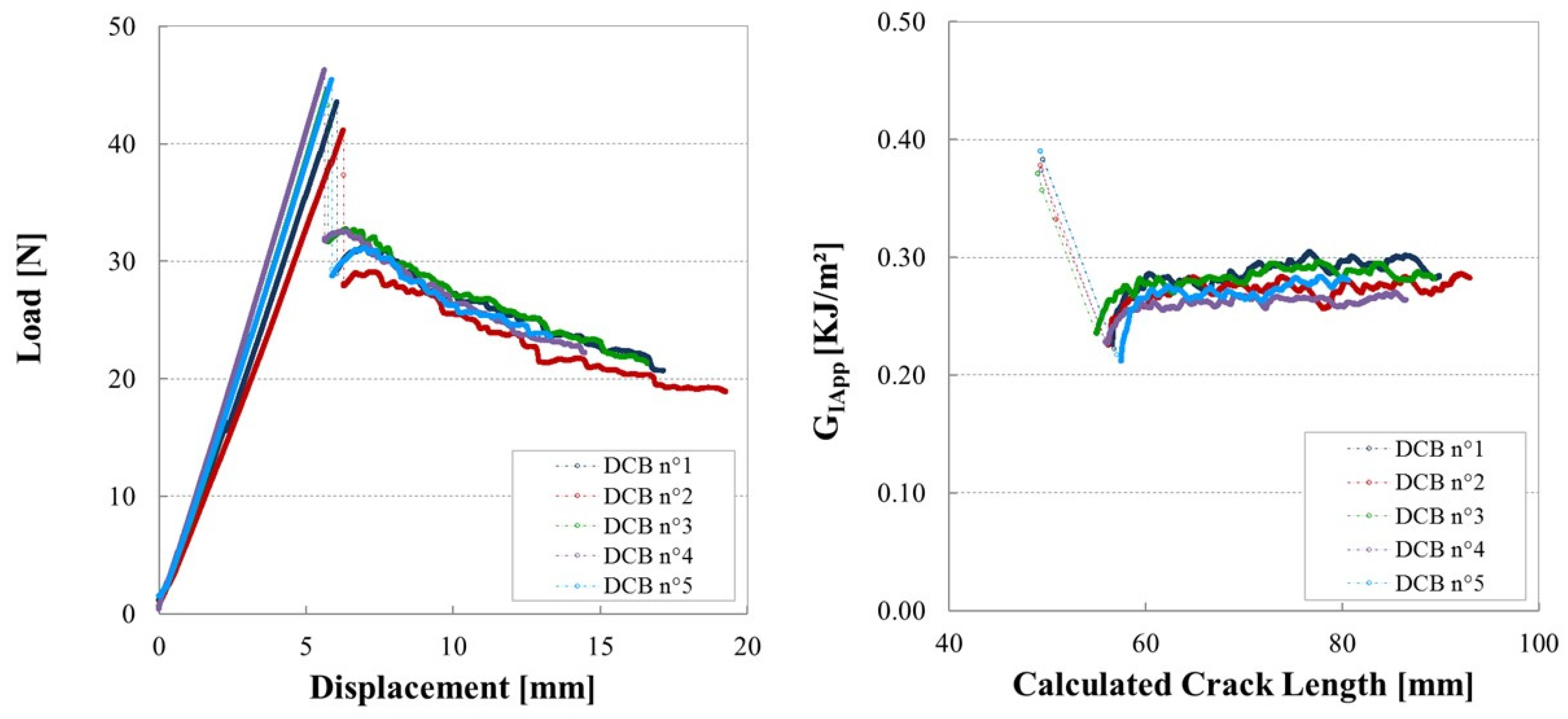

3.2. Mode I Testing of Unidirectional Composites without Singularities

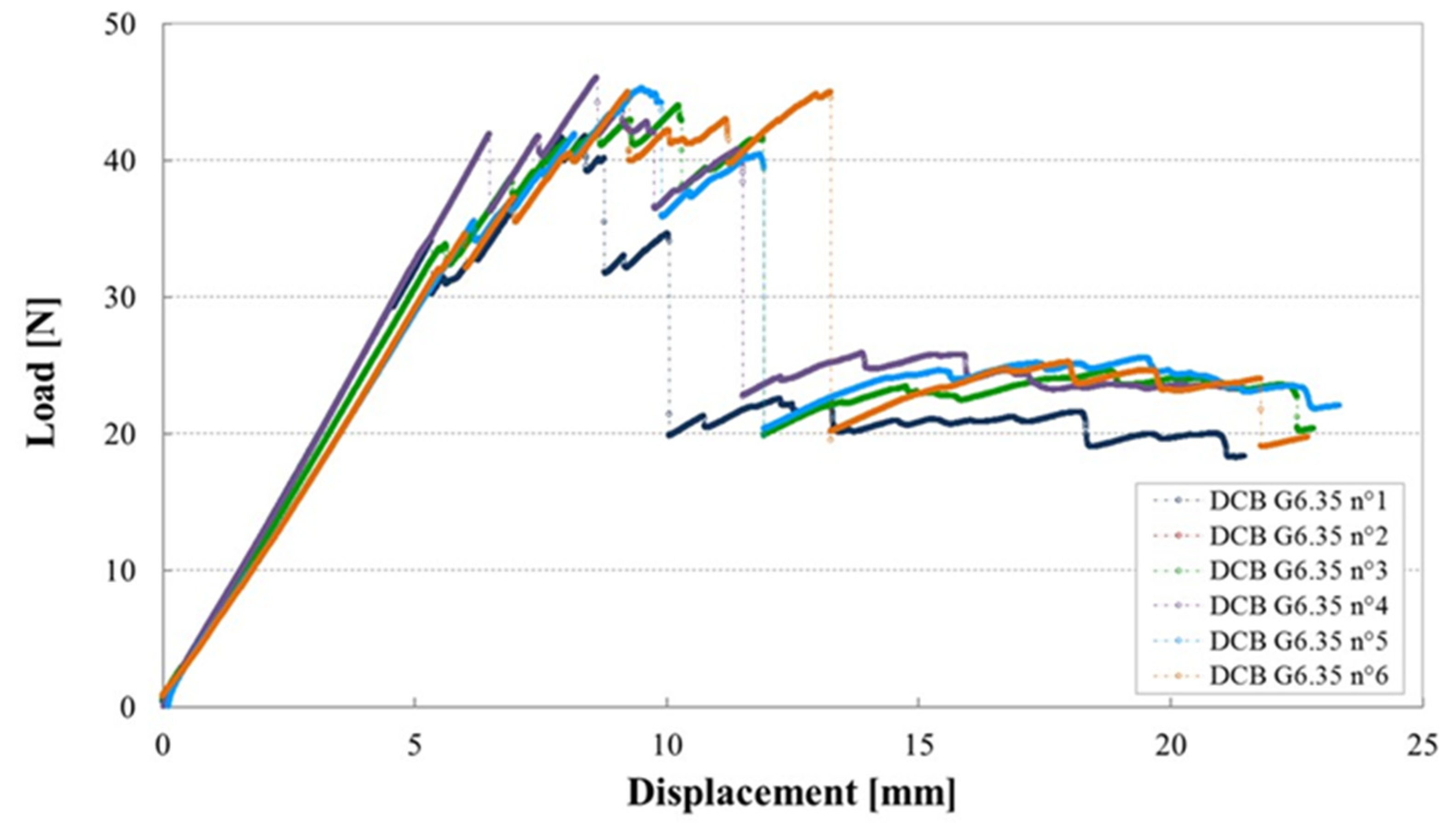

3.3. Influence of Manufacturing Defects in Mode I

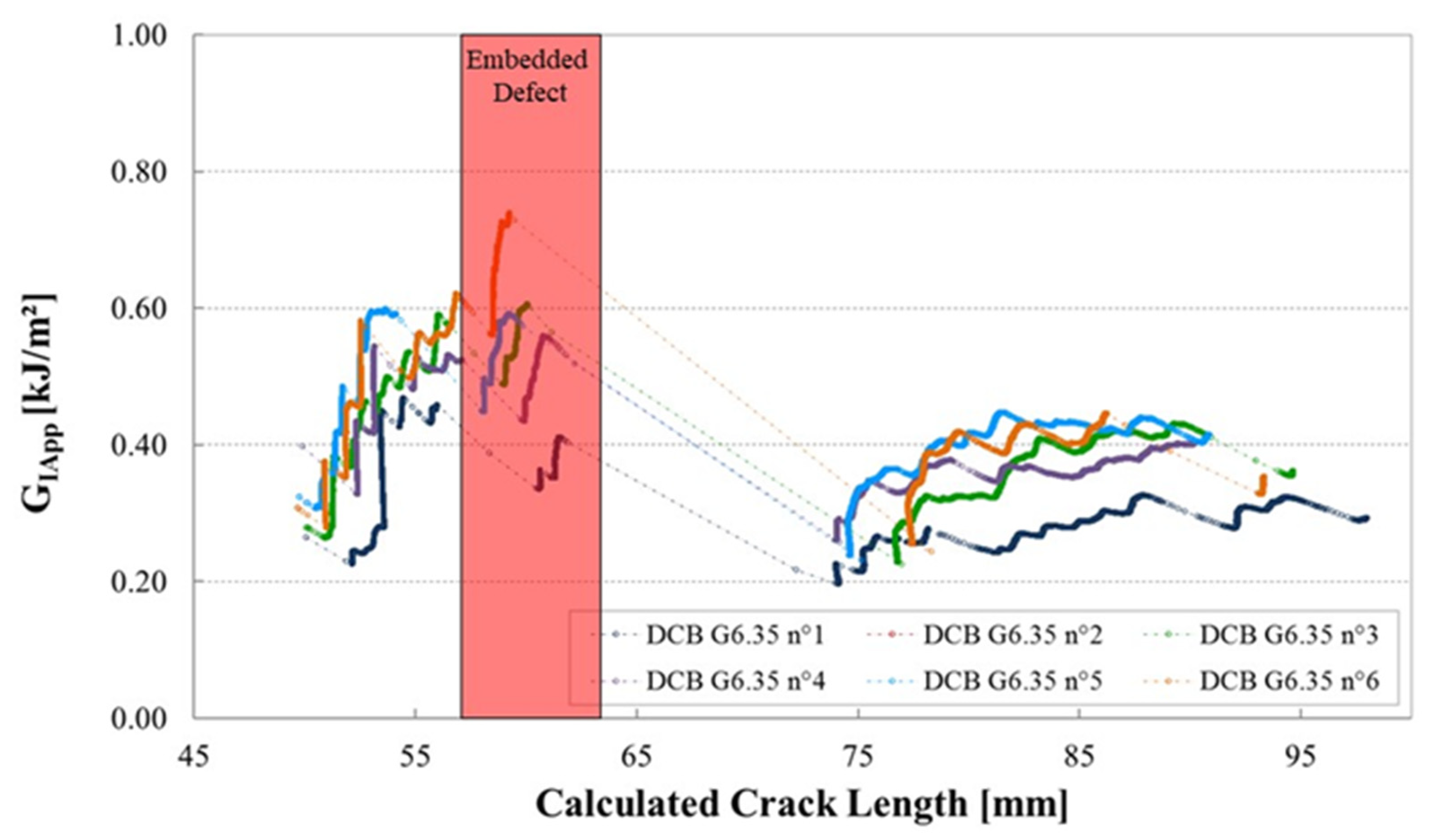

3.4. Mode II Testing of Unidirectional Laminates without Singularities

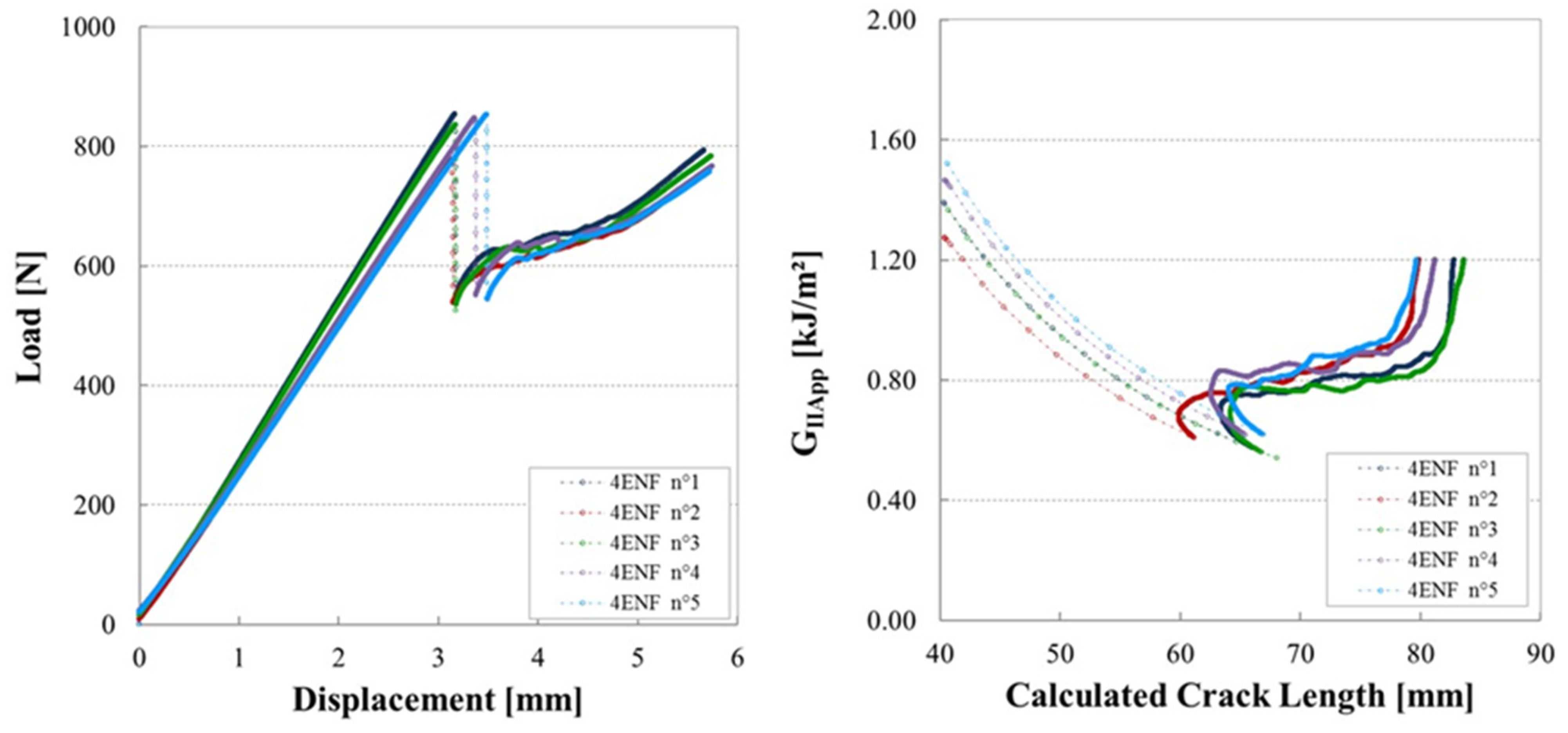

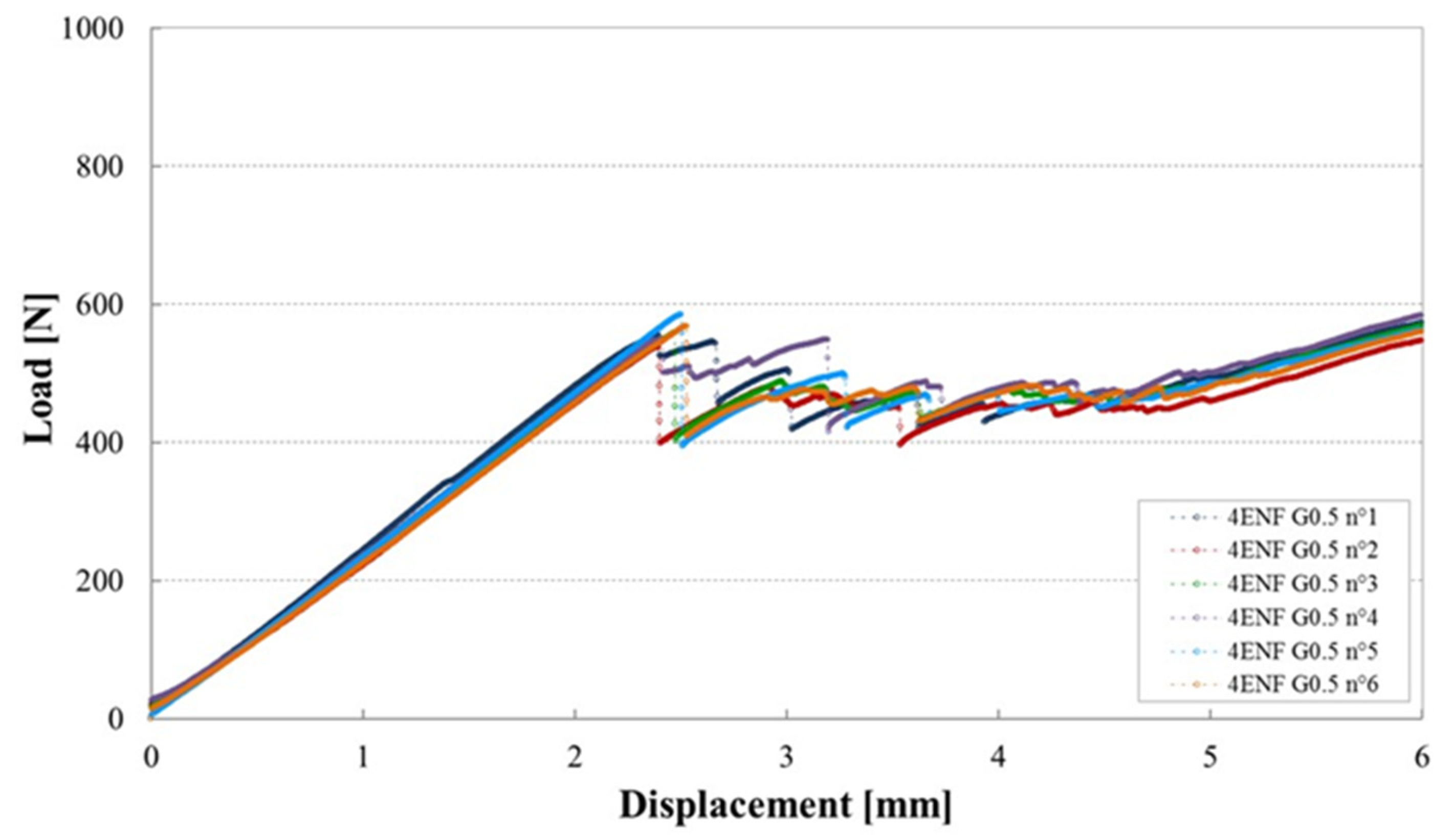

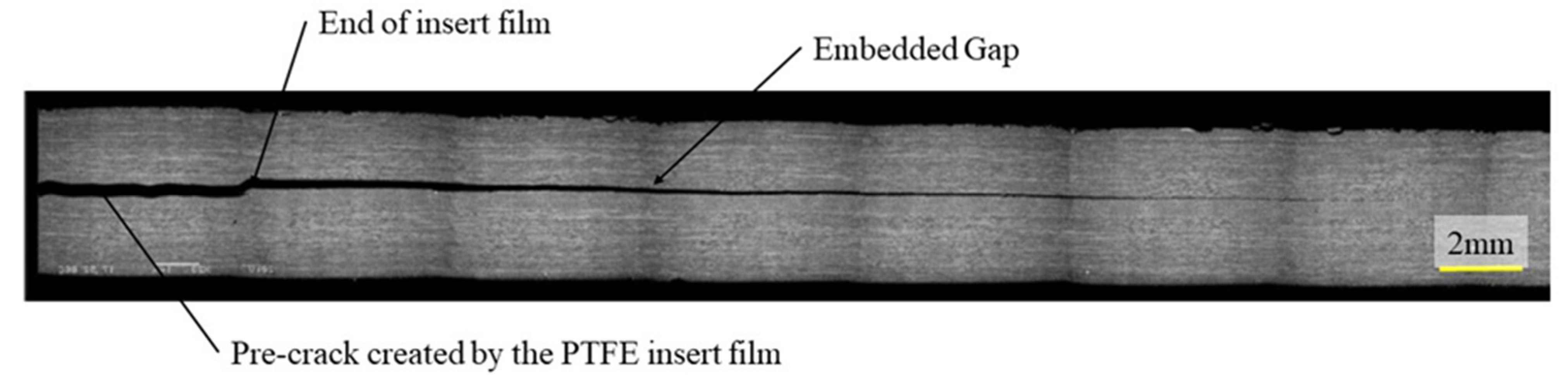

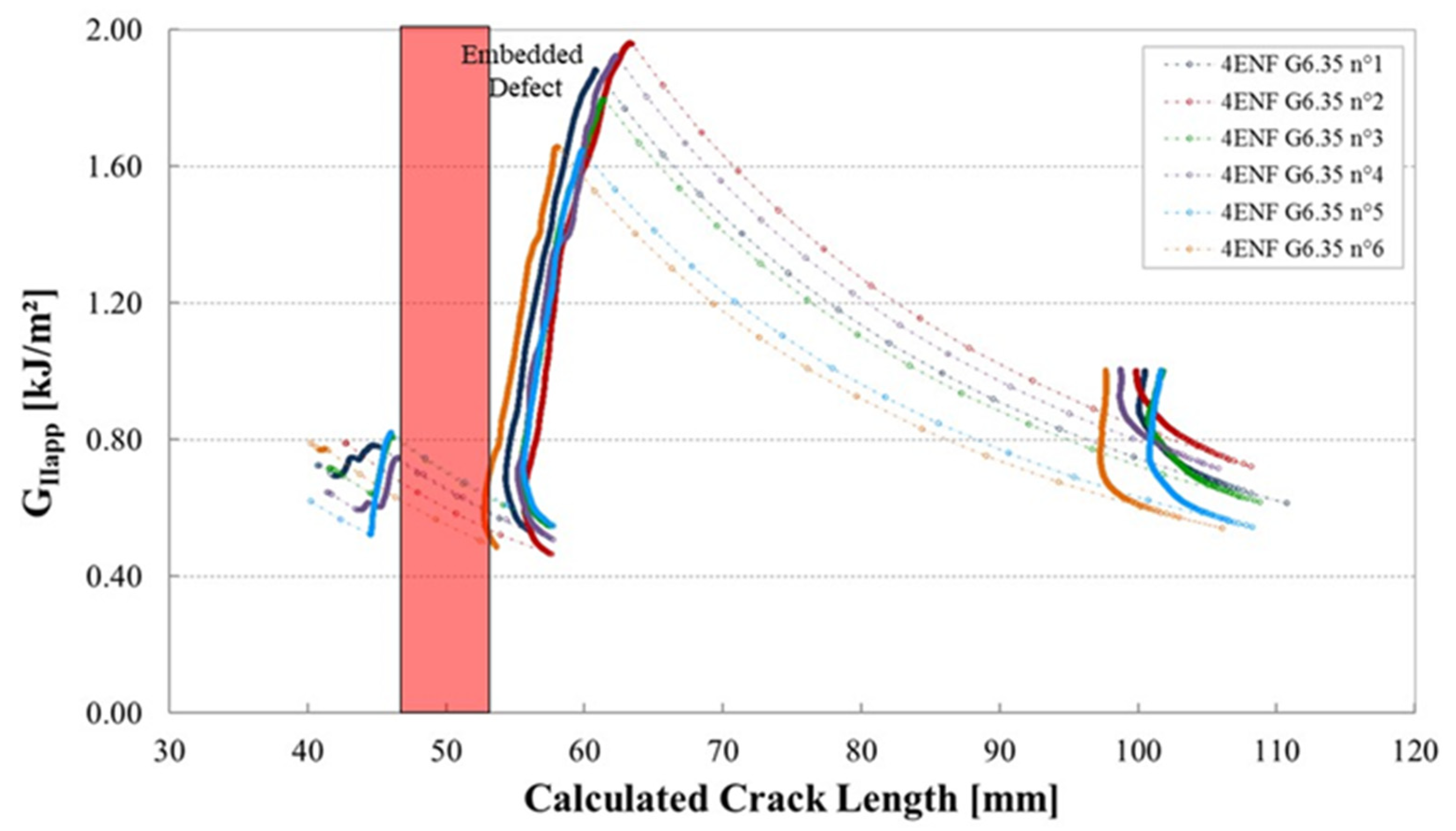

3.5. Influence of Manufacturing Defects in Mode II

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lukaszewicz, D.H.-J.A.; Ward, C.; Potter, K.D. The engineering aspects of automated prepreg layup: History, present and future. Compos. Part B Eng. 2012, 43, 997–1009. [Google Scholar] [CrossRef]

- Maung, P.; Prusty, B.G.; White, J.M.; David, M.; Phillips, A.W.; St John, N.A. Structural performance of a shape-adaptive composite hydrofoil using automated fibre placement. Eng. Struct. 2019, 183, 351–365. [Google Scholar] [CrossRef]

- Maung, P.T.; Prusty, B.G.; Phillips, A.W.; St John, N.A. Curved fibre path optimisation for improved shape adaptive composite propeller blade design. Compos. Struct. 2021, 255, 112961. [Google Scholar] [CrossRef]

- Robert, C.; Pecur, T.; Maguire, J.M.; Lafferty, A.D.; McCarthy, E.D.; Brádaigh, C.M.Ó. A novel powder-epoxy towpregging line for wind and tidal turbine blades. Compos. Part B Eng. 2020, 203, 108443. [Google Scholar] [CrossRef]

- Sawicki, A.; Minguett, P. The effect of intraply overlaps and gaps upon the compression strength of composite laminates. In Proceedings of the 39th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference and Exhibit, Structures, Structural Dynamics, Long Beach, CA, USA, 20–23 April 1998; p. 744. [Google Scholar] [CrossRef]

- Blom, A.W.; Lopes, C.S.; Kromwijk, P.J.; Gurdal, Z.; Camanho, P.P. A Theoretical Model to Study the Influence of Tow-drop Areas on the Stiffness and Strength of Variable-stiffness Laminates. J. Compos. Mater. 2009, 43, 403–425. [Google Scholar] [CrossRef]

- Turoski, L.E. Effects of Manufactoring Defects Ont the Strength of Toughened Carbon/Epoxy Prepreg Composites. Ph.D. Thesis, Montana State University, Bozeman, MT, USA, 2000. [Google Scholar]

- Boon, Y.D.; Joshi, S.C.; Bhudolia, S.K. Review: Filament Winding and Automated Fiber Placement with In Situ Consolidation for Fiber Reinforced Thermoplastic Polymer Composites. Polymers 2021, 13, 1951. [Google Scholar] [CrossRef]

- Woigk, W.; Hallett, S.R.; Jones, M.I.; Kuhtz, M.; Hornig, A.; Gude, M. Experimental investigation of the effect of defects in Automated Fibre Placement produced composite laminates. Compos. Struct. 2018, 201, 1004–1017. [Google Scholar] [CrossRef] [Green Version]

- Oromiehie, E.; Prusty, B.G.; Compston, P.; Rajan, G. Automated fibre placement based composite structures: Review on the defects, impacts and inspections techniques. Compos. Struct. 2019, 224, 110987. [Google Scholar] [CrossRef]

- Croft, K.; Lessard, L.; Pasini, D.; Hojjati, M.; Chen, J.; Yousefpour, A. Experimental study of the effect of automated fiber placement induced defects on performance of composite laminates. Compos. Part A Appl. Sci. Manuf. 2011, 42, 484–491. [Google Scholar] [CrossRef] [Green Version]

- Legay, P. Etude De L’influence De Défauts Sur Les Propriétés Mécaniques De Matériaux Composites Fabriqués Par Le Procédé De Placement De Fibres. Ph.D. Thesis, Ecole Polytechnique de Montréal, Montréal, QC, Canada, 2011. [Google Scholar]

- Falcó, O.; Mayugo, J.A.; Lopes, C.S.; Gascons, N.; Costa, J. Variable-stiffness composite panels: Defect tolerance under in-plane tensile loading. Compos. Part A Appl. Sci. Manuf. 2014, 63, 21–31. [Google Scholar] [CrossRef] [Green Version]

- Rhead, A.; Dodwell, T.; Butler, R. The effect of tow gaps on compression after impact strength of robotically laminated structures. Comput. Mater. Contin. 2013, 35, 1–16. [Google Scholar]

- Falcó, O.; Lopes, C.S.; Mayugo, J.A.; Gascons, N.; Renart, J. Effect of tow-drop gaps on the damage resistance and tolerance of Variable-Stiffness Panels. Compos. Struct. 2014, 116, 94–103. [Google Scholar] [CrossRef] [Green Version]

- Elsherbini, Y.M.; Hoa, S. V Experimental and numerical investigation of the effect of gaps on fatigue behavior of unidirectional carbon/epoxy automated fiber placement laminates. J. Compos. Mater. 2017, 51, 759–772. [Google Scholar] [CrossRef]

- Lan, M.; Cartié, D.; Davies, P.; Baley, C. Microstructure and tensile properties of carbon-epoxy laminates produced by automated fibre placement: Influence of a caul plate on the effects of gap and overlap embedded defects. Compos. Part A Appl. Sci. Manuf. 2015, 78, 124–134. [Google Scholar] [CrossRef] [Green Version]

- Lan, M.; Cartié, D.; Davies, P.; Baley, C. Influence of embedded gap and overlap fiber placement defects on the microstructure and shear and compression properties of carbon-epoxy laminates. Compos. Part A Appl. Sci. Manuf. 2016, 82, 198–207. [Google Scholar] [CrossRef] [Green Version]

- Comer, A.J.; Ray, D.; Obande, W.O.; Jones, D.; Lyons, J.; Rosca, I.; Higgins, R.M.O.; McCarthy, M.A. Mechanical characterisation of carbon fibre–PEEK manufactured by laser-assisted automated-tape-placement and autoclave. Compos. Part A Appl. Sci. Manuf. 2015, 69, 10–20. [Google Scholar] [CrossRef]

- Ray, D.; Comer, A.J.; Lyons, J.; Obande, W.; Jones, D.; Higgins, R.M.O.; McCarthy, M.A. Fracture toughness of carbon fiber/polyether ether ketone composites manufactured by autoclave and laser-assisted automated tape placement. J. Appl. Polym. Sci. 2015, 132, 41643. [Google Scholar] [CrossRef]

- Stokes-Griffin, C.M.; Compston, P. The effect of processing temperature and placement rate on the short beam strength of carbon fibre–PEEK manufactured using a laser tape placement process. Compos. Part A Appl. Sci. Manuf. 2015, 78, 274–283. [Google Scholar] [CrossRef]

- Grouve, W.J.B.; Warnet, L.L.; Rietman, B.; Visser, H.A.; Akkerman, R. Optimization of the tape placement process parameters for carbon–PPS composites. Compos. Part A Appl. Sci. Manuf. 2013, 50, 44–53. [Google Scholar] [CrossRef]

- Zhou, W.; Cheng, Q.; Xu, Q.; Zhu, W.; Ke, Y. Deformation and fracture mechanisms of automated fiber placement pre-preg laminates under out-of-plane tensile loading. Compos. Struct. 2021, 255, 112948. [Google Scholar] [CrossRef]

- Ghayour, M.; Ganesan, R.; Hojjati, M. Flexural response of composite beams made by Automated Fiber Placement process: Effect of fiber tow gaps. Compos. Part B Eng. 2020, 201, 108368. [Google Scholar] [CrossRef]

- Le Guen-Geffroy, A.; Davies, P.; Le Gac, P.-Y.; Habert, B. Influence of Seawater Ageing on Fracture of Carbon Fiber Reinforced Epoxy Composites for Ocean Engineering. Oceans 2020, 1, 198–214. [Google Scholar] [CrossRef]

- Coriolis. Available online: https://www.coriolis-composites.com/ (accessed on 1 September 2021).

- Laksimi, A.; Benzeggagh, M.L.; Jing, G.; Hecini, M.; Roelandt, J.M. Mode I interlaminar fracture of symmetrical cross-ply composites. Compos. Sci. Technol. 1991, 41, 147–164. [Google Scholar] [CrossRef]

- Benzeggagh, M.L.; Gong, X.J.; Laksimi, A.; Roelandt, J.M. On the mode I delamination test and the importance of laminate lay-ups. Polym. Eng. Sci. 1991, 31, 1286–1292. [Google Scholar] [CrossRef]

- Gong, X.J.; Hurez, A.; Verchery, G. On the determination of delamination toughness by using multidirectional DCB specimens. Polym. Test. 2010, 29, 658–666. [Google Scholar] [CrossRef]

- 15024 IS0 15024, Fiber Reinforced Plastic Composites—Determination of Mode I Interlaminar Fracture Toughness, GIC, for Unidirectionnally Reinforced Materials; International Organization for Standardization: Geneva, Switzerland, 2001.

- Martin, R.H.; Davidson, B.D. Mode II fracture toughness evaluation using four point bend, end notched flexure test. Plast. Rubber Compos. 1999, 28, 401–406. [Google Scholar] [CrossRef]

- Davies, P.; Sims, G.D.; Blackman, B.R.K.; Brunner, A.J.; Kageyama, K.; Hojo, M.; Tanaka, K.; Murri, G.; Rousseau, C.; Gieseke, B.; et al. Comparison of test configurations for determination of mode II interlaminar fracture toughness results from international collaborative test programme. Plast. Rubber Compos. 1999, 28, 432–437. [Google Scholar] [CrossRef] [Green Version]

- Cartié, D.; Davies, P.; Peleau, M.; Partridge, I.K. The influence of hydrostatic pressure on the interlaminar fracture toughness of carbon/epoxy composites. Compos. Part B Eng. 2006, 37, 292–300. [Google Scholar] [CrossRef] [Green Version]

- Whitney, J.M.; Browning, C.E. On short-beam shear tests for composite materials. Exp. Mech. 1985, 25, 294–300. [Google Scholar] [CrossRef]

- Brunner, A.J.; Blackman, B.R.K. Delamination Fracture in Cross-Ply Laminates: What can be Learned from Experiment? In European Structural Integrity Society; Blackman, B.R.K., Pavan, A., Williams, J.G., Eds.; Elsevier: Amsterdam, The Netherlands, 2003; Volume 32, pp. 433–444. [Google Scholar] [CrossRef]

- Cartié, D.D.R.; Laffaille, J.-M.; Partridge, I.K.; Brunner, A.J. Fatigue delamination behaviour of unidirectional carbon fibre/epoxy laminates reinforced by Z-Fiber® pinning. Eng. Fract. Mech. 2009, 76, 2834–2845. [Google Scholar] [CrossRef] [Green Version]

- Aksoy, A.; Carlsson, L.A. Crack tip yield zone estimates in mode II interlaminar fracture of interleaved composites. Eng. Fract. Mech. 1991, 39, 525–534. [Google Scholar] [CrossRef]

- Davies, P. Influence of ENF Specimen Geometry and Friction on the Mode II Delamination Resistance of Carbon/PEEK. J. Thermoplast. Compos. Mater. 1997, 10, 353–361. [Google Scholar] [CrossRef]

- Ozdil, F.; Carlsson, L.A. Plastic zone estimates in mode I interlaminar fracture of interleaved composites. Eng. Fract. Mech. 1992, 41, 645–658. [Google Scholar] [CrossRef]

- Paris, I.; Poursartip, A. Delamination Crack Tip Behavior at Failure in Composite Laminates under Mode I Loading. J. Thermoplast. Compos. Mater. 1998, 11, 57–69. [Google Scholar] [CrossRef]

- Chai, H. The characterization of Mode I delamination failure in non-woven, multidirectional laminates. Composites 1984, 15, 277–290. [Google Scholar] [CrossRef]

| Mode I Delamination Toughness (kJ/m2) | ||

|---|---|---|

| Embedded Defect Region | Propagation a = 80 mm | |

| Gap 0.5 mm—Without CP | 0.565 (±) 0.136 | 0.425 (±) 0.090 |

| Gap 0.5 mm—With CP | 0.701 (±) 0.137 | 0.371 (±) 0.073 |

| Gap 3.175 mm—Without CP | 0.623 (±) 0.098 | 0.431 (±) 0.127 |

| Gap 3.175 mm—With CP | 0.641 (±) 0.196 | 0.384 (±) 0.061 |

| Gap 6.35 mm—Without CP | 0.498 (±) 0.177 | 0.373 (±) 0.055 |

| Gap 6.35 mm—With CP | 0.558 (±) 0.117 | 0.353 (±) 0.068 |

| Overlap 3.175 mm—Without CP | 0.559 (±) 0.141 | 0.389 (±) 0.099 |

| Overlap 3.175 mm—With CP | 0.460 (±) 0.071 | 0.402 (±) 0.014 |

| Mode II Delamination Toughness (kJ/m2) | ||

|---|---|---|

| Embedded Defect Region | Propagation a = 75 mm | |

| Gap 0.5 mm—Without CP | 0.576 (±) 0.052 | 0.447 (±) 0.079 |

| Gap 0.5 mm—With CP | 0.702 (±) 0.037 | 0.583 (±) 0.075 |

| Gap 3.175 mm—Without CP | 0.1727 (±) 0.130 | 0.725 (±) 0.074 |

| Gap 3.175 mm—With CP | 0.944 (±) 0.069 | 0.472 (±) 0.045 |

| Gap 6.35 mm—Without CP | 1.752 (±) 0.112 | 0.641 (±) 0.070 |

| Gap 6.35 mm—With CP | 1.809 (±) 0.135 | 0.625 (±) 0.079 |

| Overlap 3.175 mm—Without CP | 0.642 (±) 0.088 | 0.461 (±) 0.067 |

| Overlap 3.175 mm—With CP | 0.592 (±) 0.089 | 0.434 (±) 0.038 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cartié, D.; Lan, M.; Davies, P.; Baley, C. Influence of Embedded Gap and Overlap Fiber Placement Defects on Interlaminar Properties of High Performance Composites. Materials 2021, 14, 5332. https://doi.org/10.3390/ma14185332

Cartié D, Lan M, Davies P, Baley C. Influence of Embedded Gap and Overlap Fiber Placement Defects on Interlaminar Properties of High Performance Composites. Materials. 2021; 14(18):5332. https://doi.org/10.3390/ma14185332

Chicago/Turabian StyleCartié, Denis, Marine Lan, Peter Davies, and Christophe Baley. 2021. "Influence of Embedded Gap and Overlap Fiber Placement Defects on Interlaminar Properties of High Performance Composites" Materials 14, no. 18: 5332. https://doi.org/10.3390/ma14185332

APA StyleCartié, D., Lan, M., Davies, P., & Baley, C. (2021). Influence of Embedded Gap and Overlap Fiber Placement Defects on Interlaminar Properties of High Performance Composites. Materials, 14(18), 5332. https://doi.org/10.3390/ma14185332