An Experimental Study on Mechanical Properties for the Static and Dynamic Compression of Concrete Eroded by Sulfate Solution

Abstract

:1. Introduction

1.1. Research Background

1.2. Research Significance

1.3. Research Program

2. Materials and Methods

2.1. Raw Materials

2.2. Test Equipment and Method

2.2.1. Dynamic Compression and Static Compression Test

2.2.2. Ultrasonic Test

2.2.3. Microscopic Test

3. Results

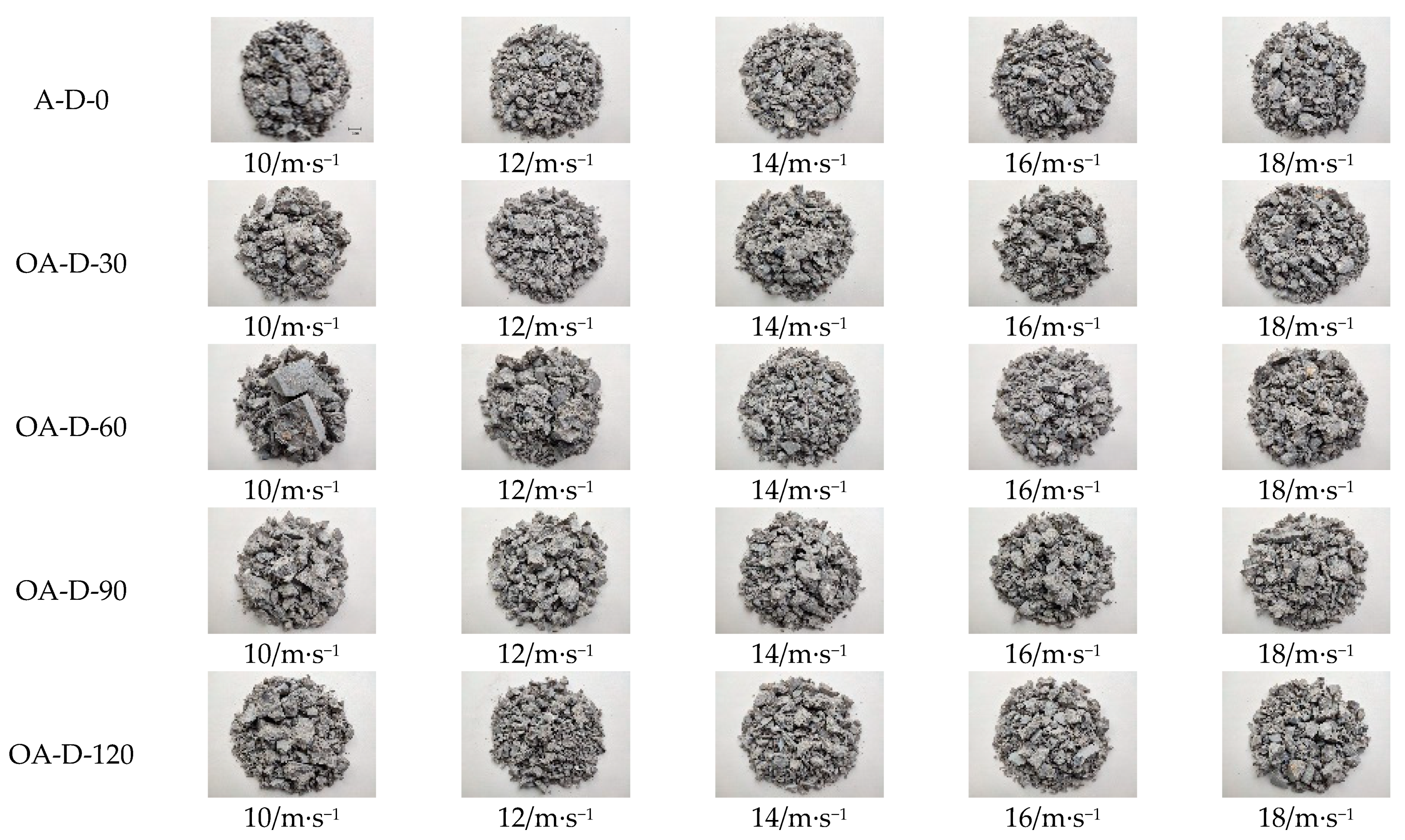

3.1. Dynamic Failure Mode

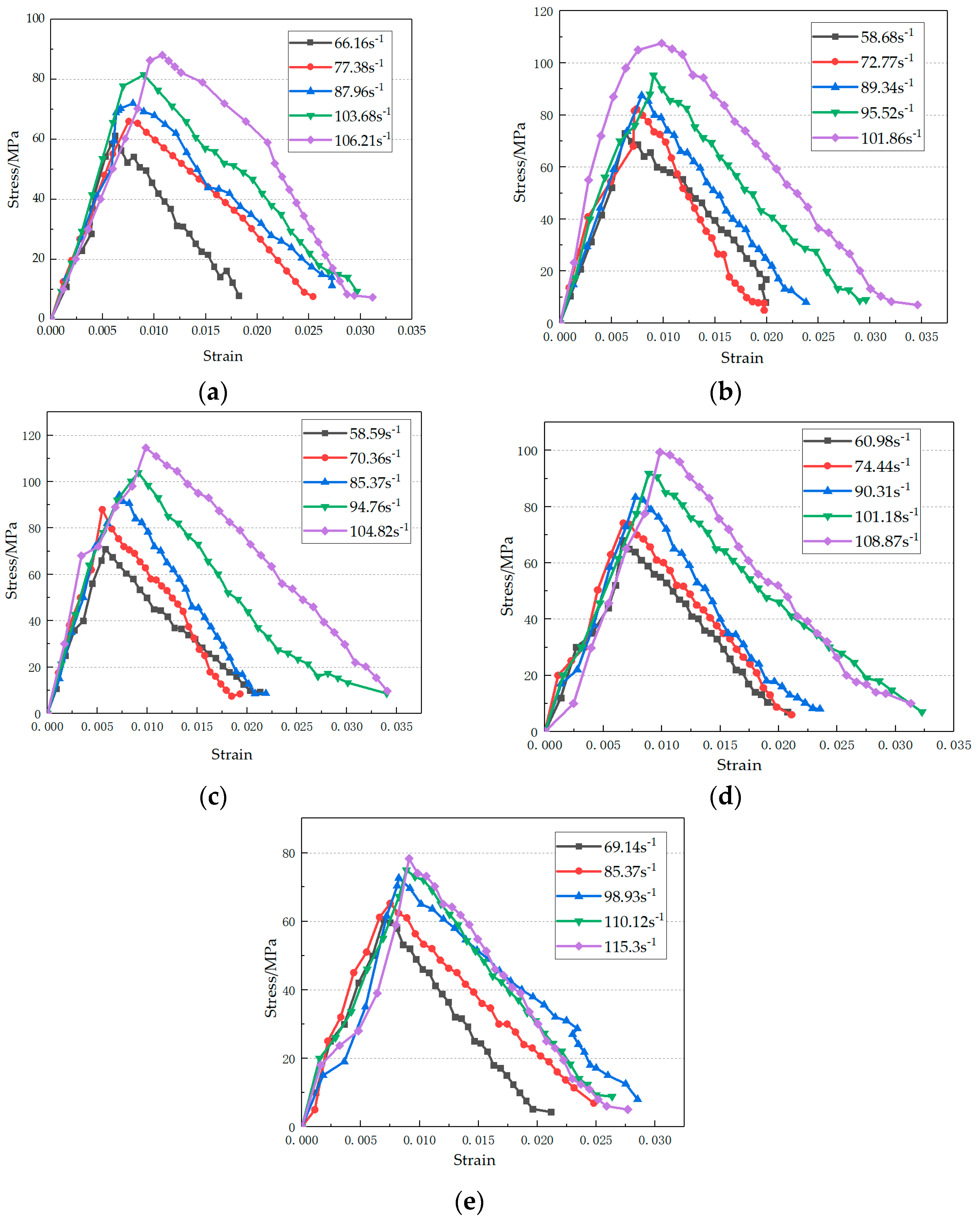

3.2. Dynamic Stress–Strain Curve

3.3. Dynamic Mechanical Related Properties

4. Analysis of Relevant Mechanisms

5. Discussion

6. Conclusions

- (1)

- The dynamic and static mechanical properties of concrete are weakened to a certain extent after sulfate erosion. The dynamic strain rate effect is significant, the dynamic compressive strength is decreased, and the impact toughness and deformation capacity are also weakened.

- (2)

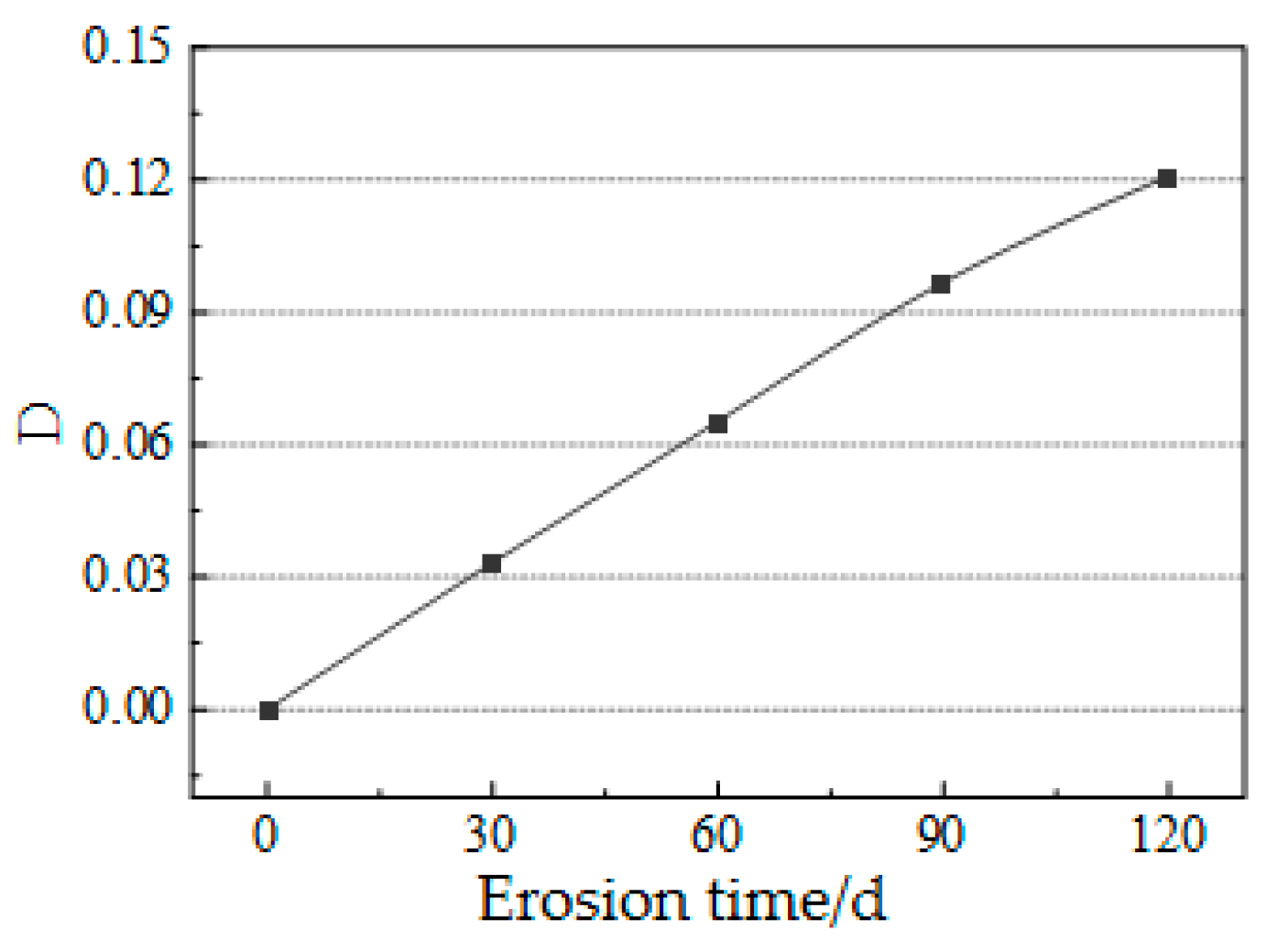

- There are two main factors affecting the dynamic and static mechanical properties of concrete after being corroded by sulfate solution, including continuous hydration of concrete in solution and sulfate erosion. These two effects have two completely opposite influence trends on the dynamic and static mechanical properties of concrete. Hydration strengthens the properties of concrete, while sulfate erosion weakens the properties.

- (3)

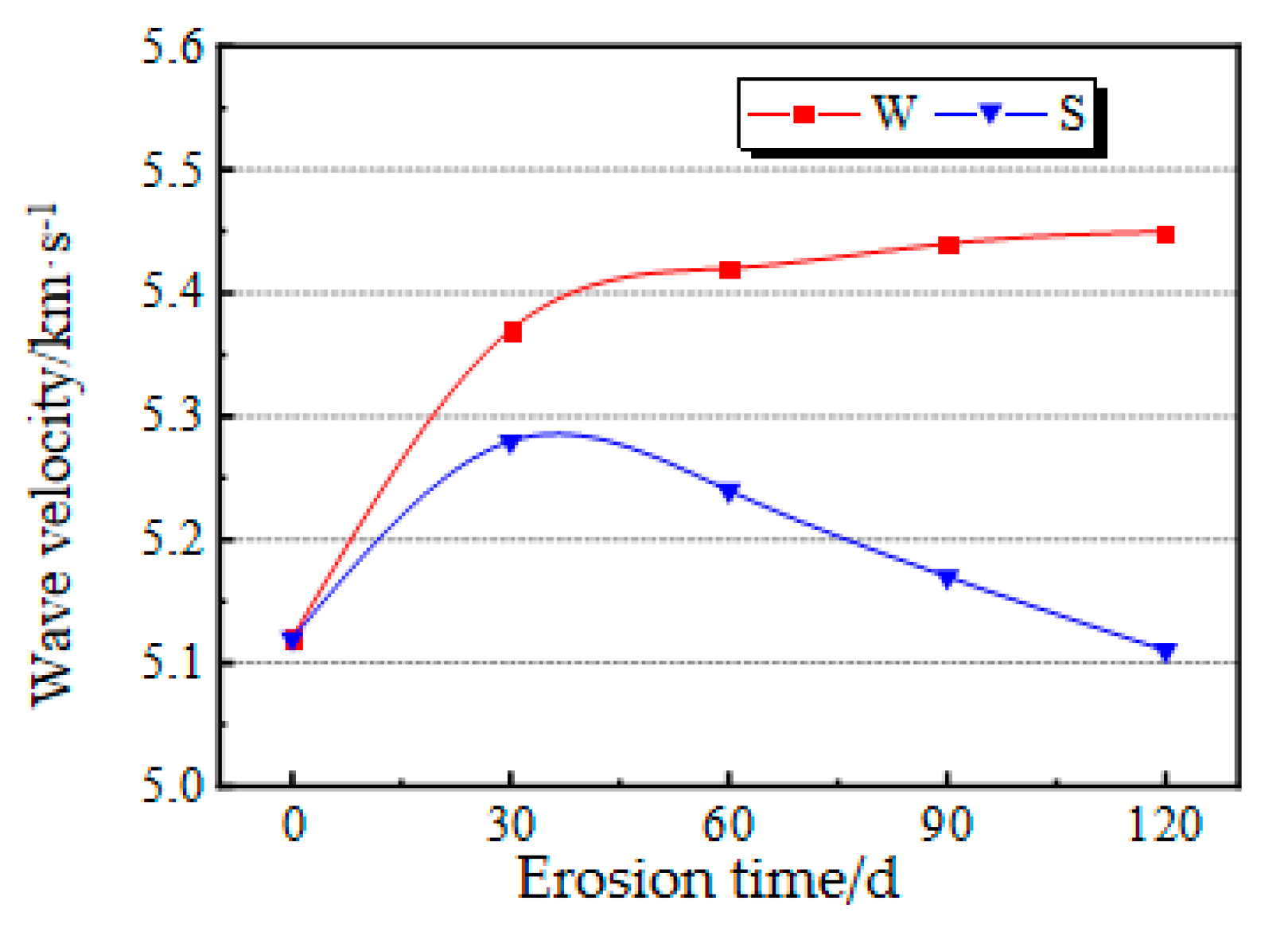

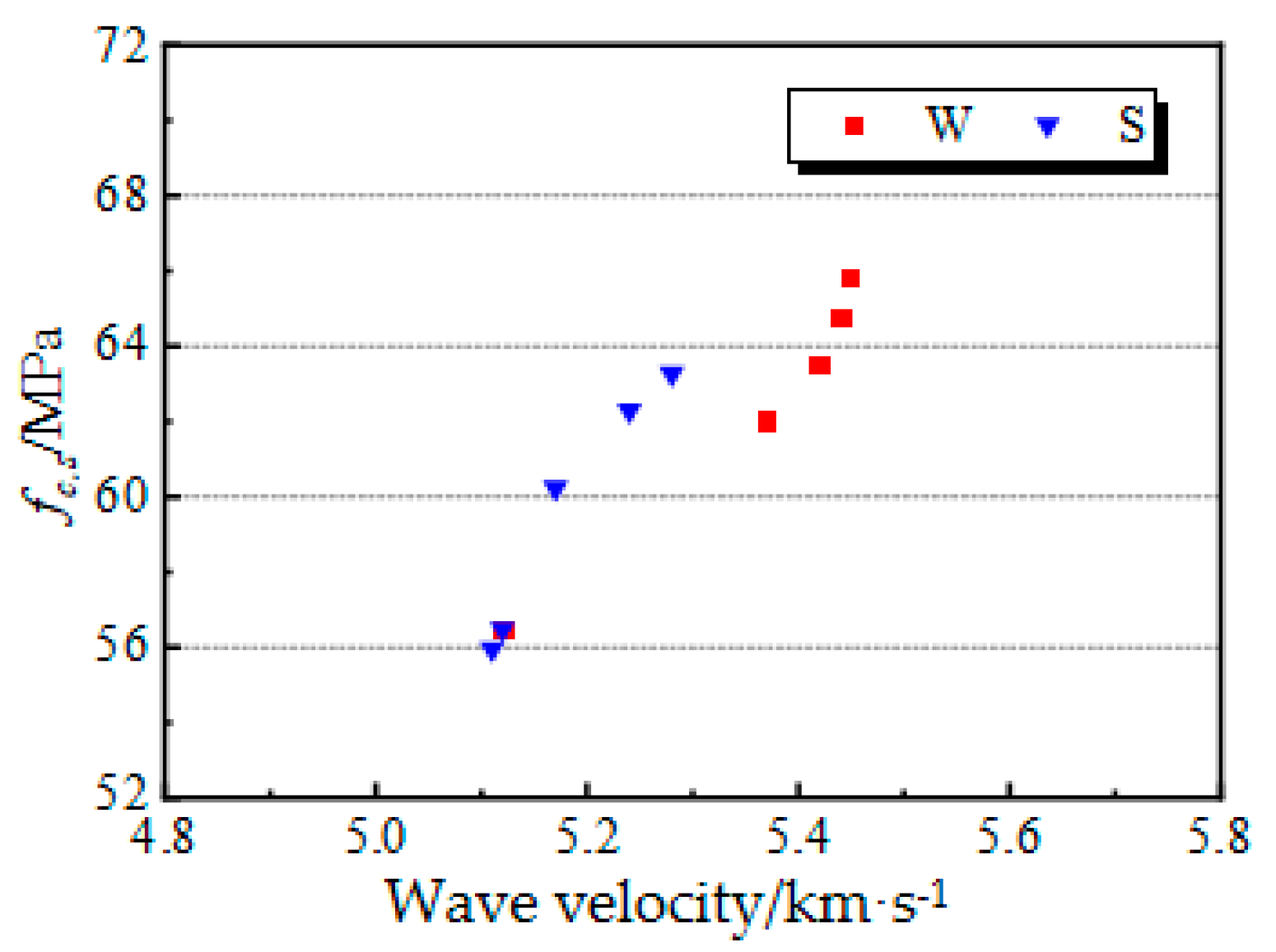

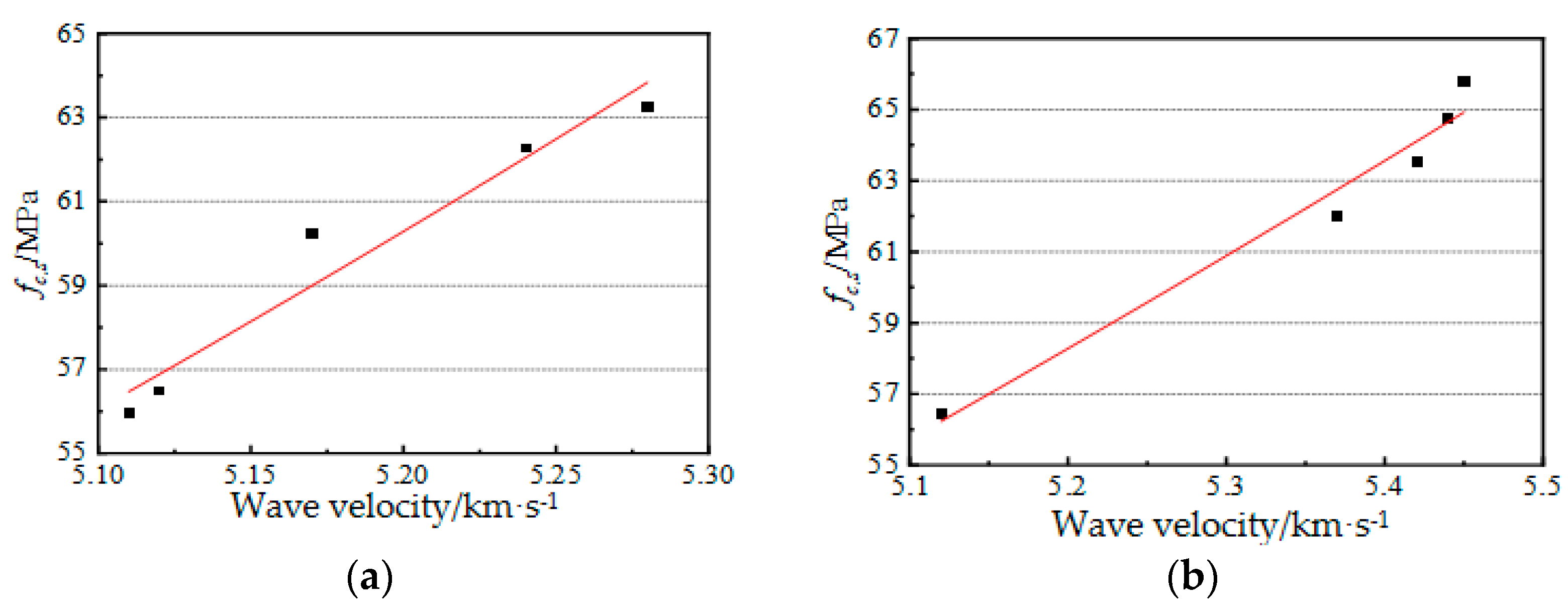

- The law of changes in longitudinal wave velocity is similar to that of strength. Due to the changes in strength and internal pore structure of the test pieces after sulfate erosion. The longitudinal wave velocity is slower than that of concrete under normal environment and distilled water immersion condition. In addition, the compressive strength and the compressional wave velocity develop. In the same direction, in response to external influences, both the compressive strength and the compressional wave velocity of concrete have a decreasing trend after sulfate erosion.

- (4)

- For the concrete eroded by sulfate, the internal structure changed, within which a large number of low-strength consolidation products may be formed. In addition, the increase in the volume of reaction products and the crystals with strength weaker than that of normal gels may compromise the concrete strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brara, A.; Klepaczko, J.R. Experimental Characterization of Concrete in Dynamic Tension. Mech. Mater. 2006, 38, 253–267. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, W.; Wu, M.; Shen, B.; Li, M.; Xu, G.; Zhang, B.; Ding, Q.; Chen, X. Experimental Study on the Utilization of Copper Tailing as Micronized Sand to Prepare High Performance Concrete. Constr. Build. Mater. 2020, 244, 118312. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Weinberg, K. A Review on Split Hopkinson Bar Experiments on the Dynamic Characterisation of Concrete. Constr. Build. Mater. 2018, 190, 1264–1283. [Google Scholar] [CrossRef]

- Lacidogna, G.; Piana, G.; Accornero, F.; Carpinteri, A. Multi-Technique Damage Monitoring of Concrete Beams: Acoustic Emission, Digital Image Correlation, Dynamic Identification. Constr. Build. Mater. 2020, 242, 118114. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Y.; Shi, C.; Chen, X. Experimental and Numerical Study on Tensile Strength and Failure Pattern of High Performance Steel Fiber Reinforced Concrete under Dynamic Splitting Tension. Constr. Build. Mater. 2020, 259, 119796. [Google Scholar] [CrossRef]

- Safehian, M.; Ramezanianpour, A.A. Assessment of Service Life Models for Determination of Chloride Penetration into Silica Fume Concrete in the Severe Marine Environmental Condition. Constr. Build. Mater. 2013, 48, 287–294. [Google Scholar] [CrossRef]

- Tang, S.W.; Yao, Y.; Andrade, C.; Li, Z.J. Recent Durability Studies on Concrete Structure. Cem. Concr. Res. 2015, 78, 143–154. [Google Scholar] [CrossRef]

- Al-Amoudi, O.S.B. Sulfate Attack and Reinforcement Corrosion in Plain and Blended Cements Exposed to Sulfate Environments. Build. Environ. 1998, 33, 53–61. [Google Scholar] [CrossRef]

- Baghabra Al-Amoudi, O.S. Attack on Plain and Blended Cements Exposed to Aggressive Sulfate Environments. Cem. Concr. Compos. 2002, 24, 305–316. [Google Scholar] [CrossRef]

- Li, R.; Hou, H.; Hu, D.; Zou, Y. Effect of Concrete Micro-Mechanical Properties under the Coupled Corrosion of Sulfate and High Water Head. Energies 2021, 14, 5039. [Google Scholar] [CrossRef]

- Zou, D.; Qin, S.; Liu, T.; Jivkov, A. Experimental and Numerical Study of the Effects of Solution Concentration and Temperature on Concrete under External Sulfate Attack. Cem. Concr. Res. 2021, 139, 106284. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, W.; Mu, S.; Šavija, B.; Liu, Q. Numerical Investigation of External Sulfate Attack and Its Effect on Chloride Binding and Diffusion in Concrete. Constr. Build. Mater. 2021, 285, 122806. [Google Scholar] [CrossRef]

- Liu, P.; Chen, Y.; Yu, Z. Effects of Erosion Form and Admixture on Cement Mortar Performances Exposed to Sulfate Environment. Crystals 2020, 10, 774. [Google Scholar] [CrossRef]

- Guo, J.; Wang, K.; Qi, C. Determining the Mineral Admixture and Fiber on Mechanics and Fracture Properties of Concrete under Sulfate Attack. J. Mar. Sci. Eng. 2021, 9, 251. [Google Scholar] [CrossRef]

- Hekal, E.E.; Kishar, E.; Mostafa, H. Magnesium Sulfate Attack on Hardened Blended Cement Pastes under Different Circumstances. Cem. Concr. Res. 2002, 32, 1421–1427. [Google Scholar] [CrossRef]

- Tan, Y.; Yu, H.; Ma, H.; Zhang, Y.; Wu, C. Study on the Micro-Crack Evolution of Concrete Subjected to Stress Corrosion and Magnesium Sulfate. Constr. Build. Mater. 2017, 141, 453–460. [Google Scholar] [CrossRef]

- Liu, T.; Zou, D.; Teng, J.; Yan, G. The Influence of Sulfate Attack on the Dynamic Properties of Concrete Column. Constr. Build. Mater. 2012, 28, 201–207. [Google Scholar] [CrossRef]

- Sarkar, S.; Mahadevan, S.; Meeussen, J.C.L.; van der Sloot, H.; Kosson, D.S. Numerical Simulation of Cementitious Materials Degradation under External Sulfate Attack. Cem. Concr. Compos. 2010, 32, 241–252. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Qian, C.; Song, H. A New Chemo-Mechanical Model of Damage in Concrete under Sulfate Attack. Constr. Build. Mater. 2016, 115, 536–543. [Google Scholar] [CrossRef] [Green Version]

- Sun, C.; Chen, J.; Zhu, J.; Zhang, M.; Ye, J. A New Diffusion Model of Sulfate Ions in Concrete. Constr. Build. Mater. 2013, 39, 39–45. [Google Scholar] [CrossRef]

- Hou, W.; He, F.; Liu, Z. Characterization Methods for Sulfate Ions Diffusion Coefficient in Calcium Sulphoaluminate Mortar Based on AC Impedance Spectroscopy. Constr. Build. Mater. 2021, 289, 123169. [Google Scholar] [CrossRef]

- Jiang, L.; Niu, D.; Yuan, L.; Fei, Q. Durability of Concrete under Sulfate Attack Exposed to Freeze–Thaw Cycles. Cold Reg. Sci. Technol. 2015, 112, 112–117. [Google Scholar] [CrossRef]

- Park, Y.-S.; Suh, J.-K.; Lee, J.-H.; Shin, Y.-S. Strength Deterioration of High Strength Concrete in Sulfate Environment. Cem. Concr. Res. 1999, 29, 1397–1402. [Google Scholar] [CrossRef]

- Al-Akhras, N.M. Durability of Metakaolin Concrete to Sulfate Attack. Cem. Concr. Res. 2006, 36, 1727–1734. [Google Scholar] [CrossRef]

- Zhao, G.; Guo, M.; Cui, J.; Li, J.; Xu, L. Partially-Exposed Cast-in-Situ Concrete Degradation Induced by Internal-External Sulfate and Magnesium Multiple Coupled Attack. Constr. Build. Mater. 2021, 294, 123560. [Google Scholar] [CrossRef]

- Ouyang, W.; Chen, J.; Jiang, M. Evolution of Surface Hardness of Concrete under Sulfate Attack. Constr. Build. Mater. 2014, 53, 419–424. [Google Scholar] [CrossRef] [Green Version]

- Qi, B.; Gao, J.; Chen, F.; Shen, D. Evaluation of the Damage Process of Recycled Aggregate Concrete under Sulfate Attack and Wetting-Drying Cycles. Constr. Build. Mater. 2017, 138, 254–262. [Google Scholar] [CrossRef]

- Geng, J.; Sun, Q.; Zhang, Y.; Cao, L.; Zhang, W. Studying the Dynamic Damage Failure of Concrete Based on Acoustic Emission. Constr. Build. Mater. 2017, 149, 9–16. [Google Scholar] [CrossRef]

- Anay, R.; Soltangharaei, V.; Assi, L.; DeVol, T.; Ziehl, P. Identification of Damage Mechanisms in Cement Paste Based on Acoustic Emission. Constr. Build. Mater. 2018, 164, 286–296. [Google Scholar] [CrossRef]

- China Building Materials Industry Association. GB 175-2007. General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China; Standardization Administration of China: Beijing, China, 2007. [Google Scholar]

- Xia, W.; Xu, J.; Nie, L. Research on the Mechanical Performance of Carbon Nanofiber Reinforced Concrete under Impact Load Based on Fractal Theory. Crystals 2021, 11, 387. [Google Scholar] [CrossRef]

- Ahmad, A.; Farooq, F.; Ostrowski, K.A.; Śliwa-Wieczorek, K.; Czarnecki, S. Application of Novel Machine Learning Techniques for Predicting the Surface Chloride Concentration in Concrete Containing Waste Material. Materials 2021, 14, 2297. [Google Scholar] [CrossRef] [PubMed]

| Serial Number | Erosion Time | Impact Speed/m·s−1 | IT (kJ/m3) | |||||

|---|---|---|---|---|---|---|---|---|

| OA-D-0 | 0 d | 10 | 61.66 | 61.25 | 6.02 | 17.94 | 1.08 | 619.27 |

| 12 | 77.38 | 66.03 | 7.55 | 22.04 | 1.17 | 872.59 | ||

| 14 | 87.96 | 72.04 | 7.95 | 24.32 | 1.28 | 1041.13 | ||

| 16 | 103.68 | 81.59 | 9.00 | 27.86 | 1.44 | 1323.35 | ||

| 18 | 106.21 | 88.11 | 9.59 | 31.77 | 1.56 | 1691.18 | ||

| OA-D-30 | 30 d | 10 | 58.68 | 72.95 | 6.27 | 19.52 | 1.15 | 843.77 |

| 12 | 72.77 | 82.31 | 7.42 | 19.35 | 1.30 | 835.12 | ||

| 14 | 89.43 | 87.46 | 7.90 | 23.81 | 1.38 | 1210.49 | ||

| 16 | 95.52 | 95.32 | 9.05 | 29.60 | 1.51 | 1702.45 | ||

| 18 | 101.86 | 107.56 | 9.83 | 34.59 | 1.70 | 2295.51 | ||

| OA-D-60 | 60 d | 10 | 58.59 | 70.95 | 5.82 | 21.29 | 1.14 | 839.00 |

| 12 | 70.63 | 79.61 | 6.45 | 19.30 | 1.28 | 980.63 | ||

| 14 | 85.37 | 91.41 | 7.57 | 21.91 | 1.47 | 1221.35 | ||

| 16 | 94.76 | 103.86 | 9.10 | 34.00 | 1.67 | 1999.34 | ||

| 18 | 104.82 | 114.61 | 9.85 | 34.06 | 1.84 | 2331.36 | ||

| OA-D-90 | 90 d | 10 | 60.98 | 68.00 | 6.63 | 20.75 | 1.13 | 757.76 |

| 12 | 74.44 | 74.18 | 6.72 | 21.11 | 1.23 | 952.03 | ||

| 14 | 90.31 | 83.34 | 7.75 | 23.53 | 1.38 | 1228.89 | ||

| 16 | 101.18 | 91.86 | 8.89 | 32.26 | 1.53 | 1838.85 | ||

| 18 | 108.87 | 99.38 | 9.85 | 31.31 | 1.65 | 1827.22 | ||

| OA-D-120 | 120 d | 10 | 69.14 | 60.59 | 6.95 | 21.15 | 1.08 | 694.53 |

| 12 | 83.57 | 65.21 | 7.50 | 25.80 | 1.17 | 986.77 | ||

| 14 | 98.93 | 72.62 | 8.23 | 28.53 | 1.30 | 1240.58 | ||

| 16 | 110.12 | 74.94 | 8.81 | 27.36 | 1.34 | 1135.85 | ||

| 18 | 115.30 | 78.34 | 9.10 | 27.68 | 1.40 | 1196.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, A.; Xu, J.; Xia, W. An Experimental Study on Mechanical Properties for the Static and Dynamic Compression of Concrete Eroded by Sulfate Solution. Materials 2021, 14, 5387. https://doi.org/10.3390/ma14185387

Yao A, Xu J, Xia W. An Experimental Study on Mechanical Properties for the Static and Dynamic Compression of Concrete Eroded by Sulfate Solution. Materials. 2021; 14(18):5387. https://doi.org/10.3390/ma14185387

Chicago/Turabian StyleYao, Ao, Jinyu Xu, and Wei Xia. 2021. "An Experimental Study on Mechanical Properties for the Static and Dynamic Compression of Concrete Eroded by Sulfate Solution" Materials 14, no. 18: 5387. https://doi.org/10.3390/ma14185387