Sustainable Applications for Utilizing Antimony Tailing Coarse Aggregate (ATCA) in Concrete: Characteristic of ATCA and Toxicity Risks of Concrete

Abstract

:1. Introduction

2. Background of a Real Case Study

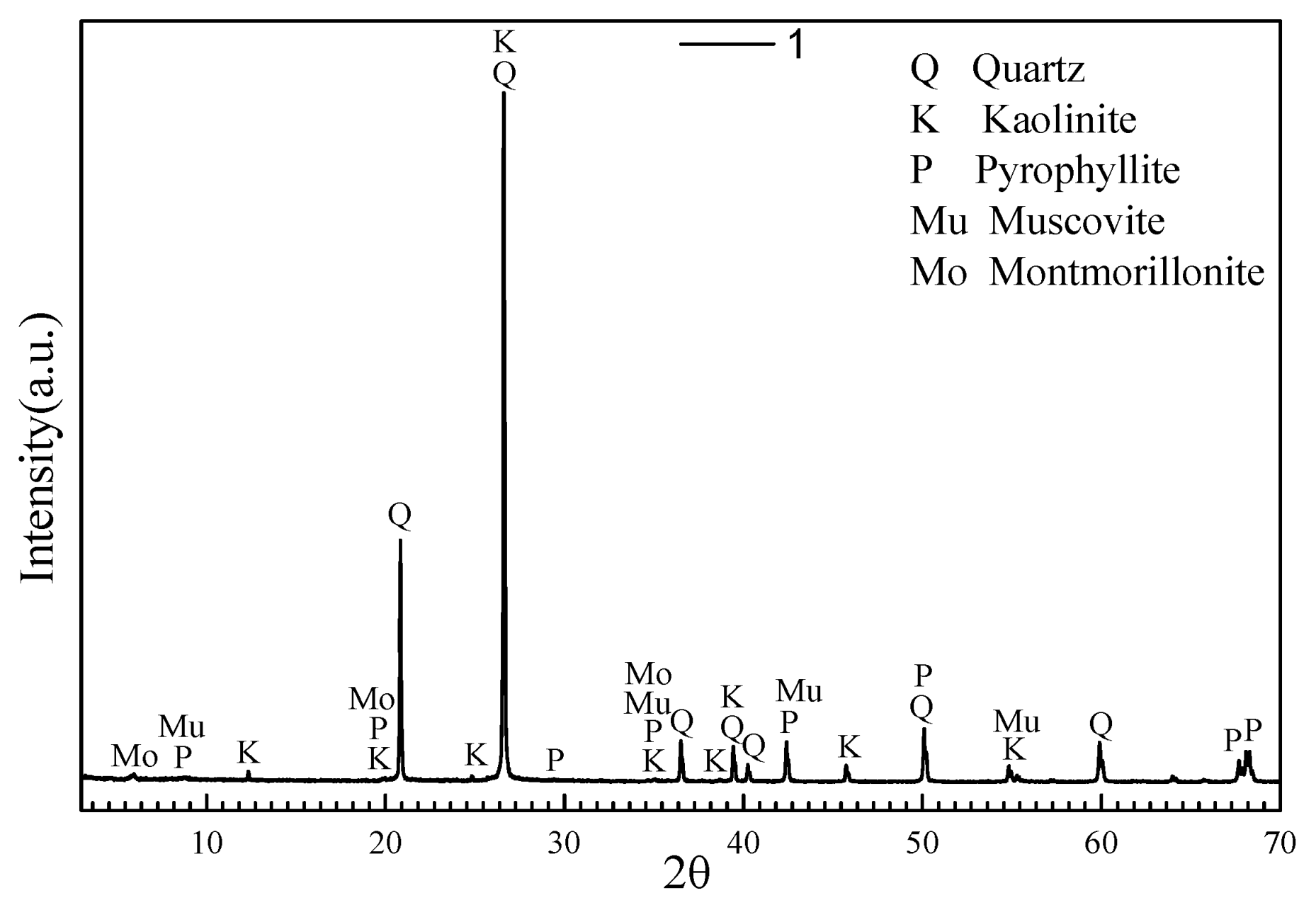

3. The Main Chemical Composition of ATCA

3.1. Sampling

3.2. Experiment Methodology

3.3. Results and Discussion

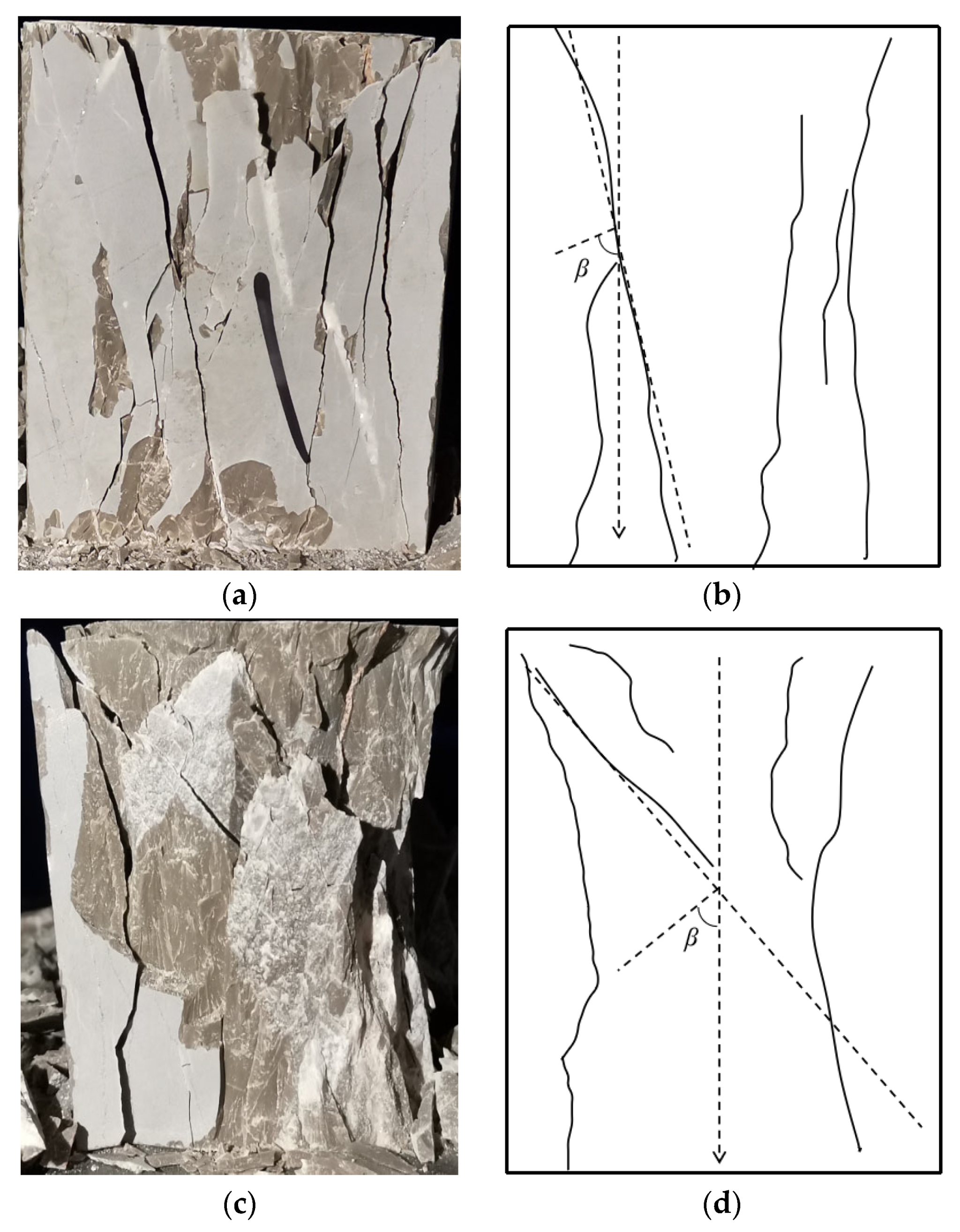

4. Rock Mechanical Properties

4.1. Experimental Design

4.2. Results and Discussions

4.2.1. Compressive Strength of Cubic Samples

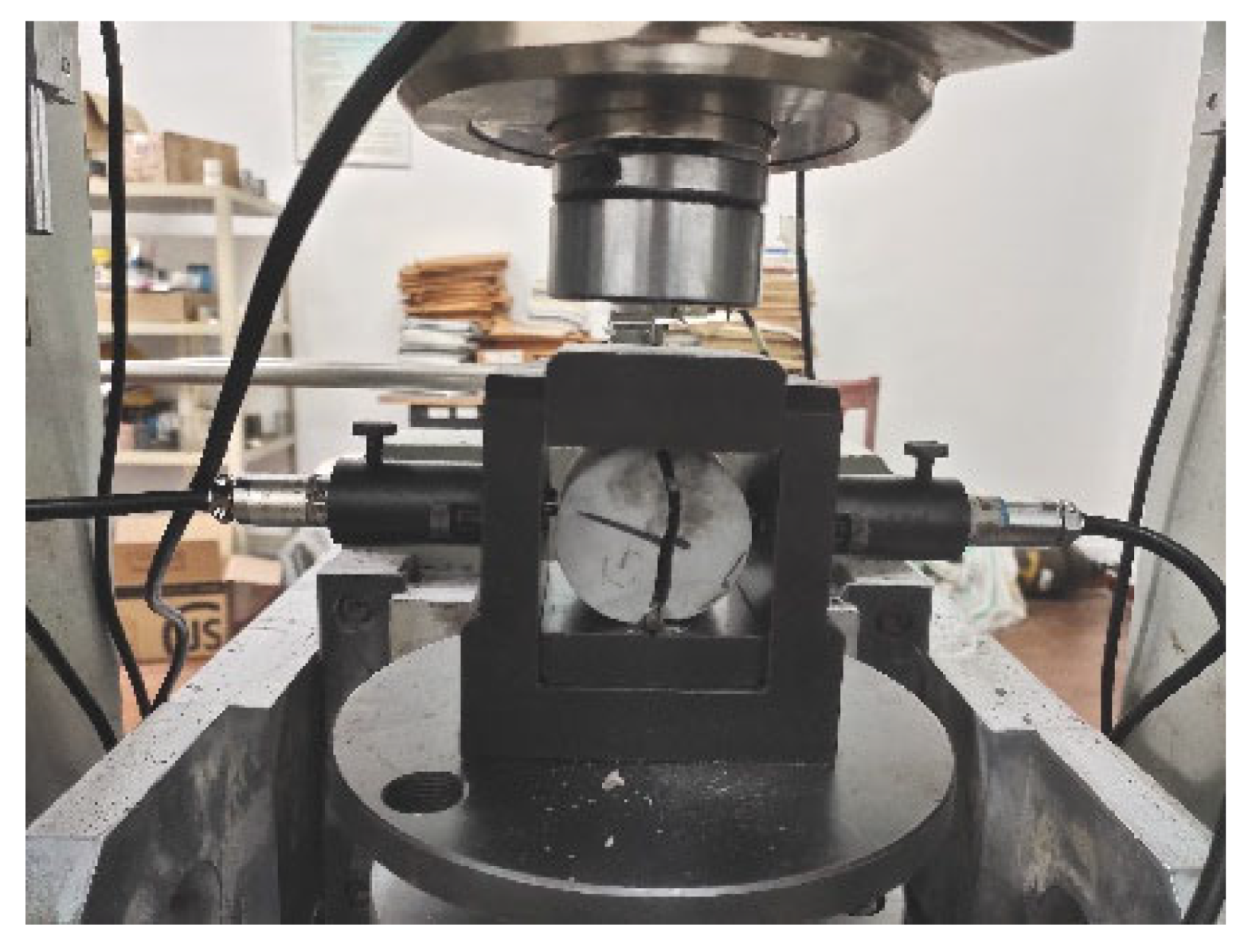

4.2.2. Splitting Tensile Strength

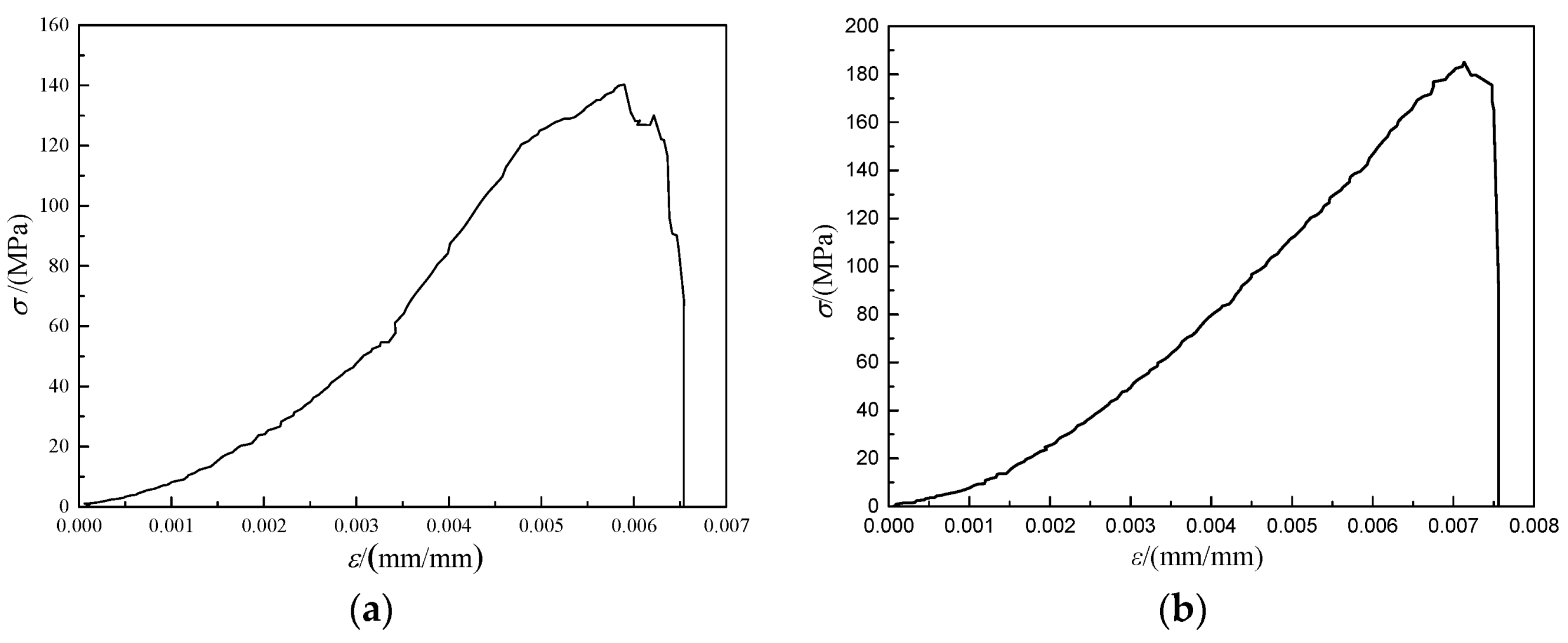

4.2.3. Compressive Elastic Modulus

5. The Quality of ATCA

5.1. Experiment Methodology

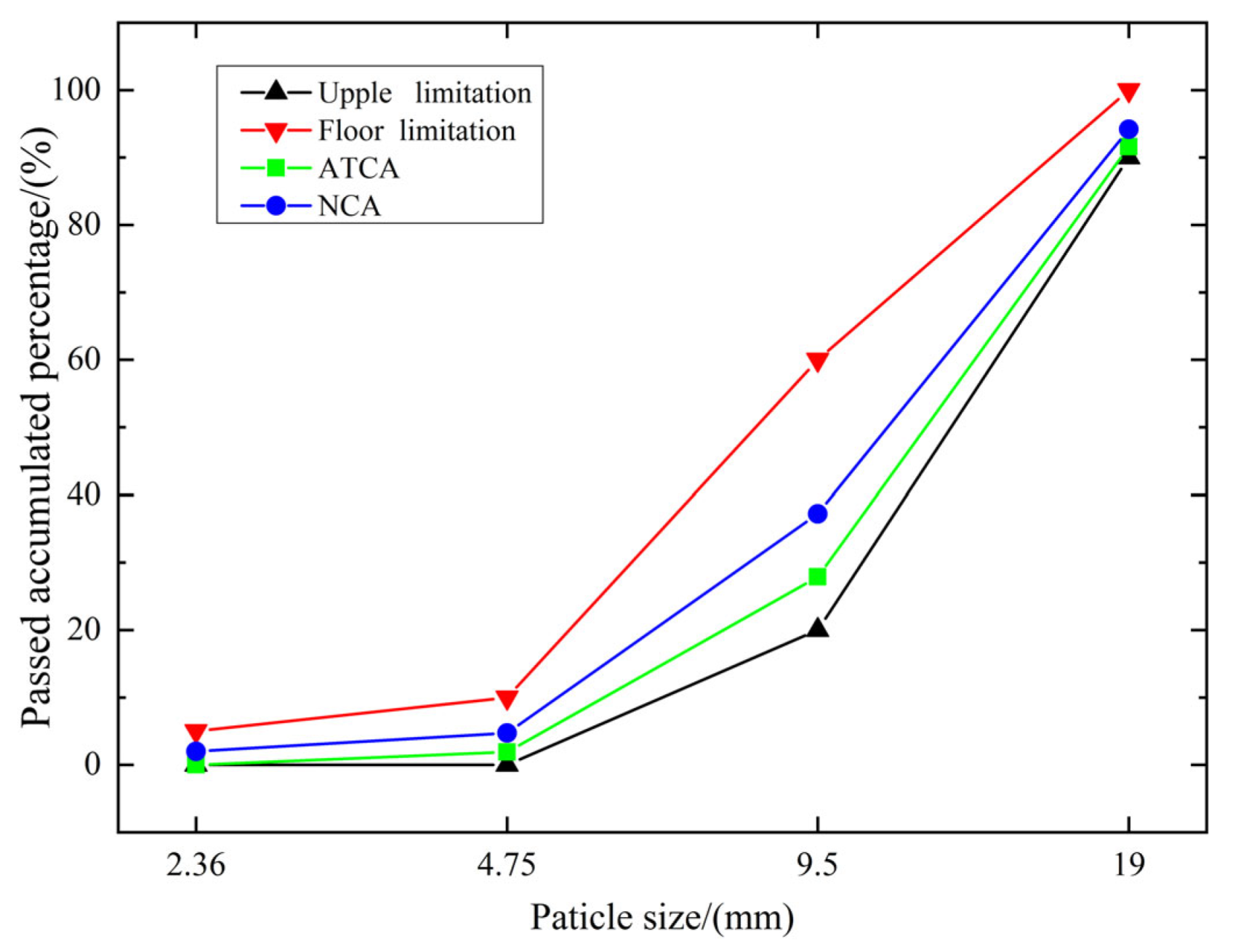

5.2. Gradation

5.3. Density Water Absorption and ASR

5.4. Other Indices of Material Quality

5.5. Discussion

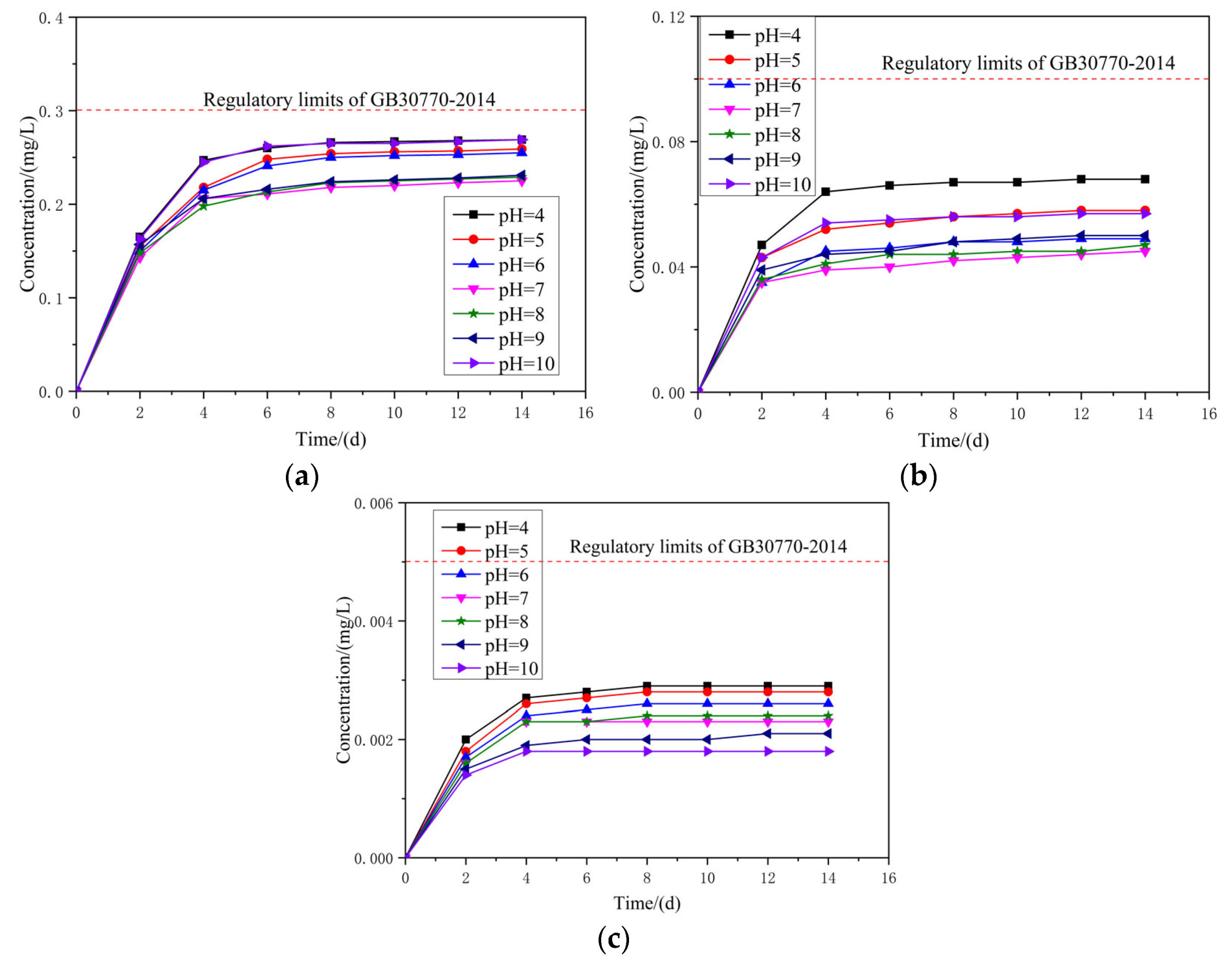

6. The Leaching Test of ATCA Concrete

6.1. Experiment Methodology

6.2. Results and Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deng, R.; Tang, Z.; Hou, B.; Ren, B.; Hursthouse, A. Microbial diversity in soils from antimony mining sites: Geochemicalcontrol promotes species enrichment. Environ. Chem. Lett. 2020, 18, 911–922. [Google Scholar] [CrossRef] [Green Version]

- Aduriz, H.R.; Bodnariuk, P.; Coq, B.; Figueras, F. Alumina-supported bimetallics of palladium alloyed with germanium, tin, lead, or antimony from organometallic precursors: I. Preparation and characterization. J. Catal. 1989, 119, 97–107. [Google Scholar] [CrossRef]

- Krishna, L.; Lalonde, A.D.; Moran, P.D. Increase in the thermoelectric power produced by mechanically alloyed Pb1x Snx Te due to the presence of 15 nm Sno2 inclusions. J. Appl. Phys. 2011, 110, 8. [Google Scholar] [CrossRef]

- Liu, S. The further processing antimony products in china. Multipurp. Util. Miner. Resour. 2003, 1, 29–32. [Google Scholar]

- Fei, J.; Min, X.; Wang, Z.; Pang, Z.; Liang, Y.; Ke, Y. Health and ecological risk assessment of heavy metals pollution in an antimony mining region: A case study from south china. Environ. Sci. Pollut. Res. Int. 2017, 24, 27573–27586. [Google Scholar] [CrossRef] [PubMed]

- He, M. Distribution and phytoavailability of antimony at an antimony mining and smelting area, Hunan, China. Environ. Geochem. Health 2007, 29, 209–219. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Le, X.C.; McKnight-Whitford, A.; Xia, Y.; Wu, F.; Elswick, E.; Johnson, C.C.; Zhu, C. Antimony speciation and contamination of waters in the Xikuangshan antimony mining and smelting area, China. Environ. Geochem. Health 2010, 32, 401–413. [Google Scholar] [CrossRef] [PubMed]

- Fu, Z.; Wu, F.; Mo, C.; Deng, Q.; Meng, W.; Giesy, J.P. Comparison of arsenic and antimony biogeochemical behavior in water, soil and tailings from Xikuangshan, China. Sci. Total Environ. 2016, 539, 97–104. [Google Scholar] [CrossRef]

- Gebel, T.; Christensen., S.; Dunkelberg, H. Comparative and environmental genotoxicity of antimony and arsenic. Anticancer Res. 1997, 17, 2603–2607. [Google Scholar]

- Hammel, W.; Debus, R.; Steubing, L. Mobility of antimony in soil and its availability to plants. Chemosphere 2000, 41, 1791–1798. [Google Scholar] [CrossRef]

- Krachler, M.; Zheng, J.; Koerner, R.; Zdanowicz, C.; Fisher, D.; Shotyk, W. Increasing atmospheric antimony contamination in the northern hemisphere: Snow and ice evidence from devon island, arctic canada. J. Environ. Monit. 2005, 7, 1169–1176. [Google Scholar] [CrossRef] [PubMed]

- Hiller, E.; Lalinská, B.; Chovan, M.; Jurkovič, Ľ.; Klimko, T.; Jankulár, M.; Hovorič, R.; Šottník, P.; Fľaková, R.; Ženišová, Z.; et al. Arsenic and antimony contamination of waters, stream sediments and soils in the vicinity of abandoned antimony mines in the western carpathians, slovakia. Appl. Geochem. 2012, 27, 598–614. [Google Scholar] [CrossRef]

- Mori, C.; Orsini, A.; Migon, C. Impact of arsenic and antimony contamination on benthic invertebrates in a minor corsican river. Hydrobiologia 1999, 392, 73–80. [Google Scholar] [CrossRef]

- Okkenhaug, G.; Zhu, Y.; He, J.; Li, X.; Luo, L.; Mulder, J. Antimony (Sb) and arsenic (As) in Sb mining impacted paddy soil from Xikuangshan, China: Differences in mechanisms controlling soil sequestration and uptake in rice. Environ. Sci. Technol. 2012, 46, 3155–3162. [Google Scholar] [CrossRef]

- Zhou, S.; Hursthouse, A. The impact of physical properties on the leaching of potentially toxic elements from antimony ore processing wastes. Int. J. Environ. Res. Public Health 2019, 16, 2355. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiada, W. Antimony vein deposits of China. Ore Geol. Rev. 1993, 8, 213–232. [Google Scholar] [CrossRef]

- Zhou, S.; Andrew, H.; Chen, T. Pollution characteristics of Sb, As, Hg, Pb, Cd and Zn in soils from different zones of Xikuangshan antimony mine. J. Anal. Methods Chem. 2019, 2019, 2754385. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Deng, R.; Ren, B.; Hou, B.; Hursthouse, A. Preparation of a novel Fe3O4/HCO composite adsorbent and the mechanism for the removal of antimony (III) from aqueous solution. Sci. Rep. 2019, 9, 13021. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Y.; Liu, S.; Dehghani, A.; Wang, X. Mechanical, chemical and hydrothermal activation for waste glass reinforced cement. Constr. Build. Mater. 2021, 301, 124361. [Google Scholar] [CrossRef]

- Ferreira, L.; Brito, J.D.; Saikia, N. Influence of curing conditions on the mechanical performance of concrete containing recycled plastic aggregate. Constr. Build. Mater. 2012, 36, 196–204. [Google Scholar] [CrossRef]

- Sun, J.; Lin, S.; Zhang, G.; Sun, Y.; Wang, X. The effect of graphite and slag on electrical and mechanical properties of electrically conductive cementitious composites. Constr. Build. Mater. 2021, 281, 122606. [Google Scholar] [CrossRef]

- Thomas, S.T.; Damare, A.; Gupta, R.C. Strength and durability characteristics of copper tailing concrete. Constr. Build. Mater. 2013, 48, 894–900. [Google Scholar] [CrossRef]

- Sharma, R.; Khan, R.A. Sustainable use of copper slag in self compacting concrete containing supplementary cementitious materials. J. Clean. Prod. 2017, 151, 179–192. [Google Scholar] [CrossRef]

- Huang, X.; Ni, W.; Wang, Z.; Zhu, L. Preparation of autoclaved aerated concrete using copper tailings and blast furnace slag. Constr. Build. Mater. 2011, 27, 1–5. [Google Scholar] [CrossRef]

- Zhou, G.Y.; Li, W.; Chen, Y.; Song, Y. Study on recovery of lead-zinc tailing ore by electrochemical flotation. Appl. Mech. Mater. 2014, 3547, 1451–1454. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Eren, O. Recycling of copper tailings as an additive in cement mortars. Constr. Build Mater. 2012, 37, 723–727. [Google Scholar] [CrossRef]

- Choi, Y.W.; Kim, Y.J.; Choi, O.; Lee, K.M.; Lachemi, M. Utilization of tailings from tungsten mine waste as a substitution material for cement. Constr. Build. Mater. 2009, 23, 2481–2486. [Google Scholar] [CrossRef]

- Nie, Y.; Liu, S.; Dai, Q. Mineral processing experiment of quartz from gold ore tailing. Adv. Mater. Res. 2013, 2262, 2475–2477. [Google Scholar] [CrossRef]

- Gayana, B.C.; Chandar, K.R. Sustainable use of mine waste and tailings with suitable admixture as aggregates in concrete pavements-A review. Adv. Concr. Constr. 2018, 6, 221–243. [Google Scholar]

- Zhao, S.; Fan, J.; Sun, W. Utilization of iron ore tailings as fine aggregate in ultra-high performance. Constr. Build. Mater. 2014, 50, 540–548. [Google Scholar] [CrossRef]

- Lv, X.; Shen, W.; Wang, L.; Dong, Y.; Zhang, J.; Xie, Z. A comparative study on the practical utilization of iron tailings as a complete replacement of normal aggregates in dam concrete with different gradation. J. Clean. Prod. 2019, 211, 704–715. [Google Scholar] [CrossRef]

- Vijayaraghavan, J.; Jude, A.B.; Thivya, J. Effect of copper slag, iron slag and recycled concrete aggregate on the mechanical properties of concrete. Resour. Policy 2017, 53, 219–225. [Google Scholar] [CrossRef]

- Wang, J.; Li, B.; Li, L.; Zuo, C.; Wang, Y. Feasibility Study of Antimony Waste Rock Coarse Aggregate High Strength Concrete. In Proceedings of the 17th Biennial International Conference on Engineering, Science, Construction, and Operations in Challenging Environments, Seattle, WA, USA, 19–23 April 2021. [Google Scholar]

- Cocke, D. The binding chemistry and leaching mechanisms of hazardous substances in cementitious solidification/stabilization systems. J. Hazard. Mater. 1990, 24, 231–253. [Google Scholar] [CrossRef]

- Sanchez, F.; Gervais, C.; Garrabrant, A.; Barna, R.; Kosson, D. Leaching of inorganic contaminants from cement-based waste materials as a result of carbonation during intermittent wetting. Waste Manag. 2002, 22, 249–260. [Google Scholar] [CrossRef]

- Moszkowicz, O. Study of mineralogy and leaching behavior of stabilized/solidified sludge using differential acid neutralization analysis: Part I: Experimental study. Cem. Concr. Res. 2009, 39, 501–509. [Google Scholar]

- Argane, R.; Benzaazoua, M.; Hakkou, R.; Bouamrane, A. Reuse of base-metal tailings as aggregates for rendering mortars: Assessment of immobilization performances and environmental behavior. Constr. Build. Mater. 2015, 96, 296–306. [Google Scholar] [CrossRef]

- Barna, R.; Moszkowicz, P.; Gervais, C. Leaching assessment of road materials containing primary lead and zinc slags. Waste Manag. 2004, 24, 945–955. [Google Scholar] [CrossRef]

- Zhou, Y.; Duan, X.; Chen, T.; Yan, B.; Li, L. Mechanical Properties and Toxicity Risks of Lead-Zinc Sulfide Tailing-Based Construction Materials. Materials 2021, 14, 2940. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Eren, Ö. Copper tailings as a potential additive in concrete: Consistency, strength and toxic metal immobilization properties. Indian J. Eng. Mater. Sci. 2012, 19, 79–86. [Google Scholar]

- Huang, X.C.; Xu, X.D.; Chen, Q.N.; Liu, Y.F. Reliability analysis of the anti-sliding of a retaining wall subjected to seismic loads. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2021, 235, 853–862. [Google Scholar]

- MOTOC. Test Methods of Rock for Highway Engineering (JTG E41-2005); Ministry of Transport of China: Beijing, China, 2005.

- Goodman, R.E. Introduction to Rock Mechanics, 2nd ed.; Wiley: Berkeley, CA, USA, 1989; pp. 151–184. [Google Scholar]

- Huang, X.C.; Zhou, X.P. Reliability analysis of a large-scale landslide using SOED-based RSM. Environ. Earth Sci. 2017, 76, 794. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Tang, S.; Zheng, H.; Zhou, C.; Zhu, M. Flexural behavior of a 30-meter full-scale simply supported prestressed concrete box girder. Appl. Sci. 2020, 10, 3076. [Google Scholar] [CrossRef]

- Zhou, C.; Li, L.; Wang, J. Modified bar simulation method for shear lag analysis of non-prismatic composite box girders with corrugated steel webs. Thin-Walled Struct. 2020, 155, 106957. [Google Scholar] [CrossRef]

- CNSMC. Pebble and Crushed Stone for Constrction (GB/T 14685-2011); China National Standardization Management Committee: Beijing, China, 2005.

- MOEP. Emission Standards of Pollutants for Stannum, Antimony and Mercury Industries (GB 30770-2014); Ministry of Environmental Protection: Beijing, China, 2014.

| Chemical Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | TiO2 | MnO | FeO | P2O5 | LOI |

| wt.% | 88.78 | 3.86 | 0.98 | 0.61 | 0.11 | 0.42 | 0.02 | 0.17 | 0.03 | 0.27 | 0.04 | 2.98 |

| No. | Experiments | Sample Shape | Sample Size (mm) |

|---|---|---|---|

| 1 | Cubic compressive strength | Cube | 70 × 70 × 70 |

| 2 | Splitting tensile strength | Cylinder | Ø50 × 50 |

| 3 | Prism compressive strength | Cylinder | Ø50 × 100 |

| 4 | Elasticity modulus | Cylinder | Ø50 × 100 |

| Description | Apparent Density (kg/cm3) | Gross Bulk Density (kg/cm3) | Loose Bulk Density (kg/cm3) | Void Ratio (%) | Water Absorption (%) | ASR (‰) |

|---|---|---|---|---|---|---|

| ATCA | 2653 | 2592 | 1497 | 38.26 | 0.7 | 0.80 |

| NCA | 2608 | 2533 | 1512 | 38.93 | 0.8 | 0.71 |

| Regulatory limits | ≥2500 | / | ≥1350 | <47 | Grade Ⅰ | <1 |

| Description | Needle-Flake Content | Firmness | Crushing Value | Abrasion Resistance | Dust Content | Clay Lump Content | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Result | Grade | Result | Grade | Result | Grade | Result | Grade | Result | Grade | Result | Grade | ||

| Classification | ≤5 | Ⅰ | ≤5 | Ⅰ | ≤10 | Ⅰ | ≤28 | Ⅰ | ≤0.5% | Ⅰ | 0 | Ⅰ | |

| ≤15 | Ⅱ | ≤8 | Ⅱ | ≤20 | Ⅱ | ≤30 | Ⅱ | ≤1.0% | Ⅱ | ≤0.5% | Ⅱ | ||

| ≤25 | Ⅲ | ≤12 | Ⅲ | ≤30 | Ⅲ | ≤35 | Ⅲ | ≤1.5% | Ⅲ | ≤0.7% | Ⅲ | ||

| Test results | ATCA | 4.50% | Ⅰ | 3.00% | Ⅰ | 9.20% | Ⅰ | 18.0% | Ⅰ | 0.40% | Ⅰ | 0.10% | Ⅱ |

| NCA | 3.50% | Ⅰ | 3.60% | Ⅰ | 14.80% | Ⅱ | 24.5% | Ⅰ | 0.72% | Ⅱ | 0.18% | Ⅱ | |

| Cement | ATCA | Manufactured Sand | Water | Superplasticizer |

|---|---|---|---|---|

| 485 | 1047 | 758 | 160 | 5.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Li, L.; Zhang, L.; Li, B.; Deng, R.; Shi, D. Sustainable Applications for Utilizing Antimony Tailing Coarse Aggregate (ATCA) in Concrete: Characteristic of ATCA and Toxicity Risks of Concrete. Materials 2021, 14, 5480. https://doi.org/10.3390/ma14195480

Wang J, Li L, Zhang L, Li B, Deng R, Shi D. Sustainable Applications for Utilizing Antimony Tailing Coarse Aggregate (ATCA) in Concrete: Characteristic of ATCA and Toxicity Risks of Concrete. Materials. 2021; 14(19):5480. https://doi.org/10.3390/ma14195480

Chicago/Turabian StyleWang, Jianqun, Long Li, Longwei Zhang, Bei Li, Renjian Deng, and Defeng Shi. 2021. "Sustainable Applications for Utilizing Antimony Tailing Coarse Aggregate (ATCA) in Concrete: Characteristic of ATCA and Toxicity Risks of Concrete" Materials 14, no. 19: 5480. https://doi.org/10.3390/ma14195480

APA StyleWang, J., Li, L., Zhang, L., Li, B., Deng, R., & Shi, D. (2021). Sustainable Applications for Utilizing Antimony Tailing Coarse Aggregate (ATCA) in Concrete: Characteristic of ATCA and Toxicity Risks of Concrete. Materials, 14(19), 5480. https://doi.org/10.3390/ma14195480