Microstructural Tailoring and Enhancement in Compressive Properties of Additive Manufactured Ti-6Al-4V Alloy through Heat Treatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Selective Laser Melting

2.3. Heat Treatment

2.4. Microstructural Investigations

2.5. Mechanical Properties

3. Results and Discussions

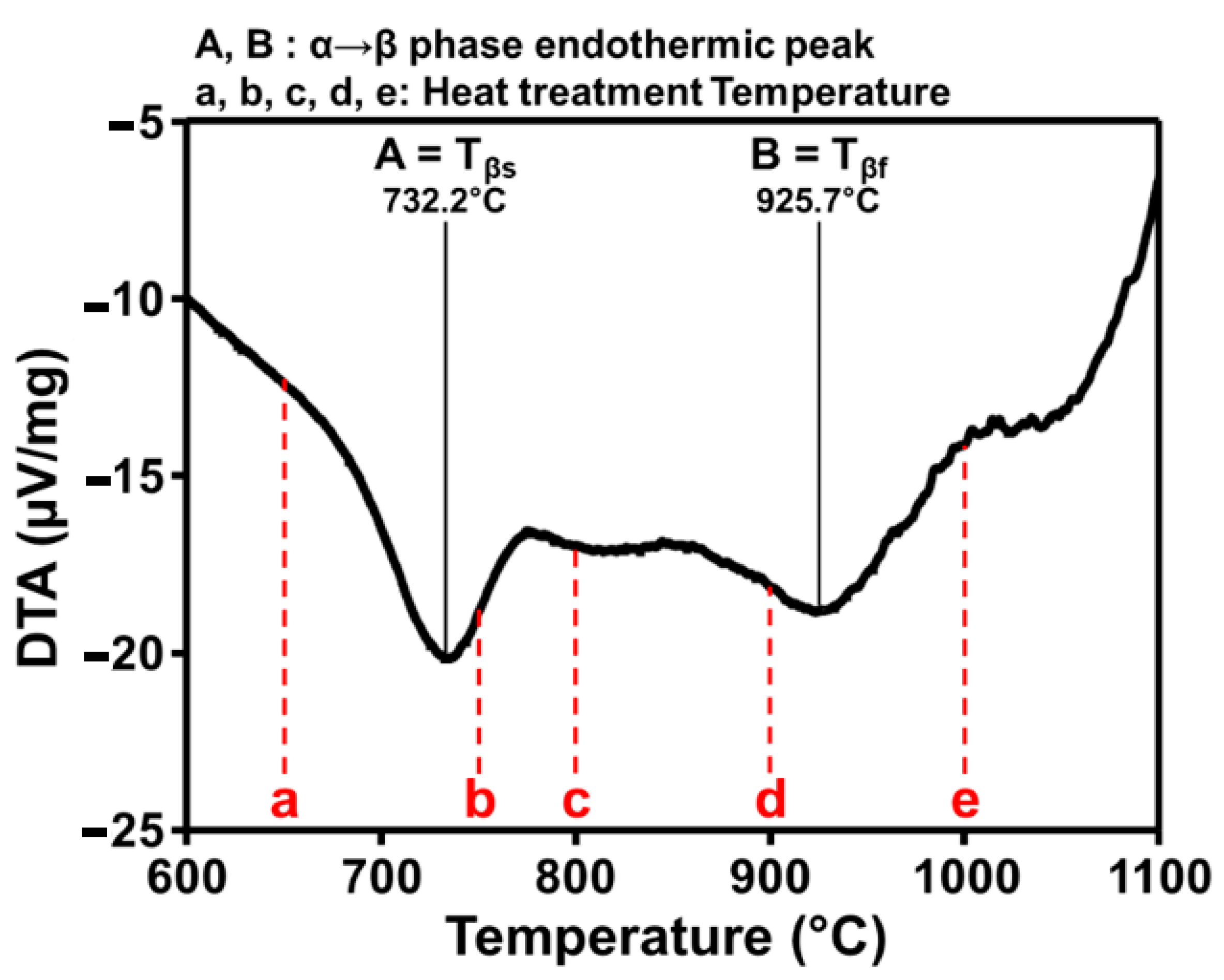

3.1. Phase Transformation Studies

3.2. Phase Evolution

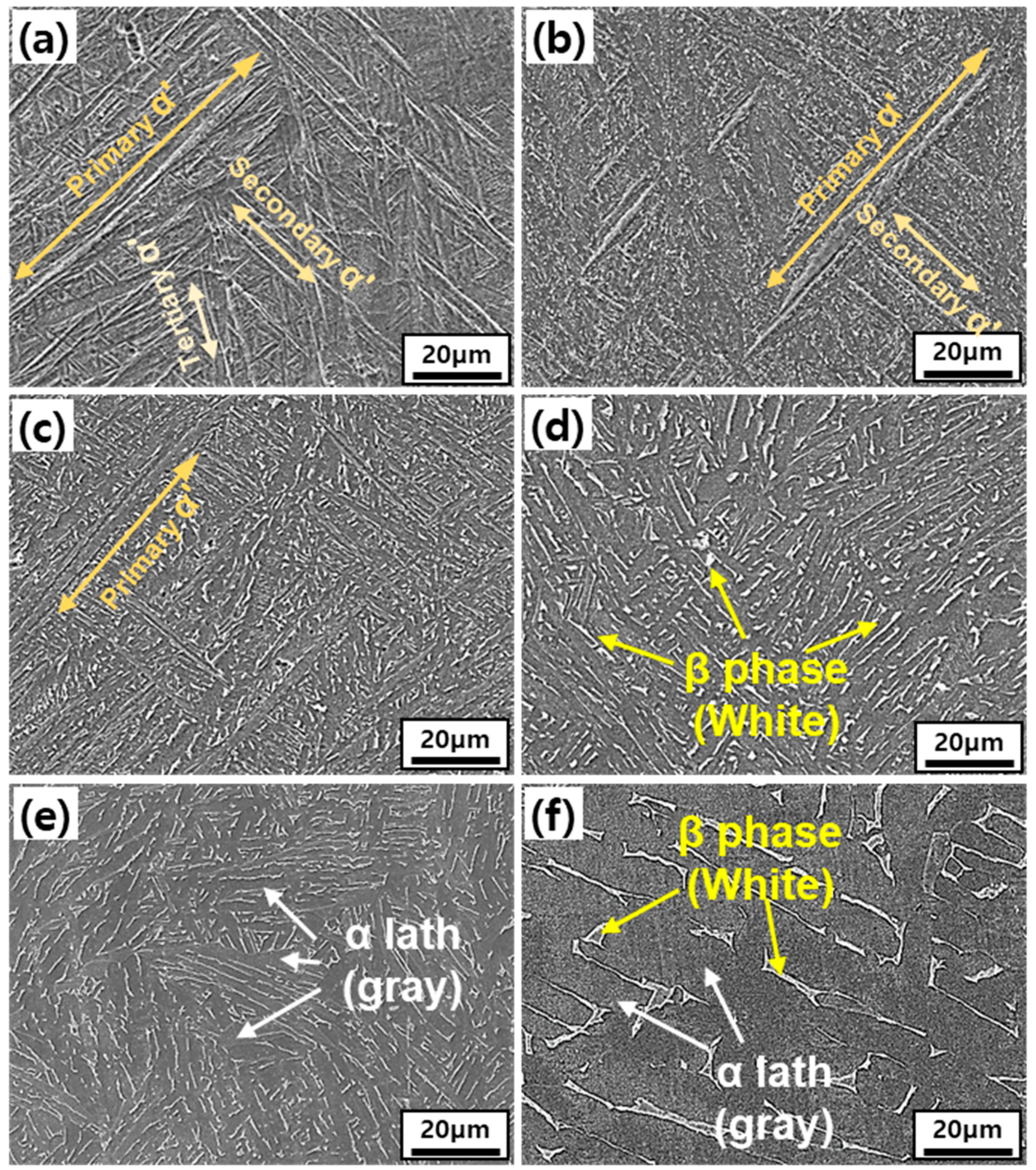

3.3. Microstructure

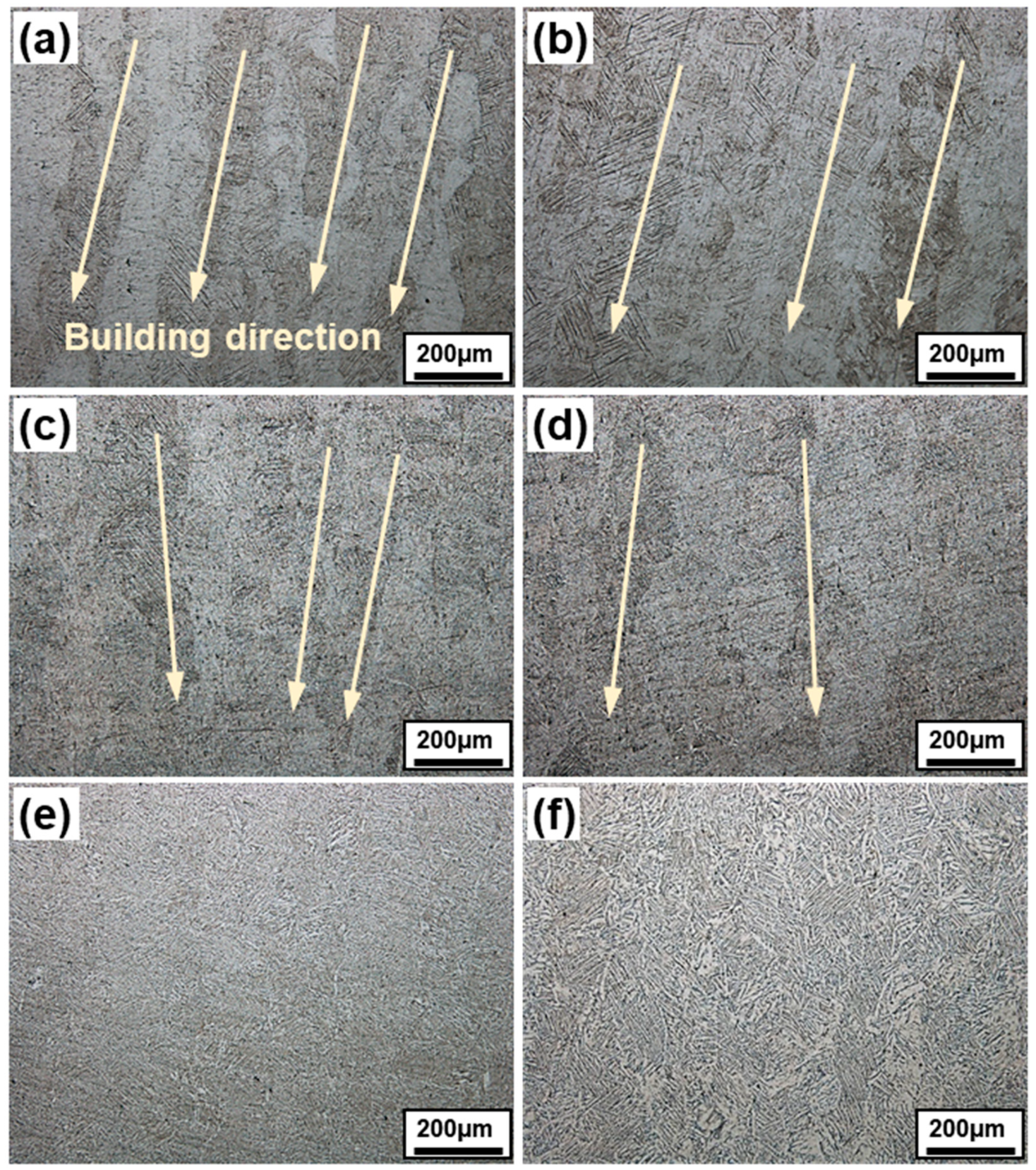

3.4. Microhardness

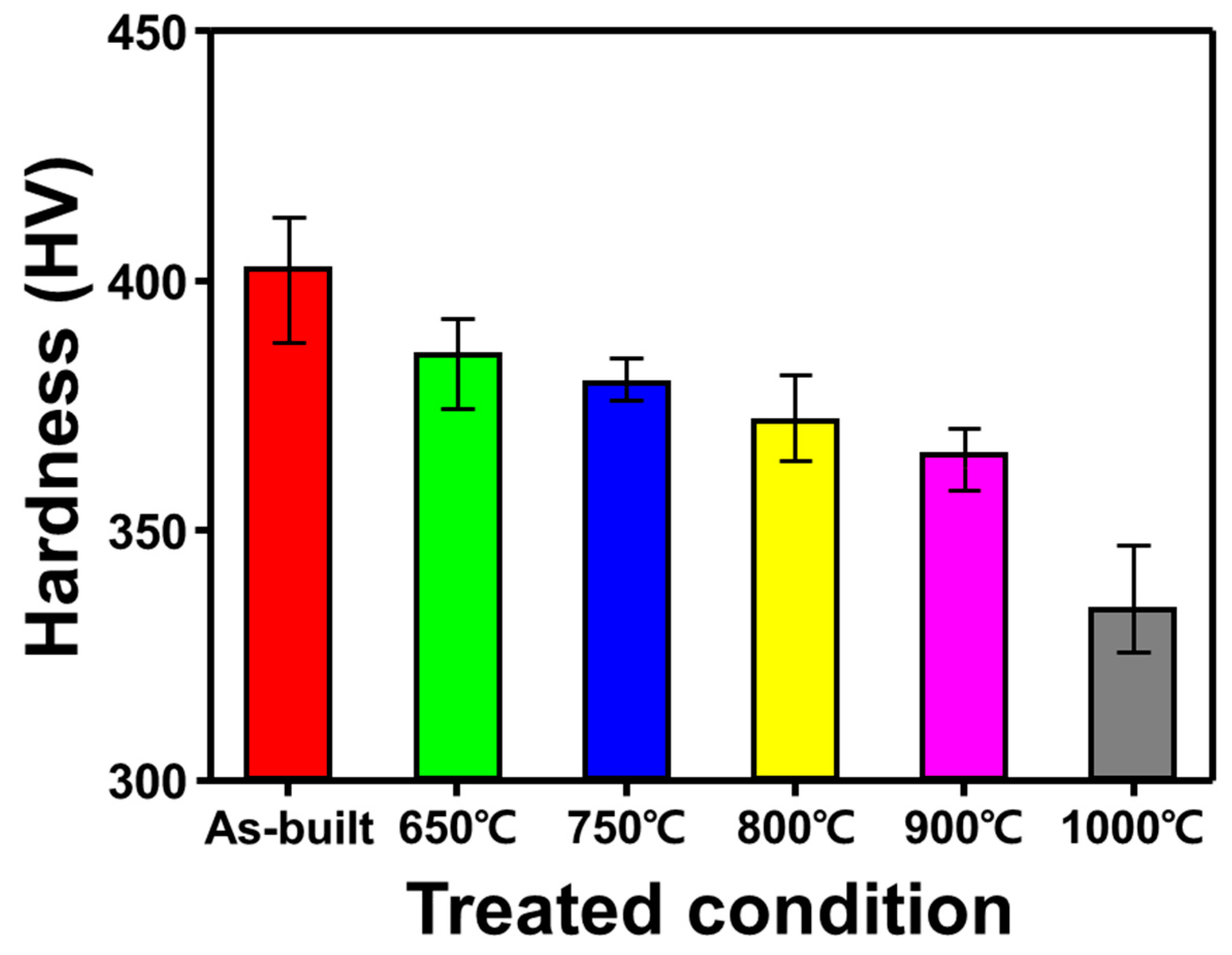

3.5. Compressive Test

- (1)

- As-built sample is fully α′-martensite, which is brittle, a major cause of the inferior deformability of as-built SLM Ti-6Al-4V alloy.

- (2)

- Morphological of α′-martensite is acicular which induces anisotropy and hence poor mechanical properties.

- (3)

- The internal stresses in the sample due to a rapid solidification during the SLM causes premature destruction of the as-built sample.

- (4)

- As-built samples are highly textured due to the layer-by-layer manufacturing which causes the sample to be anisotropic as a whole.

4. Conclusions

- The columnar grain growth in SLM Ti-6Al-4V alloy along the build direction was gradually removed after heat treatment. The decomposition of the fully α′-martensitic phase of the as-built sample produced a lamellar α + β structure gradually after heat treatment.

- The microstructure of SLM Ti-6Al-4V alloy is almost free from columnar grains beyond 900 °C with an increased size of lamellae. The width of the lamella at 100 °C was almost more than twice the value obtained at 900 °C. The effect of heat treatment of SLM Ti-6Al-4V alloy effective for homogenizing the two-phase microstructure of the alloy.

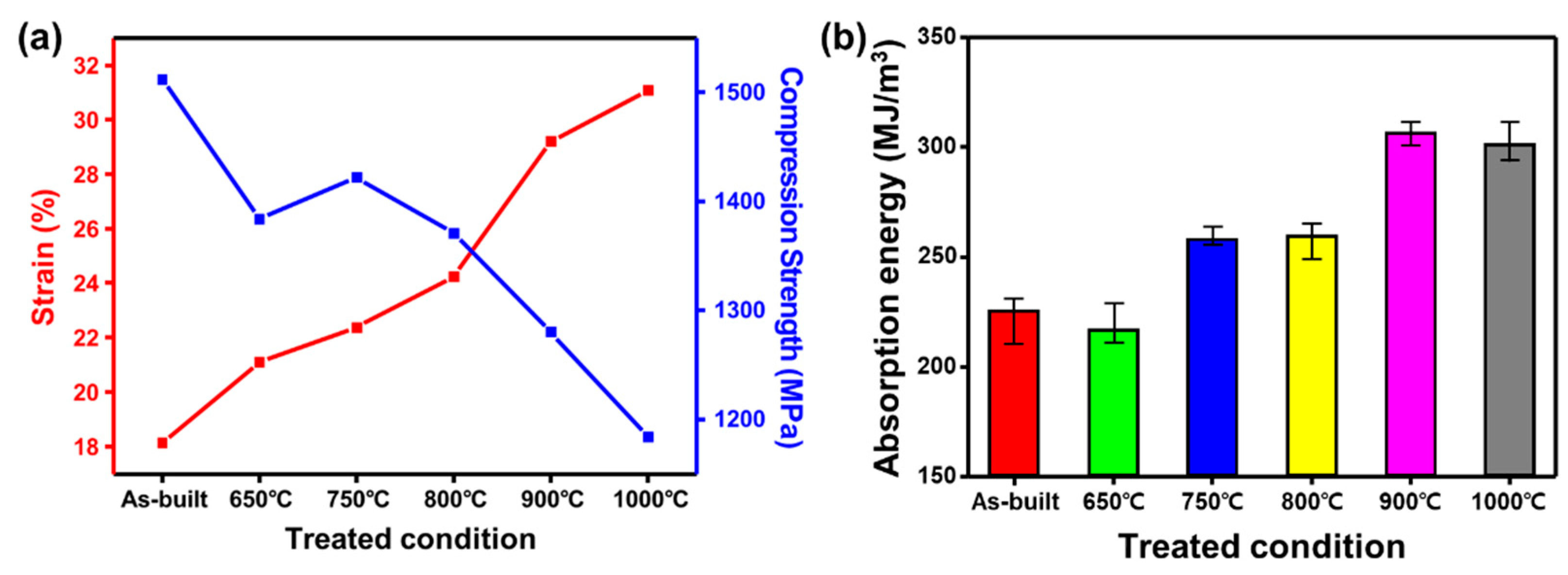

- The microhardness and compressive strength of Ti-6Al-4V samples were maximum in the as-built condition. The heat treatment of as-built samples contributed to an enhancement of the elongation and deformation energy at the cost of their strength.

- The elongation (18–29%) and the absorption energy of SLM Ti-6Al-4V alloys varied from 213–284 MJ/m3 while the compressive strength showed a reduction from 1512 to 1182 MPa, with an increase in temperature up to 1000 °C. The optimal heat treatment condition was found to be 900 °C due to a balanced strength and ductility relationship.

- The resultant mechanical properties of the alloy correspond to the variation in microstructural features and can be adjusted according to the heat treatment temperature. Thus, SLM a Ti-6Al-4V with a controlled microstructure through heat treatment can be ensured, as compared to those of cast products obtained through conventional manufacturing methods.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gibson, L.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2015; pp. 19–42. [Google Scholar]

- Kadirgama, K.; Harun, W.S.W.; Tarlochan, F.; Samykano, M.; Ramasamy, D.; Azir, M.Z.; Mehboob, H. Statistical and optimize of lattice structures with selective laser melting (SLM) of Ti6AL4V material. Int. J. Adv. Manuf. Technol. 2018, 97, 495–510. [Google Scholar] [CrossRef]

- Sharma, A.; Oh, M.C.; Kim, J.T.; Srivastava, A.K.; Ahn, B. Investigation of electrochemical corrosion behavior of additive manufactured Ti–6Al–4V alloy for medical implants in different electrolytes. J. Alloy. Compd. 2020, 830, 154620. [Google Scholar] [CrossRef]

- Marta, K.J.; Wojciech, J.; Witkowska, I. The heat treatment influence on the structure and mechanical properties of Ti6Al4V alloy manufactured by SLM technology. Innov. Biomed. Eng. 2018, 623, 319–327. [Google Scholar]

- Zhuang, J.R.; Lee, Y.T.; Hsieh, W.H.; Yang, A.S. Determination of melt pool dimensions using DOE-FEM and RSM with process window during SLM of Ti6Al4V powder. Opt. Laser Technol. 2018, 103, 59–76. [Google Scholar] [CrossRef]

- Wauthle, R.; Vrancken, B.; Beynaerts, B.; Jorissen, K.; Schrooten, J.; Kruth, J.P.; Humbeeck, J.V. Effects of build orientation and heat treatment on the microstructure and mechanical properties of selective laser melted Ti6Al4V lattice structures. Addit. Manuf. 2015, 5, 77–84. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall. Mater. Trans. A 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium, 1st ed.; Springer: Berlin, Germany, 2003. [Google Scholar]

- Peters, M.; Lütjering, G.; Ziegler, G. Control of microstructures of (α + β) titanium alloys. Z. Metallkd. 1983, 74, 274–282. [Google Scholar]

- Lütjering, G. Influence of processing on microstructure and mechanical properties of (α + β) titanium alloys. Mater. Sci. Eng. A 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Wu, H.; Sun, Z.; Cao, J.; Yin, Z. Formation and evolution of tri-modal microstructure during dual heat treatment for TA15 Ti-alloy. J. Alloys Compd. 2019, 786, 894–905. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- He, J.; Li, D.; Jiang, W.; Ke, L.; Qin, G.; Ye, Y.; Qin, Q.; Qiu, D. The martensitic transformation and mechanical properties of Ti6Al4V prepared via selective laser melting. Materials 2019, 12, 321. [Google Scholar] [CrossRef] [Green Version]

- Vila, P.B.; Gussone, J.; Haubrich, J.; Sandlöbes, S.; Silva, J.C.D.; Cloetens, P.; Schell, N.; Requena, G. Inducing stable α + β microstructures during selective laser melting of Ti-6Al-4V using intensified intrinsic heat treatments. Materials 2017, 10, 268. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Fang, G.; Leeflang, S.; Bottger, A.J.; Zadpoor, A.A.; Zhou, J. Effect of subtransus heat treatment on the microstructure and mechanical properties of additively manufactured Ti-6Al-4V alloy. J. Alloy. Compd. 2018, 735, 1562–1575. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, L.; Craeghs, T.; Humbeeck, J.V.; Kruth, J.P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Kruth, J.P.; Badrossamay, M.; Yasa, E.; Deckers, J.; Thijs, L.; Humbeeck, J.V. Part and material properties in selective laser melting of metals. In Proceedings of the 16th International Symposium on Electromachining, Shanghai, China, 19–23 April 2010. [Google Scholar]

- Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A.; Höges, S.; Wissenbach, K. Ductility of a Ti-6Al-4V alloy produced by selective laser melting of prealloyed powders. Rapid Prototyp. J. 2010, 16, 450–459. [Google Scholar] [CrossRef]

- Khan, M.R. Microstructural Investigation of Selective Laser Melted Ti-6Al-4V. In B. Eng. Final Year Project Report; University of Stellenbosch: Stellenbosch, South Africa, 2014. [Google Scholar]

- Bey, V.; Lore, T.; Kruth, J.P.; Jan, V.H. Heat treatment of Ti6Al4V produced by Selective Laser Melting Microstructure and mechanical properties. J. Alloy. Compd. 2012, 541, 177–185. [Google Scholar]

- Kim, Y.K.; Park, S.H.; Yu, J.H.; AlMangour, B.; Lee, K.A. Improvement in the high-temperature creep properties via heat treatment of Ti-6Al-4V alloy manufactured by selective laser melting. Mater. Sci. Eng. A 2018, 715, 33–40. [Google Scholar] [CrossRef]

- Wu, S.; Lu, Y.; Gan, Y.; Huang, T.; Zhao, C.; Lin, J.; Guo, S.; Lin, J. Microstructural evolution and microhardness of a selective-laser-melted Ti–6Al–4V alloy after post heat treatments. J. Alloy. Compd. 2016, 672, 643–652. [Google Scholar] [CrossRef]

- Chen, R.; Zheng, D.; Guo, J.; Ma, T.; Ding, H.; Su, Y.; Fu, H.A. A novel method for grain refinement and microstructure modification in TiAl alloy by ultrasonic vibration. Mater. Sci. Eng. A 2016, 653, 23–26. [Google Scholar]

- Kumar, P.; Prakash, O.; Ramamurty, U. Micro-and meso-structures and theirinfluence on mechanical properties of selectively laser melted Ti-6Al-4V. Acta Mater. 2018, 154, 246–260. [Google Scholar] [CrossRef]

- Mohamed, D.N.; Robert, T.; Thorsten, B. Fatigue and fracture toughness of Ti-6Al-4V titanium alloy manufactured by selective laser melting. Adv. Mater.Res. 2014, 1019, 248–253. [Google Scholar]

- Cain, V.; Thijs, L.; Humbeeck, J.V.; Hooreweder, B.V.; Knutsen, R. Crack propagation and fracture toughness of Ti6Al4V alloy produced by selective laser melting. Addit. Manuf. 2015, 5, 68–76. [Google Scholar] [CrossRef]

- Rice, R.C.; Jackson, J.L.; Bakuckas, J.; Thompson, S. Metallic Materials Properties Development and Standardization; National Technical Information Service Distributor: Springfield, VA, USA, 2003.

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin, Germany, 2007. [Google Scholar]

- Liu, Y.; Zhang, J.; Li, S.J.; Hou, W.T.; Wang, H.; Xu, Q.S.; Hao, Y.L.; Yang, R. Effect of HIP treatment on fatigue crack growth behavior of Ti-6Al-4V alloy fabricatedby electron beam melting. Acta Metall. Sin. 2017, 30, 1163–1168. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.T.; Schneibel, J.H.; Maziasz, P.J.; Wright, J.L.; Easton, D.S. Tensile properties and fracture toughness of TiAl alloys with controlled microstructures. Intermetallics 1996, 4, 429–440. [Google Scholar] [CrossRef]

- Wang, D.; Dou, W.; Yang, Y. Research on Selective Laser Melting of Ti6Al4V: Surface Morphologies, Optimized Processing Zone, and Ductility Improvement Mechanism. Metals 2018, 8, 471. [Google Scholar] [CrossRef] [Green Version]

- Yolton, C.F.; Froes, F.H.; Malone, R.F. Alloying element effects in metastable beta titanium alloys. Metall. Trans. A 1979, 10, 132–134. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2017, 17, 63. [Google Scholar] [CrossRef] [Green Version]

- Wei, X.; Milan, B.; Shoujin, S.; Joe, E.; Liu, Q.; Kay, L.; Xia, K.; Ma, Q. Additive manufacturing of strong and ductile Ti-6Al-4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2015, 85, 74–84. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, B. Microstructural Tailoring and Enhancement in Compressive Properties of Additive Manufactured Ti-6Al-4V Alloy through Heat Treatment. Materials 2021, 14, 5524. https://doi.org/10.3390/ma14195524

Ahn B. Microstructural Tailoring and Enhancement in Compressive Properties of Additive Manufactured Ti-6Al-4V Alloy through Heat Treatment. Materials. 2021; 14(19):5524. https://doi.org/10.3390/ma14195524

Chicago/Turabian StyleAhn, Byungmin. 2021. "Microstructural Tailoring and Enhancement in Compressive Properties of Additive Manufactured Ti-6Al-4V Alloy through Heat Treatment" Materials 14, no. 19: 5524. https://doi.org/10.3390/ma14195524

APA StyleAhn, B. (2021). Microstructural Tailoring and Enhancement in Compressive Properties of Additive Manufactured Ti-6Al-4V Alloy through Heat Treatment. Materials, 14(19), 5524. https://doi.org/10.3390/ma14195524