Sizing the Depth and Width of Narrow Cracks in Real Parts by Laser-Spot Lock-In Thermography

Abstract

:1. Introduction

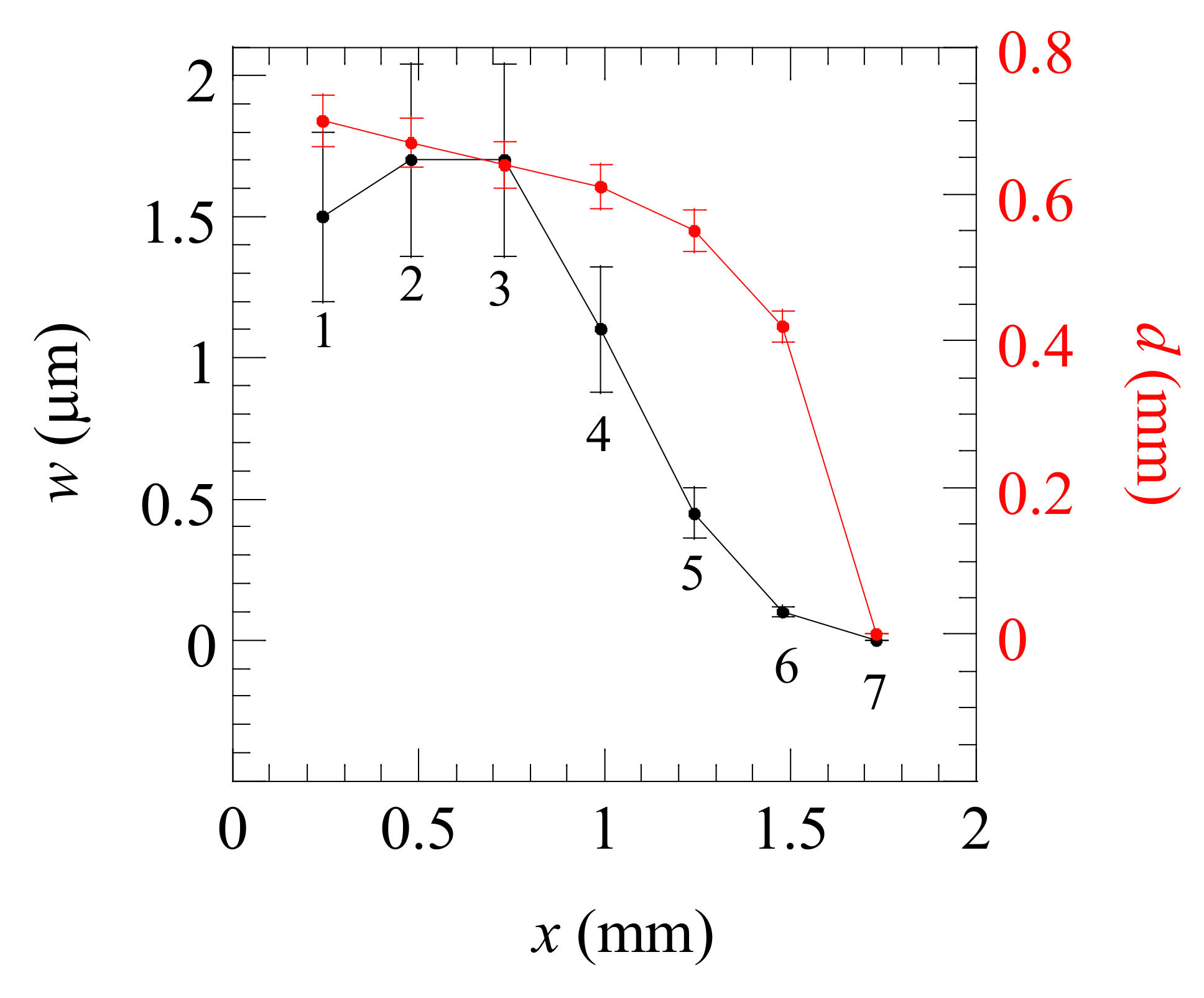

2. Background

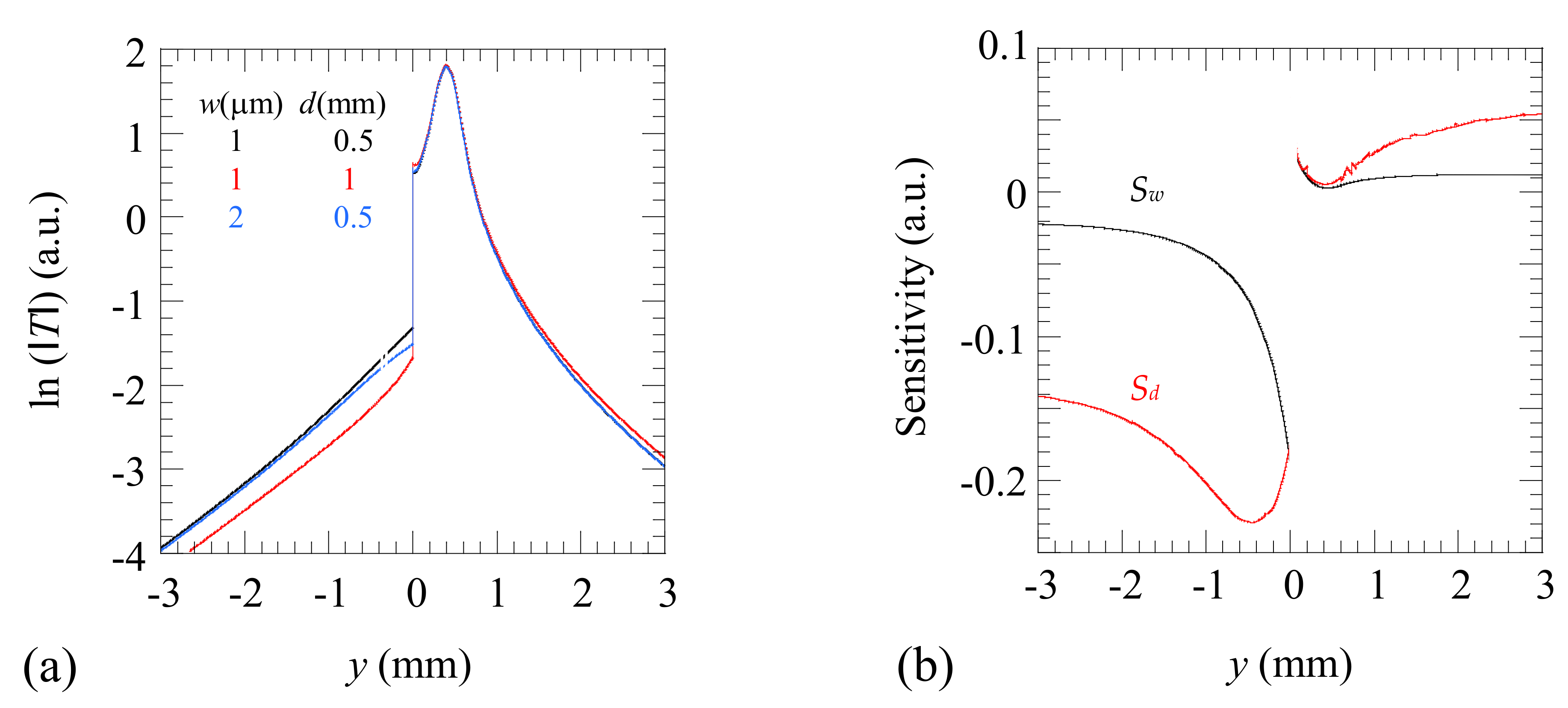

2.1. Analytical Model: Vertical Cracks of Infinite Depth

2.2. Numerical Model: Vertical Cracks of Finite Depth

- (1)

- The crack is introduced in a natural manner as a 2-D conformal interface on the domain triangulation (see Figure 3) leading to the low-complexity spatial discretizations.

- (2)

- The crack internal domain (air) is not required to be triangulated since it is modeled as a thermal resistance boundary (see Figure 3).

- (3)

- Very efficient computation, avoiding calculations over very large or complicated meshes.

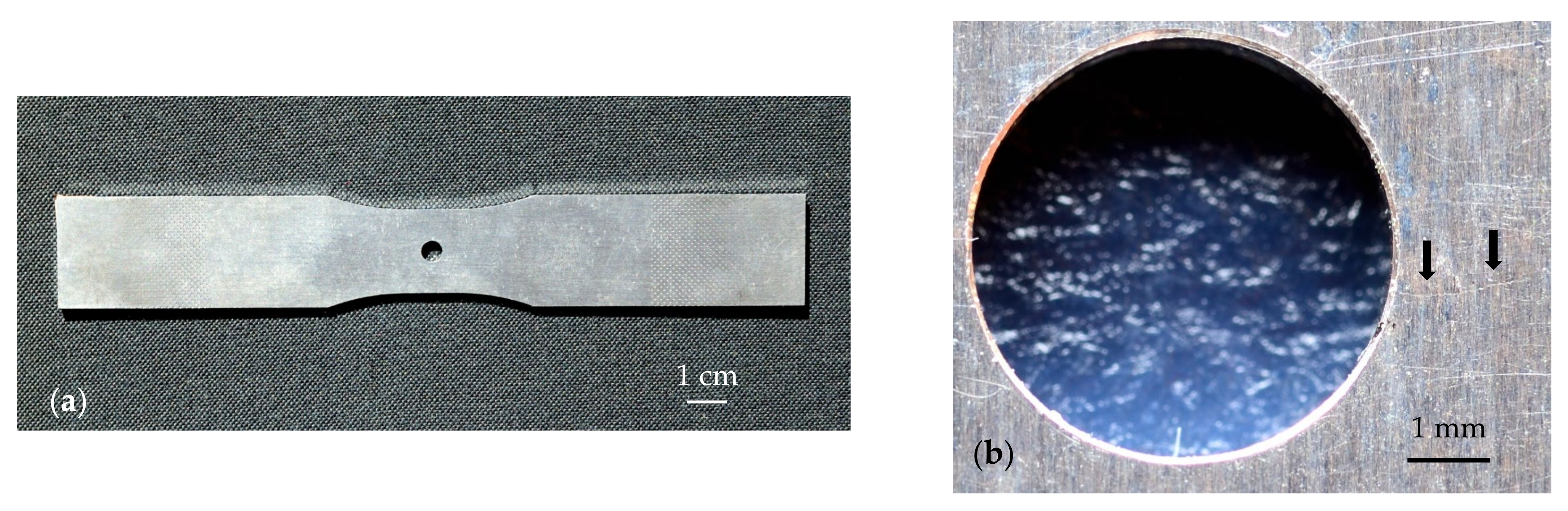

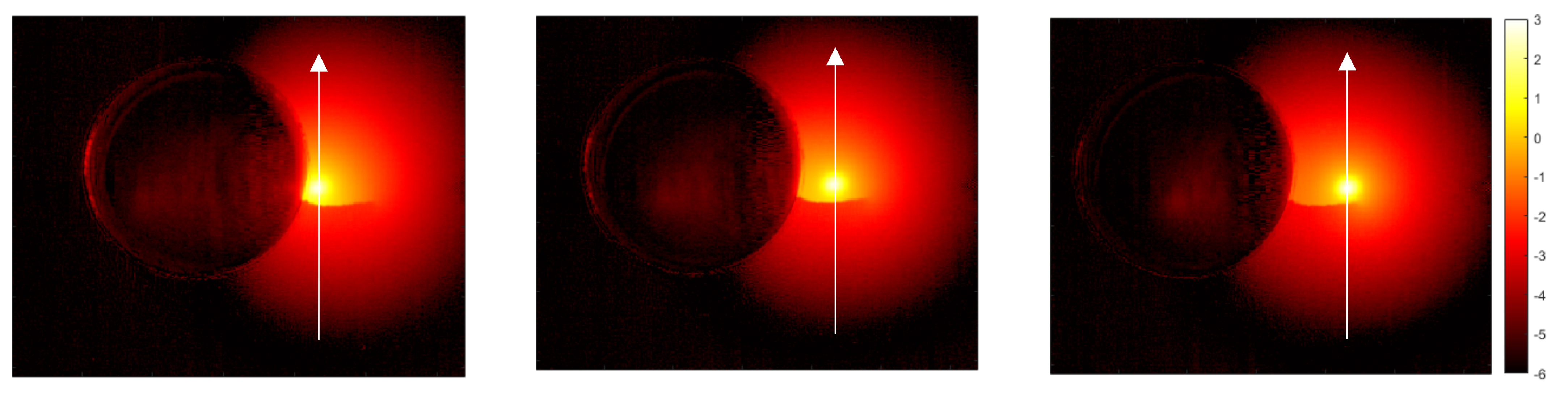

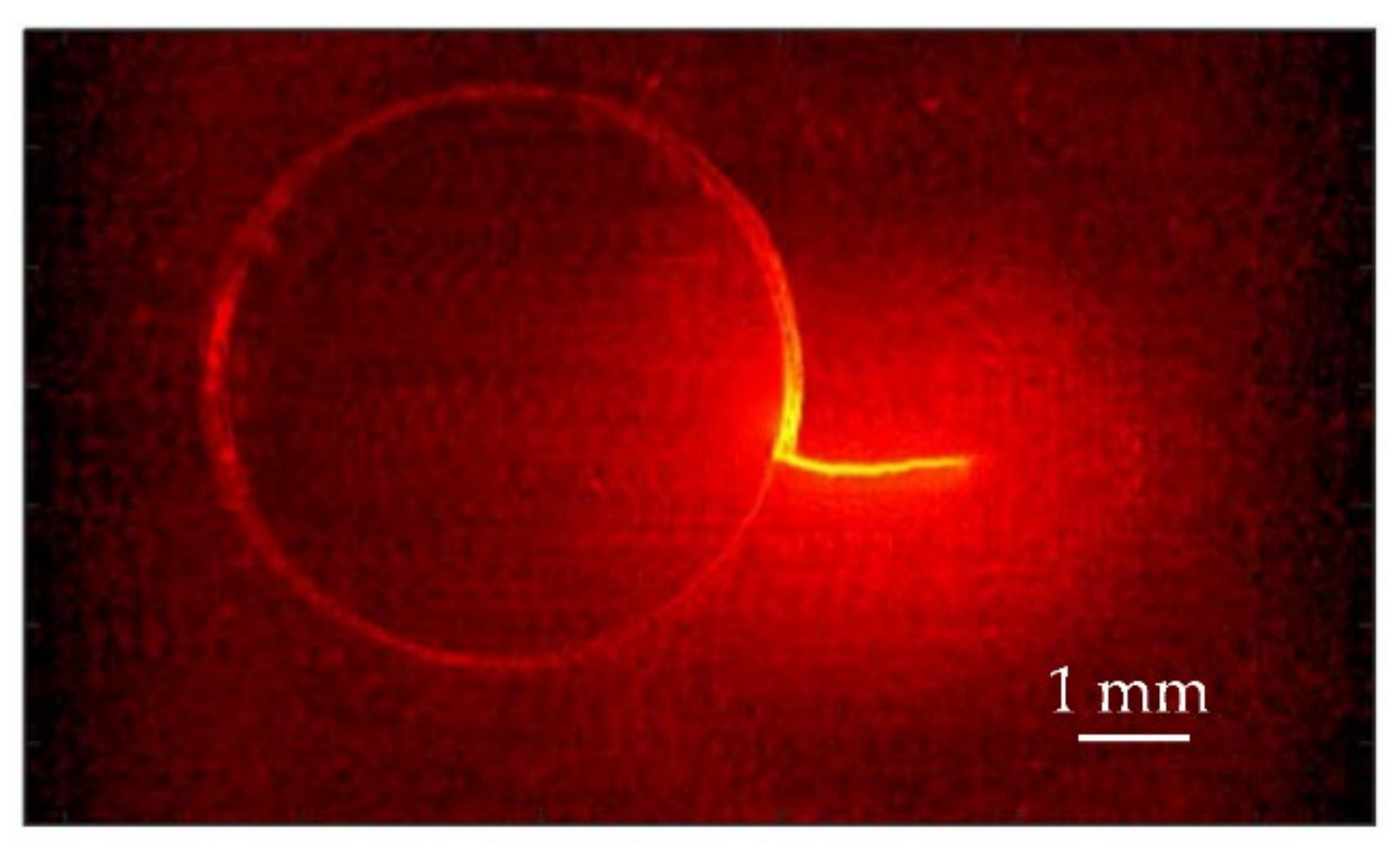

3. Experimental Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Kubiak, E.J. Infrared detection of fatigue cracks and other near-surface defects. Appl. Opt. 1968, 7, 1743–1747. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.Q.; Kuo, P.K.; Favro, L.D.; Thomas, R.L. A novel “flying-spot” infrared camera for imaging very fast thermal-wave phenomena. In Photoacoustic and Photothermal Phenomena II Springer Series in Optical Sciences; Springer: Berlin/Heidelberg, Germany, 1990; Volume 62, pp. 24–26. [Google Scholar]

- Cline, H.E.; Anthony, T.R. Heat treating and melting material with scanning laser or electron beam. J. Appl. Phys. 1977, 48, 3895–3900. [Google Scholar] [CrossRef]

- Gruss, C.; Balageas, D. Theoretical and experimental applications of the flying spot camera. In Proceedings of the QIRT 92—Eurotherm Series 27, Paris, France, 7–9 July 1992. [Google Scholar] [CrossRef]

- Bodnar, J.L.; Egée, M.; Menu, C.; Besnard, R.; Le Blanc, A.; Pigeon, M.; Sellier, J.Y. Cracks detection by a moving photothermal probe. J. Phys. IV Colloq. C7 1994, 4, c7-591–c7-594. [Google Scholar] [CrossRef]

- Krapez, J.C. Résolution spatiale de la camera thermique à source volante. Int. J. Therm. Sci. 1999, 38, 769–779. [Google Scholar] [CrossRef]

- Joubert, P.Y.; Hermosilla-Lara, S.; Placko, D.; Lepoutre, F.; Piriou, M. Enhancement of open-crack detection in flying-spot photothermal non-destructive testing using physical effect identification. QIRT J. 2006, 3, 53–70. [Google Scholar] [CrossRef]

- Schlichting, J.; Ziegler, M.; Dey, A.; Maierhofer, C.; Kreutzbruck, M. Efficient data evaluation for thermographic crack detection. QIRT J. 2011, 8, 119–123. [Google Scholar] [CrossRef]

- Li, T.; Almond, D.P.; Rees, D.A.S. Crack imaging by scanning laser-line thermography and laser-spot thermography. Meas. Sci. Technol. 2011, 22, 035701. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Almond, D.P.; Rees, D.A.S. Crack imaging by scanning pulsed laser spot thermography. NDT&E Int. 2011, 44, 216–225. [Google Scholar]

- Burrows, S.E.; Dixon, S.; Pickering, S.G.; Li, T.; Almond, D.P. Thermographic detection of surface breaking defects using scanning laser source. NDT&E Int. 2011, 44, 589–596. [Google Scholar]

- Maffren, T.; Juncar, P.; Lepoutre, F.; Deban, G. Crack detection in high-pressure turbine blades with flying spot active thermography in the SWIR range. AIP Conf. Proc. 2012, 1430, 515–522. [Google Scholar]

- Yang, J.; Choi, J.; Hwang, S.; An, Y.-K.; Sohn, H. A reference-free micro defect visualization using pulse laser scanning thermography and image processing. Meas. Sci. Technol. 2016, 27, 085601. [Google Scholar] [CrossRef]

- Thiam, A.; Kneip, J.C.; Cicala, E.; Caulier, Y.; Jouvard, J.M.; Mattei, S. Modeling and optimization of open crack detection by flying spot thermography. NDT&E Int. 2017, 89, 67–73. [Google Scholar]

- Jiao, D.; Shi, W.; Liu, Z.; Xie, H. Laser multi-mode scanning thermography method for fast inspection of micro-cracks in TBCs surface. J. Nondestr. Eval. 2018, 37, 30. [Google Scholar] [CrossRef]

- Montinaro, N.; Cerniglia, D.; Pitarresi, G. Evaluation of vertical cracks by means of flying laser thermography. J. Nondestr. Eval. 2019, 38, 48. [Google Scholar] [CrossRef]

- Puthiyaveettil, N.; Thomas, K.R.; Unnikrishnakurup, S.; Myrach, P.; Ziegler, M.; Balasubramaniam, K. Laser line scanning thermography for surface breaking crack detection: Modeling and experimental study. Infrared Phys. Technol. 2020, 104, 103141. [Google Scholar] [CrossRef]

- Pech-May, N.W.; Oleaga, A.; Mendioroz, A.; Omella, A.J.; Celorrio, R.; Salazar, A. Vertical cracks characterization using lock-in thermography: I. Infinite cracks. Meas. Sci. Technol. 2014, 25, 115601. [Google Scholar] [CrossRef]

- Pech-May, N.W.; Oleaga, A.; Mendioroz, A.; Salazar, A. Fast characterization of the width of vertical cracks using pulsed laser spot infrared thermography. J. Nondestruct. Eval. 2016, 35, 22. [Google Scholar] [CrossRef]

- González, J.; Mendioroz, A.; Sommier, A.; Batsale, J.C.; Pradere, C.; Salazar, A. Fast sizing of the width of infinite vertical cracks using Flying Spot thermography. NDT&E Int. 2019, 103, 166–172. [Google Scholar]

- Schlichting, J.; Maierhofer, C.; Kreutzbruck, M. Defect sizing by local excitation thermography. QIRT J. 2011, 8, 51–63. [Google Scholar] [CrossRef]

- Schlichting, J.; Maierhofer, C.; Kreutzbruck, M. Crack sizing by laser excited thermography. NDT&E Int. 2012, 45, 133–140. [Google Scholar]

- Streza, M.; Fedala, Y.; Roger, J.P.; Tessier, G.; Boue, C. Heat transfer modelling for surface crack depth evaluation. Meas. Sci. Technol. 2013, 24, 045602. [Google Scholar]

- Fedala, Y.; Streza, M.; Roger, J.P.; Tessier, G.; Boue, C. Open crack depth sizing by laser stimulated infrared lock-in thermography. J. Phys. D Appl. Phys. 2014, 47, 465501. [Google Scholar] [CrossRef]

- Bu, C.; Tang, Q.; Liu, Y.; Jin, X.; Sun, Z.; Yan, Z. A theoretical study on vertical finite cracks detection using pulsed laser spot thermography (PLST). Infrared Phys. Technol. 2015, 71, 475–480. [Google Scholar] [CrossRef]

- Qiu, J.; Pei, C.; Liu, H.; Chen, Z. Quantitative evaluation of surface crack depth with laser spot thermography. Int. J. Fatigue 2017, 101, 80–85. [Google Scholar] [CrossRef] [Green Version]

- Boué, C.; Holé, S. Open crack depth sizing by multi-speed continuous laser stimulated lock-in thermography. Meas. Sci. Technol. 2017, 28, 065901. [Google Scholar] [CrossRef] [Green Version]

- Scalbi, A.; Olmi, R.; Inglese, G. Evaluation of fractures in a concrete slab by means of laser-spot thermography. Int. J. Heat Mass Transf. 2019, 141, 282–293. [Google Scholar] [CrossRef]

- Boué, C.; Holé, S. Comparison between multi-frequency and multi-speed laser lock-in thermography methods for the evaluation of crack depth in metal. QIRT J. 2020, 17, 223–234. [Google Scholar] [CrossRef]

- Ishizaki, T.; Igami, T.; Nagano, H. Measurement of local thermal contact resistance with a periodic heating method using microscale lock-in thermography. Rev. Sci. Instrum. 2020, 91, 064901. [Google Scholar] [CrossRef]

- Qiu, J.; Pei, C.; Yang, Y.; Wang, R.; Liu, H.; Chen, Z. Remote measurement and shape reconstruction of surface-breaking fatigue cracks by laser-line thermography. Int. J. Fatigue 2020, 142, 105950. [Google Scholar] [CrossRef]

- Omella, A.J.; Celorrio, R.; Pardo, D. Sensitivity and uncertainty analysis by discontinuous Galerkin of lock-in thermography for crack characterization. Comput. Methods Appl. Mech. Eng. 2021, 373, 113523. [Google Scholar] [CrossRef]

- Johnson, C. Numerical Solution of Partial Differential Equations by the Finite Element Method; Cambridge University Press: Cambridge, UK, 1987. [Google Scholar]

- Celorrio, R.; Omella, A.J.; Pech-May, N.W.; Oleaga, A.; Mendioroz, A.; Salazar, A. Vertical cracks characterization using lock-in thermography: II. Finite cracks. Meas. Sci. Technol. 2014, 25, 115602. [Google Scholar] [CrossRef]

- Breitenstein, O.; Langenkamp, M. Lock-in Thermography; Springer: Berlin/Heidelberg, Germany, 2003; p. 32. [Google Scholar]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids, 2nd ed.; Oxford University Press: Oxford, UK, 1959; p. 20. [Google Scholar]

- Weller, H.G.; Tabor, G.; Jasak, H.; Fureby, C. A tensorial approach to computational continuum mechanics using object-oriented techniques. Comput. Phys. 1998, 12, 620–632. [Google Scholar] [CrossRef]

| Mesh overall size (spatial directions as in Figure 1) | x-direction: 14µ y-direction: 14µ z-direction: 7µ |

| Mesh cell number | 75,000 (average) |

| Hardware | Intel Xeon Gold 5218 2.3–3.9 GHz 16 core/32 thread RAM DDR4 128 Gb |

| Direct problem computing time | 3 min (average) |

| Inverse problem computing time | 200 min (average) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colom, M.; Rodríguez-Aseguinolaza, J.; Mendioroz, A.; Salazar, A. Sizing the Depth and Width of Narrow Cracks in Real Parts by Laser-Spot Lock-In Thermography. Materials 2021, 14, 5644. https://doi.org/10.3390/ma14195644

Colom M, Rodríguez-Aseguinolaza J, Mendioroz A, Salazar A. Sizing the Depth and Width of Narrow Cracks in Real Parts by Laser-Spot Lock-In Thermography. Materials. 2021; 14(19):5644. https://doi.org/10.3390/ma14195644

Chicago/Turabian StyleColom, Mateu, Javier Rodríguez-Aseguinolaza, Arantza Mendioroz, and Agustín Salazar. 2021. "Sizing the Depth and Width of Narrow Cracks in Real Parts by Laser-Spot Lock-In Thermography" Materials 14, no. 19: 5644. https://doi.org/10.3390/ma14195644

APA StyleColom, M., Rodríguez-Aseguinolaza, J., Mendioroz, A., & Salazar, A. (2021). Sizing the Depth and Width of Narrow Cracks in Real Parts by Laser-Spot Lock-In Thermography. Materials, 14(19), 5644. https://doi.org/10.3390/ma14195644