Performance of Plain Concrete and Cement Blocks with Cement Partially Replaced by Cement Kiln Dust

Abstract

:1. Introduction

2. Research Goal and Methodology

3. Experimental Work

CKD Materials

4. Procedures and Result Discussion

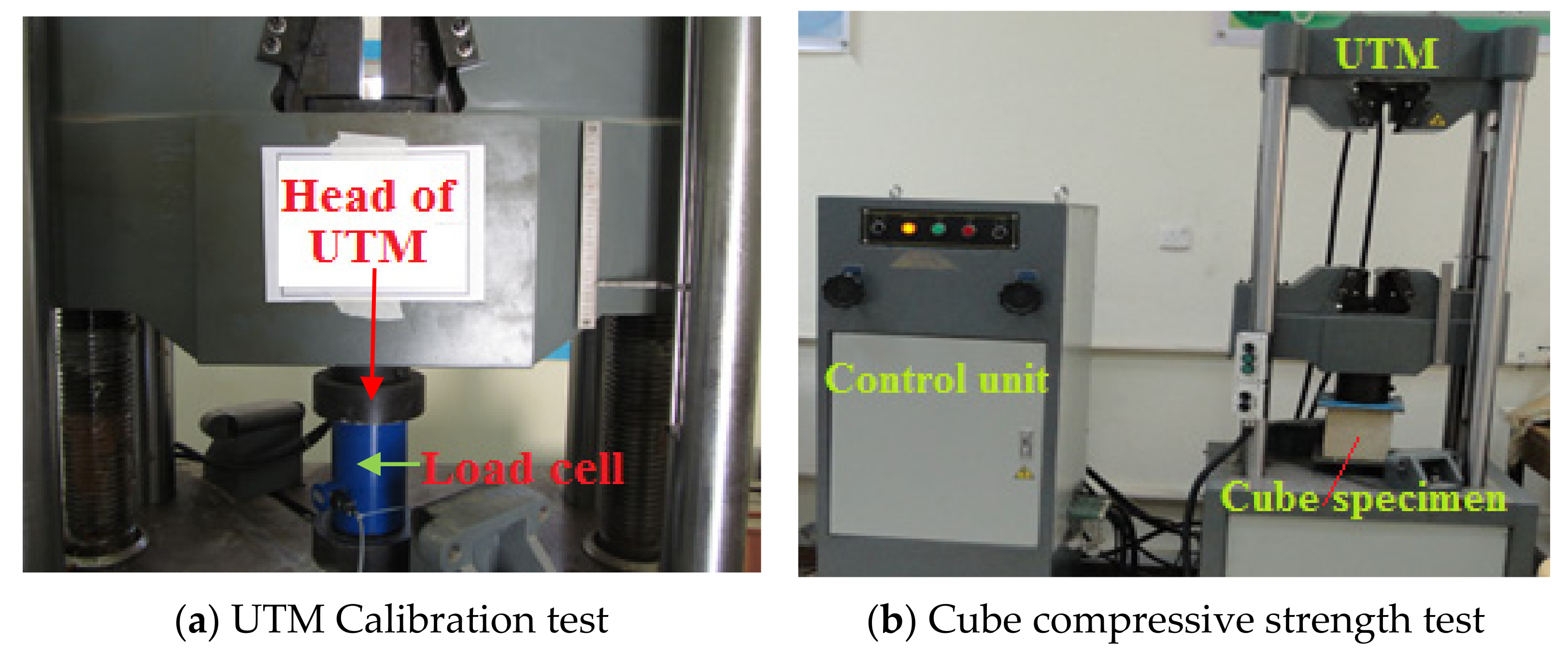

4.1. Concrete

4.1.1. Effect of CKD on Concrete Compressive Strength

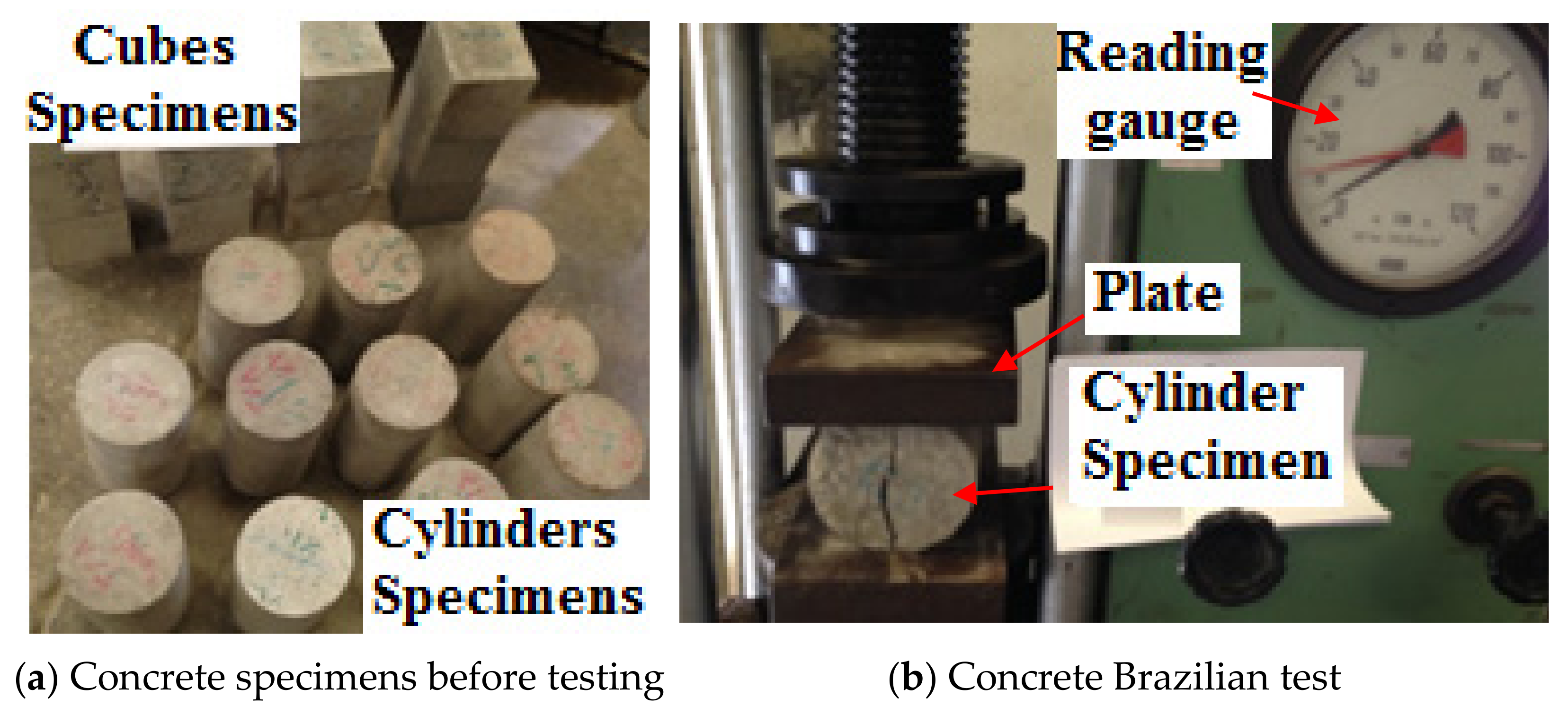

4.1.2. Effect of CKD on Concrete Tensile Strength

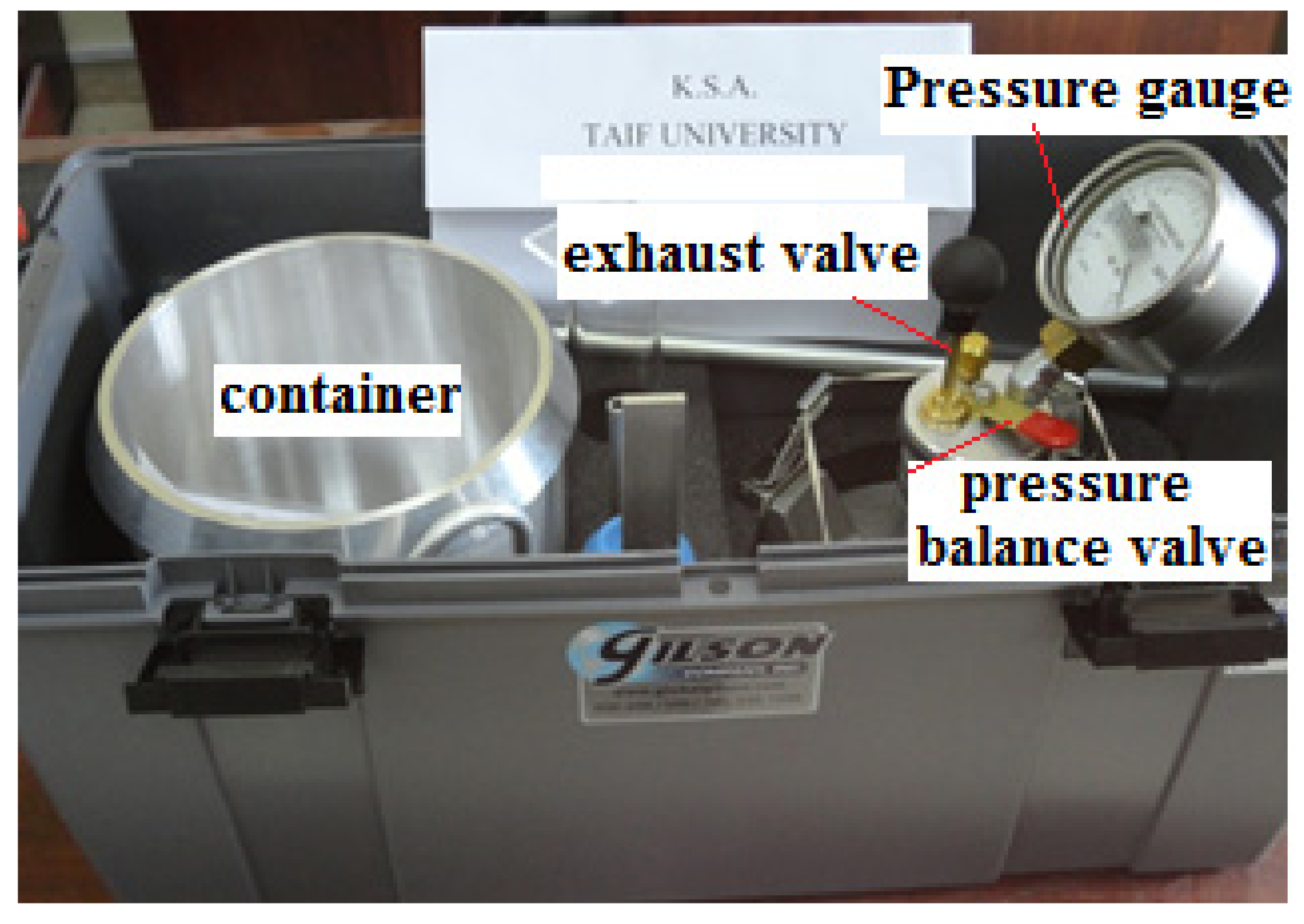

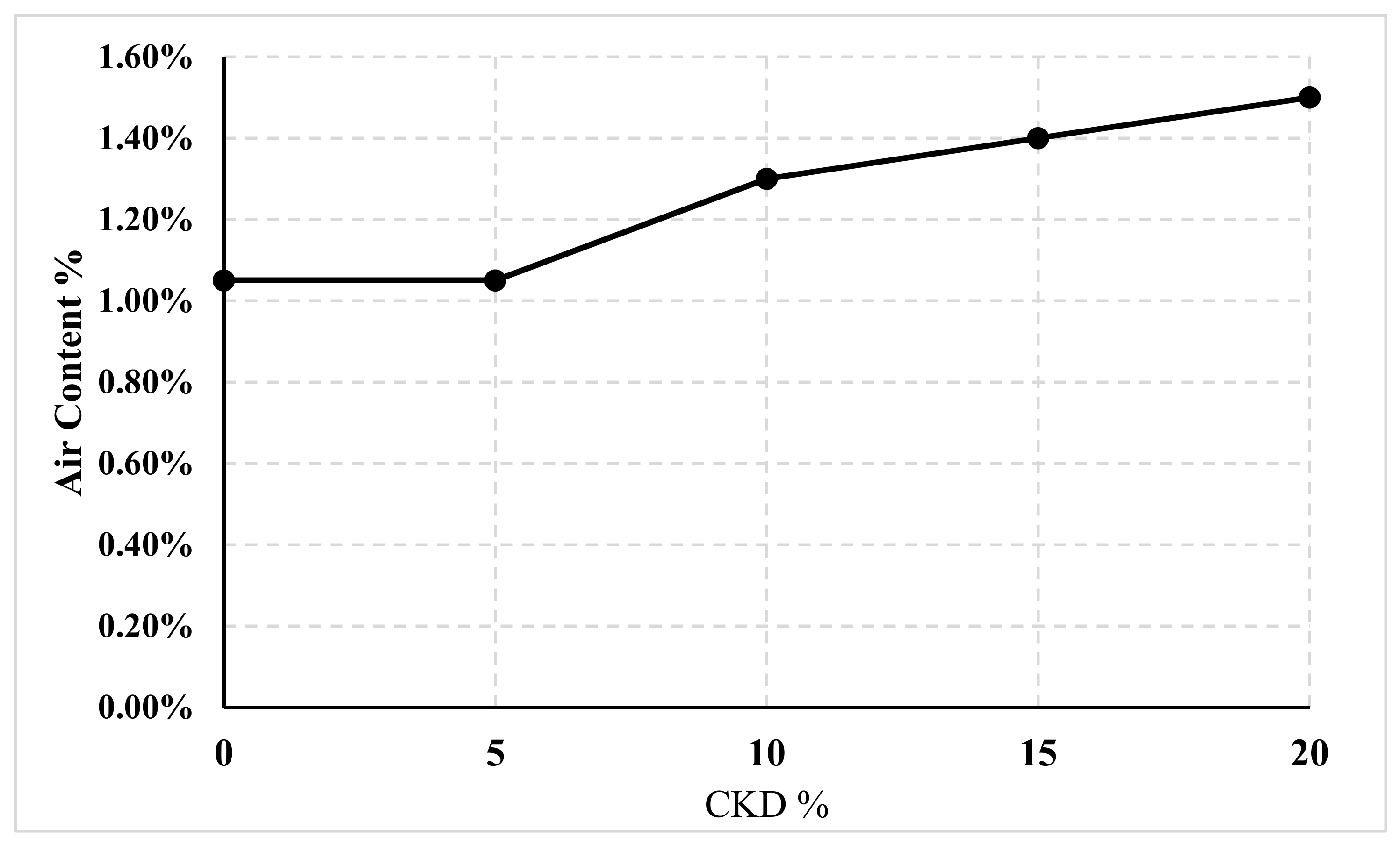

4.1.3. Effect of CKD on Air Content

4.1.4. Water Cement Ratio and CKD Replacement Effects

4.2. Hollow Cement Blocks

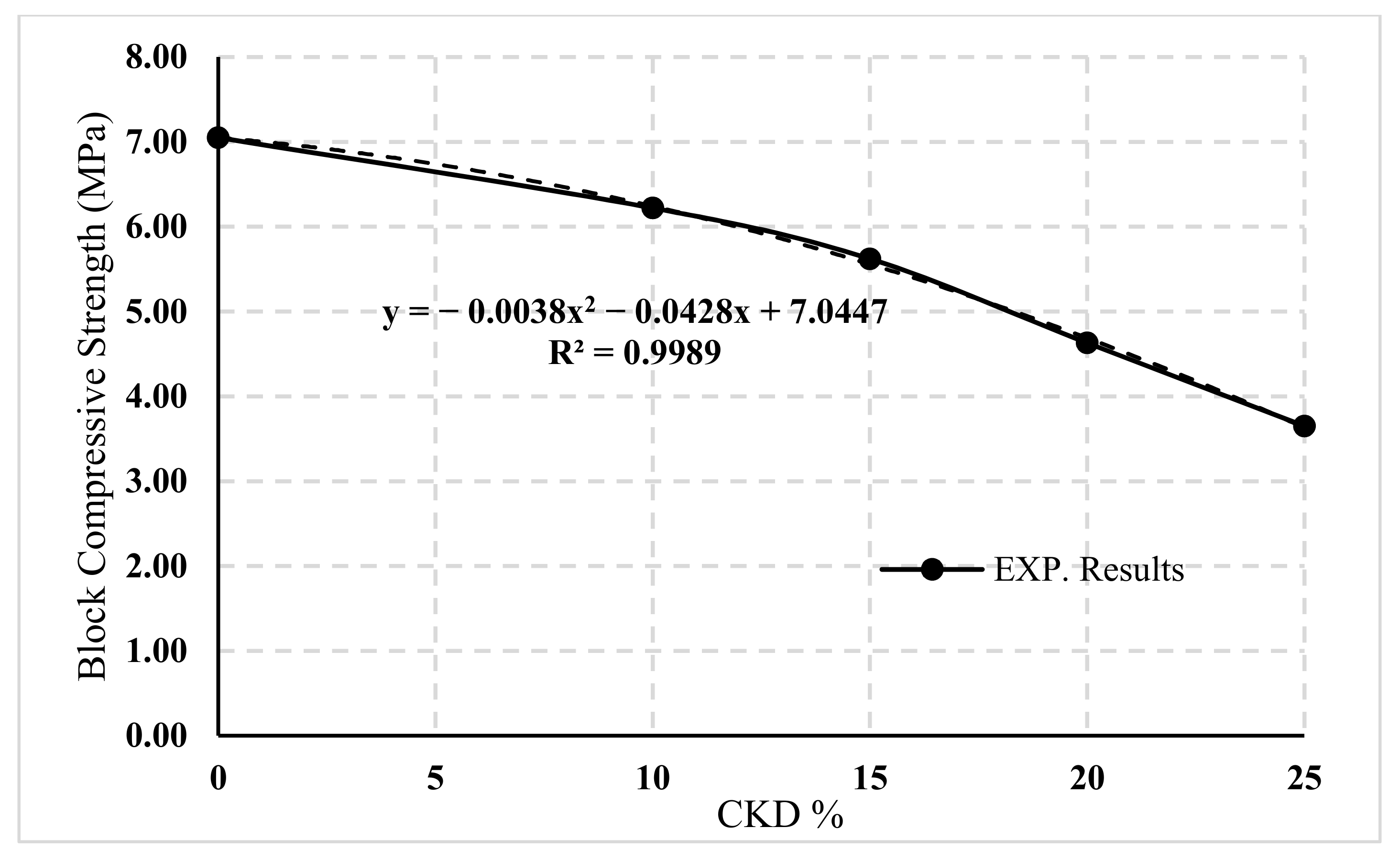

4.2.1. Effect of CKD on Cement Block Compressive Strength

4.2.2. Effect of CKD on Cement Block Absorption

5. Assessment of the Application Tests

6. Summary and Conclusions

- CKD has a detrimental impact on compressive strength, as evidenced by the fact that as the amount increased, the compressive strength of the concrete and cement block specimens decreased. An equation corresponding to each was presented to anticipate this reduction.

- Regarding the concrete tensile strength, there was no significant difference between 0% and 5% CKD, which was only approximately 3%.

- In the concrete mix, the percentage of air content from 0% to 5% CKD replacements made no difference; however, when CKD was increased to 10%, 15%, and 20%, it increased by 24%, 33%, and 43%, respectively.

- The percentage of water absorption due to partial replacement by CKD in cement blocks can be increased up to 25% within the allowed limits.

- This research demonstrates that CKD can be used as a primary component in concrete (e.g., plain concrete, curbs, and cement tiles) and cement block products.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tam, V.W.; Soomro, M.; Evangelista, A.C. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Łasica, W.; Dydek, K.; Boczkowska, A. An Experimental Study of Possible Post-War Ferronickel Slag Waste Disposal in Szklary (Lower Silesian, Poland) as Partial Aggregate Substitute in Concrete: Characterization of Physical, Mechanical, and Thermal Properties. Materials 2021, 14, 2552. [Google Scholar] [CrossRef] [PubMed]

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Chalangaran, N.; Farzampour, A.; Paslar, N.; Fatemi, H. Experimental investigation of sound transmission loss in concrete containing recycled rubber crumbs. Adv. Concr. Constr. 2021, 11, 447–454. [Google Scholar]

- Farzampour, A. Compressive behavior of concrete under environmental effects. In Compressive Strength of Concrete; Intech Open: London, UK, 2019. [Google Scholar]

- Mansouri, I.; Shahheidari, F.S.; Hashemi, S.M.; Farzampour, A. Investigation of steel fiber effects on concrete abrasion resistance. Adv. Concr. Constr. 2020, 9, 367–374. [Google Scholar]

- Chalangaran, N.; Farzampour, A.; Paslar, N. Nano silica and metakaolin effects on the behavior of concrete containing rubber crumbs. CivilEng 2020, 1, 264–274. [Google Scholar] [CrossRef]

- Rahmani, A.H.; Almatroudi, A.; Babiker, A.Y.; Khan, A.A.; Alsahly, M.A. Effect of exposure to cement dust among the workers: An evaluation of health-related complications. Open Access Maced. J. Med Sci. 2018, 6, 1159. [Google Scholar] [CrossRef] [Green Version]

- Omidianidost, A.; Gharavandi, S.; Azari, M.R.; Hashemian, A.H.; Ghasemkhani, M.; Rajati, F.; Jabari, M. Occupational exposure to respirable dust, crystalline silica and its pulmonary effects among workers of a cement factory in Kermanshah, Iran. Tanaffos 2019, 18, 157. [Google Scholar]

- Shah, K.; An, N.; Ma, W.; Ara, G.; Ali, K.; Kamanova, S.; Zuo, X.; Han, M.; Ren, X.; Xing, L. Chronic cement dust load induce novel damages in foliage and buds of Malus domestica. Sci. Rep. 2020, 10, 1–2. [Google Scholar] [CrossRef]

- Shanshal, S.A.; Al-Qazaz, H.K. Consequences of cement dust exposure on pulmonary function in cement factory workers. Am. J. Ind. Med. 2021, 64, 192–197. [Google Scholar] [CrossRef]

- Khanna, O.S. Characterizaton and Utilization of Cement Klin Dust (CKDs) as Partial Replacements of Portland Cement. Ph.D Thesis, Department of Civil Engineering, University of Toronto, Toronto, ON, Canada, 2009. [Google Scholar]

- Maslehuddin, O.S.B.; Al-Amoudi, M.K.; Rahman, M.R.; Ali, M.S.B. Properties of cement kiln dust concrete. Constr. Build. Mater. 2009, 23, 62357–62361. [Google Scholar] [CrossRef]

- Maslehuddin, O.S.B.; Al-Amoudi, M.; Shameem, M.K.; Rahman, M.R.; Ali, M.I. Usage of cement kiln dust in cement products- Research review and preliminary investigations. Constr. Build. Mater. 2008, 22, 2369–2375. [Google Scholar] [CrossRef] [Green Version]

- Ravindrarajah, R.S. Usage of cement kiln dust in concrete. Int. J. Cem. Compos. Lightweight Concr. 1982, 4, 95–102. [Google Scholar] [CrossRef]

- El-Sayed, H.A.; Gabr, N.A.; Hanafi, S.; Mohran, M.A. Reutilization of by-Pass Kiln Dust in Cement Manufacture; International Conference on Blended Cement in Construction: Sheffield, UK, 1991. [Google Scholar]

- Batis, G.; Rakanta, E.; Sideri, E.; Chaniotakis, E.; Papageorgiou, A. Advantages of Simultaneous Use of Cement Kiln Dust and Blast Furnace Slag; International Conference on Challenges of Concrete Construction; University of Dundee: Dundee, UK, 2002. [Google Scholar]

- Abo-El-Enein, S.A. Utilization of Cement Kiln Dust in Cement Industry and Building Products; First international Symposium on the cement Industry: Assiut, Egypt, 1997; pp. 8–10. [Google Scholar]

- Shoaib, M.M.; Balaha, M.M.; Abdel-Rahman, A.G. Influence of cement kiln dust substitution on the mechanical properties of concrete. Cem. Concr. 2000, 30, 337–371. [Google Scholar] [CrossRef]

- Al-Harthy, A.S.; Al-Maamary, F.T. Effect of cement kiln dust CKD on mortar and concrete mixtures. Constr. Build. Mater. 2003, 17, 353–360. [Google Scholar] [CrossRef]

- Mosleh, A.M. Evaluation of By-Pass Dust for the Production of Blended Cement Containing BF Slag. Master’s Thesis, Institute of Environmental Studies and Research, Ain Shams University, Cairo, Egypt, 1996. [Google Scholar]

- Heikal, M.; Aiad, I.; Helmy, I.M. Portland cement clinker, granulated slag and by bass cement dust composites. Cem. Concr. Res. 2002, 32, 1805–1812. [Google Scholar] [CrossRef]

- Udoeyo, F.F.; Rindap, P.I. Cement kiln dust as a material for building blocks. Glob. J. Eng. Res. 2002, 1, 73–78. [Google Scholar] [CrossRef] [Green Version]

- British Standards Institution (BSI). Testing Concrete. Method for Making Test Cubes from Fresh Concrete; BS 1881-108; British Standards Institution: London, UK, 1983. [Google Scholar]

- British Standards Institution (BSI). Methods for the Determination of Compressive Strength of Concrete; BS 1881-116; British Standards Institution: London, UK, 1983. [Google Scholar]

- Elamary, A.S.; Taha, I. Determining the Shear Capacity of Steel Beams with Corrugated Webs by Using Optimised Regression Learner Techniques. Materials 2021, 14, 2364. [Google Scholar] [CrossRef]

- Corish, A.; Coleman, T. Cement kiln dust. Concrete 1995, 29, 40–42. [Google Scholar]

- Bhatty, M.S.Y. Kiln dust cement blends, evaluated. Rock Prod. 1984, 88, 47–65. [Google Scholar]

- Siddique, R.; Rajor, A. Use of cement kiln dust in cement concrete and its leachate characteristics. Resour. Conserv. Recycl. 2012, 61, 59–68. [Google Scholar]

- American Society for Testing and Materials (ASTM). Practice for Making and Curing Concrete Test Specimens in the Field; ASTM C31/C31M; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM C496-90; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; Annu. Book ASTM Stand.: West Conshohocken, PA, USA, 1991; pp. 266–269.

- ASTM C231/C231M-17a; Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method. In American Society of Testing and Materials; ASTM: West Conshohocken, PA, USA, 2017; pp. 1–10.

- Al-Rezaiqi, J.; Alnuaimi, A.; Hago, A.W. Efficiency factors of burnt clay and cement kiln dust and their effects on properties of blended concrete. Appl. Clay Sci. 2018, 157, 51–64. [Google Scholar] [CrossRef]

- ASTM. Sampling and Testing Concrete Masonry Units and Related Units C140/C140M-15a; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

| No. | Test | Specimen Dimension | No. of Specimens |

|---|---|---|---|

| 1 | Chemical analysis | Cement kiln dust (CKD) | 1 |

| 2 | Concrete compressive strength | Cube (150 mm × 150 mm × 150 mm) | 42 |

| 3 | Concrete tensile strength | Cylinder (15 mm in diameter; 30 mm in height) | 12 |

| 4 | Concrete air content | Gilson container | 15 |

| 5 | Blocks compressive strength | Hollow cement blocks (200 mm × 200 mm × 400 mm) | 30 |

| 6 | Block absorption | Hollow cement blocks (200 mm × 200 mm × 400 mm) | 20 |

| Chemical Composition (%) | CKD (UK) [14] | CKD AL Madina Cement Factory (AL Madina KSA) | OPC |

|---|---|---|---|

| SiO2 | 11–16 | 18.20 | 22 |

| Al2O3 | 3–6 | 4.52 | 5 |

| Fe2O3 | 1–4 | 2.92 | 3 |

| CaO | 38–50 | 49.40 | 64 |

| MgO | 0–2 | 1.21 | 1 |

| SO3 | 4–18 | 5.66 | 3 |

| K2O | 3–13 | 2.38 | <1 |

| Na2O | 0–2 | 3.84 | <1 |

| Cl | 0–5 | 5.90 | <0.10 |

| Loss on ignition | 5–25 | 17.10 | 1 |

| Free Cao | 1–10 | 4.24 | 2 |

| No. | Cube Compressive Strength after 28 Days (MPa) | |||||||

|---|---|---|---|---|---|---|---|---|

| % of CKD | 0% | 2% | 5% | 8% | 10% | 15% | 20% | |

| 1 | From cement portion in concrete mixes | 29 | 28.2 | 28 | 27.6 | 27 | 24.5 | 19.2 |

| 2 | 29.3 | 29 | 27.5 | 27.3 | 26.3 | 25 | 18.5 | |

| 3 | 28.45 | 28.1 | 27.6 | 26.5 | 26.5 | 23.8 | 18.2 | |

| 4 | 28.41 | 28.3 | 28 | 27 | 26.8 | 23.7 | 19 | |

| 5 | 28.66 | 28 | 27.5 | 26.4 | 26.2 | 24.2 | 18.4 | |

| 6 | 28.5 | 28.1 | 28.2 | 27.2 | 26.2 | 24 | 18.3 | |

| Average (MPa) | 28.724 | 28.45 | 27.8 | 27 | 26.5 | 24.2 | 18.6 | |

| No | % of CKD | Tensile Strength (MPa) | Average (MPa) | |||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |||

| 1 | 0% | 2.97 | 3.11 | 2.83 | 2.90 | 3.00 | 2.95 | 2.95 |

| 2 | 5% | 2.81 | 2.86 | 2.68 | 2.74 | 2.85 | 2.87 | 2.80 |

| No. (1) | % CKD (2) | % Air Content (3) | % Air Content Average (4) |

|---|---|---|---|

| 1 | 0 | 1.05 | 1.05 |

| 2 | 1.05 | ||

| 3 | 1.00 | ||

| 1 | 5 | 1.05 | 1.05 |

| 2 | 1.05 | ||

| 3 | 1.10 | ||

| 1 | 10 | 1.30 | 1.30 |

| 2 | 1.35 | ||

| 3 | 1.25 | ||

| 1 | 15 | 1.35 | 1.40 |

| 2 | 1.45 | ||

| 3 | 1.35 | ||

| 1 | 20 | 1.45 | 1.50 |

| 2 | 1.60 | ||

| 3 | 1.50 |

| % of CKD | Crushing Load (kN) | Strength (MPa) Net Area | Strength (MPa) Gross Area | ||

|---|---|---|---|---|---|

| Per Specimen | Average | Per Specimen | Average | ||

| 0 | 55.5 | 12.31 | 11.89 | 7.30 | 7.05 |

| 56.00 | 12.42 | 7.36 | |||

| 52.30 | 11.60 | 6.88 | |||

| 50.50 | 11.20 | 6.64 | |||

| 52.75 | 11.70 | 6.94 | |||

| 54.56 | 12.10 | 7.18 | |||

| 10 | 48.25 | 10.70 | 10.50 | 6.34 | 6.22 |

| 47.80 | 10.60 | 6.29 | |||

| 45.70 | 10.14 | 6.01 | |||

| 47.50 | 10.54 | 6.25 | |||

| 48.00 | 10.65 | 6.32 | |||

| 46.64 | 10.35 | 6.14 | |||

| 15 | 37.82 | 8.39 | 9.50 | 4.97 | 5.62 |

| 46.7 | 10.36 | 6.14 | |||

| 42.2 | 9.36 | 5.55 | |||

| 44.3 | 9.83 | 5.83 | |||

| 43.17 | 9.58 | 5.68 | |||

| 42.59 | 9.45 | 5.60 | |||

| 20 | 35.11 | 7.79 | 7.80 | 4.62 | 4.63 |

| 35.98 | 7.98 | 4.73 | |||

| 34.24 | 7.6 | 4.50 | |||

| 35.41 | 7.85 | 4.66 | |||

| 35.27 | 7.82 | 4.64 | |||

| 35.00 | 7.76 | 4.61 | |||

| 25 | 27.34 | 6.06 | 6.15 | 3.60 | 3.65 |

| 28.2 | 6.26 | 3.71 | |||

| 27.56 | 6.11 | 3.62 | |||

| 27.82 | 6.17 | 3.66 | |||

| 27.73 | 6.15 | 3.65 | |||

| 27.59 | 6.12 | 3.63 | |||

| % CKD | Weight (N) | Average Weight (N) | % Absorption | |||

|---|---|---|---|---|---|---|

| After Oven | After Submerged | Water Absorbed | Dry Weight | Water | ||

| 0 | 196.35 | 204.20 | 7.85 | 191.64 | 8.18 | 4.27 |

| 189.70 | 198.15 | 8.45 | ||||

| 191.00 | 198.90 | 7.90 | ||||

| 189.50 | 198.00 | 8.50 | ||||

| 10 | 196.80 | 205.90 | 9.10 | 190.13 | 9.48 | 4.98 |

| 186.20 | 196.10 | 9.90 | ||||

| 186.50 | 196.40 | 9.90 | ||||

| 191.00 | 200.00 | 9.00 | ||||

| 15 | 185.75 | 195.95 | 10.20 | 185.61 | 9.913 | 5.34 |

| 185.40 | 195.15 | 9.75 | ||||

| 185.20 | 195.00 | 9.80 | ||||

| 186.10 | 196.00 | 9.90 | ||||

| 20 | 186.75 | 197.95 | 11.20 | 187.01 | 11.53 | 6.16 |

| 187.60 | 199.40 | 11.80 | ||||

| 186.60 | 198.20 | 11.60 | ||||

| 187.10 | 198.60 | 11.50 | ||||

| 25 | 182.45 | 194.20 | 11.75 | 186.04 | 11.74 | 6.31 |

| 188.00 | 199.80 | 11.80 | ||||

| 188.30 | 200.00 | 11.70 | ||||

| 185.40 | 197.10 | 11.70 | ||||

| Test Type | % CKD | Mean | Standard Deviation | Min. | Max |

|---|---|---|---|---|---|

| Concrete compressive strength | 2 | 0.985 | 0.009 | 0.972 | 0.996 |

| 5 | 0.968 | 0.019 | 0.939 | 0.989 | |

| 8 | 0.940 | 0.014 | 0.921 | 0.954 | |

| 10 | 0.923 | 0.016 | 0.898 | 0.943 | |

| 15 | 0.843 | 0.007 | 0.834 | 0.853 | |

| 20 | 0.648 | 0.014 | 0.631 | 0.669 | |

| Concrete tensile | 5 | 0.950 | 0.017 | 0.920 | 0.973 |

| Concrete air content | 5 | 1.033 | 0.058 | 1.000 | 1.100 |

| 10 | 1.258 | 0.025 | 1.238 | 1.286 | |

| 15 | 1.339 | 0.049 | 1.286 | 1.381 | |

| 20 | 1.468 | 0.077 | 1.381 | 1.524 | |

| Block compressive strength | 10 | 0.884 | 0.019 | 0.862 | 0.905 |

| 15 | 0.798 | 0.028 | 0.749 | 0.834 | |

| 20 | 0.657 | 0.017 | 0.638 | 0.679 | |

| 25 | 0.517 | 0.016 | 0.501 | 0.541 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alharthi, Y.M.; Elamary, A.S.; Abo-El-Wafa, W. Performance of Plain Concrete and Cement Blocks with Cement Partially Replaced by Cement Kiln Dust. Materials 2021, 14, 5647. https://doi.org/10.3390/ma14195647

Alharthi YM, Elamary AS, Abo-El-Wafa W. Performance of Plain Concrete and Cement Blocks with Cement Partially Replaced by Cement Kiln Dust. Materials. 2021; 14(19):5647. https://doi.org/10.3390/ma14195647

Chicago/Turabian StyleAlharthi, Yasir M., Ahmed S. Elamary, and Waleed Abo-El-Wafa. 2021. "Performance of Plain Concrete and Cement Blocks with Cement Partially Replaced by Cement Kiln Dust" Materials 14, no. 19: 5647. https://doi.org/10.3390/ma14195647

APA StyleAlharthi, Y. M., Elamary, A. S., & Abo-El-Wafa, W. (2021). Performance of Plain Concrete and Cement Blocks with Cement Partially Replaced by Cement Kiln Dust. Materials, 14(19), 5647. https://doi.org/10.3390/ma14195647