Thermal Conductivity of Sand-Lime Products Modified with Foam Glass Granulate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fine Sand

2.2. Lime

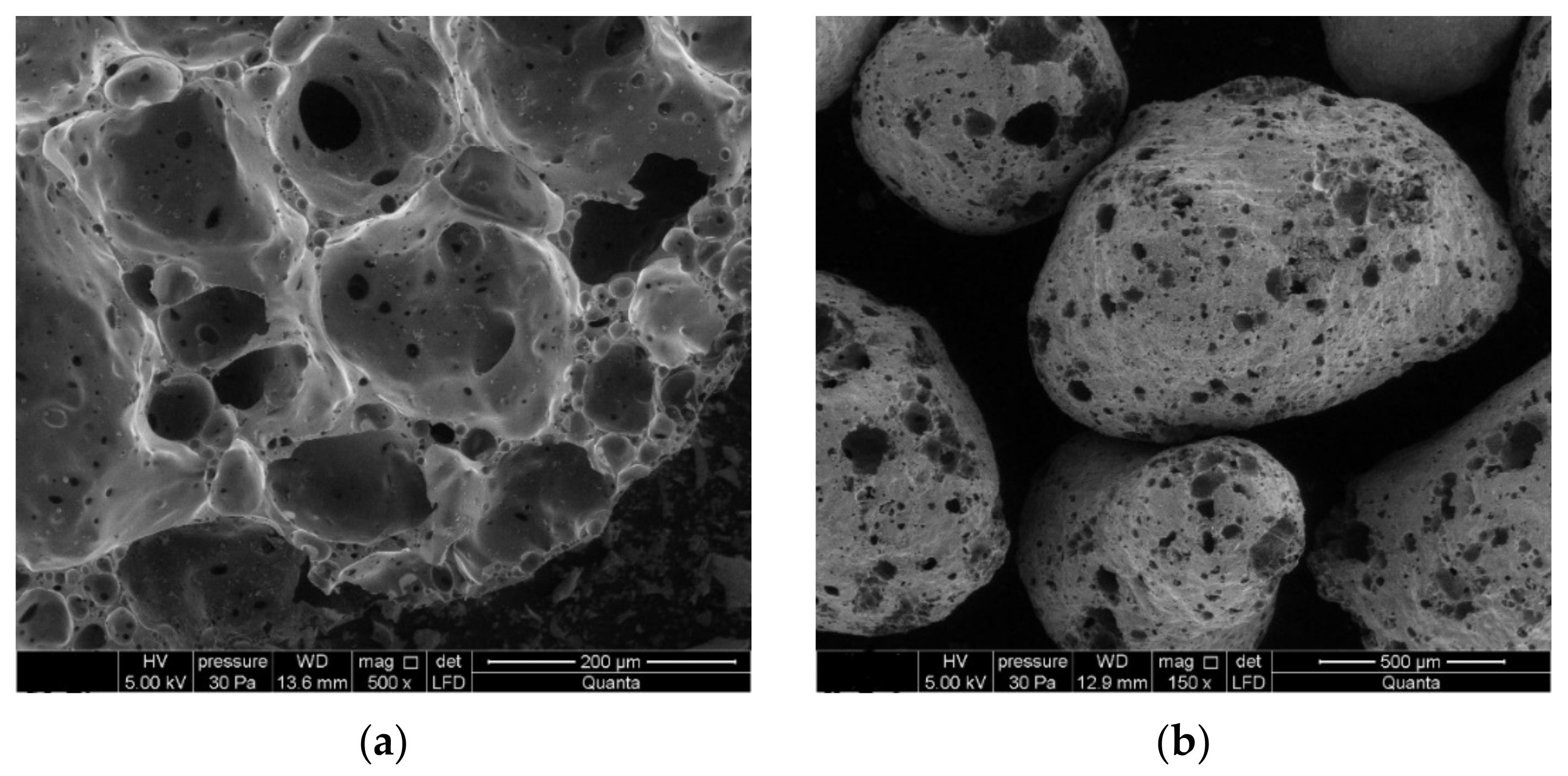

2.3. Characteristics of the Filler

2.4. Bulk Density Test

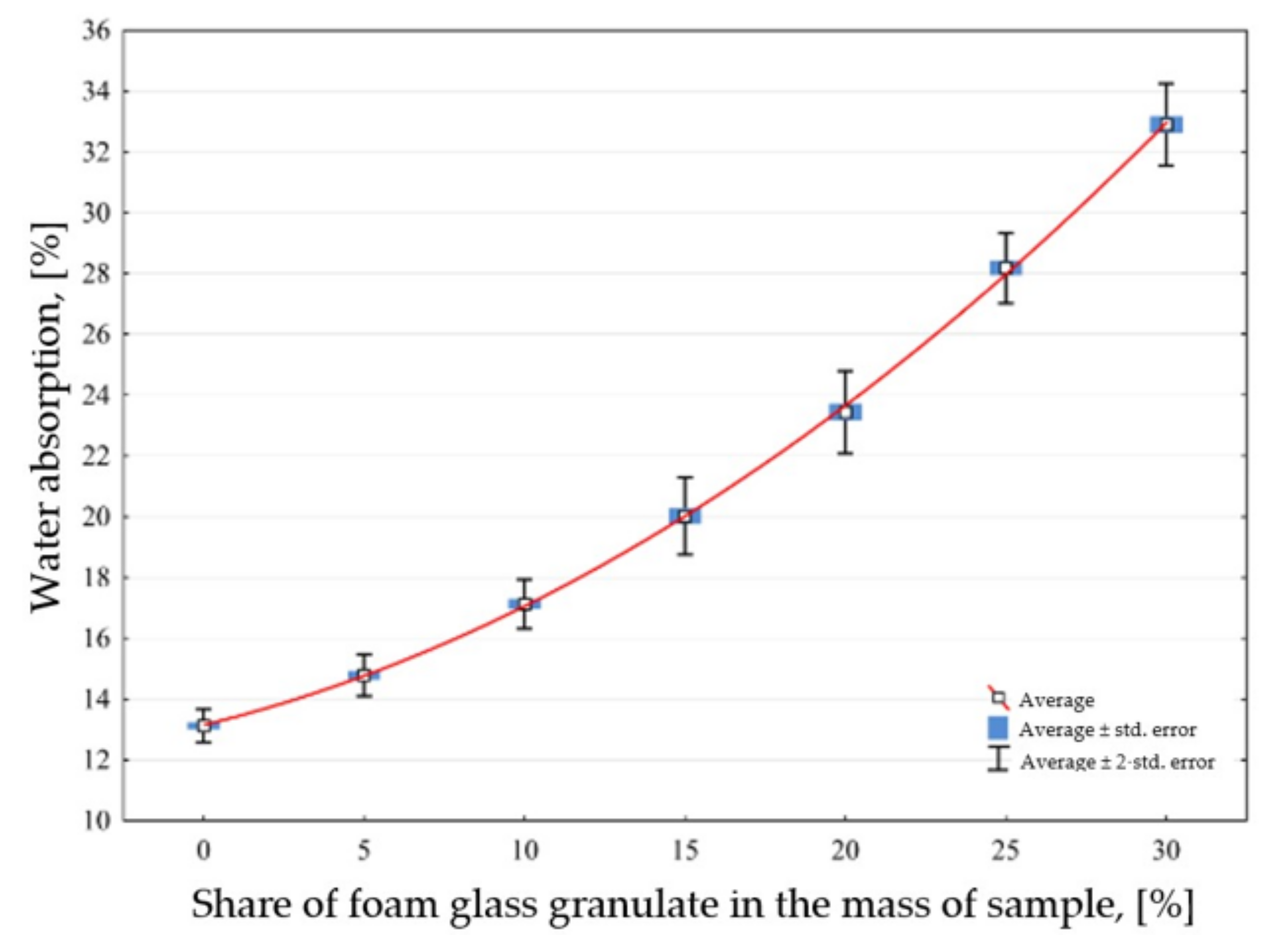

2.5. Water Absorption Test

2.6. Determination of the Pore Size Distribution by Mercury Porosimetry

2.7. Determination of the Thermal Conductivity Coefficient

3. Results

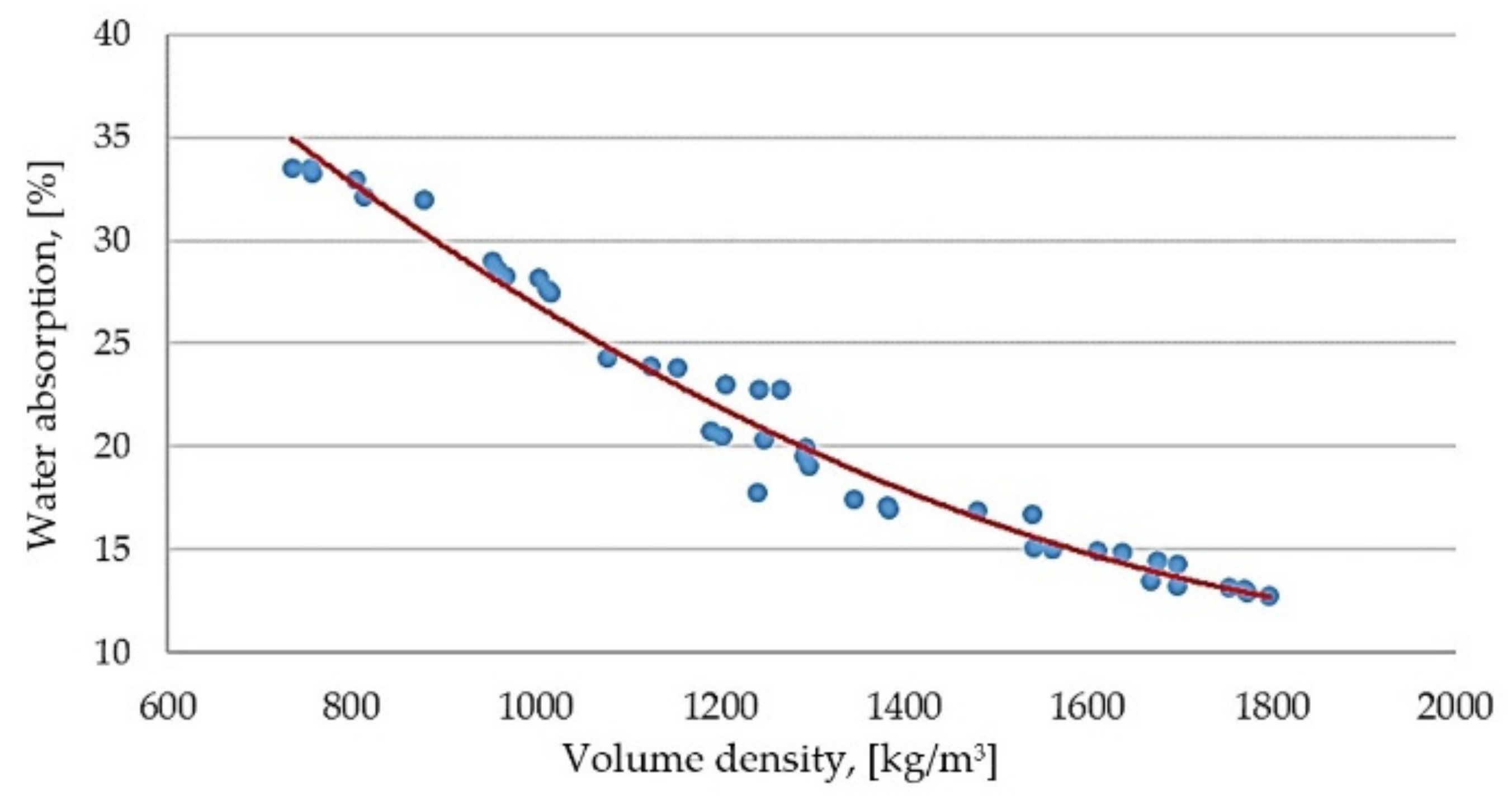

3.1. Dependence of Water Absorption on Volume Density

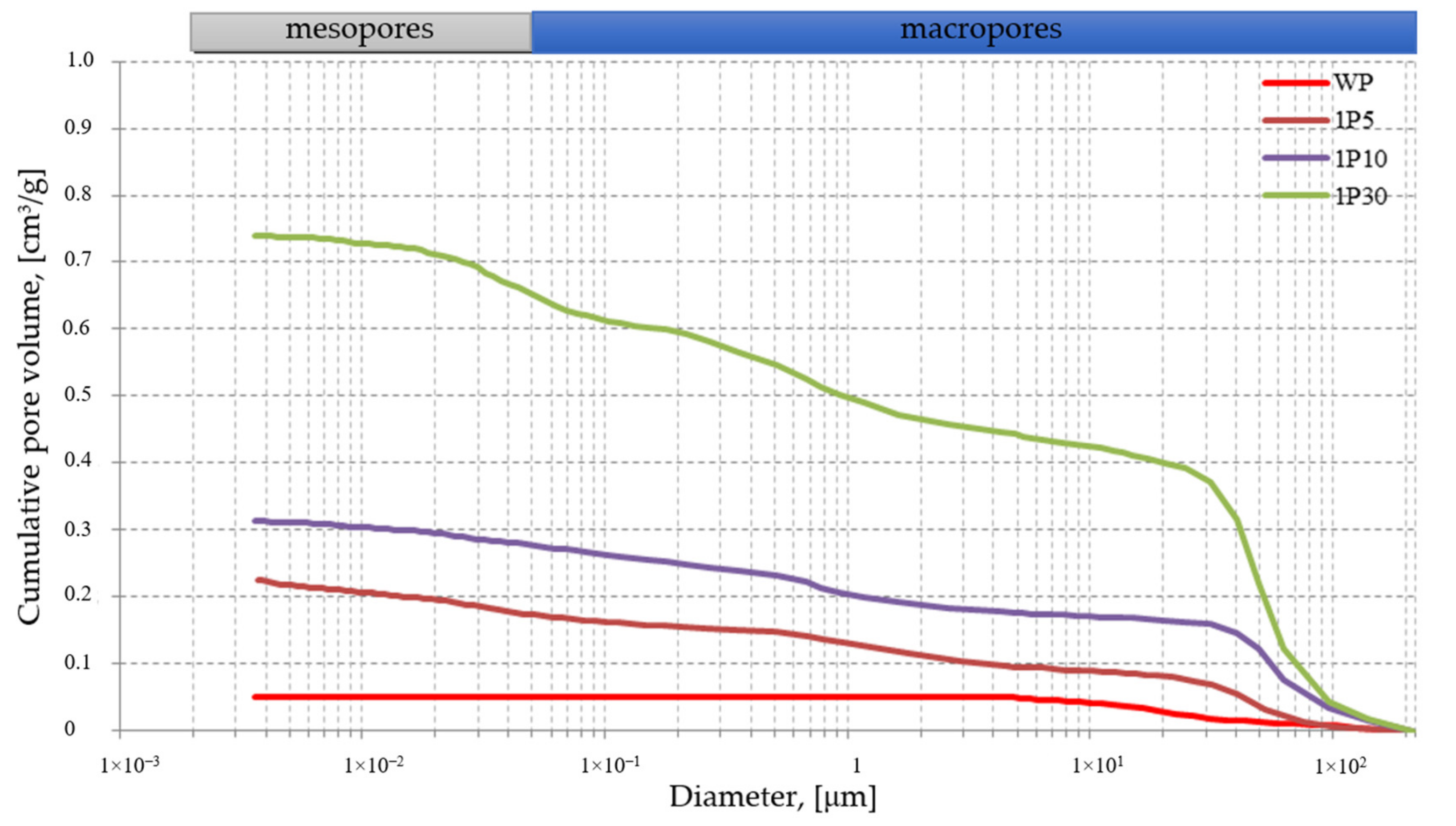

3.2. Pore Size Distribution

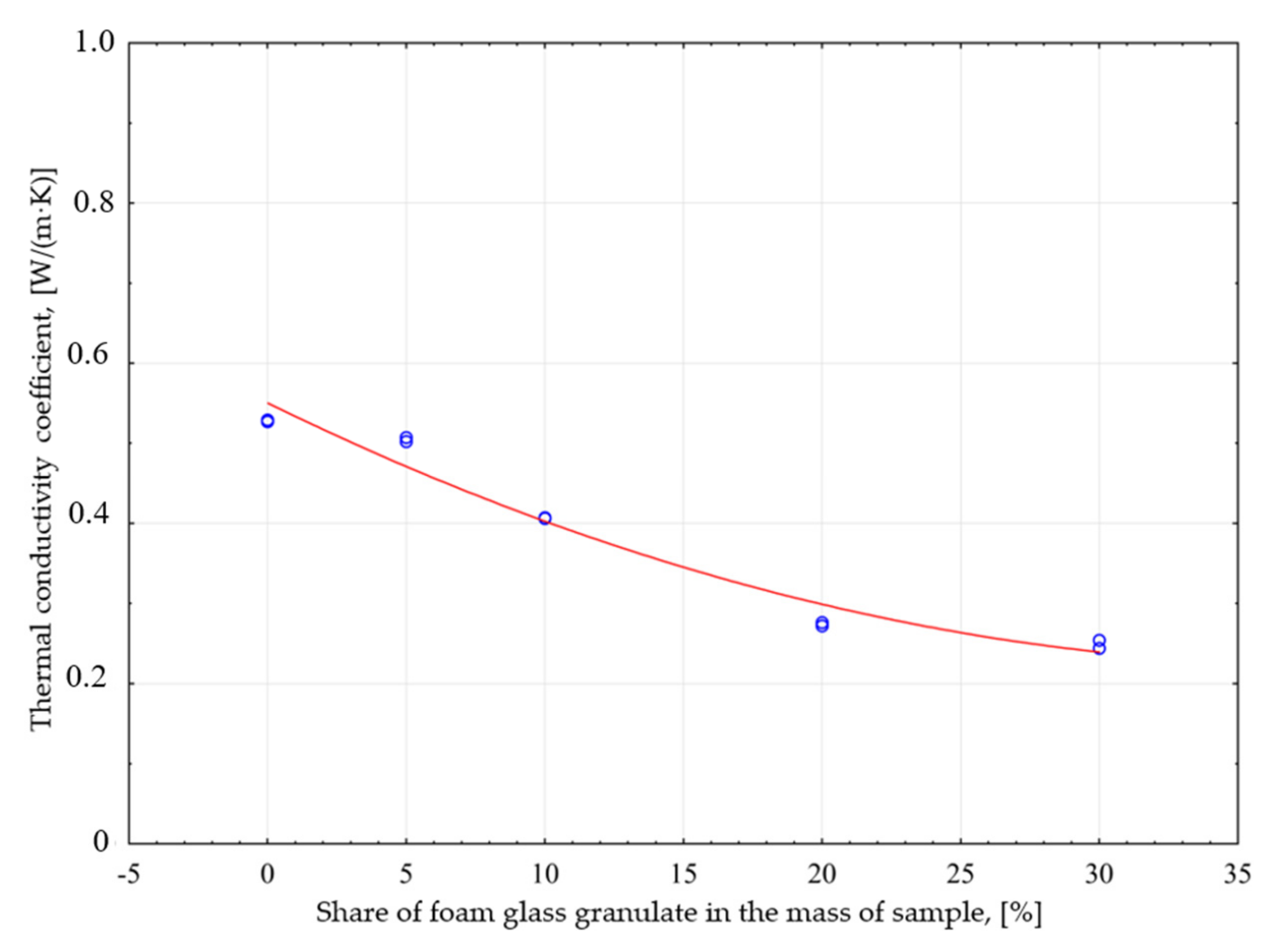

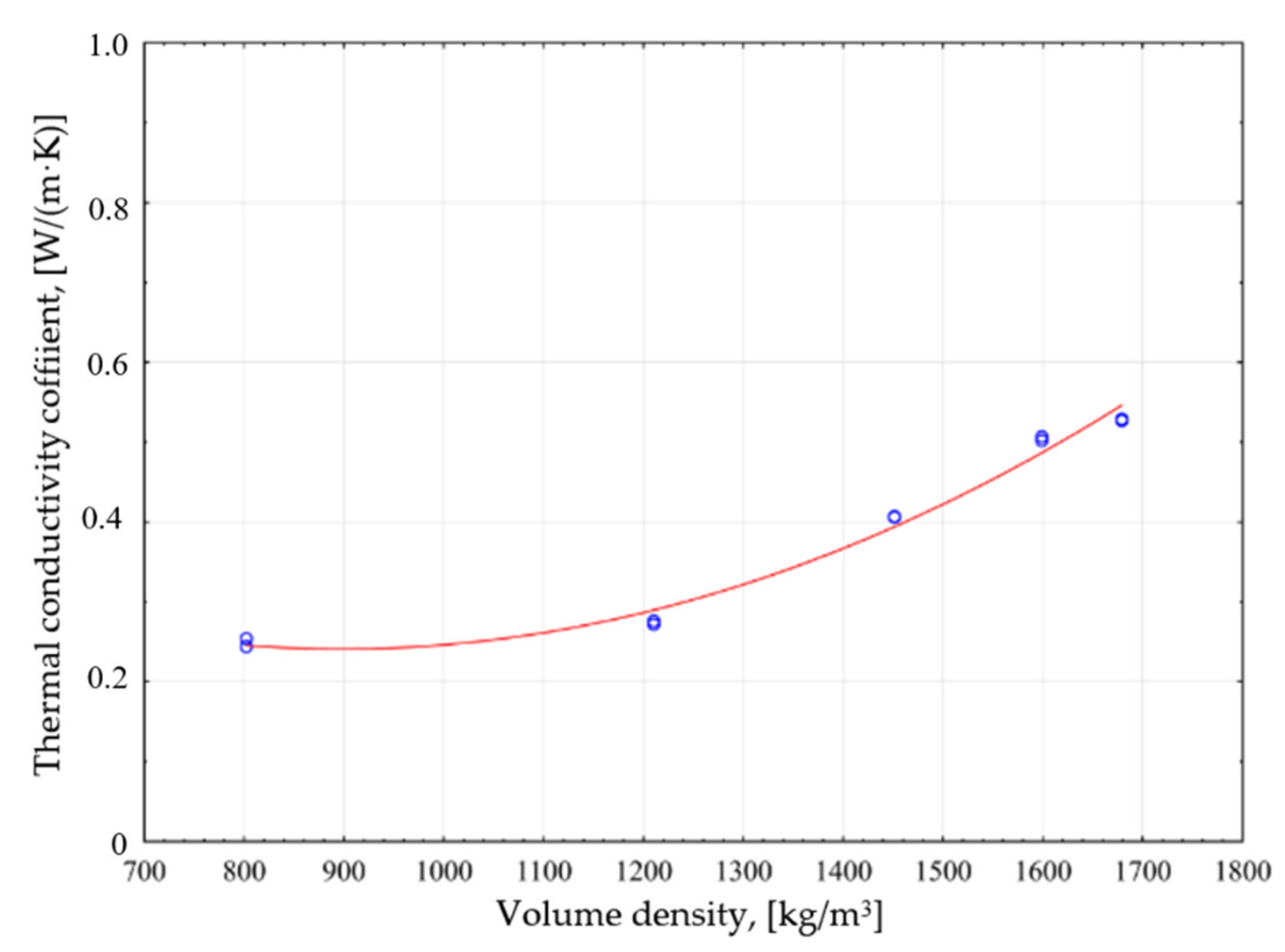

3.3. Dependence of Thermal Conductivity on Bulk Density

4. Conclusions

- The use of a light filler of granulated foam glass (GFG) in sand-lime products will allow the obtaining of products with good thermal insulation properties, i.e., characterized by a significantly reduced value of the thermal conductivity coefficient compared to traditional products;

- The conducted research made it possible to adjust the appropriate mathematical models that characterize the impact of the amount of fillers on the functional properties of the modified products;

- An increased effective porosity of the sand-lime products in the range of the analyzed diameters has a positive effect on the value of the thermal conductivity coefficient of products modified with the filler used;

- Although the GFG filler itself, according to the manufacturer’s declared properties, has a low degree of water absorption, the sand-lime samples autoclaved with the GFG filler are characterized by water absorption that increases significantly;

- The results apply only to samples modified with GFG of a specific fraction, i.e., the dimensions of 0.25–0.5 mm. At this stage of the research it is not possible to state that the changes in water absorption along with the bulk density and the changes in the thermal conductivity coefficient along with the bulk density expressed by the formulas presented in this article will be applicable to the use of GFG of a different fraction. A separate article will be devoted to this topic after an appropriate amount of research has been carried out on materials containing other fractions;

- In terms of the possibility of using the presented modification in the industry, especially from the technological and constructional point of view, the authors assumed that the compressive strength of the products should not be less than 5 MPa. Taking into account the changes in the performance characteristics described in this publication and in the article [39], it is indicated that the strength requirements are met by the modified GFG sand-lime samples where the amount in the sample does not exceed 25%. Such samples are characterized by a thermal conductivity coefficient of not less than 0.24 W/(m·K), and therefore it is more than 50% lower than for traditional products.

- Considering the value of water absorption, the possible use of the modified GFG products will involve the use of waterproofing in places exposed to contact with water.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kuśnierz, A. Glass Recykling. Pract. Inst. Ceram. I Mater. Bud. 2010, 3, 22–33. [Google Scholar]

- Yang, S.; Lu, J.X.; Poon, C.S. Recycling of waste glass in cement mortars: Mechanical properties under high temperature loading. Resour. Conserv. Recycl. 2021, 174, 105831. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerdan, F. What a Waste 2.0. Aglobal Snapshot of Solid Waste Management to 2050. Urban Development; DC World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Eurostat (European Commission). Energy, Transport and Environment Statistics, Statistical Book; Eurostat (European Commission): Luxembourg, 2020. [Google Scholar]

- Mallum, I.; Mohd.Sam, A.R.; Lim, N.H.A.S.; Omolayo, N. Sustainable Utilization of Waste Glass in Concrete: A Review. Silicon 2021, 1–16. [Google Scholar] [CrossRef]

- Chen, Z.; Poon, C.S.; Li, J.S. Utilization of glass cullet to enhance the performance of recycled aggregate unbound sub-base. J. Clean. Prod. 2020, 288, 125083. [Google Scholar] [CrossRef]

- Kurpińska, M.; Grzyl, B.; Pszczoła, M.; Kristowski, A. The Application of Granulated Expanded Glass Aggregate with Cement Grout as an Alternative Solution for Sub-Grade and Frost-Protection Sub-Base Layer in Road Construction. Materials 2019, 12, 3528. [Google Scholar] [CrossRef] [Green Version]

- Lakov, L.; Jivov, B.; Ivanova, Y.; Yordanov, S.; Toncheva, K. Alternative possibilities for application of foamed silicate materials. Mach. Technol. Mater. 2021, 15, 25–27. [Google Scholar]

- Omoding, N.; Cunningham, L.S.; Lane-Serff, G.F. Effect of using recycled waste glass coarse aggregates on the hydrodynamic abrasion resistance of concreto. Constr. Build. Mater. 2020, 268, 121177. [Google Scholar] [CrossRef]

- Bostanci, S.C. Engineering Properties and Sustainability Assessment of Recycled Glass Sand Concrete. Eur. J. Sci. Technol. 2019, 12, 117–130. [Google Scholar] [CrossRef]

- Pingping, H.; Zhang, B.; Lu, J.X.; Poon, C.S. ASR expansion of alkali-activated cement glass aggregate mortars. Constr. Build. Mater. 2020, 261, 119925. [Google Scholar]

- Duraman, S.B.; Li, Q. Recycled Glass Cullet as Fine Aggregate and Partial Cement Replacement in Concrete. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1144, p. 012010. [Google Scholar]

- Małek, M.; Łasica, W.; Jackowski, M.; Kadela, M. Effect of Waste Glass Addition as a Replacement for Fine Aggregate on Properties of Mortar. Materials 2020, 13, 3189. [Google Scholar] [CrossRef] [PubMed]

- Sikora, P.; Horszczaruk, E.; Skoczylas, K.; Rucinska, T. Thermal properties of cement mortars containing waste glass aggregate and nanosilica. Procedia Eng. 2017, 196, 159–166. [Google Scholar] [CrossRef]

- Bostanci, S.C. Use of waste marble dust and recycled glass for sustainable concrete production. J. Od Clean. Prod. 2020, 251, 119785. [Google Scholar] [CrossRef]

- Dachowski, R.; Kostrzewa, P. The use of waste materials in the construction industry. Procedia Eng. 2016, 161, 754–758. [Google Scholar] [CrossRef] [Green Version]

- Owsiak, Z.; Kostrzewa, P. Efects of Bentonite Additives on Autoclaved Sand-Lime Product Properties. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 251, p. 012021. [Google Scholar]

- Dachowski, R.; Stępień, A. Impact of modification of sand-lime mass with organic compounds on the microstructure and mechanical features of silicate bricks. In Environmental Engineering. Proceedings of the International Conference on Environmental Engineering; Vilnius Gediminas Technical University: Vilnius, Lithuania, 2014. [Google Scholar]

- Stępień, A.; Kostrzewa, P.; Dachowski, R. Influence of barium and lithium compounds on silica autoclaved materials properties and on the microstructure. J. Clean. Prod. 2019, 236, 117507. [Google Scholar] [CrossRef]

- Stepien, A.; Potrzeszcz-Sut, B.; Kostrzewa, P. Influence and application of glass cullet in autoclaved materials. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Jasińska, I. The properties of silicate products modified by LDPE granulates. Struct. Environ. 2013, 5, 11–14. [Google Scholar]

- Kostrzewa, P.; Stępień, A. Autoclaved Sand-Lime Products with a Polypropylene Mesh. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 022069. [Google Scholar] [CrossRef] [Green Version]

- Dachowski, R.; Nowek, M. Landfill leachate as an additive in sand-lime products. Procedia Eng. 2016, 161, 572–576. [Google Scholar] [CrossRef] [Green Version]

- Fang, Y.; Gu, Y.; Kang, Q.; Wen, Q.; Dai, P. Utilization of copper tailing for autoclaved sand–lime brick. Constr. Build. Mater. 2011, 25, 867–872. [Google Scholar] [CrossRef]

- Stepien, A.; Potrzeszcz-Sut, B.; Prentice, D.P.; Oey, T.J.; Balonis, M. The Role of Glass Compounds in Autoclaved Bricks. Buildings 2020, 10, 41. [Google Scholar] [CrossRef] [Green Version]

- Borek, K.; Czapik, P.; Dachowski, R. Recycled Glass as a Substitute for Quartz Sand in Silicate Products. Materials 2020, 13, 1030. [Google Scholar] [CrossRef] [Green Version]

- Stepień, A.; Leśniak, M.; Sitarz, M. A Sustainable Autoclaved Material Made of Glass Sand. Buildings 2019, 9, 232. [Google Scholar] [CrossRef] [Green Version]

- Stępień, A. Analysis of Porous Structure in Autoclaved Materials Modified by Glass Sand. Crystals 2021, 11, 408. [Google Scholar] [CrossRef]

- Schumacher, K.; Saßmannshausen, N.; Pritzel, C.; Trettin, T. Lightweight aggregate concrete with an open structure and a porous matrix with an improved ratio of compressive strength to dry density. Constr. Build. Mater. 2020, 264, 120167. [Google Scholar] [CrossRef]

- Šeputyte-Jucike, J.; Sinica, M. The effect of expanded glass and polystyrene waste on the properties of lightweight aggregate concreto. Eng. Struct. Technol. 2016, 8, 31–40. [Google Scholar]

- Chung, S.-Y.; Abd Elrahman, M.; Sikora, P.; Rucinska, T.; Horszczaruk, E.; Stephan, D. Evaluation of the Effects of Crushed and Expanded Waste Glass Aggregates on the Material Properties of Lightweight Concrete Using Image-Based Approaches. Materials 2017, 10, 1354. [Google Scholar] [CrossRef] [Green Version]

- Limbachiya, M.; Meddah, M.S.; Fotiadou, S. Performance of granulated foam glass concrete. Constr. Build. Mater. 2012, 28, 759–768. [Google Scholar] [CrossRef]

- Vaganov, V.; Popov, M.; Korjakins, A.; Šahmenko, G. Effect of CNT on Microstructure and Mineralogical Composition of Lightweight Concrete with Granulated Foam Glass. Procedia Eng. 2017, 172, 1204–1211. [Google Scholar] [CrossRef]

- Bubenik, J.; Zach, J. The use of foam glass based aggregates for the production of ultra-lightweight porous concrete for the production of noise barrier wall panels. Transp. Res. Procedia 2019, 40, 639–646. [Google Scholar] [CrossRef]

- Asztalos, F.; Kocserha, I. Laminar foam glass as a lightweight concrete aggregate. J. Phys. Conf. Ser. 2020, 1527, 012041. [Google Scholar] [CrossRef]

- Kurpińska, M.; Ferenc, T. Experimental and Numerical Investigation of Mechanical Properties of Lightweight Concretes (LWCs) with Various Aggregates. Materials 2020, 13, 3474. [Google Scholar] [CrossRef]

- Dachowski, R.; Jasinska, I. The effect of adding foamed glass granules on porosity of silicate products. Arch. Inst. Civ. Eng. 2012, 13, 51–53. [Google Scholar]

- Jasińska, I. Effect of modification of sand-lime products on their basic functional properties. Tech. Trans. 2014, 1-B, 39–45. [Google Scholar]

- Jasińska, I. Effect of foam glass granule fillers modification of lime-sand products on their microstructure. Open Eng. 2019, 9, 299–306. [Google Scholar] [CrossRef] [Green Version]

- PN-EN 772-1+A1:2015-10 Methods of Test for Masonry Units—Part 1: Determination of Compressive Strength; Comite Europeen de Normalisation: Warsaw, Poland, 2015.

- PN-EN ISO 14688-2:2008-05 Geotechnical Identification and Research—Soil Determination and Classification—Part 2: Classification Rules; Comite Europeen de Normalisation: Warsaw, Poland, 2018.

- PN-EN 772-13:2001 Masonry Test Methods—Part 13: Determination of the Net and Gross Density of Masonry Members in the Dry State (Excluding Natural Stone); Comite Europeen de Normalisation: Warsaw, Poland, 2001.

- PN-EN 771-2+A1:2015-10 Requirements for Masonry Elements. Part 2: Calcium Silicate Masonry Elements; Comite Europeen de Normalisation: Warsaw, Poland, 2017.

- PN-EN 772-21:2011 Methods of Test for Masonry Units—Part 21: Determination of Water Absorption of Clay and Calcium Silicate Masonry Units by Cold Water Absorption; Comite Europeen de Normalisation: Warsaw, Poland, 2011.

- Petri, M. Podstawy Technologii Materiałów Budowlanych i Metody Badan; Jan Małolepszy, E., Ed.; Wydawnictwa AGH: Kraków, Polland, 2013. [Google Scholar]

- Semyrka, R.; Jarzyna, J.A.; Krakowska, P.I.; Semyrka, G. Zastosowanie analizy porozymetrycznej dla oceny przestrzeni porowej skał w profilach utworów karbonu dolnego i karbonu środkowego północno-zachodniej Polski. Gospod. Surowcami Miner. 2015, 31, 123–140. [Google Scholar] [CrossRef]

- Semyrka, R.; Semyrka, G.; Zych, I. Zmienność parametrów petrograficznych subfacji dolomitu głownego zachodniej strefy półwyspu grotowa w świetle badań porozymetrycznych, Zeszyty Naukowe AGH. Geologia 2008, 24, 445–468. [Google Scholar]

- Zapotoczna-Sytek, G.; Mamont-Cieśla, K.; Rybarczyk, T. Naturalna promieniotwórczość wyrobów budowlanych, w tym autoklawizowanego betonu komórkowego. Przegląd Budowlany 2012, 83, 39–42. [Google Scholar]

- Schober, G. Porosity in autoclave aerated concrete (AAC): A review on pore structure, types of porosity, measurement methods and effects of porosity on properties. In Proceedings of the 5th International Conference on Autoclaved Aerated Concrete, Bydgoszcz, Poland, 14–17 September 2011. [Google Scholar]

- Firkowicz-Pogorzelska, K. Metodyka określania wartości obliczeniowej współczynnika przewodzenia ciepła materiałów budowlanych. Prace Inst. Tech. Bud. 2011, 3, 33–53. [Google Scholar]

- International Organization for Standardization (ISO). ISO 8301:1991 Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus; ISO: Geneva, Switzerland, 1991. [Google Scholar]

| CaO + MgO [%] | MgO [%] | CO2 [%] | SO3 [%] | t60 [min] | tmax [min] | T60 [°C] |

| 94.72 | 0.97 | 1.47 | 0.18 | 00:59 | 7:20 | 74.80 |

| Lime Active [%] | Capability [dm3/10 kg] | Passed through a Sieve | ||||

| 2 mm [%] | 0.2 mm [%] | 0.09 mm [%] | ||||

| 91.22 | 28.00 | 100.00 | 99.72 | 96.68 | ||

| Sample | Apparent Density, ρ [kg/m3] | Effective Porosity, Pe [%] | Average Diameter, d50 [μm] | Share of Mesopores, [%] | Share of Macropores, [%] |

|---|---|---|---|---|---|

| WP | 1728 | 8.72 | 24 | 0 | 100 |

| 1P5 | 1575 | 35.49 | 20 | 22.9 | 77.1 |

| 1P10 | 1369 | 43.01 | 33 | 11.5 | 88.5 |

| 1P30 | 842 | 62.31 | 31 | 11.3 | 88.7 |

| Sample | Thermal Conductivity Coefficient, λ [W/(m·K)] | Average Value of the Thermal Conductivity Coefficient, λ [W/(m·K)] | Volume Density, ρ [kg/m3] |

|---|---|---|---|

| WP | 0.527 | 0.528 | 1679.1 |

| 0.529 | |||

| 1P5 | 0.502 | 0.505 | 1598.9 |

| 0.507 | |||

| 1P10 | 0.406 | 0.407 | 1451.3 |

| 0.407 | |||

| 1P20 | 0.272 | 0.274 | 1210.1 |

| 0.276 | |||

| 1P30 | 0.244 | 0.249 | 802.0 |

| 0.254 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jasińska, I.; Dachowski, R.; Jaworska-Wędzińska, M. Thermal Conductivity of Sand-Lime Products Modified with Foam Glass Granulate. Materials 2021, 14, 5678. https://doi.org/10.3390/ma14195678

Jasińska I, Dachowski R, Jaworska-Wędzińska M. Thermal Conductivity of Sand-Lime Products Modified with Foam Glass Granulate. Materials. 2021; 14(19):5678. https://doi.org/10.3390/ma14195678

Chicago/Turabian StyleJasińska, Iga, Ryszard Dachowski, and Monika Jaworska-Wędzińska. 2021. "Thermal Conductivity of Sand-Lime Products Modified with Foam Glass Granulate" Materials 14, no. 19: 5678. https://doi.org/10.3390/ma14195678

APA StyleJasińska, I., Dachowski, R., & Jaworska-Wędzińska, M. (2021). Thermal Conductivity of Sand-Lime Products Modified with Foam Glass Granulate. Materials, 14(19), 5678. https://doi.org/10.3390/ma14195678