Application of Advanced Machine Learning Approaches to Predict the Compressive Strength of Concrete Containing Supplementary Cementitious Materials

Abstract

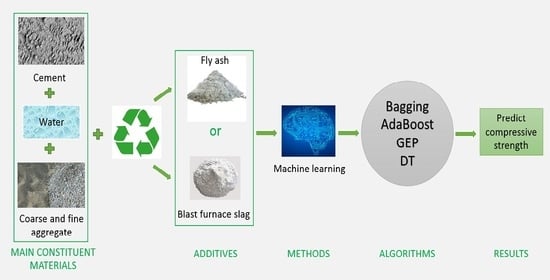

:1. Introduction

2. Research Methodology

2.1. Data Description

2.2. Techniques Employed

2.3. Description of Machine Learning Algorithms

3. Results and Analysis

3.1. Statistical Analysis

3.2. K-Fold Cross-Validation

3.3. Sensitivity Analysis

4. Discussions

5. Conclusions

- The bagging model was more effective at prediction than the other employed models, as evidenced by its better coefficient of determination (R2) and lower error values. The R2 for the bagging, AdaBoost, GEP, and DT models was noted to be 0.92, 0.82, 0.81, and 0.79, respectively. However, the results of all the models were in the acceptable range.

- Statistical analysis and the k-fold cross-validation method have also proven the satisfactory performance of the employed models. These checks also corroborated the bagging model’s superior performance over the other analyzed models.

- Sensitivity analysis of input parameters revealed that coarse aggregate, fine aggregate, and cement contributed 24.7%, 18.4%, and 16.2%, respectively, to the prediction of the results, while other input parameters contributed less.

- The SML techniques can forecast the strength properties of concrete with higher accuracy without requiring additional time for sample casting and testing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amran, M.; Fediuk, R.; Murali, G.; Avudaiappan, S.; Ozbakkaloglu, T.; Vatin, N.; Karelina, M.; Klyuev, S.; Gholampour, A. Fly ash-based eco-efficient concretes: A comprehensive review of the short-term properties. Materials 2021, 14, 4264. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Ji, T.; Gao, S.-J.; Yang, Z.; Wu, N. Characteristics and applications of sugar cane bagasse ash waste in cementitious materials. Materials 2018, 12, 39. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, S.S.; Qudoos, A.; Jakhrani, S.H.; Lee, J.B.; Kim, H.G. Influence of coarse aggregates and silica fume on the mechanical properties, durability, and microstructure of concrete. Materials 2019, 12, 3324. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chu, S.H.; Kwan, A.K.H. Mixture design of self-levelling ultra-high performance FRC. Constr. Build. Mater. 2019, 228, 116761. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Use of glass and nylon fibers in concrete for controlling early age micro cracking in bridge decks. Constr. Build. Mater. 2016, 125, 800–808. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Hybrid fiber concrete with different basalt fiber length and content. Struct. Concr. 2021. [Google Scholar] [CrossRef]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Al Yousef, R.; Al Abduljabbar, H.; Sufian, M. Effect of coconut fiber length and content on properties of high strength concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef] [Green Version]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef] [Green Version]

- Shi, T.; Li, Z.; Guo, J.; Gong, H.; Gu, C. Research progress on CNTs/CNFs-modified cement-based composites—A review. Constr. Build. Mater. 2019, 202, 290–307. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Effectiveness of hair and wave polypropylene fibers for concrete roads. Constr. Build. Mater. 2018, 166, 581–591. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Ali, M. Cracking behaviour and constitutive modelling of hybrid fibre reinforced concrete. J. Build. Eng. 2020, 30, 101272. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Effect of super plasticizer on the properties of medium strength concrete prepared with coconut fiber. Constr. Build. Mater. 2018, 182, 703–715. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Efficiency of basalt fiber length and content on mechanical and microstructural properties of hybrid fiber concrete. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 2135–2152. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Chaopeng, X.; Ali, M. Experimental and analytical study of hybrid fiber reinforced concrete prepared with basalt fiber under high temperature. Fire Mater. 2021. [Google Scholar] [CrossRef]

- Li, L.; Khan, M.; Bai, C.; Shi, K. Uniaxial tensile behavior, flexural properties, empirical calculation and microstructure of multi-scale fiber reinforced cement-based material at elevated temperature. Materials 2021, 14, 1827. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, W.; Ahmad, A.; Ostrowski, K.A.; Aslam, F.; Joyklad, P. A scientometric review of waste material utilization in concrete for sustainable construction. Case Stud. Constr. Mater. 2021, 15, e00683. [Google Scholar] [CrossRef]

- Ahmad, W.; Ahmad, A.; Ostrowski, K.A.; Aslam, F.; Joyklad, P.; Zajdel, P. Sustainable approach of using sugarcane bagasse ash in cement-based composites: A systematic review. Case Stud. Constr. Mater. 2021, 15, e00698. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Juenger, M.C.; Snellings, R.; Bernal, S.A. Supplementary cementitious materials: New sources, characterization, and performance insights. Cem. Concr. Res. 2019, 122, 257–273. [Google Scholar] [CrossRef]

- Li, K.; Qin, M.; Gui, Q. Durability properties of structural concretes containing secondary cementitious materials. Green Mater. 2019, 7, 40–51. [Google Scholar] [CrossRef]

- Tosti, L.; van Zomeren, A.; Pels, J.R.; Damgaard, A.; Comans, R.N. Life cycle assessment of the reuse of fly ash from biomass combustion as secondary cementitious material in cement products. J. Clean. Prod. 2020, 245, 118937. [Google Scholar] [CrossRef]

- Diaz-Loya, I.; Juenger, M.; Seraj, S.; Minkara, R. Extending supplementary cementitious material resources: Reclaimed and remediated fly ash and natural pozzolans. Cem. Concr. Compos. 2019, 101, 44–51. [Google Scholar] [CrossRef]

- De Matos, P.R.; Oliveira, J.C.P.; Medina, T.M.; Magalhães, D.C.; Gleize, P.J.P.; Schankoski, R.A.; Pilar, R. Use of air-cooled blast furnace slag as supplementary cementitious material for self-compacting concrete production. Constr. Build. Mater. 2020, 262, 120102. [Google Scholar] [CrossRef]

- Shubbar, A.A.; Jafer, H.; Dulaimi, A.; Hashim, K.; Atherton, W.; Sadique, M. The development of a low carbon binder produced from the ternary blending of cement, ground granulated blast furnace slag and high calcium fly ash: An experimental and statistical approach. Constr. Build. Mater. 2018, 187, 1051–1060. [Google Scholar] [CrossRef]

- Dananjayan, R.R.T.; Kandasamy, P.; Andimuthu, R. Direct mineral carbonation of coal fly ash for CO2 sequestration. J. Clean. Prod. 2016, 112, 4173–4182. [Google Scholar] [CrossRef]

- Ukwattage, N.; Ranjith, P.; Yellishetty, M.; Bui, H.H.; Xu, T. A laboratory-scale study of the aqueous mineral carbonation of coal fly ash for CO2 sequestration. J. Clean. Prod. 2015, 103, 665–674. [Google Scholar] [CrossRef]

- Şahmaran, M.; Li, V.C. Durability properties of micro-cracked ECC containing high volumes fly ash. Cem. Concr. Res. 2009, 39, 1033–1043. [Google Scholar] [CrossRef]

- Lee, K.M.; Lee, H.K.; Lee, S.H.; Kim, G.Y. Autogenous shrinkage of concrete containing granulated blast-furnace slag. Cem. Concr. Res. 2006, 36, 1279–1285. [Google Scholar] [CrossRef]

- Ahmad, A.; Farooq, F.; Niewiadomski, P.; Ostrowski, K.; Akbar, A.; Aslam, F.; Alyousef, R. Prediction of compressive strength of fly ash based concrete using individual and ensemble algorithm. Materials 2021, 14, 794. [Google Scholar] [CrossRef]

- Su, M.; Zhong, Q.; Peng, H.; Li, S. Selected machine learning approaches for predicting the interfacial bond strength between FRPs and concrete. Constr. Build. Mater. 2021, 270, 121456. [Google Scholar] [CrossRef]

- Nguyen, K.; Nguyen, Q.D.; Le, T.A.; Shin, J.; Lee, K. Analyzing the compressive strength of green fly ash based geopolymer concrete using experiment and machine learning approaches. Constr. Build. Mater. 2020, 247, 118581. [Google Scholar] [CrossRef]

- Ahmad, A.; Farooq, F.; Ostrowski, K.; Śliwa-Wieczorek, K.; Czarnecki, S. Application of novel machine learning techniques for predicting the surface chloride concentration in concrete containing waste material. Materials 2021, 14, 2297. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, A.; Chaiyasarn, K.; Farooq, F.; Ahmad, W.; Suparp, S.; Aslam, F. Compressive strength prediction via gene expression programming (GEP) and artificial neural network (ANN) for concrete containing RCA. Buildings 2021, 11, 324. [Google Scholar] [CrossRef]

- Sufian, M.; Ullah, S.; Ostrowski, K.; Ahmad, A.; Zia, A.; Śliwa-Wieczorek, K.; Siddiq, M.; Awan, A. An experimental and empirical study on the use of waste marble powder in construction material. Materials 2021, 14, 3829. [Google Scholar] [CrossRef] [PubMed]

- Machine Learning Repository, Center for Machine Learning and Intelligent Systems. Available online: https://archive.ics.uci.edu/ml/datasets/concrete+compressive+strength (accessed on 3 August 2007).

- Yeh, I.-C. Modeling of strength of high-performance concrete using artificial neural networks. Cem. Concr. Res. 1998, 28, 1797–1808. [Google Scholar] [CrossRef]

- Yeh, I.-C. Analysis of strength of concrete using design of experiments and neural networks. J. Mater. Civ. Eng. 2006, 18, 597–604. [Google Scholar] [CrossRef]

- Yeh, I.C. Prediction of strength of fly ash and slag concrete by the use of artificial neural networks. J. Chin. Inst. Civil Hydraul. Eng. 2003, 15, 659–663. [Google Scholar]

- Gandomi, A.H.; Roke, D.A. Assessment of artificial neural network and genetic programming as predictive tools. Adv. Eng. Softw. 2015, 88, 63–72. [Google Scholar] [CrossRef]

- Ribeiro, M.H.D.M.; dos Santos Coelho, L. Ensemble approach based on bagging, boosting and stacking for short-term prediction in agribusiness time series. Appl. Soft Comput. 2020, 86, 105837. [Google Scholar] [CrossRef]

- Dou, J.; Yunus, A.P.; Bui, D.T.; Merghadi, A.; Sahana, M.; Zhu, Z.; Chen, C.-W.; Han, Z.; Pham, B.T. Improved landslide assessment using support vector machine with bagging, boosting, and stacking ensemble machine learning framework in a mountainous watershed, Japan. Landslides 2020, 17, 641–658. [Google Scholar] [CrossRef]

- Freund, Y.; Schapire, R.E.; Abe, N. A short introduction to boosting. J. Jpn. Soc. Artif. Intell. 1999, 14, 1612. [Google Scholar]

- Ying, C.; Qi-Guang, M.; Jia-Chen, L.; Lin, G. Advance and prospects of AdaBoost algorithm. Acta Autom. Sin. 2013, 39, 745–758. [Google Scholar]

- Farooq, F.; Ahmed, W.; Akbar, A.; Aslam, F.; Alyousef, R. Predictive modeling for sustainable high-performance concrete from industrial wastes: A comparison and optimization of models using ensemble learners. J. Clean. Prod. 2021, 292, 126032. [Google Scholar] [CrossRef]

- Aslam, F.; Farooq, F.; Amin, M.N.; Khan, K.; Waheed, A.; Akbar, A.; Javed, M.F.; Alyousef, R.; Alabdulijabbar, H. Applications of gene expression programming for estimating compressive strength of high-strength concrete. Adv. Civ. Eng. 2020, 2020, 1–23. [Google Scholar] [CrossRef]

- Ahmad, A.; Ostrowski, K.; Maślak, M.; Farooq, F.; Mehmood, I.; Nafees, A. Comparative study of supervised machine learning algorithms for predicting the compressive strength of concrete at high temperature. Materials 2021, 14, 4222. [Google Scholar] [CrossRef]

| Parameter | Input Variable | |||||||

|---|---|---|---|---|---|---|---|---|

| Cement [kg/m3] | Blast Furnace Slag [kg/m3] | Fly Ash [kg/m3] | Water [kg/m3] | Superplasticizer [kg/m3] | Coarse Aggregate [kg/m3] | Fine Aggregate [kg/m3] | Age [days] | |

| Mean | 281.17 | 73.90 | 54.19 | 181.57 | 6.20 | 972.92 | 773.58 | 45.66 |

| Standard Error | 3.26 | 2.69 | 1.99 | 0.67 | 0.19 | 2.42 | 2.50 | 1.97 |

| Median | 272.90 | 22.00 | 0.00 | 185.00 | 6.35 | 968.00 | 779.51 | 28.00 |

| Mode | 425.00 | 0.00 | 0.00 | 192.00 | 0.00 | 932.00 | 594.00 | 28.00 |

| Standard Deviation | 104.51 | 86.28 | 64.00 | 21.36 | 5.97 | 77.75 | 80.18 | 63.17 |

| Range | 438.00 | 359.40 | 200.10 | 125.25 | 32.20 | 344.00 | 398.60 | 364.00 |

| Minimum | 102.00 | 0.00 | 0.00 | 121.75 | 0.00 | 801.00 | 594.00 | 1.00 |

| Maximum | 540.00 | 359.40 | 200.10 | 247.00 | 32.20 | 1145.00 | 992.60 | 365.00 |

| Machine Learning Technique | MAE (MPa) | MSE (MPa) | RMSE (MPa) |

|---|---|---|---|

| Bagging | 3.257 | 20.566 | 4.535 |

| AdaBoost | 5.126 | 47.376 | 6.883 |

| Gene expression programming | 5.24 | 50.69 | 7.12 |

| Decision tree | 5.88 | 57.30 | 7.57 |

| K-Fold | Bagging | AdaBoost | GEP | DT | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MAE | MSE | RMSE | R2 | MAE | MSE | RMSE | R2 | MAE | MSE | RMSE | R2 | MAE | MSE | RMSE | R2 | |

| 1 | 6.32 | 93.27 | 9.66 | 0.78 | 11.37 | 352.19 | 18.77 | 0.79 | 8.82 | 144.16 | 12.01 | 0.64 | 7.19 | 104.48 | 10.22 | 0.79 |

| 2 | 3.8 | 23.84 | 4.88 | 0.89 | 6.98 | 88.87 | 9.43 | 0.66 | 4.96 | 44.64 | 6.68 | 0.81 | 7.06 | 89.92 | 9.48 | 0.88 |

| 3 | 4.02 | 57.12 | 7.56 | 0.75 | 7.14 | 87.44 | 9.35 | 0.82 | 6.97 | 78.53 | 8.86 | 0.69 | 5.21 | 50.22 | 7.09 | 0.64 |

| 4 | 6.21 | 59.64 | 7.72 | 0.68 | 8.52 | 120.48 | 10.98 | 0.55 | 7.82 | 107.62 | 10.37 | 0.97 | 7.79 | 108.75 | 10.43 | 0.98 |

| 5 | 6.44 | 53.77 | 7.33 | 0.76 | 5.78 | 69.19 | 8.32 | 0.47 | 6.78 | 68.60 | 8.28 | 0.94 | 6.00 | 70.30 | 8.38 | 0.91 |

| 6 | 5.25 | 80.87 | 8.99 | 0.78 | 10.45 | 305.18 | 17.47 | 0.83 | 8.11 | 91.29 | 9.55 | 0.88 | 8.39 | 130.51 | 11.42 | 0.71 |

| 7 | 4.27 | 26.34 | 5.13 | 0.92 | 6.6 | 55.82 | 7.47 | 0.86 | 5.18 | 44.09 | 6.64 | 0.72 | 5.38 | 53.56 | 7.32 | 0.84 |

| 8 | 4.72 | 54.81 | 7.4 | 0.58 | 6.68 | 83.73 | 9.15 | 0.4 | 8.55 | 129.71 | 11.39 | 0.76 | 7.91 | 100.65 | 10.03 | 0.93 |

| 9 | 5.68 | 55 | 7.42 | 0.73 | 7.33 | 92.23 | 9.6 | 0.68 | 9.25 | 154.31 | 12.42 | 0.95 | 5.26 | 48.27 | 6.95 | 0.66 |

| 10 | 4.57 | 47.7 | 6.91 | 0.83 | 5.89 | 56.63 | 7.53 | 0.74 | 6.82 | 79.24 | 8.90 | 0.93 | 5.25 | 58.76 | 7.67 | 0.75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, W.; Ahmad, A.; Ostrowski, K.A.; Aslam, F.; Joyklad, P.; Zajdel, P. Application of Advanced Machine Learning Approaches to Predict the Compressive Strength of Concrete Containing Supplementary Cementitious Materials. Materials 2021, 14, 5762. https://doi.org/10.3390/ma14195762

Ahmad W, Ahmad A, Ostrowski KA, Aslam F, Joyklad P, Zajdel P. Application of Advanced Machine Learning Approaches to Predict the Compressive Strength of Concrete Containing Supplementary Cementitious Materials. Materials. 2021; 14(19):5762. https://doi.org/10.3390/ma14195762

Chicago/Turabian StyleAhmad, Waqas, Ayaz Ahmad, Krzysztof Adam Ostrowski, Fahid Aslam, Panuwat Joyklad, and Paulina Zajdel. 2021. "Application of Advanced Machine Learning Approaches to Predict the Compressive Strength of Concrete Containing Supplementary Cementitious Materials" Materials 14, no. 19: 5762. https://doi.org/10.3390/ma14195762

APA StyleAhmad, W., Ahmad, A., Ostrowski, K. A., Aslam, F., Joyklad, P., & Zajdel, P. (2021). Application of Advanced Machine Learning Approaches to Predict the Compressive Strength of Concrete Containing Supplementary Cementitious Materials. Materials, 14(19), 5762. https://doi.org/10.3390/ma14195762