Effect of Early Curing Temperature on the Tunnel Fire Resistance of Self-Compacting Concrete Coated with Aerogel Cement Paste

Abstract

:1. Introduction

2. Experimental

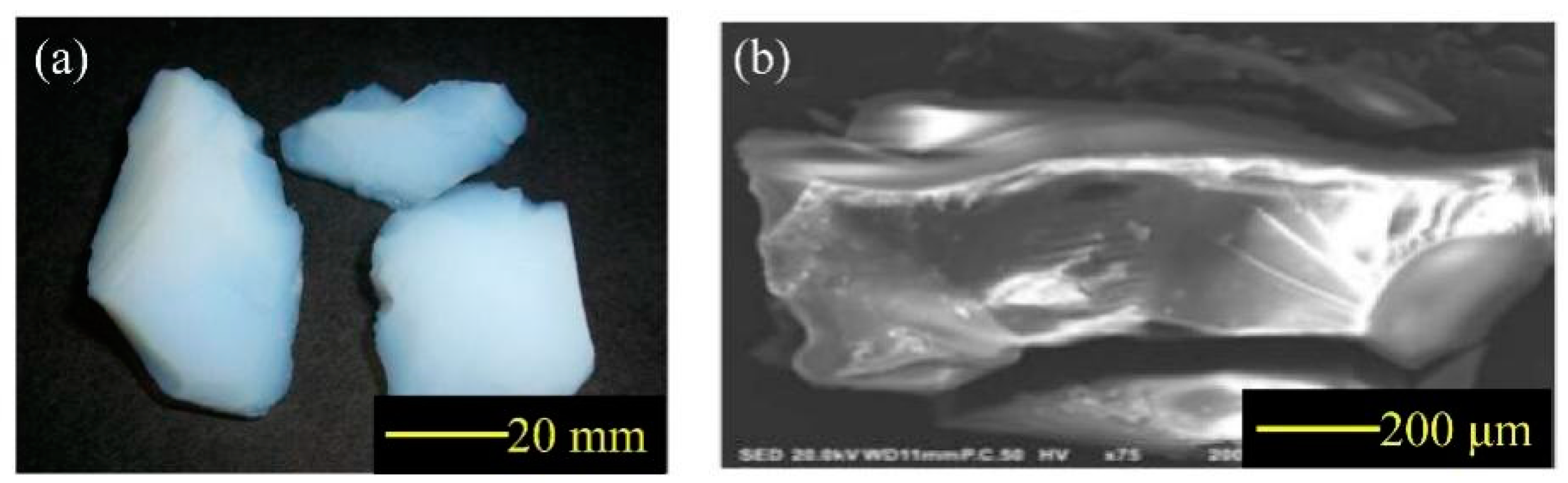

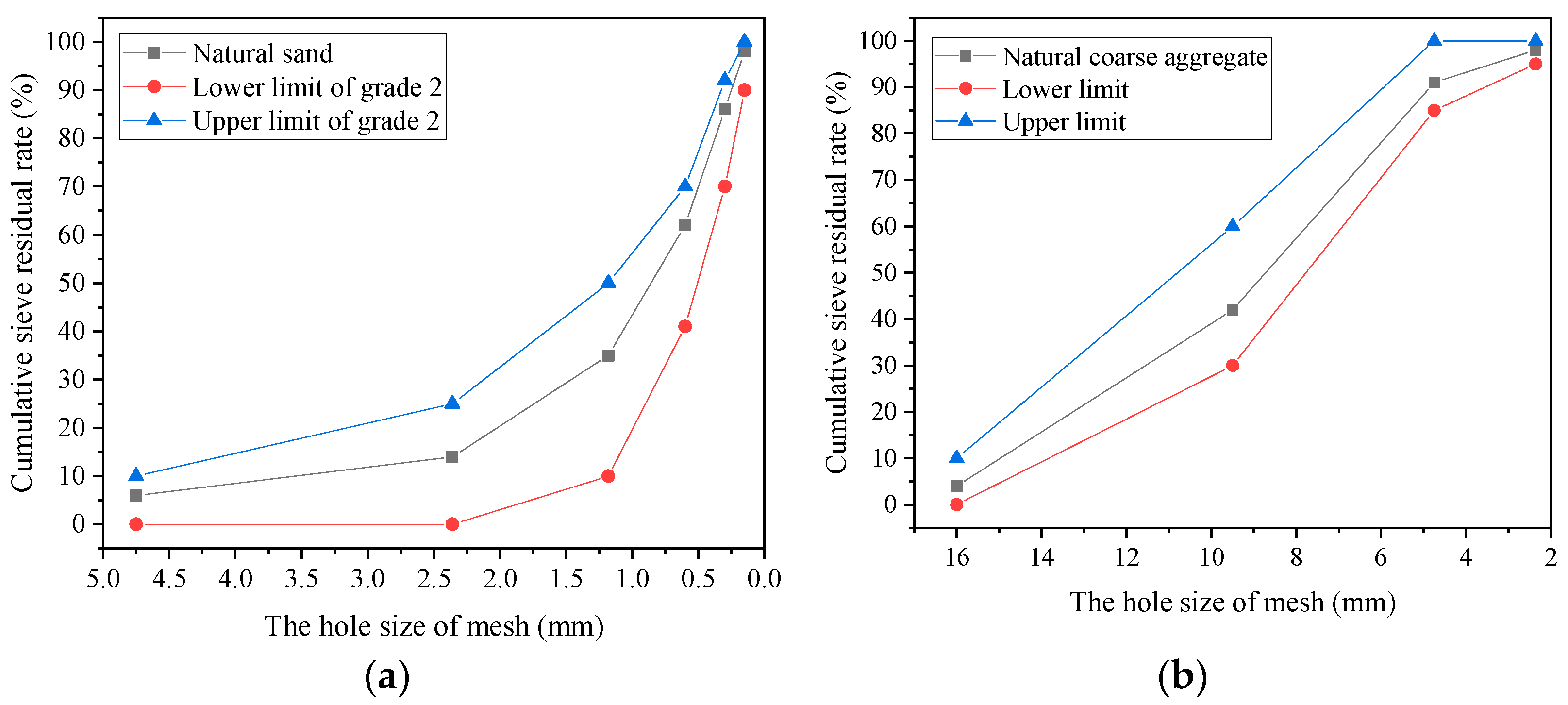

2.1. Materials

2.2. Preparation of ACP and SCC

2.3. Measurements

2.3.1. Physical and Mechanical Properties of ACP

2.3.2. Simulated Tunnel Fire

2.3.3. SEM

3. Results and Discussion

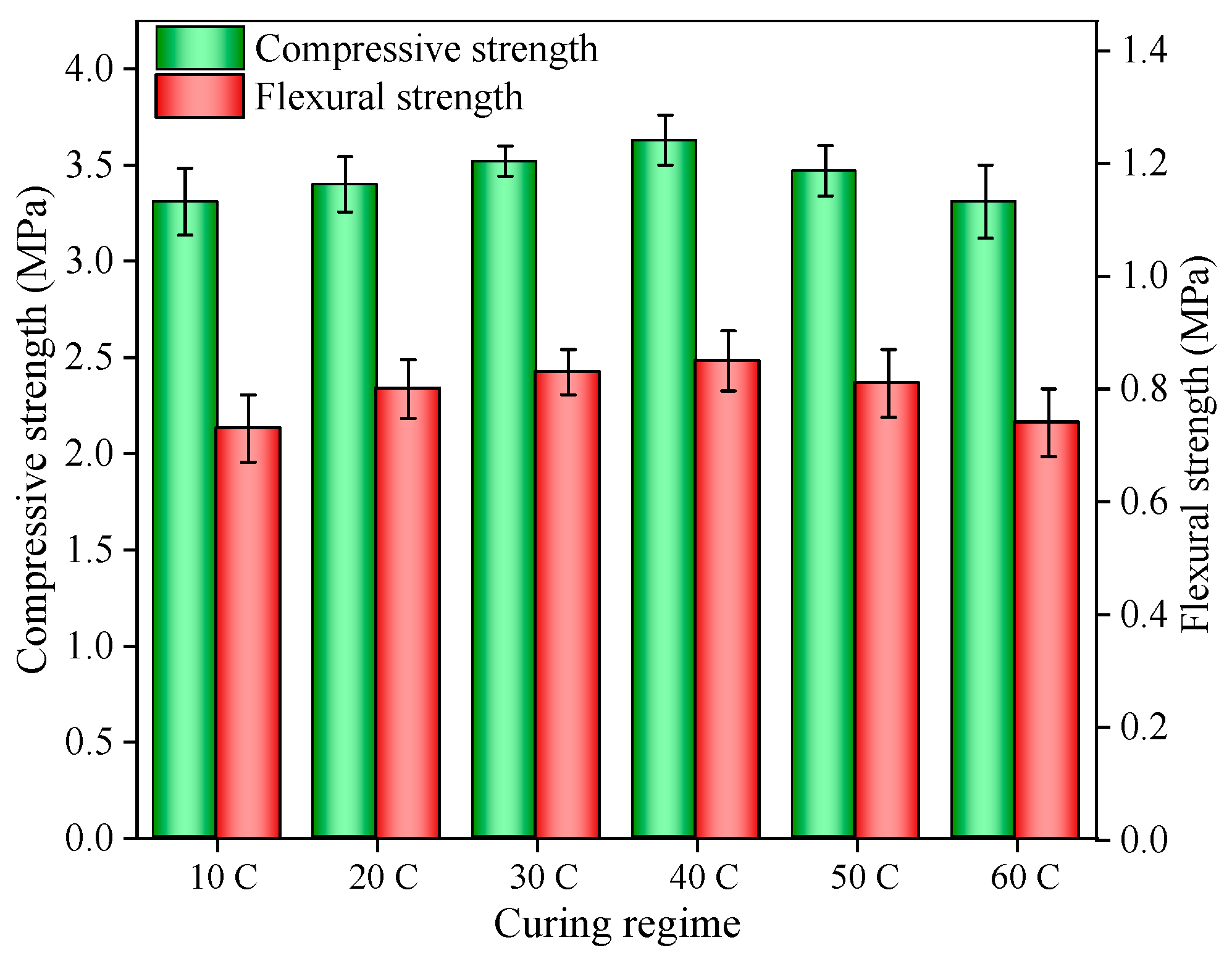

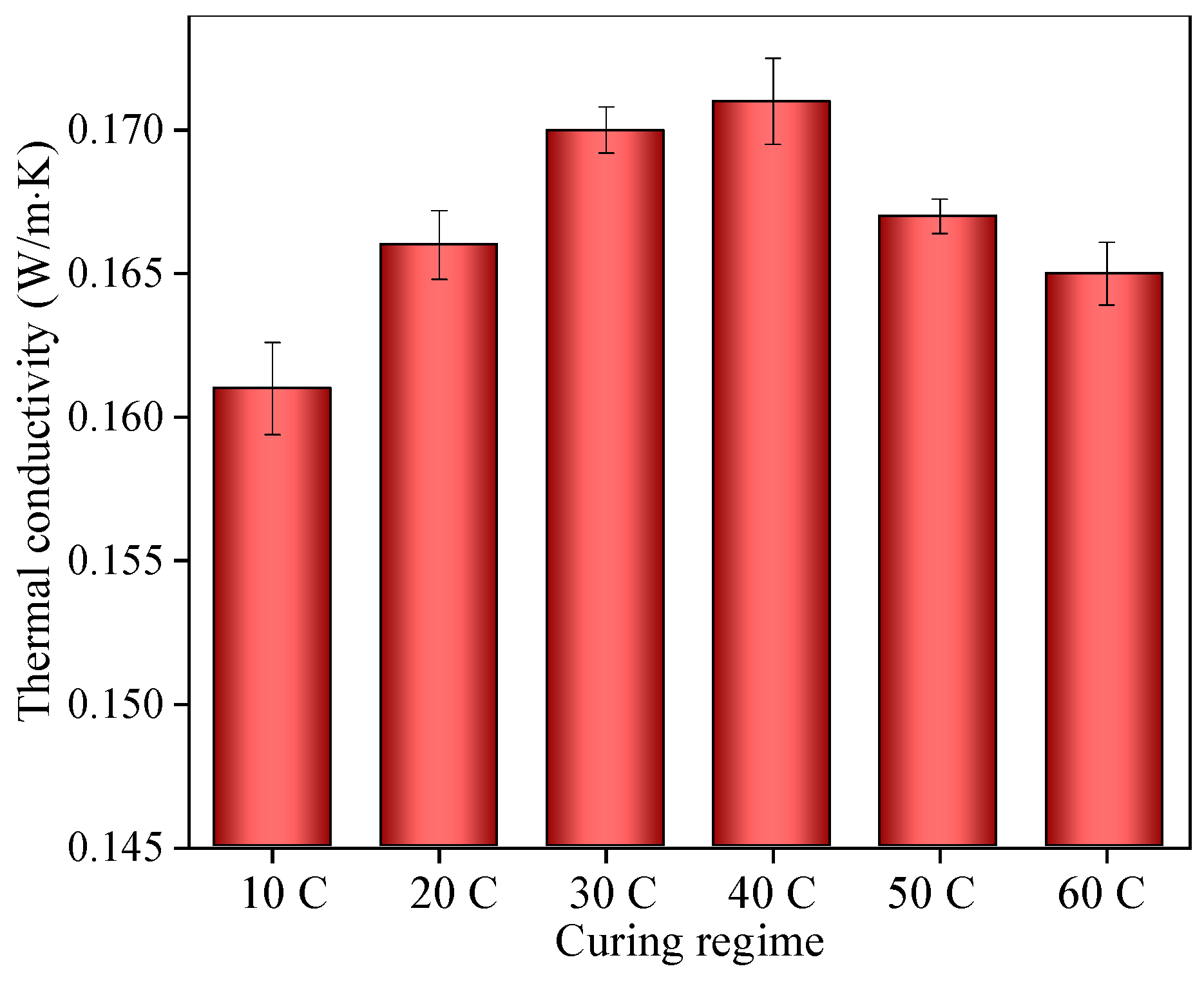

3.1. Physical Properties of ACP

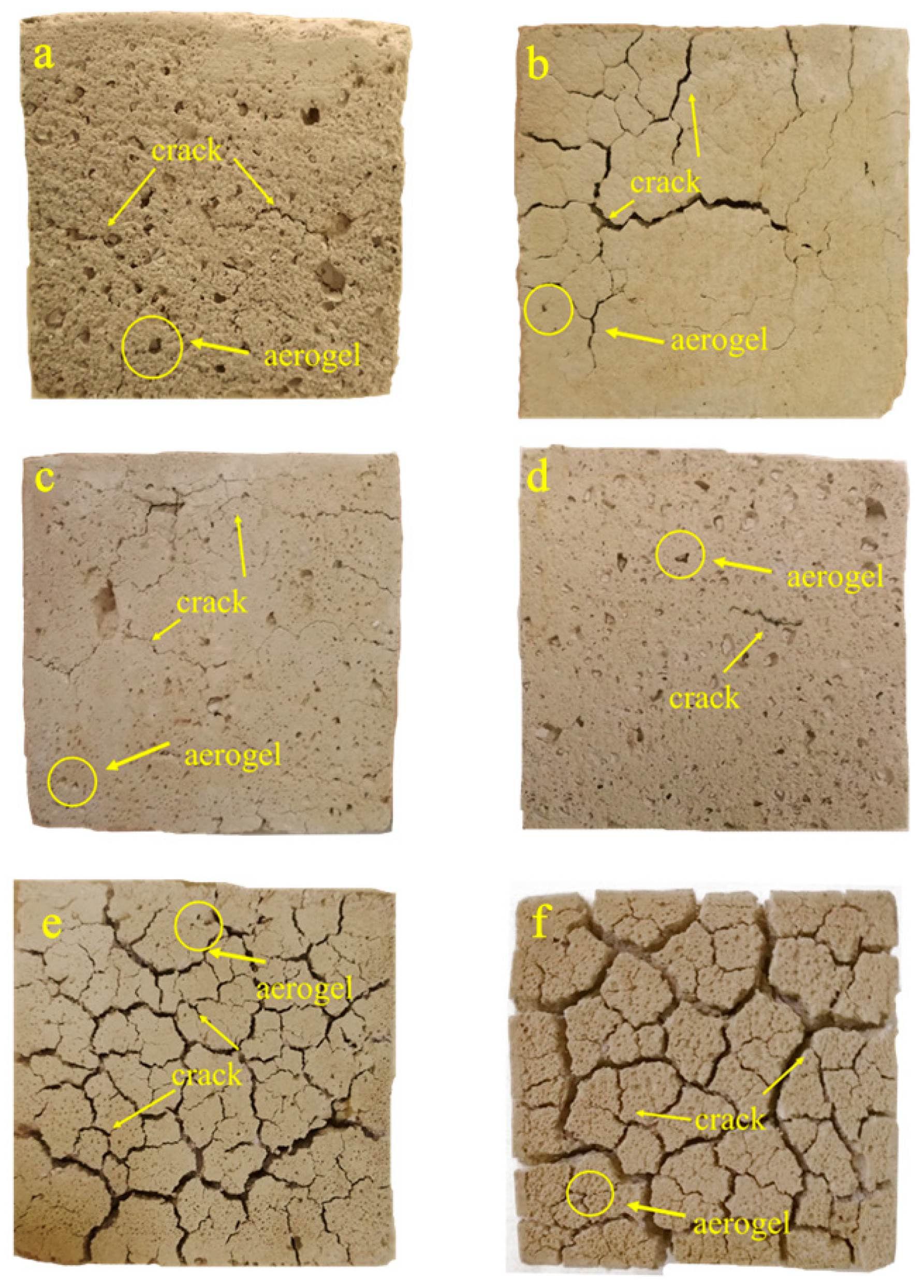

3.2. Macroscopic Morphology of ACP

3.3. Mass Loss of ACP

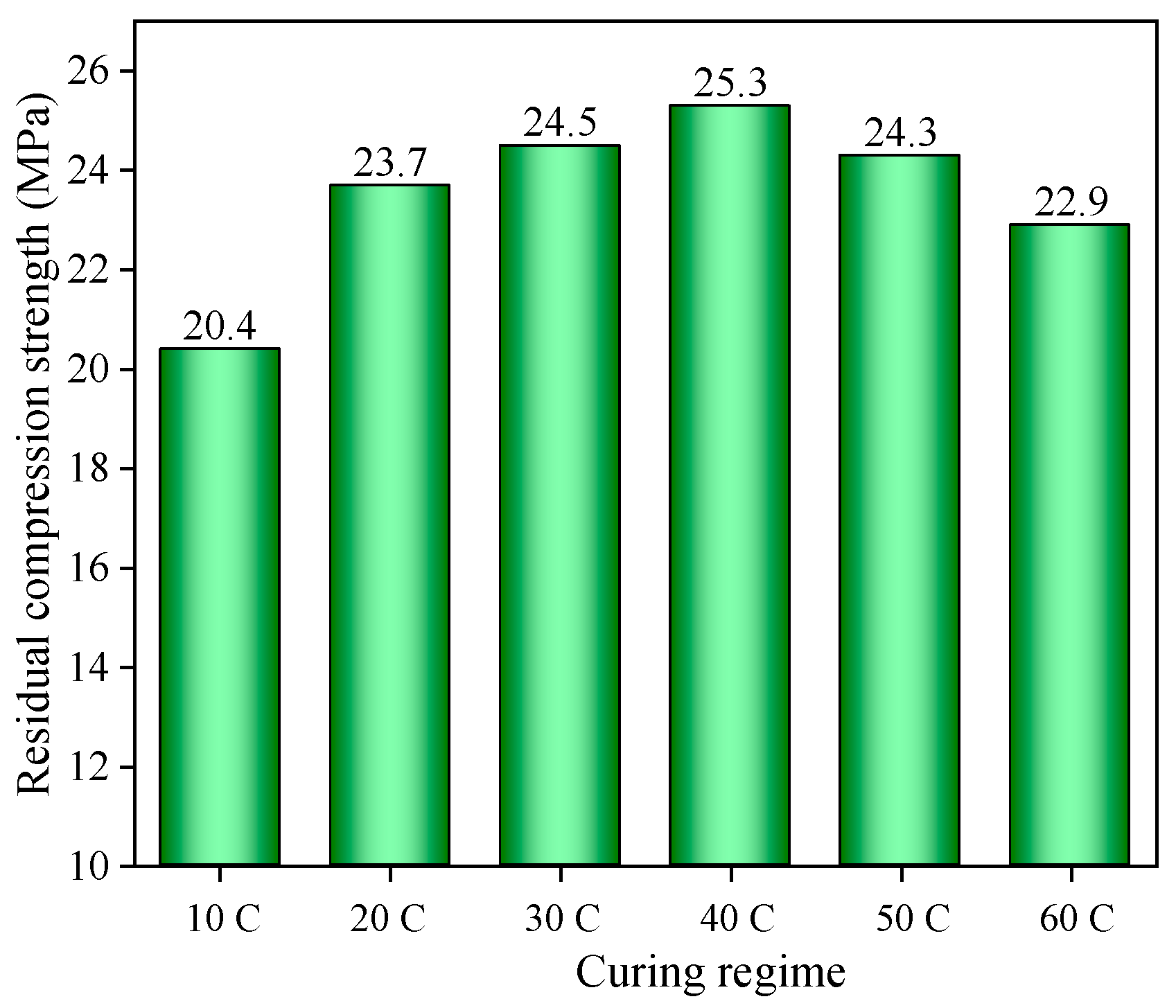

3.4. The Residual Compressive Strength of SCC Coated with APC

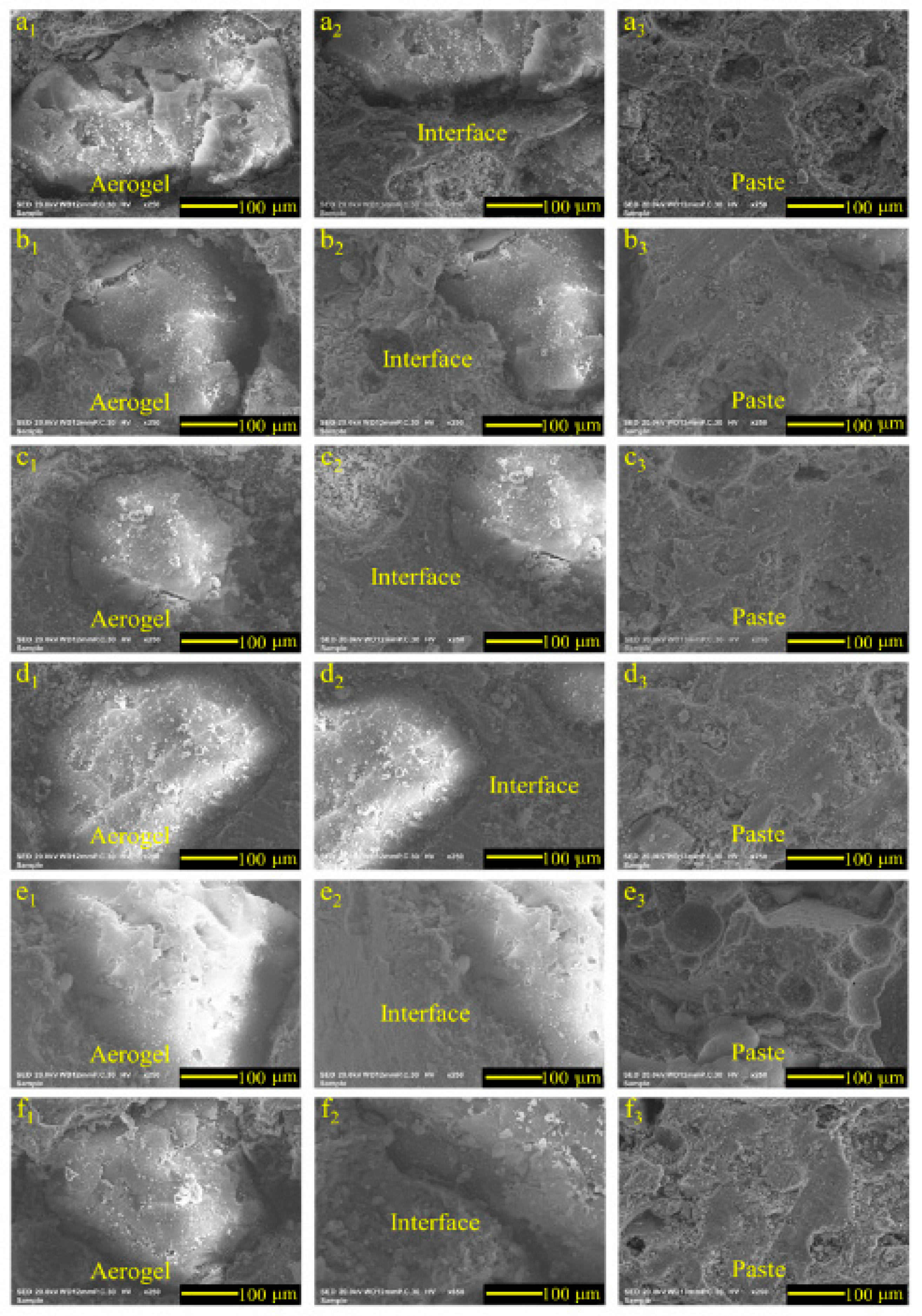

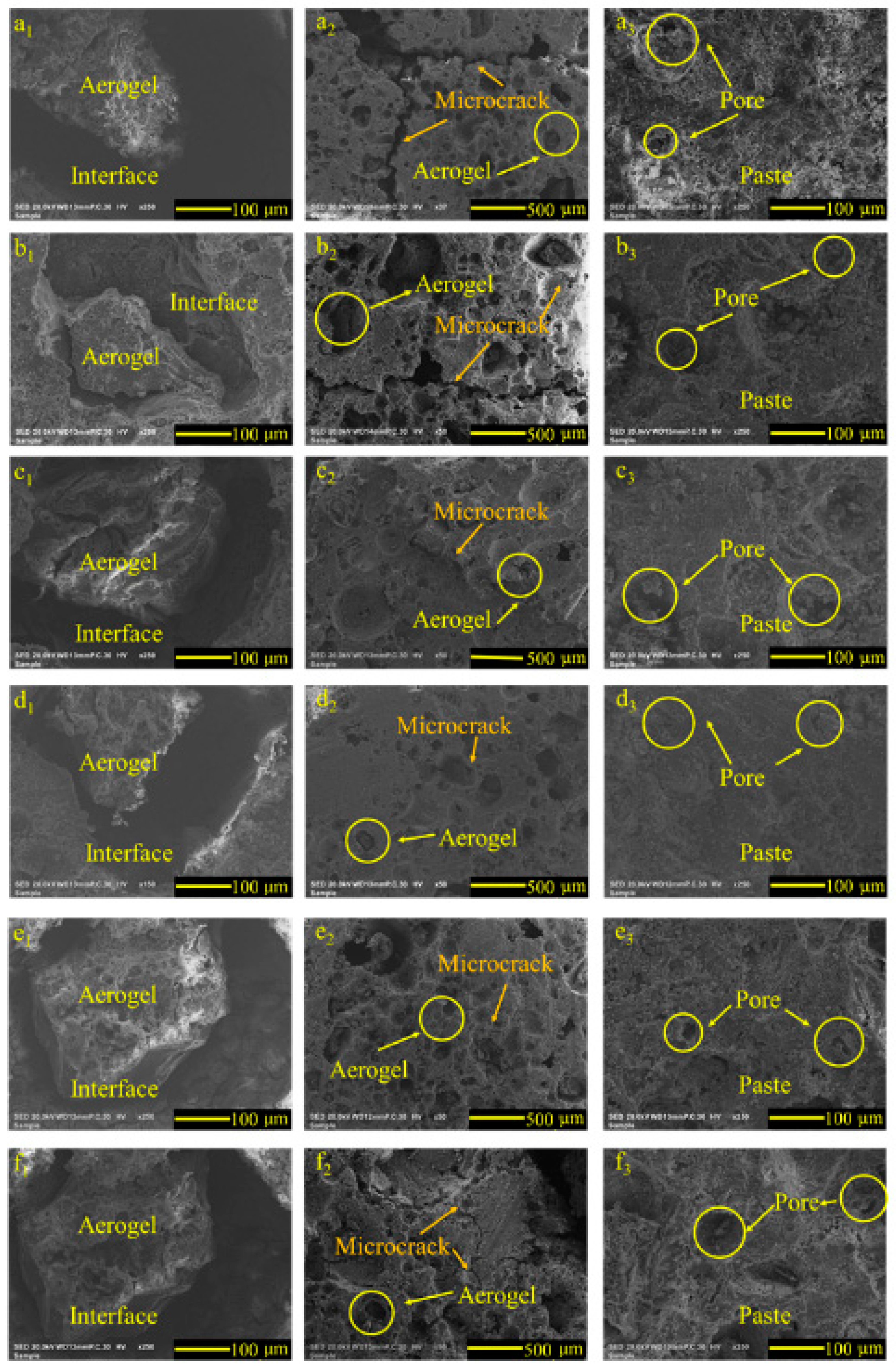

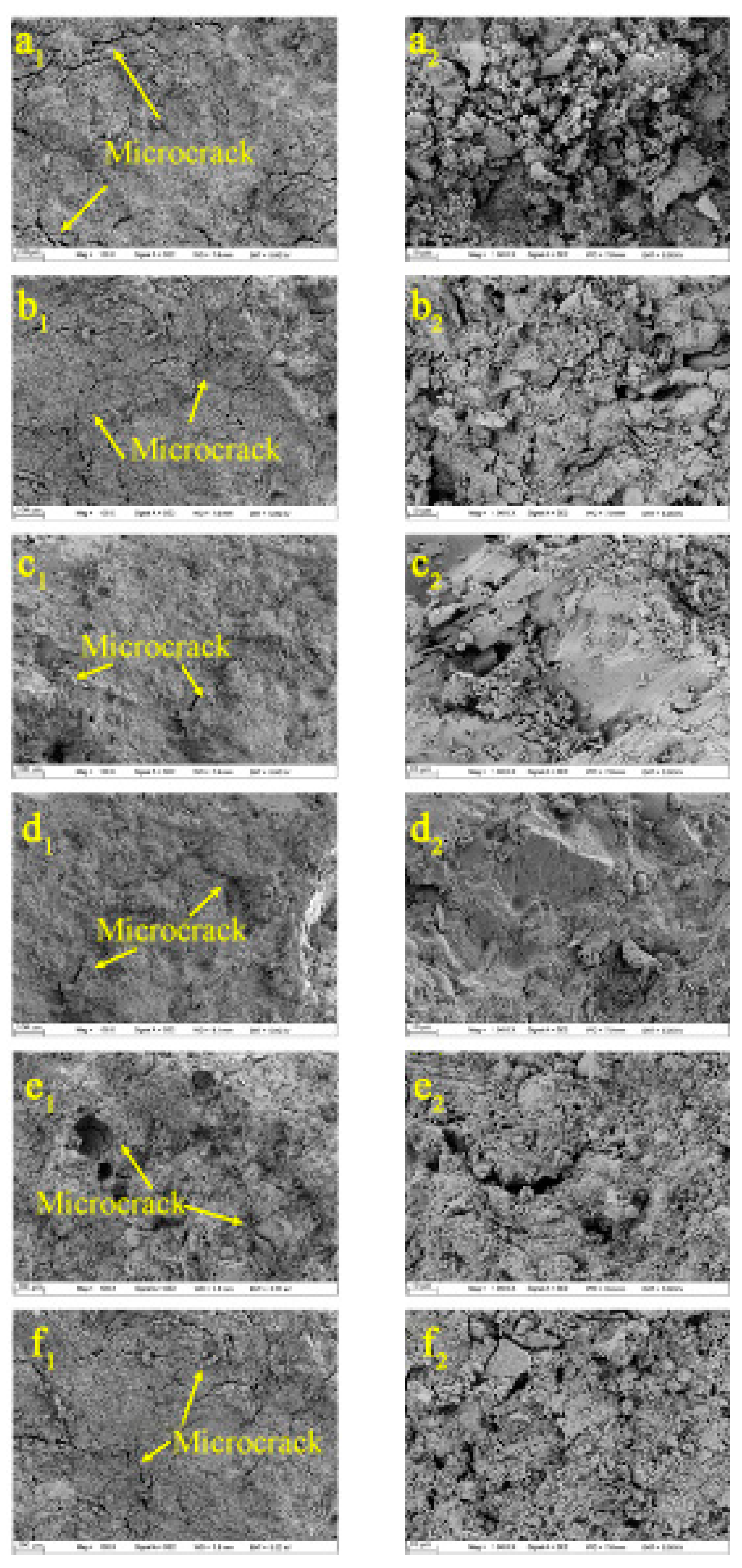

3.5. SEM Analysis of ACP before and after Tunnel Fire

3.6. SEM Analysis of SCC Coated with ACP after Tunnel Fire

4. Conclusions

- (1)

- The compressive strength and flexural strength of ACP increased at first and then decreased later with the increase of early curing temperature. The highest compressive strength and flexural strength of ACP occurred in the specimen under 40 °C early curing.

- (2)

- For the ACP specimen, the aerogels on the surface shrank greatly and cracks generated after the tunnel fire, although no large area of spalling occurred. The ACP under 40 °C early curing exhibited the minimum number of cracks and mass loss after the tunnel fire.

- (3)

- The residual compressive strength of SCC coated with 10 mm ACP after the tunnel fire was only 50–60% of the initial compressive strength. The residual compressive strength of SCC increased at first as the early curing temperature of the ACP increased up to 40 °C and then decreased when the temperature of the ACP increased from 40 °C to 60 °C.

- (4)

- Too high or too low early curing temperature reduced the thermal conductivity of ACP but accelerated the formation and expansion of microcracks during the tunnel fire.

- (5)

- With respect to the thermal conductivity and microstructure, ACP under 40 °C early curing had the best tunnel fire resistance and heat insulation performance. In addition, the SCC coated with ACP under 40 °C early curing showed the best tunnel fire resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Dai, Q.; Si, R.; Ma, Y.; Guo, S. Fresh and mechanical performance and freeze-thaw durability of steel fiber-reinforced rubber self-compacting concrete (SRSCC). J. Clean. Prod. 2020, 277, 123180. [Google Scholar] [CrossRef]

- Ramezanianpour, A.; Esmaeili, K.; Ghahari, S.A. Influence of initial steam curing and different types of mineral additives on mechanical and durability properties of self-compacting concrete. Constr. Build. Mater. 2014, 73, 187–194. [Google Scholar] [CrossRef]

- Broere, W. Urban underground space: Solving the problems of today’s cities. Tunn. Undergr. Space Technol. 2016, 55, 245–248. [Google Scholar] [CrossRef] [Green Version]

- Su, N.; Hsu, K.-C.; Chai, H.-W. A simple mix design method for self-compacting concrete. Cem. Concr. Res. 2001, 31, 1799–1807. [Google Scholar] [CrossRef]

- Filho, F.A.; Barragán, B.; Casas, J.; El Debs, A. Hardened properties of self-compacting concrete—A statistical approach. Constr. Build. Mater. 2010, 24, 1608–1615. [Google Scholar] [CrossRef] [Green Version]

- Pintado, X.; Barragán, B.E. Homogeneity of self-compacting concretes used in tunnel strengthening—A case study. Tunn. Undergr. Space Technol. 2009, 24, 647–653. [Google Scholar] [CrossRef]

- Domone, P.L. A review of the hardened mechanical properties of self-compacting concrete. Cem. Concr. Compos. 2007, 29, 1–12. [Google Scholar] [CrossRef]

- Huang, Y.; Li, Y.; Dong, B.; Li, J.; Liang, Q. Numerical investigation on the maximum ceiling temperature and longitudinal decay in a sealing tunnel fire. Tunn. Undergr. Space Technol. 2018, 72, 120–130. [Google Scholar] [CrossRef]

- Du, S.; Zhang, Y.; Sun, Q.; Gong, W.; Geng, J.; Zhang, K. Experimental study on color change and compression strength of concrete tunnel lining in a fire. Tunn. Undergr. Space Technol. 2018, 71, 106–114. [Google Scholar] [CrossRef]

- Tao, J.; Yuan, Y.; Taerwe, L. Compressive strength of self-compacting concrete during high-temperature exposure. J. Mater. Civ. Eng. 2010, 22, 1005–1011. [Google Scholar] [CrossRef]

- Niknezhad, D.; Bonnet, S.; Leklou, N.; Amiri, O. Effect of thermal damage on mechanical behavior and transport properties of self-compacting concrete incorporating polypropylene fibers. J. Adhes. Sci. Technol. 2019, 33, 2535–2566. [Google Scholar] [CrossRef]

- Kim, J.-H.J.; Lim, Y.M.; Won, J.P.; Park, H.G. Fire resistant behavior of newly developed bottom-ash-based cementitious coating applied concrete tunnel lining under RABT fire loading. Constr. Build. Mater. 2010, 24, 1984–1994. [Google Scholar] [CrossRef]

- Ji, G.; Li, G.; Alaywan, W. A new fire resistant FRP for externally bonded concrete repair. Constr. Build. Mater. 2013, 42, 87–96. [Google Scholar] [CrossRef]

- An, L.; Wang, J.; Petit, D.; Armstrong, J.N.; Li, C.; Hu, Y.; Huang, Y.; Shao, Z.; Ren, S. A scalable crosslinked fiberglass-aerogel thermal insulation composite. Appl. Mater. Today 2020, 21, 100843. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Wood, C.J.; Riffat, S.B. Toward aerogel based thermal superinsulation in buildings: A comprehensive review. Renew. Sustain. Energy Rev. 2014, 34, 273–299. [Google Scholar] [CrossRef]

- Shafi, S.; Navik, R.; Ding, X.; Zhao, Y. Improved heat insulation and mechanical properties of silica aerogel/glass fiber composite by impregnating silica gel. J. Non-Crystalline Solids 2018, 503–504, 78–83. [Google Scholar] [CrossRef]

- Kim, S.; Seo, J.; Cha, J.; Kim, S. Chemical retreating for gel-typed aerogel and insulation performance of cement containing aerogel. Constr. Build. Mater. 2013, 40, 501–505. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, P.; Li, X. Design approach for improving fire-resistance performance of tunnel lining based on SiO2 aerogel coating. J. Perform. Constr. Facil. 2020, 34, 04020031. [Google Scholar] [CrossRef]

- Zhu, P.; Brunner, S.; Zhao, S.; Griffa, M.; Leemann, A.; Toropovs, N.; Malekos, A.; Koebel, M.M.; Lura, P. Study of physical properties and microstructure of aerogel-cement mortars for improving the fire safety of high-performance concrete linings in tunnels. Cem. Concr. Compos. 2019, 104, 103414. [Google Scholar] [CrossRef]

- Tam, C.M.; Tam, V.W.-Y. Microstructural behaviour of reactive powder concrete under different heating regimes. Mag. Concr. Res. 2012, 64, 259–267. [Google Scholar] [CrossRef]

- Ng, S.; Jelle, B.P.; Zhen, Y.P.; Wallevik, O.H. Effect of storage and curing conditions at elevated temperatures on aerogel-incorporated mortar samples based on UHPC recipe. Constr. Build. Mater. 2016, 106, 640–649. [Google Scholar] [CrossRef]

- Wang, X.; Xu, D.; Zhu, P.; Chen, C.; Qian, Z. Effect of curing temperature on tunnel fire insulation of aerogel cement paste coatings. J. Wuhan Univ. Technol. Sci. Ed. 2021, 36, 93–102. [Google Scholar] [CrossRef]

- Robalo, K.; Soldado, E.; Costa, H.; do Carmo, R.; Alves, H.; Julio, E. Efficiency of cement content and of compactness on mechanical performance of low cement concrete designed with packing optimization. Constr. Build. Mater. 2021, 266, 121077. [Google Scholar] [CrossRef]

- Ruuska, T.; Vinha, J.; Kivioja, H. Measuring thermal conductivity and specific heat capacity values of inhomogeneous materials with a heat flow meter apparatus. J. Build. Eng. 2017, 9, 135–141. [Google Scholar] [CrossRef]

- Pichler, C.; Schmid, M.; Traxl, R.; Lackner, R. Influence of curing temperature dependent microstructure on early-age concrete strength development. Cem. Concr. Res. 2017, 102, 48–59. [Google Scholar] [CrossRef]

- Zhao, Q.; Liu, X.; Jiang, J. Effect of curing temperature on creep behavior of fly ash concrete. Constr. Build. Mater. 2015, 96, 326–333. [Google Scholar] [CrossRef]

- Shen, D.; Jiao, Y.; Kang, J.; Feng, Z.; Shen, Y. Influence of ground granulated blast furnace slag on early-age cracking potential of internally cured high performance concrete. Constr. Build. Mater. 2019, 233, 117083. [Google Scholar] [CrossRef]

- Ng, S.; Jelle, B.P.; Sandberg, L.I.C.; Gao, T.; Wallevik, O.H. Experimental investigations of aerogel-incorporated ultra-high performance concrete. Constr. Build. Mater. 2015, 77, 307–316. [Google Scholar] [CrossRef]

- Li, H.; Ni, D.; Liang, G.; Guo, Y.; Dong, B. Mechanical performance and microstructure of cement paste/mortar modified by VAEC dispersible powder cured under different temperatures. Constr. Build. Mater. 2021, 278, 122446. [Google Scholar] [CrossRef]

- Turuallo, G.; Soutsos, M.N. Supplementary cementitious materials: Strength development of self-compacting concrete under different curing temperature. Procedia Eng. 2015, 125, 699–704. [Google Scholar] [CrossRef] [Green Version]

- Borštnar, M.; Daneu, N.; Dolenec, S. Phase development and hydration kinetics of belite-calcium sulfoaluminate cements at different curing temperatures. Ceram. Int. 2020, 46, 29421–29428. [Google Scholar] [CrossRef]

- Ng, S.; Jelle, B.P.; Stæhli, T. Calcined clays as binder for thermal insulating and structural aerogel incorporated mortar. Cem. Concr. Compos. 2016, 72, 213–221. [Google Scholar] [CrossRef]

| Binding Material | SiO2 | Al2O3 | Fe2O3 | TiO2 | SO3 | CaO | Na2O | MgO | K2O | Other |

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 12.54 | 4.41 | 3.41 | 0.59 | 1.96 | 72.97 | 0.26 | 0.21 | 0.90 | 2.75 |

| Fly ash | 37.96 | 24.35 | 12.06 | 1.97 | 0.95 | 14.83 | 2.27 | 1.03 | 1.86 | 2.72 |

| Silica fume | 94.30 | 0.04 | – | – | 0.08 | 1.21 | – | 0.08 | 0.01 | 4.28 |

| Water Reduction Rate (%) | Chloride Ion Content (%) | Alkali Content (%) | Water Content (%) | Solid Content (%) | pH |

|---|---|---|---|---|---|

| 25 | 0.038 | ≤0.2 | <3 | 40 ± 2 | 8.3 |

| Ratio of Bleeding Rate (%) | Gas Content (%) | Solid Content (%) | Corrosion of Reinforcement | pH |

|---|---|---|---|---|

| 49.3 | 5.3 | 15 | No | 8.2 |

| Particle Size (mm) | Porosity (%) | Density (kg/m3) | Thermal Conductivity (W/m·K) |

|---|---|---|---|

| 0–2 | > 90 | 100 | 0.020 |

| Cement | Water | Aerogel | Silica Fume | Fly Ash | Air-Entraining Agent | Water Reducer |

|---|---|---|---|---|---|---|

| 324 | 180 | 65 | 36 | 90 | 4.5 | 4.5 |

| Cement | Fly Ash | Silica Fume | Slag | Water | Fine Aggregate | Coarse Aggregate | Water Reducer |

|---|---|---|---|---|---|---|---|

| 335 | 111.7 | 55.8 | 55.8 | 173.1 | 814 | 858 | 1.7 |

| Curing Regime | Early Curing (RH > 95%) | Wet Curing Time (13–24 °C, 70 ± 15% RH) | Dry Curing Time (13–24 °C, 70 ± 15% RH) |

|---|---|---|---|

| 10 C | 10 °C, 1 days | 14 days | 14 days |

| 20 C | 20 °C, 1 days | 14 days | 14 days |

| 30 C | 30 °C, 1 days | 14 days | 14 days |

| 40 C | 40 °C, 1 days | 14 days | 14 days |

| 50 C | 50 °C, 1 days | 14 days | 14 days |

| 60 C | 60 °C, 1 days | 14 days | 14 days |

| Reference | Temperature (°C) | Compressive Strength (MPa) | Flexural Strength (MPa) | Permeability (mm) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|---|

| [2] | 60–70 | ↓ | – | ↑ | – |

| [21] | 80–120 | ↓ | ↓ | – | ↓ |

| [25] | 15–70 | ↓ | – | – | – |

| [26] | 20–90 | ↑first, ↓ after 50 °C | – | – | – |

| [29] | 60–100 | ↓ | ↓ | – | – |

| [30] | 20–50 | ↑ | – | – | – |

| [31] | 20–60 | ↑first, ↓ after 40 °C | – | – | – |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, K.-L.; Li, S.-J.; Zhu, P.-H. Effect of Early Curing Temperature on the Tunnel Fire Resistance of Self-Compacting Concrete Coated with Aerogel Cement Paste. Materials 2021, 14, 5782. https://doi.org/10.3390/ma14195782

Huang K-L, Li S-J, Zhu P-H. Effect of Early Curing Temperature on the Tunnel Fire Resistance of Self-Compacting Concrete Coated with Aerogel Cement Paste. Materials. 2021; 14(19):5782. https://doi.org/10.3390/ma14195782

Chicago/Turabian StyleHuang, Kai-Lin, Shu-Jin Li, and Ping-Hua Zhu. 2021. "Effect of Early Curing Temperature on the Tunnel Fire Resistance of Self-Compacting Concrete Coated with Aerogel Cement Paste" Materials 14, no. 19: 5782. https://doi.org/10.3390/ma14195782

APA StyleHuang, K.-L., Li, S.-J., & Zhu, P.-H. (2021). Effect of Early Curing Temperature on the Tunnel Fire Resistance of Self-Compacting Concrete Coated with Aerogel Cement Paste. Materials, 14(19), 5782. https://doi.org/10.3390/ma14195782