Durability Properties of Ultra-High Performance Lightweight Concrete (UHPLC) with Expanded Glass

Abstract

:1. Introduction

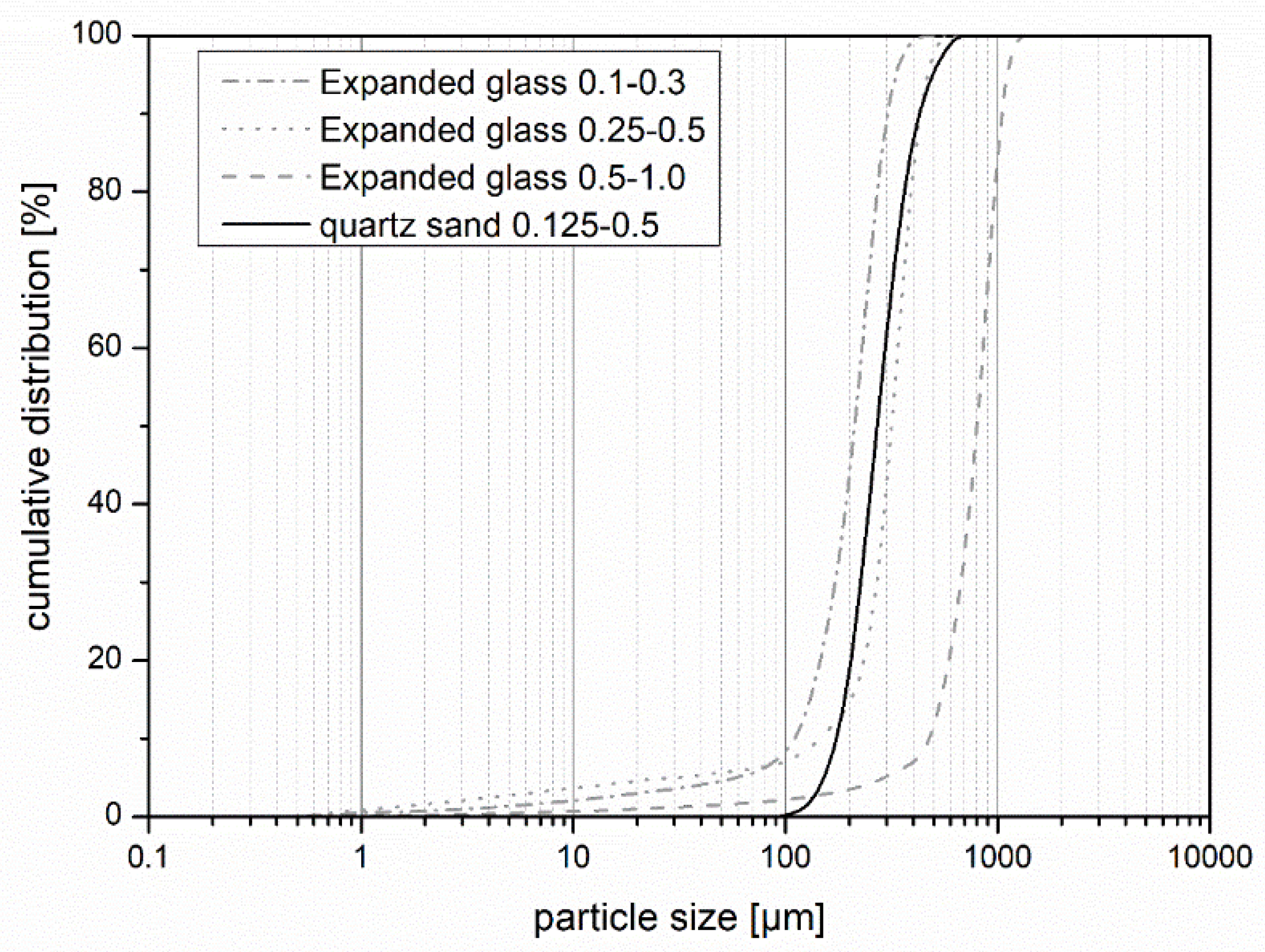

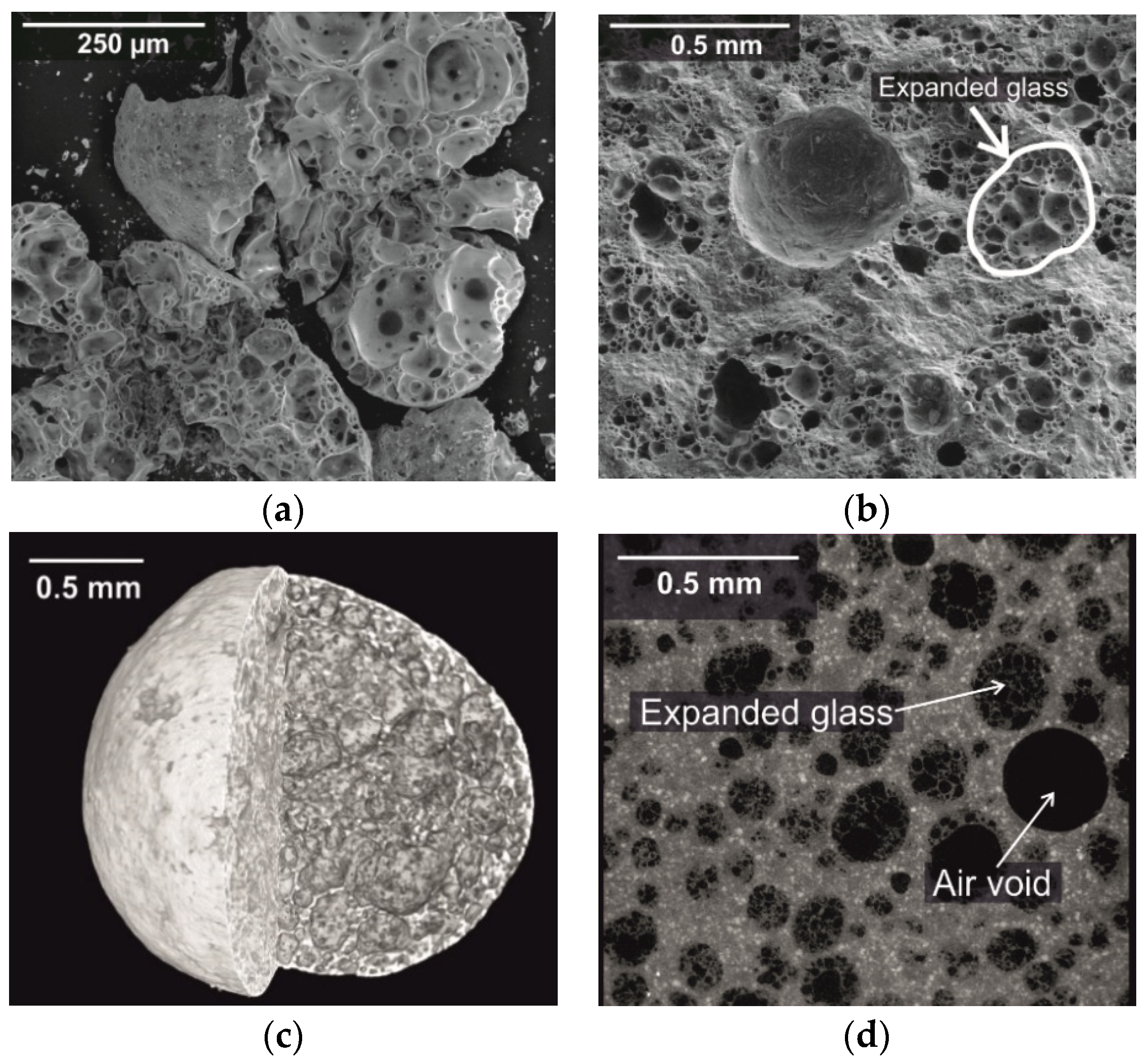

2. Materials

3. Methods

3.1. Compressive Stength and Bulk Density

3.2. Microstructure

3.3. Resistance to Concrete Corrosion

3.4. Resistance to Reinforcement Corrosion

| KN | Carbonation coefficient under natural conditions (mm/year−1) |

| a | Conversion factor from 1 day to 1 year = = 19.10 |

| b | Conversion factor from 4.0 auf 0.4 vol% CO2 = |

| c | Correction factor for raoid carbonation = 1.36 |

| KS | Carbonation coefficient at 4.0 vol% CO2 (mm/day−1) |

| dKM | Mean value of carbonation depth (mm) |

| t | Time (days/years) |

| R | Gas constant, R = 8.315 (J/(K-mol)) |

| T | Absolute mean temperature of the solutions during the experiment (K) |

| z | Ion load, for chloride ions z = 1 (-) |

| F | Faraday’s constant, F = 9.649–104 (J/(V-mol)) |

| E | electric field strength (V/m) |

| xd | Mean penetration depth of the chloride ions of the two halves of the specimen (m) |

| t | Test duration (duration of voltage application) (s) |

| erf−1 | Inverse error function |

| cd | Color change-inducing chloride concentration, cd = 0.07 (mol/L) |

| c0 | Chloride concentration of the potassium hydroxide solution (mol/L) |

4. Results

4.1. Compressive Strength

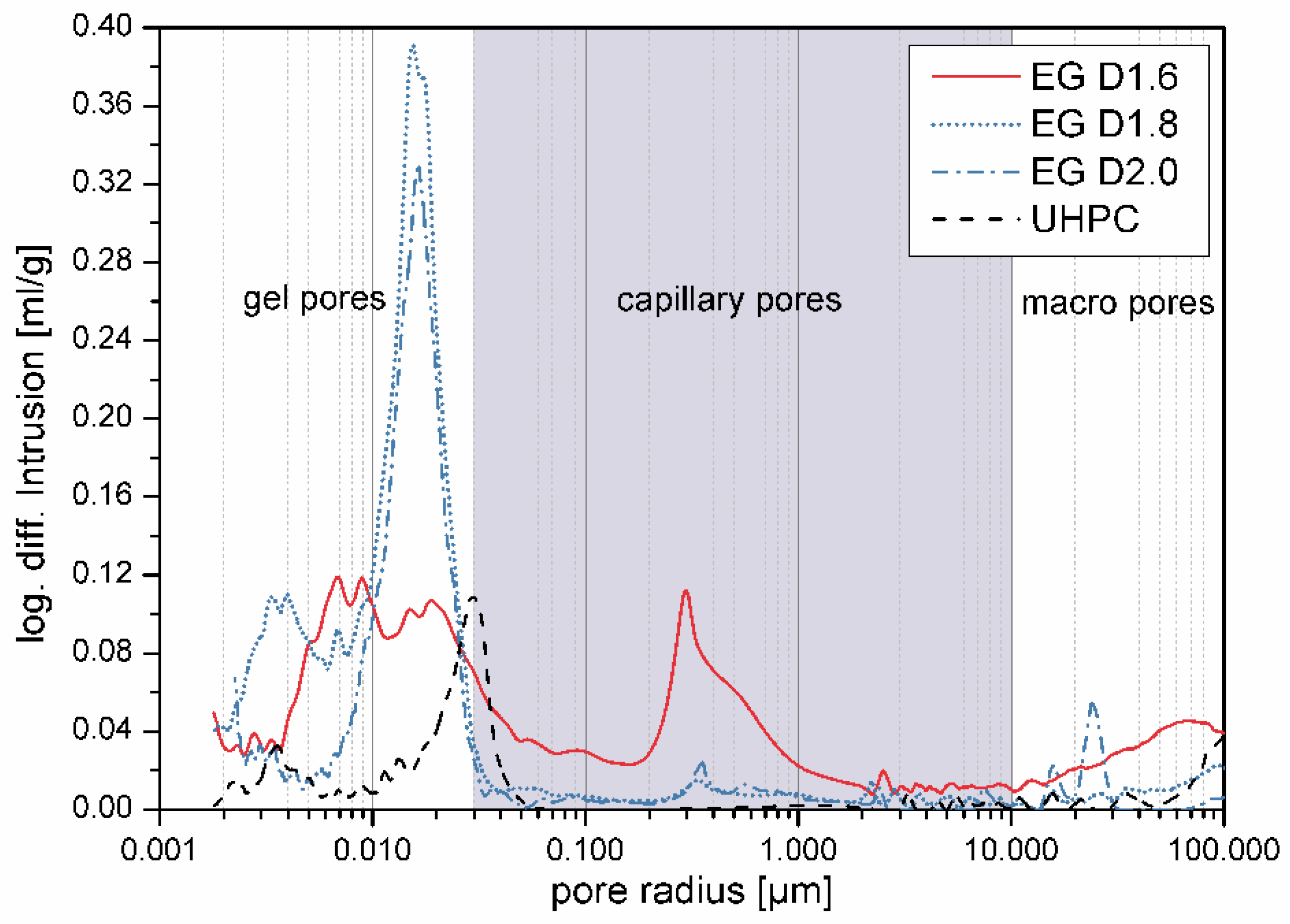

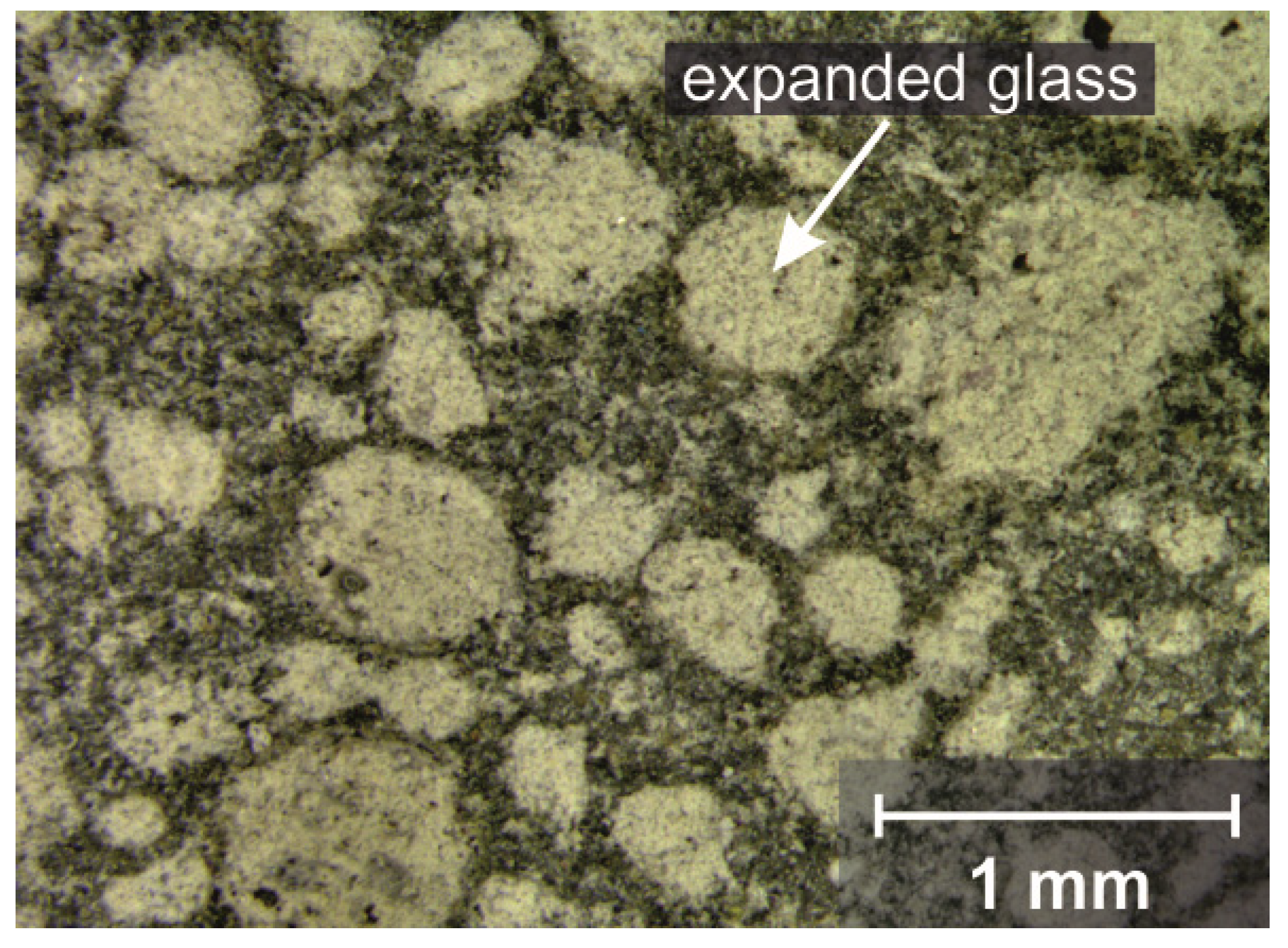

4.2. Microstructure

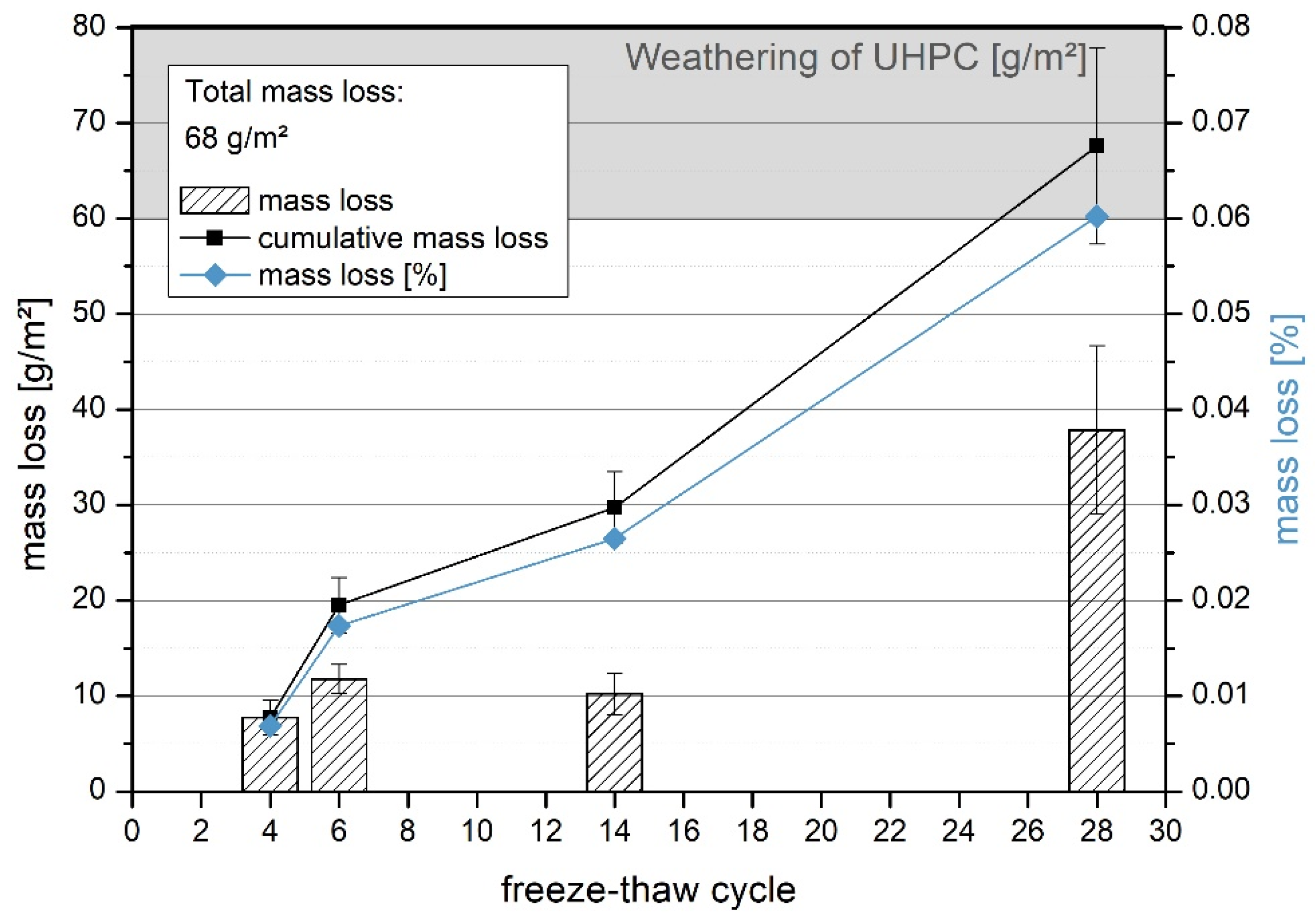

4.3. Freeze-Thaw, Acid, and Abrasion Resistance

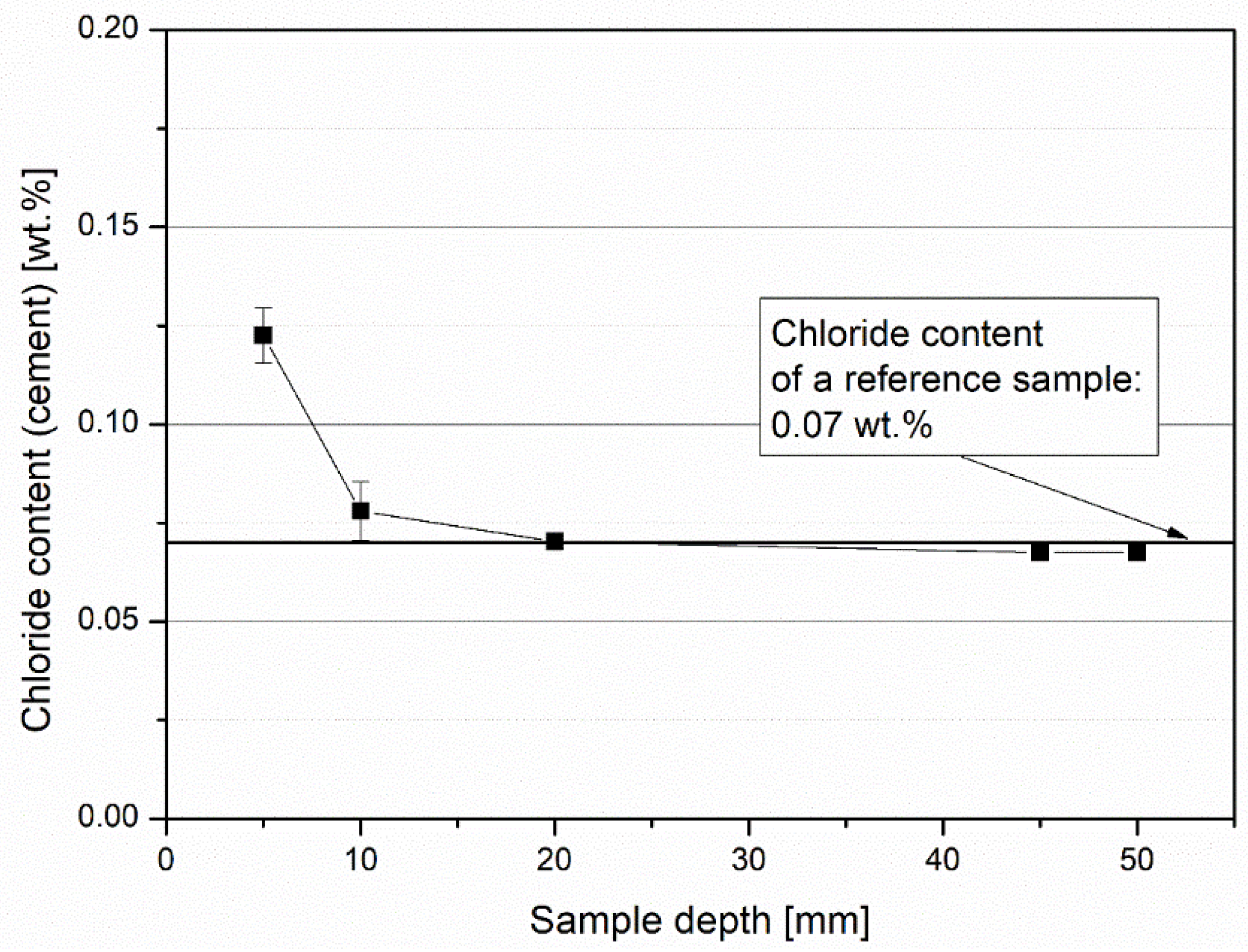

4.4. Carbonation and Chloride Diffusion

5. Discussion

6. Conclusions

- The compressive strength of the tested concretes was between 60 and 100 MPa with a bulk density of 1.6–1.9 kg/dm3. Thus, the performance was increased compared to conventional lightweight structural concretes. This resulted in a new class of materials that needs to be investigated in more detail.

- The analysis of the pore structure showed that the concretes investigated had increased porosity in the capillary pore (EG D1.6) and gel porosity (EG D1.8 and EG D2.0) regions. However, this was due to the porosity of the embedded expanded glass grains and not to the matrix. Therefore, the microstructure had few capillary pores.

- In frost tests, the high impermeability of the concrete structure ensured very good properties. Little weathering (68 g/m2) was measured

- The material showed very good resistance to sulfate attack at pH 3.5. However, other chemicals and pH ranges need to be investigated depending on the application.

- Abrasion by a grinding wheel, on the other hand, showed increased wear. The light aggregate, which had a low compressive strength, had a negative influence on the abrasion resistance. In the case of direct mechanical stress, it must therefore be checked in advance whether the resistance is sufficient.

- A rapid carbonation chamber was used to study the carbonation progress. A very low carbonation coefficient of 0.5 mm/year-1 was obtained. This allowed the concrete cover to be reduced.

- The chloride diffusion coefficient was also low and allowed structures to come into contact with salt water.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schmidt, M.; Fehling, E.; Fröhlich, S.; Thiemicke, J. Nachhaltiges Bauen mit Ultra-Hochfestem Beton. Ergebnisse des Schwerpunktprogrammes 1182 = Sustainable Building with Ultra-High Performance Concrete; Schriftenreihe Baustoffe und Massivbau, H. 22; Kassel University Press: Kassel, Germany, 2014. [Google Scholar]

- Faust, T. Leichtbeton im Konstruktiven Ingenieurbau; Ernst & Sohn: Berlin, Germany, 2003. [Google Scholar]

- German Committee for Reinforced Concrete (DAfStb). Heft 561: Sachstandsbericht Ultrahochfester Beton; Beuth Verlag: Berlin, Germany, 2008. [Google Scholar]

- EN 206:2013+A2:2021. Concrete—Specification, Performance, Production and Conformity; European Committee for Standardization: Berlin, Germany, 2021.

- French Standard NF P18-710. National Addition to Eurocode 2—Design of Concrete Structures: Specific Rules for Ultra-High Performance Fibre-Reinforced Concrete (UHPFRC); Association Française de Normalization: Paris, France, 2016.

- French Standard NF P18-470. Concrete—Ultra-High Performance Fibre-Reinforced Concrete—Specification, Performance, Production and Conformity; Association Française de Normalization: Paris, France, 2016.

- Merkblatt SIA 2052:2016. Ultra-Hochleistungs-Faserbeton (UHFB), Baustoffe, Bemessung und Ausführung; Swiss Association for Standardization: Winterthur, Swiss, 2016.

- Fehling, E. Ultra-High Performance Concrete UHPC. Fundamentals, Design, Examples. BetonKalender; Ernst & Sohn: Berlin, Germany, 2014. [Google Scholar] [CrossRef]

- Schmidt, M.; Alfres, C. Die neue DAfStb-Richtlinie UHFB—Teil 1: Betontechnik und Ausführung; BFT International Bauverlag BV GmbH: Gütersloh, Germany, 2018; Heft 02. [Google Scholar]

- Leutbecher, T. Die neue DAfStb-Richtlinie UHFB—Teil2: Bemessung und Konstruktion; BFT International Bauverlag BV GmbH: Gütersloh, Germany, 2018; Heft 02. [Google Scholar]

- Ibrahim, M.; Ahmad, A.; Barry, M.S.; Alhems, L.M.; Suhoothi, A.M. Durability of Structural Lightweight Concrete Containing Expanded Perlite Aggregate. Int. J. Concr. Struct. Mater. 2020, 14, 1–15. [Google Scholar] [CrossRef]

- Ke, Y.; Ortola, S.; Beaucour, A.L.; Dumontet, H. Identification of microstructural characteristics in lightweight aggregate concretes by micromechanical modelling including the interfacial transition zone (ITZ). Cem. Concr. Res. 2010, 40, 1590–1600. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 12390-3:2019. Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; Beuth Verlag: Berlin, Germany, 2019. [Google Scholar]

- International Organization for Standardization. ISO 15901-1:2016. Evaluation of Pore Size Distribution and Porosity of Solid Materials by Mercury Porosity and Gas Adsorption; Beuth Verlag: Berlin, Germany, 2019. [Google Scholar]

- European Committee for Standardization. EN 12390-8: 2019. Testing Hardened Concrete—Part 8: Depth of Penetration of Water under Pressure; Beuth Verlag: Berlin, Germany, 2019. [Google Scholar]

- European Committee for Standardization/Technical Specification. CEN/TS 12390-9:2016. Testing Hardened Concrete—Part 9: Freeze-Thaw Resistance with de-Icing Salts—Scaling; Beuth Verlag: Berlin, Germany, 2017. [Google Scholar]

- Franke, L.; Oly, M.; Witt, S. Richtlinie für die Prüfung von Mörteln für den Einsatz im Sielbau. Fassung 2001. Tis. Tiefbau Ing. Straßenbau 2001, 43, 23–27. [Google Scholar]

- European Committee for Standardization. EN 1339:2003. Concrete Paving Flags—Requirements and Test Methods; Beuth Verlag: Berlin, Germany, 2003. [Google Scholar]

- Swiss Association for Standardization. SIA 262/1:2013. Concrete Structure—Supplementary Spcifications; Beuth Verlag: Berlin, Germany, 2013. [Google Scholar]

- Bundesanstalt für Wasserbau. BAW Merkblatt: Dauerhaftigkeitsbemessung und -Bewertung von Stahlbetonbauwerken bei Carbonatisierung und Chlorideinwirkung (MDCC); Baundesanstalt für Wasserbaum: Karlsruhe, Germany, 2019. [Google Scholar]

- Dorner, H.; Kleiner, G. Anleitung zur Bestimmung des Chloridgehaltes von Beton; Deutscher Ausschuss für Stahlbeton/Deutsches Institut für Normung: Berlin, Germany; Beuth Verlag: Berlin, Germany, 1989. [Google Scholar]

- German Institute for Standardisation. DIN 1045-2. Concrete, Reinforced and Prestressed Concrete Structures—Part 2: Concrete—Specification, Properties, Production and Conformity—Application Rules for DIN EN 206-1; Beuth Verlag: Berlin, Germany, 2008. [Google Scholar]

- Thienel, K.-C. Materialtechnologische Eigenschaften der Leichtbetone aus Blähton; Wilhelm Ernst & Sohn Verlag: Berlin, Germany, 1997. [Google Scholar]

- DafStb. Heft 455: Wasserdurchlässigkeit und Selbstheilung von Trennrissen in Beton; Beuth Verlag: Berlin, Germany, 1996. [Google Scholar]

- Setzer, M.J. Zum Mikrogefüge des Zementsteins und Dessen Einfluss auf das Mechanische Verhalten des Betons; Zement und Beton Heft 85/86; TU Wien Science Center: Vienna, Austria, 1975. [Google Scholar]

- Müller, C.; Palecki, S.; Möser, B.; Franke, L. Durability of Ultra-High Performance Concrete (UHPC). In Proceedings of the 3rd Fib International Congress, Washington, DC, USA, 29 May—2 June 2010. [Google Scholar]

- Karagöl, F.; Yegin, Y.; Polat, R.; Benli, A.; Demirboğa, R. The influence of lightweight aggregate, freezing-thawing procedure and air entraining agent on freezing-thawing damage. Struct. Concr. 2018, 19, 1328–1340. [Google Scholar] [CrossRef]

- Mao, J.; Ayuta, K. Freeze–Thaw Resistance of Lightweight Concrete and Aggregate at Different Freezing Rates. J. Mater. Civ. Eng. 2008, 20, 78–84. [Google Scholar] [CrossRef]

- Lotfy, A.; Hossain, K.M.A.; Lachemi, M. Durability properties of lightweight self-consolidating concrete developed with three types of aggregates. Constr. Build. Mater. 2016, 106, 43–54. [Google Scholar] [CrossRef]

- Deutscher Beton- und Bautechnikverein e.V. Heft 33 Chemischer Angriff auf Betonbauwerke-Bewertung des Angriffsgrads und Geeignete Schutzprinzipien; Deutscher Beton- und Bautechnikverein: Berlin, Germany, 2014. [Google Scholar]

- Wang, H.-Y. Durability of self-consolidating lightweight aggregate concrete using dredged silt. Constr. Build. Mater. 2009, 23, 2332–2337. [Google Scholar] [CrossRef]

- European Committee for Standardization. EN 13813:2017. Screed Material and Floor Screeds—Screed Material—Properties and Requirements; Beuth Verlag: Berlin, Germany, 2017. [Google Scholar]

- Youm, K.S.; Moon, J.; Cho, J.Y.; Kim, J.J. Experimental study on strength and durability of lightweight aggregate concrete containing silica fume. Constr. Build. Mater. 2016, 114, 517–527. [Google Scholar] [CrossRef]

- Orosz, M.; Nagy, B.; Tóth, E. Hygrothermal behawior of ultr-lightweight polystyrrene concrete. Pollack Period. 2017, 12, 53–66. [Google Scholar] [CrossRef]

| Raw Materials | Unit | EG D1.6 | EG D1.8 | EG D2.0 | UHPC [1] |

|---|---|---|---|---|---|

| Cement (CEM I 52.5 R) | (kg/m3) | 771.90 | 775 | ||

| Silica fume uncompacted | (kg/m3) | 163.65 | 164 | ||

| Superplasticizer | (kg/m3) | 30.40 (3.9 % bwoc) | 23.5 (3.0% bwoc) | ||

| Hydrophobing agent | (kg/m3) | 15.45 (2.0 % bwoc) | - | ||

| Quartz flour | (kg/m3) | 199.00 | 193 | ||

| Quartz sand (0.125/0.5 mm) | (kg/m3) | - | 338.99 | 627.76 | 946 |

| Expanded glass (0.1/0.3 mm) | (kg/m3) | - | 49.86 | 29.43 | - |

| Expanded glass (0.25/0.5 mm) | (kg/m3) | 122.45 | 128.83 | 67.61 | - |

| Expanded glass (0.5/1 mm) | (kg/m3) | 94.75 | - | - | - |

| Parameters of the Mix Design | |||||

| Water/binder ratio | (kg/kg) | 0.21 | |||

| Calculated fresh concrete density | (kg/m3) | 1.56 | 1.86 | 2.07 | 2.31 |

| Hardened concrete bulk density (20 °C; 65% r.h.) | (kg/m3) | 1.59 | 1.79 | 1.97 | 2.30 |

| Dry bulk density (oven-dry) | (kg/m3) | 1.51 | 1.72 | 1.90 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Umbach, C.; Wetzel, A.; Middendorf, B. Durability Properties of Ultra-High Performance Lightweight Concrete (UHPLC) with Expanded Glass. Materials 2021, 14, 5817. https://doi.org/10.3390/ma14195817

Umbach C, Wetzel A, Middendorf B. Durability Properties of Ultra-High Performance Lightweight Concrete (UHPLC) with Expanded Glass. Materials. 2021; 14(19):5817. https://doi.org/10.3390/ma14195817

Chicago/Turabian StyleUmbach, Cristin, Alexander Wetzel, and Bernhard Middendorf. 2021. "Durability Properties of Ultra-High Performance Lightweight Concrete (UHPLC) with Expanded Glass" Materials 14, no. 19: 5817. https://doi.org/10.3390/ma14195817

APA StyleUmbach, C., Wetzel, A., & Middendorf, B. (2021). Durability Properties of Ultra-High Performance Lightweight Concrete (UHPLC) with Expanded Glass. Materials, 14(19), 5817. https://doi.org/10.3390/ma14195817