Microstructural Characterization and Mechanical Properties of L-PBF Processed 316 L at Cryogenic Temperature

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Methods

3. Results and Discussion

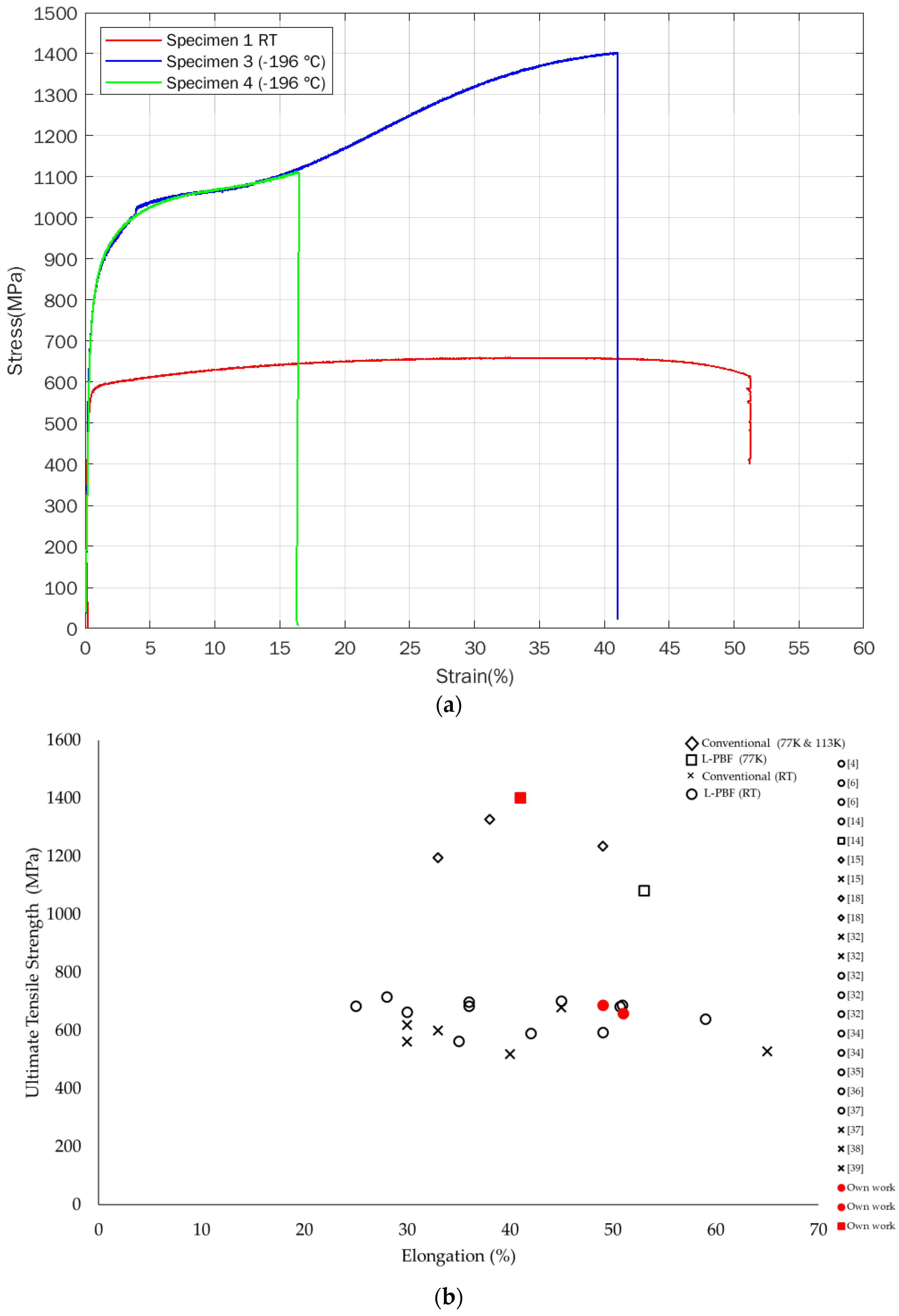

3.1. Mechanical Properties

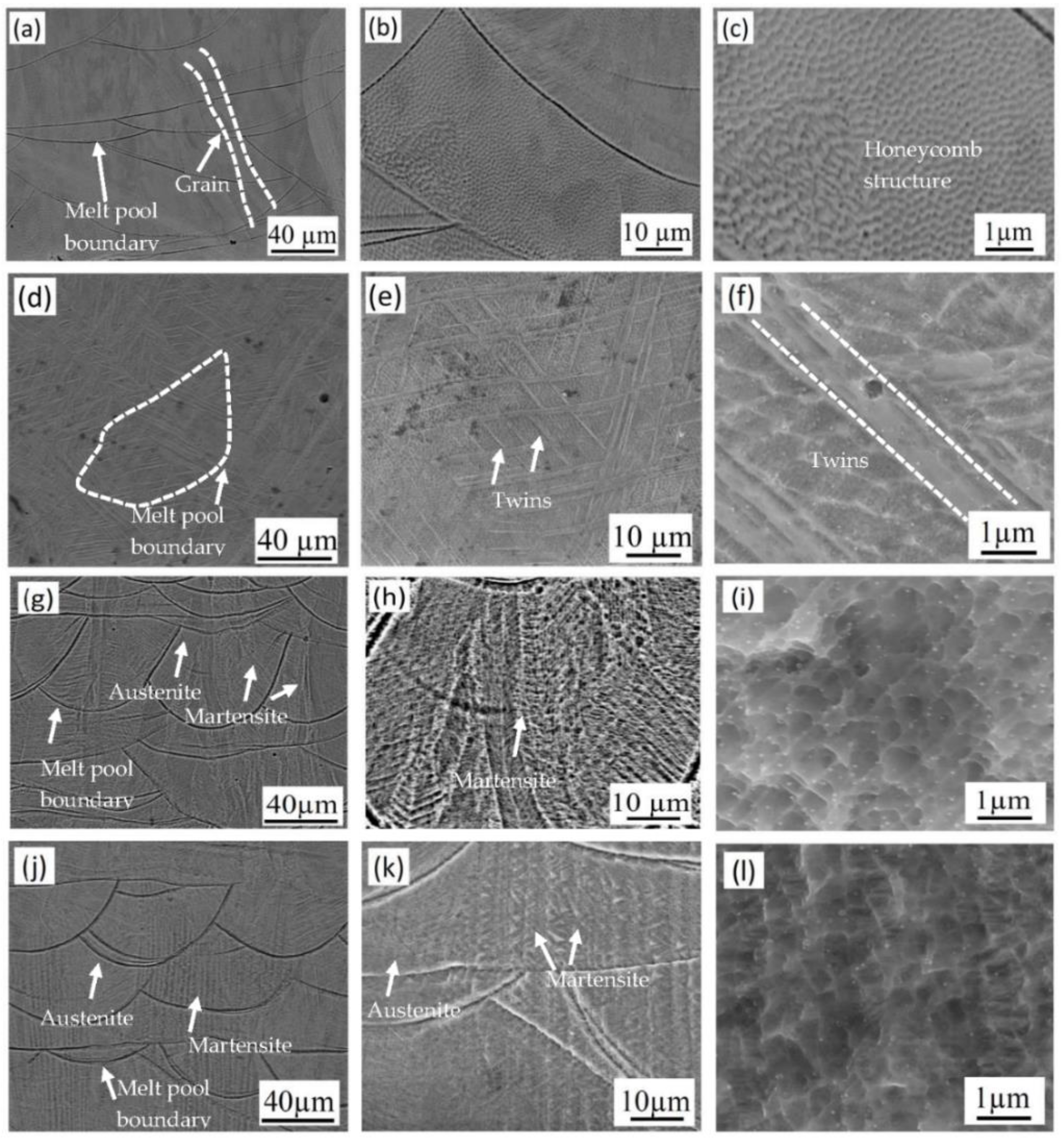

3.2. Microstructures

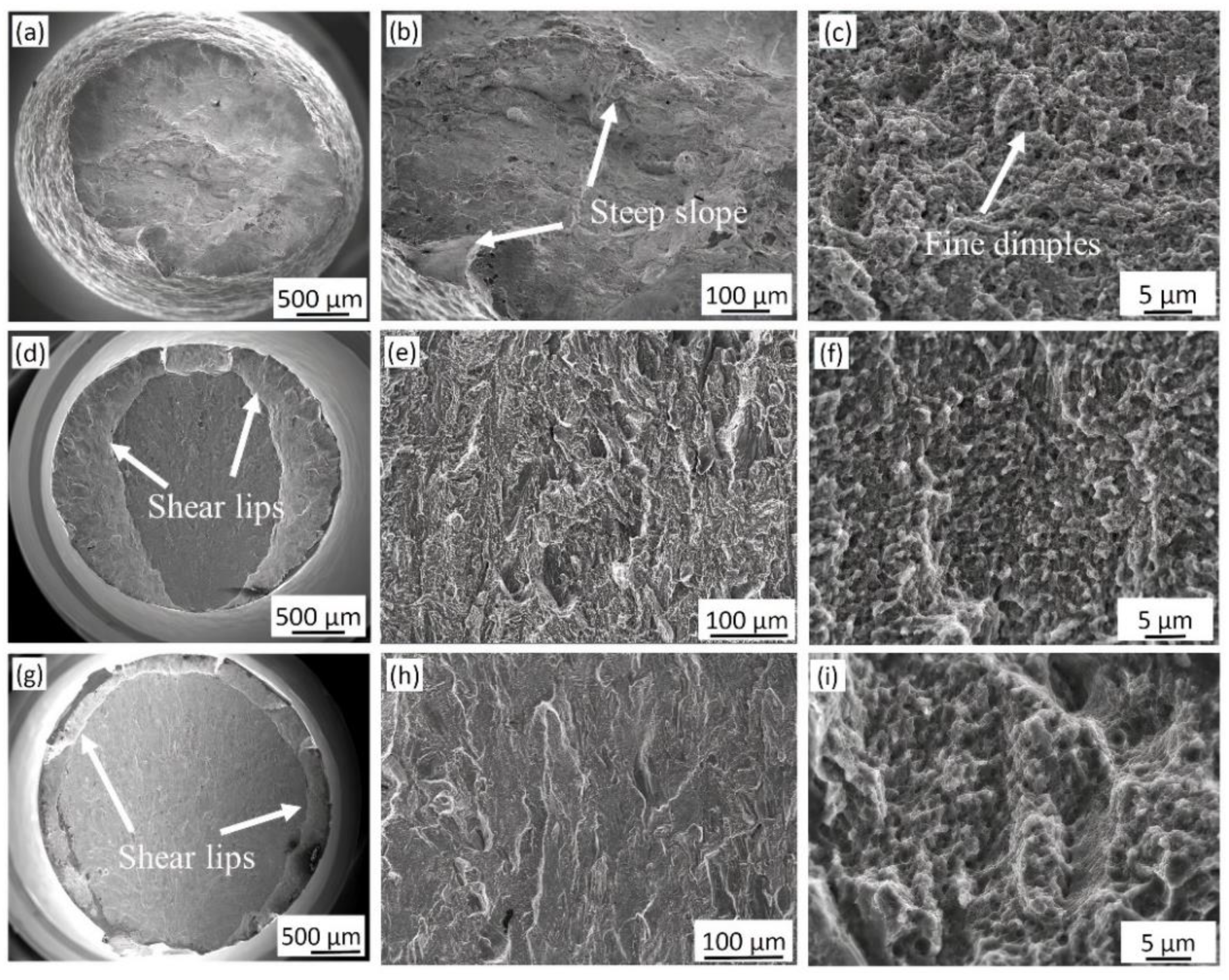

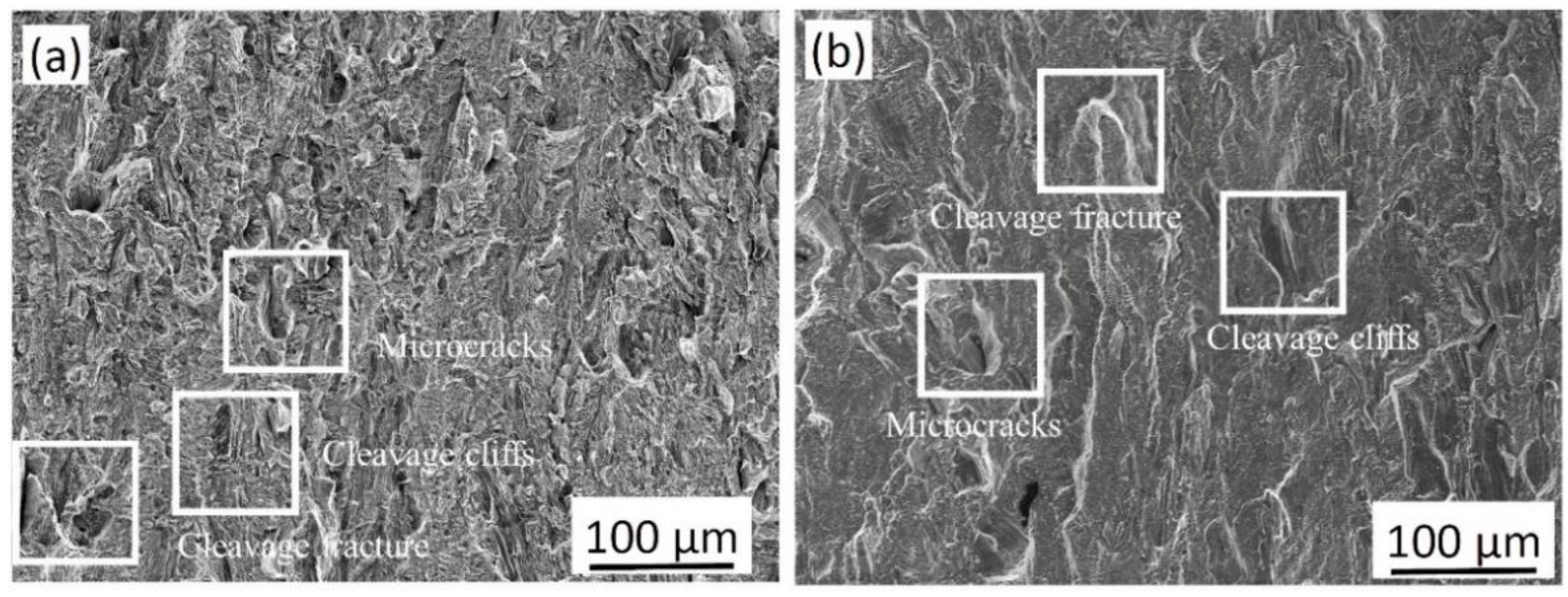

3.3. Fractography

3.4. XRD Analysis

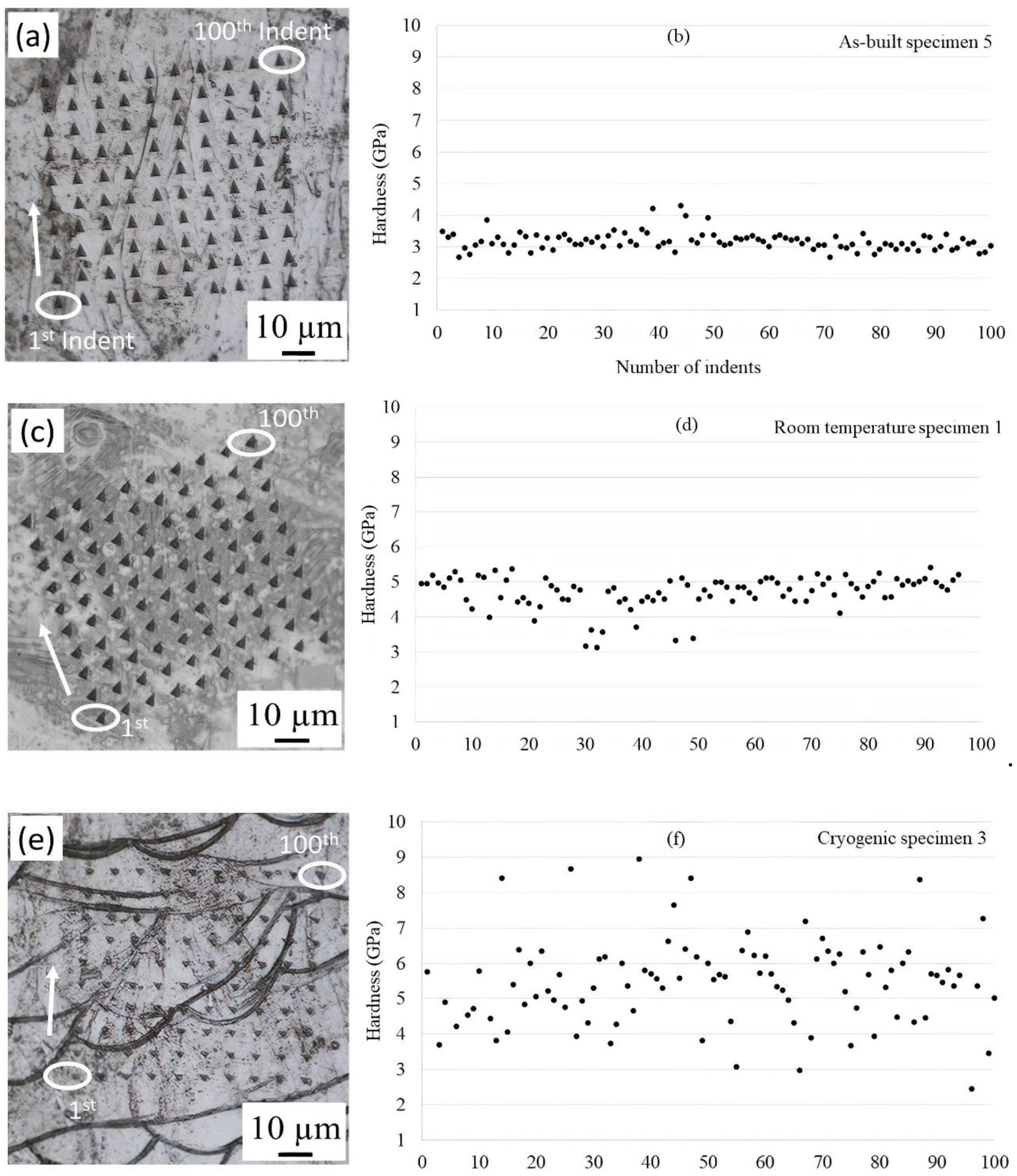

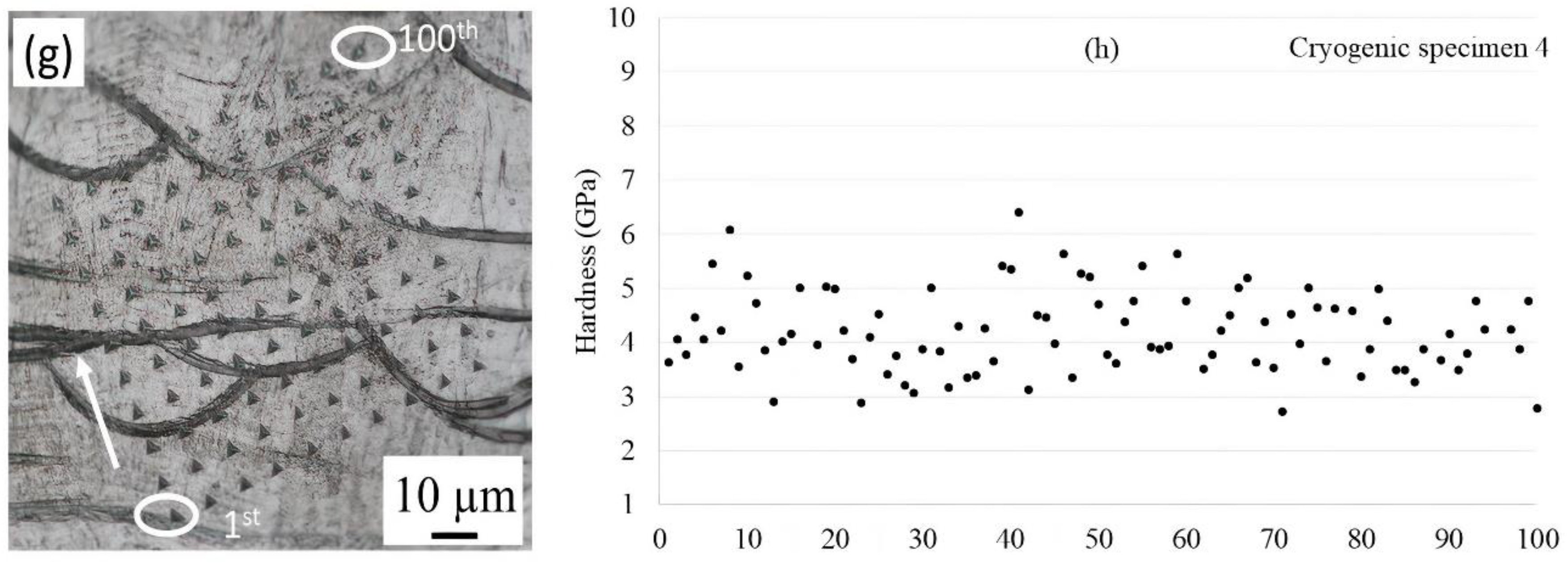

3.5. Nanoindentation Tests

4. Conclusions

- There was a significant increase in the yield and ultimate tensile strength at −196 °C compared to room temperature, on average 31% and 86%, respectively. However, the ductility remained at a reasonable level (over 40%) due to the existence of austenite.

- XRD results showed that no martensite formed during cooling to −196 °C or during tensile testing at room temperature. However, both ε and α martensite are detectable in cryogenic samples after tensile testing.

- Different martensite phases were indicated by a variation in the nanohardness values of the cryogenic samples, ranging from 3–9 GPa. The hardness values of the room temperature specimen 1 were in the range of 3–5 GPa.

- The microstructures of the −196 °C temperature specimens were different from that of the room temperature specimen. In addition to the melt pool boundaries, thin, parallel, and plate-like structures were observed, which could indicate martensite inside the grain boundaries in the cryogenic specimen.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shen, Y.F.; Li, X.X.; Sun, X.; Wang, Y.D.; Zuo, L. Twinning and martensite in a 304 austenitic stainless steel. Mater. Sci. Eng. A 2012, 552, 514–522. [Google Scholar] [CrossRef]

- Tsopanos, S.; Mines, R.A.W.; McKown, S.; Shen, Y.; Cantwell, W.J.; Brooks, W.; Sutcliffe, C.J. The influence of processing parameters on the mechanical properties of selectively laser melted stainless steel microlattice structures. J. Manuf. Sci. Eng. 2010, 132, 132. [Google Scholar] [CrossRef]

- Song, B.; Zhao, X.; Li, S.; Han, C.; Wei, Q.; Wen, S.; Shi, Y. Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: A review. Front. Mech. Eng. 2015, 10, 111–125. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.; Vedani, M. Microstructure and fracture behavior of 316L austenitic stainless steel produced by selective laser melting. J. Mater. Sci. Technol. 2016, 32, 738–744. [Google Scholar] [CrossRef]

- Yan, F.K.; Liu, G.Z.; Tao, N.R.; Lu, K. Strength and ductility of 316L austenitic stainless steel strengthened by nano-scale twin bundles. Acta Mater. 2012, 60, 1059–1071. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zhu, T. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–71. [Google Scholar] [CrossRef] [Green Version]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Druzgalski, C.L.; Ashby, A.; Guss, G.; King, W.E.; Roehling, T.T.; Matthews, M.J. Process optimization of complex geometries using feed forward control for laser powder bed fusion additive manufacturing. Addit. Manuf. 2020, 34, 101169. [Google Scholar] [CrossRef]

- Wohlers, T. Wohlers Report; Wohlers Associates Inc.: Fort Collins, CO, USA, 2014. [Google Scholar]

- Barz, A.; Buer, T.; Haasis, H.D. A study on the effects of additive manufacturing on the structure of supply networks. IFAC-PapersOnLine 2016, 49, 72–77. [Google Scholar] [CrossRef]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mater. Process. Technol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef] [Green Version]

- Kamath, C.; El-Dasher, B.; Gallegos, G.F.; King, W.E.; Sisto, A. Density of additively-manufactured, 316L SS parts using laser powder-bed fusion at powers up to 400 W. Int. J. Adv. Manuf. Technol. 2014, 74, 65–78. [Google Scholar] [CrossRef] [Green Version]

- Bidulský, R.; Bidulská, J.; Gobber, F.S.; Kvačkaj, T.; Petroušek, P.; Actis-Grande, M.; Manfredi, D. Case Study of the Tensile Fracture Investigation of Additive Manufactured Austenitic Stainless Steels Treated at Cryogenic Conditions. Materials 2020, 13, 3328. [Google Scholar] [CrossRef]

- Suzuki, K.; Fukakura, J.; Kashiwaya, H. Cryogenic fatigue properties of 304L and 316L stainless steels compared to mechanical strength and increasing magnetic permeability. J. Test. Eval. 1988, 16, 190–197. [Google Scholar]

- Seetharaman, V.; Krishnan, R. Influence of the martensitic transformation on the deformation behaviour of an AISI 316 stainless steel at low temperatures. J. Mater. Sci. 1981, 16, 523–530. [Google Scholar] [CrossRef]

- Crivoi, M.R.; Hoyos, J.J.; Izumi, M.T.; de Aguiar, D.J.M.; Namur, R.S.; Terasawa, A.L.; Cintho, O.M. In situ analysis of cryogenic strain of AISI 316L stainless steel using synchrotron radiation. Cryogenics 2020, 105, 103020. [Google Scholar] [CrossRef]

- Lee, K.J.; Chun, M.S.; Kim, M.H.; Lee, J.M. A new constitutive model of austenitic stainless steel for cryogenic applications. Comput. Mater. Sci. 2009, 46, 1152–1162. [Google Scholar] [CrossRef]

- Li, Z.; Voisin, T.; McKeown, J.T.; Ye, J.; Braun, T.; Kamath, C.; Wang, Y.M. Tensile properties, strain rate sensitivity, and activation volume of additively manufactured 316L stainless steels. Int. J. Plast. 2019, 120, 395–410. [Google Scholar] [CrossRef]

- Naraghi, R. Martensitic Transformation in Austenitic Stainless Steels. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, August 2009. [Google Scholar]

- Huang, C.X.; Yang, G.; Gao, Y.L.; Wu, S.D.; Li, S.X. Investigation on the nucleation mechanism of deformation-induced martensite in an austenitic stainless steel under severe plastic deformation. J. Mater. Res. 2007, 22, 724–729. [Google Scholar] [CrossRef]

- Larbalestier, D.C.; King, H.W. Austenitic stainless steels at cryogenic temperatures 1—Structural stability and magnetic properties. Cryogenics 1973, 13, 160–168. [Google Scholar] [CrossRef]

- Lecroisey, F.; Pineau, A. Martensitic transformations induced by plastic deformation in the Fe-Ni-Cr-C system. Metall. Mater. Trans. B 1972, 3, 391–400. [Google Scholar] [CrossRef]

- Otte, H.M. The formation of stacking faults in austenite and its relation to martensite. Acta Metall. 1957, 5, 614–627. [Google Scholar] [CrossRef]

- Spencer, K.; Embury, J.D.; Conlon, K.T.; Véron, M.; Bréchet, Y. Strengthening via the formation of strain-induced martensite in stainless steels. Mater. Sci. Eng. A 2004, 387, 873–881. [Google Scholar] [CrossRef]

- Spencer, K.; Véron, M.; Yu-Zhang, K.; Embury, J.D. The strain induced martensite transformation in austenitic stainless steels: Part 1–Influence of temperature and strain history. Mater. Sci. Technol. 2009, 25, 7–17. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Compagnon, E.; Godin, B.; Korsunsky, A.M. Investigation of martensite transformation in 316L stainless steel. Mater. Today Proc. 2015, 2, 251–260. [Google Scholar] [CrossRef]

- Garion, C.; Skoczeń, B.; Sgobba, S. Constitutive modelling and identification of parameters of the plastic strain-induced martensitic transformation in 316L stainless steel at cryogenic temperatures. Int. J. Plast. 2006, 22, 1234–1264. [Google Scholar] [CrossRef]

- Czarkowski, P.; Krawczynska, A.T.; Slesinski, R.; Brynk, T.; Budniak, J.; Lewandowska, M.; Kurzydlowski, K.J. Low temperature mechanical properties of 316L type stainless steel after hydrostatic extrusion. Fusion Eng. Des. 2011, 86, 2517–2521. [Google Scholar] [CrossRef]

- ISO 6892-1. Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- ISO 6892-3. Metallic Materials—Tensile Testing—Part 3—Method of Test at Low Temperature; International Organization for Standardization: Geneva, Switzerland, 2015. [Google Scholar]

- Tolosa, I.; Garciandía, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Pham, M.S.; Dovgyy, B.; Hooper, P.A. Twinning induced plasticity in austenitic stainless steel 316L made by additive manufacturing. Mater. Sci. Eng. A 2017, 704, 102–111. [Google Scholar] [CrossRef]

- Qiu, C.; Al Kindi, M.; Aladawi, A.S.; Al Hatmi, I. A comprehensive study on microstructure and tensile behaviour of a selectively laser melted stainless steel. Sci. Rep. 2018, 8, 7785. [Google Scholar] [CrossRef]

- Zhong, Y.; Liu, L.; Wikman, S.; Cui, D.; Shen, Z. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J. Nucl. Mater. 2016, 470, 170–178. [Google Scholar] [CrossRef]

- Saeidi, K.; Kvetková, L.; Lofaj, F.; Shen, Z. Austenitic stainless steel strengthened by the in situ formation of oxide nanoinclusions. RSC Adv. 2015, 5, 20747–20750. [Google Scholar] [CrossRef] [Green Version]

- Mower, T.M.; Long, M.J. Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng. A 2016, 651, 198–213. [Google Scholar] [CrossRef]

- ASTM Committee F42 on Additive Manufacturing Technologies ASTM Committee F42 on Additive Manufacturing Technologies. Subcommittee F42. 91 on Terminology. Standard Terminology for Additive Manufacturing Technologies; Astm International: West Conshohocken, PA, USA, 2012.

- Brnic, J.; Niu, J.; Canadija, M.; Turkalj, G.; Lanc, D. Behavior of AISI 316L steel subjected to uniaxial state of stress at elevated temperatures. J. Mater. Sci. Technol. 2009, 25, 175. [Google Scholar]

- Nalepka, K.; Skoczeń, B.; Ciepielowska, M.; Schmidt, R.; Tabin, J.; Schmidt, E.; Chulist, R. Phase Transformation in 316L Austenitic Steel Induced by Fracture at Cryogenic Temperatures: Experiment and Modelling. Materials 2021, 14, 127. [Google Scholar] [CrossRef]

- Li, J.; Zhou, Z.; Wang, S.; Mao, Q.; Fang, C.; Li, Y.; Zhu, X. Deformation mechanisms and enhanced mechanical properties of 304L stainless steel at liquid nitrogen temperature. Mater. Sci. Eng. A 2020, 798, 140133. [Google Scholar] [CrossRef]

- Paredes, M.; Grolleau, V.; Wierzbicki, T. On Ductile Fracture of 316L Stainless Steels at Room and Cryogenic Temperature Level: An Engineering Approach to Determine Material Parameters. Materialia 2020, 100624. [Google Scholar] [CrossRef]

- Yasa, E.; Kruth, J.P. Microstructural investigation of Selective Laser Melting 316L stainless steel parts exposed to laser re-melting. Procedia Eng. 2011, 19, 389–395. [Google Scholar] [CrossRef]

- Lebedev, A.A.; Kosarchuk, V.V. Influence of phase transformations on the mechanical properties of austenitic stainless steels. Int. J. Plast. 2000, 16, 749–767. [Google Scholar] [CrossRef]

- Solomon, N.; Solomon, I. Deformation induced martensite in AISI 316 stainless steel. Rev. Metal. 2010, 46, 121. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Chen, Y.; Yang, S.; Gao, N. Microstructural evolution and strengthening of selective laser melted 316L stainless steel processed by high-pressure torsion. Mater. Charact. 2020, 159, 110012. [Google Scholar] [CrossRef]

- Nohara, K.; Ono, Y.; Ohashi, N. Composition and grain size dependencies of strain-induced martensitic transformation in metastable austenitic stainless steels. Tetsu--Hagané 1977, 63, 772–782. [Google Scholar] [CrossRef] [Green Version]

- Ma, M.; Wang, Z.; Zeng, X. A comparison on metallurgical behaviors of 316L stainless steel by selective laser melting and laser cladding deposition. Mater. Sci. Eng. A 2017, 685, 265–273. [Google Scholar] [CrossRef]

- Leicht, A.; Rashidi, M.; Klement, U.; Hryha, E. Effect of process parameters on the microstructure, tensile strength and productivity of 316L parts produced by laser powder bed fusion. Mater. Charact. 2020, 159, 110016. [Google Scholar] [CrossRef]

- Spencer, K.; Conlon, K.T.; Bréchet, Y.; Embury, J.D. The strain induced martensite transformation in austenitic stainless steels: Part 2–Effect of internal stresses on mechanical response. Mater. Sci. Technol. 2009, 25, 18–28. [Google Scholar] [CrossRef]

- Qin, W.; Li, J.; Liu, Y.; Kang, J.; Zhu, L.; Shu, D.; Li, Y. Effects of grain size on tensile property and fracture morphology of 316L stainless steel. Mater. Lett. 2019, 254, 116–119. [Google Scholar] [CrossRef]

- Bartolomeu, F.; Buciumeanu, M.; Pinto, E.; Alves, N.; Carvalho, O.; Silva, F.S.; Miranda, G. 316L stainless steel mechanical and tribological behavior—A comparison between selective laser melting, hot pressing and conventional casting. Addit. Manuf. 2017, 16, 81–89. [Google Scholar] [CrossRef]

- Roa, J.J.; Fargas, G.; Mateo, A.; Jiménez-Piqué, E. Dependence of nanoindentation hardness with crystallographic orientation of austenite grains in metastable stainless steels. Mater. Sci. Eng. A 2015, 645, 188–195. [Google Scholar] [CrossRef]

- Liu, L.; Ding, Q.; Zhong, Y.; Zou, J.; Wu, J.; Chiu, Y.L.; Shen, Z. Dislocation network in additive manufactured steel breaks strength–ductility trade-off. Mater. Today 2018, 21, 354–361. [Google Scholar] [CrossRef] [Green Version]

- Heidarzadeh, A.; Neikter, M.; Enikeev, N.; Cui, L.; Forouzan, F.; Mousavian, R.T. Post-treatment of additively manufactured Fe–Cr–Ni stainless steels by high pressure torsion: TRIP effect. Mater. Sci. Eng. A 2021, 811, 141086. [Google Scholar] [CrossRef]

- Tromas, C.; Stinville, J.C.; Templier, C.; Villechaise, P. Hardness and elastic modulus gradients in plasma-nitrided 316L polycrystalline stainless steel investigated by nanoindentation tomography. Acta Mater. 2012, 60, 1965–1973. [Google Scholar] [CrossRef]

- Furnémont, Q.; Kempf, M.; Jacques, P.J.; Göken, M.; Delannay, F. On the measurement of the nanohardness of the constitutive phases of TRIP-assisted multiphase steels. Mater. Sci. Eng. A 2002, 328, 26–32. [Google Scholar] [CrossRef]

- Taylor, M.D.; Choi, K.S.; Sun, X.; Matlock, D.K.; Packard, C.E.; Xu, L.; Barlat, F. Correlations between nanoindentation hardness and macroscopic mechanical properties in DP980 steels. Mater. Sci. Eng. A 2014, 597, 431–439. [Google Scholar] [CrossRef]

- Sun, S.J.; Tian, Y.Z.; An, X.H.; Lin, H.R.; Wang, J.W.; Zhang, Z.F. Ultrahigh cryogenic strength and exceptional ductility in ultrafine-grained CoCrFeMnNi high-entropy alloy with fully recrystallized structure. Mater. Today Nano 2018, 4, 46–53. [Google Scholar] [CrossRef]

| Element | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe | O |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Powder | 0.014 | 1.69 | 0.70 | 0.014 | 0.004 | 17.8 | 2.38 | 12.5 | 0.09 | Bal | 165 ppm |

| L-PBF | 0.008 | 1.43 | 0.49 | 0.015 | 0.007 | 18.04 | 2.59 | 11.77 | 0.074 | Bal | Not measured |

| Processing Parameters | Contents |

|---|---|

| Powder size | 10–45 μm |

| Building atmosphere | Argon |

| Build direction | Horizontal |

| Scanning speed | 900 mm/s |

| Hatching distance | 0.06 mm |

| Layer thickness | 30 μm |

| Laser power | 195 W |

| Scanning strategy | Meander |

| Alloy | Test Temperature | YS (MPa) | UTS (MPa) | Elongation (%) |

|---|---|---|---|---|

| 316 L specimen 1 | Room Temperature | 570 | 660 | 51 |

| 316 L specimen 2 | Room Temperature | 594 | 689 | 49 |

| 316 L specimen 3 | −196 °C | 751 | 1403 | 41 |

| 316 L specimen 4 | −196 °C | 770 | 1113 | 16 |

| Material | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation % | Temperature Condition | Method | References |

|---|---|---|---|---|---|---|

| 316 L | 554 | 685 | 36 | RT | L-PBF | [4] |

| 316 L | 590 | 700 | 36 | RT | L-PBF | [6] |

| 316 L | 450 | 640 | 59 | RT | L-PBF | [6] |

| 316 L | 499 | 564 | 35 | RT | L-PBF | [14] |

| 316 L | 726 | 1083 | 53 | 77K | L-PBF | [14] |

| 316 L | 314 | 1235 | 49 | 77K | Conventional | [15] |

| 316 L | 216 | 529 | 65 | RT | Conventional | [15] |

| 316 | 590 | 1196 | 33 | 113K | Conventional | [18] |

| 316 | 494 | 1328 | 38 | 113K | Conventional | [18] |

| 316 L | 220 | 520 | 40 | RT | Conventional | [32] |

| 316 L | 270 | 680 | 45 | RT | Conventional | [32] |

| 316 L | 663 | 685 | 25 | RT | L-PBF | [32] |

| 316 L | 602 | 664 | 30 | RT | L-PBF | [32] |

| 316 L | 557 | 591 | 42 | RT | L-PBF | [32] |

| 316 L | 555 | 684 | 50.7 | RT | L-PBF | [34] |

| 316 L | 561 | 688 | 50.9 | RT | L-PBF | [34] |

| 316 L | 487 | 594 | 49 | RT | L-PBF | [35] |

| 316 L | 456 | 703 | 45 | RT | L-PBF | [36] |

| 316 L | 496 | 717 | 28 | RT | L-PBF | [37] |

| 316 L | 345 | 563 | 30 | RT | Conventional | [37] |

| 316L | 310 | 620 | 30 | RT | Conventional | [38] |

| 316L | 468 | 600 | 33 | RT | Conventional | [39] |

| Alloy | HV0.1 |

|---|---|

| Specimen 1 (RT) | 651 ± 19 |

| Specimen 3 (−196 °C) | 1046 ± 87 |

| Specimen 4 (−196 °C) | 735 ± 69 |

| Specimen 5 (As-built condition) | 439 ± 27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mishra, P.; Åkerfeldt, P.; Forouzan, F.; Svahn, F.; Zhong, Y.; Shen, Z.J.; Antti, M.-L. Microstructural Characterization and Mechanical Properties of L-PBF Processed 316 L at Cryogenic Temperature. Materials 2021, 14, 5856. https://doi.org/10.3390/ma14195856

Mishra P, Åkerfeldt P, Forouzan F, Svahn F, Zhong Y, Shen ZJ, Antti M-L. Microstructural Characterization and Mechanical Properties of L-PBF Processed 316 L at Cryogenic Temperature. Materials. 2021; 14(19):5856. https://doi.org/10.3390/ma14195856

Chicago/Turabian StyleMishra, Pragya, Pia Åkerfeldt, Farnoosh Forouzan, Fredrik Svahn, Yuan Zhong, Zhijian James Shen, and Marta-Lena Antti. 2021. "Microstructural Characterization and Mechanical Properties of L-PBF Processed 316 L at Cryogenic Temperature" Materials 14, no. 19: 5856. https://doi.org/10.3390/ma14195856