Fabrication of Ultra-Fine-Grained W-TiC Alloys by a Simple Ball-Milling and Hydrogen Reduction Method

Abstract

:1. Introduction

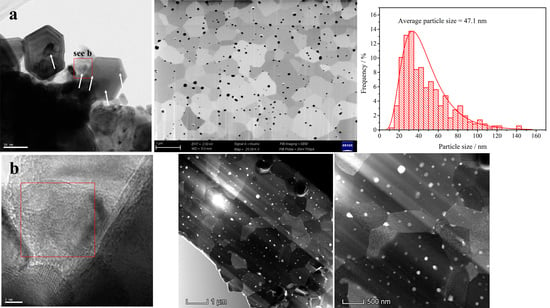

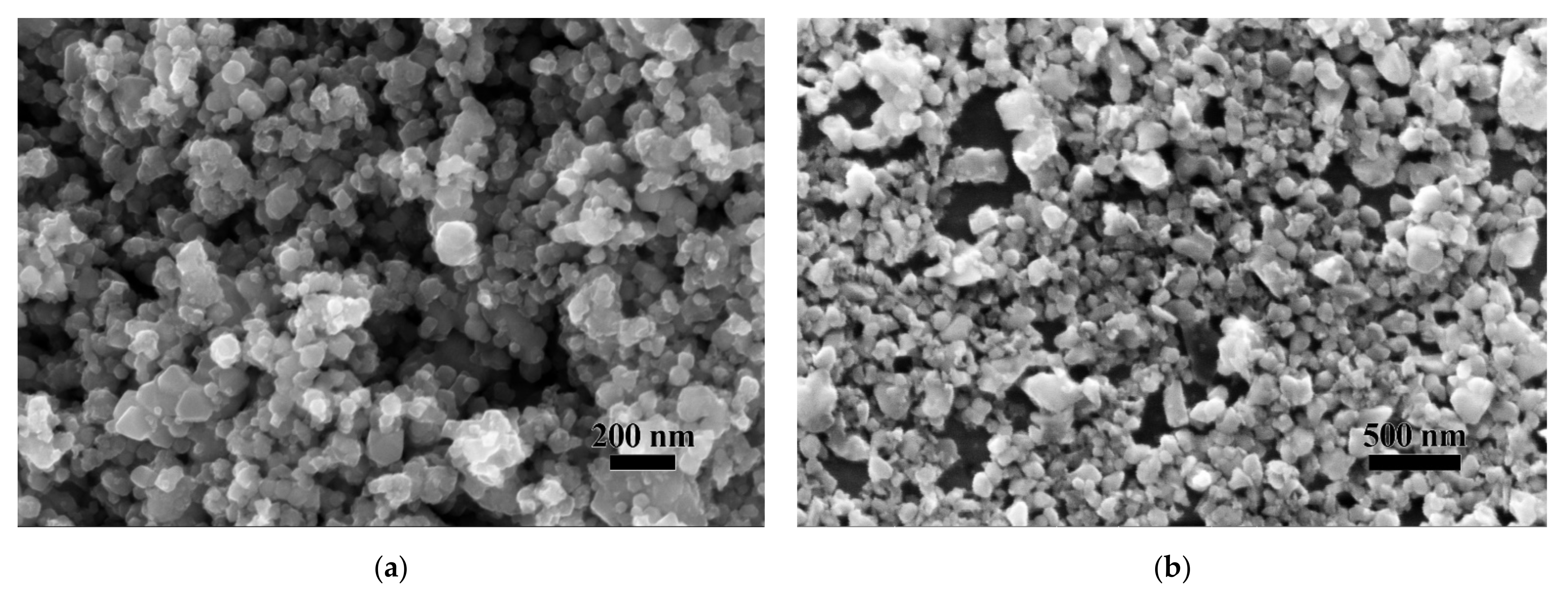

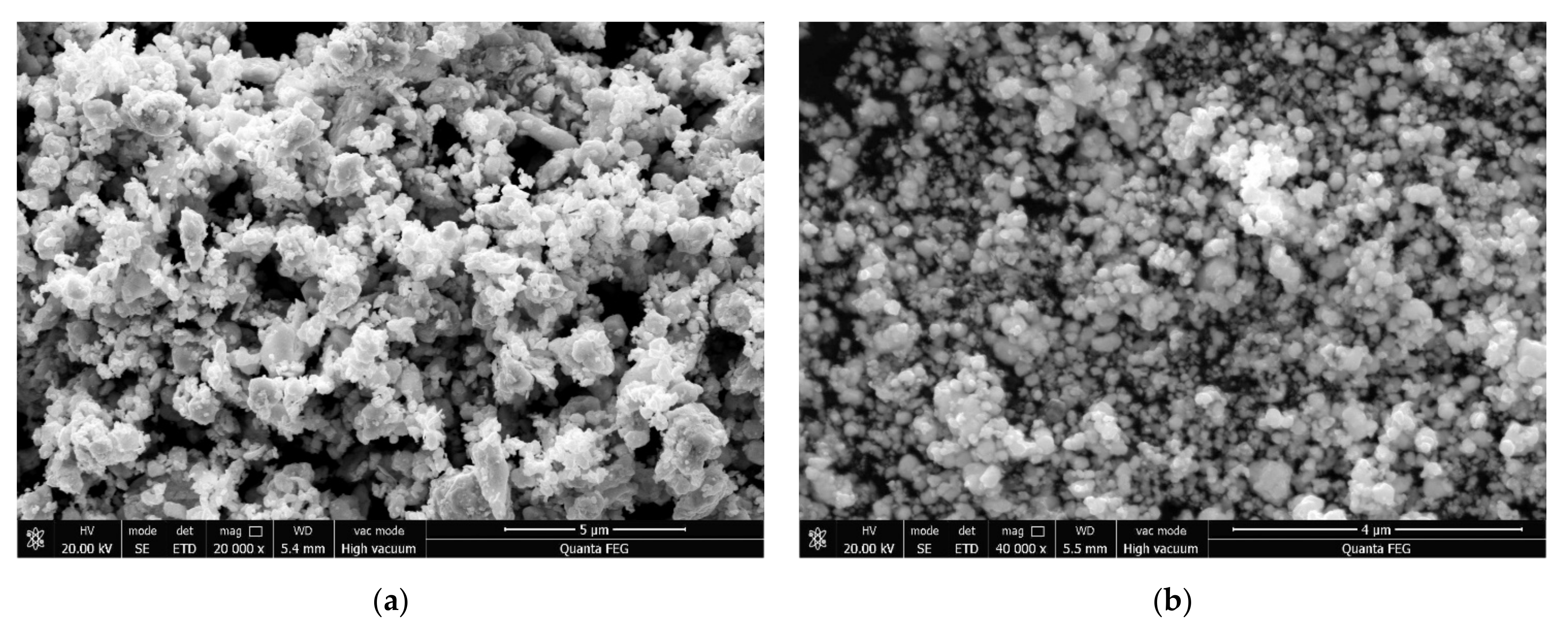

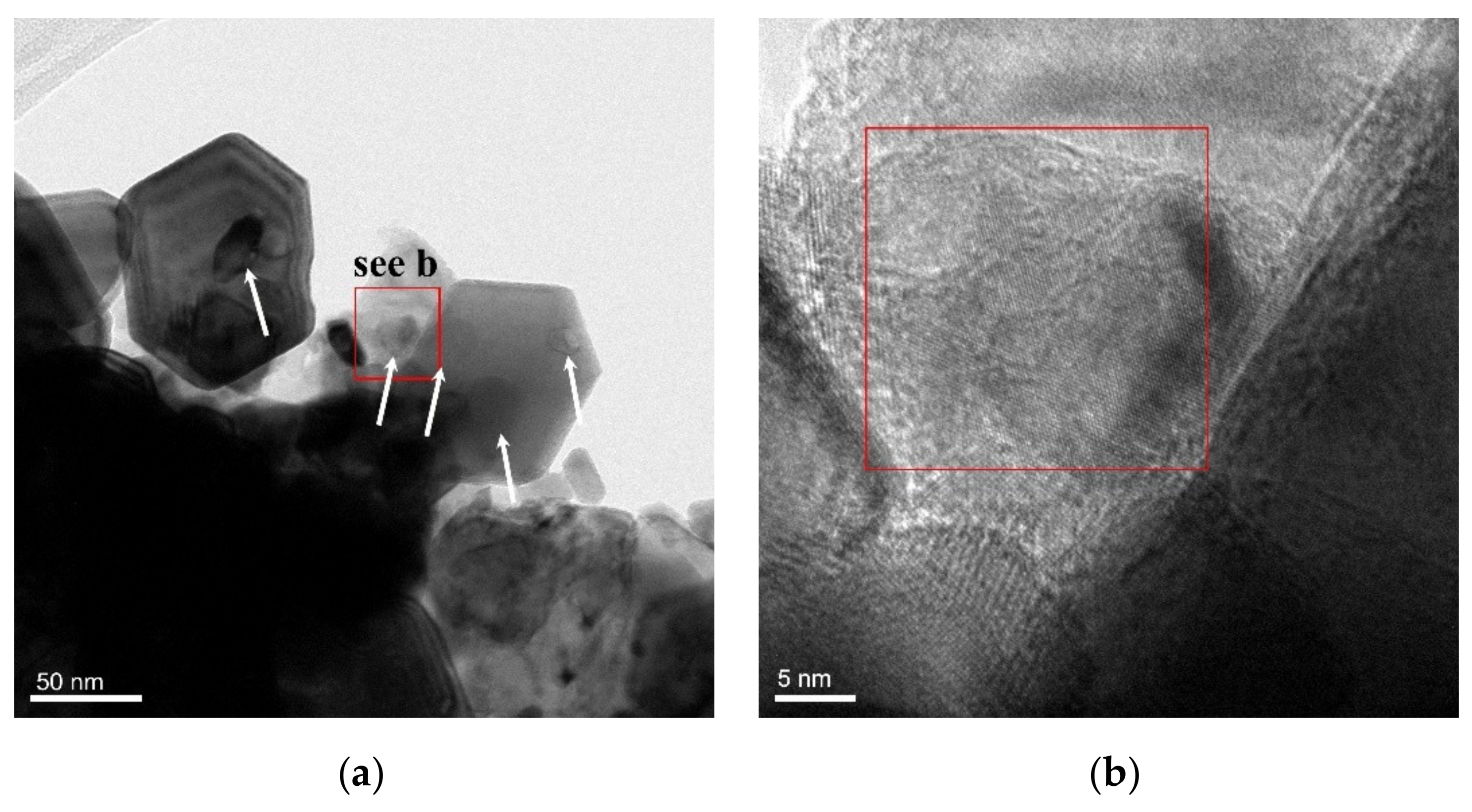

2. Materials and Methods

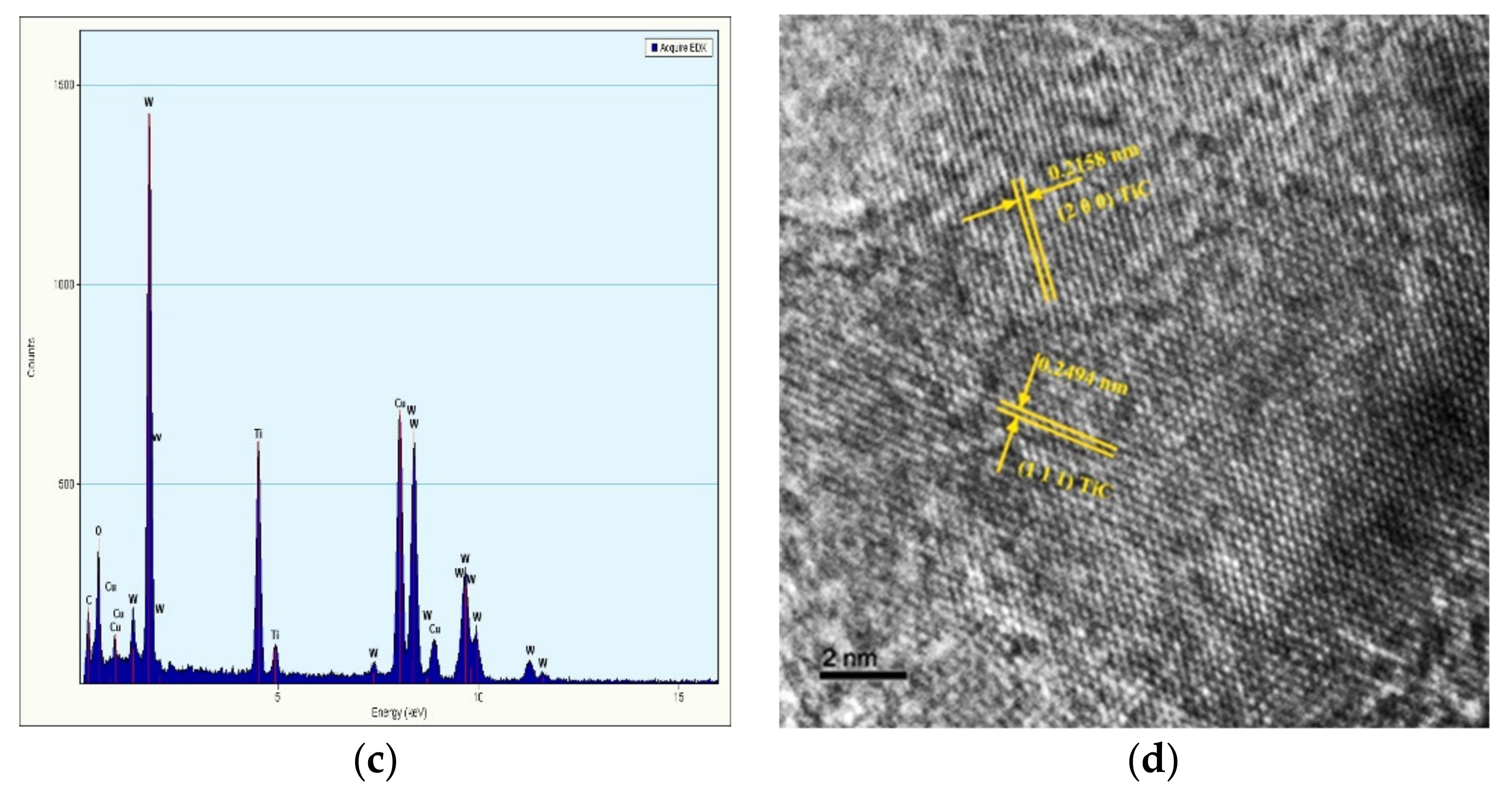

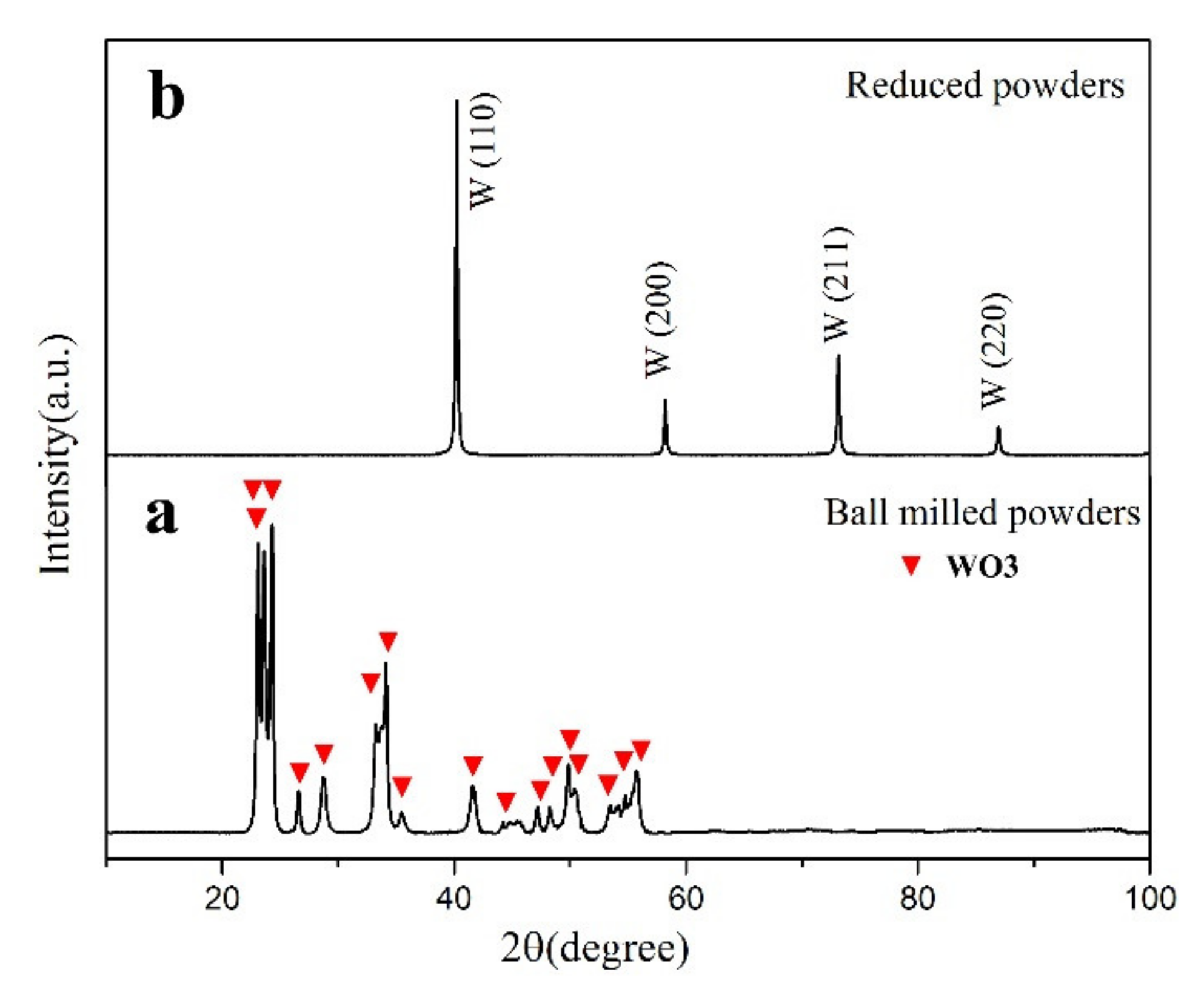

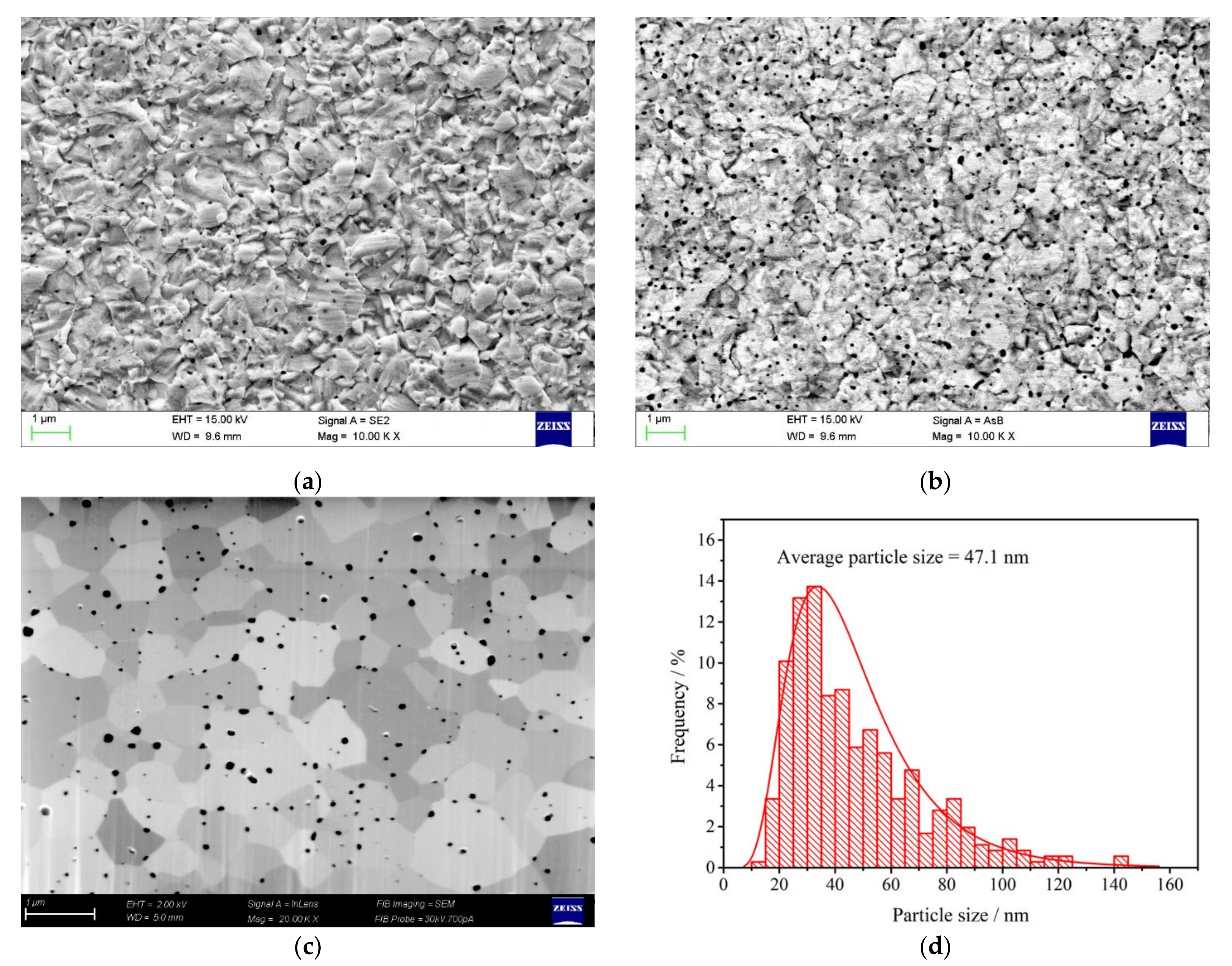

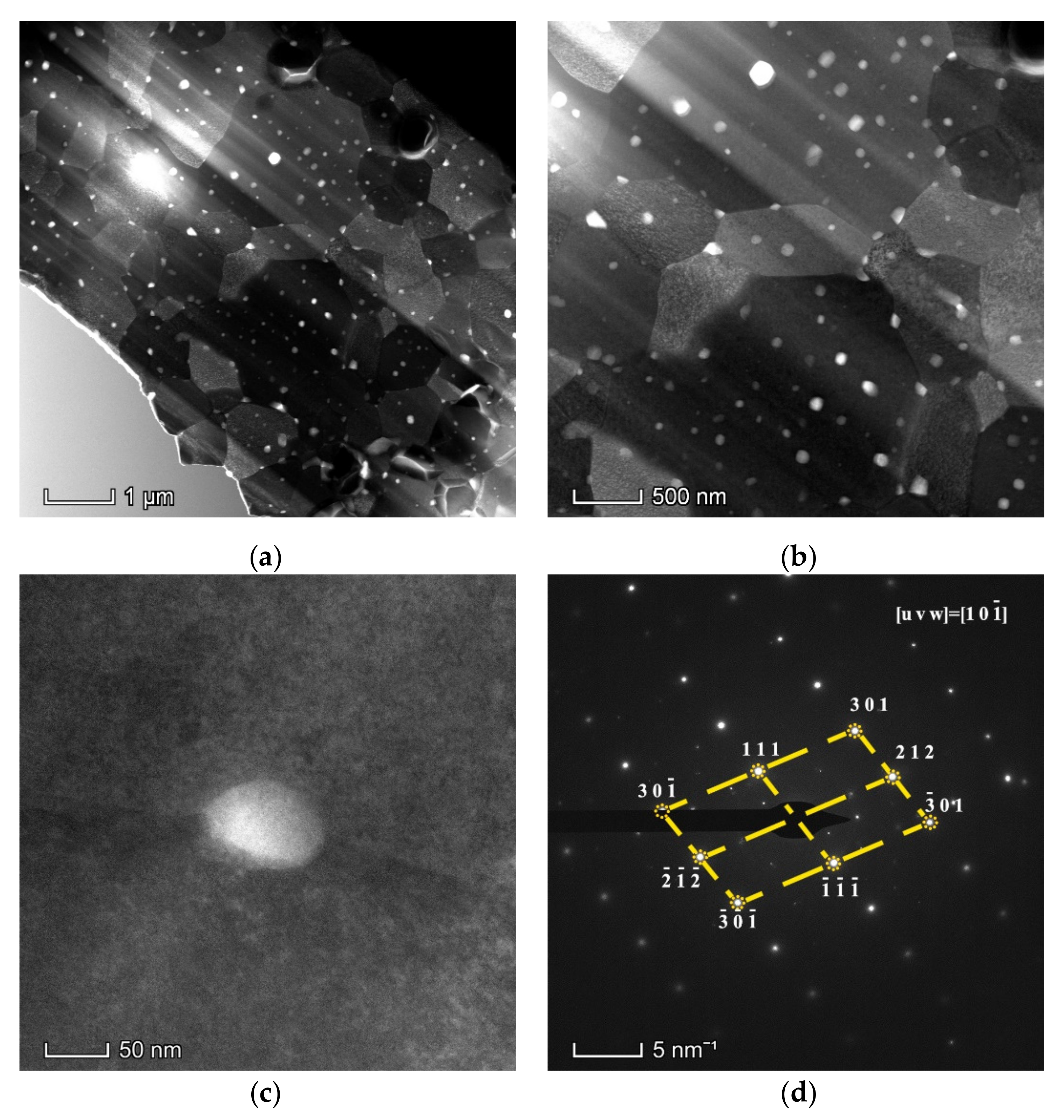

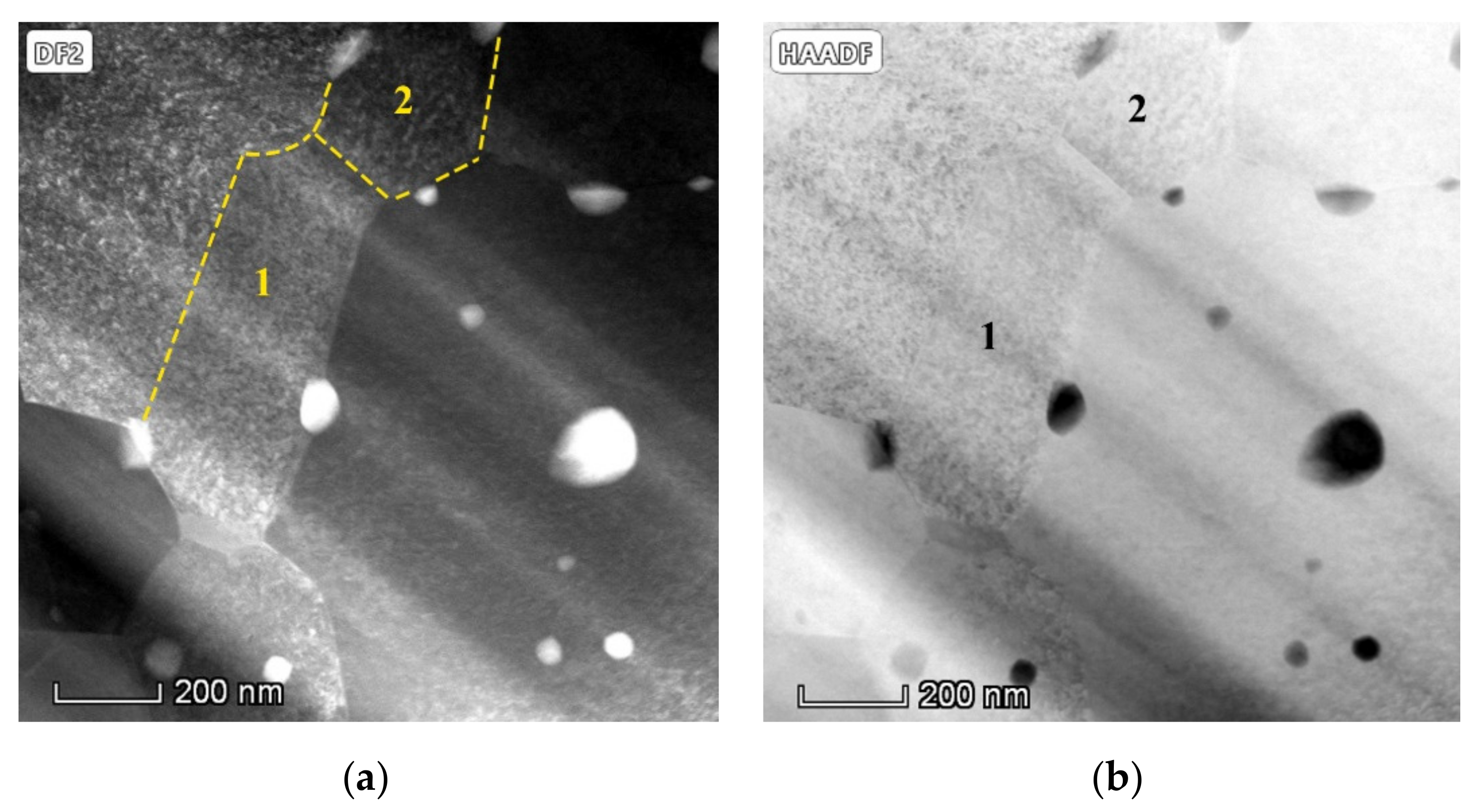

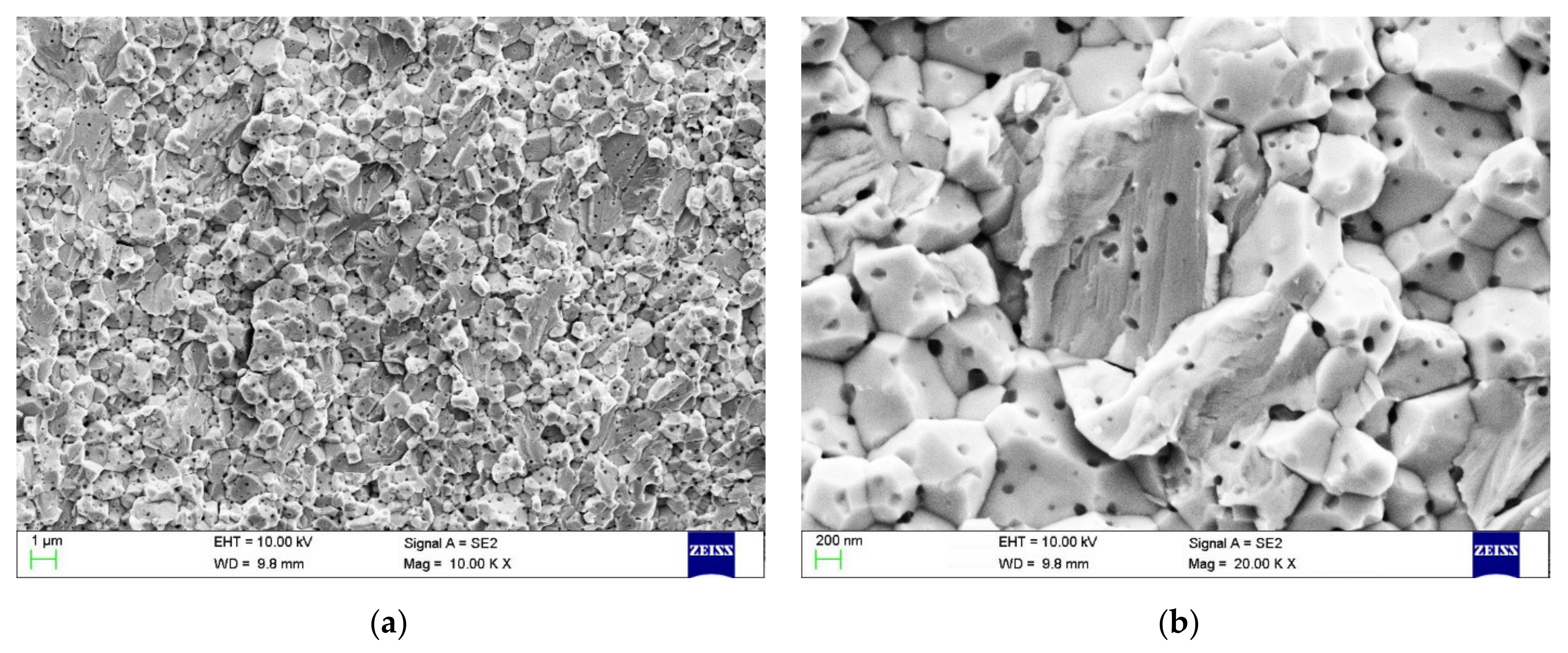

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, Z.; Xu, G.; Suo, J. Effect of Transition Layer on Properties of Tungsten-Tantalum (W-Ta) Laminated Composite. Metals 2020, 10, 558. [Google Scholar] [CrossRef]

- Li, J.; Wu, Y.; Zhou, B.; Wei, Z. Laser Powder Bed Fusion of Pure Tungsten: Effects of Process Parameters on Morphology, Densification, Microstructure. Materials 2020, 14, 165. [Google Scholar] [CrossRef]

- Zhang, H.; Ge, L.; Shi, M.; Ren, P. Densification behavior, mechanical properties and thermal shock resistance of tungsten alloys fabricated at low temperature. Mater. Des. 2014, 58, 290–297. [Google Scholar] [CrossRef]

- Fang, Z.Z.; Ren, C.; Simmons, M.; Sun, P. The effect of Ni doping on the mechanical behavior of tungsten. Int. J. Refract. Met. Hard Mater. 2020, 92, 105281. [Google Scholar] [CrossRef]

- Jiang, D.Y.; Ouyang, C.Y.; Liu, S.Q. Mechanical properties of W–Ti alloys from first-principles calculations. Fusion Eng. Des. 2016, 106, 34–39. [Google Scholar] [CrossRef]

- Hu, Z.; Zhao, Y.; Guan, K.; Wang, Z.; Ma, Z. Pure tungsten and oxide dispersion strengthened tungsten manufactured by selective laser melting: Microstructure and cracking mechanism. Addit. Manuf. 2020, 36, 101579. [Google Scholar] [CrossRef]

- Terentyev, D.; Dubinko, A.; Riesch, J.; Lebediev, S.; Volkov, I.; Zhurkin, E. Performance of tungsten fibers for Wf/W composites under cyclic tensile load. Int. J. Refract. Met. Hard Mater. 2019, 86, 105094. [Google Scholar] [CrossRef]

- Tian, X.F.; Gong, M.; Zhang, P.Y.; Yu, K. Study of the defect evolution in hydrogen/helium mixture beam irradiated W-ZrC alloy using positron annihilation spectroscopy. Acta Met. Sin. 2021, 57, 121–128. [Google Scholar] [CrossRef]

- He, B.; Huang, B.; Xiao, Y.; Lian, Y.; Liu, X.; Tang, J. Preparation and thermal shock characterization of yttrium doped tungsten-potassium alloy. J. Alloy. Compd. 2016, 686, 298–305. [Google Scholar] [CrossRef]

- Xie, Z.; Liu, R.; Miao, S.; Yang, X.D.; Zhang, T.; Wang, X.P.; Fang, Q.F.; Liu, C.S.; Luo, G.N.; Lian, Y.Y.; et al. Extraordinary high ductility/strength of the interface designed bulk W-ZrC alloy plate at relatively low temperature. Sci. Rep. 2015, 5, 16014. [Google Scholar] [CrossRef]

- Mudanyi, R.K.; Cramer, C.L.; Elliott, A.M.; Unocic, K.A.; Guo, Q.; Kumar, D. W-ZrC composites prepared by reactive melt infiltration of Zr2Cu alloy into binder jet 3D printed WC preforms. Int. J. Refract. Met. Hard Mater. 2020, 94, 105411. [Google Scholar] [CrossRef]

- Hu, W.; Kong, X.; Du, Z.; Khan, A.; Ma, Z. Synthesis and characterization of nano TiC dispersed strengthening W alloys via freeze-drying. J. Alloy. Compd. 2020, 859, 157774. [Google Scholar] [CrossRef]

- Kurishita, H.; Amano, Y.; Kobayashi, S.; Nakai, K.; Arakawa, H.; Hiraoka, Y.; Takida, T.; Takebe, K.; Matsui, H. Development of ultra-fine grained W–TiC and their mechanical properties for fusion applications. J. Nucl. Mater. 2007, 367, 1453–1457. [Google Scholar] [CrossRef]

- Kurishita, H.; Matsuo, S.; Arakawa, H.; Narui, M.; Yamazaki, M.; Sakamoto, T.; Kobayashi, S.; Nakai, K.; Takida, T.; Takebe, K.; et al. High temperature tensile properties and their application to toughness enhancement in ultra-fine grained W-(0–15)wt% TiC. J. Nucl. Mater. 2009, 386, 579–582. [Google Scholar] [CrossRef]

- Kurishita, H.; Matsuo, S.; Arakawa, H.; Sakamoto, T.; Kobayashi, S.; Nakai, K.; Takida, T.; Kato, M.; Kawai, M.; Yoshida, N. Development of re-crystallized W–1.1%TiC with enhanced room-temperature ductility and radiation performance. J. Nucl. Mater. 2010, 398, 87–92. [Google Scholar] [CrossRef]

- Lang, S.; Yan, Q.; Sun, N.; Zhang, X.; Deng, L.; Wang, Y.; Ge, C. Microstructure, basic thermal–mechanical and Charpy impact properties of W-0.1 wt.% TiC alloy via chemical method. J. Alloy. Compd. 2016, 660, 184–192. [Google Scholar] [CrossRef]

- Lang, S.; Yan, Q.; Sun, N.; Zhang, X.; Ge, C. Effects of TiC content on microstructure, mechanical properties, and thermal conductivity of W-TiC alloys fabricated by a wet-chemical method. Fusion Eng. Des. 2017, 121, 366–372. [Google Scholar] [CrossRef]

- Wang, Y.; Xie, Z.; Wang, M.; Deng, H.; Yang, J.; Jiang, Y.; Zhang, T.; Wang, X.; Fang, Q.; Liu, C. The superior thermal stability and tensile properties of hot rolled W-HfC alloys. Int. J. Refract. Met. Hard Mater. 2019, 81, 42–48. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, Q. Morphology evolution of La2O3 and crack characteristic in W–La2O3 alloy under transient heat loading. J. Nucl. Mater. 2014, 451, 283–291. [Google Scholar] [CrossRef]

- Xu, Q.; Ding, X.; Luo, L.; Miyamoto, M.; Tokitani, M.; Zhang, J.; Wu, Y. D 2 retention and microstructural evolution during He irradiation in candidate plasma facing material W-La 2 O 3 alloy. J. Nucl. Mater. 2017, 496, 227–233. [Google Scholar] [CrossRef]

- Zhao, M.; Zhou, Z.; Zhong, M.; Tan, J.; Lian, Y.; Liu, X. Thermal shock behavior of fine grained W–Y 2 O 3 materials fabricated via two different manufacturing technologies. J. Nucl. Mater. 2015, 470, 236–243. [Google Scholar] [CrossRef]

- Lang, E.; Madden, N.; Smith, C.; Krogstad, J.; Allain, J. Microstructural and compositional effects of transition metal carbide additions on dispersion-strengthened tungsten fabricated via spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2018, 75, 279–286. [Google Scholar] [CrossRef]

- Song, G.-M.; Wang, Y.-J.; Zhou, Y. Thermomechanical properties of TiC particle-reinforced tungsten composites for high temperature applications. Int. J. Refract. Met. Hard Mater. 2003, 21, 1–12. [Google Scholar] [CrossRef]

- Xie, Z.; Liu, R.; Miao, S.; Yang, X.; Zhang, T.; Fang, Q.; Wang, X.; Liu, C.; Lian, Y.; Liu, X.; et al. High thermal shock resistance of the hot rolled and swaged bulk W–ZrC alloys. J. Nucl. Mater. 2015, 469, 209–216. [Google Scholar] [CrossRef]

- Ishijima, Y.; Kannari, S.; Kurishita, H.; Hasegawa, M.; Hiraoka, Y.; Takida, T.; Takebe, K. Processing of fine-grained W materials without detrimental phases and their mechanical properties at 200–432K. Mater. Sci. Eng. A 2008, 473, 7–15. [Google Scholar] [CrossRef]

- Lu, K.; Lu, L.; Suresh, S. Strengthening Materials by Engineering Coherent Internal Boundaries at the Nanoscale. Science 2009, 324, 349–352. [Google Scholar] [CrossRef] [Green Version]

- Xie, X.; Jing, K.; Xie, Z.; Liu, R.; Yang, J.; Fang, Q.; Liu, C.; Wu, X. Mechanical properties and microstructures of W–TiC and W–Y2O3 alloys fabricated by hot-pressing sintering. Mater. Sci. Eng. A 2021, 819, 141496. [Google Scholar] [CrossRef]

- Xia, M.; Yan, Q.; Xu, L.; Zhu, L.; Guo, H.; Ge, C. Synthesis of TiC/W core–shell nanoparticles by precipitate-coating process. J. Nucl. Mater. 2012, 430, 216–220. [Google Scholar] [CrossRef]

- Liu, R.; Wang, X.; Hao, T.; Liu, C.; Fang, Q. Characterization of ODS-tungsten microwave-sintered from sol–gel prepared nano-powders. J. Nucl. Mater. 2014, 450, 69–74. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, L.; Wei, S.; Pan, K.; Aindow, M.; Yang, Y. Microstructure and preparation of an ultra-fine-grained W-Al 2 O 3 composite via hydrothermal synthesis and spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2018, 72, 149–156. [Google Scholar] [CrossRef]

- Lang, S.-T.; Yan, Q.-Z.; Sun, N.-B.; Zhang, X.-X. Preparation of W–TiC alloys from core–shell structure powders synthesized by an improved wet chemical method. Rare Met. 2018, 1–9. [Google Scholar] [CrossRef]

- Liu, N.; Dong, Z.; Ma, Z.; Yu, L.; Li, C.; Liu, C.; Guo, Q.; Liu, Y. Eliminating bimodal structures of W-Y2O3 composite nanopowders synthesized by wet chemical method via controlling reaction conditions. J. Alloy. Compd. 2018, 774, 122–128. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, G.J.; Jiang, F.; Ding, X.; Sun, Y.J.; Sun, J.; Ma, E. Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility. Nat. Mater. 2013, 12, 344–350. [Google Scholar] [CrossRef]

- Lang, S.; Yan, Q.; Sun, N.; Zhang, X.; Ge, C. Microstructures, Mechanical Properties and Thermal Conductivities of W-0.5 wt.%TiC Alloys Prepared via Ball Milling and Wet Chemical Method. J. Miner. Met. Mater. Soc. 2017, 69, 1992–1996. [Google Scholar] [CrossRef]

- Tan, J.; Zhou, Z.; Qu, D.; Ma, Y.; Li, M. Fabrication of ultra fine grained W-TiC composites by spark plasma sintering. Rare Met. Mater. Eng. 2011, 40, 1990–1993. [Google Scholar]

- Munoz, A.; Savoini, B.; Tejado, E.; Monge, M.A.; Pastor, J.Y.; Pareja, R. Microstructural and mechanical characteristics of W–2Ti and W–1TiC processed by hot isostatic pressing. J. Nucl. Mater. 2014, 455, 306–310. [Google Scholar] [CrossRef] [Green Version]

- Ueda, Y.; Schmid, K.; Balden, M.; Coenen, J.; Loewenhoff, T.; Ito, A.; Hasegawa, A.; Hardie, C.; Porton, M.; Gilbert, M. Baseline high heat flux and plasma facing materials for fusion. Nucl. Fusion 2017, 57, 092006. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Liu, W.; Xu, Y.; Liu, C.; Pan, B.; Liang, Y.; Fang, Q.; Chen, J.-L.; Luo, G.-N.; Lu, G.-H.; et al. Radiation resistance of nano-crystalline iron: Coupling of the fundamental segregation process and the annihilation of interstitials and vacancies near the grain boundaries. Acta Mater. 2016, 109, 115–127. [Google Scholar] [CrossRef]

- Li, X.; Liu, W.; Xu, Y.; Liu, C.; Fang, Q.; Pan, B.; Wang, Z. Energetic and kinetic behaviors of small vacancy clusters near a symmetric Σ5(310)/[001] tilt grain boundary in bcc Fe. J. Nucl. Mater. 2013, 440, 250–256. [Google Scholar] [CrossRef]

| Sample | Synthesis Method | Average Grain Size (μm) | Relative Density (%) | Micro Hardness (Hv0.2) | Bending Strength (MPa) |

|---|---|---|---|---|---|

| W-0.5TiC (this work) | ball-milling + hydrogen reduction + SPS | 0.7 | 97.65 | 785 | 1132.7 |

| W-0.5TiC-wc [34] | wet-chemical method + SPS | 0.91 | 97.61 | 739.10 | 1065.72 |

| W-0.5TiC-bm [34] | ball-milling + SPS | 0.80 | 97.37 | 753.05 | 705.87 |

| W-0.5TiC [35] | high-energy ball-milling + SPS | 0.5 | 98.6 | 655.10 | 1021 |

| W-1.0TiC [36] | mechanical alloying + HIP | ~1.0 | 95.3 | 714.28 | ~800 |

| W-0.5TiC [13] | mechanical alloying + HIP | 0.129 | ~99 | - | 1600–2000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lang, S.; Sun, N.; Cao, J.; Yu, W.; Yang, Z.; Hou, S. Fabrication of Ultra-Fine-Grained W-TiC Alloys by a Simple Ball-Milling and Hydrogen Reduction Method. Materials 2021, 14, 5865. https://doi.org/10.3390/ma14195865

Lang S, Sun N, Cao J, Yu W, Yang Z, Hou S. Fabrication of Ultra-Fine-Grained W-TiC Alloys by a Simple Ball-Milling and Hydrogen Reduction Method. Materials. 2021; 14(19):5865. https://doi.org/10.3390/ma14195865

Chicago/Turabian StyleLang, Shaoting, Ningbo Sun, Junhui Cao, Weixin Yu, Zhijun Yang, and Shusen Hou. 2021. "Fabrication of Ultra-Fine-Grained W-TiC Alloys by a Simple Ball-Milling and Hydrogen Reduction Method" Materials 14, no. 19: 5865. https://doi.org/10.3390/ma14195865

APA StyleLang, S., Sun, N., Cao, J., Yu, W., Yang, Z., & Hou, S. (2021). Fabrication of Ultra-Fine-Grained W-TiC Alloys by a Simple Ball-Milling and Hydrogen Reduction Method. Materials, 14(19), 5865. https://doi.org/10.3390/ma14195865