Development of Co-Based Amorphous Composite Coatings Synthesized by Laser Cladding for Neutron Shielding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Powders and Coatings

2.2. Characterization of Powders and Coatings

2.3. Neutron Shielding Test

3. Results and Discussion

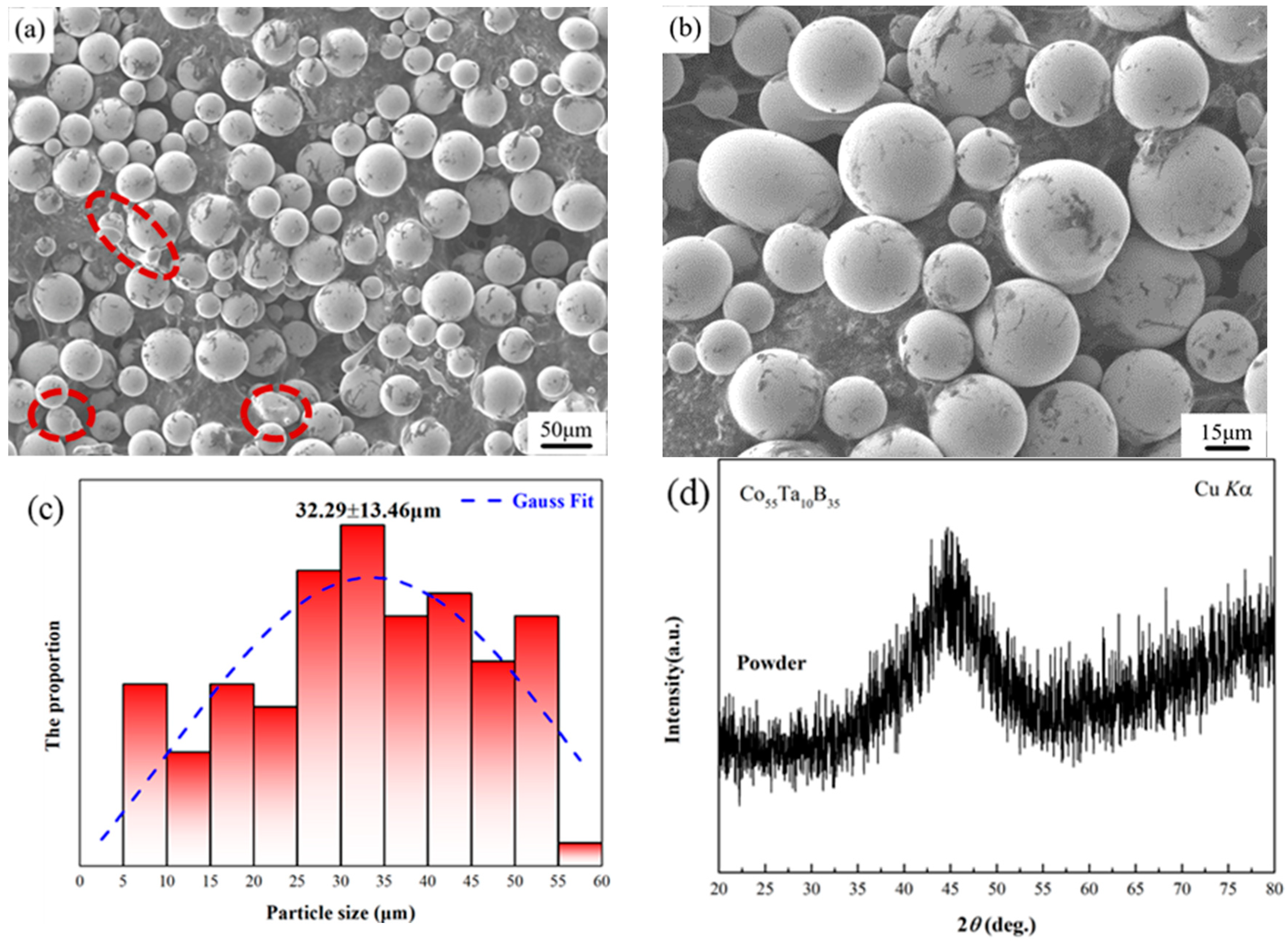

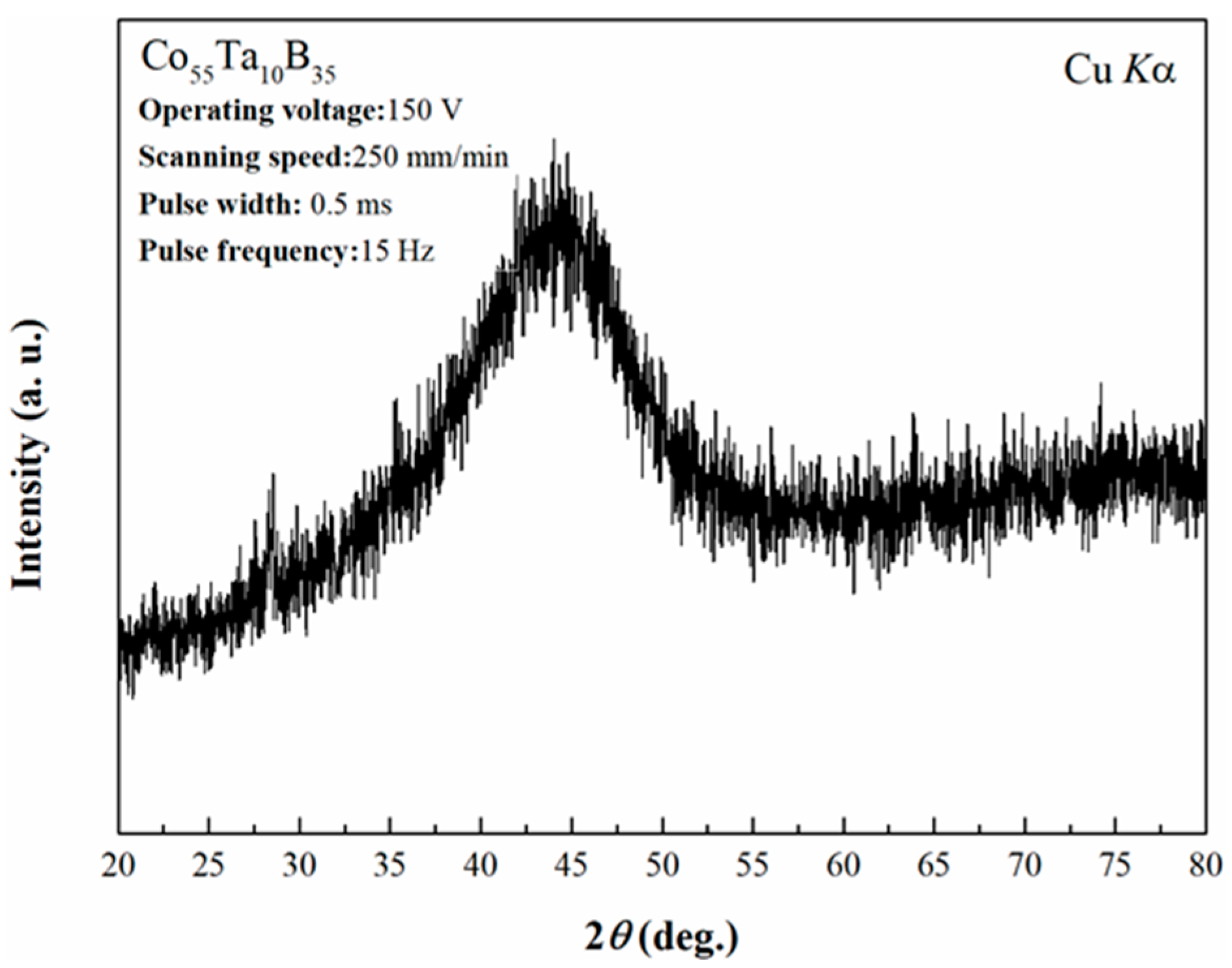

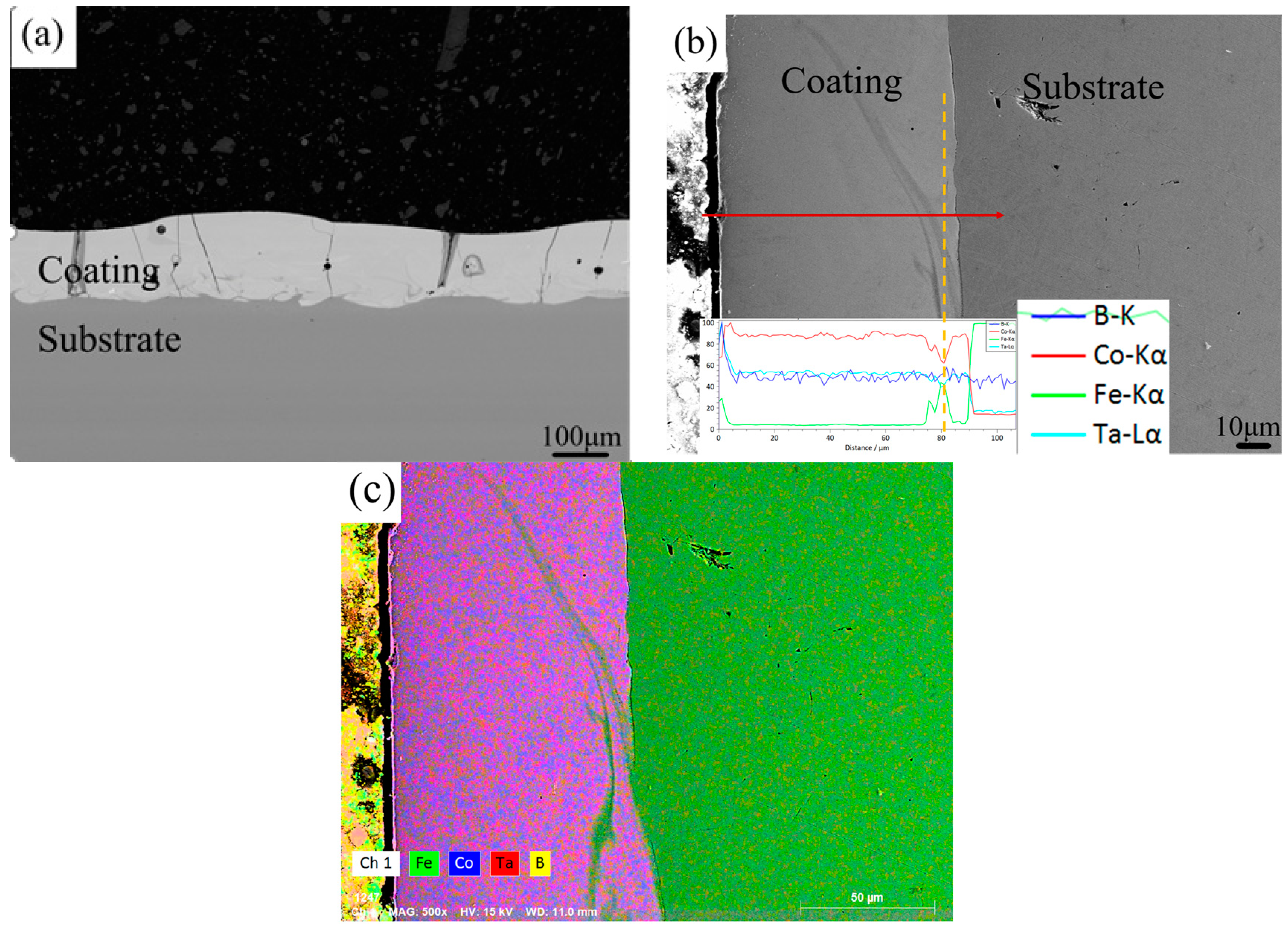

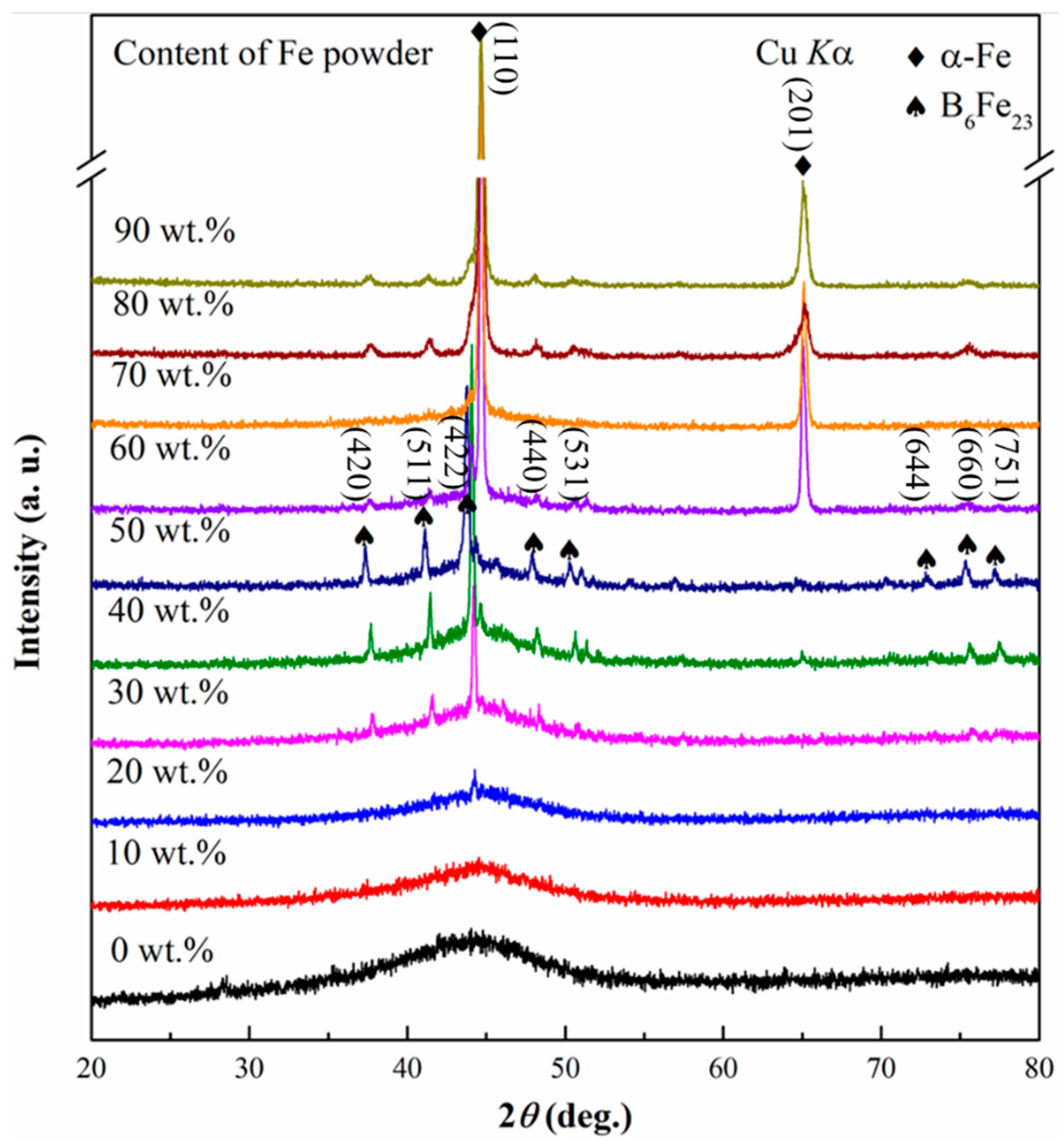

3.1. Characterization of Powders and Coatings

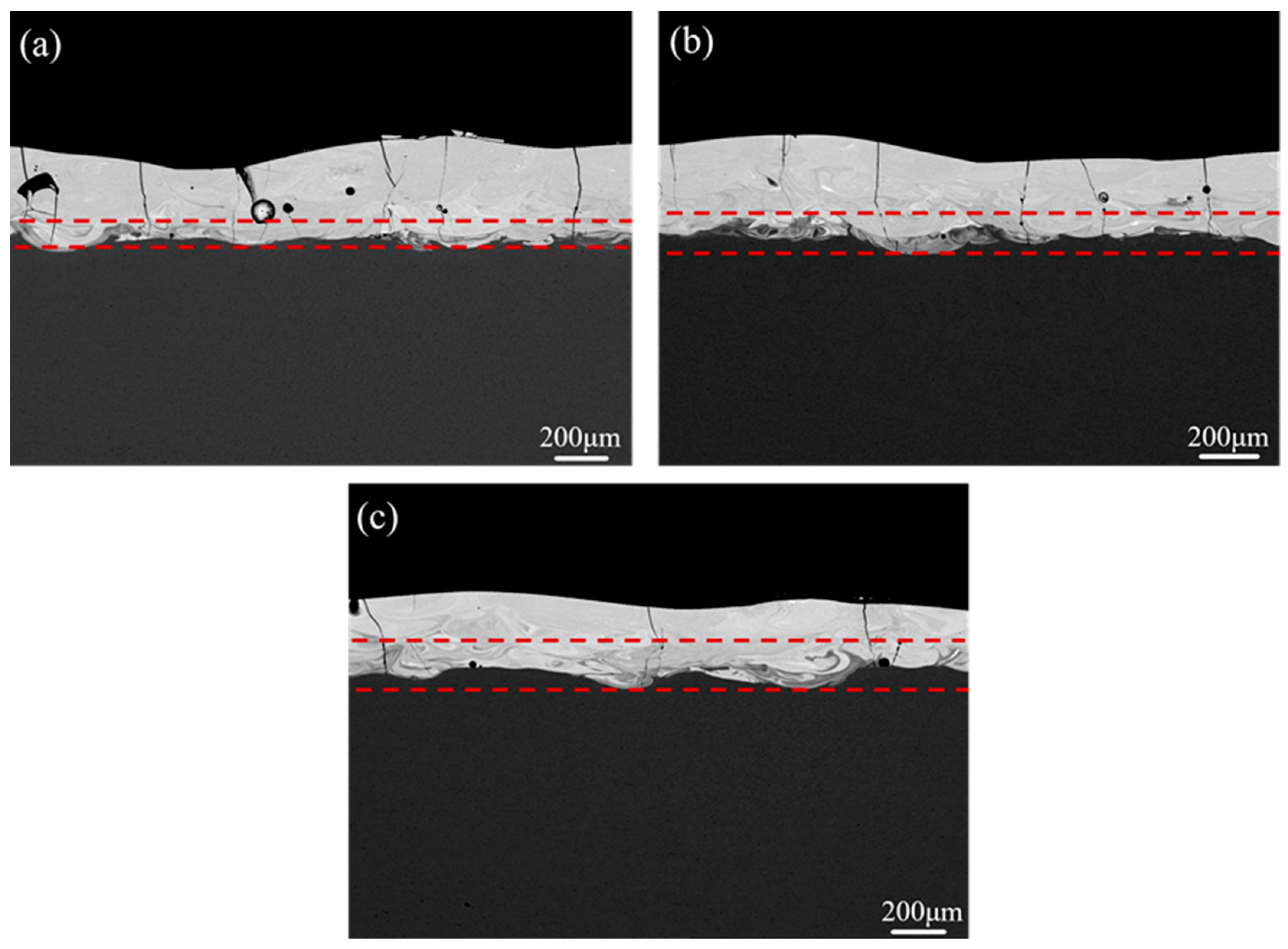

3.2. Investigation of Crack Control Methods

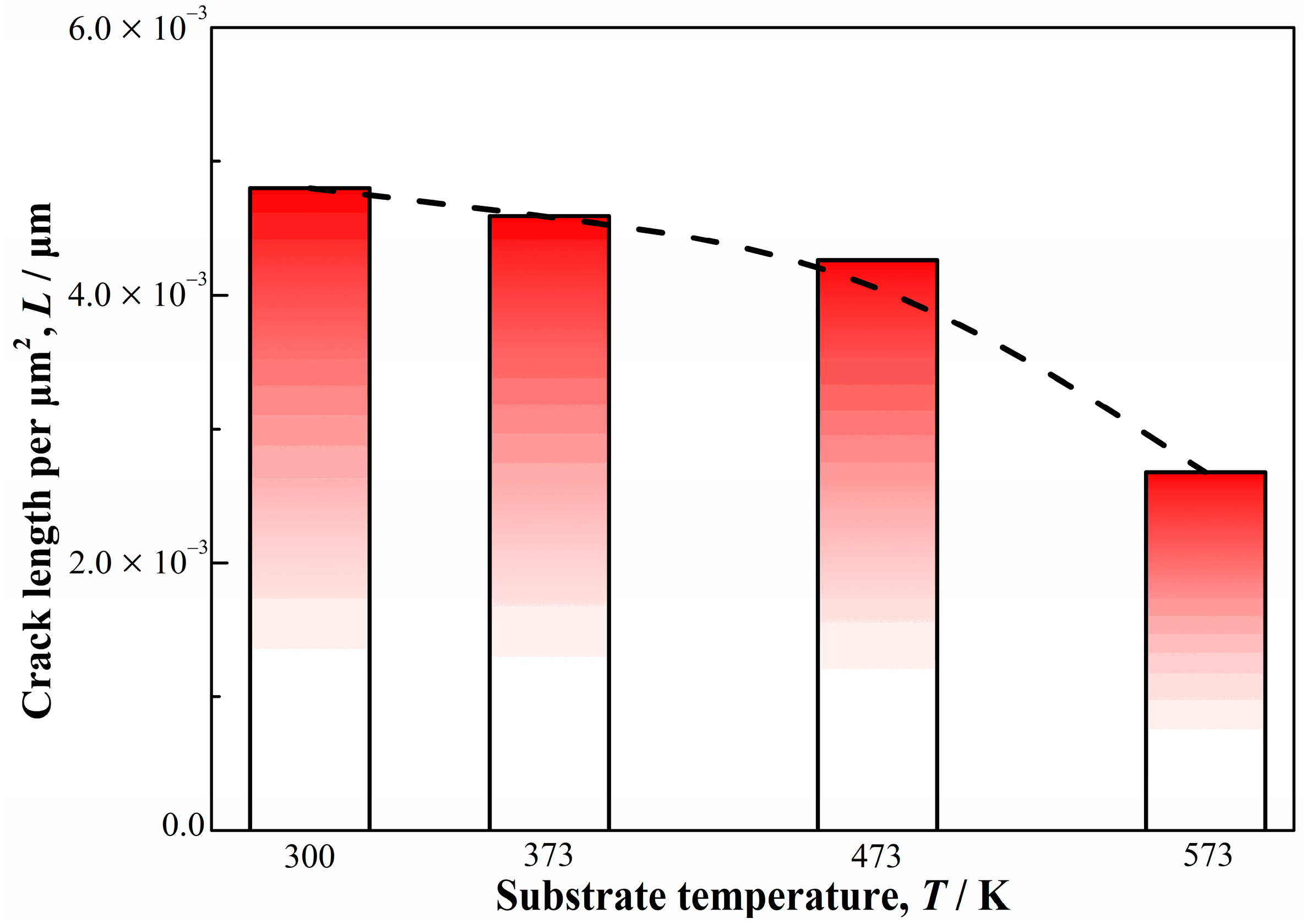

3.2.1. Effect of Substrate Temperature on Coating

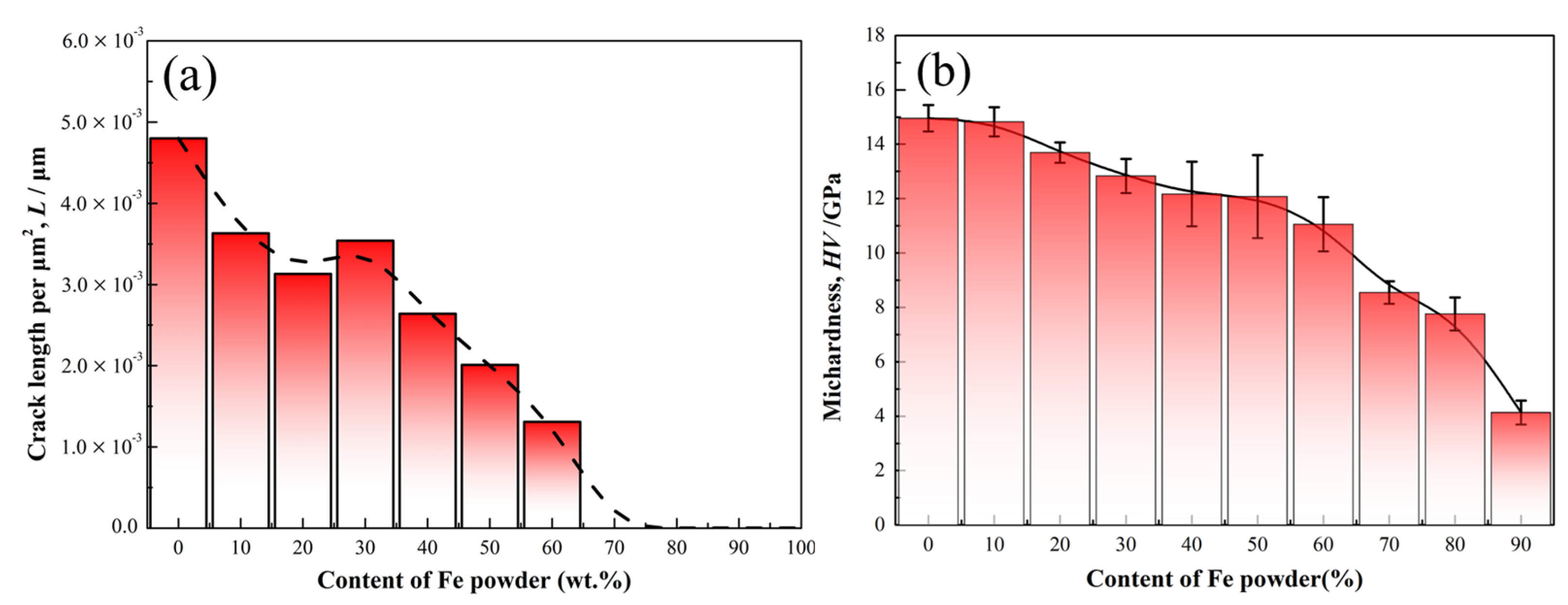

3.2.2. Fabrication of Composite Coatings with the Introduction of Fe Powder

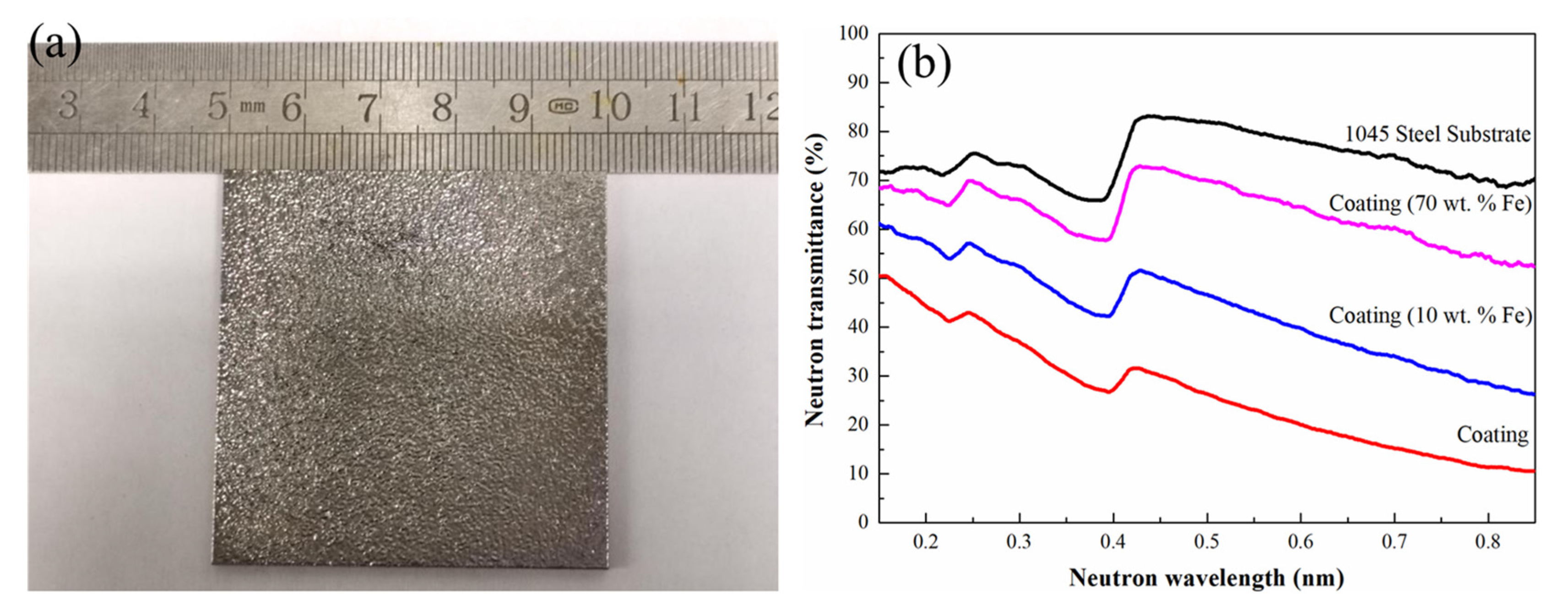

3.3. Neutron Shielding Performance Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ashby, M.; Greer, A. Metallic glasses as structural materials. Scr. Mater. 2006, 54, 321–326. [Google Scholar] [CrossRef]

- Wang, W. Elastic moduli and behaviors of metallic glasses. J. Non-Cryst. Solids 2005, 351, 1481–1485. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, G.; Wang, Y.; Li, H.; Qin, Z.; Lu, X. Crack-free Fe-based amorphous coating synthesized by laser cladding. Mater. Lett. 2018, 210, 46–50. [Google Scholar] [CrossRef]

- Yasir, M.; Zhang, C.; Wang, W.; Jia, Y.; Liu, L. Enhancement of impact resistance of Fe-based amorphous coating by Al2O3 dispersion. Mater. Lett. 2016, 171, 112–116. [Google Scholar] [CrossRef]

- Guo, S.; Pan, F.; Zhang, H.; Zhang, D.; Wang, J.; Miao, J.; Su, C.; Zhang, C. Fe-based amorphous coating for corrosion protection of magnesium alloy. Mater. Des. 2016, 108, 624–631. [Google Scholar] [CrossRef]

- Kobayashi, A.; Yano, S.; Kimura, H.; Inoue, A. Fe-based metallic glass coatings produced by smart plasma spraying process. Mater. Sci. Eng. B 2008, 148, 110–113. [Google Scholar] [CrossRef]

- Zhang, C.; Chu, Z.; Wei, F.; Qin, W.; Yang, Y.; Dong, Y.; Huang, D.; Wang, L. Optimizing process and the properties of the sprayed Fe-based metallic glassy coating by plasma spraying. Surf. Coat. Technol. 2017, 319, 1–5. [Google Scholar] [CrossRef]

- Jayaraj, J.; Sordelet, D.J.; Kim, D.H.; Kim, Y.C.; Fleury, E. Corrosion behaviour of Ni–Zr–Ti–Si–Sn amorphous plasma spray coating. Corros. Sci. 2006, 48, 950–964. [Google Scholar] [CrossRef]

- Ajdelsztajn, L.; Dannenberg, J.; Lopez, J.; Yang, N.; Farmer, J.; Lavernia, E.J. High-velocity oxygen fuel thermal spray of Fe-based amorphous alloy: A numerical and experimental study. Met. Mater. Trans. A 2009, 40, 2231–2240. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Z.; Wang, L.; Wang, F.; Zhang, H.; Liu, Y.; Xu, S. Formation and corrosion behavior of Fe-based amorphous metallic coatings by HVOF thermal spraying. Surf. Coat. Technol. 2009, 204, 563–570. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, L.; He, D.Y.; Wang, F.C.; Liu, Y.B. Microstructure and wear resistance of Fe-based amorphous metallic coatings prepared by HVOF thermal spraying. J. Therm. Spray Technol. 2010, 19, 1287–1293. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, L.; Han, B.; Huang, G.; Cao, Q.; Sun, M. Influence of parameters on the cold spraying FeCoCrMoBCY amorphous coatings. Surf. Eng. 2020, 1–13. [Google Scholar] [CrossRef]

- Sun, C.; Zhou, X.-L.; Xie, C. Effect of processing conditions on Al-based amorphous/nanocrystalline coating by cold-spraying. Surf. Coat. Technol. 2019, 362, 97–104. [Google Scholar] [CrossRef]

- Wu, X.; Hong, Y. Fe-based thick amorphous-alloy coating by laser cladding. Surf. Coat. Technol. 2001, 141, 141–144. [Google Scholar] [CrossRef]

- Wang, Y.; Li, G.; Shi, Z.; Liu, M.; Zhang, X.; Liu, Y. Effects of graphite addition on the microstructure and properties of laser cladding Zr–Al–Ni–Cu amorphous coatings. J. Alloys Compd. 2014, 610, 713–717. [Google Scholar] [CrossRef]

- Zhang, P.; Yan, H.; Yao, C.; Li, Z.; Yu, Z.; Xu, P. Synthesis of Fe–Ni–B–Si–Nb amorphous and crystalline composite coatings by laser cladding and remelting. Surf. Coat. Technol. 2011, 206, 1229–1236. [Google Scholar] [CrossRef]

- Zheng, B.; Zhou, Y.; Smugeresky, J.E.; Lavernia, E.J. Processing and Behavior of Fe-Based Metallic Glass Components via Laser-Engineered Net Shaping. Met. Mater. Trans. A 2009, 40, 1235–1245. [Google Scholar] [CrossRef]

- Marattukalam, J.J.; Pacheco, V.; Karlsson, D.; Riekehr, L.; Lindwall, J.; Forsberg, F.; Jansson, U.; Sahlberg, M.; Hjörvarsson, B. Development of process parameters for selective laser melting of a Zr-based bulk metallic glass. Addit. Manuf. 2020, 33, 101124. [Google Scholar] [CrossRef]

- Yang, G.; Lin, X.; Liu, F.; Hu, Q.; Ma, L.; Li, J.; Huang, W. Laser solid forming Zr-based bulk metallic glass. Intermetallics 2012, 22, 110–115. [Google Scholar] [CrossRef]

- Liu, W.; Hou, Y.; Liu, C.; Wang, Y.; Jiang, R.; Xu, G. Hot corrosion behavior of a centimeter Fe-based amorphous composite coating prepared by laser cladding in molten Na2SO4 + K2SO4 salts. Surf. Coat. Technol. 2015, 270, 33–38. [Google Scholar] [CrossRef]

- Yoshioka, H.; Asami, K.; Kawashima, A.; Hashimoto, K. ChemInform Abstract: Laser-Processed Corrosion-Resistant Amorphous Ni-Cr-P-B Surface Alloys on a Mild Steel. ChemInform 1987, 18. [Google Scholar] [CrossRef]

- Yue, T.; Su, Y.P. Laser cladding of SiC reinforced Zr65Al7.5Ni10Cu17.5 amorphous coating on magnesium substrate. Appl. Surf. Sci. 2008, 255, 1692–1698. [Google Scholar] [CrossRef]

- Lan, X.; Wu, H.; Liu, Y.; Zhang, W.; Li, R.; Chen, S.; Zai, X.; Hu, T. Microstructures and tribological properties of laser cladded Ti-based metallic glass composite coatings. Mater. Charact. 2016, 120, 82–89. [Google Scholar] [CrossRef]

- Kim, J.; Lee, D.; Shin, S.; Lee, C. Phase evolution in Cu54Ni6Zr22Ti18 bulk metallic glass Nd:YAG laser weld. Mater. Sci. Eng. A 2006, 434, 194–201. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, C.; Lee, D.; Sun, J.; Shin, S.; Bae, J. Pulsed Nd:YAG laser welding of Cu54Ni6Zr22Ti18 bulk metallic glass. Mater. Sci. Eng. A 2007, 872–875. [Google Scholar] [CrossRef]

- Zhu, Q.; Qu, S.; Wang, X.; Zou, Z. Synthesis of Fe-based amorphous composite coatings with low purity materials by laser cladding. Appl. Surf. Sci. 2007, 253, 7060–7064. [Google Scholar] [CrossRef]

- Gargarella, P.; Almeida, A.; Vilar, R.; Afonso, C.R.M.; Peripolli, S.; Rios, C.T.; Bolfarini, C.; Botta, W.J.; Kiminami, C.S. Formation of Fe-based glassy matrix composite coatings by laser processing. Surf. Coat. Technol. 2014, 240, 336–343. [Google Scholar] [CrossRef] [Green Version]

- Lu, Z.-X.; Li, R.; Li, Y.; Zhang, T. Amorphization of Ni61 Nb39 alloy by laser surface treatment. J. Iron Steel Res. Int. 2016, 23, 37–41. [Google Scholar] [CrossRef]

- Li, R.; Li, Z.; Zhu, Y.; Qi, K. Structure and corrosion resistance properties of Ni–Fe–B–Si–Nb amorphous composite coatings fabricated by laser processing. J. Alloys Compd. 2013, 580, 327–331. [Google Scholar] [CrossRef]

- Li, X.; Kang, C.; Huang, H.; Sercombe, T. The role of a low-energy–density re-scan in fabricating crack-free Al85Ni5Y6Co2Fe2 bulk metallic glass composites via selective laser melting. Mater. Des. 2014, 63, 407–411. [Google Scholar] [CrossRef] [Green Version]

- Ye, X.; Shin, Y.C. Synthesis and characterization of Fe-based amorphous composite by laser direct deposition. Surf. Coat. Technol. 2014, 239, 34–40. [Google Scholar] [CrossRef]

- Jung, H.Y.; Choi, S.J.; Prashanth, K.G.; Stoica, M.; Scudino, S.; Yi, S.; Kühn, U.; Kim, D.H.; Kim, K.B.; Eckert, J. Fabrication of Fe-based bulk metallic glass by selective laser melting: A parameter study. Mater. Des. 2015, 86, 703–708. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, C.-S.; Han, L.; Dong, C. Influence of laser power on microstructure and properties of laser clad Co-based amorphous composite coatings. Surf. Interf. 2017, 6, 18–23. [Google Scholar] [CrossRef]

- Shu, F.; Tian, Z.; Zhao, H.; He, W.; Sui, S.; Liu, B. Synthesis of amorphous coating by laser cladding multi-layer Co-based self-fluxed alloy powder. Mater. Lett. 2016, 176, 306–309. [Google Scholar] [CrossRef]

- Shu, F.; Tian, Y.; Zhou, J.; He, W.; Zhao, H.; Xu, B. Microstructure and mechanical properties of two-layer laser-cladded Co-based coatings. J. Therm. Spray Technol. 2019, 28, 1330–1338. [Google Scholar] [CrossRef]

- Jiang, Q.Y. Improvement of microstructure, hardness, and mechanical properties of cobalt-based amorphous coating via laser cladding. Strength Mater. 2019, 51, 450–461. [Google Scholar] [CrossRef]

- Wang, J.; Li, R.; Hua, N.; Zhang, T. Co-based ternary bulk metallic glasses with ultrahigh strength and plasticity. J. Mater. Res. 2011, 26, 2072–2079. [Google Scholar] [CrossRef]

- Inoue, A.; Shen, B.; Koshiba, H.; Kato, H.; Yavari, A.R. Cobalt-based bulk glassy alloy with ultrahigh strength and soft magnetic properties. Nat. Mater. 2003, 2, 661–663. [Google Scholar] [CrossRef]

- Cao, L.; Ke, Y.B.; Tao, J.Z.; Du, H.L.; Gu, X.D.; Zhu, L. Preparation and properties of B4C/PTFE neutron absorbing composites. Mater. Sci. 2018, 8, 762–774. [Google Scholar]

- Li, J.; Wang, Y.; Yi, J.; Hussain, I.; Li, R.; Zhang, B.; Wang, G. Strain-energy transport during fracture of metallic glasses. J. Alloy Compd. 2016, 680, 43–53. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.J.; Shen, J.; Sun, J.F. Bulk metallic glasses: Smaller is softer. Appl. Phys. Lett. 2007, 90, 081919. [Google Scholar] [CrossRef]

- Inoue, A. Amorphous, nanoquasicrystalline and nanocrystalline alloys in Al-based systems. Prog. Mater. Sci. 1998, 43, 365–520. [Google Scholar] [CrossRef]

| Substrate Temperature | 300 K | 373 K | 473 K | 573 K |

|---|---|---|---|---|

| Co (at.%) | 78.86 | 76.68 | 75.63 | 75.51 |

| Ta (at.%) | 11.43 | 11.01 | 10.93 | 10.92 |

| Fe (at.%) | 9.71 | 12.31 | 13.44 | 13.57 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Bi, J.; Meng, Z.; Ke, Y.; Li, R.; Zhang, T. Development of Co-Based Amorphous Composite Coatings Synthesized by Laser Cladding for Neutron Shielding. Materials 2021, 14, 279. https://doi.org/10.3390/ma14020279

Liu X, Bi J, Meng Z, Ke Y, Li R, Zhang T. Development of Co-Based Amorphous Composite Coatings Synthesized by Laser Cladding for Neutron Shielding. Materials. 2021; 14(2):279. https://doi.org/10.3390/ma14020279

Chicago/Turabian StyleLiu, Xiaobin, Jiazi Bi, Ziyang Meng, Yubin Ke, Ran Li, and Tao Zhang. 2021. "Development of Co-Based Amorphous Composite Coatings Synthesized by Laser Cladding for Neutron Shielding" Materials 14, no. 2: 279. https://doi.org/10.3390/ma14020279

APA StyleLiu, X., Bi, J., Meng, Z., Ke, Y., Li, R., & Zhang, T. (2021). Development of Co-Based Amorphous Composite Coatings Synthesized by Laser Cladding for Neutron Shielding. Materials, 14(2), 279. https://doi.org/10.3390/ma14020279