Effect of High Calcium Fly Ash, Ladle Furnace Slag, and Limestone Filler on Packing Density, Consistency, and Strength of Cement Pastes

Abstract

:1. Introduction

2. Materials and Methods

3. Results

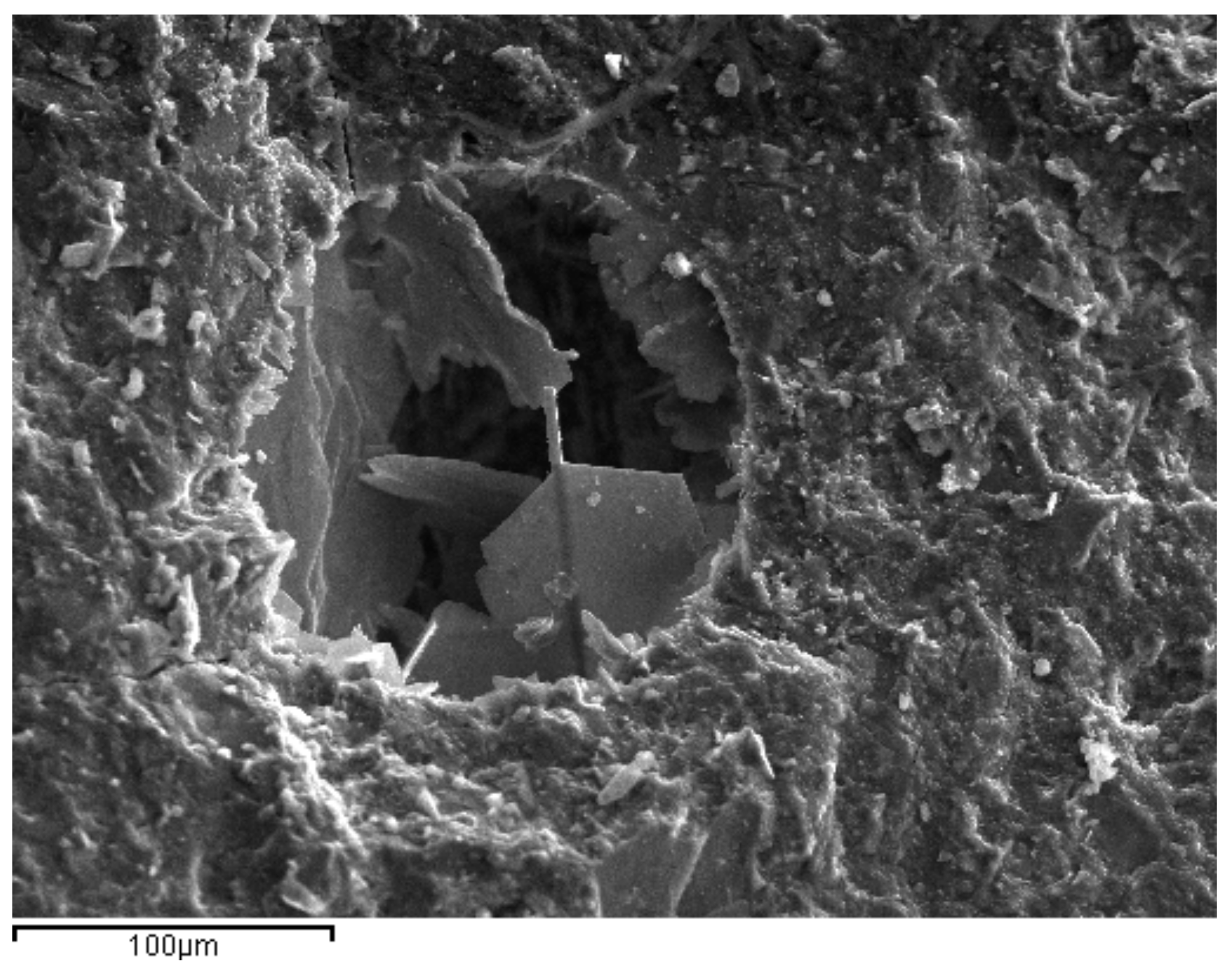

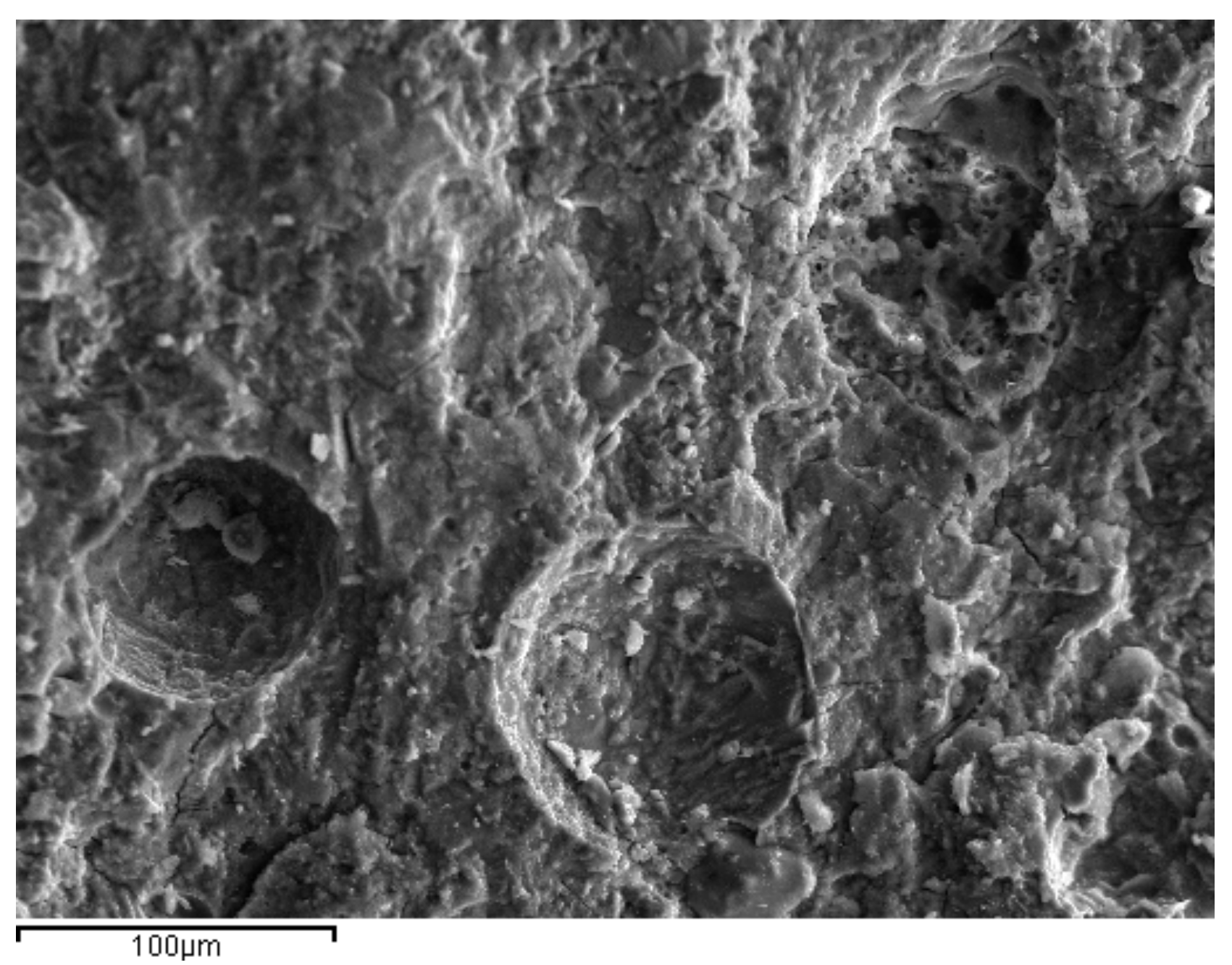

3.1. Material Properties

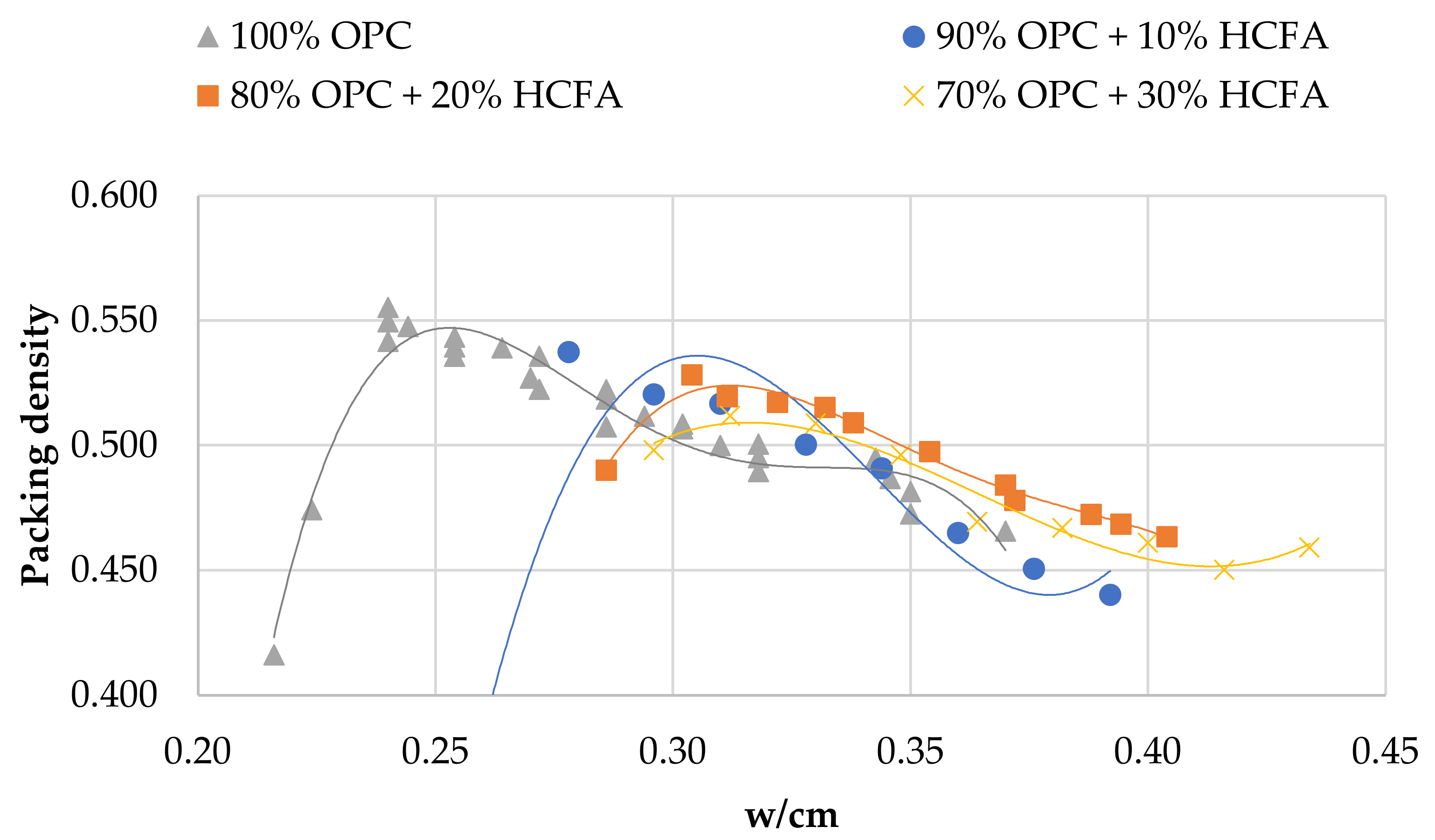

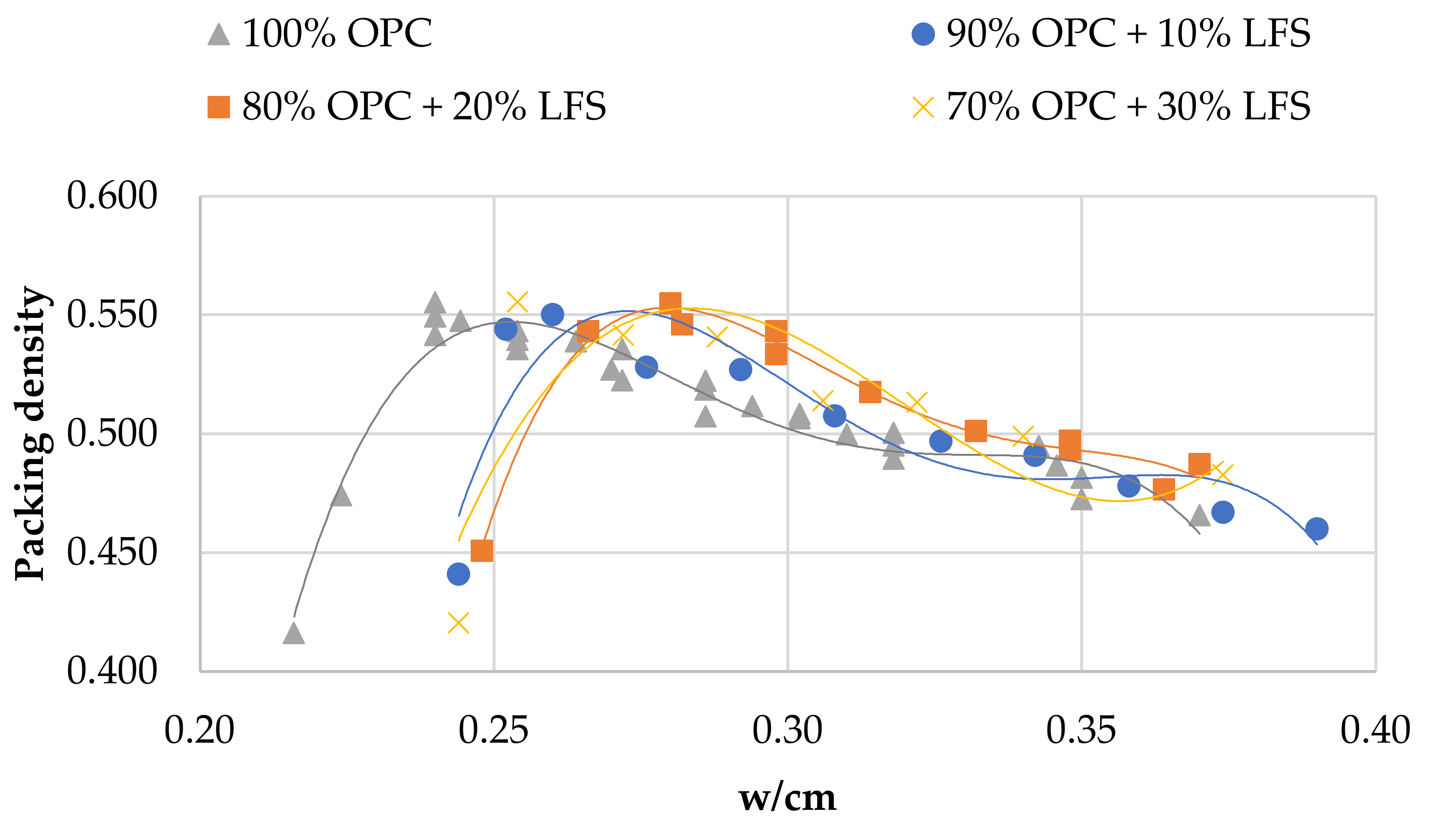

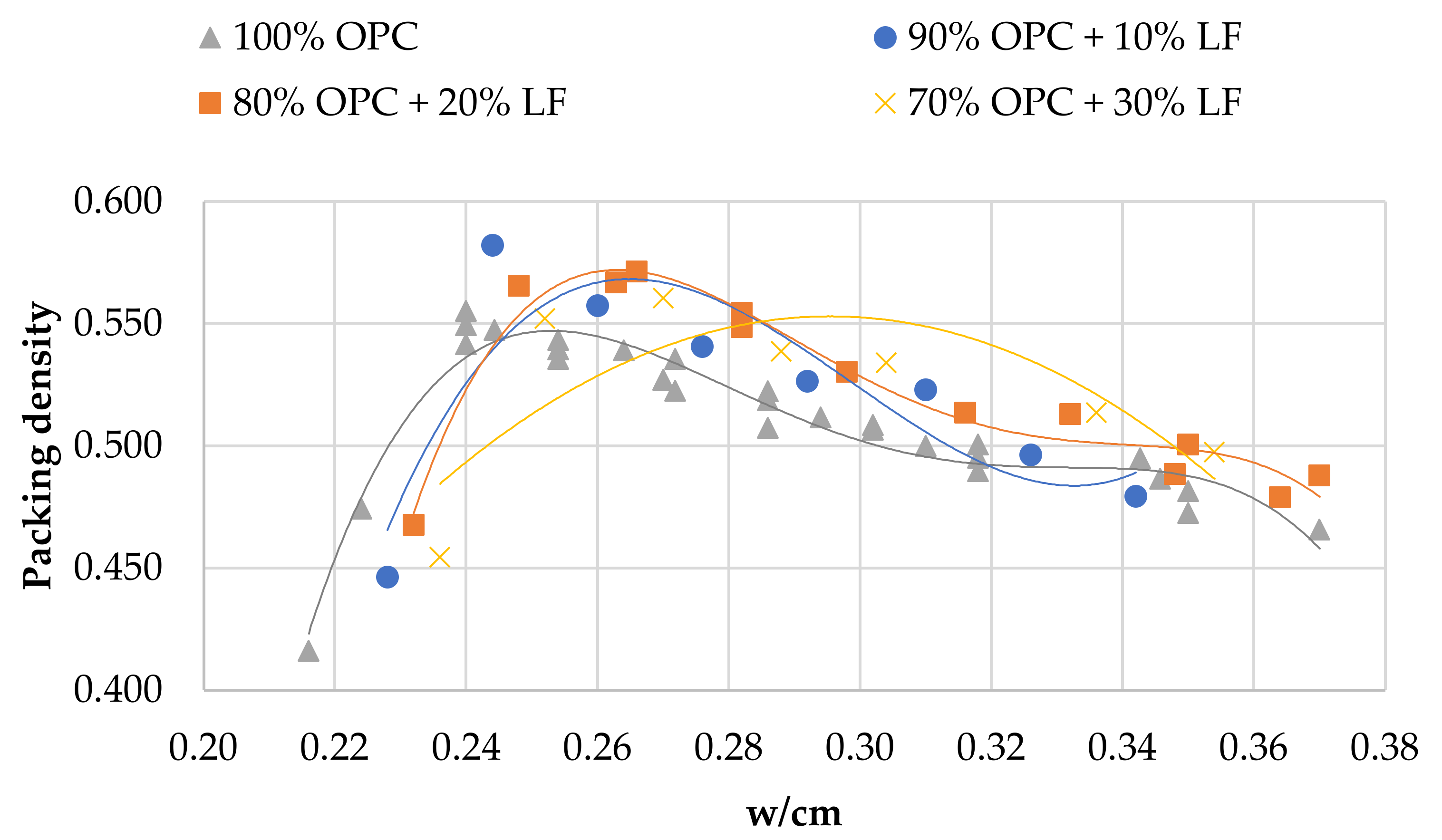

3.2. Effect on Wet Packing Density

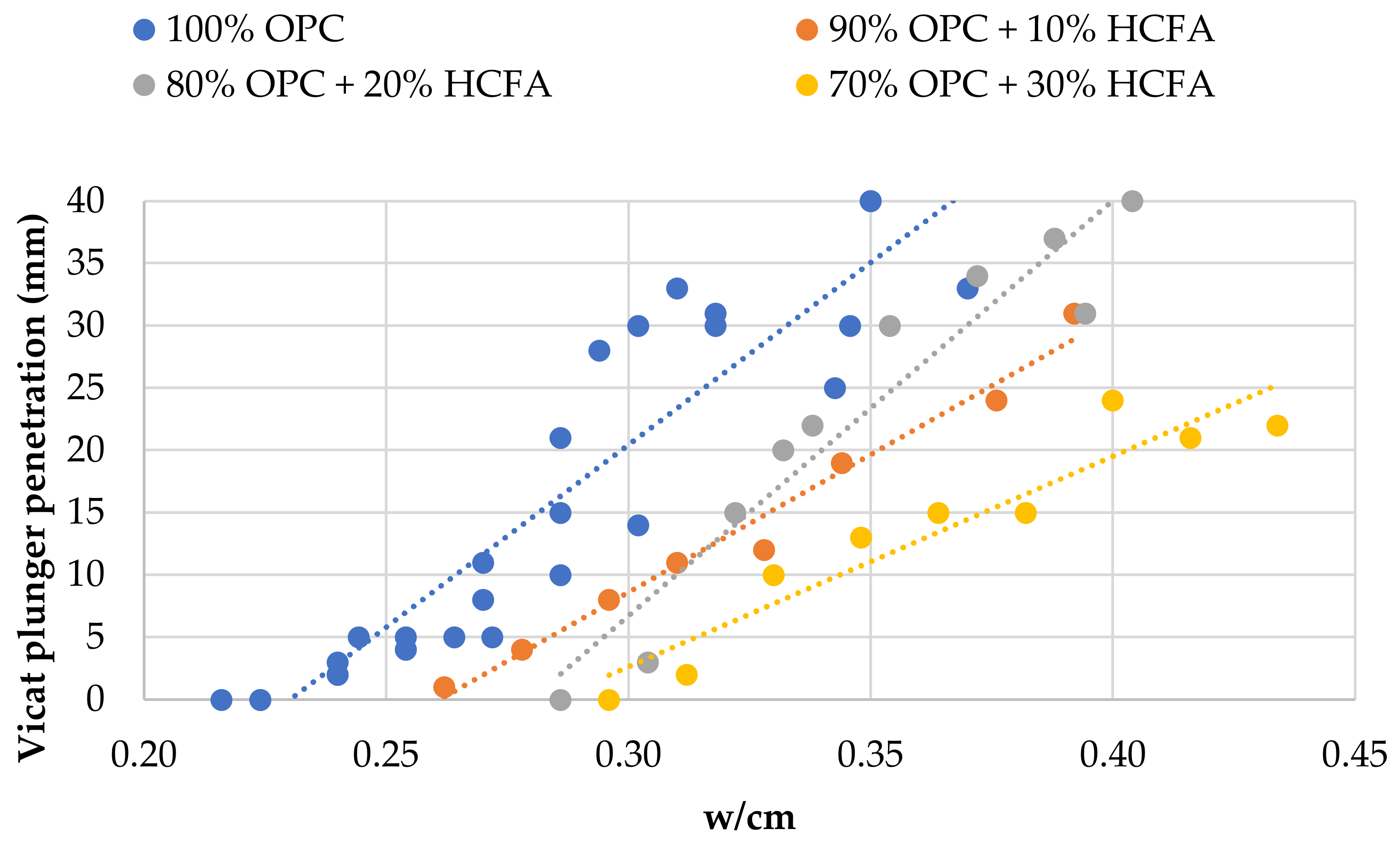

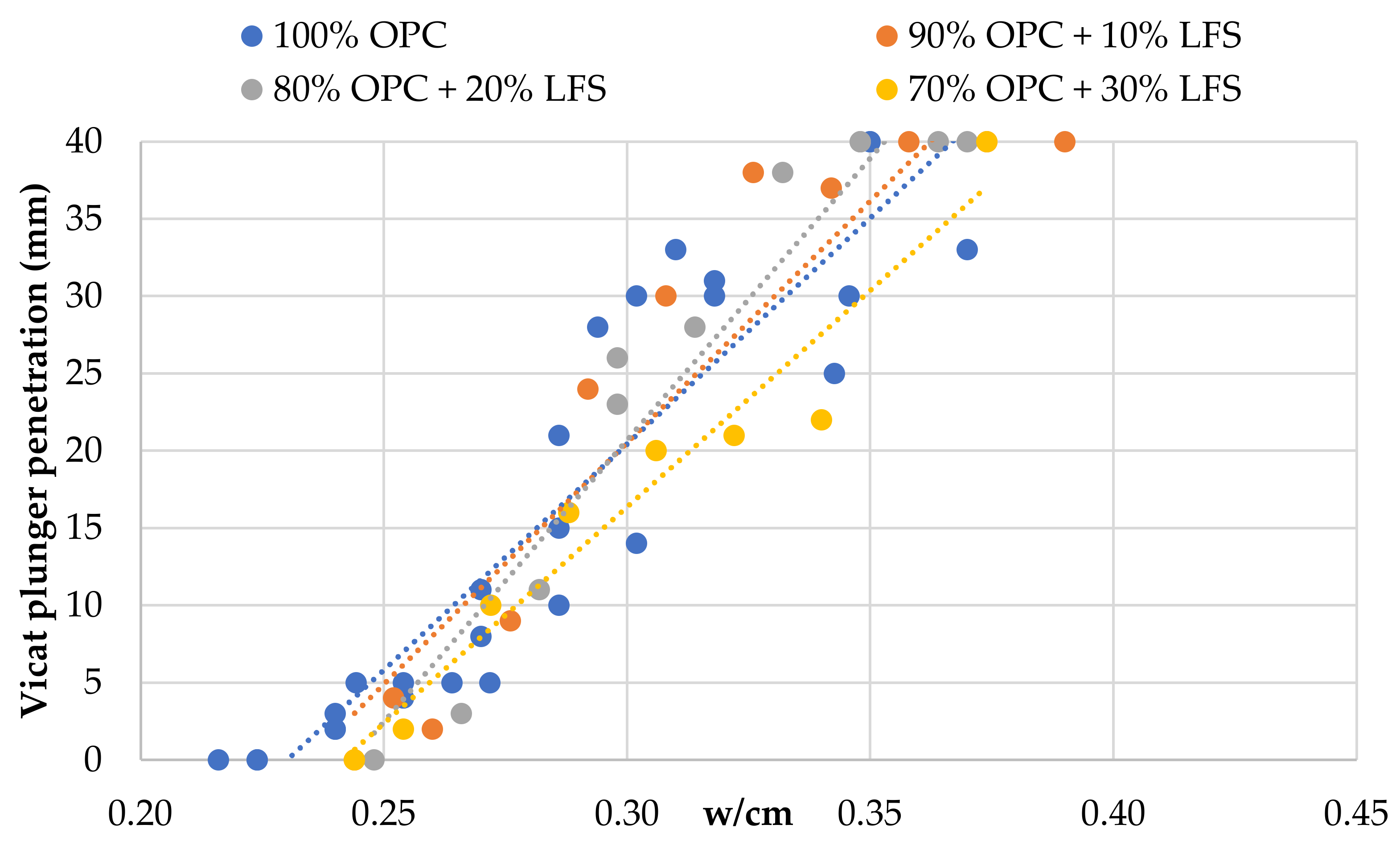

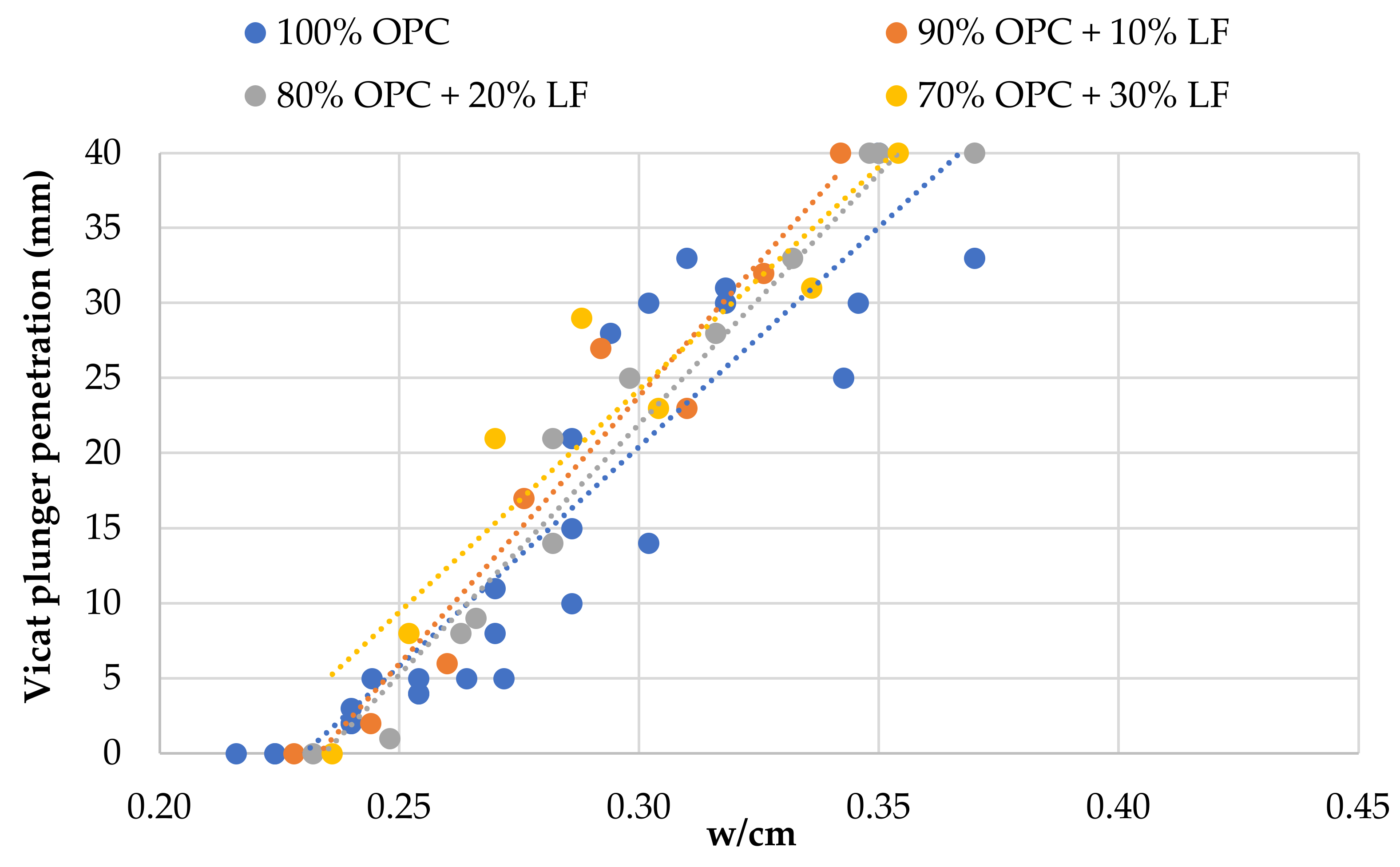

3.3. Effect on Consistency

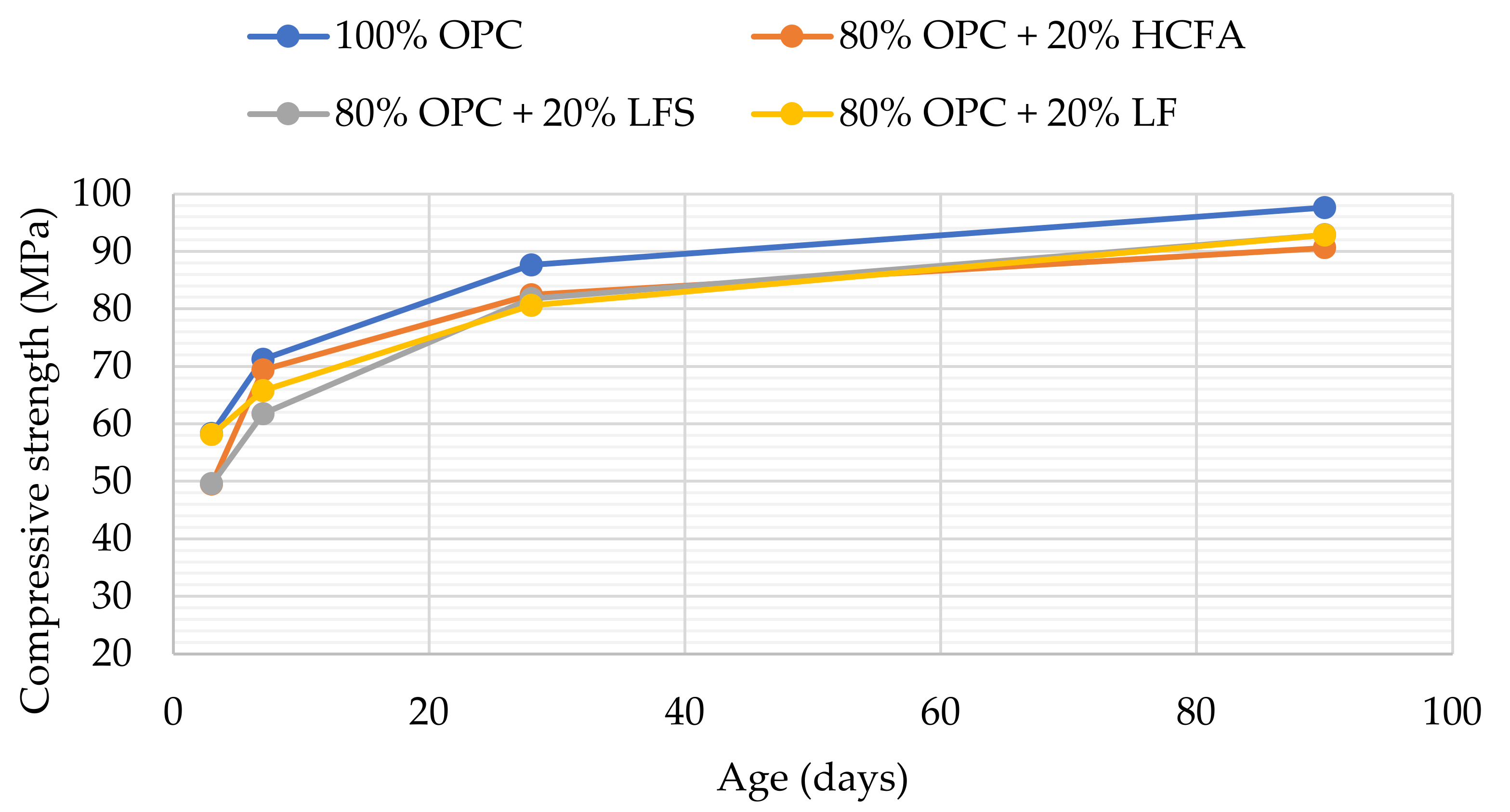

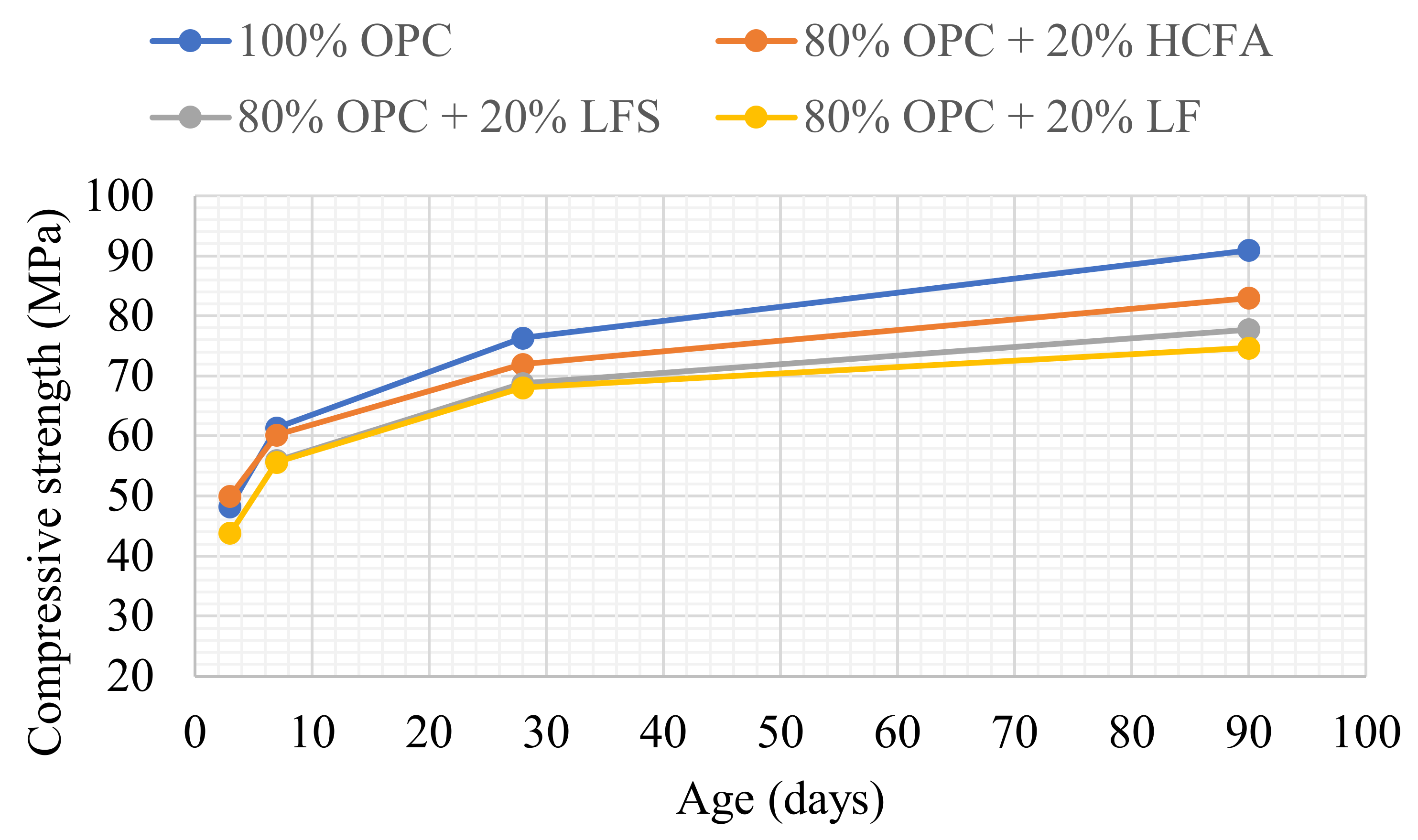

3.4. Effect on Strength Development in Binary and Ternary Pastes

4. Discussion

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Scrivener, K.L.; Juilland, P.; Monteiro, P.J.M. Advances in understanding hydration of Portland cement. Cem. Concr. Res. 2015, 78, 38–56. [Google Scholar] [CrossRef]

- De Weerdt, K.; Haha, M.B.; Le Saout, G.; Kjellsen, K.O.; Justnes, H.; Lothenbach, B. Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- Wang, C.; Yang, C.; Liu, F.; Wan, C.; Pu, X. Cement & Concrete Composites Preparation of Ultra-High Performance Concrete with common technology and materials. Cem. Concr. Compos. 2012, 34, 538–544. [Google Scholar] [CrossRef]

- Snellings, R.; Salze, A.; Scrivener, K.L. Use of X-ray diffraction to quantify amorphous supplementary cementitious materials in anhydrous and hydrated blended cements. Cem. Concr. Res. 2014, 64, 89–98. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Long, G.; Wang, X.; Xie, Y. Very-high-performance concrete with ultrafine powders. Cem. Concr. Res. 2002, 32, 601–605. [Google Scholar] [CrossRef]

- Proske, T.; Hainer, S.; Rezvani, M.; Graubner, C.A. Eco-friendly concretes with reduced water and cement contents-Mix design principles and laboratory tests. Cem. Concr. Res. 2013, 51, 38–46. [Google Scholar] [CrossRef]

- Anastasiou, E.K.; Liapis, A.; Papayianni, I. Comparative life cycle assessment of concrete road pavements using industrial by-products as alternative materials. Resour. Conserv. Recycl. 2015, 101. [Google Scholar] [CrossRef]

- Mueller, F.V.; Wallevik, O.H.; Khayat, K.H. Linking solid particle packing of Eco-SCC to material performance. Cem. Concr. Compos. 2014, 54, 117–125. [Google Scholar] [CrossRef]

- Bentz, D.P.; Sato, T.; De La Varga, I.; Weiss, W.J. Fine limestone additions to regulate setting in high volume fly ash mixtures. Cem. Concr. Compos. 2012, 34, 11–17. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Siddique, R. Recent advances in understanding the role of supplementary cementitious materials in concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Mehdipour, I.; Khayat, K.H. Effect of supplementary cementitious material content and binder dispersion on packing density and compressive strength of sustainable cement paste. ACI Mater. J. 2016, 113, 361–372. [Google Scholar] [CrossRef]

- Bentz, D.P.; Hansen, A.S.; Guynn, J.M. Optimization of cement and fly ash particle sizes to produce sustainable concretes. Cem. Concr. Compos. 2011, 33, 824–831. [Google Scholar] [CrossRef]

- Soliman, N.A.; Tagnit-Hamou, A. Using particle packing and statistical approach to optimize eco-efficient ultra-high-performance concrete. ACI Mater. J. 2017, 114, 847–858. [Google Scholar] [CrossRef]

- Wang, X.; Yu, R.; Song, Q.; Shui, Z.; Liu, Z.; Wu, S.; Hou, D. Optimized design of ultra-high performance concrete (UHPC) with a high wet packing density. Cem. Concr. Res. 2019, 126, 105921. [Google Scholar] [CrossRef]

- Arora, A.; Aguayo, M.; Hansen, H.; Castro, C.; Federspiel, E.; Mobasher, B.; Neithalath, N. Microstructural packing- and rheology-based binder selection and characterization for Ultra-high Performance Concrete (UHPC). Cem. Concr. Res. 2018, 103, 179–190. [Google Scholar] [CrossRef]

- Jones, M.R.; Zheng, L.; Newlands, M.D. Comparison of particle packing models for proportioning concrete constituents for minimum voids ratio. Mater. Struct. Constr. 2002, 34, 301–309. [Google Scholar] [CrossRef]

- Fennis, S.A.A.M.; Walraven, J.C. Using particle packing technology for sustainable concrete mixture design. Heron 2012, 57, 73–101. [Google Scholar]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- De Larrard, F. Concrete Mixture Proportioning: A Scientific Approach; E & FN Spon: London, UK, 1999. [Google Scholar]

- Fennis, S.A.A.M.; Walraven, J.C.; Den Uijl, J.A. Compaction-interaction packing mode.Regarding the effect of fillers in concrete mixture design. Mater. Struct. Constr. 2013, 46, 463–478. [Google Scholar] [CrossRef]

- Zhang, T.; Yu, Q.; Wei, J.; Zhang, P. Efficient utilization of cementitious materials to produce sustainable blended cement. Cem. Concr. Compos. 2012, 34, 692–699. [Google Scholar] [CrossRef]

- De Larrard, F.; Sedran, T. Mixture-proportioning of high-performance concrete. Cem. Concr. Res. 2002, 32, 1699–1704. [Google Scholar] [CrossRef]

- Mehdipour, I.; Khayat, K.H. Understanding the role of particle packing characteristics in rheo-physical properties of cementitious suspensions: A literature review. Constr. Build. Mater. 2018, 161, 340–353. [Google Scholar] [CrossRef]

- De Belie, N.; Soutsos, M.; Gruyaert, E. Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials: State-Of-The-Art Report of the RILEM Technical Committee 238-SCM, Working Group 4; Springer: Ghent, Belgium, 2018; ISBN 978-3-319-70606-1. [Google Scholar]

- Felekoǧlu, B.; Türkel, S.; Kalyoncu, H. Optimization of fineness to maximize the strength activity of high-calcium ground fly ash-Portland cement composites. Constr. Build. Mater. 2009, 23, 2053–2061. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of fly ash on Portland cement systems. Part II. High-calcium fly ash. Cem. Concr. Res. 2000, 30, 1647–1654. [Google Scholar] [CrossRef]

- Sideris, K.K.; Tassos, C.; Chatzopoulos, A. Production of durable self-compacting concrete using ladle furnace slag (LFS) as filler material. Procedia Eng. 2015, 108, 592–597. [Google Scholar] [CrossRef] [Green Version]

- Setién, J.; Hernández, D.; González, J.J. Characterization of ladle furnace basic slag for use as a construction material. Constr. Build. Mater. 2009, 23, 1788–1794. [Google Scholar] [CrossRef]

- Huang, W.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Effect of cement substitution by limestone on the hydration and microstructural development of ultra-high performance concrete (UHPC). Cem. Concr. Compos. 2017, 77, 86–101. [Google Scholar] [CrossRef]

- Lothenbach, B.; Le Saout, G.; Gallucci, E.; Scrivener, K. Influence of limestone on the hydration of Portland cements. Cem. Concr. Res. 2008, 38, 848–860. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Nonat, A. Hydration of cementitious materials, present and future. Cem. Concr. Res. 2011, 41, 651–665. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; Wong, H.H.C. Packing density of cementitious materials: Part 2-packing and flow of OPC + PFA + CSF. Mater. Struct. Constr. 2008, 41, 773–784. [Google Scholar] [CrossRef]

- Marchetti, G.; Rahhal, V.F.; Irassar, E.F. Influence of packing density and water film thickness on early-age properties of cement pasteswith limestone filler and metakaolin. Mater. Struct. Constr. 2017, 50, 1–11. [Google Scholar] [CrossRef]

- Wong, H.H.C.; Kwan, A.K.H. Packing density of cementitious materials: Part 1—Measurement using a wet packing method. Mater. Struct. 2008, 41, 689–701. [Google Scholar] [CrossRef]

- EN 197-1:2011: Cement. Composition, Specifications and Conformity Criteria for Common Cements; CEN: Brussels, Belgium, 2011.

- ASTM C188-14: Standard Test Method for Density of Hydraulic Cement; ASTM International: West Conshohocken, PA, USA, 2014.

- EN 196-3:2016; Methods of Testing Cement. Determination of Setting Times and Soundness; CEN: Brussels, Belgium, 2016.

- Lecomte, A.; Mechling, J.M.; Diliberto, C. Compaction index of cement paste of normal consistency. Constr. Build. Mater. 2009, 23, 3279–3286. [Google Scholar] [CrossRef]

- Anastasiou, E.K.; Papayianni, I.; Papachristoforou, M. Behavior of self compacting concrete containing ladle furnace slag and steel fiber reinforcement. Mater. Des. 2014, 59. [Google Scholar] [CrossRef]

- Papayianni, J. Use of a high-calcium fly ash in blended type cement production. Cem. Concr. Compos. 1993, 15, 231–235. [Google Scholar] [CrossRef]

- Knop, Y.; Peled, A. Sustainable blended cements-Influences of packing density on cement paste chemical efficiency. Materials 2018, 11, 625. [Google Scholar] [CrossRef] [Green Version]

- Sakai, E.; Masuda, K.; Kakinuma, Y.; Aikawa, Y. Effects of shape and packing density of powder particles on the fluidity of cement pastes with limestone powder. J. Adv. Concr. Technol. 2009, 7, 347–354. [Google Scholar] [CrossRef] [Green Version]

- Nawaz, A.; Julnipitawong, P.; Krammart, P.; Tangtermsirikul, S. Effect and limitation of free lime content in cement-fly ash mixtures. Constr. Build. Mater. 2016, 102, 515–530. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; Chen, J.J. Roles of Packing Density and Water Film Thickness in Rheology and Strength of Cement Paste. J. Adv. Concr. Technol. 2012, 10, 332–344. [Google Scholar] [CrossRef] [Green Version]

- Fennis, S.A.A.M.; Walraven, J.C.; Nijland, T.G. Measuring the packing density to lower the cement content in concrete. In Tailor Made Concrete Structures; Taylor & Francis Group: London, UK, 2008; Volume 108. [Google Scholar] [CrossRef]

- De Weerdt, K.; Kjellsen, K.O.; Sellevold, E.; Justnes, H. Synergy between fly ash and limestone powder in ternary cements. Cem. Concr. Compos. 2011, 33, 30–38. [Google Scholar] [CrossRef]

- Thongsanitgarn, P.; Wongkeo, W.; Chaipanich, A.; Poon, C.S. Heat of hydration of Portland high-calcium fly ash cement incorporating limestone powder: Effect of limestone particle size. Constr. Build. Mater. 2014, 66, 410–417. [Google Scholar] [CrossRef]

- Isaia, G.C.; Gastaldini, A.L.G.; Moraes, R. Physical and pozzolanic action of mineral additions on the mechanical strength of high-performance concrete. Cem. Concr. Compos. 2003, 25, 69–76. [Google Scholar] [CrossRef]

- Kakali, G.; Tsivilis, S.; Aggeli, E.; Bati, M. Hydration products of C3A, C3S and Portland cement in the presence of CaCO3. Cem. Concr. Res. 2000, 30, 1073–1077. [Google Scholar] [CrossRef]

| Constituents | OPC | HCFA | LFS | LF |

|---|---|---|---|---|

| CaO | 66.80 | 47.20 | 50.70 | 51.30 |

| SiO2 | 19.60 | 33.10 | 32.40 | 3.80 |

| Al2O3 | 3.74 | 7.29 | 1.36 | 1.00 |

| Fe2O3 | 2.40 | 4.00 | 2.66 | 0.40 |

| MgO | 3.91 | 3.20 | 2.77 | 1.20 |

| Na2O | 0.57 | 1.00 | 0.78 | - |

| K2O | 1.08 | 0.53 | 0.06 | - |

| LOI | 1.91 | 3.75 | 6.72 | 41.00 |

| Cl− | 0.03 | 0.04 | 0.02 | - |

| NO3− | 0.02 | - | - | - |

| SO42− | 1.49 | 4.81 | 0.43 | - |

| Material | Median Particle Size Diameter d50 (μm) | Specific Surface Area (m2/kg) | Apparent Specific Density (kg/m3) |

|---|---|---|---|

| OPC | 12.22 | 642 | 3140 |

| HCFA | 39.92 | 307 | 2420 |

| LFS | 31.47 | 496 | 2590 |

| LF | 18.45 | 480 | 2620 |

| Solid Constituents (% wt.) | w/cm Ratio | Packing Density | Consistency | 28-Day Compressive Strength (MPa) |

|---|---|---|---|---|

| 100% OPC | 0.24 | 0.542 | - | 87.7 |

| 100% OPC | 0.35 | 0.487 | normal | 76.4 |

| 80% OPC + 20% HCFA | 0.31 | 0.520 | - | 82.4 |

| 80% OPC + 20% HCFA | 0.39 | 0.469 | normal | 72.0 |

| 80% OPC + 20% LFS | 0.28 | 0.549 | - | 81.8 |

| 80% OPC + 20% LFS | 0.35 | 0.497 | normal | 68.8 |

| 80% OPC + 20% LF | 0.26 | 0.567 | - | 80.6 |

| 80% OPC + 20% LF | 0.35 | 0.496 | normal | 68.1 |

| 70% OPC + 20% HCFA + 10% LFS | 0.30 | 0.539 | - | 77.0 |

| 70% OPC + 20% HCFA + 10% LF | 0.29 | 0.534 | - | 84.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anastasiou, E.K. Effect of High Calcium Fly Ash, Ladle Furnace Slag, and Limestone Filler on Packing Density, Consistency, and Strength of Cement Pastes. Materials 2021, 14, 301. https://doi.org/10.3390/ma14020301

Anastasiou EK. Effect of High Calcium Fly Ash, Ladle Furnace Slag, and Limestone Filler on Packing Density, Consistency, and Strength of Cement Pastes. Materials. 2021; 14(2):301. https://doi.org/10.3390/ma14020301

Chicago/Turabian StyleAnastasiou, Eleftherios K. 2021. "Effect of High Calcium Fly Ash, Ladle Furnace Slag, and Limestone Filler on Packing Density, Consistency, and Strength of Cement Pastes" Materials 14, no. 2: 301. https://doi.org/10.3390/ma14020301

APA StyleAnastasiou, E. K. (2021). Effect of High Calcium Fly Ash, Ladle Furnace Slag, and Limestone Filler on Packing Density, Consistency, and Strength of Cement Pastes. Materials, 14(2), 301. https://doi.org/10.3390/ma14020301