Ecotoxicity and Essential Properties of Fine-Recycled Aggregate

Abstract

:1. Introduction

2. Materials and Methodology

2.1. Materials

- (1)

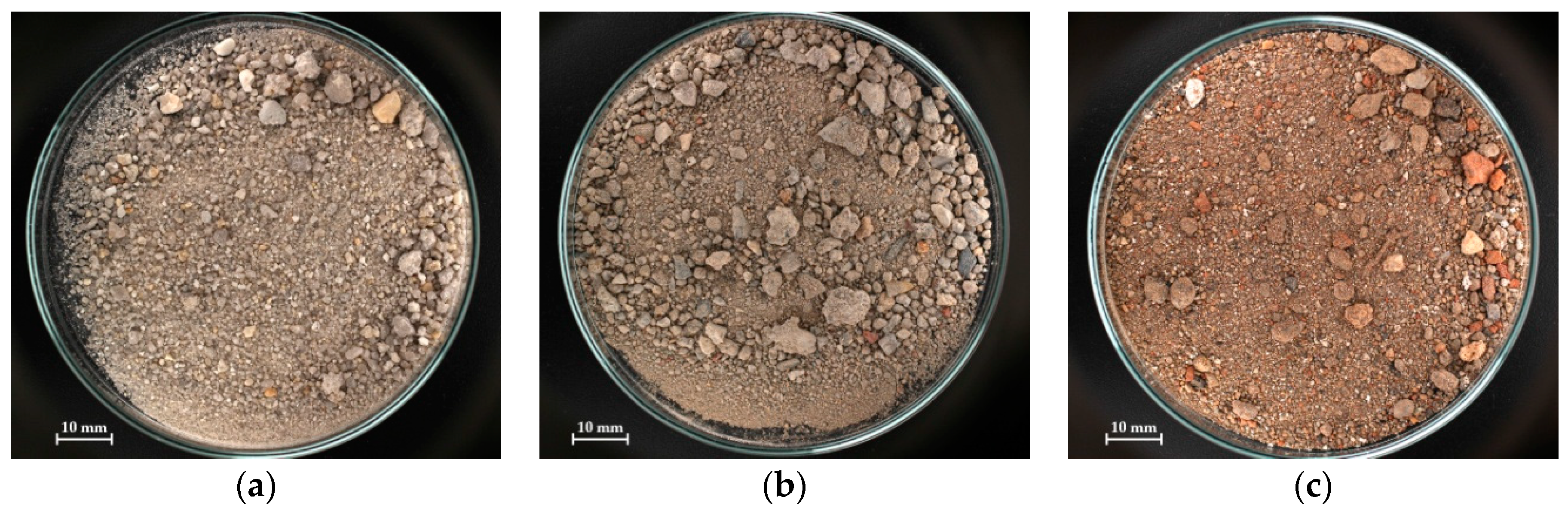

- RA 1 was prepared from reinforcement concrete in the recycling center by the two-steps recycling process. The crushed and separated recycled aggregate of fraction 16/128 mm from the first step of recycling process was crushed and sieved to the fractions in the second step.

- (2)

- RA 2 originated from highway and was partially prepared in the recycling center to fraction 64/128 mm. Afterwards, the fraction 64/128 was crushed and sieved into the fractions in the laboratory.

- (3)

- RA 3 originated from the ground floor structures and was partially prepared in the recycling center to fraction 64/128 mm. Afterwards, the fraction 64/128 was crushed and sieved into the fractions in the laboratory.

- (4)

- RA 4 originated from the masonry structures and contains mostly red bricks, mortar, and plasters. It was prepared from reinforcement concrete in the recycling center by the two-steps recycling process. The crushed and separated recycled aggregate of fraction 16/128 mm from the first step of recycling process was crushed and sieved to the fractions in the second step.

2.2. Physical and Geometrical Properties

2.2.1. Fineness Modulus

2.2.2. Fines Content

2.3. Ecotoxicity Experiments

2.3.1. Freshwater Algae Toxicity Test

2.3.2. Mustard Germination Toxicity Test

2.3.3. Lemna Growth Inhibition Test

2.3.4. Daphnia Acute Toxicity Test

2.3.5. Evaluation of Ecotoxicity Data

3. Results and Discussion

3.1. Physical and Geometrical Properties

3.2. Ecotoxicity

4. Conclusions

- The water absorption of RA 1–4 is up to ten times higher than NA. The highest absorption was measured on RA 1, the lowest on RA 3.

- The highest density was measured on RA 3, which corresponds with the lowest water absorption measured on this sample.

- Samples RA 1 and RA 2 provided higher number of fine particles in the particle size distribution and the limits of the current standards have not been fulfilled.

- Ecotoxicity of the tested leachates increased from non-toxic effect in NA, RA 1, and RA 4 to inhibitory effect or mild toxicity in RA 2 and RA 3 in following order:

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of Recycled Concrete Aggregate and Their Influence in New Concrete Production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Evangelista, L.; Guedes, M.; de Brito, J.; Ferro, A.C.; Pereira, M.F. Physical, Chemical and Mineralogical Properties of Fine Recycled Aggregates Made from Concrete Waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- Czech Technical Standard CSN EN 12620+A1. In Aggregate for Concrete; Czech Office for Standards: Prague, Czech Republic, 2002; Available online: https://shop.bsigroup.com/ProductDetail/?pid=000000000030152181 (accessed on 19 January 2021). (In Czech)

- Czech Technical standard CSN EN 206+A1. In Concrete; Specification, Performance, Production and Conformity; Czech Office for Standards: Prague, Czech Republic, 2018. (In Czech)

- Evangelista, L.; de Brito, J. Concrete with Fine Recycled Aggregates: A Review. Eur. J. Environ. Civ. Eng. 2014, 18, 129–172. [Google Scholar] [CrossRef]

- Kwan, A.K.H.; Ng, P.L.; Huen, K.Y. Effects of Fines Content on Packing Density of Fine Aggregate in Concrete. Constr. Build. Mater. 2014, 61, 270–277. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical Behaviour of Concrete Made with Fine Recycled Concrete Aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of Concrete Incorporating Fine Recycled Aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Debieb, F.; Kenai, S. The Use of Coarse and Fine Crushed Bricks as Aggregate in Concrete. Constr. Build. Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Yang, J.; Du, Q.; Bao, Y. Concrete with Recycled Concrete Aggregate and Crushed Clay Bricks. Const. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Cachim, P.B. Mechanical Properties of Brick Aggregate Concrete. Const. Build. Mater. 2009, 23, 1292–1297. [Google Scholar] [CrossRef]

- Kobetičová, K.; Černý, R. Ecotoxicology of Building Materials: A Critical Review of Recent Studies. J. Clean. Prod. 2017, 165, 500–508. [Google Scholar] [CrossRef]

- Kokkali, V.; van Delft, W. Overview of Commercially Available Bioassays for Assessing Chemical Toxicity in Aqueous Samples. TrAC Trends Anal. Chem. 2014, 61, 133–155. [Google Scholar] [CrossRef]

- Hájek, P.; Fiala, C.; Kynčlová, M. Life Cycle Assessments of Concrete Structures—A Step towards Environmental Savings. Struct. Concr. 2011, 12, 13–22. [Google Scholar] [CrossRef]

- Limbachiya, M.C.; Leelawat, T.; Dhir, R.K. Use of Recycled Concrete Aggregate in High-Strength Concrete. Mat. Struct. 2000, 33, 574–580. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.-C.; Zhang, H.; Wang, Y. Durability of Recycled Aggregate Concrete—A Review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Mariaková, D.; Vlach, T.; Pavlů, T. Glass Waste Powder Utilization in High Performance Concrete. Acta Polytech. CTU Proc. 2019, 21, 24–27. [Google Scholar] [CrossRef]

- EEA. Effectiveness of Environmental Taxes and Charges for Managing Sand, Gravel and Rock Extraction in Selected EU Countries; European Environmetal Agengy: Copenhaguen, Denmark, 2008. [Google Scholar]

- Pedro, D.; de Brito, J.; Evangelista, L. Structural Concrete with Simultaneous Incorporation of Fine and Coarse Recycled Concrete Aggregates: Mechanical, Durability and Long-Term Properties. Const. Build. Mater. 2017, 154, 294–309. [Google Scholar] [CrossRef]

- Fortova, K.; Pavlu, T. The Utilization of the Finest Fraction of Recycled Aggregate from CDW for Concrete; IOP Publishing: Bristol, UK, 2019; Volume 290. [Google Scholar]

- Hennebert, P.; van der Sloot, H.A.; Rebischung, F.; Weltens, R.; Geerts, L.; Hjelmar, O. Hazard Property Classification of Waste According to the Recent Propositions of the EC Using Different Methods. Waste Manag. 2014, 34, 1739–1751. [Google Scholar] [CrossRef]

- EN 933-1. In Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method; Czech Office for Standards, Metrology and Testing: Prague, Czech Republic, 2012. (In Czech)

- Czech Technical Standard CSN EN 12620. In Aggregate for Concrete; Czech Office for Standards: Prague, Czech Republic, 2003; Available online: http://www.technicke-normy-csn.cz/721502-csn-en-12620_4_67612.html (accessed on 19 January 2021). (In Czech)

- Czech Technical Standard CSN EN 1097-1. In Tests for Mechanical and Physical Properties of Aggregates—Part 1: Determination of the Resistance to Wear (Micro-Deva); Czech Office for Standards: Prague, Czech Republic, 2011. (In Czech)

- European Committee for Standardization EN12457-4. In Characterization of Waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 4: One Stage Batch Test at a Liquid to Solid Ratio of 10 L/kg for Materials with Particle Size below 10 mm (without or with Size Reduction); CEN: Brussels, Belgium, 2002.

- ISO 8692. In Water Quality—Fresh Water Algal Growth Inhibition Test with Unicellular Green Algae; ISO: Brussels, Belgium, 2012.

- Bold, H.C. The Morphology of Chlamydomonas chlamydogama, Sp. Nov. Bull. Torrey Bot. Club 1949, 76, 101–108. [Google Scholar] [CrossRef]

- Wellburn, A.R. The Spectral Determination of Chlorophylls a and b, as Well as Total Carotenoids, Using Various Solvents with Spectrophotometers of Different Resolution. J. Plant Physiol. 1994, 144, 307–313. [Google Scholar] [CrossRef]

- ISO 20079. In Water Quality—Determination of Toxic Effect of Water Constituents and Waste to Duckweed (Lemna minor)—Duckweed Growth Inhibition Test; ISO: Brussels, Belgium, 2005.

- ISO 6341. In Determination of Inhibition of the Mobility of Daphnia magna Straus (Cladocera, Crustacea)—Acute Toxicity Test; ISO: Brussels, Belgium, 2012.

- Klüttgen, B.; Dülmer, U.; Engels, M.; Ratte, H.T. ADaM, an Artificial Freshwater for the Culture of Zooplankton. Water Res. 1994, 28, 743–746. [Google Scholar] [CrossRef]

- Alves, A.V.; Vieira, T.F.; de Brito, J.; Correia, J.R. Mechanical Properties of Structural Concrete with Fine Recycled Ceramic Aggregates. Constr. Build. Mater. 2014, 64, 103–113. [Google Scholar] [CrossRef]

- Uddin, M.T.; Mahmood, A.H.; Kamal, M.R.I.; Yashin, S.M.; Zihan, Z.U.A. Effects of Maximum Size of Brick Aggregate on Properties of Concrete. Const. Build. Mater. 2017, 134, 713–726. [Google Scholar] [CrossRef]

- Chen, H.-J.; Yen, T.; Chen, K.-H. Use of Building Rubbles as Recycled Aggregates. Cem. Concr. Res. 2003, 33, 125–132. [Google Scholar] [CrossRef]

- Malasarn, D.; Kropat, J.; Hsieh, S.I.; Finazzi, G.; Casero, D.; Loo, J.A.; Pellegrini, M.; Wollman, F.-A.; Merchant, S.S. Zinc Deficiency Impacts CO2 Assimilation and Disrupts Copper Homeostasis in Chlamydomonas reinhardtii. J. Biol. Chem. 2013, 288, 10672–10683. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, W. Site-Specific Barium Toxicity to Common Duckweed, Lemna minor. Aquat. Toxicol. 1988, 12, 203–212. [Google Scholar] [CrossRef]

- Golding, L.A.; McKnight, K.; Binet, M.; Adams, M.; Apte, S.C. Toxicity of Dissolved and Precipitated Forms of Barium to a Freshwater Alga (Chlorella sp. 12) and Water Flea (Ceriodaphnia dubia). Environ. Toxicol. Chem. 2018, 37, 1632–1642. [Google Scholar] [CrossRef]

- Kočí, V.; Mocová, K.; Kulovaná, M.; Vosáhlová, S. Phytotoxicity Tests of Solid Wastes and Contaminated Soils in the Czech Republic. Environ. Sci. Pollut. Res. 2010, 17, 611–623. [Google Scholar] [CrossRef]

- Choi, J.B.; Bae, S.M.; Shin, T.Y.; Ahn, K.Y.; Woo, S.D. Evaluation of Daphnia magna for the Ecotoxicity Assessment of Alkali Leachate from Concrete. Int. J. Ind. Entomol. 2013, 26, 41–46. [Google Scholar] [CrossRef] [Green Version]

- Rodrigues, P.; Silvestre, J.D.; Flores-Colen, I.; Viegas, C.A.; Ahmed, H.H.; Kurda, R.; de Brito, J. Evaluation of the Ecotoxicological Potential of Fly Ash and Recycled Concrete Aggregates Use in Concrete. Appl. Sci. 2020, 10, 351. [Google Scholar] [CrossRef] [Green Version]

- Mocová, K.A.; Sackey, L.N.A.; Renkerová, P. Environmental Impact of Concrete and Concrete-Based Construction Waste Leachates. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Prague, Czech Republic, 2–4 July 2019. [Google Scholar]

- Barbosa, R.; Lapa, N.; Dias, D.; Mendes, B. Concretes Containing Biomass Ashes: Mechanical, Chemical, and Ecotoxic Performances. Const. Build. Mater. 2013, 48, 457–463. [Google Scholar] [CrossRef]

| Physical Properties | NA | RA 1 | RA 2 | RA 3 | RA 4 |

|---|---|---|---|---|---|

| 0/4 mm | 0/4 mm | 0/4 mm | 0/4 mm | 0/4 mm | |

| Fineness modulus | 2.10 | 2.90 | 2.57 | 1.92 | 2.53 |

| σ | 0.06 | 0.03 | 0.08 | 0.88 | 0.14 |

| Content of fines | 2.0% | 3.4% | 3.1% | 3.2% | 5.1% |

| σ | 0.2% | 0.0% | 0.8% | 1.7% | 1.1% |

| Type of Aggregate | Fraction (mm) | Oven-Dry Density (kg/m3) | Water Absorption (%) | ||

|---|---|---|---|---|---|

| ρ RD | σ | WA24 | σ | ||

| NA | 0.063/4 | 2674 | 38 | 0.29 | 0.31 |

| RA 1 | 0.063/4 | 2175 | 87 | 8.80 | 1.03 |

| RA 2 | 0.063/4 | 2217 | 89 | 6.92 | 0.60 |

| RA 3 | 0,063/4 | 2390 | 29 | 2.93 | 0.80 |

| RA 3 | 1/4 | 2490 | 81 | 2.13 | 0.53 |

| RA 4 | 0.063/4 | 2412 | 118 | 2.99 | 0.56 |

| Chemical Properties | NA | RA1 | RA2 | RA3 | RA4 | |

|---|---|---|---|---|---|---|

| Leachates | pH | 8.1 ± 0.6 | 10.3 ± 0.0 | 12.2 ± 0.0 | 11.7 ± 0.1 | 8.6 ± 0.0 |

| el. conductivity (µS·cm−2) | 27 ± 3 | 545 ± 13 | 7150 ± 80 | 2730 ± 10 | 1129 ± 6 | |

| Element (mg/l) | Ca | 3 | 80.08 | 660.57 | 146 | 216.98 |

| Na | 1 | 13.733 | 8.83 | 9.92 | 20.71 | |

| As | <0.4 | <0.4 | <0.3 | <0.3 | <0.4 | |

| Zn | 0.027 | ~0.012 | ~0.011 | ~0.008 | 0.023 | |

| Cu | <0.01 | ~0.02 | <0.02 | <0.02 | ~0.02 | |

| Cr | <0.05 | ~0.05 | ~0.1 | <0.05 | <0.05 | |

| Ba | <0.1 | <0.1 | 1.056 | ~0.2 | <0.1 | |

| Se | <0.4 | <0.4 | <0.5 | <0.5 | <0.4 | |

| Pb | <0.04 | <0.04 | <0.06 | <0.06 | <0.04 | |

| Hg | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | |

| Properties. of Control Media | pH | Lemna | Algae | Sinapis | Daphnia |

| 5.5 ± 0.1 | 6.6 ± 0.1 | 7.8 ± 0.2 | 7.8 ± 0.2 | ||

| el. conductivity (µS·cm−2) | 977 ± 15 | 853 ± 12 | 625 ± 7 | 829 ±15 |

| Type of Aggregate | Daphnia | Sinapis | Algae GR | Algae Chl | Lemna GR | Lemna Chl | Toxicity Level |

|---|---|---|---|---|---|---|---|

| NA | |||||||

| EC50 | ˃100 | ˃100 | ~100 | ~97 | ~100 | ˃100 | |

| TC | A1 | A1 | A2 | A2 | A1 | A1 | non-toxic |

| RA 1 | |||||||

| EC50 | ˃100 | ˃100 | ~100 | ~99 | 78 | ˃100 | |

| TC | A2 | A3 | A2 | A2 | A3 | A2 | non-toxic |

| RA 2 | |||||||

| EC50 | ~5 | ˃100 | ~54 | ~49 | ~6 | 9 | |

| TC | C | A3 | A3 | B | C | C | Inhibitory—mild toxic |

| RA 3 | |||||||

| EC50 | ~7 | ˃100 | ˃100 | ~95 | 16 | 26 | |

| TC | C | A3 | A1 | B | B | B | Inhibitory—mild toxic |

| RA 4 | |||||||

| EC50 | ˃100 | ˃100 | ˃100 | ˃100 | ˃100 | ˃100 | |

| TC | A1 | A2 | A2 | A2 | A1 | A2 | non-toxic |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mariaková, D.; Anna Mocová, K.; Fořtová, K.; Ryparová, P.; Pešta, J.; Pavlů, T. Ecotoxicity and Essential Properties of Fine-Recycled Aggregate. Materials 2021, 14, 463. https://doi.org/10.3390/ma14020463

Mariaková D, Anna Mocová K, Fořtová K, Ryparová P, Pešta J, Pavlů T. Ecotoxicity and Essential Properties of Fine-Recycled Aggregate. Materials. 2021; 14(2):463. https://doi.org/10.3390/ma14020463

Chicago/Turabian StyleMariaková, Diana, Klára Anna Mocová, Kristina Fořtová, Pavla Ryparová, Jan Pešta, and Tereza Pavlů. 2021. "Ecotoxicity and Essential Properties of Fine-Recycled Aggregate" Materials 14, no. 2: 463. https://doi.org/10.3390/ma14020463

APA StyleMariaková, D., Anna Mocová, K., Fořtová, K., Ryparová, P., Pešta, J., & Pavlů, T. (2021). Ecotoxicity and Essential Properties of Fine-Recycled Aggregate. Materials, 14(2), 463. https://doi.org/10.3390/ma14020463