Porous Ultrahigh Molecular Weight Polyethylene/Functionalized Activated Nanocarbon Composites with Improved Biocompatibility

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.2.1. Preparation of FANC

2.2.2. Preparation of UHMWPE/FANC12.5

2.2.3. Preparation of Porous UHMWPE/FANC12.5

2.3. Testing and Characterization

2.3.1. FT-IR Spectroscopy and Morphological Analysis

2.3.2. Porosity Testing of Porous UHMWPE/FANC12.5

2.3.3. Mechanical Property Testing

2.3.4. Hydrophilicity Testing

2.3.5. Cell Viability Testing

2.3.6. Fluorescence Imaging

3. Results and Discussion

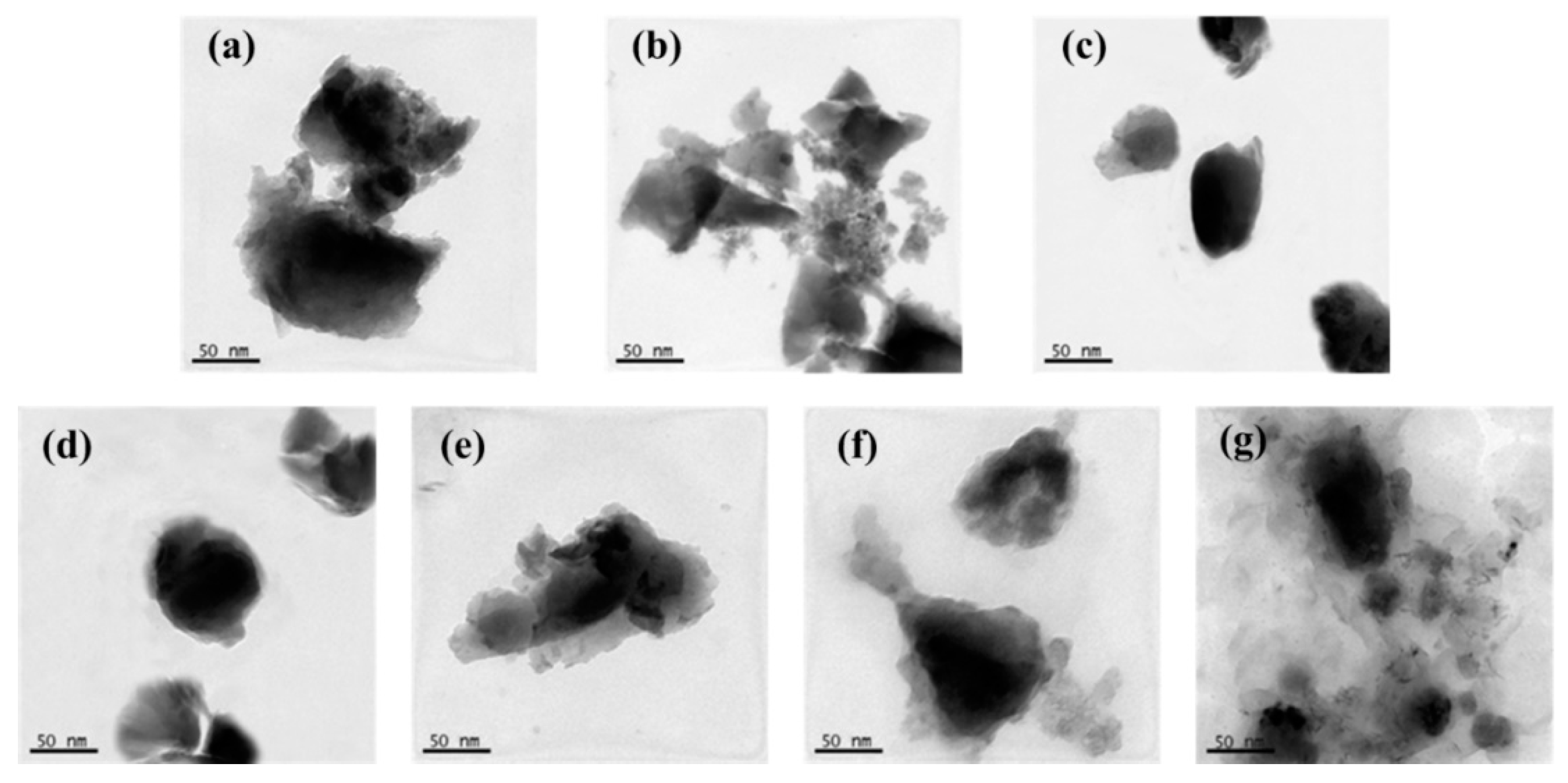

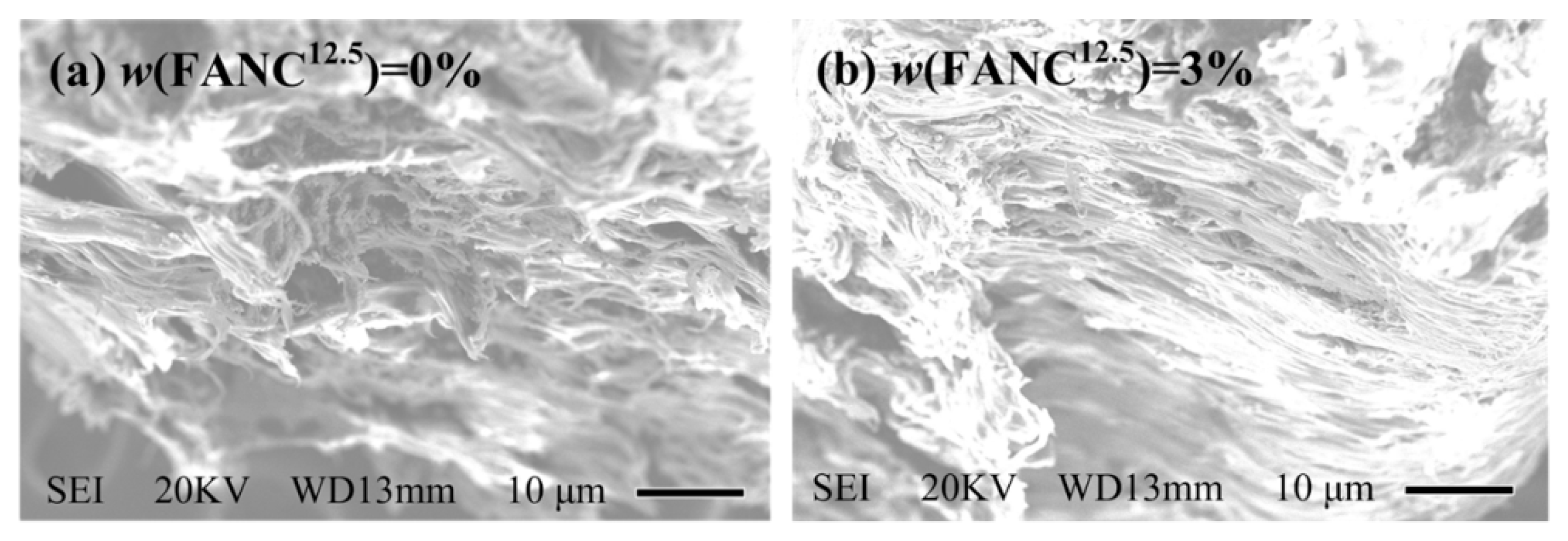

3.1. FT-IR Spectroscopy and Morphological Analysis

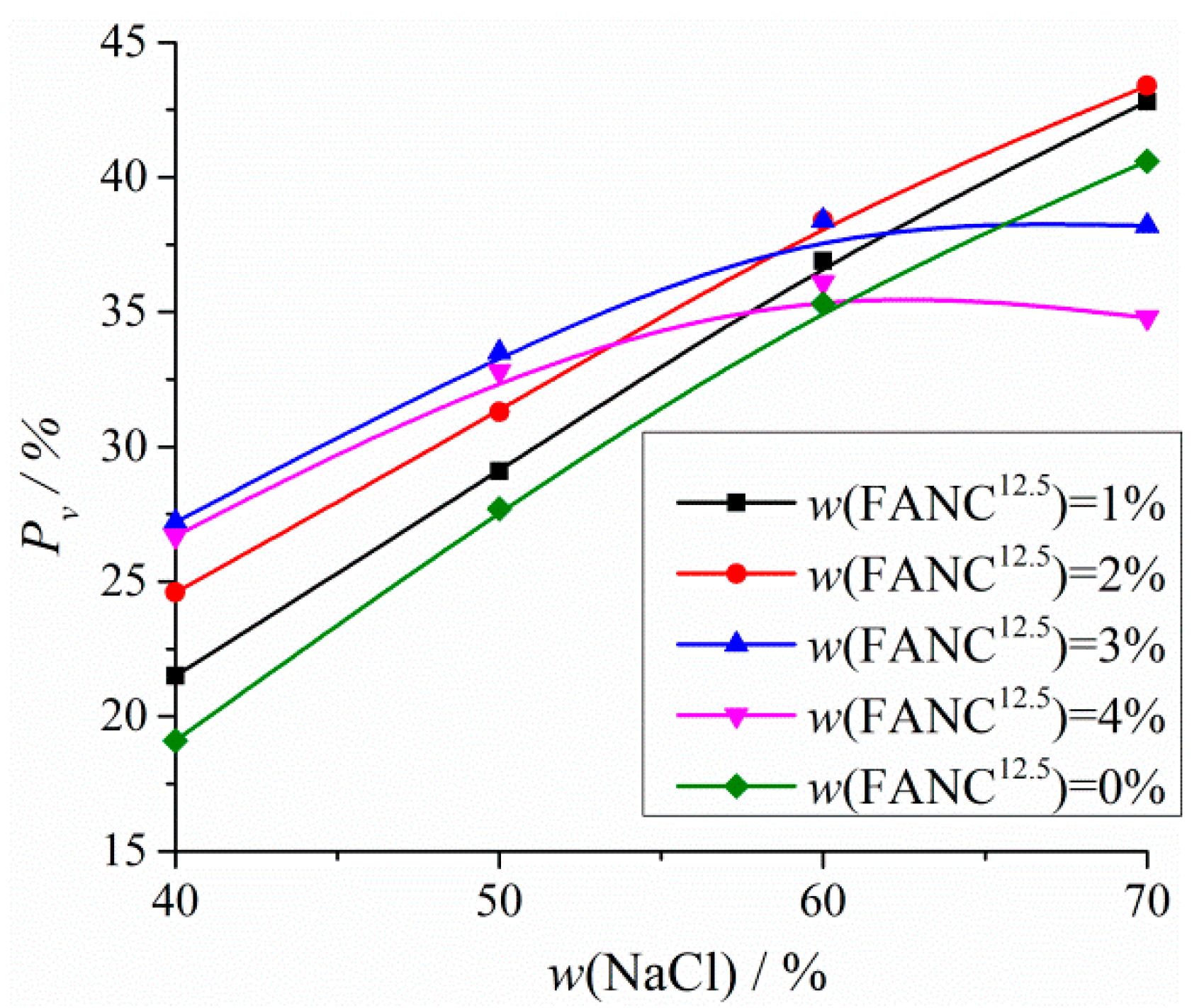

3.2. Balance between Porosity and Tensile Properties

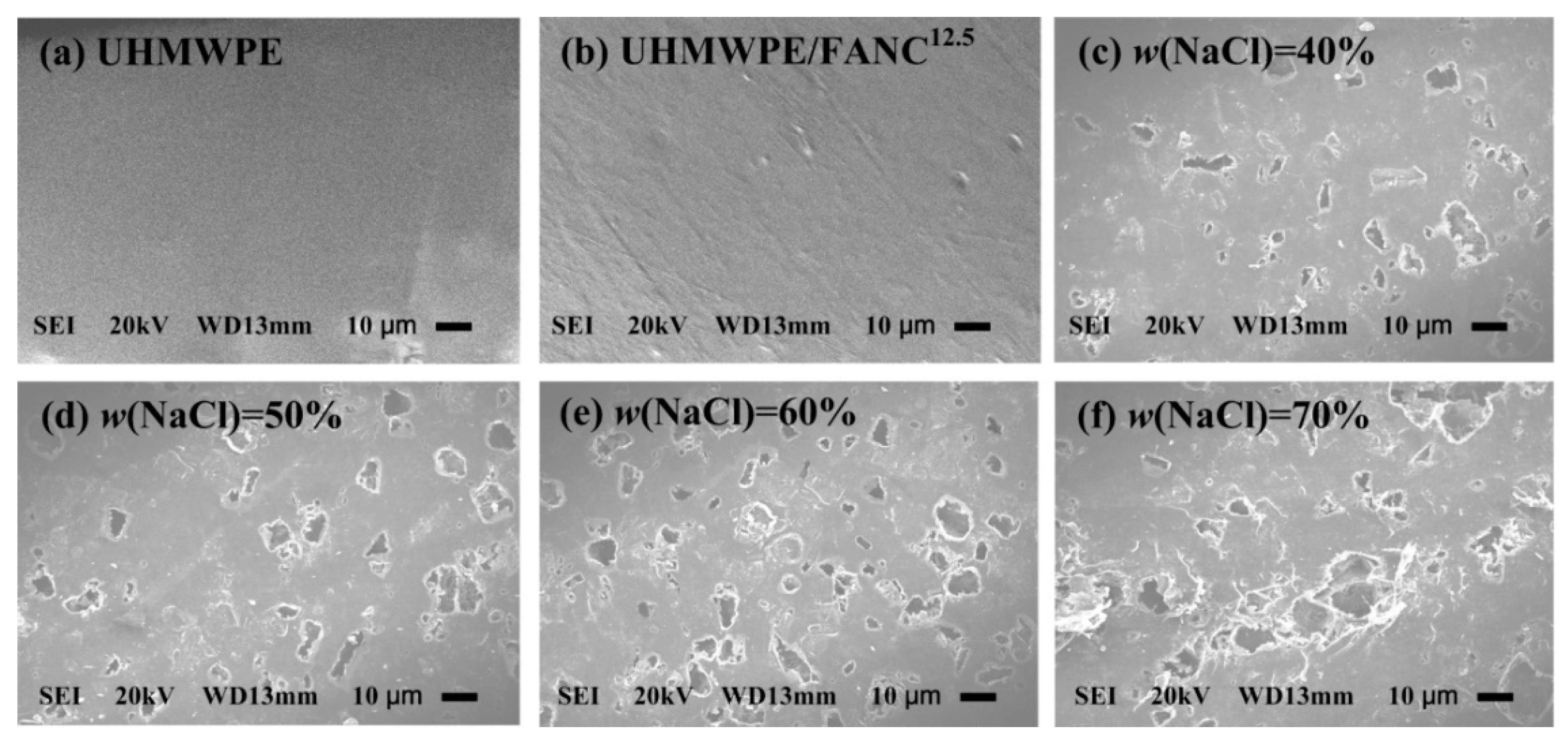

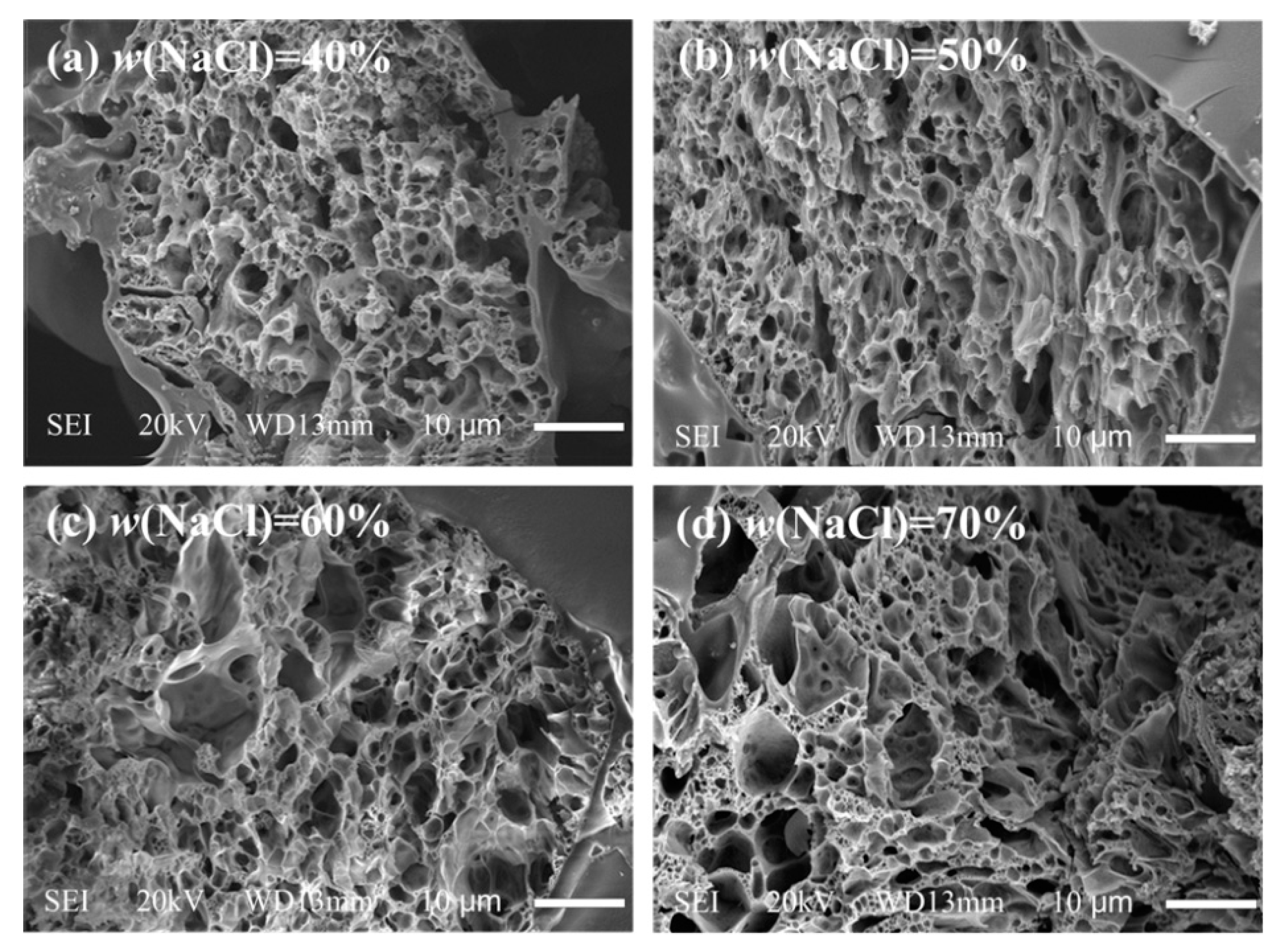

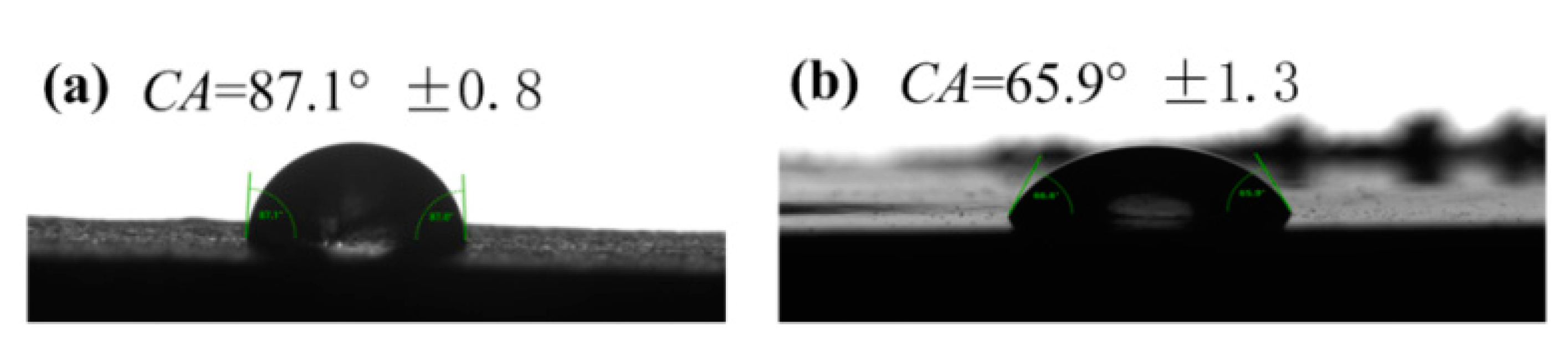

3.3. Surface Morphology and Wettability

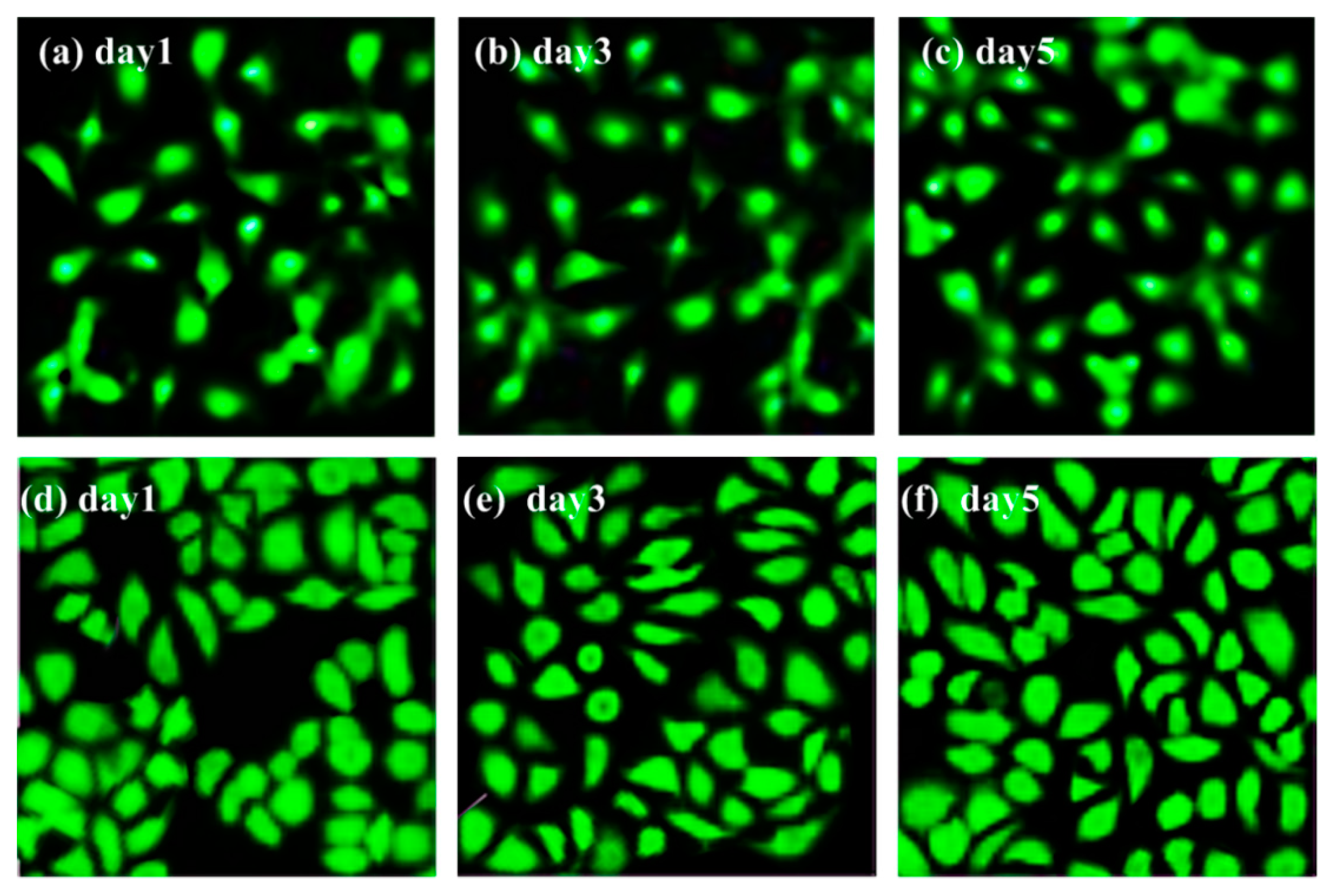

3.4. Biocompatibility

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Spector, M.; Flemming, W.R.; Kreutner, A.; Sauer, B.W. Bone growth into porous high-density polyethylene. J. Biomed. Mater. Res. 1976, 10, 595–603. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Zhao, J.; Koshut, W.J.; Watt, J.; Riboh, J.C.; Gall, K.; Wiley, B.J. A Synthetic Hydrogel Composite with the Mechanical Behavior and Durability of Cartilage. Adv. Funct. Mater. 2020, 30, 2003451. [Google Scholar] [CrossRef]

- Wu, G.; Zhao, C.H.; Qin, H.L.; Zhao, X.Z. Preparation and tribological behaviors of porous UHMWPE using as Aartificial cartilage. Adv. Mater. Res. 2011, 199, 651–654. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Y.; Zhang, H.; Wang, G.; Wei, H.; Zhang, X.; Ma, N. Bioinspired Conductive Hydrogel with Ultrahigh Toughness and Stable Antiswelling Properties for Articular Cartilage Replacement. ACS Mater. Lett. 2021, 3, 807–814. [Google Scholar] [CrossRef]

- Poliakov, A.; Pakhaliuk, V.; Popov, V.L. Current Trends in Improving of Artificial Joints Design and Technologies for Their Arthroplasty. Front. Mech. Eng. 2020, 6, 4. [Google Scholar] [CrossRef]

- Popov, V.L.; Poliakov, A.M.; Pakhaliuk, V.I. Synovial joints. Tribology, regeneration, regenerative rehabilitation and arthroplasty. Lubricants 2021, 9, 15. [Google Scholar] [CrossRef]

- No, Y.J.; Tarafder, S.; Reischl, B.; Ramaswamy, Y.; Dunstan, C.R.; Friedrich, O.; Lee, C.H.; Zreiqat, H. High-Strength Fiber-Reinforced Composite Hydrogel Scaffolds as Biosynthetic Tendon Graft Material. ACS Biomater. Sci. Eng. 2020, 6, 1887–1898. [Google Scholar] [CrossRef]

- Zheng, Y.D.; Wang, Y.J.; Chen, X.F.; Liu, Q.; Wu, G. Characterization and properties of poly(vinyl alcohol)/hydroxylapatite hydrogels prepared by compound in situ with sol gel method. Chem. J. Chin. Univ. 2005, 26, 1735–1738. [Google Scholar]

- Baker, M.I.; Walsh, S.P.; Schwartz, Z.; Boyan, B.D. A review of polyvinyl alcohol and its uses in cartilage and orthopedic applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2012, 100, 1451–1457. [Google Scholar] [CrossRef]

- Bykova, I.; Weinhardt, V.; Kashkarova, A.; Lebedev, S.; Baumbach, T.; Pichugin, V.; Zaitsev, K.; Khlusov, I. Physical properties and biocompatibility of UHMWPE-derived materials modified by synchrotron radiation. J. Mater. Sci. Mater. Med. 2014, 25, 1843–1852. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Olalde, B.; Ayerdi-Izquierdo, A.; Fernández, R.; García-Urkia, N.; Atorrasagasti, G.; Bijelic, G. Fabrication of ultrahigh-molecular-weight polyethylene porous implant for bone application. J. Polym. Eng. 2020, 40, 685–692. [Google Scholar] [CrossRef]

- Scholz, R.; Knyazeva, M.; Porchetta, D.; Nils, W.; Fedor, S.; Alexey, S. Development of biomimetic in vitro fatigue assessment for UHMWPE implant materials. J. Mech. Behav. Biomed. Mater. 2018, 85, 94–101. [Google Scholar] [CrossRef]

- Senatov, F.S.; Chubrik, A.V.; Maksimkin, A.V.; Kolesnikov, E.A.; Salimon, A.I. Comparative analysis of structure and mechanical properties of porous PEEK and UHMWPE biomimetic scaffolds. Mater. Lett. 2019, 239, 63–66. [Google Scholar] [CrossRef]

- Ribeiro, R.; Ganguly, P.; Darensbourg, D.; Usta, M.; Ucisik, A.H.; Liang, H. Biomimetic study of a polymeric composite material for joint repair applications. J. Mater. Res. 2007, 22, 1632–1639. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, S.; Zhang, L.; Zhu, P.; Zhang, G. Design and Characterization of the Surface Porous UHMWPE Composite Reinforced by Graphene Oxide. Polymers 2021, 13, 482. [Google Scholar] [CrossRef]

- Fan, W. Study on preparation and properties of porous bionic bone materials based on UHMWPE. New Chem. Mater. 2020, 48, 86–90. (In Chinese) [Google Scholar]

- Zhu, Y.; Kong, L.; Farhadi, F.; Xia, W.; Chang, J.; He, Y.; Li, H. An injectable continuous stratified structurally and functionally biomimetic construct for enhancing osteochondral regeneration. Biomaterials 2019, 192, 149–158. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Gao, S.; He, J.; An, Z.; Shao, C.; Ding, Y.; Jin, Z. Study on preparing of ultrahigh-molecular weight polyethylene microporous materials by novel non-dense injection molding method. J. Appl. Polym. Sci. 2021, 138, 51008. [Google Scholar] [CrossRef]

- Li, J.; Fu, R.; Wang, J.; Gu, X.; Zhao, W. The porous UHMWPE prepared by Templates-Leaching method and its structure. Plastics 2013, 42, 52–55. (In Chinese) [Google Scholar]

- Shutov, F. Cellular UHMWPE produced by non-foaming leaching technique: Morphology and properties. J. Cell. Plast. 2002, 38, 163–176. [Google Scholar] [CrossRef]

- Wu, G.; Zhang, W.; Wang, C. Study on the UHMWPE cartilage materials based on T-L technique. J. Funct. Mater. 2007, 38, 1694–1697. [Google Scholar]

- Sanguanruksa, I.; Rujiavanit, R.; Dupaphol, P. Porous polyethylene membranes by template-leaching technique preparation and characterization. Polym. Test. 2004, 23, 91–99. [Google Scholar] [CrossRef]

- Jaggi, H.S.; Kumar, S.; Das, D.; Satapathy, B.K.; Ray, A.R. Morphological correlations to mechanical performance of hydroxyapatite-filled HDPE/UHMWPE composites. J. Appl. Polym. Sci. 2015, 132, 41251. [Google Scholar] [CrossRef]

- Ramesh, N.; Moratti, S.C.; Dias, G.J. Hydroxyapatite-polymer biocomposites for bone regeneration: A review of current trends. J. Biomed. Mater. Res. Part B Appl. Biomater. 2018, 106, 2046–2057. [Google Scholar] [CrossRef] [PubMed]

- Thompson, B.C.; Murray, E.; Wallace, G.G. Graphite Oxide to Graphene. Biomaterials to Bionics. Adv. Mater. 2015, 27, 7563–7582. [Google Scholar] [CrossRef]

- Mahanta, A.K.; Senapati, S.; Paliwal, P.; Krishnamurthy, S.; Hemalatha, S.; Maiti, P. Nanoparticle-Induced Controlled Drug Delivery Using Chitosan-Based Hydrogel and Scaffold: Application to Bone Regeneration. Mol. Pharm. 2018, 16, 327–338. [Google Scholar] [CrossRef] [PubMed]

- Xue, Q.; Wang, Y. Impact of hyperbaric oxygen on nano-hydroxyapatite/ carboxymethyl chitosan/zoledronic acid biocomposite for bone tissue engineering. J. Clust. Sci. 2021, 32, 1–7. [Google Scholar]

- Pishbin, F.; Mouriño, V.; Flor, S.; Kreppel, S.; Salih, V.; Ryan, M.P.; Boccaccini, A.R. Electrophoretic Deposition of Gentamicin-Loaded Bioactive Glass/Chitosan Composite Coatings for Orthopaedic Implants. ACS Appl. Mater. Interfaces 2014, 6, 8796–8806. [Google Scholar] [CrossRef]

- Fan, W.-X.; Wang, C.-K.; Tsai, C.-C.; Ding, Y.; Tu, Z.-D.; Huang, C.-M.; Huang, K.-S.; Yeh, J.-T. Ultradrawing properties of ultrahigh molecular weight polyethylenes/functionalized activated nanocarbon as-prepared fibers. RSC Adv. 2016, 6, 3165–3175. [Google Scholar] [CrossRef]

- Fan, W.-X.; Tu, Z.-D.; Huang, C.-M.; Huang, K.-S.; Yeh, J.-T. Preparation of cellulose nanofibers and their improvement on ultradrawing properties of ultrahigh molecular weight polyethylene nanocomposite fibers. Polym. Adv. Technol. 2017, 28, 708–716. [Google Scholar] [CrossRef]

- Fan, W.-X.; Ding, Y.; Tu, Z.-D.; Huang, K.-S.; Huang, C.-M.; Yeh, J.-T. Enhancement on ultimate tensile properties of ultrahigh molecular weight polyethylene composite fibers filled with activated nanocarbon particles with varying specific surface areas. Polym. Eng. Sci. 2018, 58, 980–990. [Google Scholar] [CrossRef]

- Lv, Z.; Li, X.; Chen, X.; Li, X.; Wu, M.; Li, Z. One-Step Site-Specific Activation Approach for Preparation of Hierarchical Porous Carbon Materials with High Electrochemical Performance. ACS Appl. Energy Mater. 2019, 2, 8767–8782. [Google Scholar] [CrossRef]

- Wang, F.; Liu, H.; Ou, J.; Li, W. Fast fabrication of super hydrophobic surfaces on hardened cement paste using sodium laurate aqueous solution. Constr. Build. Mater. 2021, 278, 122385. [Google Scholar] [CrossRef]

- Tang, A.; Li, J.; Zhao, S.; Liu, T.; Wang, Q.; Wang, J. Biodegradable Tissue Engineering Scaffolds Based on Nanocellulose/PLGA Nanocomposite for NIH 3T3 Cell Cultivation. J. Nanosci. Nanotechnol. 2017, 17, 3888–3895. [Google Scholar] [CrossRef]

- Alves, A.C.; Thibeaux, R.; Toptan, F.; Pinto, A.M.P.; Ponthiaux, P.; David, B. Influence of macroporosity on NIH/3T3 adhesion, proliferation, and osteogenic differentiation of MC3T3-E1 over bio-functionalized highly porous titanium implant material. J. Biomed. Mater. Res. Part B Appl. Biomater. 2019, 107, 73–85. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, C.; Qiao, W.; Wang, C.; Wang, H.; Zhou, Y.; Gu, S.; Xu, W.; Zhuang, Y.; Shi, J.; Yang, H. Effect of poly (lactic acid) porous membrane prepared via phase inversion induced by water droplets on 3T3 cell behavior. Int. J. Biol. Macromol. 2021, 183, 2205–2214. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.; Zhang, W.; Wang, C. Tribological study of porous ultra-high molecular weight polyethylene. Tribology 2007, 27, 539–543. (In Chinese) [Google Scholar]

- Pawlak, Z.; Pai, R.; Mrela, A.; Kaczmarek, M.; Yusuf, K.Q.; Urbaniak, W. Natural articular cartilage: A smart biointerface. J. Comput. Methods Sci. Eng. 2019, 19, 479–489. [Google Scholar] [CrossRef]

- Hoey, D.; Taylor, D. Quantitative analysis of the effect of porosity on the fatigue strength of bone cement. Acta Biomat. 2009, 5, 719–726. [Google Scholar] [CrossRef] [PubMed]

- Evans, S.L. Effects of porosity on the fatigue performance of polymethyl methacrylate bone cement: An analytical investigation. Proc. Inst. Mech. Eng. H J. Eng. Med. 2006, 220, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Rambabu, K.; Alyammahi, J.; Bharath, G.; Thanigaivelan, A.; Sivarajasekar, N.; Banat, F. Nano-activated carbon derived from date palm coir waste for efficient sequestration of noxious 2,4-dichlorophenoxyacetic acid herbicide. Chemosphere 2021, 282, 131103. [Google Scholar] [CrossRef] [PubMed]

| Content of FANC12.5 in UHMWPE/FANC12.5 (wt.%) | δf (MPa) | |||

|---|---|---|---|---|

| w (NaCl) = 40% | w (NaCl) = 50% | w (NaCl) = 60% | w (NaCl) = 70% | |

| 0 | 17.1 ± 0.12 | 15.3 ± 0.14 | 10.2 ± 0.19 | 5.6 ± 0.24 |

| 1 | 15.2 ± 0.16 | 13.4 ± 0.16 | 8.5 ± 0.21 | 3.8 ± 0.26 |

| 2 | 16.3 ± 0.14 | 14.3 ± 0.16 | 9.3 ± 0.21 | 4.9 ± 0.24 |

| 3 | 17.6 ± 0.09 | 15.7 ± 0.13 | 14.3 ± 0.15 | 6.2 ± 0.21 |

| 4 | 18.2 ± 0.08 | 16.9 ± 0.11 | 15.1 ± 0.14 | 11.1 ± 0.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, W.; Fu, X.; Li, Z.; Ou, J.; Yang, Z.; Xiang, M.; Qin, Z. Porous Ultrahigh Molecular Weight Polyethylene/Functionalized Activated Nanocarbon Composites with Improved Biocompatibility. Materials 2021, 14, 6065. https://doi.org/10.3390/ma14206065

Fan W, Fu X, Li Z, Ou J, Yang Z, Xiang M, Qin Z. Porous Ultrahigh Molecular Weight Polyethylene/Functionalized Activated Nanocarbon Composites with Improved Biocompatibility. Materials. 2021; 14(20):6065. https://doi.org/10.3390/ma14206065

Chicago/Turabian StyleFan, Wangxi, Xiuqin Fu, Zefang Li, Junfei Ou, Zhou Yang, Meng Xiang, and Zhongli Qin. 2021. "Porous Ultrahigh Molecular Weight Polyethylene/Functionalized Activated Nanocarbon Composites with Improved Biocompatibility" Materials 14, no. 20: 6065. https://doi.org/10.3390/ma14206065

APA StyleFan, W., Fu, X., Li, Z., Ou, J., Yang, Z., Xiang, M., & Qin, Z. (2021). Porous Ultrahigh Molecular Weight Polyethylene/Functionalized Activated Nanocarbon Composites with Improved Biocompatibility. Materials, 14(20), 6065. https://doi.org/10.3390/ma14206065