Production of Aluminum AA6061 Hybrid Nanocomposite from Waste Metal Using Hot Extrusion Process: Strength Performance and Prediction by RSM and Random Forest

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of Hybrid Aluminum Nanocomposite

2.2. Response Surface Methodology (RSM)

2.3. Random Forest Model

2.3.1. Particle Swarm Optimisation (PSO)

2.3.2. RF Hyper-Parameter Optimisation and Evaluation

3. Results and Discussion

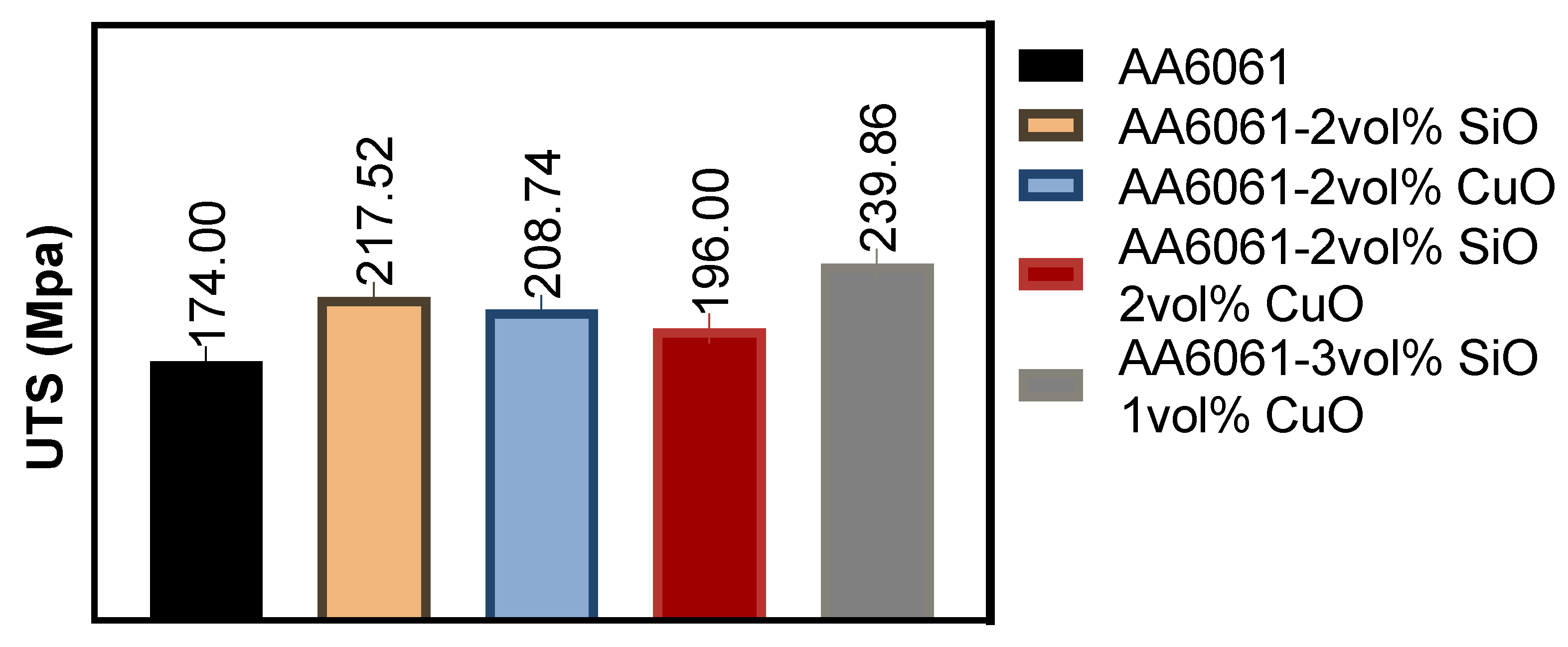

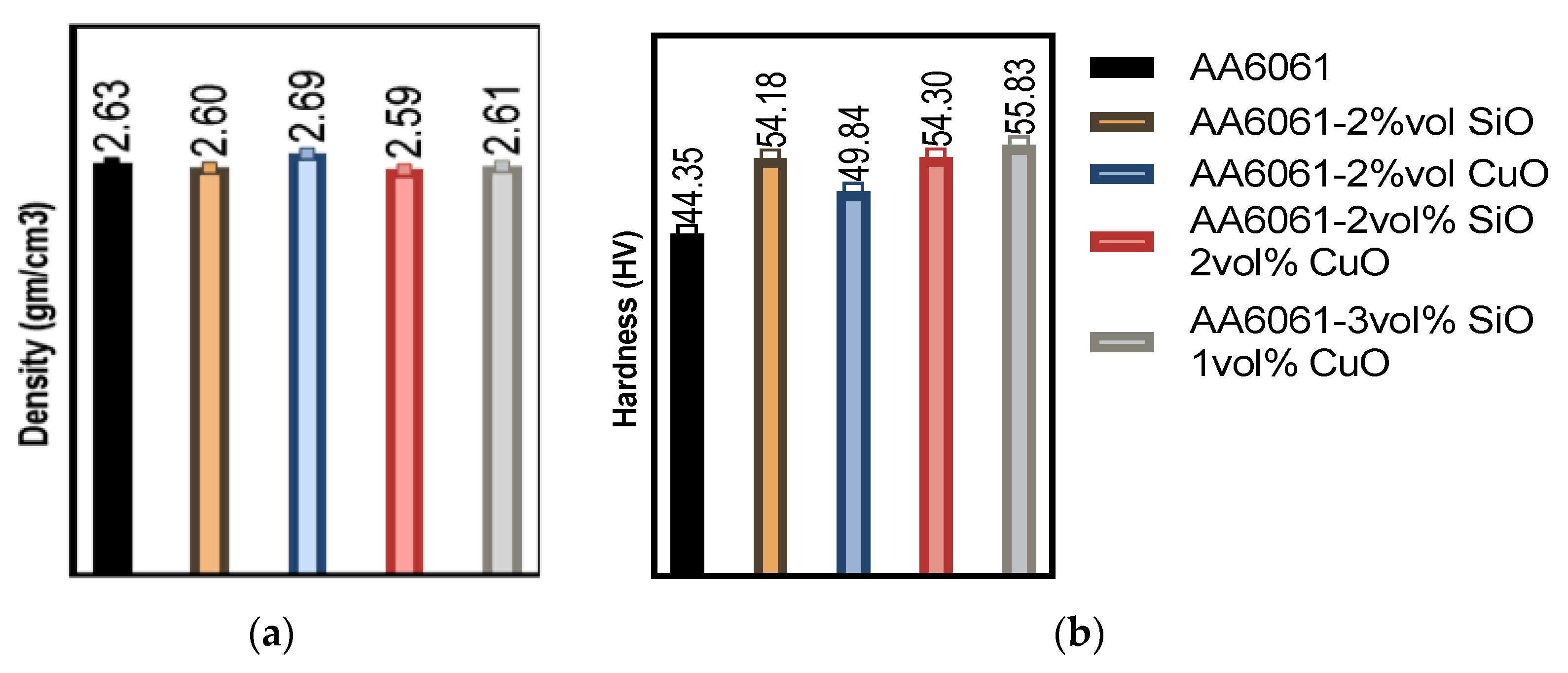

3.1. Comparison between Single and Hybrid Nano-Reinforcement

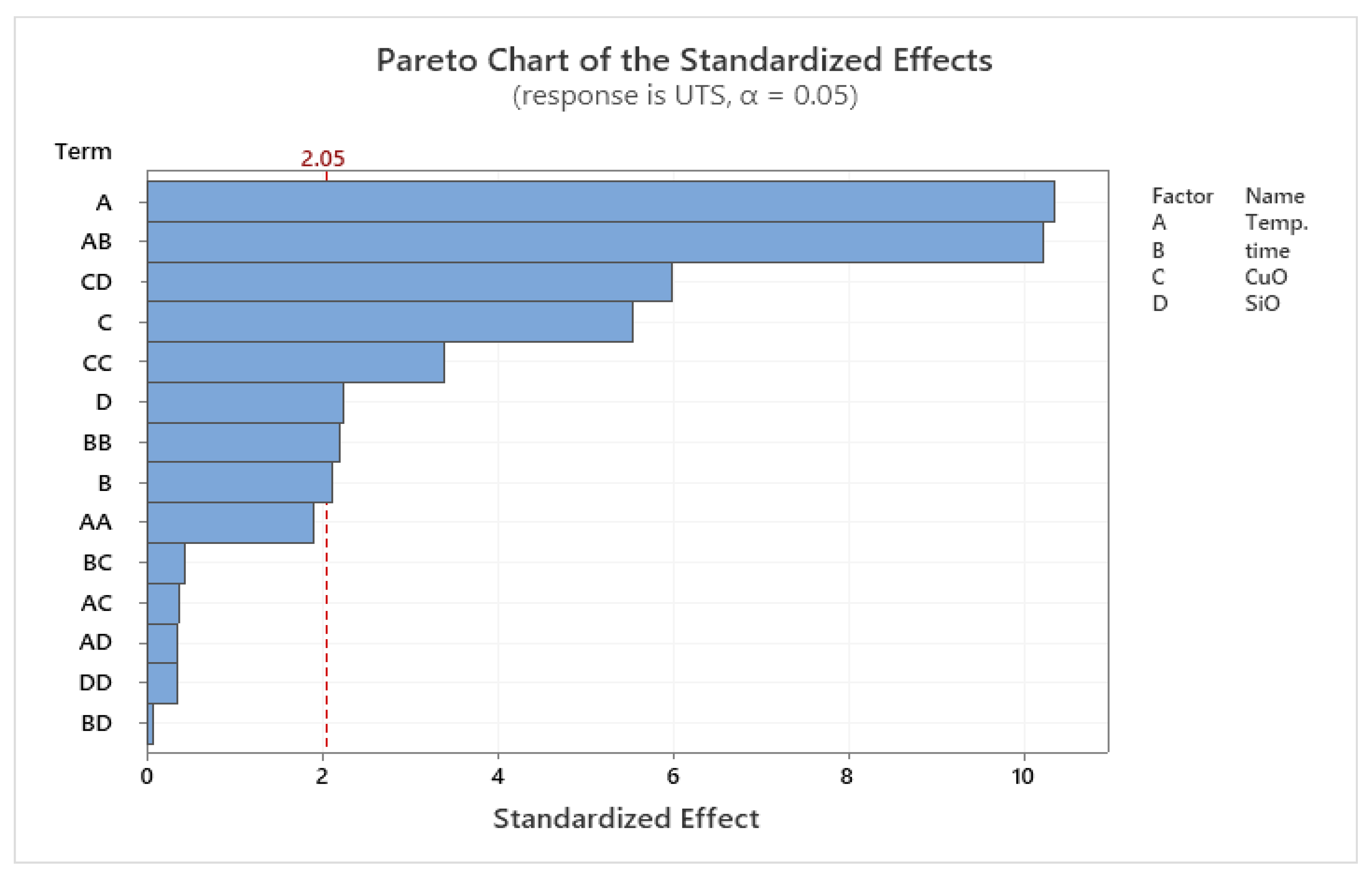

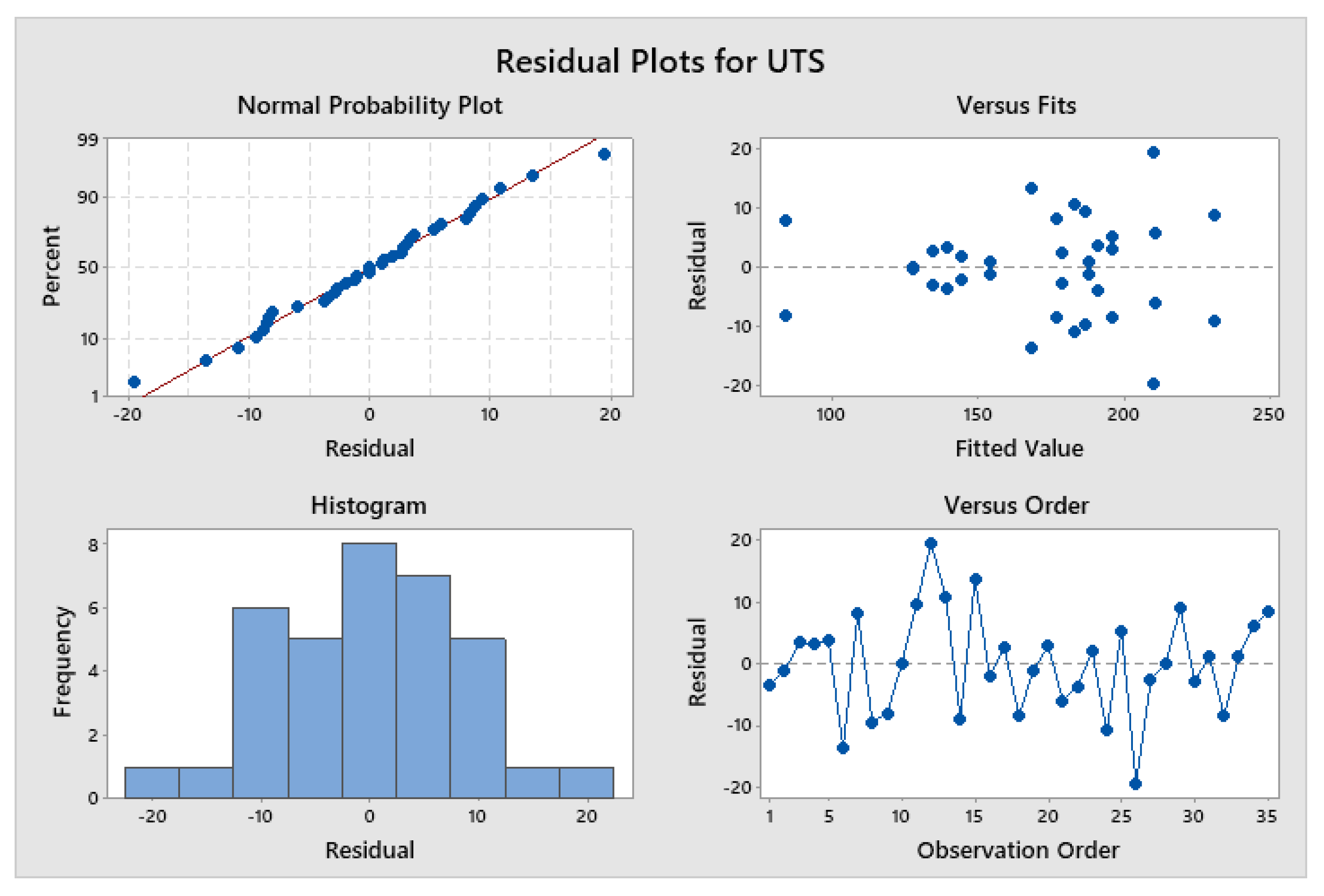

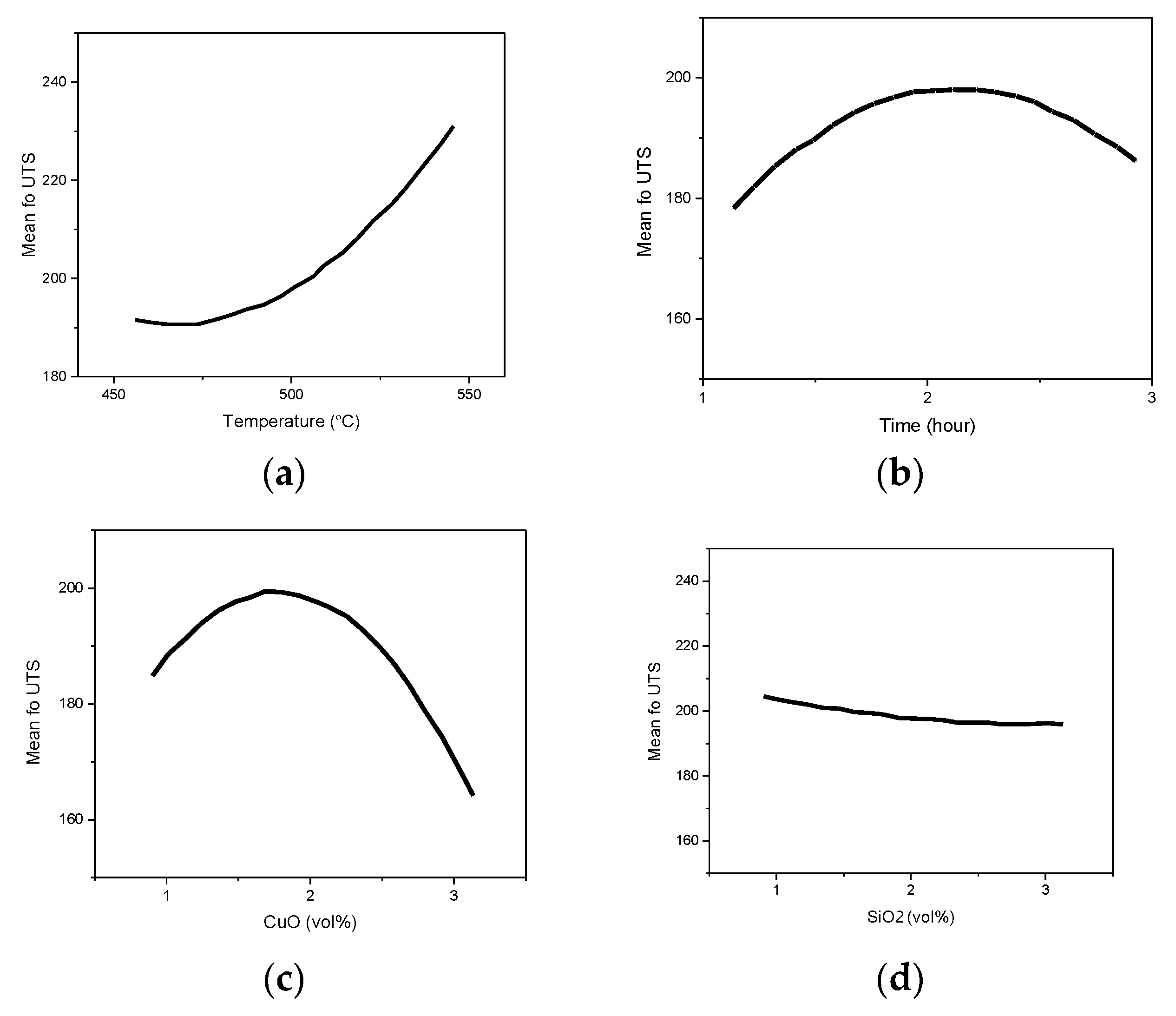

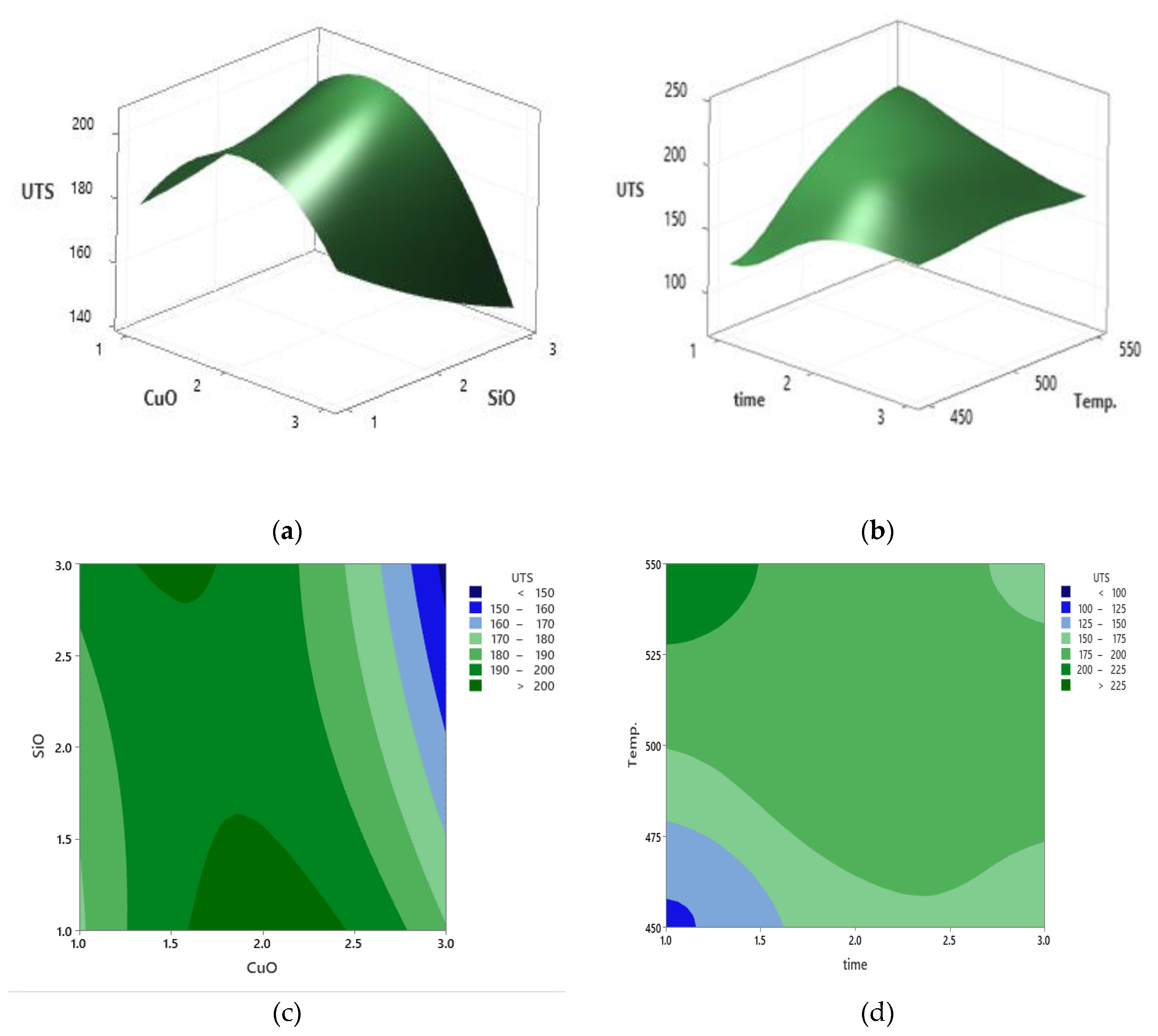

3.2. Response Surface Methodology (RSM) for UTS

× Time − 25.27CuO × CuO + 2.59SiO2 × SiO2 − 0.4277Temp. × Time + 0.0152Temp. × CuO − 0.0148Temp. ×

SiO2 + 0.92Time × CuO + 0.15Time × SiO2 − 12.51CuO × SiO2

Optimisation of UTS

3.3. RSM for Microhardness

PHti − 1.633CuO × CuO − 0.093SiO2 × SiO2 + 0.00260PHT × PHti − 0.00399PHT × CuO + 0.03361PHT × SiO2

+ 0.239PHti × CuO + 0.392PHti × SiO2 + 0.783CuO × SiO2

Optimisation of Microhardness

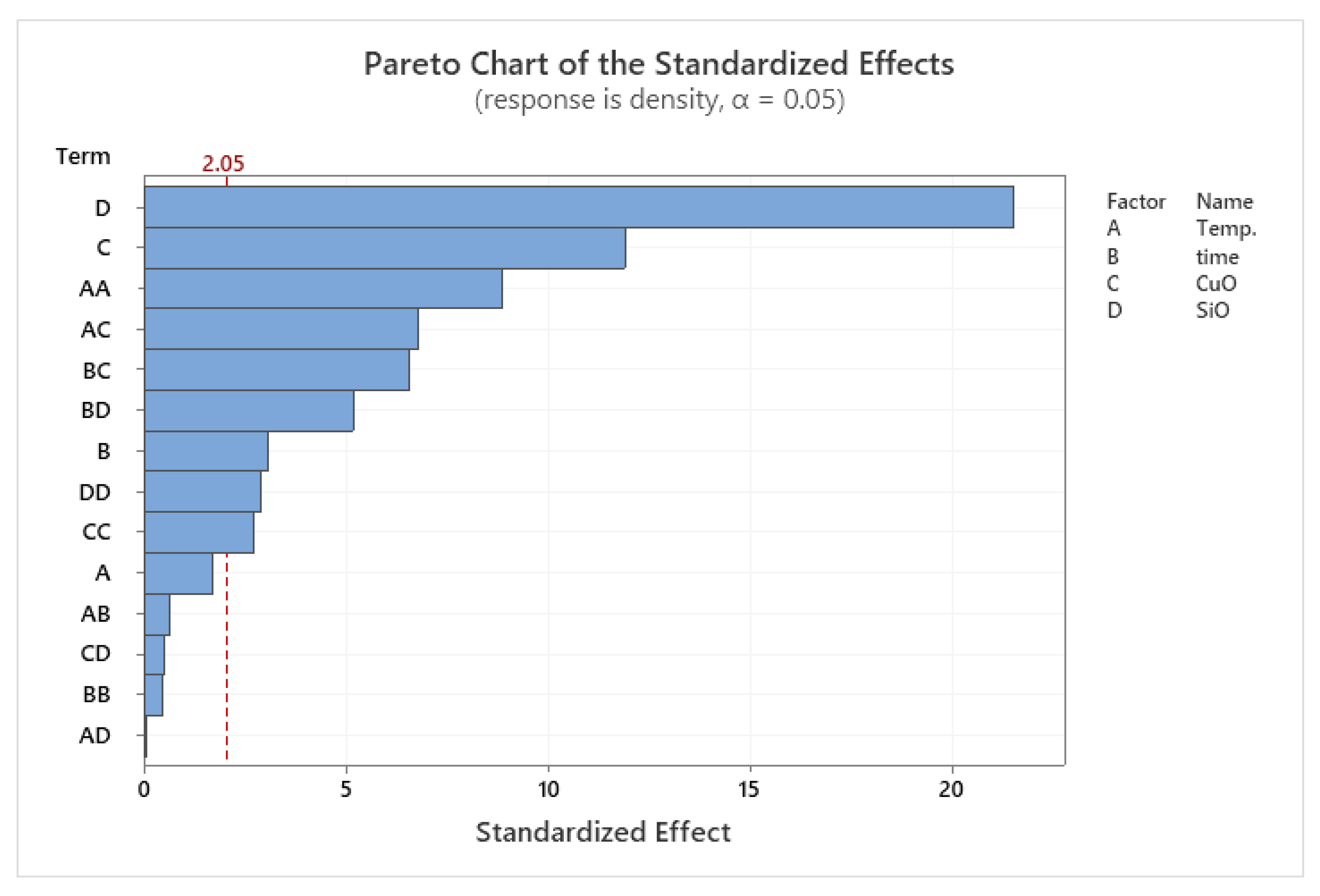

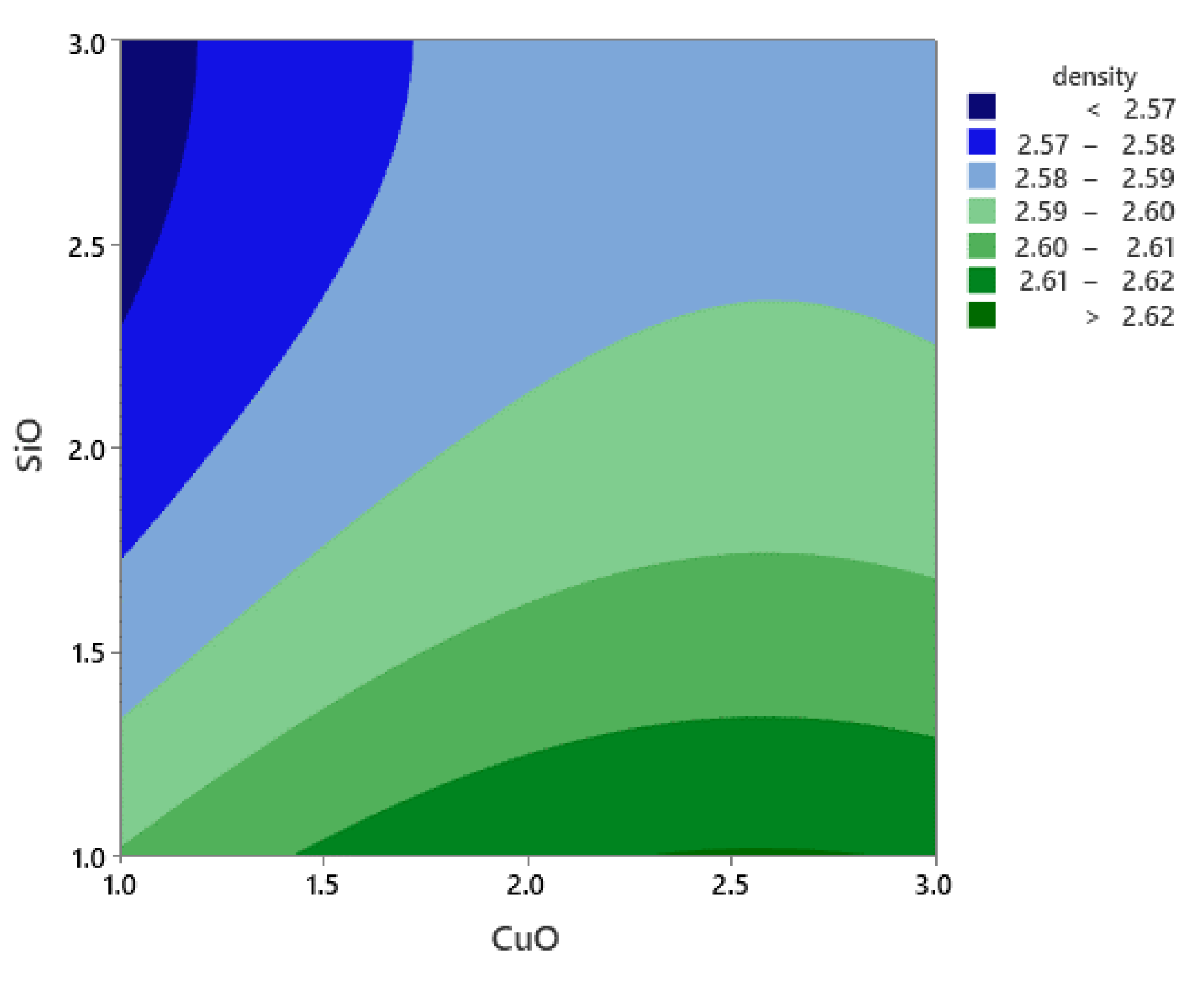

3.4. RSM for Density

PHT + 0.00137PHti × PHti − 0.00808CuO × CuO + 0.00857SiO2 × SiO2 + 0.000011PHT × PHti − 0.000113PHT × CuO

+ 0.000001PHT × SiO2 − 0.005456PHti × CuO − 0.004300PHti × SiO2 + 0.000425CuO × SiO2

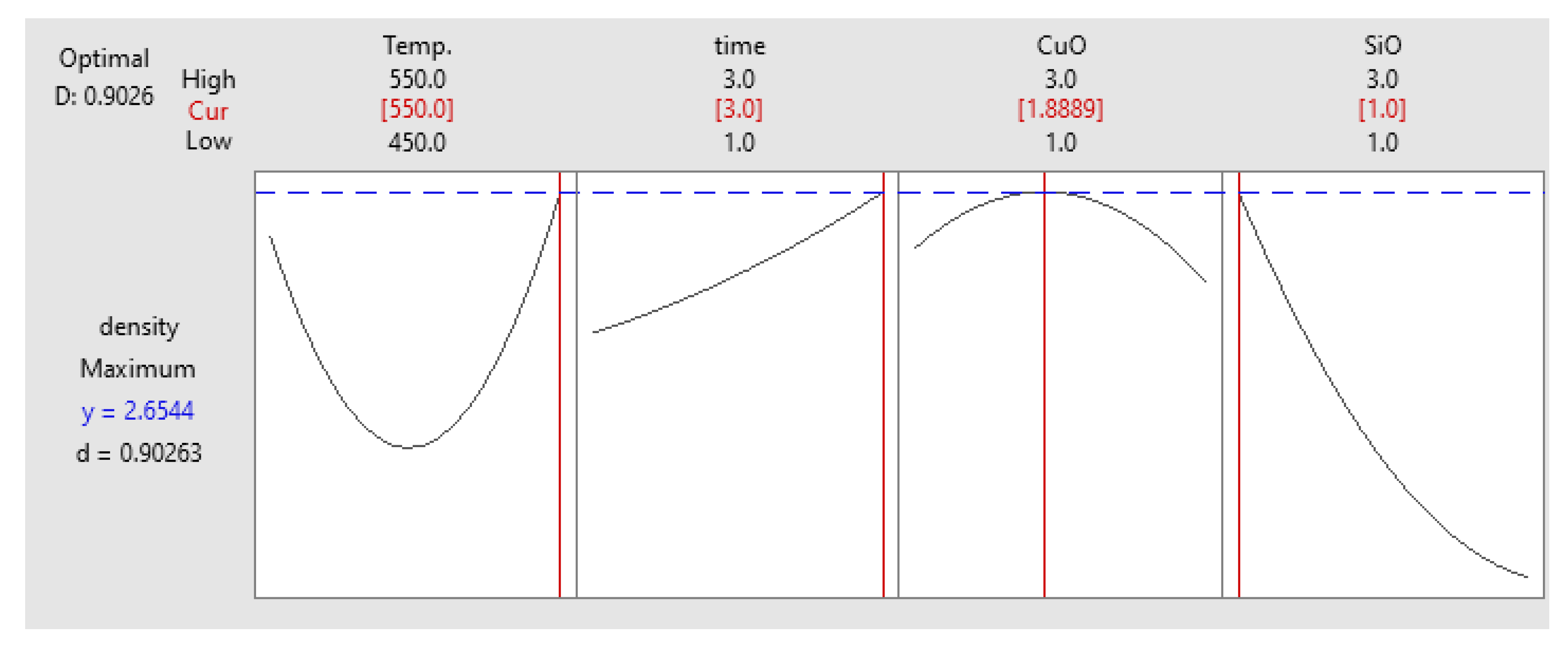

Optimisation of Density

3.5. Multi-Objective Optimisation

3.6. Confirmation Test

3.7. Overall RF Results for Validation and Prediction

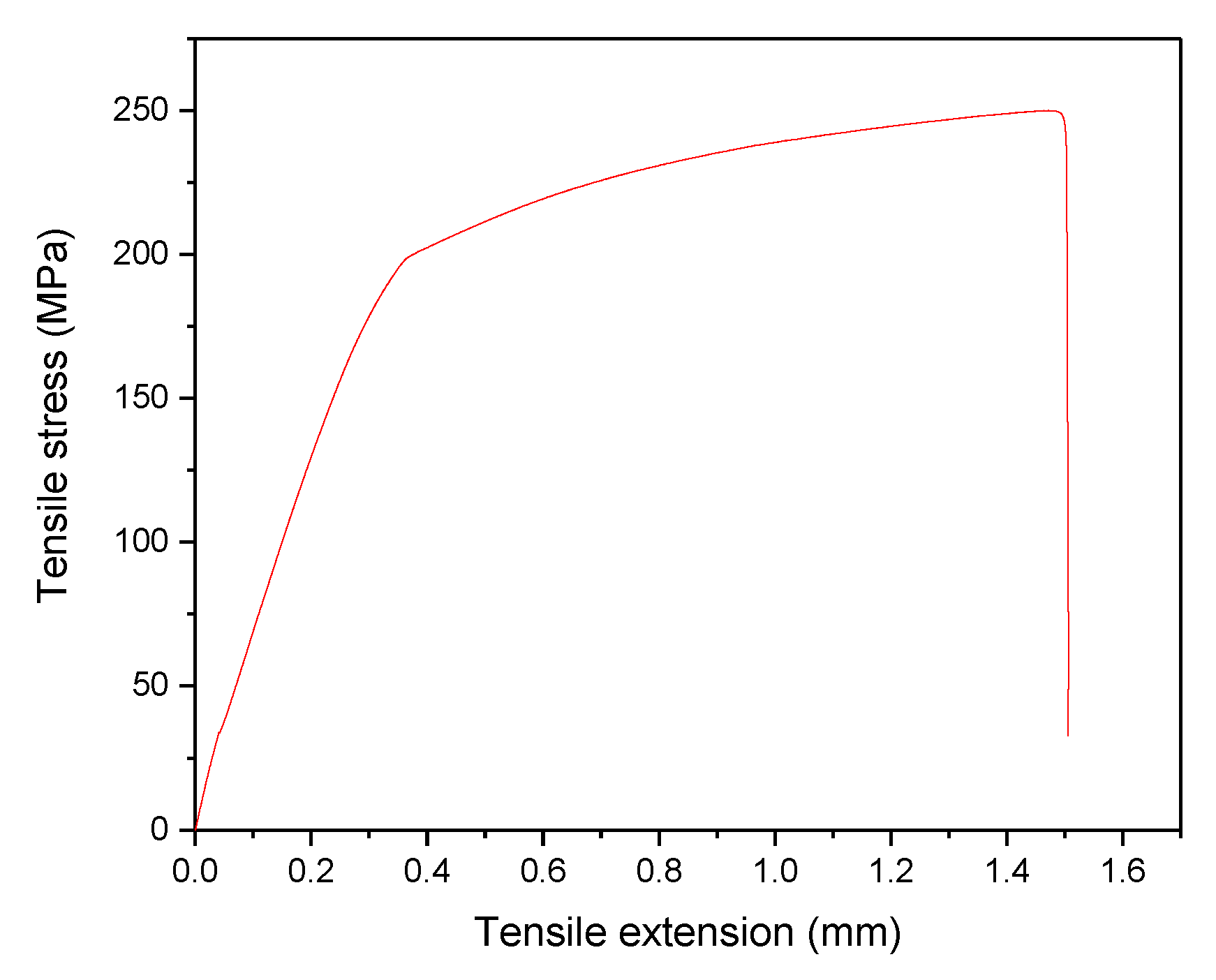

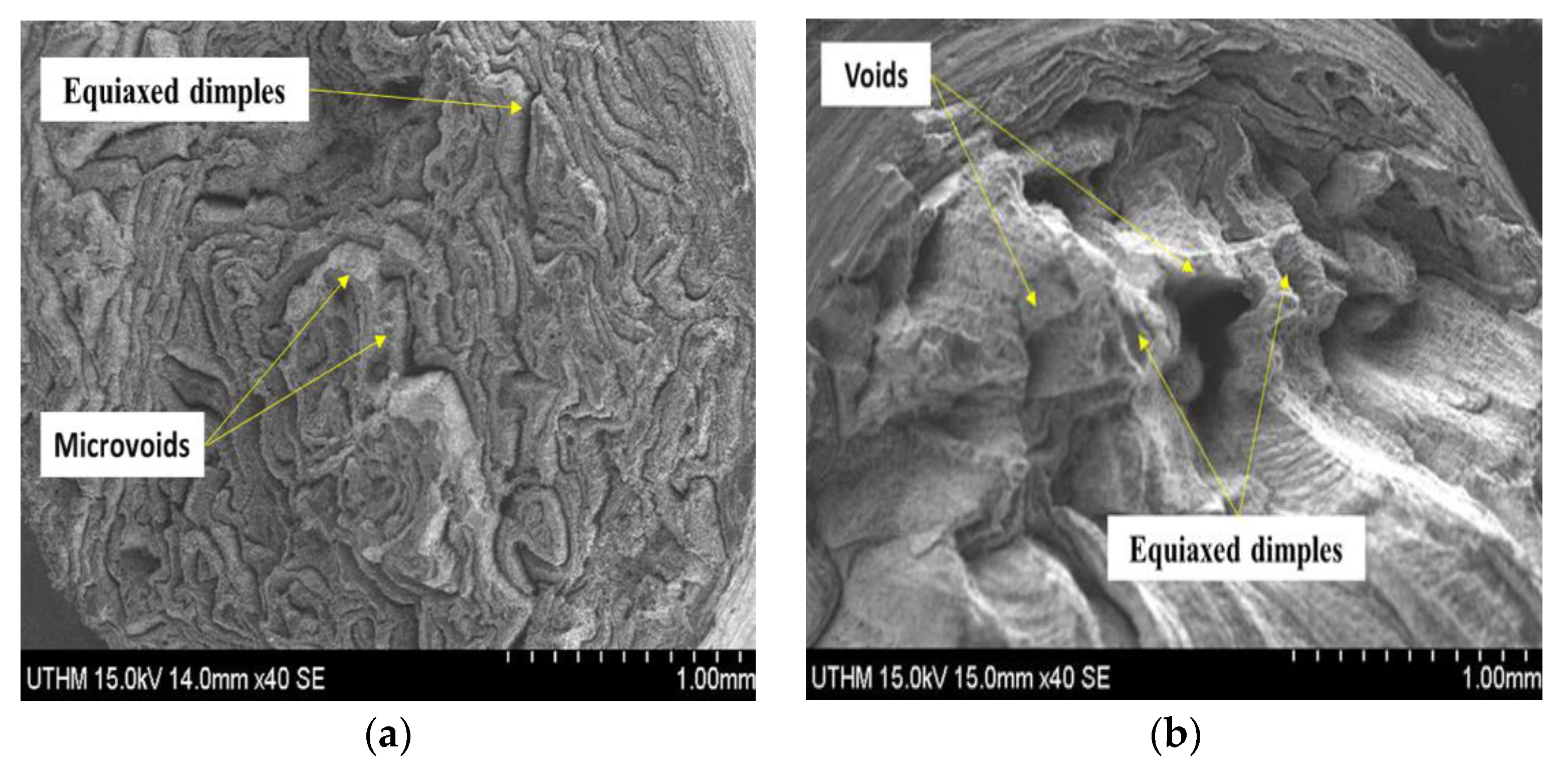

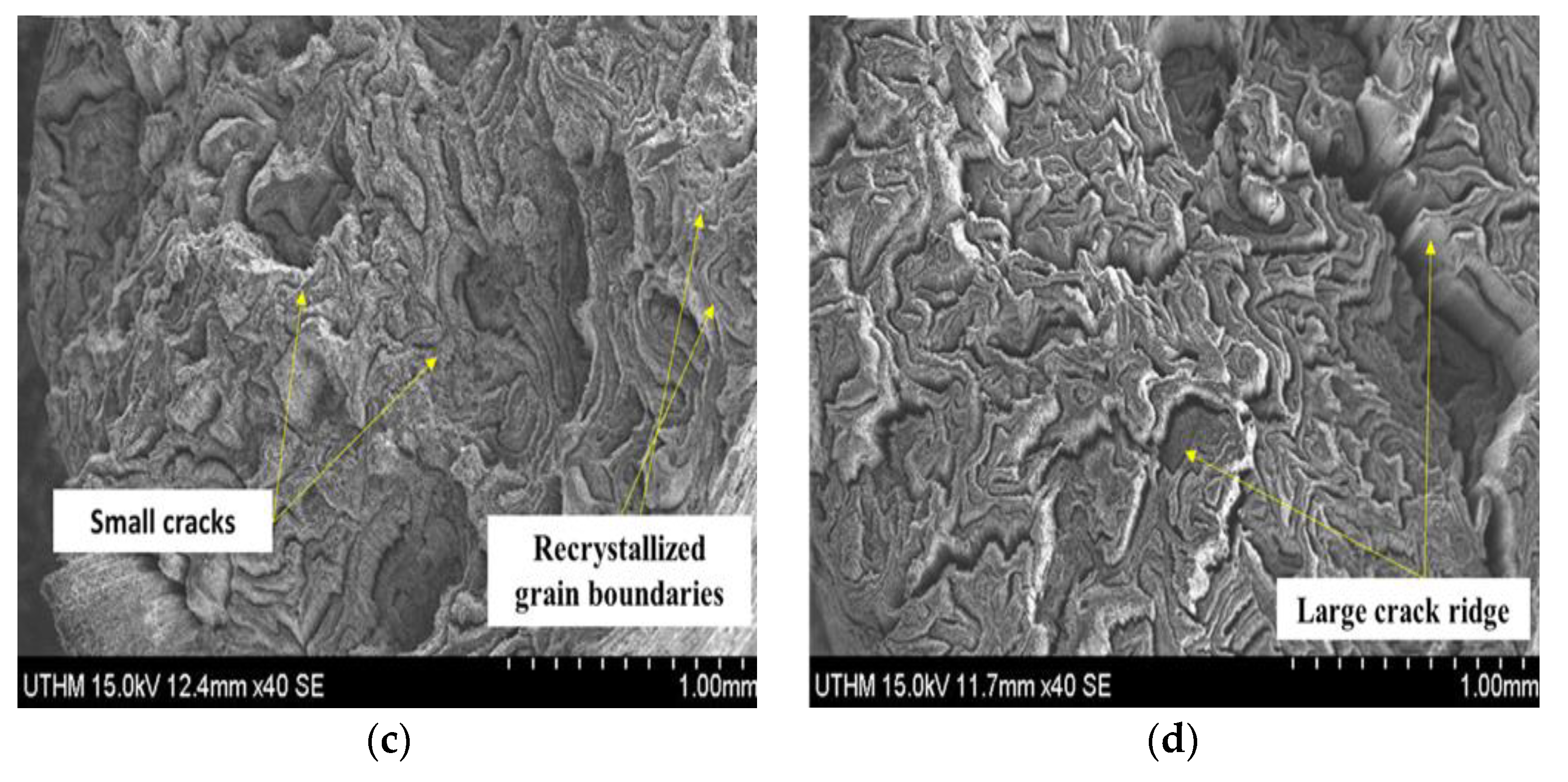

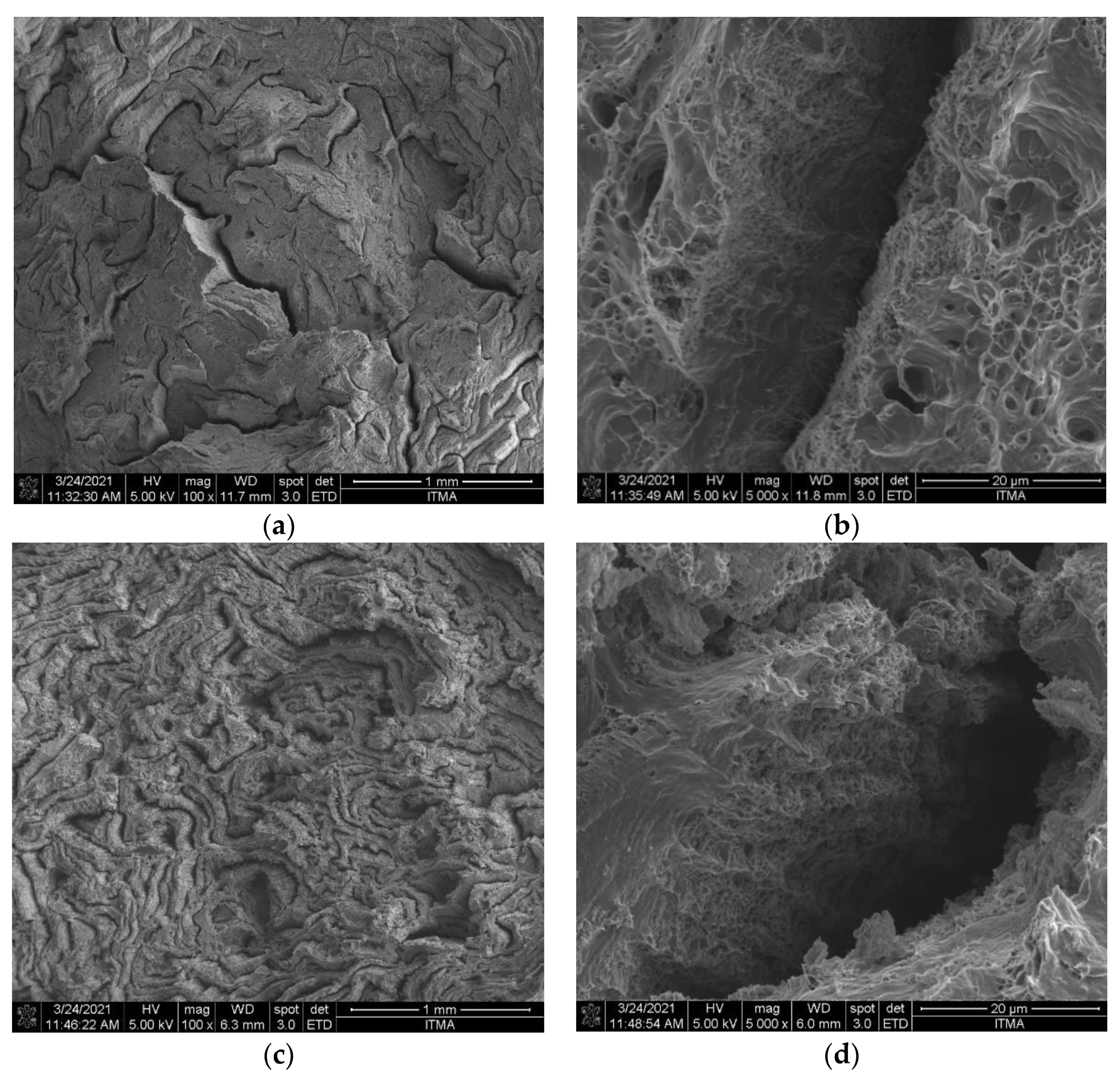

3.8. Fractographic Analysis of Tensile Sample

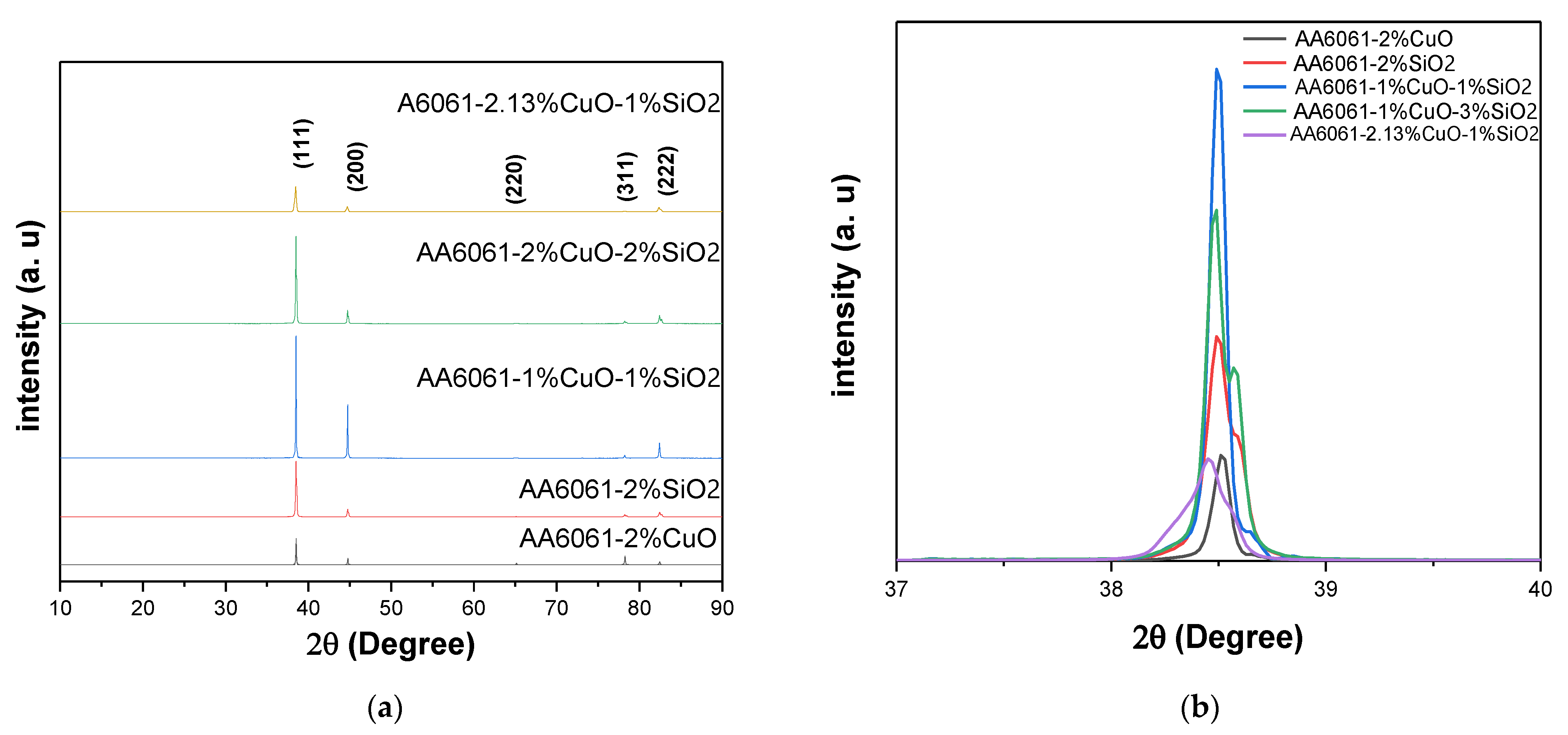

3.9. X-ray Diffraction (XRD) Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmad, A.; Lajis, M.A.; Yusuf, N.K.; Wagiman, A. Hot Press Forging as The Direct Recycling Technique of Aluminium—A Review. ARPN J. Eng. Appl. Sci. 2016, 11, 2258–2265. [Google Scholar]

- Birbilis, N.; Hinton, B. Fundamentals of Aluminium Metallurgy; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Rady, M.; Mustapa, M.; Harimon, M.; Ibrahim, M.; Shamsudin, S.; Lajis, M.; Wagiman, A.; Msebawi, M.; Yusof, F. Effect of hot extrusion parameters on microhardness and microstructure in direct recycling of aluminium chips. Mater. Werkst. 2019, 50, 718–723. [Google Scholar] [CrossRef]

- Lee, C.J.; Murakami, R.-I.; Suh, C.M. Fatigue properties of aluminum alloy (a6061-t6) with ultrasonic nano-crystal surface modification. Int. J. Mod. Phys. B 2010, 24, 2512–2517. [Google Scholar] [CrossRef]

- Hamzah, M.Q.; Mezan, S.O.; Tuama, A.N.; Jabbar, A.H.; Agam, M.A. Study and Characterisation of Polystyrene/Titanium Dioxide Nanocomposites (PS/TiO2 NCs) for Photocatalytic Degradation Application: A Review. Int. J. Eng. Technol. 2018, 7, 538–543. [Google Scholar] [CrossRef]

- Güley, V.; Güzel, A.; Jäger, A.; Ben Khalifa, N.; Tekkaya, A.; Misiolek, W. Effect of die design on the welding quality during solid state recycling of AA6060 chips by hot extrusion. Mater. Sci. Eng. A 2013, 574, 163–175. [Google Scholar] [CrossRef]

- Mahdi, A.S.; Mustapa, M.S.; Latif, N.A.; Ab Kadir, M.I.; Samsi, M.A. Heat treatment for an recycling aluminum aa6061 using milling process at various holding aging time. Int. J. Eng. Technol. 2016, 8, 2582–2587. [Google Scholar] [CrossRef] [Green Version]

- Hussein Rady, M.; Mustapa, M.S.; Wagiman, A.; Al-Alimi, S.; Shamsudin, S.; Lajis, M.A.; Mansor, M.N.; Harimon, M.A. Effect of the heat treatment on mechanical and physical properties of direct recycled aluminium alloy (AA6061). Int. J. Integr. Eng. 2020, 12, 82–89. [Google Scholar] [CrossRef]

- Shamsudin, S.; Lajis, M.; Zhong, Z. Solid-state recycling of light metals: A review. Adv. Mech. Eng. 2016, 8, 1687814016661921. [Google Scholar] [CrossRef] [Green Version]

- Safiuddin, M.; Jumaat, M.Z.; Salam, M.A.; Islam, M.S.; Hashim, R. Utilisation of solid wastes in construction materials. Int. J. Phys. Sci. 2010, 5, 1952–1963. [Google Scholar]

- Allaker, R.P. Nanoparticles and the Control of Oral Biofilms; Elsevier Inc.: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Zhu, H.; Dong, K.; Huang, J.; Li, J.; Wang, G.; Xie, Z. Reaction mechanism and mechanical properties of an aluminum-based composite fabricated in-situ from Al–SiO2 system. Mater. Chem. Phys. 2014, 145, 334–341. [Google Scholar] [CrossRef]

- Huo, H.; Woo, K.D. In situ synthesis of Al2O3 particulate-reinforced Al matrix composite by low temperature sintering. J. Mater. Sci. 2006, 41, 3249–3253. [Google Scholar] [CrossRef]

- Issa, H.K.; Taherizadeh, A.; Maleki, A.; Ghaei, A. Development of an aluminum/amorphous nano-SiO2 composite using powder metallurgy and hot extrusion processes. Ceram. Int. 2017, 43, 14582–14592. [Google Scholar] [CrossRef]

- Rady, M.H.; Mahdi, A.S.; Mustapa, M.S.; Shamsudin, S.; Lajis, M.A.; Msebawi, M.S.; Siswanto, W.A.; Al Alimi, S. Effect of Heat Treatment on Tensile Strength of Direct Recycled Aluminium Alloy (AA6061). Mater. Sci. Forum 2019, 961, 80–87. [Google Scholar] [CrossRef]

- Sabbar, H.M.; Shamsudin, S.; Abbas, M.A.; Msebawi, M.S.; Mustapa, M.S.; Lajis, M.A.; Rady, M.H.; Al Alim, S. Study on the Wear Influence for Recycled AA6061 Aluminum/Al2O3 Utilizing the Face Central-Full Factorial Technique (FCFFT). In Advances in Material Sciences and Engineering; Springer: Berlin/Heidelberg, Germany, 2020; pp. 599–608. [Google Scholar]

- Cai, Z.; Zhang, C.; Wang, R.; Peng, C.; Wu, X. Effect of copper content on microstructure and mechanical properties of Al/Sip composites consolidated by liquid phase hot pressing. Mater. Des. 2016, 110, 10–17. [Google Scholar] [CrossRef]

- Raju, P.V.K.; Rajesh, S.; Rao, J.B.; Bhargava, N. Tribological behavior of Al-Cu alloys and innovative Al-Cu metal matrix composite fabricated using stir-casting technique. Mater. Today Proc. 2018, 5, 885–896. [Google Scholar] [CrossRef]

- Ferguson, J.; Aguirre, I.; Lopez, H.; Schultz, B.F.; Cho, K.; Rohatgi, P.K. Tensile properties of reactive stir-mixed and squeeze cast Al/CuOnp-based metal matrix nanocomposites. Mater. Sci. Eng. A 2014, 611, 326–332. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.; Mahmoodi, M.; Ansari, R. A comprehensive predicting model for thermomechanical properties of particulate metal matrix nanocomposites. J. Alloy. Compd. 2018, 739, 164–177. [Google Scholar] [CrossRef]

- Hitziger, M.; Ließ, M. Comparison of Three Supervised Learning Methods for Digital Soil Mapping: Application to a Complex Terrain in the Ecuadorian Andes. Appl. Environ. Soil Sci. 2014, 2014, 1–12. [Google Scholar] [CrossRef]

- Jamson, A.H.; Merat, N.; Carsten, O.M.; Lai, F.C. Behavioural changes in drivers experiencing highly-automated vehicle control in varying traffic conditions. Transp. Res. Part C Emerg. Technol. 2013, 30, 116–125. [Google Scholar] [CrossRef] [Green Version]

- Suzuki, Y.; Hino, H.; Hawai, T.; Saito, K.; Kotsugi, M.; Ono, K. Symmetry prediction and knowledge discovery from X-ray diffraction patterns using an interpretable machine learning approach. Sci. Rep. 2020, 10, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Papadopoulos, S.; Azar, E.; Woon, W.L.; Kontokosta, C. Evaluation of tree-based ensemble learning algorithms for building energy performance estimation. J. Build. Perform. Simul. 2017, 11, 322–332. [Google Scholar] [CrossRef]

- McWilliams, C.J.; Lawson, D.J.; Santos-Rodriguez, R.; Gilchrist, I.D.; Champneys, A.; Gould, T.H.; Thomas, M.J.; Bourdeaux, C.P. Towards a decision support tool for intensive care discharge: Machine learning algorithm development using electronic healthcare data from MIMIC-III and Bristol, UK. BMJ Open 2019, 9, e025925. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hajjem, A.; Bellavance, F.; Larocque, D. Mixed-effects random forest for clustered data. J. Stat. Comput. Simul. 2014, 84, 1313–1328. [Google Scholar] [CrossRef]

- Chiba, R.; Yoshimura, M. Solid-state recycling of aluminium alloy swarf into c-channel by hot extrusion. J. Manuf. Process. 2015, 17, 1–8. [Google Scholar] [CrossRef]

- Kondoh, K.; Luangvaranunt, T.; Aizawa, T. Solid-State Recycle Processing for Magnesium Alloy Waste via Direct Hot Forging. Mater. Trans. 2002, 43, 322–325. [Google Scholar] [CrossRef]

- Fann, K.-J.; Chen, C.-C. Grain Size in Aluminum Alloy 6061 under Hot Ring Compression Test and after T6 Temper. Appl. Sci. 2017, 7, 372. [Google Scholar] [CrossRef]

- Ab Rahim, S.; Lajis, M.; Ariffin, S. A Review on Recycling Aluminum Chips by Hot Extrusion Process. Procedia CIRP 2015, 26, 761–766. [Google Scholar] [CrossRef] [Green Version]

- Majdi, H.; Razaghian, A.; Emamy, M.; Motallebi, N. The effects of Cu addition and solutionising heat treatment on the microstructure and wear properties of hot-extruded Al–Mg2Si eutectic alloy. Adv. Mater. Process. Technol. 2017, 3, 164–173. [Google Scholar] [CrossRef]

- Rachman, A.; Ratnayake, R.C. Machine learning approach for risk-based inspection screening assessment. Reliab. Eng. Syst. Saf. 2019, 185, 518–532. [Google Scholar] [CrossRef]

- Li, S.; Zhang, X. Research on orthopedic auxiliary classification and prediction model based on XGBoost algorithm. Neural Comput. Appl. 2020, 32, 1971–1979. [Google Scholar] [CrossRef]

- Injadat, M.; Moubayed, A.; Nassif, A.B.; Shami, A. Systematic ensemble model selection approach for educational data mining. Knowl. -Based Syst. 2020, 200, 105992. [Google Scholar] [CrossRef]

- Eberhart, R.C.; Shi, Y. Comparison between genetic algorithms and particle swarm optimization. In International Conference on Evolutionary Programming; Springer: Berlin/Heidelberg, Germeny, 1998; Volume 1447, pp. 611–616. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Y.; Wang, Y.; Wang, L.; Song, X.; Zhao, X. Survival Risk Prediction of Esophageal Cancer Based on Self-Organizing Maps Clustering and Support Vector Machine Ensembles. IEEE Access 2020, 8, 131449–131460. [Google Scholar] [CrossRef]

- Das, S.; Chandrasekaran, M.; Samanta, S. Comparison of Mechanical properties of AA6061 reinforced with (SiC/B4C) micro/nano ceramic particle reinforcements. Mater. Today Proc. 2018, 5, 18110–18119. [Google Scholar] [CrossRef]

- Elanchezhian, C.; Ramanth, B.; Bhaskar, G.B.; Vivekanandhan, M. An Investigation of the Mechanical Properties of HybridComposites in Applications of Automotive Industry. Mater. Today Proc. 2019, 16, 875–882. [Google Scholar] [CrossRef]

- Gayathri, J.; Elansezhian, R. Influence of dual reinforcement (nano CuO + reused spent alumina catalyst) on microstructure and mechanical properties of aluminium metal matrix composite. J. Alloy. Compd. 2020, 829, 154538. [Google Scholar] [CrossRef]

- Pandiyan, A.; Kumar, G.A.; Ranganthan, S.; Madhu, S. Optimization of wear performance on aluminium die cast A360-M1 master alloy using response surface method. Mater. Today Proc. 2019, 22, 551–557. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, J.; Kumar, S. Experimental Investigation on Surface Characteristics in Powder-Mixed Electrodischarge Machining of AA6061/10%SiC Composite. Mater. Manuf. Process. 2014, 29, 287–297. [Google Scholar] [CrossRef]

- Shamsudin, S.; Zhong, Z.W.; Ab Rahim, S.N.; Lajis, M.A. The influence of temperature and preheating time in extrudate quality of solid-state recycled aluminum. Int. J. Adv. Manuf. Technol. 2017, 90, 2631–2643. [Google Scholar] [CrossRef]

- Sahoo, B.; Narsimhachary, D.; Paul, J. Tribological characteristics of aluminium-CNT/graphene/graphite surface nanocomposites: A comparative study. Surf. Topogr. Metrol. Prop. 2019, 7, 034001. [Google Scholar] [CrossRef]

- Fogagnolo, J.B.; Ruiz-Navas, E.M.; Simón, M.A.; Martinez, M.A. Recycling of aluminium alloy and aluminium matrix composite chips by pressing and hot extrusion. J. Mater. Process. Technol. 2003, 143, 792–795. [Google Scholar] [CrossRef]

- Paulraj, G.M.; Parth, S.; Debraj, B. Hydrothermal Pretreatment of Tender Coconut Coir and Optimization of Process Parameters Using Response Surface Methodology. In Urbanization Challenges in Emerging Economies: Energy and Water Infrastructure; Transportation Infrastructure; and Planning and Financing; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 178–188. [Google Scholar]

- Ravikumar, M.; Reddappa, H.; Suresh, R. Aluminium Composites Fabrication Technique and Effect of Improvement in Their Mechanical Properties—A Review. Mater. Today Proc. 2018, 5, 23796–23805. [Google Scholar] [CrossRef]

- Jin, L.; Xue, J.; Zhang, Z.; Hu, Y. Effects of Thermal Frequency on Microstructures, Mechanical and Corrosion Properties of AA6061 Joints. Appl. Sci. 2018, 8, 540. [Google Scholar] [CrossRef] [Green Version]

- Sharma, N.; Khanna, R.; Singh, G.; Kumar, V. Fabrication of 6061 aluminum alloy reinforced with Si3N4/n-Gr and its wear performance optimization using integrated RSM-GA. Part. Sci. Technol. 2017, 35, 731–741. [Google Scholar] [CrossRef]

- Reddy, P.V.; Prasad, P.R.; Krishnudu, D.M.; Goud, E.V. An Investigation on Mechanical and Wear Characteristics of Al 6063/TiC Metal Matrix Composites Using RSM. J. Bio- Tribo-Corros. 2019, 5, 90. [Google Scholar] [CrossRef]

- Khamis, S.; Lajis, M.; Albert, R. A Sustainable Direct Recycling of Aluminum Chip (AA6061) in Hot Press Forging Employing Response Surface Methodology. Procedia CIRP 2015, 26, 477–481. [Google Scholar] [CrossRef] [Green Version]

- Rajakumar, S.; Muralidharan, C.; Balasubramanian, V. Predicting tensile strength, hardness and corrosion rate of friction stir welded AA6061-T6 aluminium alloy joints. Mater. Des. 2011, 32, 2878–2890. [Google Scholar] [CrossRef]

- Camposeco-Negrete, C. Optimization of cutting parameters using Response Surface Method for minimizing energy consumption and maximizing cutting quality in turning of AISI 6061 T6 aluminum. J. Clean. Prod. 2015, 91, 109–117. [Google Scholar] [CrossRef]

- Adam, S.P.; Alexandropoulos, S.-A.N.; Pardalos, P.M.; Vrahatis, M.N. No free lunch theorem: A review. Approx. Optim. 2019, 145, 57–82. [Google Scholar] [CrossRef]

- Sathyajith, S.; Kalainathan, S. Effect of laser shot peening on precipitation hardened aluminum alloy 6061-T6 using low energy laser. Opt. Lasers Eng. 2012, 50, 345–348. [Google Scholar] [CrossRef]

| Parameter | Value/Type |

|---|---|

| Shape of the Die | Round |

| Ratio used in extrusion, R | 5.4 |

| Diameter of the billet, Ø (mm) | 30 |

| Speed during extrusion, s (mm/s) | 1 |

| Container temp., (°C) | 300 |

| Die temp., (°C) | 300 |

| Symbol | Process Parameter | Levels | References | ||

|---|---|---|---|---|---|

| Low (−1) | Center (0) | High (+1) | |||

| A | Preheating temperature (PHT) (°C) | 450 | 500 | 550 | [29,30] |

| B | Preheating time (PHti) (hour) | 1 | 2 | 3 | [29] |

| C | Volume fraction CuO (%vol) | 1 | 2 | 3 | [19,31] |

| D | Volume fraction SiO2 (%vol) | 1 | 2 | 3 | [14] |

| Model | Selected Hyperparameter | Type | Search Space |

|---|---|---|---|

| RF | n estimators | Discrete | [5, 50] |

| Max depth | Discrete | [5, 50] | |

| Min samples split | Discrete | [2, 7] | |

| Min samples leaf | Discrete | [1, 7] | |

| Max features | Discrete | [1, 4] |

| Model | N Estimators | Max Depth | Min Sample Split | Min Sample Leaf | Max Feature |

|---|---|---|---|---|---|

| Random Forest | 35 | 27 | 2 | 1 | 4 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value | Effect |

|---|---|---|---|---|---|---|

| Model | 15 | 48,434.2 | 3228.9 | 23.00 | 0.000 | Significant |

| Blocks | 1 | 115.5 | 115.5 | 0.82 | 0.372 | |

| Linear | 4 | 20,656.5 | 5164.1 | 36.78 | 0.000 | |

| Temp. | 1 | 15,017.1 | 15,017.1 | 106.95 | 0.000 | Significant |

| Time | 1 | 621.5 | 621.5 | 4.43 | 0.044 | Significant |

| CuO | 1 | 4311.5 | 4311.5 | 30.71 | 0.000 | Significant |

| SiO2 | 1 | 706.4 | 706.4 | 5.03 | 0.033 | Significant |

| Square | 4 | 3680.1 | 920.0 | 6.55 | 0.001 | Significant |

| Temp. × Temp. | 1 | 504.9 | 504.9 | 3.60 | 0.068 | |

| Time × Time | 1 | 675.3 | 675.3 | 4.81 | 0.036 | |

| CuO × CuO | 1 | 1608.9 | 1608.9 | 11.46 | 0.002 | |

| SiO2 × SiO2 | 1 | 16.9 | 16.9 | 0.12 | 0.731 | |

| Two-Way Interaction | 6 | 19,711.1 | 3285.2 | 23.40 | 0.000 | Significant |

| Temp. × Time | 1 | 14,635.9 | 14,635.9 | 104.24 | 0.000 | |

| Temp. × CuO | 1 | 18.4 | 18.4 | 0.13 | 0.720 | |

| Temp. × SiO2 | 1 | 17.6 | 17.6 | 0.13 | 0.726 | |

| Time × CuO | 1 | 27.1 | 27.1 | 0.19 | 0.664 | |

| Time × SiO2 | 1 | 0.7 | 0.7 | 0.00 | 0.945 | |

| CuO × SiO2 | 1 | 5011.5 | 5011.5 | 35.69 | 0.000 | |

| Error | 29 | 4071.9 | 140.4 | |||

| Lack-of-Fit | 10 | 1808.9 | 180.9 | 1.52 | 0.208 | Not significant |

| Pure Error | 19 | 2263.0 | 119.1 | |||

| Total | 44 | 52,506.1 |

| R-Sq | R-Sq (Adj) | R-Sq (Pred) |

|---|---|---|

| 92.24% | 88.23% | 80.84% |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value | Effect |

|---|---|---|---|---|---|---|

| Model | 15 | 651.886 | 43.459 | 18.51 | 0.000 | Significant |

| Blocks | 1 | 85.364 | 85.364 | 36.35 | 0.000 | |

| Linear | 4 | 369.472 | 92.368 | 39.33 | 0.000 | |

| Temp. | 1 | 245.486 | 245.486 | 104.54 | 0.000 | Significant |

| Time | 1 | 9.986 | 9.986 | 4.25 | 0.048 | Significant |

| CuO | 1 | 79.224 | 79.224 | 33.74 | 0.000 | Significant |

| SiO2 | 1 | 34.775 | 34.775 | 14.81 | 0.001 | Significant |

| Square | 4 | 163.133 | 40.783 | 17.37 | 0.000 | Significant |

| Temp. × Temp. | 1 | 64.799 | 64.799 | 27.59 | 0.000 | |

| Time × Time | 1 | 0.010 | 0.010 | 0.00 | 0.949 | |

| CuO × CuO | 1 | 6.721 | 6.721 | 2.86 | 0.101 | |

| SiO2 × SiO2 | 1 | 0.022 | 0.022 | 0.01 | 0.924 | |

| 2-Way Interaction | 6 | 118.504 | 19.751 | 8.41 | 0.000 | Significant |

| Temp. × Time | 1 | 0.539 | 0.539 | 0.23 | 0.636 | |

| Temp. × CuO | 1 | 1.277 | 1.277 | 0.54 | 0.467 | |

| Temp. × SiO2 | 1 | 90.346 | 90.346 | 38.47 | 0.000 | |

| Time × CuO | 1 | 1.828 | 1.828 | 0.78 | 0.385 | |

| Time × SiO2 | 1 | 4.913 | 4.913 | 2.09 | 0.159 | |

| CuO × SiO2 | 1 | 19.601 | 19.601 | 8.35 | 0.007 | |

| Error | 29 | 68.100 | 2.348 | |||

| Lack-of-Fit | 10 | 35.669 | 3.567 | 2.09 | 0.080 | Not significant |

| Pure Error | 19 | 32.431 | 1.707 | |||

| Total | 44 | 719.986 |

| R-Sq | R-Sq (Adj) | R-Sq (Pred) |

|---|---|---|

| 90.54% | 85.65% | 76.79% |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value | Effect |

|---|---|---|---|---|---|---|

| Model | 15 | 0.025872 | 0.001725 | 78.13 | 0.000 | Significant |

| Blocks | 1 | 0.000218 | 0.000218 | 9.89 | 0.004 | |

| Linear | 4 | 0.013605 | 0.003401 | 154.07 | 0.000 | |

| Temp. | 1 | 0.000064 | 0.000064 | 2.89 | 0.100 | Not significant |

| Time | 1 | 0.000207 | 0.000207 | 9.36 | 0.005 | Significant |

| CuO | 1 | 0.003124 | 0.003124 | 141.51 | 0.000 | Significant |

| SiO2 | 1 | 0.010210 | 0.010210 | 462.52 | 0.000 | Significant |

| Square | 4 | 0.003494 | 0.000873 | 39.57 | 0.000 | Significant |

| Temp. × Temp. | 1 | 0.001726 | 0.001726 | 78.17 | 0.000 | |

| Time × Time | 1 | 0.000005 | 0.000005 | 0.22 | 0.646 | |

| CuO × CuO | 1 | 0.000164 | 0.000164 | 7.44 | 0.011 | |

| SiO2 × SiO2 | 1 | 0.000185 | 0.000185 | 8.39 | 0.007 | |

| 2-Way Interaction | 6 | 0.002574 | 0.000429 | 19.43 | 0.000 | Significant |

| Temp. × Time | 1 | 0.000009 | 0.000009 | 0.41 | 0.527 | |

| Temp. × CuO | 1 | 0.001015 | 0.001015 | 45.97 | 0.000 | |

| Temp. × SiO2 | 1 | 0.000000 | 0.000000 | 0.01 | 0.941 | |

| Time × CuO | 1 | 0.000953 | 0.000953 | 43.15 | 0.000 | |

| Time × SiO2 | 1 | 0.000592 | 0.000592 | 26.80 | 0.000 | |

| CuO × SiO2 | 1 | 0.000006 | 0.000006 | 0.26 | 0.613 | |

| Error | 29 | 0.000640 | 0.000022 | |||

| Lack-of-Fit | 10 | 0.000251 | 0.000025 | 1.23 | 0.334 | Not significant |

| Pure Error | 19 | 0.000389 | 0.000020 | |||

| Total | 44 | 0.026512 |

| R-Sq | R-Sq (Adj) | R-Sq (Pred) |

|---|---|---|

| 97.59% | 96.34% | 94.58% |

| CT | Temp. | Time | CuO | SiO2 |

|---|---|---|---|---|

| 1 | 550 | 1.46 | 1.52 | 3 |

| 2 | 541 | 2.25 | 2.13 | 1 |

| 3 | 541 | 2.25 | 2.13 | 0.5 |

| CT | Experimental | Predicted (RF) | Predicted (RSM) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| UTS | Hardness | Density | UTS | Hardness | Density | UTS | Hardness | Density | |

| 1 | 245.51 | 55 | 2.58 | 243.865 | 54.637 | 2.579 | 238.004 | 49.727 | 2.417 |

| 2 | 232.66 | 47 | 2.63 | 226.47 | 46.87 | 2.61 | 225.704 | 47.829 | 2.29 |

| 3 | 210.04 | 45 | 2.6 | 212.78 | 45.4 | 2.62 | 232.328 | 46.417 | 2.288 |

| CT | RF Prediction Error | RSM Prediction Error | ||||

|---|---|---|---|---|---|---|

| UTS | Hardness | Density | UTS | Hardness | Density | |

| CT 1 | 0.67% | 0.66% | 0.03% | 3.05% | 9.58% | 6.31% |

| CT 2 | 2.73% | 0.27% | 0.76% | 2.98% | 1.76% | 14.8% |

| CT 3 | 1.28% | 0.88% | 0.76% | 10.61% | 3.14% | 12% |

| Model | MSE | MAE | R-Squared (R2) |

|---|---|---|---|

| RF | 0.03717 | 0.13171 | 0.9628 |

| Specimen | 2 Theta | Intensity | Crystallite (Å) |

|---|---|---|---|

| AA6061-2%CuO | 38.51297 | 31342 | 91.23 |

| AA6061-2%SiO2 | 38.51251 | 83249 | 48.72 |

| AA6061-1%CuO-1%SiO2 | 38.49631 | 182419 | 96.77 |

| A6061-1%CuO-3%SiO2 | 38.50309 | 130112 | 52.12 |

| A6061-13.2%CuO-1%SiO2 | 38.45109 | 37892 | 91.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Msebawi, M.S.; Leman, Z.; Shamsudin, S.; Tahir, S.M.; Aiza Jaafar, C.N.; Ariff, A.H.M.; Zahari, N.I.; Abdellatif, A. Production of Aluminum AA6061 Hybrid Nanocomposite from Waste Metal Using Hot Extrusion Process: Strength Performance and Prediction by RSM and Random Forest. Materials 2021, 14, 6102. https://doi.org/10.3390/ma14206102

Msebawi MS, Leman Z, Shamsudin S, Tahir SM, Aiza Jaafar CN, Ariff AHM, Zahari NI, Abdellatif A. Production of Aluminum AA6061 Hybrid Nanocomposite from Waste Metal Using Hot Extrusion Process: Strength Performance and Prediction by RSM and Random Forest. Materials. 2021; 14(20):6102. https://doi.org/10.3390/ma14206102

Chicago/Turabian StyleMsebawi, Muntadher Sabah, Zulkiflle Leman, Shazarel Shamsudin, Suraya Mohd Tahir, Che Nor Aiza Jaafar, Azmah Hanim Mohamed Ariff, Nur Ismarrubie Zahari, and Abdallah Abdellatif. 2021. "Production of Aluminum AA6061 Hybrid Nanocomposite from Waste Metal Using Hot Extrusion Process: Strength Performance and Prediction by RSM and Random Forest" Materials 14, no. 20: 6102. https://doi.org/10.3390/ma14206102

APA StyleMsebawi, M. S., Leman, Z., Shamsudin, S., Tahir, S. M., Aiza Jaafar, C. N., Ariff, A. H. M., Zahari, N. I., & Abdellatif, A. (2021). Production of Aluminum AA6061 Hybrid Nanocomposite from Waste Metal Using Hot Extrusion Process: Strength Performance and Prediction by RSM and Random Forest. Materials, 14(20), 6102. https://doi.org/10.3390/ma14206102