Residual Strength and Drying Behavior of Concrete Reinforced with Recycled Steel Fiber from Tires

Abstract

:1. Introduction

1.1. The Concept of Fiber Reinforcement

1.2. Recycled Steel Fibers from Tires

2. Materials and Methods

2.1. Materials and Concrete Mixes

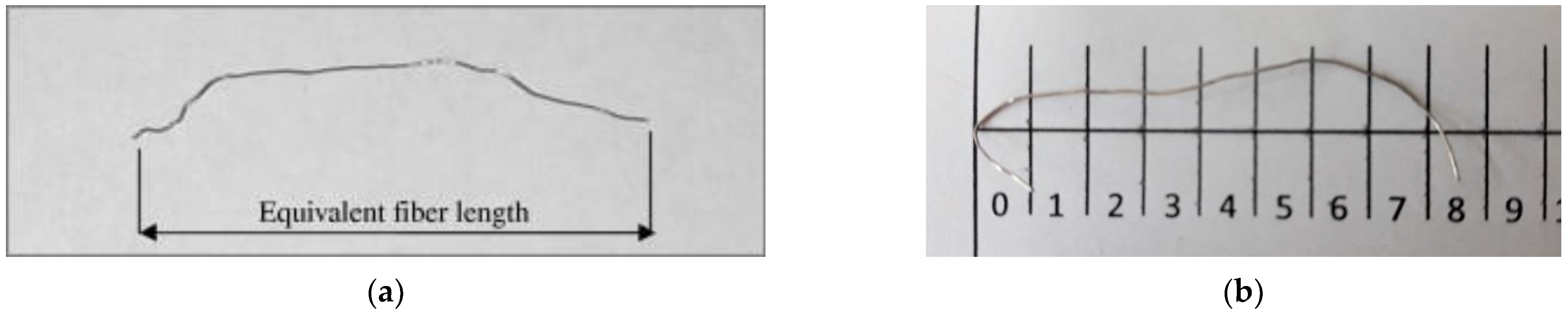

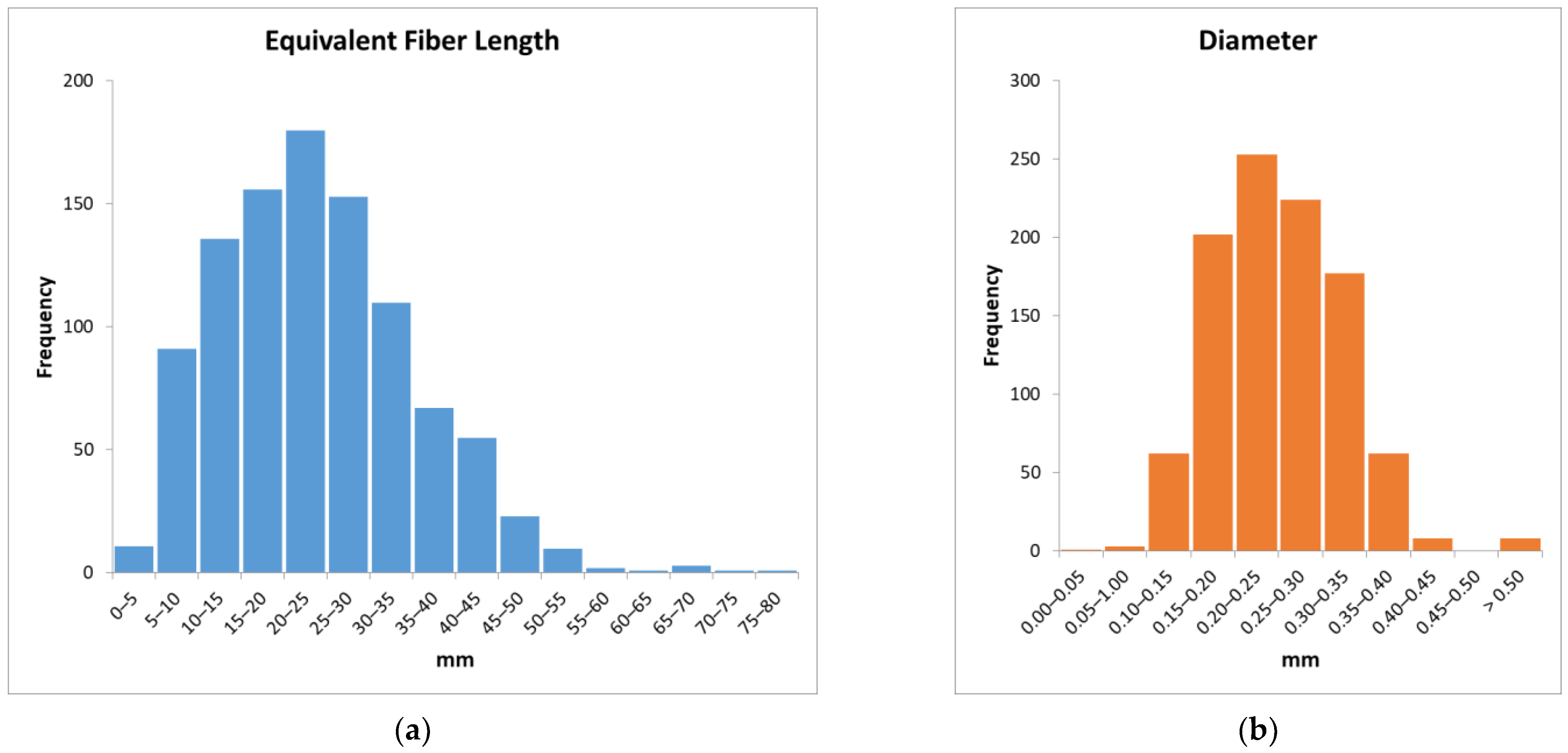

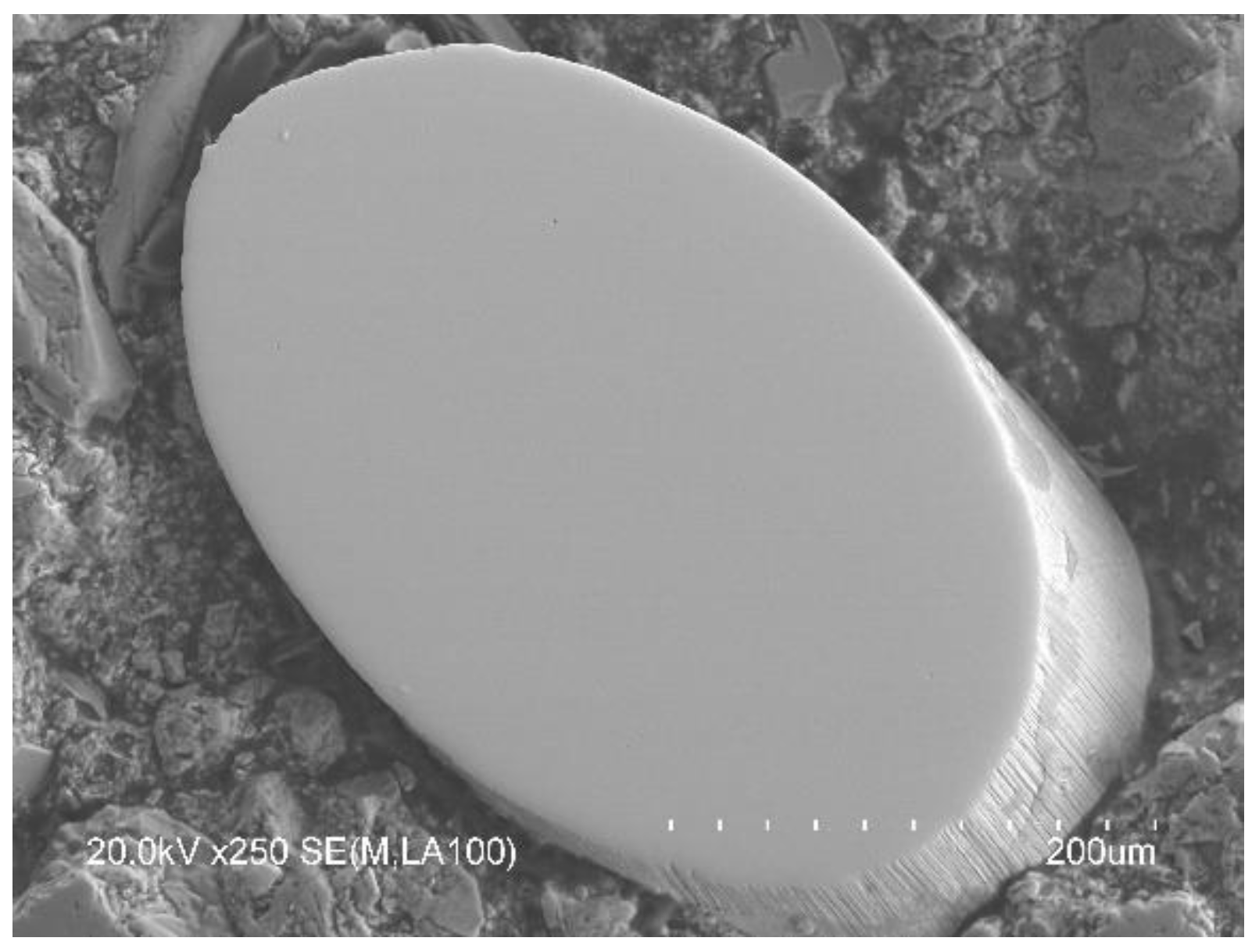

2.2. Geometrical Characterization

2.3. Testing Methods

3. Results and Discussion

3.1. Geometrical Characterization

3.2. Fresh State

3.3. Compressive Strength

3.4. Control Cracking

3.5. Residual Strength

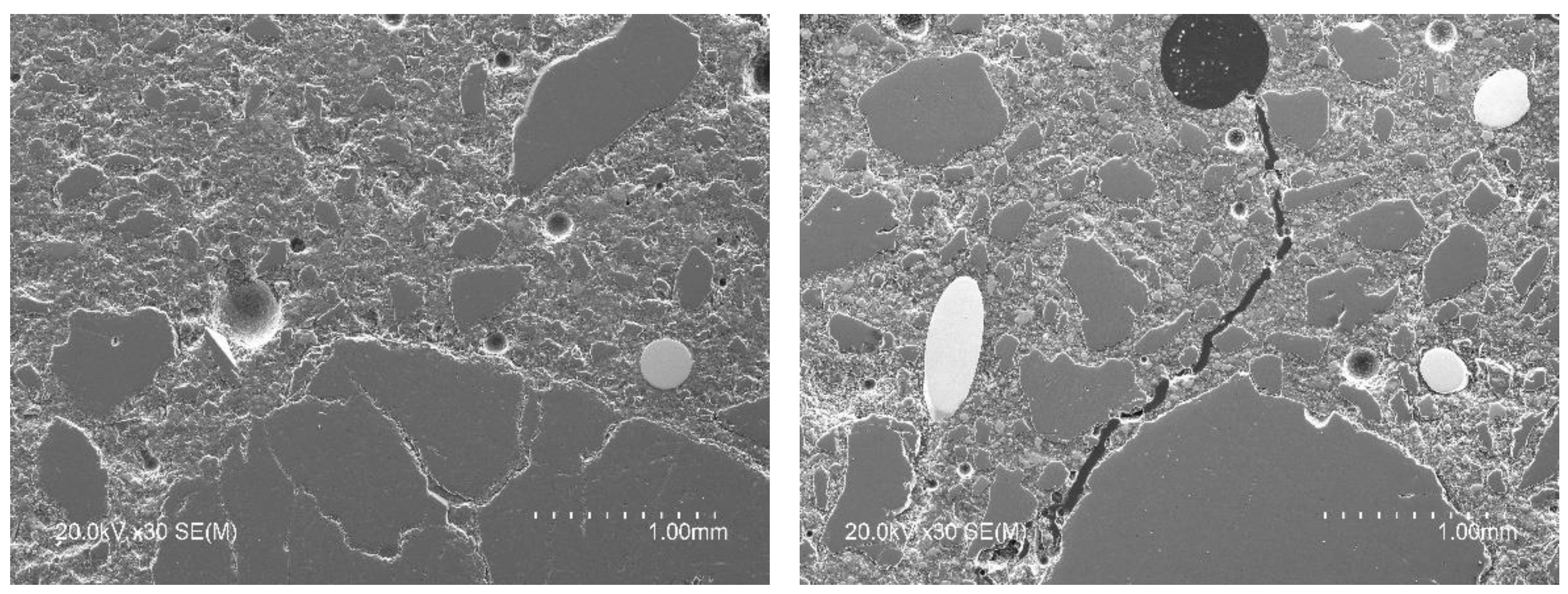

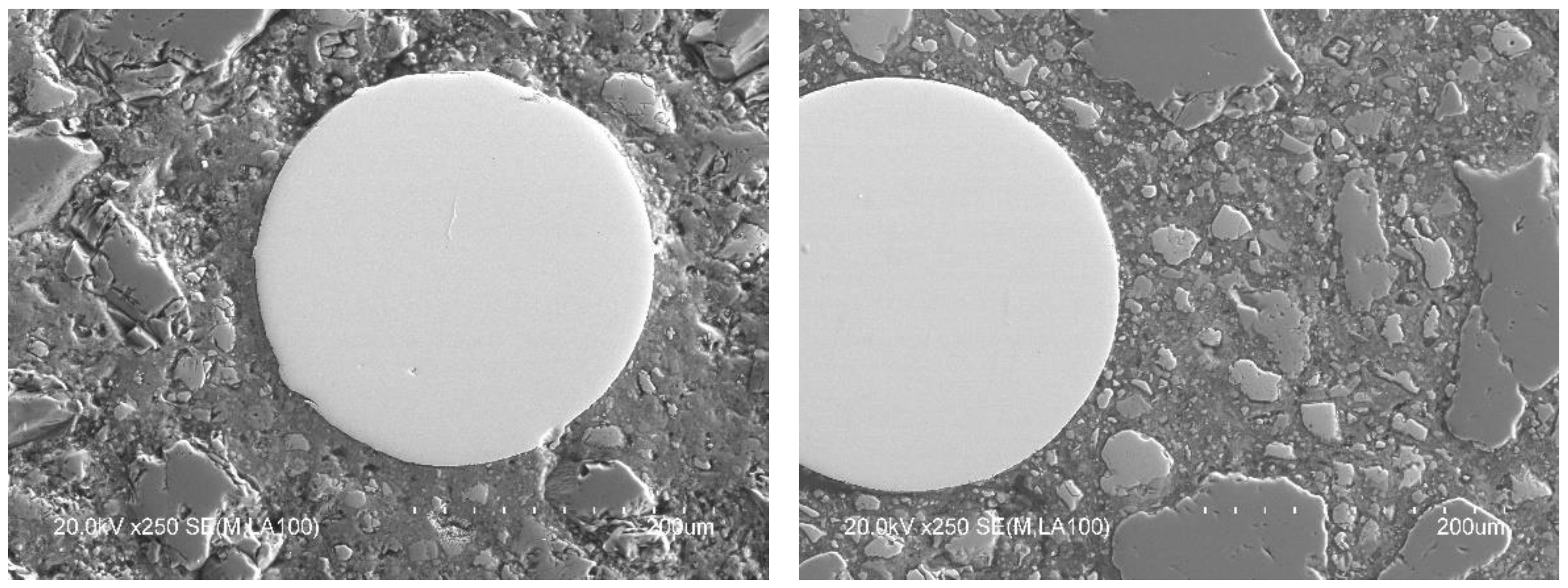

3.6. Microstructural Characterization

4. Conclusions

- The use of recycled steel fibers (RSF) from tires is viable, thus obtaining a sustainable and eco-friendly concrete.

- The variability in the shape and length of the RSF obtained by a shredding process makes a statistical analysis necessary to characterize their geometric properties. To aid in this characterization, the concept of Equivalent Fiber Length (EFL) has been defined as the length of the longest edge of the rectangular cuboid that contains the fiber.

- The addition of RSF has a similar effect on the workability of concrete as the addition of industrial fibers such as steel (SF) and polypropylene fibers (PPF), when added in similar proportions.

- RSF have the same effect on compressive strength as industrial fibers SF and PPF, when added in the same proportions. As with industrial fibers, there appears to be a fiber content threshold beyond which a decrease in strength occurs.

- The addition of RSF modified the brittle behavior of plain concrete under flexural loads, providing ductility to the material. RSF offer similar performance as industrial SF for low contents by volume (Vf = 0.26%), providing a residual strength once the first crack appears in the concrete.

- RSF can control drying shrinkage cracking during the first days as concrete in a similar way as industrial PPF for the same content of fiber in terms of volume, thereby reducing the potential for cracking.

- Microstructural analysis has shown a good integration and adhesion of the RSF with the cementitious matrix, without the presence of potential contaminants.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Magnani, A. Improvements Relating to the Manufacture of Fibrous Cement Sheets. GB Patent No. 675,713, 19 January 1951. [Google Scholar]

- Manville, J. Method of Producing Asbestos-Cement Sheets Containing Cellulosic Fiber. U.S. Patent No. 3,344,015, 3 August 1964. [Google Scholar]

- Berard, A. Improvement in Artificial Stone. U.S. Patent No. 157,903, 15 December 1874. [Google Scholar]

- Weakley, R.D. Bonding Means for Reinforced Concrete Structure. U.S. Patent No. 1,046,913, 10 December 1912. [Google Scholar]

- Meischke-Smith, W. Ferroconcrete Construction. U.S. Patent No. 1,349,901, 17 August 1920. [Google Scholar]

- Constantinesco, G. Reinforced Concrete. U.S. Patent No. 2,677,955, 11 May 1954. [Google Scholar]

- Romualdi, J.P.; Batson, G.B. Mechanics of Crack Arrest in Concrete. J. Eng. Mech. Div. 1963, 89, 147–168. [Google Scholar] [CrossRef]

- Romualdi, J.P.; Mandel, J.A. Tensile Strength of Concrete Affected by Uniformly Distributed and Closely Spaced Short Lengths of Wire Reinforcement. ACI J. Proc. 1964, 61, 657–672. [Google Scholar] [CrossRef]

- Krenchel, H. Fibre Reinforcement: Theoretical and Practical Investigations of the Elasticity and Strength of Fibre-Reinforced Materials; Akademisk Forlag: Copenhagen, Denmark, 1964. [Google Scholar]

- Shah, S.; Rangan, B.V. Fiber reinforced concrete properties. J. Am. Concr. Inst. 1971, 68, 126–135. [Google Scholar] [CrossRef]

- Naaman, A.E. A Statistical Theory of Strength for Fiber Reinforced Concrete; M.I.T.: Cambridge, MA, USA, 1972. [Google Scholar]

- Swamy, R.N.; Mangat, P.S.; Rao, C.V.S.K. The Mechanics of Fiber Reinforcement of Cement Matrices. Am. Concr. Inst. 1974, 44, 1–28. [Google Scholar] [CrossRef]

- Lee, S.C.; Oh, J.H.; Cho, J.Y. Compressive behavior of fiber-reinforced concrete with end-hooked steel fibers. Materials 2015, 8, 1442–1458. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Yousef, R.A.; Abduljabbar, H.A.; Sufian, M. Effect of Coconut Fiber Length and Content on Properties of High Strength Concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brandt, A.M. Fibre reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Vatin, N.; Huei Lee, Y.; Murali, G.; Ozbakkaloglu, T.; Klyuev, S.; Alabduljabber, H. Fibre-Reinforced Foamed Concretes: A Review. Materials 2020, 13, 4323. [Google Scholar] [CrossRef]

- Naaman, A.E. Fiber Reinforced Cement and Concrete Composites; Techno Press 3000: Sarasota, FL, USA, 2017. [Google Scholar]

- Barr, B.; Newman, P.D. Toughness of polypropylene fibre-reinforced concrete. Composites 1985, 16, 48–53. [Google Scholar] [CrossRef]

- Mindess, S.; Vondran, G. Properties of concrete reinforced with fibrillated polypropylene fibres under impact loading. Cem. Concr. Res. 1988, 18, 109–115. [Google Scholar] [CrossRef]

- Liew, K.M.; Akbar, A. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Faraj, R.H.; Hilal, N.; Mohammed, A.A.; Sherwani, A.F.H. Use of recycled fibers in concrete composites: A systematic comprehensive review. Compos. Part B Eng. 2021, 215, 108769. [Google Scholar] [CrossRef]

- ETRMA. The ETRMA Statistics Report. 2019. Available online: https://www.etrma.org/wp-content/uploads/2019/10/20191114-Statistics-booklet-2019-Final-for-web.pdf (accessed on 25 August 2021).

- European Union. Council Directive 1999/31/EC on the Landfill; no. 10. L182/1-19; European Union: Brussels, Belgium, 1999. [Google Scholar]

- ETRMA. End of Life Tyres Management—Europe—Status. 2018. Available online: https://www.etrma.org/wp-content/uploads/2020/09/Copy-of-ELT-Data-2018-002.pdf (accessed on 25 August 2021).

- Evans, A.; Evans, R. The Composition of a Tyre: Typical Components; WRAP: Banbury, UK, 2006. [Google Scholar]

- Pilakoutas, K.; Neocleous, K.; Tlemat, H. Reuse of tyre steel fibres as concrete reinforcement. Eng. Sustain. 2004, 157, 131–138. [Google Scholar] [CrossRef]

- Wu, H.C.; Lim, Y.M.; Li, V.C. Application of recycled tyre cord in concrete for shrinkage crack control. J. Mater. Sci. Lett. 1996, 15, 1828–1831. [Google Scholar] [CrossRef]

- Papakonstantinou, C.G.; Tobolski, M.J. Use of waste tire steel beads in Portland cement concrete. Cem. Concr. Res. 2006, 36, 1686–1691. [Google Scholar] [CrossRef]

- Tlemat, H.; Pilakoutas, K.; Neocleous, K. Stress-strain characteristic of SFRC using recycled fibres. Mater. Struct. Constr. 2006, 39, 365–377. [Google Scholar] [CrossRef] [Green Version]

- Caggiano, A.; Folino, P.; Lima, C.; Martinelli, E.; Pepe, M. On the mechanical response of Hybrid Fiber Reinforced Concrete with Recycled and Industrial Steel Fibers. Constr. Build. Mater. 2017, 147, 286–295. [Google Scholar] [CrossRef]

- Aiello, M.A.; Leuzzi, F.; Centonze, G.; Maffezzoli, A. Use of steel fibres recovered from waste tyres as reinforcement in concrete: Pull-out behaviour, compressive and flexural strength. Waste Manag. 2009, 29, 1960–1970. [Google Scholar] [CrossRef]

- Centonze, G.; Leone, M.; Aiello, M.A. Steel fibers from waste tires as reinforcement in concrete: A mechanical characterization. Constr. Build. Mater. 2012, 36, 46–57. [Google Scholar] [CrossRef]

- Martinelli, E.; Caggiano, A.; Xargay, H. An experimental study on the post-cracking behaviour of Hybrid Industrial/Recycled Steel Fibre-Reinforced Concrete. Constr. Build. Mater. 2015, 94, 290–298. [Google Scholar] [CrossRef]

- Centonze, G.; Leone, M.; Micelli, F.; Colonna, D.; Aiello, M.A. Concrete Reinforced with Recycled Steel Fibers from End of Life Tires: Mix-Design and Application. Key Eng. Mater. 2016, 711, 224–231. [Google Scholar] [CrossRef]

- Bensaci, H.; Menadi, B.; Kenai, S. Comparison of some Fresh and Hardened Properties of Self-Consolidating Concrete Composites Containing Rubber and Steel Fibers Recovered from Waste Tires. Nano Hybrids Compos. 2019, 24, 8–13. [Google Scholar] [CrossRef]

- Grunewald, S.; Liberato, F.; Dehn, F. Flowable fibre-reinforced concrete: Progress in understanding and development of design standards. In Proceedings 8th International RILEM Symposium on Self-Compacting Concrete; RILEM Publications: Paris, France, 2016; pp. 467–478. [Google Scholar]

- Groli, G.; Caldentey, A.P.; Soto, A.G. Cracking performance of SCC reinforced with recycled fibres—an experimental study. Struct. Concr. 2014, 15, 136–153. [Google Scholar] [CrossRef]

- Najim, K.B.; Saeb, A.; Al-Azzawi, Z. Structural behaviour and fracture energy of recycled steel fibre self-compacting reinforced concrete beams. J. Build. Eng. 2018, 17, 174–182. [Google Scholar] [CrossRef]

- Krolo, J. Innovative low cost fibre-reinforced concrete—Part II: Fracture toughness and impact strength. In Concrete Repair, Rehabilitation and Retrofitting III; CRC Press: Boca Raton, FL, USA, 2012; pp. 204–209. [Google Scholar]

- Aghaee, K.; Yazdi, M.A.; Tsavdaridis, K.D. Investigation into the mechanical properties of structural lightweight concrete reinforced with waste steel wires. Mag. Concr. Res. 2015, 67, 197–205. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Wu, H.C.; Li, V.C. Concrete reinforcement with recycled fibers. J. Mater. Civ. Eng. 2000, 12, 314–319. [Google Scholar] [CrossRef]

- Leone, M.; Centonze, G.; Colonna, D.; Micelli, F.; Aiello, M.A. Fiber-reinforced concrete with low content of recycled steel fiber: Shear behaviour. Constr. Build. Mater. 2018, 161, 141–155. [Google Scholar] [CrossRef]

- Peng, G.F.; Niu, X.J.; Long, Q.Q. Experimental Study of Strengthening and Toughening for Recycled Steel Fiber Reinforced Ultra-High Performance Concrete. Key Eng. Mater. 2014, 629–630, 104–111. [Google Scholar] [CrossRef]

- Farhan, A.H.; Dawson, A.R.; Thom, N.H. Damage propagation rate and mechanical properties of recycled steel fiber-reinforced and cement-bound granular materials used in pavement structure. Constr. Build. Mater. 2018, 172, 112–124. [Google Scholar] [CrossRef]

- CEN/TC 104. Concrete and related products. In EN 14889-2:2006 Fibres for Concrete—Part 2: Polymer Fibres—Definitions, Specifications and Conformity; European Committee for Standardization (CEN): Brussels, Belgium, 2006. [Google Scholar]

- CEN/TC 104. Concrete and related products. In EN 14889-1:2006 Fibres for Concrete—Part 1: Steel Fibres—Definitions, Specifications and Conformity; European Committee for Standardization (CEN): Brussels, Belgium, 2006. [Google Scholar]

- CEN/TC 104. Concrete and related products. In EN 14845-1:2007 Test Methods for Fibres in Concrete—Part 1: Reference Concretes; European Committee for Standardization (CEN): Brussels, Belgium, 2007. [Google Scholar]

- CEN/TC 51. Cement and building limes. In EN 197-1:2011 Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements; European Committee for Standardization (CEN): Brussels, Belgium, 2011. [Google Scholar]

- CEN/TC 104. Concrete and related products. In EN 934-2:2009+A1:2012 Admixtures for Concrete, Mortar and Grout—Part 2: Concrete Admixtures—Definitions, Requirements, Conformity, Marking and Labelling; European Committee for Standardization (CEN): Brussels, Belgium, 2012. [Google Scholar]

- CNR—Advisory Committee on Technical Recommendations for Construction. Guide for the Design and Construction of Fiber-Reinforced Concrete Structures; CNR: Rome, Italy, 2007. [Google Scholar]

- CEN/TC 104. Concrete and related products. In EN 12350-2:2019 Testing Fresh Concrete—Part 2: Slump Test; European Committee for Standardization (CEN): Brussels, Belgium, 2019. [Google Scholar]

- CEN/TC 104. Concrete and related products. In EN 12350-6:2019 Testing Fresh Concrete—Part 6: Density; European Committee for Standardization (CEN): Brussels, Belgium, 2019. [Google Scholar]

- CEN/TC 104. Concrete and related products. In EN 12350-7:2019 Testing Fresh Concrete—Part 7: Air Content—Pressure methods; European Committee for Standardization (CEN): Brussels, Belgium, 2019. [Google Scholar]

- CEN/TC 104. Concrete and related products. In EN 12390-3:2019 Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; European Committee for Standardization (CEN): Brussels, Belgium, 2019. [Google Scholar]

- CEN/TC 104. Concrete and related products. In EN 12390-1:2021 Testing Hardened Concrete—Part 1: Shape, Dimensions and Other Requirements for Specimens and Moulds; European Committee for Standardization (CEN): Brussels, Belgium, 2021. [Google Scholar]

- CEN/TC 104. Concrete and related products. In EN 12390-2:2019 Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests; European Committee for Standardization (CEN): Brussels, Belgium, 2019. [Google Scholar]

- ASTM. ASTM C1581/C1581M-18a, Standard Test Method for Determining Age at Cracking and Induced Tensile Stress Characteristics of Mortar and Concrete under Restrained Shrinkage; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar] [CrossRef]

- CEN/TC 229. Precast concrete products. In EN 14651:2005+A1:2007 Test Method for Metallic Fibre Concrete—Measuring the Flexural Tensile Strength (Limit of Proportionality (LOP), Residual); European Committee for Standardization (CEN): Brussels, Belgium, 2007. [Google Scholar]

- Ministerio de Fomento. Instrucción de Hormigón Estructural (EHE-08); Ministerio de Fomento: Madrid, Spain, 2008.

- ACI Committee 214. ACI PRC-214-11 Guide to Evaluation of Strenght Test Results of Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2011; p. 16. [Google Scholar]

- Hozo, S.P.; Djulbegovic, B.; Hozo, I. Estimating the mean and variance from the median, range, and the size of a sample. BMC Med. Res. Methodol. 2005, 5, 13. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.-H.; Hong, K.-N.; Park, J.-K.; Ko, J. Influence of Aggregate Coated with Modified Sulfur on the Properties of Cement Concrete. Materials 2014, 7, 4739. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Keppert, M.; Jerman, M.; Scheinherrová, L.; Reiterman, P.; Doušová, B.; Černý, R. Influence of free and sorbed zinc on cement hydration. J. Therm. Anal. Calorim. 2019, 138, 1935–1943. [Google Scholar] [CrossRef]

| Material | Density (kg/dm3) | Length (mm) | Diameter (mm) | Slenderness (L/d) |

|---|---|---|---|---|

| Polypropylene (PPF) | 0.91 | 12 | 0.031 | 343–387 |

| Steel (SF) | 7.8 | 36 | 0.55 | 65 |

| Constituent | Content (kg/m3) | |||

|---|---|---|---|---|

| Control Cracking Tests (Vf = 0.11%) | Residual Strength Tests (Vf = 0.26%) | |||

| PPF−CC | RSF−CC | SF−RS | RSF−RS | |

| Water | 192.5 | 192.5 | 192.5 | 192.5 |

| Cement | 350.0 | 350.0 | 350.0 | 350.0 |

| Coarse Aggregate | 985.5 | 985.5 | 983.4 | 983.4 |

| Sand | 791.2 | 791.2 | 789.5 | 789.5 |

| Superplasticizer | 1.8 | 1.8 | 1.8 | 1.8 |

| RSF | − | 8.6 | − | 20.0 |

| PPF | 1.0 | − | − | − |

| SF | − | − | 20.0 | − |

| Water/Cement Ratio (w/c) | 0.55 | 0.55 | 0.55 | 0.55 |

| Property | Control Cracking Tests | Residual Strength Tests | ||

|---|---|---|---|---|

| PPF-CC | RSF-CC | SF-RS | RSF-RS | |

| Slump (mm) | 10 | 20 | 25 | 35 |

| Density (kg/m3) | 2344 | 2351 | 2358 | 2363 |

| Air Content (%) | 2.3 | 2.0 | 2.3 | 2.1 |

| Concrete Mix | Compressive Strength, fc (N/mm2) | fcm (N/mm2) | Relative Range (%) | |

|---|---|---|---|---|

| Control Cracking Tests (Vf = 0.11%) | PPF-CC | 40.2 | 40.0 | 1.5% |

| 40.1 | ||||

| 39.6 | ||||

| RSF-CC | 39.9 | 39.7 | 8.6% | |

| 37.9 | ||||

| 41.3 | ||||

| Residual Strength Tests (Vf = 0.26%) | SF-RS | 33.1 | 34.5 | 6.4% |

| 35.0 | ||||

| 35.3 | ||||

| RSF-RS | 35.5 | 35.3 | 1.1% | |

| 35.4 | ||||

| 35.1 | ||||

| Concrete Mix | Average Age of First Crack after Drying, tcr (Days) | Average Initial Strain (×10−6) | Average Maximum Strain (×10−6) | Average Stress Rate, S (MPa/day) | Potential for Cracking by Age of First Crack | Potential for Cracking by Average Stress |

|---|---|---|---|---|---|---|

| PPF-CC | 30 | −4 | −84 | 0.13 | Low | Moderate Low |

| RSF-CC | 34 | −6 | −89 | 0.13 | Low | Moderate Low |

| Concrete Mix | Max. Load, FL (kN) | Load at CMOD = 0.5 mm, F1 (kN) | Load at CMOD = 2.5 mm, F1 (kN) | LOP (N/mm2) | fR,1 (N/mm2) | fR,3 (N/mm2) |

|---|---|---|---|---|---|---|

| SF-RS | 10.6 | 4.6 | 2.3 | 3.6 | 1.5 | 0.8 |

| 11.0 | 3.7 | 1.8 | 3.6 | 1.2 | 0.6 | |

| 10.3 | 4.3 | 2.3 | 3.5 | 1.5 | 0.8 | |

| Mean | 3.6 | 1.4 | 0.7 | |||

| Relative Range | 2.8% | 21.4% | 28.6% | |||

| RSF-RS | 12.1 | 4.3 | 2.1 | 4.1 | 1.4 | 0.7 |

| 11.3 | 4.2 | 2.2 | 3.8 | 1.4 | 0.8 | |

| 12.3 | 4.8 | 2.2 | 4.3 | 1.7 | 0.8 | |

| Mean | 4.1 | 1.5 | 0.8 | |||

| Relative Range | 12.2% | 20.0% | 12.5% | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Revuelta, D.; Carballosa, P.; García Calvo, J.L.; Pedrosa, F. Residual Strength and Drying Behavior of Concrete Reinforced with Recycled Steel Fiber from Tires. Materials 2021, 14, 6111. https://doi.org/10.3390/ma14206111

Revuelta D, Carballosa P, García Calvo JL, Pedrosa F. Residual Strength and Drying Behavior of Concrete Reinforced with Recycled Steel Fiber from Tires. Materials. 2021; 14(20):6111. https://doi.org/10.3390/ma14206111

Chicago/Turabian StyleRevuelta, David, Pedro Carballosa, José Luis García Calvo, and Filipe Pedrosa. 2021. "Residual Strength and Drying Behavior of Concrete Reinforced with Recycled Steel Fiber from Tires" Materials 14, no. 20: 6111. https://doi.org/10.3390/ma14206111

APA StyleRevuelta, D., Carballosa, P., García Calvo, J. L., & Pedrosa, F. (2021). Residual Strength and Drying Behavior of Concrete Reinforced with Recycled Steel Fiber from Tires. Materials, 14(20), 6111. https://doi.org/10.3390/ma14206111