Structure and Properties of Ti/Ti64 Graded Material Manufactured by Laser Powder Bed Fusion

Abstract

:1. Introduction

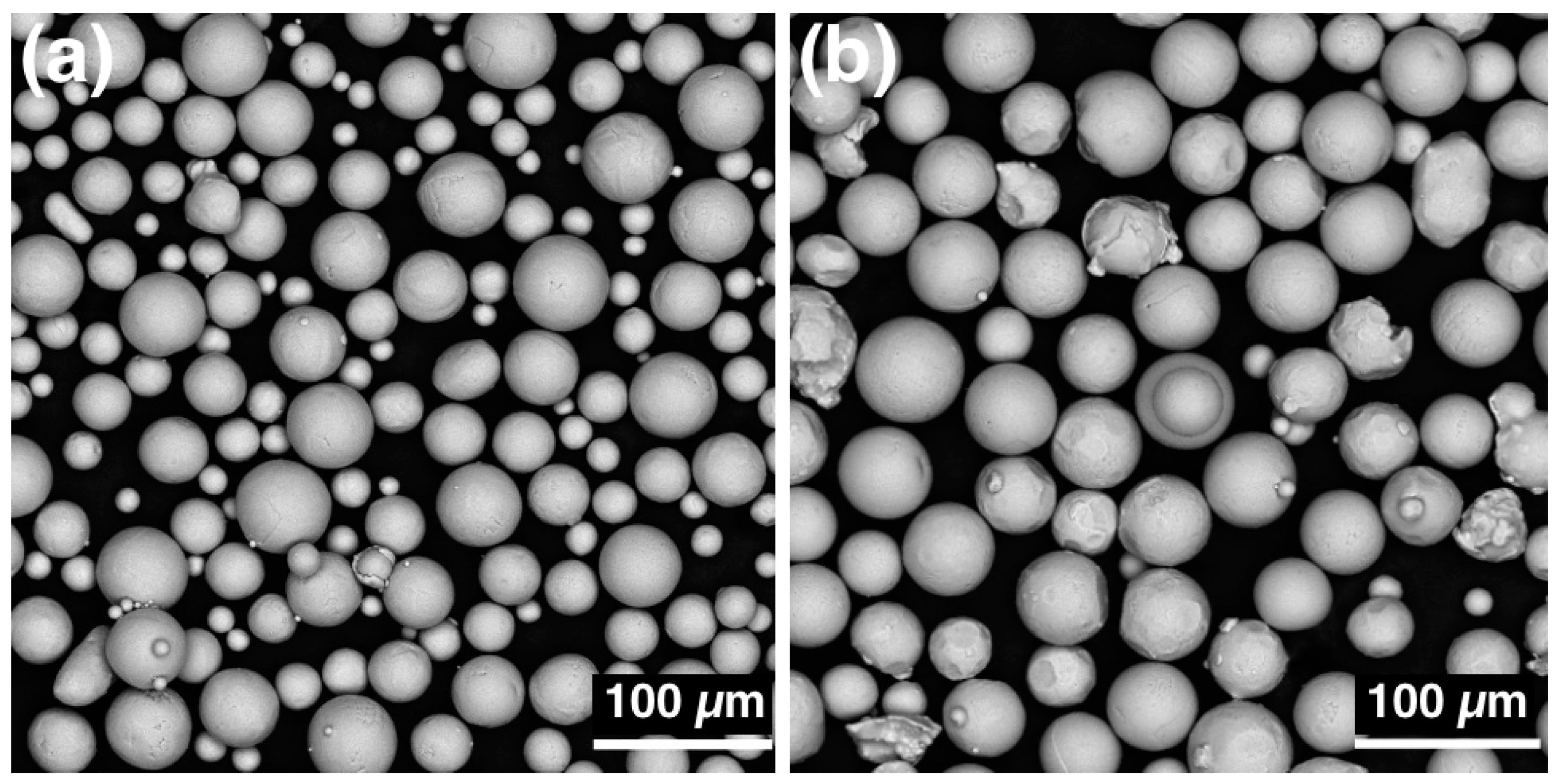

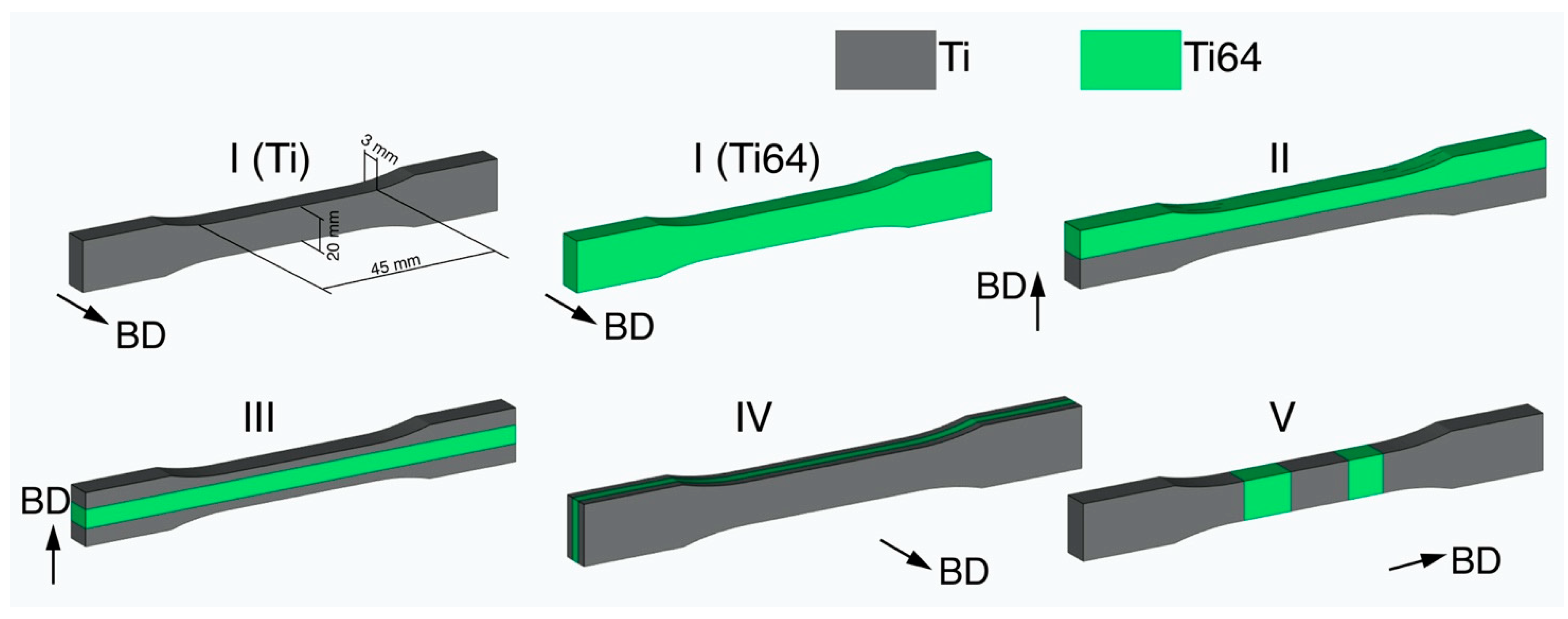

2. Materials and Methods

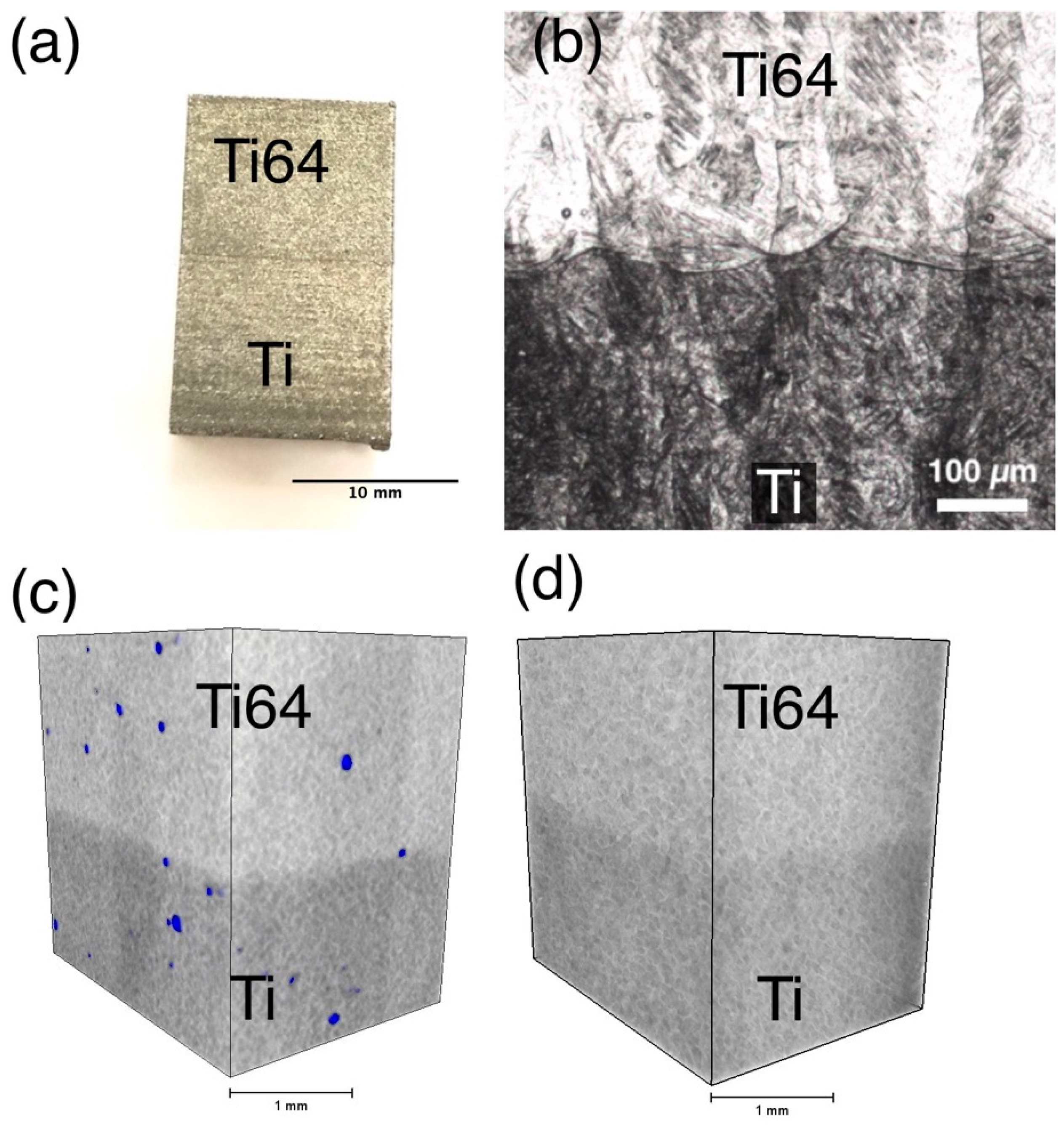

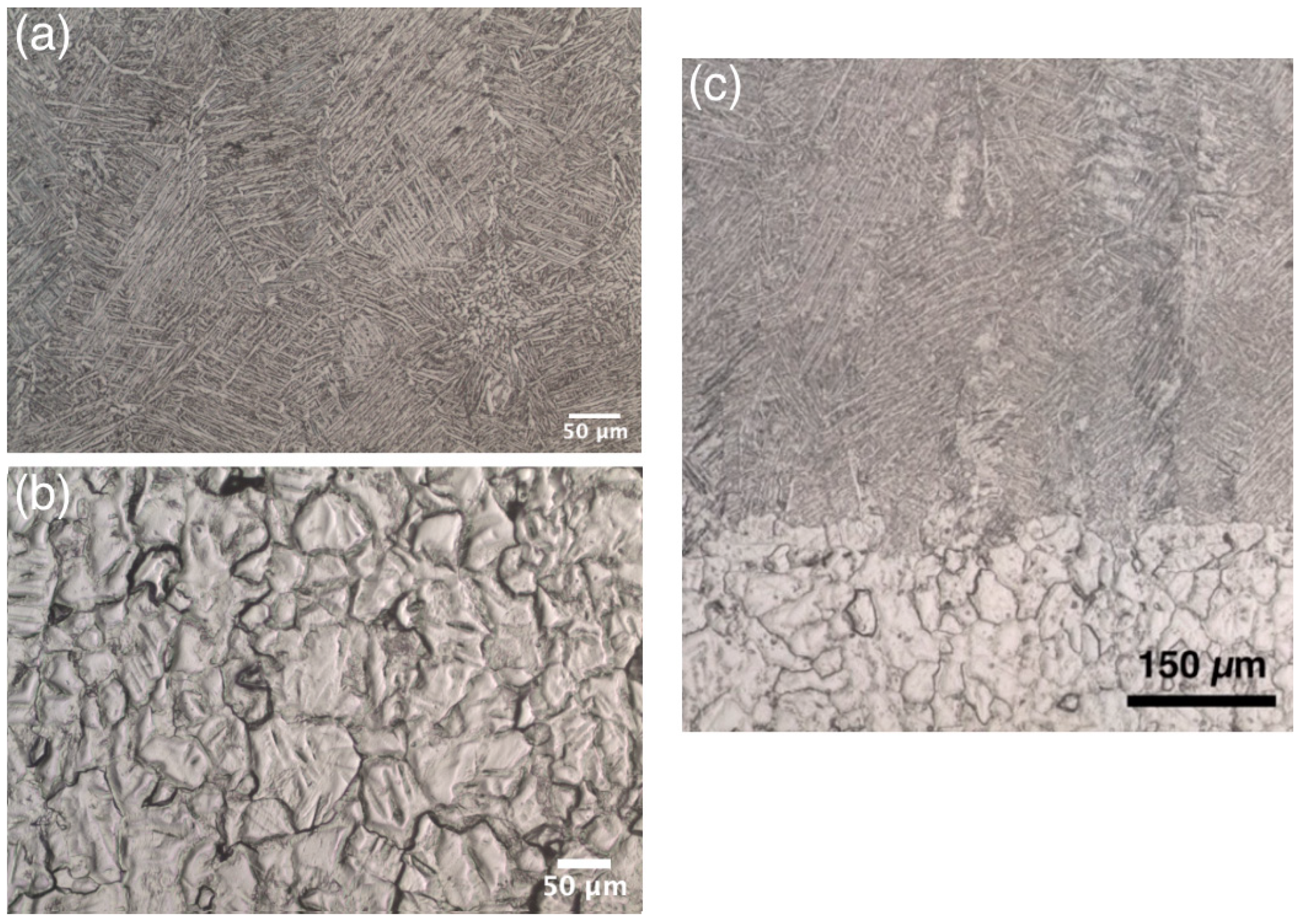

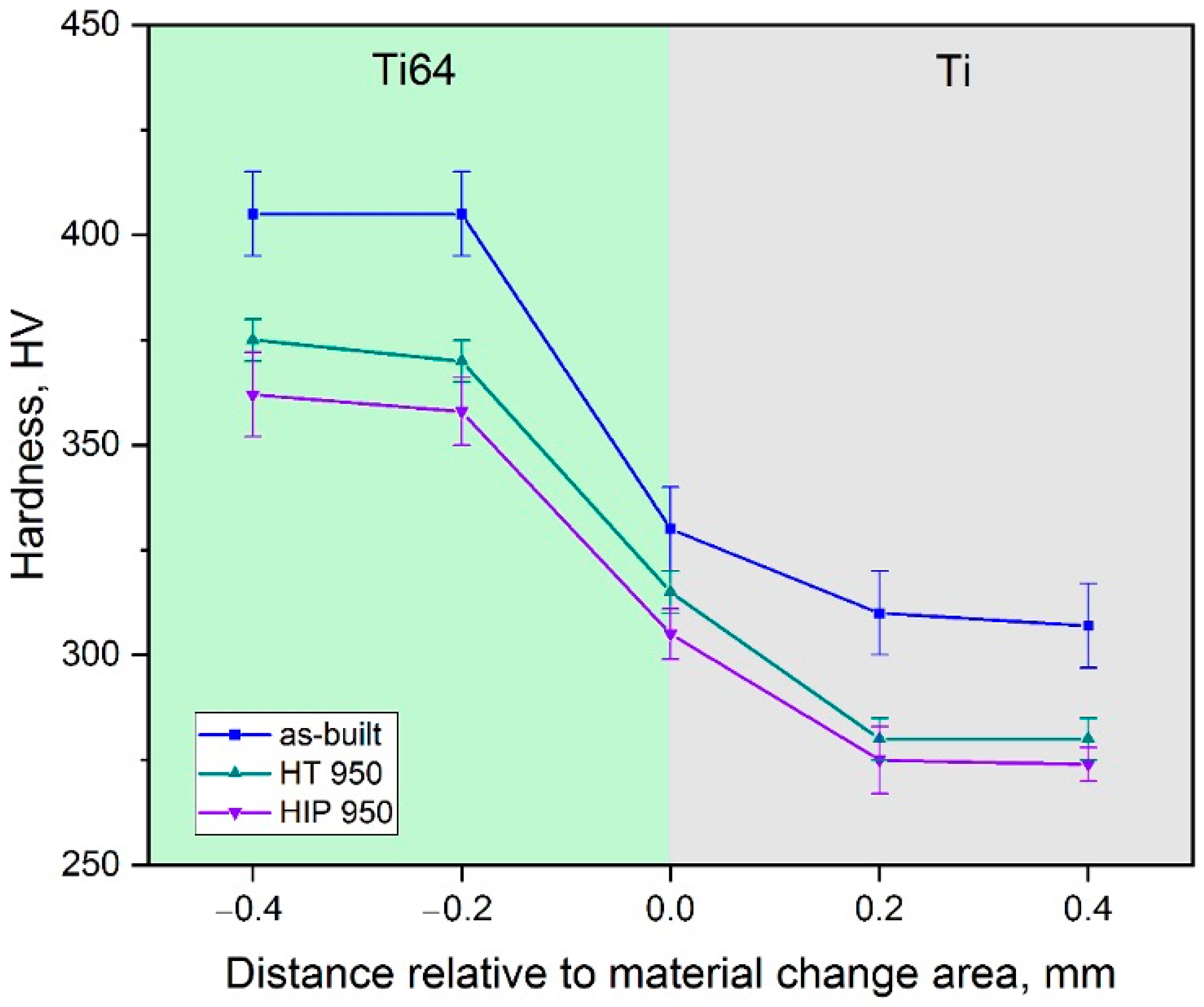

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Orme, M.E.; Gschweitl, M.; Ferrari, M.; Madera, I.; Mouriaux, F. Designing for Additive Manufacturing: Lightweighting Through Topology Optimization Enables Lunar Spacecraft. J. Mech. Des. 2017, 139, 100905. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput. Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Uriondo, A.; Esperon-Miguez, M.; Perinpanayagam, S. The present and future of additive manufacturing in the aerospace sector: A review of important aspects. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2015, 229, 2132–2147. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Attar, H.; Calin, M.; Eckert, J. Review on manufacture by selective laser melting and properties of titanium based materials for biomedical applications. Mater. Technol. 2015, 7857, 1–11. [Google Scholar] [CrossRef]

- Popovich, A.A.; Sufiiarov, V.S.; Borisov, E.V.; Polozov, I.A.; Masaylo, D.V. Design and manufacturing of tailored microstructure with selective laser melting. Mater. Phys. Mech. 2018, 38, 1–10. [Google Scholar]

- Singh, R.; Kumar, R.; Farina, I.; Colangelo, F.; Feo, L.; Fraternali, F. Multi-Material Additive Manufacturing of Sustainable Innovative Materials and Structures. Polymers 2019, 11, 62. [Google Scholar] [CrossRef] [Green Version]

- Han, D.; Lee, H. Recent advances in multi-material additive manufacturing: Methods and applications. Curr. Opin. Chem. Eng. 2020, 28, 158–166. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. R Reports 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Jing, S.; Zhang, H.; Zhou, J.; Song, G. Optimum weight design of functionally graded material gears. Chin. J. Mech. Eng. 2015, 28, 1186–1193. [Google Scholar] [CrossRef]

- Singh, A.K. A novel technique for in-situ manufacturing of functionally graded materials based polymer composite spur gears. Polym. Compos. 2019, 40, 523–535. [Google Scholar] [CrossRef]

- Arabnejad, S.; Johnston, R.B.; Pura, J.A.; Singh, B.; Tanzer, M.; Pasini, D. High-Strength Porous Biomaterials for Bone Replacement: A strategy to assess the interplay between cell morphology, mechanical properties, bone ingrowth and manufacturing constraints. ACTA Biomater. 2015, 30, 345–356. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Walker, J.; Middendorf, J.R.; Lesko, C.C.C.; Gockel, J. Multi-material laser powder bed fusion additive manufacturing in 3-dimensions. Manuf. Lett. 2021, in press. [Google Scholar] [CrossRef]

- Wei, C.; Li, L.; Zhang, X.; Chueh, Y.-H. 3D printing of multiple metallic materials via modified selective laser melting. CIRP Ann. 2018, 67, 245–248. [Google Scholar] [CrossRef] [Green Version]

- Sing, S.L.; Huang, S.; Goh, G.D.; Goh, G.L.; Tey, C.F.; Tan, J.H.K.; Yeong, W.Y. Emerging metallic systems for additive manufacturing: In-situ alloying and multi-metal processing in laser powder bed fusion. Prog. Mater. Sci. 2021, 119, 100795. [Google Scholar] [CrossRef]

- Wei, C.; Gu, H.; Sun, Z.; Cheng, D.; Chueh, Y.-H.; Zhang, X.; Huang, Y.; Li, L. Ultrasonic material dispensing-based selective laser melting for 3D printing of metallic components and the effect of powder compression. Addit. Manuf. 2019, 29, 100818. [Google Scholar] [CrossRef]

- Wei, C.; Gu, H.; Zhang, X.; Chueh, Y.; Li, L. Hybrid ultrasonic and mini-motor vibration-induced irregularly shaped powder delivery for multiple materials additive manufacturing. Addit. Manuf. 2020, 33, 101138. [Google Scholar] [CrossRef]

- Sorkin, A.; Tan, J.L.; Wong, C.H. Multi-material modelling for selective laser melting. Procedia Eng. 2017, 216, 51–57. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, Y.; Wang, D.; Song, C.; Chen, J. Microstructure and mechanical properties of CuSn/18Ni300 bimetallic porous structures manufactured by selective laser melting. Mater. Des. 2019, 165, 107583. [Google Scholar] [CrossRef]

- Bartolomeu, F.; Costa, M.M.; Alves, N.; Miranda, G.; Silva, F.S. Additive manufacturing of NiTi-Ti6Al4V multi-material cellular structures targeting orthopedic implants. Opt. Lasers Eng. 2020, 134, 106208. [Google Scholar] [CrossRef]

- Scaramuccia, M.G.; Demir, A.G.; Caprio, L.; Tassa, O.; Previtali, B. Development of processing strategies for multigraded selective laser melting of Ti6Al4V and IN718. Powder Technol. 2020, 367, 376–389. [Google Scholar] [CrossRef]

- Khaimovich, A.; Erisov, Y.; Smelov, V.; Agapovichev, A.; Petrov, I.; Razhivin, V.; Bobrovskij, I.; Kokareva, V.; Kuzin, A. Interface Quality Indices of Al–10Si–Mg Aluminum Alloy and Cr18–Ni10–Ti Stainless-Steel Bimetal Fabricated via Selective Laser Melting. Metals 2021, 11, 172. [Google Scholar] [CrossRef]

- Chen, J.; Yang, Y.; Song, C.; Zhang, M.; Wu, S.; Wang, D. Interfacial microstructure and mechanical properties of 316L /CuSn10 multi-material bimetallic structure fabricated by selective laser melting. Mater. Sci. Eng. A 2019, 752, 75–85. [Google Scholar] [CrossRef]

- Rankouhi, B.; Jahani, S.; Pfefferkorn, F.E.; Thoma, D.J. Compositional grading of a 316L-Cu multi-material part using machine learning for the determination of selective laser melting process parameters. Addit. Manuf. 2021, 38, 101836. [Google Scholar]

- Neirinck, B.; Li, X.; Hick, M. Powder Deposition Systems Used in Powder Bed-Based Multimetal Additive Manufacturing. Accounts Mater. Res. 2021, 2, 387–393. [Google Scholar] [CrossRef]

- Schneck, M.; Horn, M.; Schmitt, M.; Seidel, C.; Schlick, G.; Reinhart, G. Review on additive hybrid- and multi-material-manufacturing of metals by powder bed fusion: State of technology and development potential. Prog. Addit. Manuf. 2021, 2021, 1–14. [Google Scholar]

- Heat Exchenager—Aerosint. Available online: https://aerosint.com/heat-exchanger/ (accessed on 14 October 2021).

- Saji, V.S.; Jeong, Y.H.; Choe, H.C. A Comparative Study on Corrosion Behavior of Ti-35Nb-5Ta-7Zr Ti-6Al-4V and CP-Ti in 0.9 wt% NaC. Corros. Sci. Technol. 2009, 8, 139–142. [Google Scholar]

- Sufiiarov, V.S.; Popovich, A.A.; Borisov, E.V.; Polozov, I.A. Selective laser melting of titanium alloy and manufacturing of gas-turbine engine part blanks. Tsvetnye Met. 2015, 8, 76–80. [Google Scholar] [CrossRef] [Green Version]

- Popovich, A.; Sufiiarov, V.; Borisov, E.; Polozov, I. Microstructure and Mechanical Properties of Ti-6Al-4V Manufactured by SLM. Key Eng. Mater. 2015, 651–653, 677–682. [Google Scholar] [CrossRef]

- Tarín, P.; Gualo, A.; Simón, A.G.; Piris, N.M.; Badía, J.M. Study of Alpha-Beta Transformation in Ti-6Al-4V-ELI. Mechanical and Microstructural Characteristics. Mater. Sci. Forum 2010, 638–642, 712–717. [Google Scholar] [CrossRef]

- Pauly, S.; Wang, P.; Kühn, U.; Kosiba, K. Experimental determination of cooling rates in selectively laser-melted eutectic Al-33Cu. Addit. Manuf. 2018, 22, 753–757. [Google Scholar] [CrossRef]

- Ibrahim, K.M.; Mhaede, M.; Wagner, L. Effect of Annealing Temperature on Microstructure and Mechanical Properties of Hot Swaged cp-Ti Produced by Investment Casting. J. Mater. Eng. Perform. 2012, 21, 114–118. [Google Scholar] [CrossRef]

- Li, C.-L.; Won, J.W.; Choi, S.-W.; Choe, J.-H.; Lee, S.; Park, C.H.; Yeom, J.-T.; Hong, J.K. Simultaneous achievement of equiaxed grain structure and weak texture in pure titanium via selective laser melting and subsequent heat treatment. J. Alloys Compd. 2019, 803, 407–412. [Google Scholar] [CrossRef]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and Mechanical Properties of Ti6Al4V Parts Fabricated by Selective Laser Melting and Electron Beam Melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

| Specimen Type | Tensile Strength, MPa | Yield Strength, MPa | Elongation at Break, % |

|---|---|---|---|

| I (Ti) | 700 ± 12 | 596 ± 8 | 16 ± 4 |

| I (Ti64) | 998 ± 21 | 821 ± 11 | 10 ± 3 |

| II | 728 ± 29 | 693 ± 25 | 3 ± 1 |

| III | 760 ± 14 | 726 ± 11 | 5 ± 2 |

| IV | 839 ± 10 | 754 ± 8 | 7 ± 3 |

| V | 703 ± 36 | 667 ± 32 | 2 ± 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borisov, E.; Polozov, I.; Starikov, K.; Popovich, A.; Sufiiarov, V. Structure and Properties of Ti/Ti64 Graded Material Manufactured by Laser Powder Bed Fusion. Materials 2021, 14, 6140. https://doi.org/10.3390/ma14206140

Borisov E, Polozov I, Starikov K, Popovich A, Sufiiarov V. Structure and Properties of Ti/Ti64 Graded Material Manufactured by Laser Powder Bed Fusion. Materials. 2021; 14(20):6140. https://doi.org/10.3390/ma14206140

Chicago/Turabian StyleBorisov, Evgenii, Igor Polozov, Kirill Starikov, Anatoly Popovich, and Vadim Sufiiarov. 2021. "Structure and Properties of Ti/Ti64 Graded Material Manufactured by Laser Powder Bed Fusion" Materials 14, no. 20: 6140. https://doi.org/10.3390/ma14206140

APA StyleBorisov, E., Polozov, I., Starikov, K., Popovich, A., & Sufiiarov, V. (2021). Structure and Properties of Ti/Ti64 Graded Material Manufactured by Laser Powder Bed Fusion. Materials, 14(20), 6140. https://doi.org/10.3390/ma14206140