Influence of Adding Modifying Elements and Homogenization Annealing on Laser Melting Process of the Modified AlZnMgCu with 4%Si Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Characterization of the Modified Alloys

3.1.1. Thermo-Calc Prediction

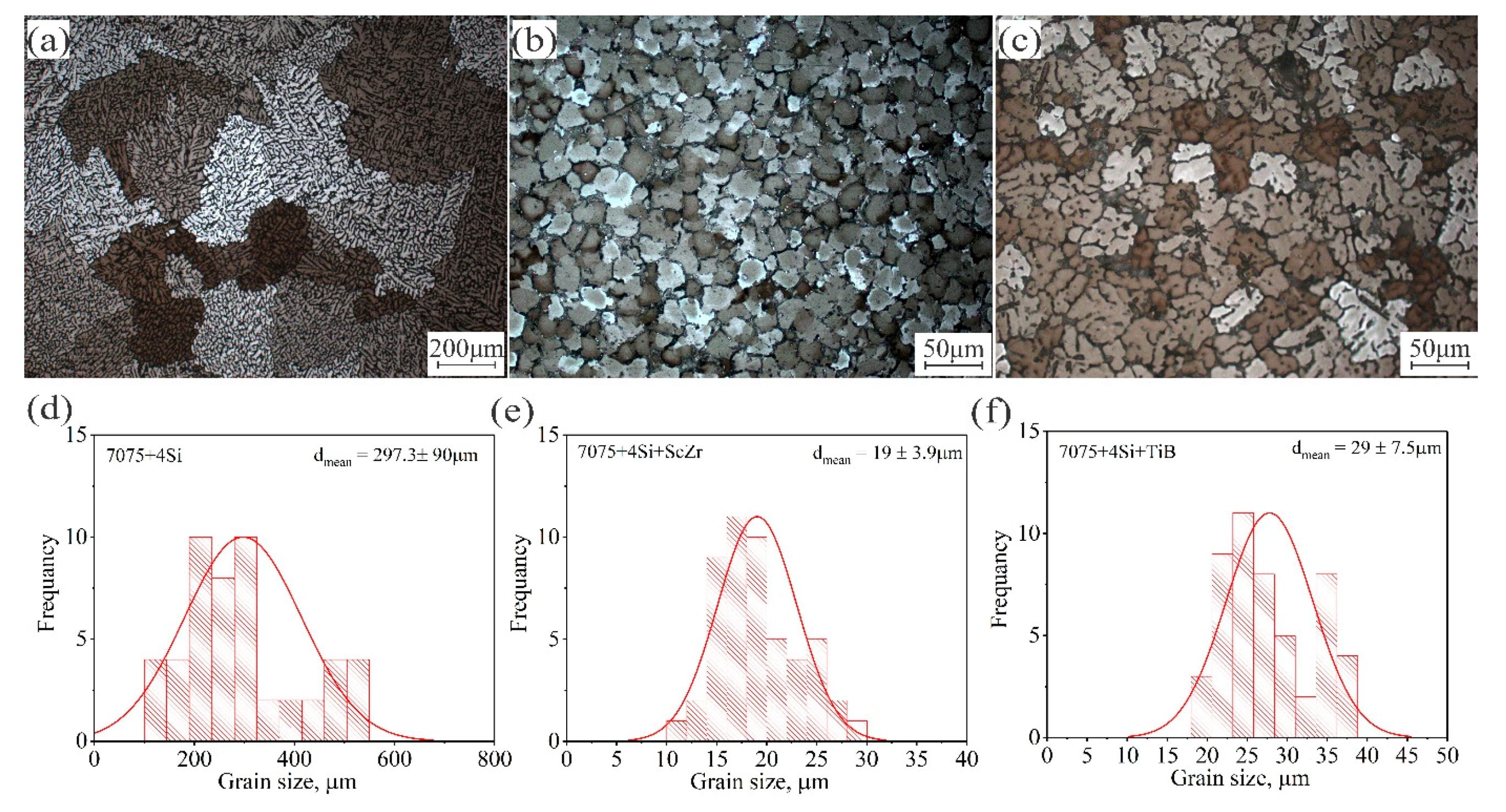

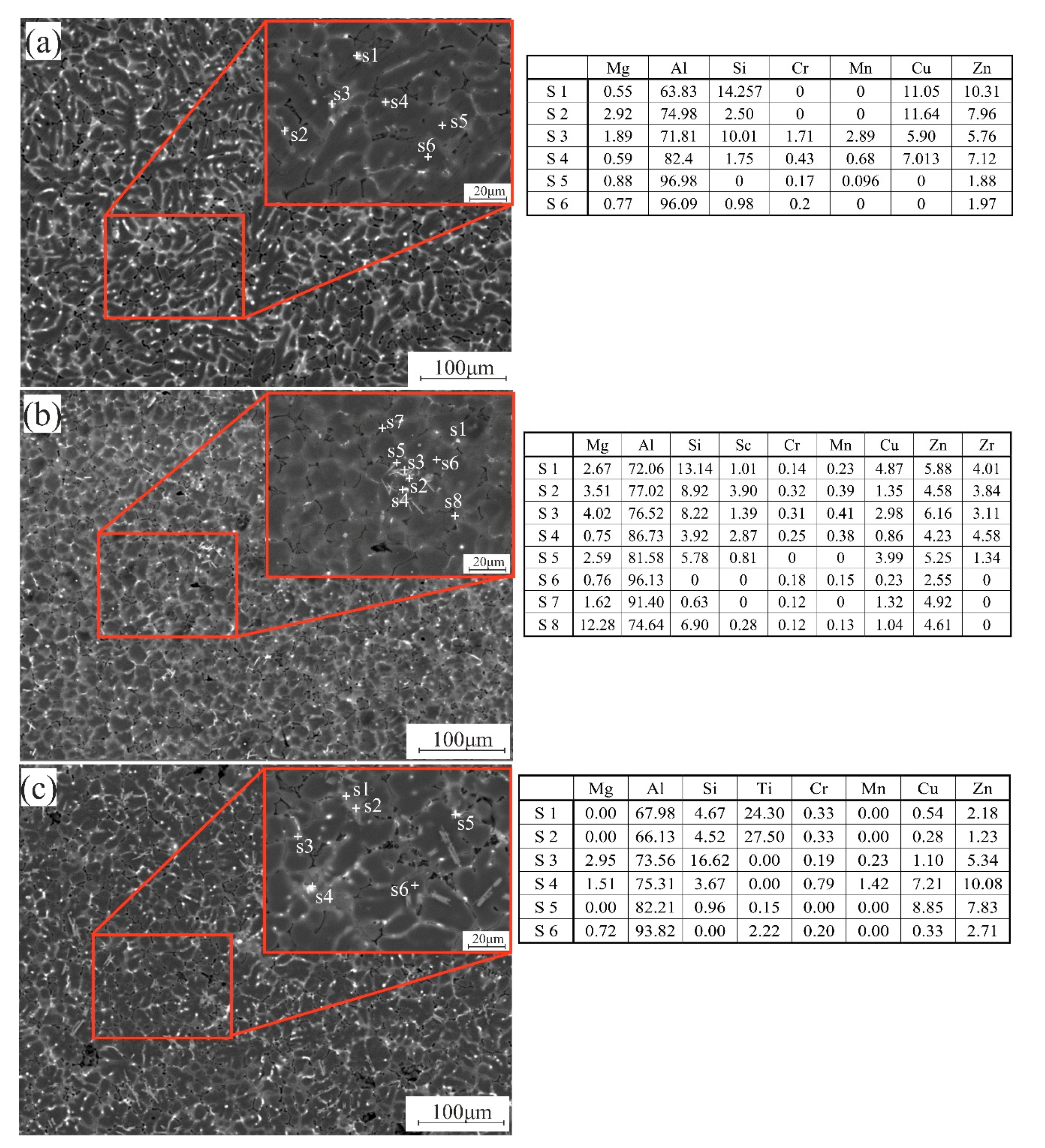

3.1.2. Microstructure Evaluation in As-Cast Condition

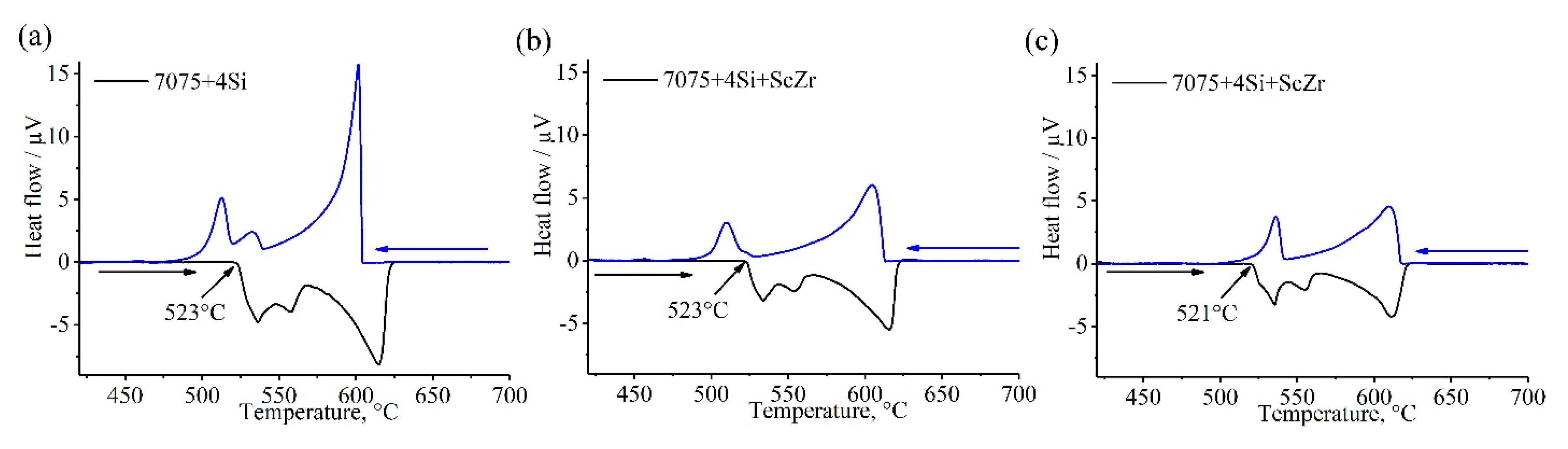

3.1.3. DSC Analysis of the As-Casted Alloys

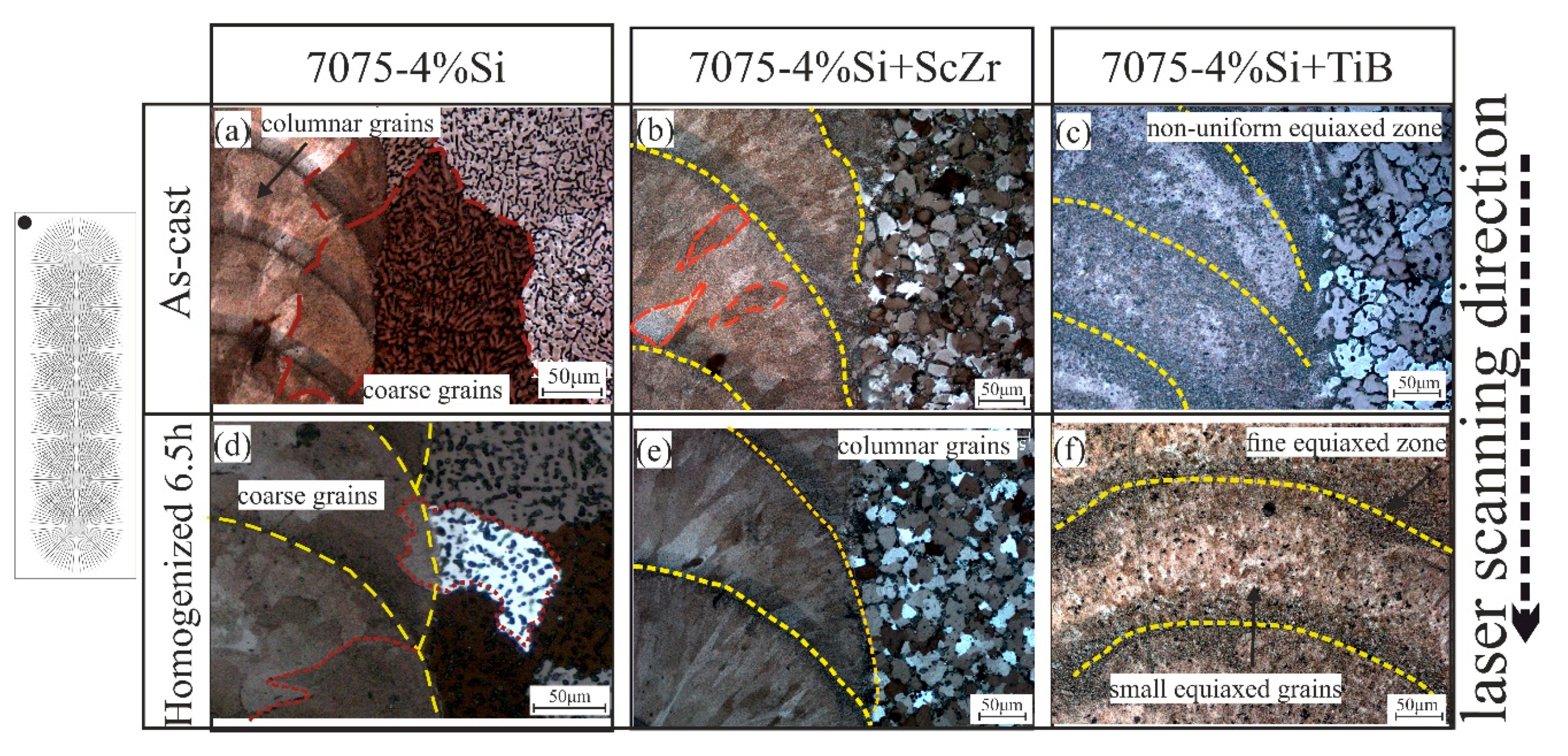

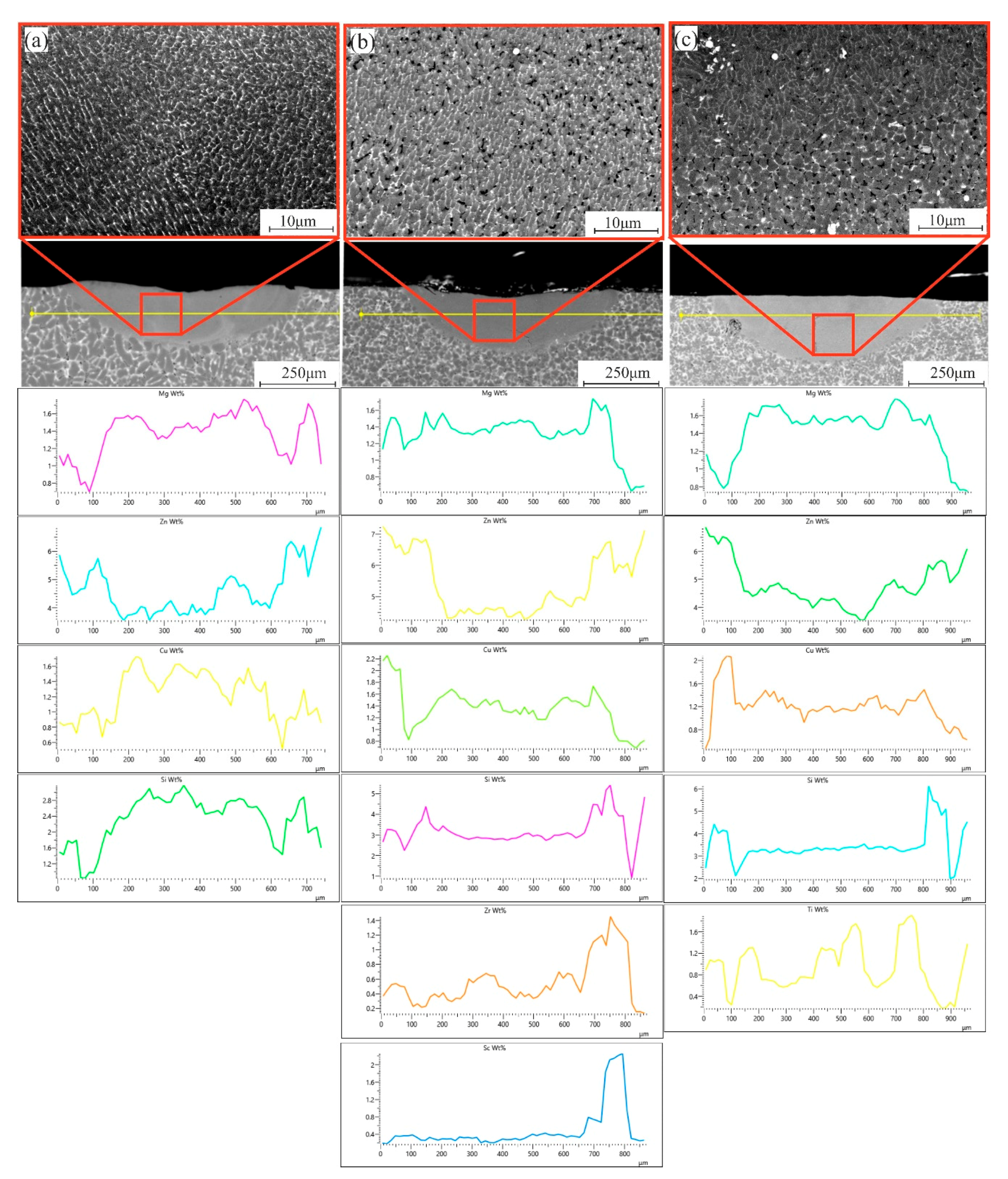

3.2. Laser Melting Process

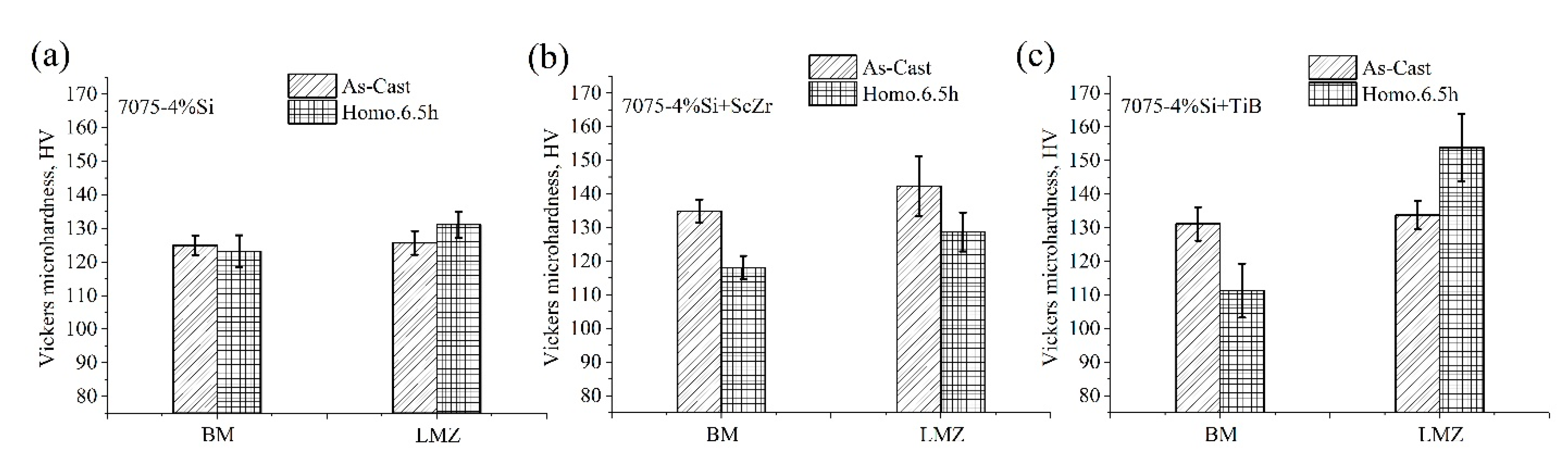

3.3. Hardness Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kotov, A.; Mikhaylovskaya, A.; Borisov, A.; Yakovtseva, O.; Portnoy, V. High-strain-rate superplasticity of the Al–Zn–Mg–Cu alloys with Fe and Ni additions. Phys. Met. Metallogr. 2017, 118, 913–921. [Google Scholar] [CrossRef]

- Zhou, B.; Liu, B.; Zhang, S. The advancement of 7xxx series aluminum alloys for aircraft structures: A review. Metals (Basel) 2021, 11. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. 2 - Review of additive manufacturing technologies and applications in the aerospace industry. In Additive Manufacturing for the Aerospace Industry; Froes, F., Boyer, R.B.T.-A.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–31. ISBN 978-0-12-814062-8. [Google Scholar]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Polmear, I.J. Light Alloys From Traditional Alloys to Nanocrystals, 4th ed.; Fourth, E., Ed.; Butterworth-Heinemann: Oxford, UK, 2005; ISBN 978-0-7506-6371-7. [Google Scholar]

- Montero Sistiaga, M.L.; Mertens, R.; Vrancken, B.; Wang, X.; Van Hooreweder, B.; Kruth, J.P.; Van Humbeeck, J. Changing the alloy composition of Al7075 for better processability by selective laser melting. J. Mater. Process. Technol. 2016, 238, 437–445. [Google Scholar] [CrossRef]

- Nie, X.; Zhang, H.; Zhu, H.; Hu, Z.; Ke, L.; Zeng, X. Effect of Zr content on formability, microstructure and mechanical properties of selective laser melted Zr modified Al-4.24Cu-1.97Mg-0.56Mn alloys. J. Alloys Compd. 2018, 764, 977–986. [Google Scholar] [CrossRef]

- Jia, Q.; Rometsch, P.; Kürnsteiner, P.; Chao, Q.; Huang, A.; Weyland, M.; Bourgeois, L.; Wu, X. Selective laser melting of a high strength Al Mn Sc alloy: Alloy design and strengthening mechanisms. Acta Mater. 2019, 171, 108–118. [Google Scholar] [CrossRef]

- Rappaz, M.; Drezet, J.M.; Gremaud, M. A new hot-tearing criterion. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 1999, 30, 449–455. [Google Scholar] [CrossRef]

- Sonawane, A.; Roux, G.; Blandin, J.J.; Despres, A.; Martin, G. Cracking mechanism and its sensitivity to processing conditions during laser powder bed fusion of a structural aluminum alloy. Materialia 2021, 15, 100976. [Google Scholar] [CrossRef]

- Fulcher, B.A.; Leigh, D.K.; Watt, T.J. Comparison of ALSI10MG and AL 6061 Processed through DMLS. 2014. Available online: http://utw10945.utweb.utexas.edu/sites/default/files/2014-035-Fulcher.pdf (accessed on 16 October 2021).

- Koutny, D.; Palousek, D.; Koukal, O.; Zikmund, T.; Pantelejev, L.; Dokoupil, F. Processing of High Strength Al-Cu Alloy Using 400W Selective Laser Melting—Initial Study. 2015. Available online: https://www.wlt.de/lim/Proceedings2015/Stick/PDF/Contribution347_final.pdf (accessed on 16 October 2021).

- Qi, T.; Zhu, H.; Yin, J.; Chen, B.; Hu, Z.; Zeng, X. POROSITY DEVELOPMENT AND CRACKING BEHAVIOR OF Al-Zn-Mg-Cu ALLOYS FABRICATED BY SELECTIVE LASER MELTING. Available online: http://utw10945.utweb.utexas.edu/sites/default/files/2017/Manuscripts/PorosityDevelopmentandCrackingBehaviorofAlZ.pdf (accessed on 16 October 2021).

- Wang, P.; Gammer, C.; Brenne, F.; Niendorf, T.; Eckert, J.; Scudino, S. A heat treatable TiB2/Al-3.5Cu-1.5Mg-1Si composite fabricated by selective laser melting: Microstructure, heat treatment and mechanical properties. Compos. Part B Eng. 2018, 147, 162–168. [Google Scholar] [CrossRef]

- Zhou, L.; Pan, H.; Hyer, H.; Park, S.; Bai, Y.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure and tensile property of a novel AlZnMgScZr alloy additively manufactured by gas atomization and laser powder bed fusion. Scr. Mater. 2019, 158, 24–28. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Nie, X.; Yin, J.; Hu, Z.; Zeng, X. Effect of Zirconium addition on crack, microstructure and mechanical behavior of selective laser melted Al-Cu-Mg alloy. Scr. Mater. 2017, 134, 6–10. [Google Scholar] [CrossRef]

- Xu, R.; Li, R.; Yuan, T.; Niu, P.; Wang, M.; Lin, Z. Microstructure, metallurgical defects and hardness of Al–Cu–Mg–Li–Zr alloy additively manufactured by selective laser melting. J. Alloys Compd. 2020, 835, 155372. [Google Scholar] [CrossRef]

- Qi, Y.; Zhang, H.; Nie, X.; Hu, Z.; Zhu, H.; Zeng, X. A high strength Al–Li alloy produced by laser powder bed fusion: Densification, microstructure, and mechanical properties. Addit. Manuf. 2020, 35, 101346. [Google Scholar] [CrossRef]

- Louvis, E.; Fox, P.; Sutcliffe, C.J. Selective laser melting of aluminium components. J. Mater. Process. Technol. 2011, 211, 275–284. [Google Scholar] [CrossRef]

- Kaufmann, N.; Imran, M.; Wischeropp, T.M.; Emmelmann, C.; Siddique, S.; Walther, F. Influence of process parameters on the quality of aluminium alloy en AW 7075 using Selective Laser Melting (SLM). Phys. Procedia 2016, 83, 918–926. [Google Scholar] [CrossRef] [Green Version]

- Khalil, A.M.; Loginova, I.S.; Solonin, A.N.; Mosleh, A.O. Controlling liquation behavior and solidification cracks by continuous laser melting process of AA-7075 aluminum alloy. Mater. Lett. 2020, 277, 128364. [Google Scholar] [CrossRef]

- Jägle, E.A.; Sheng, Z.; Wu, L.; Lu, L.; Risse, J.; Weisheit, A.; Raabe, D. Precipitation Reactions in Age-Hardenable Alloys During Laser Additive Manufacturing. Jom 2016, 68, 943–949. [Google Scholar] [CrossRef] [Green Version]

- Fan, Z.; Gao, F.; Zhou, L.; Lu, S.Z. A new concept for growth restriction during solidification. Acta Mater. 2018, 152, 248–257. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Z.; Qiu, D.; Taylor, J.A.; Easton, M.A.; Zhang, M.-X. Revisiting the role of peritectics in grain refinement of Al alloys. Acta Mater. 2013, 61, 360–370. [Google Scholar] [CrossRef]

- Kishchik, M.S.; Mikhaylovskaya, A.V.; Kotov, A.D.; Mosleh, A.O.; AbuShanab, W.S.; Portnoy, V.K. Effect of multidirectional forging on the grain structure and mechanical properties of the Al-Mg-Mn alloy. Materials (Basel) 2018, 11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xiao, Y.K.; Bian, Z.Y.; Wu, Y.; Ji, G.; Li, Y.Q.; Li, M.J.; Lian, Q.; Chen, Z.; Addad, A.; Wang, H.W. Effect of nano-TiB2 particles on the anisotropy in an AlSi10Mg alloy processed by selective laser melting. J. Alloys Compd. 2019, 798, 644–655. [Google Scholar] [CrossRef]

- Wen, X.; Wang, Q.; Mu, Q.; Kang, N.; Sui, S.; Yang, H.; Lin, X.; Huang, W. Laser solid forming additive manufacturing TiB2 reinforced 2024Al composite: Microstructure and mechanical properties. Mater. Sci. Eng. A 2019, 745, 319–325. [Google Scholar] [CrossRef]

- Carluccio, D.; Bermingham, M.J.; Zhang, Y.; StJohn, D.H.; Yang, K.; Rometsch, P.A.; Wu, X.; Dargusch, M.S. Grain refinement of laser remelted Al-7Si and 6061 aluminium alloys with Tibor® and scandium additions. J. Manuf. Process. 2018, 35, 715–720. [Google Scholar] [CrossRef]

- Tan, Q.; Zhang, J.; Mo, N.; Fan, Z.; Yin, Y.; Bermingham, M.; Liu, Y.; Huang, H.; Zhang, M.-X. A novel method to 3D-print fine-grained AlSi10Mg alloy with isotropic properties via inoculation with LaB6 nanoparticles. Addit. Manuf. 2020, 32, 101034. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Kotov, A.D.; Kishchik, M.S.; Prosviryakov, A.S.; Portnoy, V.K. The effect of isothermal multi-directional forging on the grain structure, superplasticity, and mechanical properties of the conventional al–mg-based alloy. Metals (Basel) 2019, 9, 33. [Google Scholar] [CrossRef] [Green Version]

- Shi, Y.; Rometsch, P.; Yang, K.; Palm, F.; Wu, X. Characterisation of a novel Sc and Zr modified Al–Mg alloy fabricated by selective laser melting. Mater. Lett. 2017, 196, 347–350. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Kern, K.; Palm, F.; Wegener, K. SLM-processed Sc- and Zr- modified Al-Mg alloy: Mechanical properties and microstructural effects of heat treatment. Mater. Sci. Eng. A 2017, 701, 264–273. [Google Scholar] [CrossRef]

- Qi, T.; Zhu, H.; Zeng, X.; Yin, J. Effect of Si content on the cracking behavior of selective laser melted Al7050. Rapid Prototyp. J. 2019, 25, 1592–1600. [Google Scholar] [CrossRef]

- Otani, Y.; Sasaki, S. Effects of the addition of silicon to 7075 aluminum alloy on microstructure, mechanical properties, and selective laser melting processability. Mater. Sci. Eng. A 2020, 777, 139079. [Google Scholar] [CrossRef]

- Aversa, A.; Marchese, G.; Manfredi, D.; Lorusso, M.; Calignano, F.; Biamino, S.; Lombardi, M.; Fino, P.; Pavese, M. Laser powder bed fusion of a high strength Al-Si-Zn-Mg-Cu alloy. Metals (Basel) 2018, 8, 300. [Google Scholar] [CrossRef] [Green Version]

- Kou, S. A criterion for cracking during solidification. Acta Mater. 2015, 88, 366–374. [Google Scholar] [CrossRef]

- Greer, A.L. Overview: Application of heterogeneous nucleation in grain-refining of metals. J. Chem. Phys. 2016, 145. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Huang, G.; Cao, L.; Guo, F.; Lin, L. Effect of two-stage homogenization heat treatment on microstructure and mechanical properties of aa2060 alloy. Crystals 2021, 11, 40. [Google Scholar] [CrossRef]

- Aucott, L.; Huang, D.; Dong, H.B.; Wen, S.W.; Marsden, J.; Rack, A.; Cocks, A.C.F. A Three-Stage Mechanistic Model for Solidification Cracking During Welding of Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2018, 49, 1674–1682. [Google Scholar] [CrossRef] [Green Version]

| Alloy | Alloying Elements, wt.% | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Zn | Mg | Cu | Cr | Mn | Si | Sc | Zr | Ti | B | Al | |

| 7075-4%Si | 6.4 | 2.2 | 1.1 | 0.3 | 0.23 | 4 | Bal. | ||||

| 7075-4%Si + ScZr | 6.4 | 1.9 | 1 | 0.29 | 0.3 | 4.2 | 0.29 | 0.4 | Bal. | ||

| 7075-4%Si + TiB | 6.7 | 1.8 | 1.2 | 0.26 | 0.3 | 4 | 1 | 0.2 | Bal. | ||

| Parameter | Unit | Value | Parameter | Unit | Value |

|---|---|---|---|---|---|

| power | V | 300 | Scanning speed | mm/s | 1 |

| Pulse Duration | ms | 12 | Overlap | mm | 0.15 |

| Shielding gas | Argon | Frequency | Hz | 5 | |

| Pulse shape | Ramp-down | Laser diameter | mm | 0.2–2.5 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mosleh, A.O.; Khalil, A.M.; Loginova, I.S.; Solonin, A.N. Influence of Adding Modifying Elements and Homogenization Annealing on Laser Melting Process of the Modified AlZnMgCu with 4%Si Alloys. Materials 2021, 14, 6154. https://doi.org/10.3390/ma14206154

Mosleh AO, Khalil AM, Loginova IS, Solonin AN. Influence of Adding Modifying Elements and Homogenization Annealing on Laser Melting Process of the Modified AlZnMgCu with 4%Si Alloys. Materials. 2021; 14(20):6154. https://doi.org/10.3390/ma14206154

Chicago/Turabian StyleMosleh, Ahmed O., Asmaa M. Khalil, Irina S. Loginova, and Alexey N. Solonin. 2021. "Influence of Adding Modifying Elements and Homogenization Annealing on Laser Melting Process of the Modified AlZnMgCu with 4%Si Alloys" Materials 14, no. 20: 6154. https://doi.org/10.3390/ma14206154

APA StyleMosleh, A. O., Khalil, A. M., Loginova, I. S., & Solonin, A. N. (2021). Influence of Adding Modifying Elements and Homogenization Annealing on Laser Melting Process of the Modified AlZnMgCu with 4%Si Alloys. Materials, 14(20), 6154. https://doi.org/10.3390/ma14206154