In Situ Grafted Composite Nanoparticles-Reinforced Polyurethane Elastomer Composites with Excellent Continuous Anti-Impact Performance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

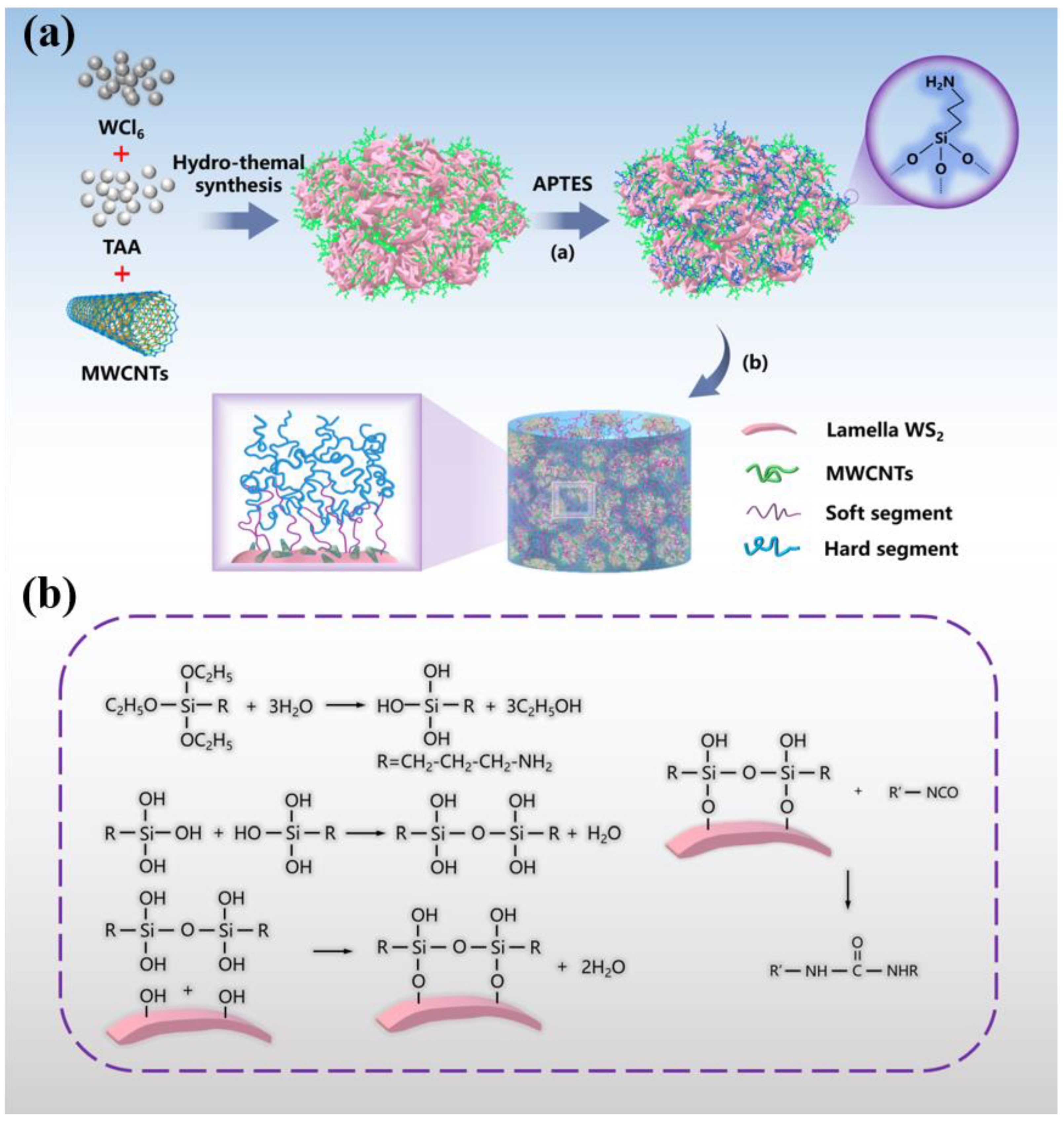

2.2. Preparation of Composite Materials

2.2.1. Preparation of WS2@MWCNTs Composite Nanoparticles

2.2.2. Preparation of A-WS2@MWCNTs/PUE Composite Materials

2.3. Characterization Methods

3. Results and Discussions

3.1. Characterization of Composite Nanoparticles

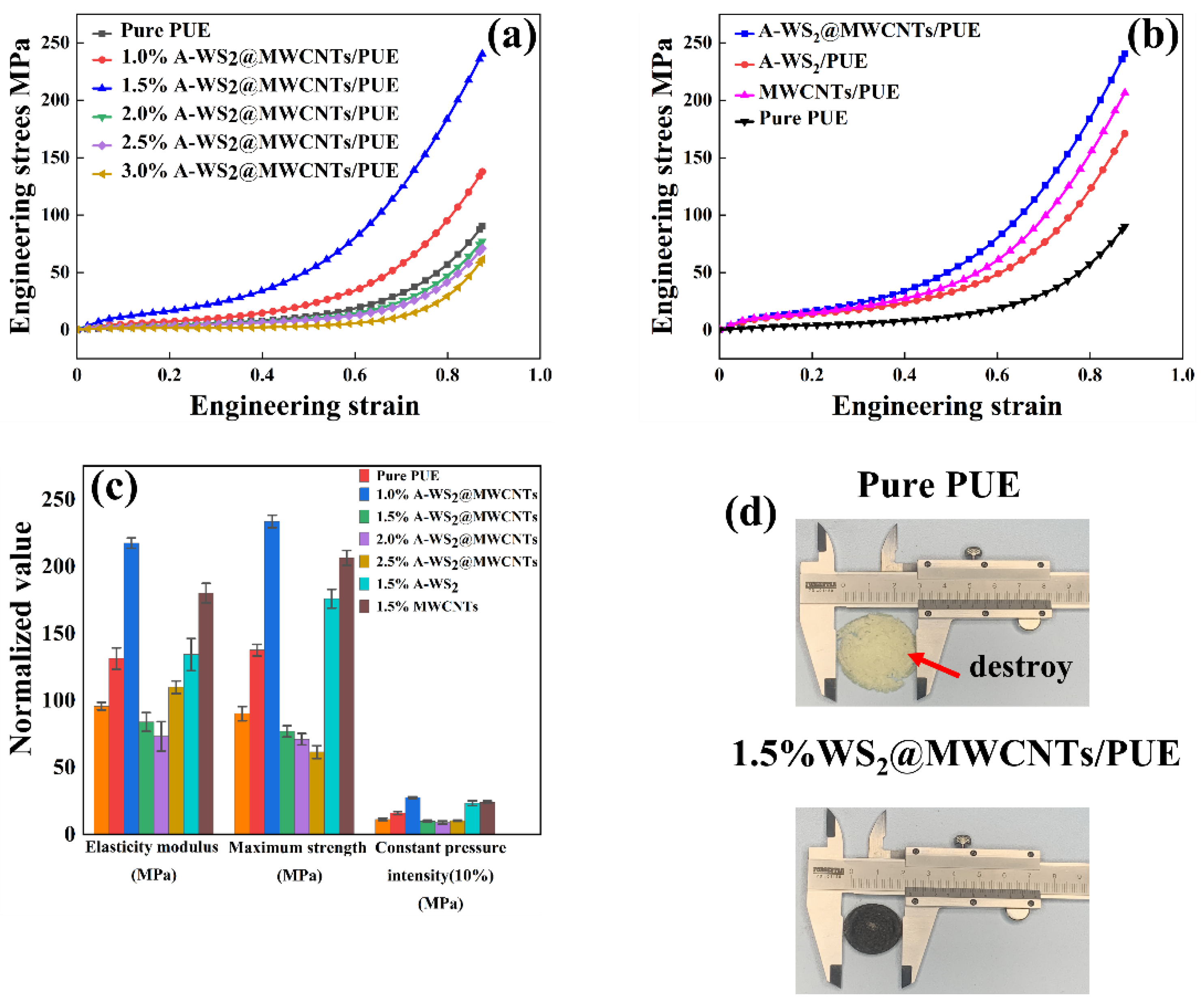

3.2. Static Mechanical Characterization

3.3. Dynamic Impact Test

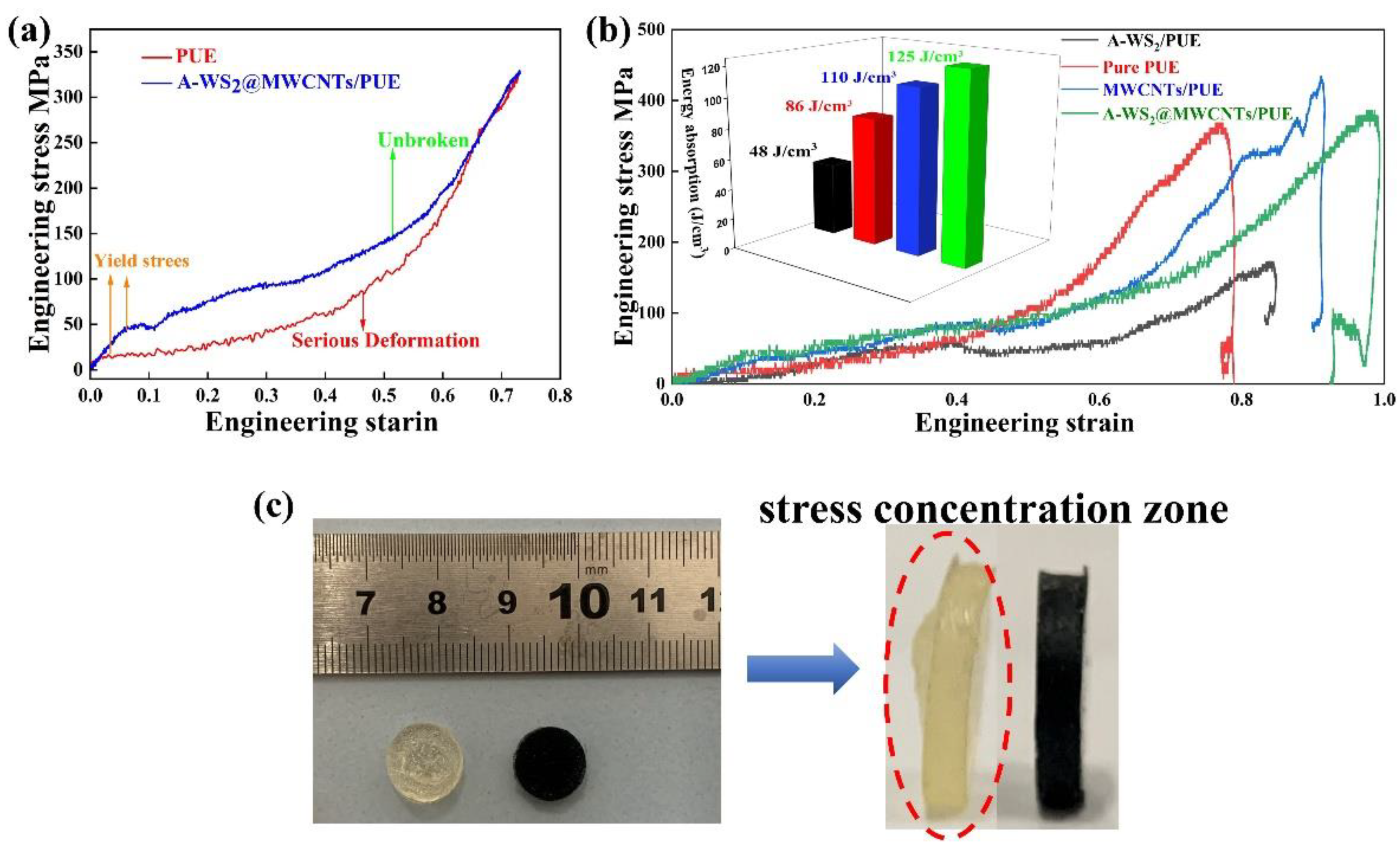

3.3.1. One-Time Impact Test

3.3.2. Continuous Cycle Impact Test

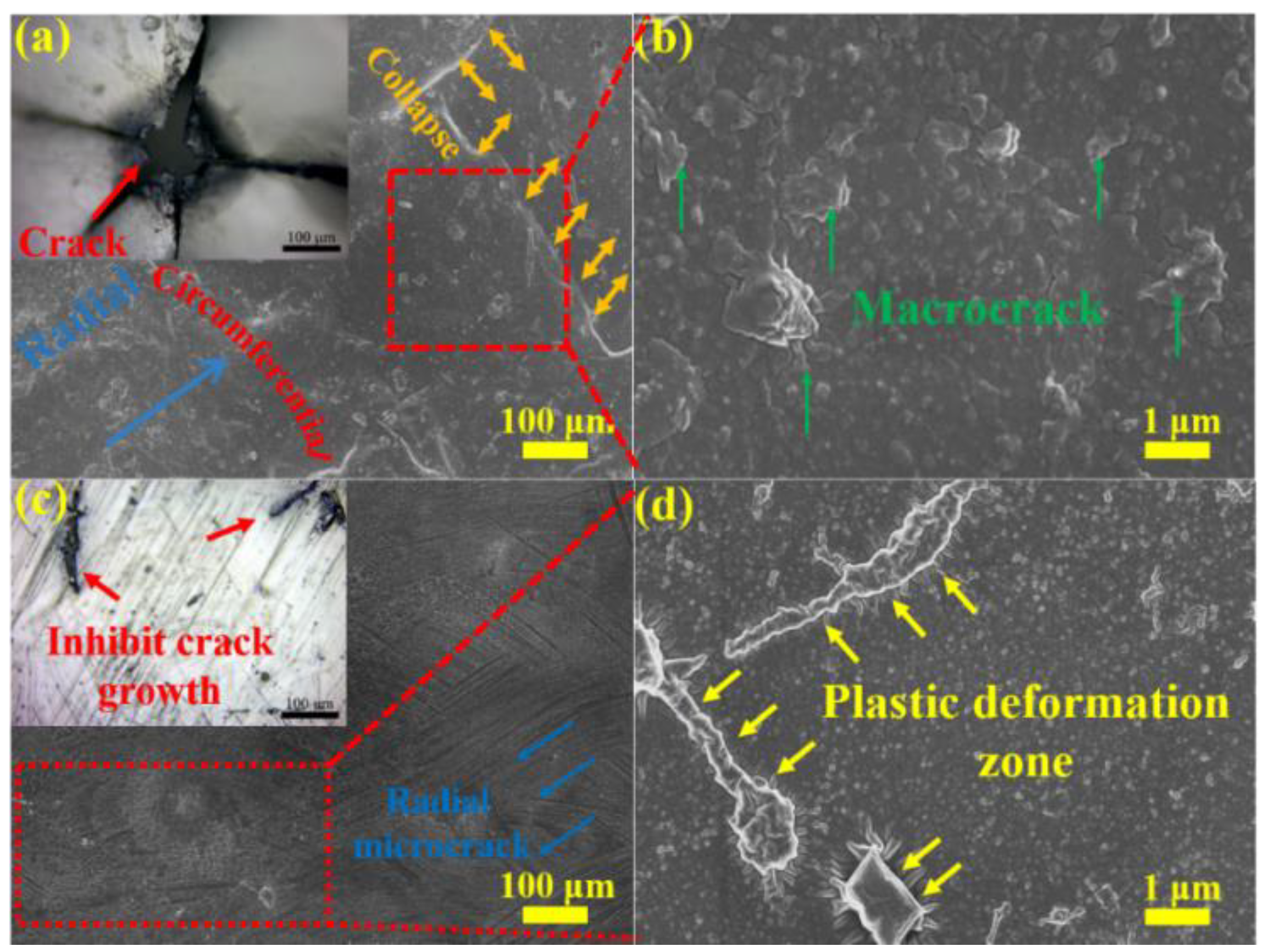

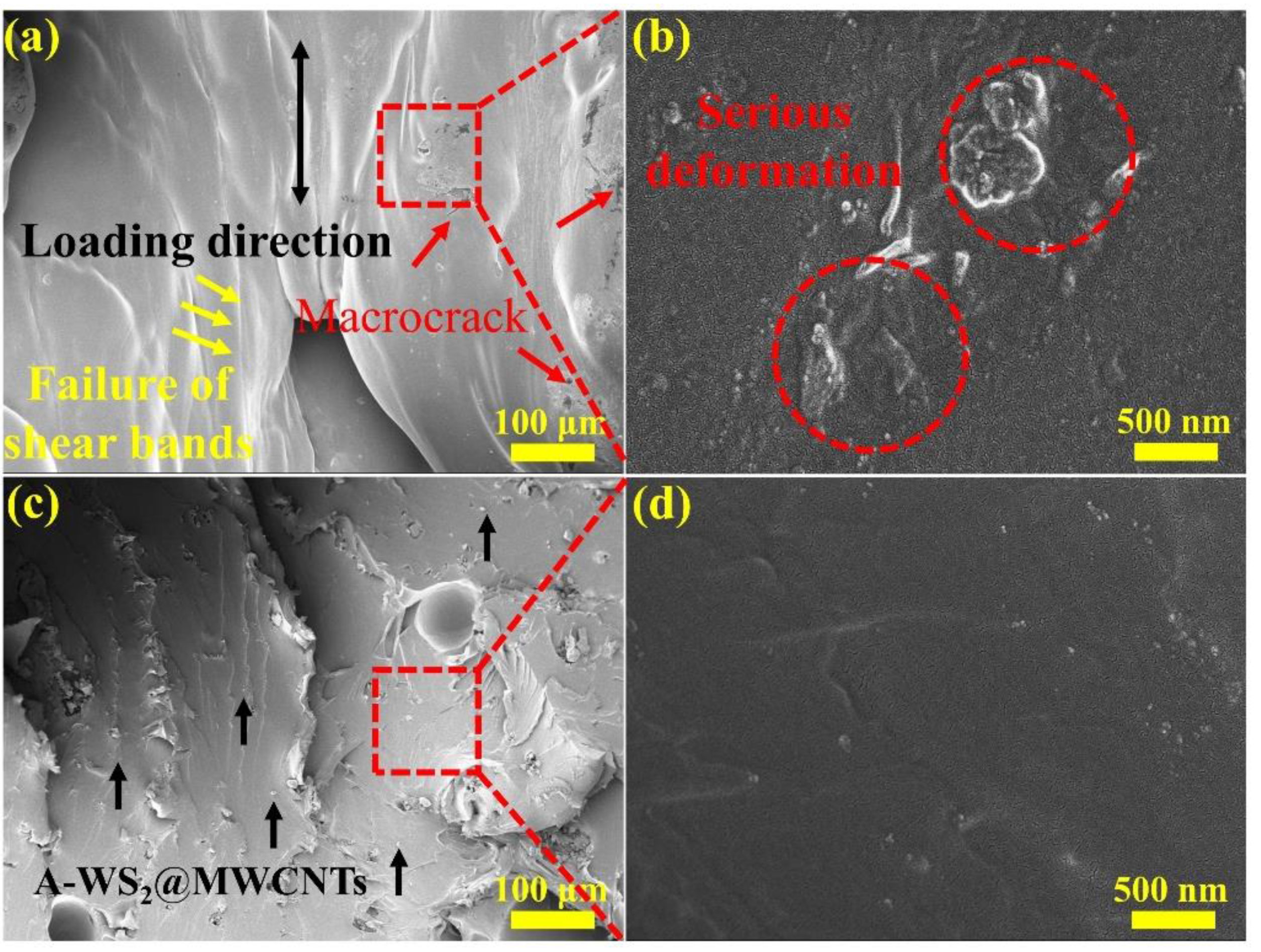

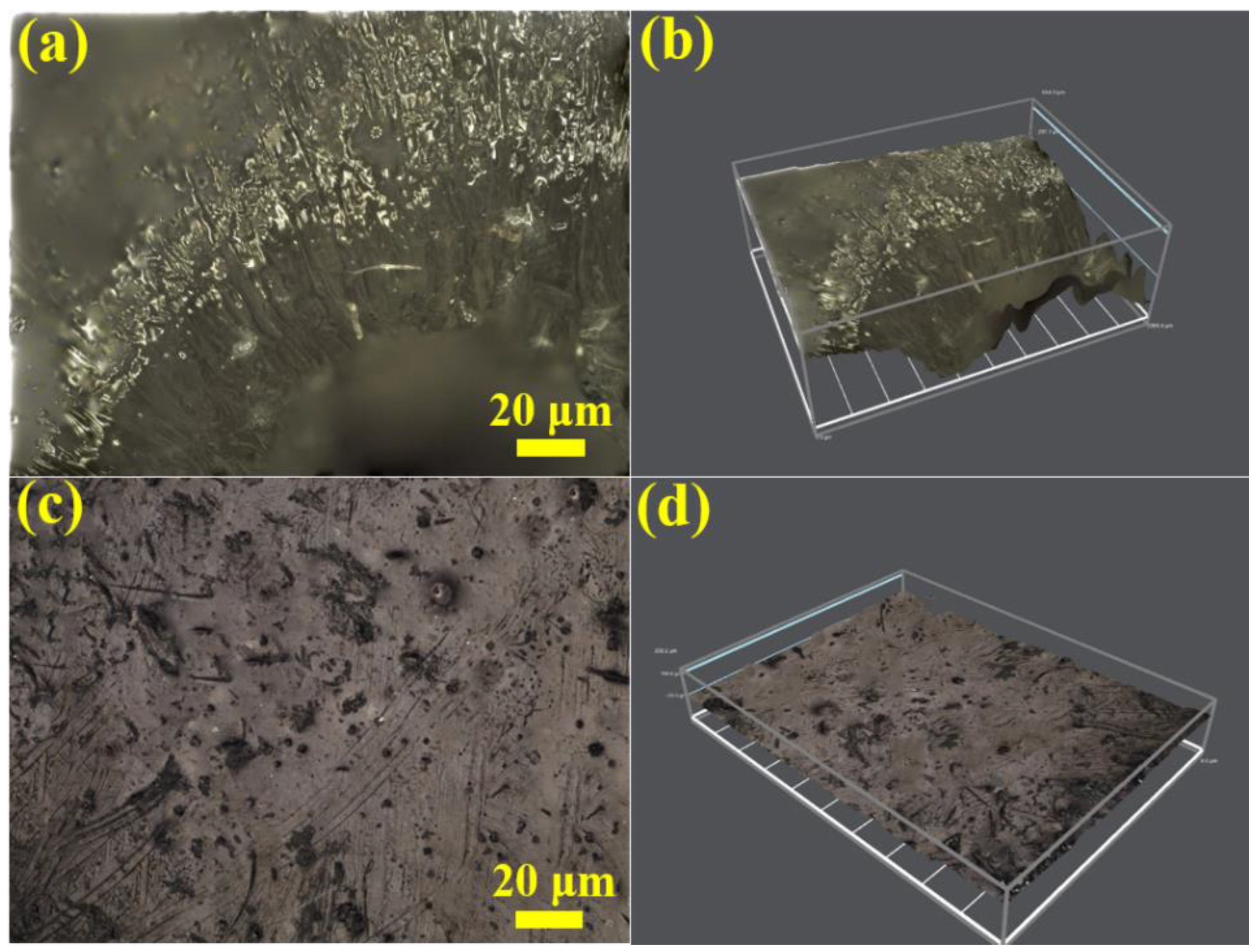

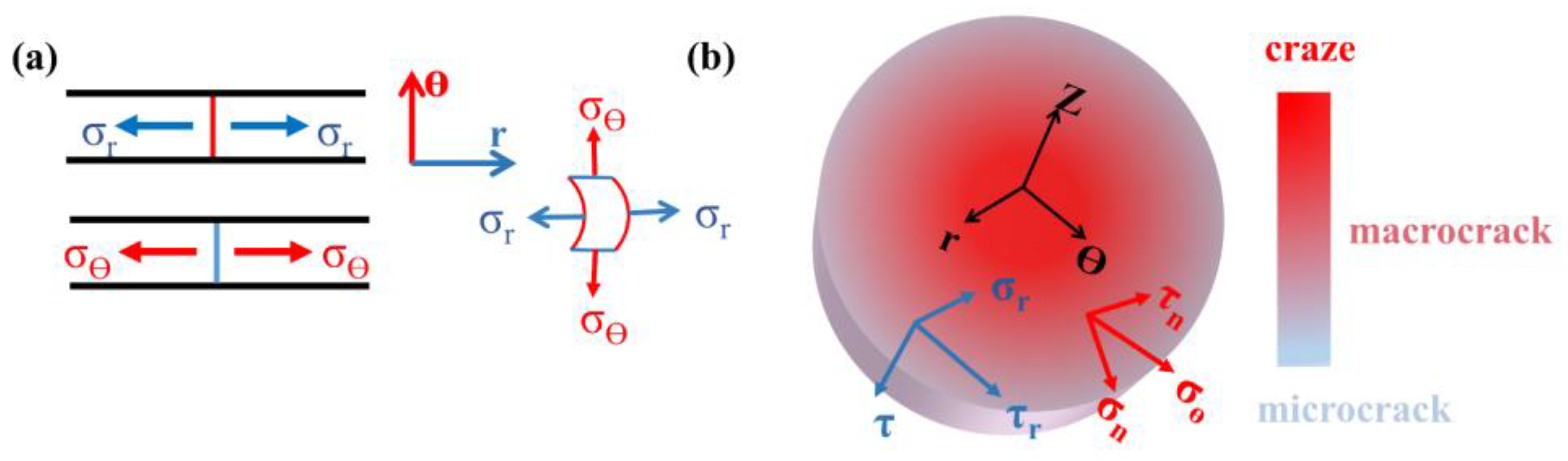

3.4. Craze Evolution, Crack Formation, and Destruction Mechanism

4. Conclusions

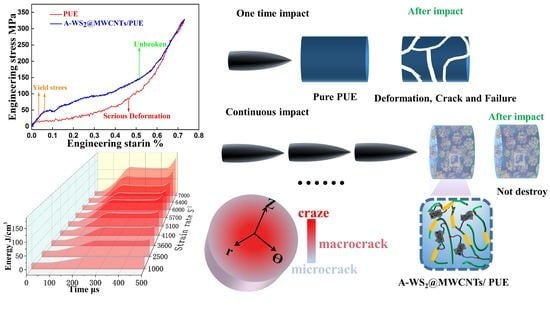

- Compared with pure PUE, the static compressive strength and dynamic yield stress of composite PUE are increased by 144.2% and 331.7%, respectively. The addition of composite filler enhances the strength and toughness of PUE and avoids the damage and softening caused by stress concentration and heat concentration under the impact effect. Most notably, the composite PUE remains intact under the successive shocks, while the pure PUE is destroyed by a single impact. The suitable impact resistance of A-WS2@MWCNTs/PUE is attributed to the suitable interface interaction between nanoparticles and PUE and the synergy between nanoparticles.

- According to the surface morphology analysis, polyurethane is prone to perforation damage in the central area under high-speed impact. However, A-WS2@MWCNTs/PUE has a large plastic deformation zone, which absorbs external energy, delays the growth of macroscopic cracks, and prevents damage to the specimen. In addition, the morphology of the section shows that A-WS2@MWCNTs is rooted in the PUE matrix, indicating that the adhesion between the matrix and the filler is suitable. This indicates that the pull-out mechanism of the nanocomposites impedes the crack propagation and promotes the toughness and energy absorption capacity of the composites.

- It can be concluded that the deformation process of PUE is a competitive process between σθ and τr by studying the damage mechanism of PUE. For A-WS2@MWCNTs/PUE, A-WS2@MWCNTs increases the critical shear strength τ0 and the critical dissociation strength σ0, making it difficult for the radial shear band to form and move. Similarly, the formation and expansion of circumferential shear zones are also hindered. Finally, the two shear bands do not extend deeply, and some regions form a discontinuous plastic deformation zone, which effectively improves energy absorption.

- Based on the characteristics of A-WS2@MWCNTs/PUE with high impact strength, it is worthy of being widely used in the field of impact protection. In addition, the damage formation process of PUE material is analyzed, and the preventing effect of nanofiller on crack propagation is explained, which lays a theoretical foundation for the subsequent development of impact-resistant nanocomposite PUE.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mostafavi, A.; Daemi, H.; Rajabi, S.; Baharvand, H. Highly tough and ultrafast self-healable dual physically crosslinked sulfated alginate-based polyurethane elastomers for vascular tissue engineering. Carbohydr. Polym. 2021, 257, 117632. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, J.; Liang, H.; Ye, S.; Zou, J.; Yang, H. A novel polyurethane elastomer with super mechanical strength and excellent self-healing performance of wide scratches. Prog. Org. Coat. 2020, 149, 105943. [Google Scholar] [CrossRef]

- Hu, F.; Gao, J.; Zhang, B.; Qi, F.; Zhao, N.; Ouyang, X. Effects of Modified Al2O3-Decorated Ionic Liquid on the Mechanical Properties and Impact Resistance of a Polyurethane Elastomer. Materials 2021, 14, 4712. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Yin, T.; Nian, G.; Suo, Z. Fatigue-resistant polyurethane elastomer composites. Extreme Mech. Lett. 2021, 48, 101434. [Google Scholar] [CrossRef]

- Zheng, Z.; Wang, Z.; Wang, L.; Liu, J.; Wu, Y.; Zhang, L. Dispersion and shear-induced orientation of anisotropic nanoparticle filled polymer nanocomposites: Insights from molecular dynamics simulation. Nanotechnology 2016, 27, 265704. [Google Scholar] [CrossRef] [PubMed]

- Araby, S.; Meng, Q.; Zhang, L.; Zaman, I.; Majewski, P.; Ma, J. Elastomeric composites based on carbon nanomaterials. Nanotechnology 2015, 26, 112001. [Google Scholar] [CrossRef] [PubMed]

- Fei, Y.; Chen, F.; Fang, W.; Xu, L.; Ruan, S.; Liu, X.; Zhong, M.; Kuang, T. High-strength, flexible and cycling-stable piezo-resistive polymeric foams derived from thermoplastic polyurethane and multi-wall carbon nanotubes. Compos. Part B Eng. 2020, 199, 108279. [Google Scholar] [CrossRef]

- He, Z.; Byun, J.-H.; Zhou, G.; Park, B.-J.; Kim, T.-H.; Lee, S.-B.; Yi, J.-W.; Um, M.-K.; Chou, T.-W. Effect of MWCNT content on the mechanical and strain-sensing performance of Thermoplastic Polyurethane composite fibers. Carbon 2019, 146, 701–708. [Google Scholar] [CrossRef]

- Zhao, W.; Liu, L.; Leng, J.; Liu, Y. Thermo-mechanical behavior prediction of particulate reinforced shape memory polymer composite. Compos. Part B Eng. 2019, 179, 107455. [Google Scholar] [CrossRef]

- Wang, E.; Dong, Y.; Islam, Z.; Yu, L.; Liu, F.; Chen, S.; Qi, X.; Zhu, Y.; Fu, Y.; Xu, Z.; et al. Effect of graphene oxide-carbon nanotube hybrid filler on the mechanical property and thermal response speed of shape memory epoxy composites. Compos. Sci. Technol. 2019, 169, 209–216. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, J.; Shen, J.; Wu, Y.; Zhang, L. Influence of various nanoparticle shapes on the interfacial chain mobility: A molecular dynamics simulation. Phys. Chem. Chem. Phys. 2014, 16, 21372–21382. [Google Scholar] [CrossRef]

- Liu, J.; Shen, J.; Zheng, Z.; Wu, Y.; Zhang, L. Revealing the toughening mechanism of graphene–polymer nanocomposite through molecular dynamics simulation. Nanotechnology 2015, 26, 291003. [Google Scholar] [CrossRef]

- Sethulekshmi, A.; Jayan, J.S.; Saritha, A.; Joseph, K. Insights into the reinforcibility and multifarious role of WS2 in polymer matrix. J. Alloy. Compd. 2021, 876, 160107. [Google Scholar] [CrossRef]

- Houssat, M.; Villeneuve-Faure, C.; Dignat, N.L.; Cambronne, J.-P. Nanoscale mechanical and electrical characterization of the interphase in polyimide/silicon nitride nanocomposites. Nanotechnology 2021, 32, 425703. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Tiwari, S.K.; Ma, Z.Y. Phase Behavior and Thermo-Mechanical Properties of IF-WS2 Reinforced PP–PET Blend-Based Nanocomposites. Polymers 2015, 54, 992–1000. [Google Scholar] [CrossRef]

- Divya, G.; Suresha, B. Impact of nano-silicon dioxide on mechanical properties of carbon fabric reinforced epoxy composites. Mater. Today Proc. 2021, 46, 8999–9003. [Google Scholar] [CrossRef]

- Kim, K.; Ju, H.; Kim, J. Surface modification of BN/Fe3O4 hybrid particle to enhance interfacial affinity for high thermal conductive material. Polymer 2016, 91, 74–80. [Google Scholar] [CrossRef]

- Pan, Z.; Xiong, J.; Liang, S.; Zou, M. Transient deformation and heat generation of solid polyurethane under impact compression. Polym. Test. 2017, 61, 269–279. [Google Scholar] [CrossRef]

- Fan, J.; Weerheijm, J.; Sluys, B. Compressive response of a glass–polymer system at various strain rates. Mech. Mater. 2016, 95, 49–59. [Google Scholar] [CrossRef]

- Pankow, M.; Attard, C.; Waas, A.M. Specimen size and shape effect in split Hopkinson pressure bar testing. J. Strain Anal. Eng. Des. 2009, 44, 689–698. [Google Scholar] [CrossRef]

- Sarva, S.S.; Deschanel, S.; Boyce, M.C.; Chen, W. Stress–strain behavior of a polyurea and a polyurethane from low to high strain rates. Polymer 2007, 48, 2208–2213. [Google Scholar] [CrossRef]

- Chen, W.; Lu, F.; Cheng, M. Tension and compression tests of two polymers under quasi-static and dynamic loading. Polym. Test. 2002, 21, 113–121. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, B.; Forrestal, M.J. A split Hopkinson bar technique for low-impedance materials. Exp. Mech. 1999, 39, 81–85. [Google Scholar] [CrossRef]

- Sharifi, T.; Nitze, F.; Barzegar, H.R.; Tai, C.-W.; Mazurkiewicz-Pawlicka, M.; Małolepszy, A.; Stobinski, L.; Wagberg, T. Nitrogen doped multi walled carbon nanotubes produced by CVD-correlating XPS and Raman spectroscopy for the study of nitrogen inclusion. Carbon 2012, 50, 3535–3541. [Google Scholar] [CrossRef]

- Panahi-Sarmad, M.; Chehrazi, E.; Noroozi, M.; Raef, M.; Razzaghi-Kashani, M.; Baian, M.A.H. Tuning the Surface Chemistry of Graphene Oxide for Enhanced Dielectric and Actuated Performance of Silicone Rubber Composites. ACS Appl. Electron. Mater. 2019, 1, 198–209. [Google Scholar] [CrossRef]

- Kumar, S.; Gupta, T.K.; Varadarajan, K. Strong, stretchable and ultrasensitive MWCNT/TPU nanocomposites for piezoresistive strain sensing. Compos. Part B Eng. 2019, 177, 107285. [Google Scholar] [CrossRef]

- Ferdous, S.F.; Sarker, F.; Adnan, A. Role of nanoparticle dispersion and filler-matrix interface on the matrix dominated failure of rigid C60-PE nanocomposites: A molecular dynamics simulation study. Polymer 2013, 54, 2565–2576. [Google Scholar] [CrossRef]

- Balazs, A.; Emrick, T.; Russell, T.P. Nanoparticle Polymer Composites: Where Two Small Worlds Meet. Science 2006, 314, 1107–1110. [Google Scholar] [CrossRef] [PubMed]

- Xia, C.; Li, J.; Cao, Y.; Kou, B.; Xiao, X.; Fezzaa, K.; Xiao, T.; Wang, Y. The structural origin of the hard-sphere glass transition in granular packing. Nat. Commun. 2015, 6, 8409. [Google Scholar] [CrossRef] [Green Version]

- Zhang, P.; Wang, Z.; Zhao, P.; Zhang, L.; Jin, X.; Xu, Y. Experimental investigation on ballistic resistance of polyurea coated steel plates subjected to fragment impact. Thin-Walled Struct. 2019, 144, 106342. [Google Scholar] [CrossRef]

- Zhou, R.X.; Hu, H.; Chen, N.L.; Feng, X.W. An Experimental and Numerical Study on the Impact Energy Absorption Characteristics of the Multiaxial Warp Knitted (MWK). Reinforced. Compos. J. Compos. Mater. 2005, 39, 525–542. [Google Scholar] [CrossRef]

- Shaker, K.; Jabbar, A.; Karahan, M.; Karahan, N.; Nawab, Y. Study of dynamic compressive behaviour of aramid and ultrahigh molecular weight polyethylene composites using Split Hopkinson Pressure Bar. J. Compos. Mater. 2016, 51, 81–94. [Google Scholar] [CrossRef]

- Stachurski, Z. Deformation mechanisms and yield strength in amorphous polymers. Prog. Polym. Sci. 1997, 22, 407–474. [Google Scholar] [CrossRef]

- Richeton, J.; Ahzi, S.; Vecchio, K.; Jiang, F.; Adharapurapu, R. Influence of temperature and strain rate on the mechanical behavior of three amorphous polymers: Characterization and modeling of the compressive yield stress. Int. J. Solids Struct. 2006, 43, 2318–2335. [Google Scholar] [CrossRef] [Green Version]

- Fan, J.; Weerheijm, J.; Sluys, B. Glass interface effect on high-strain-rate tensile response of a soft polyurethane elastomeric polymer material. Compos. Sci. Technol. 2015, 118, 55–62. [Google Scholar] [CrossRef]

- Ackland, K.; Anderson, C.; Ngo, T. Deformation of polyurea-coated steel plates under localised blast loading. Int. J. Impact Eng. 2013, 51, 13–22. [Google Scholar] [CrossRef] [Green Version]

- Roland, C.; Twigg, J.; Vu, Y.; Mott, P. High strain rate mechanical behavior of polyurea. Polymer 2007, 48, 574–578. [Google Scholar] [CrossRef]

- Zhang, L.; Yao, X.; Zang, S.; Gu, Y. Temperature- and strain rate-dependent constitutive modeling of the large deformation behavior of a transparent polyurethane interlayer. Polym. Eng. Sci. 2015, 55, 1864–1872. [Google Scholar] [CrossRef]

- Mousa, M.; Dong, Y. Novel three-dimensional interphase characterisation of polymer nanocomposites using nanoscaled topography. Nanotechnology 2018, 29, 385701. [Google Scholar] [CrossRef] [Green Version]

- Fan, J.; Fu, T. Deformation and fracture mechanism of materials under the punch loading. Mater. Lett. 2012, 74, 232–235. [Google Scholar] [CrossRef]

- Fan, J.; Weerheijm, J.; Sluys, B. Deformation to fracture evolution of a flexible polymer under split Hopkinson pressure bar loading. Polym. Test. 2018, 70, 192–196. [Google Scholar] [CrossRef]

| Sample | Relative Mass Ratio A: B: Nanoparticles (g) | Elasticity Modulus (MPa) | Maximum Strength (MPa) | Constant Pressure Intensity (10%) (MPa) |

|---|---|---|---|---|

| Pure PUE | 5:2:0 | 95.8 | 90.2 | 11.3 |

| 1.0 wt.% WS2@MWCNTs/PUE | 5:2:0.070 | 131.4 | 137.7 | 16.0 |

| 1.5 wt.% WS2@MWCNTs/PUE | 5:2:0.105 | 217.6 | 233.7 | 27.6 |

| 2.0 wt.% WS2@MWCNTs/PUE | 5:2:0.140 | 84.1 | 77.0 | 9.9 |

| 2.5 wt.% WS2@MWCNTs/PUE | 5:2:0.175 | 73.3 | 71.1 | 9.0 |

| 3.0 wt.% WS2@MWCNTs/PUE | 5:2:0.210 | 110 | 61.5 | 10.3 |

| 1.5 wt.% WS2/PUE | 5:2:0.105 | 134.3 | 176.0 | 23.3 |

| 1.5 wt.% MWCNTs/PUE | 5:2:0.105 | 180.3 | 206.5 | 24.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, F.; Zheng, Z.; Xiang, Z.; Zhang, B.; Qi, F.; Zhao, N.; Ouyang, X. In Situ Grafted Composite Nanoparticles-Reinforced Polyurethane Elastomer Composites with Excellent Continuous Anti-Impact Performance. Materials 2021, 14, 6195. https://doi.org/10.3390/ma14206195

Qi F, Zheng Z, Xiang Z, Zhang B, Qi F, Zhao N, Ouyang X. In Situ Grafted Composite Nanoparticles-Reinforced Polyurethane Elastomer Composites with Excellent Continuous Anti-Impact Performance. Materials. 2021; 14(20):6195. https://doi.org/10.3390/ma14206195

Chicago/Turabian StyleQi, Feng, Zhuoyu Zheng, Zehui Xiang, Biao Zhang, Fugang Qi, Nie Zhao, and Xiaoping Ouyang. 2021. "In Situ Grafted Composite Nanoparticles-Reinforced Polyurethane Elastomer Composites with Excellent Continuous Anti-Impact Performance" Materials 14, no. 20: 6195. https://doi.org/10.3390/ma14206195

APA StyleQi, F., Zheng, Z., Xiang, Z., Zhang, B., Qi, F., Zhao, N., & Ouyang, X. (2021). In Situ Grafted Composite Nanoparticles-Reinforced Polyurethane Elastomer Composites with Excellent Continuous Anti-Impact Performance. Materials, 14(20), 6195. https://doi.org/10.3390/ma14206195