Frictional Properties of the TiNbTaZrO Orthodontic Wire—A Laboratory Comparison to Popular Archwires

Abstract

1. Introduction

2. Materials and Methods

- A null hypothesis: there is no difference in kinetic FF between groups.

- The alternative hypothesis proposes that there is a difference at least between one pair of groups.

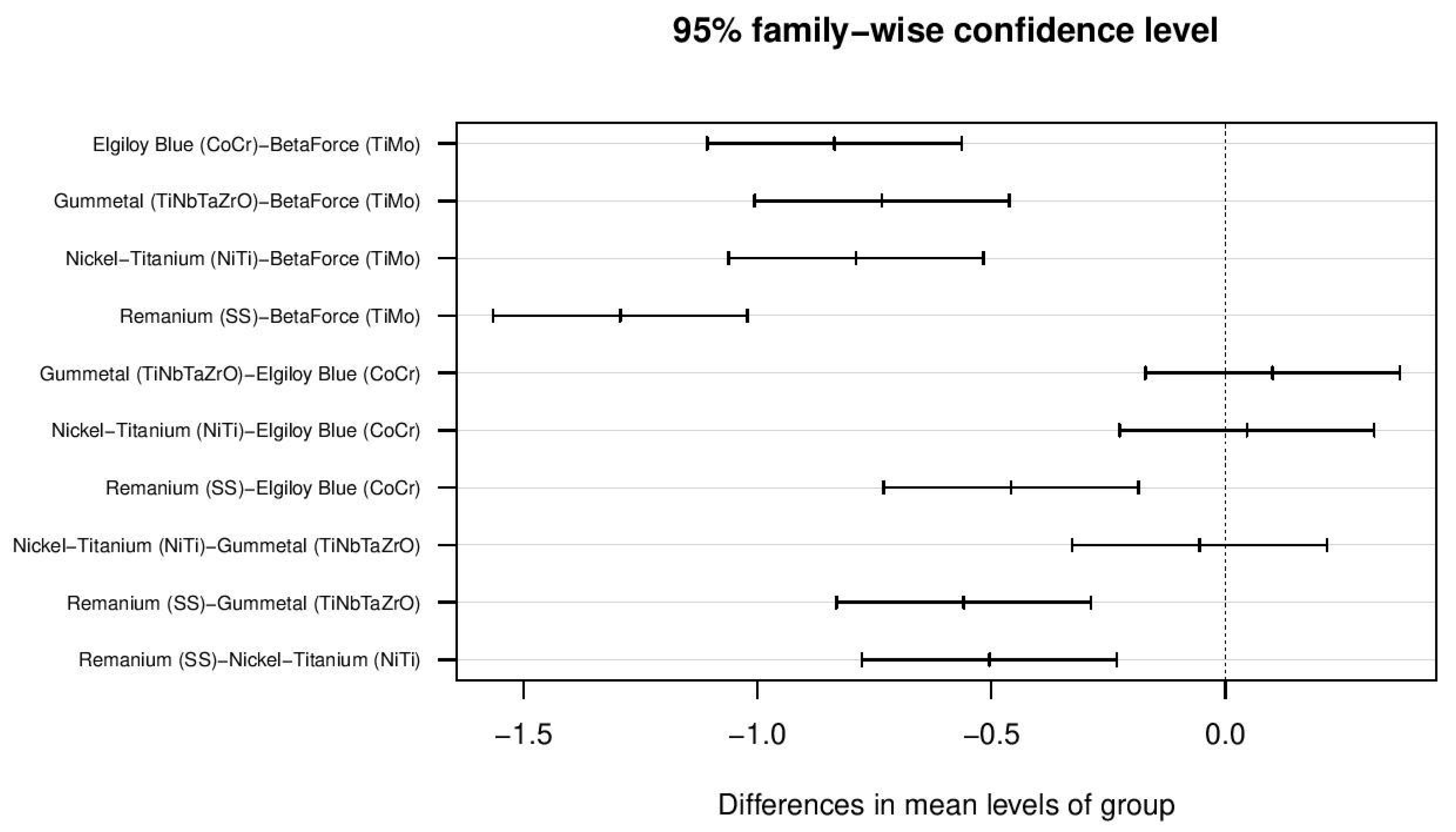

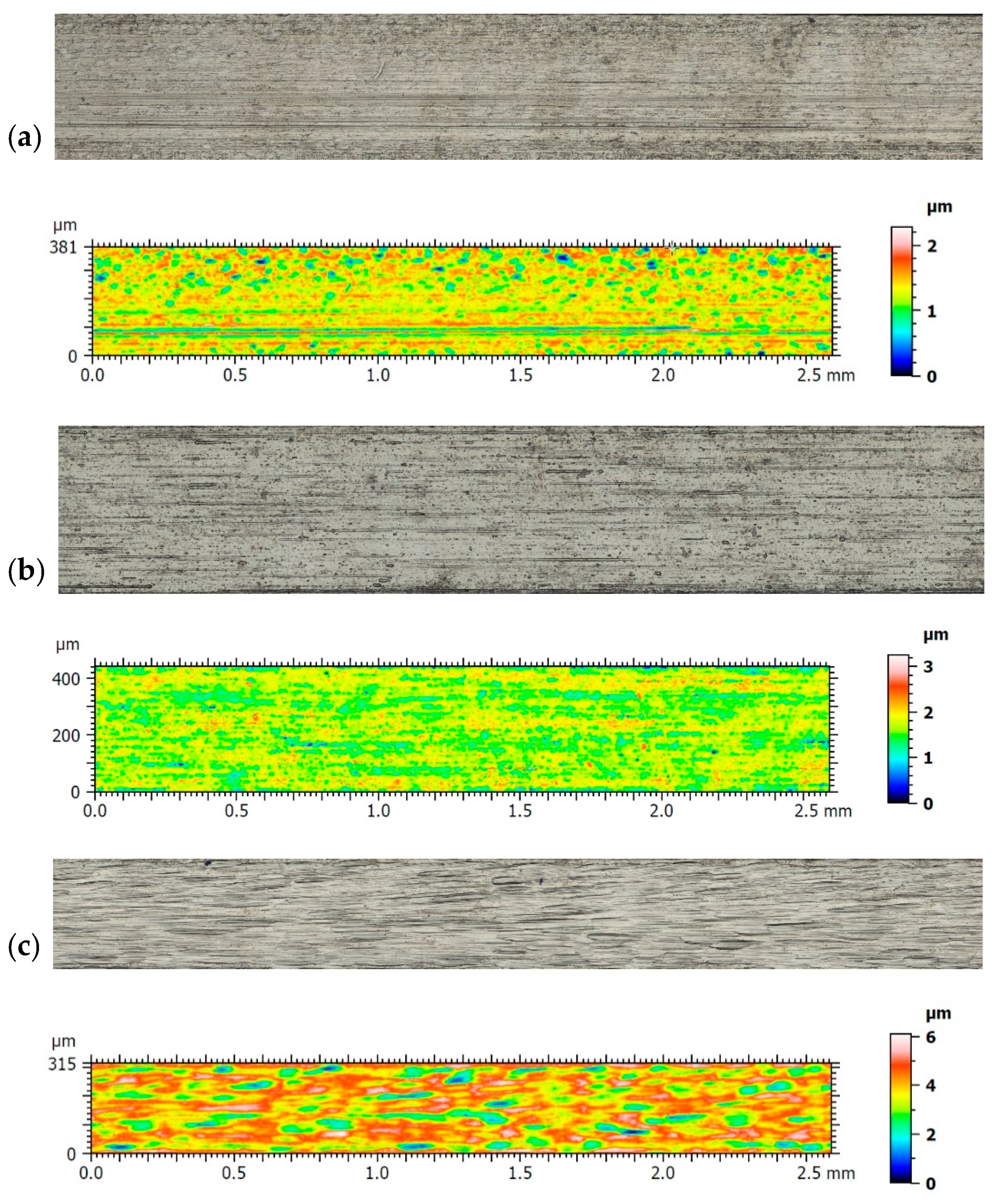

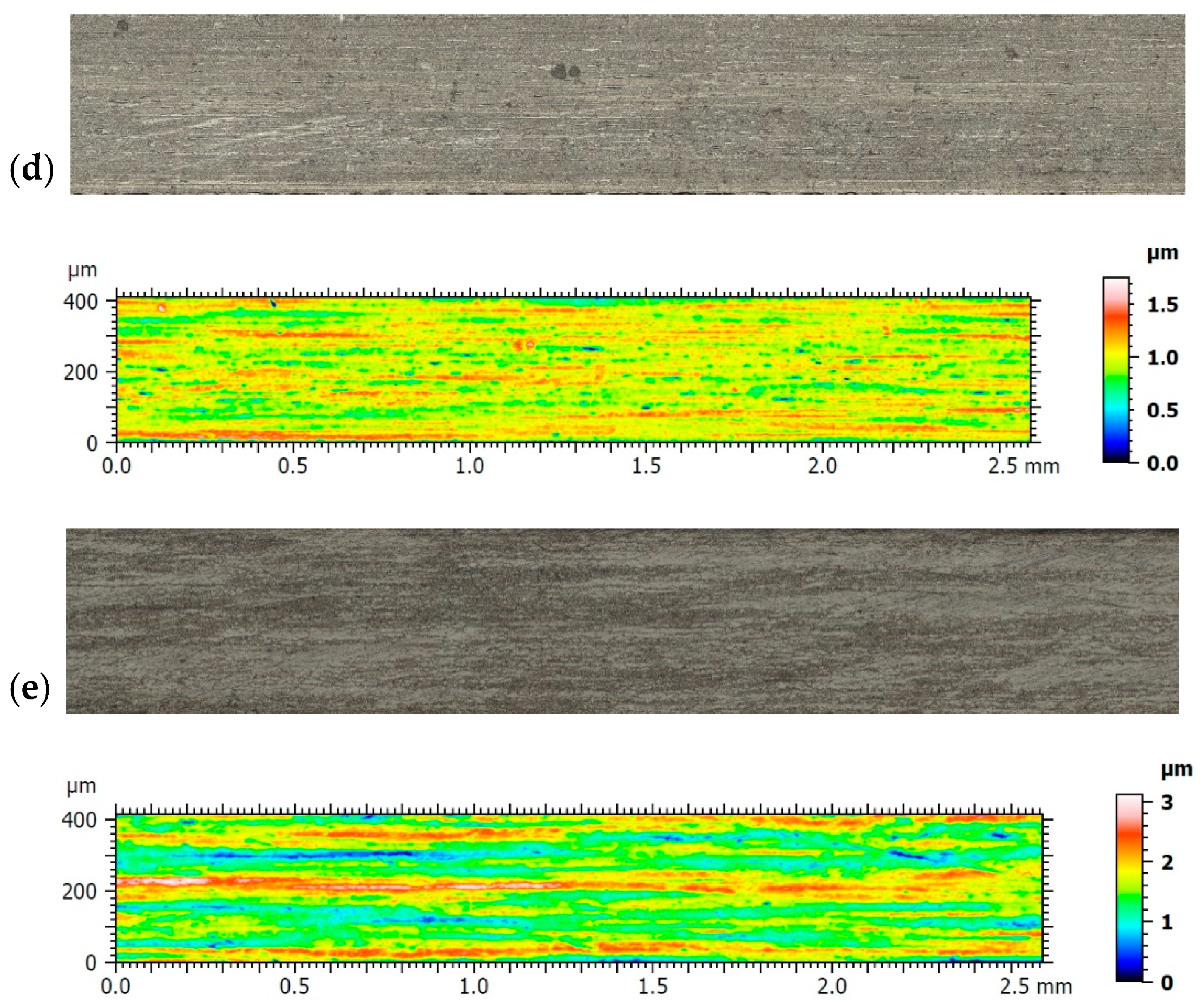

3. Results

- RSm—mean width of the roughness profile elements

- Sq—root mean square height of the scale-limited surface

- Ssk—skewness of the scale-limited surface

- Sz—maximum height of the scale-limited surface

- Sk—core height

- Spk—reduced peak height

- Svk—reduced dale height

- Smr1—material ratio at the intersection line separating hills from the core surface

- Smr2—material ratio at the intersection line separating dales from the core surface

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FF(s) | frictional force(s) |

| TiNbTaZrO | Gummetal |

| SS | stainless steel |

| NiTi | nickel-titanium |

| CoCr | cobalt-chromium |

| TiMo | titanium-molybdenum |

| β-Ti | beta-titanium |

| IQR(s) | interquartile range(s) |

| SD(s) | standard deviation(s) |

| HSD | Honest Significant Difference |

| RS | resistance to sliding |

References

- Rabinowicz, E.; Tanner, R.I. Friction and Wear of Materials. J. Appl. Mech. 1966, 33, 479. [Google Scholar] [CrossRef]

- Lo Giudice, G.; Lo Giudice, A.; Isola, G.; Fabiano, F.; Artemisia, A.; Fabiano, V.; Nucera, R.; Matarese, G. Evaluation of Bond Strength and Detachment Interface Distribution of Different Bracket Base Designs. Acta Med. Mediterr. 2015, 31, 585. [Google Scholar]

- Bordea, I.; Sîrbu, A.; Lucaciu, O.; Ilea, A.; Câmpian, R.; Todea, D.; Alexescu, T.; Aluaș, M.; Budin, C.; Pop, A. Microleakage—The Main Culprit in Bracket Bond Failure? J. Mind Med. Sci. 2019, 6, 86–94. [Google Scholar] [CrossRef]

- Omana, H.M.; Moore, R.N.; Bagby, M.D. Frictional Properties of Metal and Ceramic Brackets. J. Clin. Orthod. 1992, 26, 425–432. [Google Scholar]

- Prashant, P.S.; Nandan, H.; Gopalakrishnan, M. Friction in Orthodontics. J. Pharm. Bioallied Sci. 2015, 7, 334–338. [Google Scholar] [CrossRef]

- Isola, G.; Matarese, G.; Cordasco, G.; Perillo, L.; Ramaglia, L. Mechanobiology of the Tooth Movement during the Orthodontic Treatment: A Literature Review. Minerva Stomatol. 2016, 65, 299–327. [Google Scholar]

- Kapila, S.; Angolkar, P.V.; Duncanson, M.G.; Nanda, R.S. Evaluation of Friction between Edgewise Stainless Steel Brackets and Orthodontic Wires of Four Alloys. Am. J. Orthod. Dentofac. Orthop. 1990, 98, 117–126. [Google Scholar] [CrossRef]

- Yu, J.-H.; Wu, L.-C.; Hsu, J.-T.; Chang, Y.-Y.; Huang, H.-H.; Huang, H.-L. Surface Roughness and Topography of Four Commonly Used Types of Orthodontic Archwire. J. Med. Biol. Eng. 2011, 31, 367–370. [Google Scholar] [CrossRef]

- Verstrynge, A.; Humbeeck, J.V.; Willems, G. In-Vitro Evaluation of the Material Characteristics of Stainless Steel and Beta-Titanium Orthodontic Wires. Am. J. Orthod. Dentofac. Orthop. 2006, 130, 460–470. [Google Scholar] [CrossRef] [PubMed]

- D’Antò, V.; Rongo, R.; Ametrano, G.; Spagnuolo, G.; Manzo, P.; Martina, R.; Paduano, S.; Valletta, R. Evaluation of Surface Roughness of Orthodontic Wires by Means of Atomic Force Microscopy. Angle Orthod. 2012, 82, 922–928. [Google Scholar] [CrossRef] [PubMed]

- Kusy, R.P. A Review of Contemporary Archwires: Their Properties and Characteristics. Angle Orthod. 1997, 67, 197–207. [Google Scholar] [CrossRef] [PubMed]

- Andreasen, G.; Morrow, R.E. Laboratory and Clinical Analyses of Nitinol Wire. Am. J. Orthod. 1978, 73, 142–151. [Google Scholar] [CrossRef]

- Burstone, C.J. Variable-Modulus Orthodontics. Am. J. Orthod. 1981, 80, 1–16. [Google Scholar] [CrossRef]

- Kusy, R.P.; Whitley, J.Q.; Prewitt, M.J. Comparison of the Frictional Coefficients for Selected Archwire-Bracket Slot Combinations in the Dry and Wet States. Angle Orthod. 1991, 61, 293–302. [Google Scholar] [CrossRef] [PubMed]

- Rahilly, G.; Price, N. Nickel Allergy and Orthodontics. J. Orthod. 2003, 30, 171–174. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.-H.; Huang, H.-L.; Wu, L.-C.; Hsu, J.-T.; Chang, Y.-Y.; Huang, H.-H.; Tsai, M.-T. Friction of Stainless Steel, Nickel-Titanium Alloy, and Beta-Titanium Alloy Archwires in Two Commonly Used Orthodontic Brackets. J. Mech. Med. Biol. 2011, 11, 917–928. [Google Scholar] [CrossRef]

- Vaughan, J.L.; Duncanson, M.G.; Nanda, R.S.; Currier, G.F. Relative Kinetic Frictional Forces between Sintered Stainless Steel Brackets and Orthodontic Wires. Am. J. Orthod. Dentofac. Orthop. 1995, 107, 20–27. [Google Scholar] [CrossRef]

- Zhang, L.; Haddouti, E.-M.; Beckert, H.; Biehl, R.; Pariyar, S.; Rüwald, J.M.; Li, X.; Jaenisch, M.; Burger, C.; Wirtz, D.C.; et al. Investigation of Cytotoxicity, Oxidative Stress, and Inflammatory Responses of Tantalum Nanoparticles in THP-1-Derived Macrophages. Mediat. Inflamm. 2020, 2020, 3824593. [Google Scholar] [CrossRef]

- Mantripragada, V.P.; Lecka-Czernik, B.; Ebraheim, N.A.; Jayasuriya, A.C. An Overview of Recent Advances in Designing Orthopedic and Craniofacial Implants. J. Biomed. Mater. Res. Part A 2013, 101, 3349–3364. [Google Scholar] [CrossRef]

- Krolikowski, M.; Przestacki, D.; Chwalczuk, T.; Sobolewska, E.; Tomasik, M. Additive Manufacturing of Polyether Ether Ketone —PEEK Parts with Surface Roughness Modification by a Laser Beam. J. Neural Eng. 2020, 20, 117–124. [Google Scholar] [CrossRef]

- Chang, H.-P.; Tseng, Y.-C. A Novel β-Titanium Alloy Orthodontic Wire. Kaohsiung J. Med. Sci. 2018, 34, 202–206. [Google Scholar] [CrossRef]

- Hasegawa, S. A Concept of “En bloc” Movement of Teeth Using Gummetal Wire; Tokyo Quintessence Pub. Co. Ltd.: Tokyo, Japan, 2014. [Google Scholar]

- Saito, T.; Furuta, T.; Hwang, J.-H.; Kuramoto, S.; Nishino, K.; Suzuki, N.; Chen, R.; Yamada, A.; Ito, K.; Seno, Y.; et al. Multifunctional Alloys Obtained via a Dislocation-Free Plastic Deformation Mechanism. Science 2003, 300, 464–467. [Google Scholar] [CrossRef]

- Takada, M.; Nakajima, A.; Kuroda, S.; Horiuchi, S.; Shimizu, N.; Tanaka, E. In Vitro Evaluation of Frictional Force of a Novel Elastic Bendable Orthodontic Wire. Angle Orthod. 2018, 88, 602–610. [Google Scholar] [CrossRef] [PubMed]

- Schmeidl, K.; Janiszewska-Olszowska, J.; Grocholewicz, K. Clinical Features and Physical Properties of Gummetal Orthodontic Wire in Comparison with Dissimilar Archwires: A Critical Review. BioMed Res. Int. 2021, 2021, 6611979. [Google Scholar] [CrossRef] [PubMed]

- Grabon, W.; Pawlus, P.; Wos, S.; Koszela, W.; Wieczorowski, M. Effects of cylinder liner surface topography on friction and wear of liner-ring system at low temperature. Tribol. Int. 2018, 121, 148–160. [Google Scholar] [CrossRef]

- Wojciechowski, Ł.; Wieczorowski, M.; Mathia, T.G. Transition from the boundary lubrication to scuffing—The role of metallic surfaces morphology. Wear 2017, 392–393, 39–49. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences; Academic Press: New York, NY, USA, 2013. [Google Scholar]

- Harrison, E.; Pius, R. R for Health Data Science, 1st ed.; Chapman and Hall/CRC: Boca Raton, FL, USA, 2020; ISBN 978-0-367-42832-7. [Google Scholar]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Comparison of results of surface texture measurement obtained with stylus methods and optical methods. Metrol. Meas. Syst. 2018, 25, 589–602. [Google Scholar]

- Grochalski, K.; Wieczorowski, M.; H’Roura, J.; Le Goic, G. The Optical Aspect of Errors in Measurements of Surface Asperities Using the Optical Profilometry Method. Front. Mech. Eng. 2020, 6, 12. [Google Scholar] [CrossRef]

- Subbarao, M.; Choi, T. Accurate Recovery of Three-Dimensional Shape from Image Focus. IEEE Trans. Pattern Anal. Mach. Intell. 1995, 17, 266–274. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Problem of non-measured points in surface texture measurements. Metrol. Meas. Syst. 2017, 24, 525–536. [Google Scholar] [CrossRef]

- ISO. Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters; ISO 4287:1997; International Organization for Standardization: Geneva, Switzerland, 1997. [Google Scholar]

- ISO. Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters; ISO 25178-2:2012; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- Matarese, G.; Nucera, R.; Militi, A.; Mazza, M.; Portelli, M.; Festa, F.; Cordasco, G. Evaluation of Frictional Forces during Dental Alignment: An Experimental Model with 3 Nonleveled Brackets. Am. J. Orthod. Dentofac. Orthop. 2008, 133, 708–715. [Google Scholar] [CrossRef]

- Kusy, R.P.; Whitley, J.Q. Influence of Archwire and Bracket Dimensions on Sliding Mechanics: Derivations and Determinations of the Critical Contact Angles for Binding. Eur. J. Orthod. 1999, 21, 199–208. [Google Scholar] [CrossRef]

- Nishio, C.; Motta, A.; Elias, C.; Mucha, J. In Vitro Evaluation of Frictional Forces between Archwires and Ceramic Bracket. Am. J. Orthod. Dentofac. Orthop. 2004, 125, 56–64. [Google Scholar] [CrossRef]

- Alfonso, M.V.; Espinar, E.; Llamas, J.M.; Rupérez, E.; Manero, J.M.; Barrera, J.M.; Solano, E.; Gil, F.J. Friction Coefficients and Wear Rates of Different Orthodontic Archwires in Artificial Saliva. J. Mater. Sci. Mater. Med. 2013, 24, 1327–1332. [Google Scholar] [CrossRef]

- Bednar, J.R.; Gruendeman, G.W.; Sandrik, J.L. A Comparative Study of Frictional Forces between Orthodontic Brackets and Arch Wires. Am. J. Orthod. Dentofac. Orthop. 1991, 100, 513–522. [Google Scholar] [CrossRef]

- Petersen, A.; Rosenstein, S.; Kim, K.B.; Israel, H. Force Decay of Elastomeric Ligatures: Influence OnUnloading Force Compared to Self-Ligation. Angle Orthod. 2009, 79, 934–938. [Google Scholar] [CrossRef] [PubMed]

- Rongo, R.; Ametrano, G.; Gloria, A.; Spagnuolo, G.; Galeotti, A.; Paduano, S.; Valletta, R.; D’Antò, V. Effects of Intraoral Aging on Surface Properties of Coated Nickel-Titanium Archwires. Angle Orthod. 2013, 84, 665–672. [Google Scholar] [CrossRef] [PubMed]

- Cash, A.C.; Good, S.A.; Curtis, R.V.; McDonald, F. An Evaluation of Slot Size in Orthodontic Brackets—Are Standards as Expected? Angle Orthod. 2004, 74, 450–453. [Google Scholar] [CrossRef]

- Kłos, S.; Janiszewska-Olszowska, J. Precision of the Dimensions of Orthodontic Bracket Slots—Systematic Review. Pomeranian J. Life Sci. 2019, 65, 62–71. [Google Scholar] [CrossRef][Green Version]

- Lugo Ancona, M.A.; Ruíz Díaz, R.; Marichi Rodríguez, F.; Padilla Olvera, S. Variations in slot size of self-ligating brackets. Rev. Mex. Ortod. 2015, 3, 224–227. [Google Scholar] [CrossRef]

- Akchurin, A.; Bosman, R.; Lugt, P.M.; van Drogen, M. Analysis of Wear Particles Formed in Boundary-Lubricated Sliding Contacts. Tribol. Lett. 2016, 63, 16. [Google Scholar] [CrossRef]

- Ho, K.S.; West, V.C. Friction Resistance between Edgewise Brackets and Archwires. Aust. Orthod. J. 1991, 12, 95–99. [Google Scholar]

- Leal, R.C.; Amaral, F.L.B.; França, F.M.G.; Basting, R.T.; Turssi, C.P. Role of Lubricants on Friction between Self-Ligating Brackets and Archwires. Angle Orthod. 2014, 84, 1049–1053. [Google Scholar] [CrossRef] [PubMed]

- Loftus, B.P.; Artum, J. A Model for Evaluating Friction during Orthodontic Tooth Movement. Eur. J. Orthod. 2001, 23, 253–261. [Google Scholar] [CrossRef] [PubMed]

- Adina, S.; Dipalma, G.; Bordea, I.R.; Lucaciu, O.; Feurdean, C.; Inchingolo, A.D.; Septimiu, R.; Malcangi, G.; Cantore, S.; Martin, D.; et al. Orthopedic Joint Stability Influences Growth and Maxillary Development: Clinical Aspects. J. Biol. Regul. Homeost. Agents 2020, 34, 747–756. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M.; Krolczyk, G. Material ratio curve as information on the state of surface topography—A review. Precis. Eng. 2020, 65, 240–258. [Google Scholar] [CrossRef]

| Group 1 | Mean | SD | Median | TM 2 | Min | Max | Skew | Kurtosis | SE | IQR | Q1 | Q3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Remanium (SS) | 0.639 | 0.139 | 0.640 | 0.628 | 0.216 | 1.446 | 1.693 | 6.502 | <0.0001 | 0.141 | 0.548 | 0.689 |

| Nickel-Titanium (NiTi) | 1.143 | 0.306 | 1.087 | 1.114 | 0.005 | 2.319 | 1.020 | 1.508 | <0.0001 | 0.399 | 0.917 | 1.316 |

| Elgiloy Blue (CoCr) | 1.097 | 0.354 | 1.014 | 1.078 | 0.011 | 2.267 | 0.409 | −0.932 | <0.0001 | 0.569 | 0.813 | 1.382 |

| BetaForce (TiMo) | 1.932 | 0.307 | 1.930 | 1.934 | 0.152 | 2.839 | −0.138 | 0.253 | <0.0001 | 0.431 | 1.727 | 2.158 |

| Gummetal (TiNbTaZrO) | 1.198 | 0.208 | 1.181 | 1.192 | 0.129 | 1.694 | 0.192 | 0.060 | <0.0001 | 0.244 | 1.064 | 1.308 |

| Group | Sample | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

| Remanium (SS) | 0.45 | 0.88 | 0.5 | 0.61 | 0.64 | 0.72 | 0.55 | 0.73 | 0.65 | 0.65 |

| Nickel-Titanium (NiTi) | 1.35 | 1.04 | 0.94 | 0.93 | 1.31 | 1.66 | 0.84 | 0.91 | 1.06 | 0.86 |

| Elgiloy Blue (CoCr) | 0.86 | 1.47 | 1.03 | 0.99 | 1.49 | 0.64 | 1.22 | 1.24 | 1.24 | 0.79 |

| BetaForce (TiMo) | 1.94 | 1.81 | 2.26 | 2.03 | 2.03 | 1.71 | 1.8 | 1.93 | 2.1 | 1.71 |

| Gummetal (TiNbTaZrO) | 1.11 | 1.25 | 0.97 | 1.08 | 1.47 | 1.17 | 1.06 | 1.51 | 1.21 | 1.14 |

| Df | Sum Sq | Mean Sq | F Value | Pr (>F) | Df |

|---|---|---|---|---|---|

| Group | 4 | 8.645 | 2.1612 | 47.13 | 1.55 × 10−15 |

| Residuals | 45 | 2.063 | 0.0459 | - | - |

| Group Variable | Df1 | Df2 | F-Value | Pr (>F) |

|---|---|---|---|---|

| Group | 45 | 4 | 2.236 | 0.08 |

| Pairwise Group Comparison | Difference * | t-Value | Pr(>|t|) |

|---|---|---|---|

| Elgiloy Blue (CoCr)—BetaForce (TiMo) | −0.83522 | −8.722 | <0.0001 |

| Gummetal (TiNbTaZrO)—BetaForce (TiMo) | −0.73392 | −7.664 | <0.0001 |

| Nickel-Titanium (NiTi)—BetaForce (TiMo) | −0.78896 | −8.239 | <0.0001 |

| Remanium (SS)—BetaForce (TiMo) | −1.29306 | −13.503 | <0.0001 |

| Gummetal (TiNbTaZrO)—Elgiloy Blue (CoCr) | 0.10130 | 1.058 | 0.826769 |

| Nickel-Titanium (NiTi)—Elgiloy Blue (CoCr) | 0.04626 | 0.483 | 0.988543 |

| Remanium (SS)—Elgiloy Blue (CoCr) | −0.45784 | −4.781 | 0.000196 |

| Nickel-Titanium (NiTi)—Gummetal (TiNbTaZrO) | −0.05504 | −0.575 | 0.978098 |

| Remanium (SS)—Gummetal (TiNbTaZrO) | −0.55914 | −5.839 | <0.0001 |

| Remanium (SS)—Nickel-Titanium (NiTi) | −0.50409 | −5.264 | <0.0001 |

| Orthodontic Wire | Remanium (SS) | Nickel-Titanium (NiTi) | Elgiloy Blue (CoCr) | BetaForce (TiMo) | Gummetal (TiNbTaZrO) |

|---|---|---|---|---|---|

| Remanium (SS) | + | + | + | + | |

| Nickel-Titanium (NiTi) | + | − | + | − | |

| Elgiloy Blue (CoCr) | + | − | + | − | |

| BetaForce (TiMo) | + | + | + | + | |

| Gummetal (TiNbTaZrO) | + | − | − | + |

| Orthodontic Wire | RSm µm | Sq µm | Ssk - | Sz µm | Sk µm | Spk µm | Svk µm | Smr1 % | Smr2 % |

|---|---|---|---|---|---|---|---|---|---|

| Remanium | 31.0 | 0.26 | −0.72 | 2.28 | 0.56 | 0.20 | 0.39 | 8.5 | 85.0 |

| NiTi | 30.8 | 0.27 | −0.68 | 3.25 | 0.62 | 0.22 | 0.39 | 7.7 | 86.3 |

| Elgiloy Blue | 42.7 | 0.89 | −0.48 | 6.10 | 2.33 | 0.45 | 1.08 | 6.5 | 88.1 |

| BetaForce | 25.3 | 0.16 | −0.41 | 1.75 | 0.36 | 0.16 | 0.22 | 10.5 | 88.9 |

| Gummetal | 33.0 | 0.41 | 0.14 | 3.11 | 1.07 | 0.44 | 0.37 | 10.4 | 91.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmeidl, K.; Wieczorowski, M.; Grocholewicz, K.; Mendak, M.; Janiszewska-Olszowska, J. Frictional Properties of the TiNbTaZrO Orthodontic Wire—A Laboratory Comparison to Popular Archwires. Materials 2021, 14, 6233. https://doi.org/10.3390/ma14216233

Schmeidl K, Wieczorowski M, Grocholewicz K, Mendak M, Janiszewska-Olszowska J. Frictional Properties of the TiNbTaZrO Orthodontic Wire—A Laboratory Comparison to Popular Archwires. Materials. 2021; 14(21):6233. https://doi.org/10.3390/ma14216233

Chicago/Turabian StyleSchmeidl, Krzysztof, Michal Wieczorowski, Katarzyna Grocholewicz, Michal Mendak, and Joanna Janiszewska-Olszowska. 2021. "Frictional Properties of the TiNbTaZrO Orthodontic Wire—A Laboratory Comparison to Popular Archwires" Materials 14, no. 21: 6233. https://doi.org/10.3390/ma14216233

APA StyleSchmeidl, K., Wieczorowski, M., Grocholewicz, K., Mendak, M., & Janiszewska-Olszowska, J. (2021). Frictional Properties of the TiNbTaZrO Orthodontic Wire—A Laboratory Comparison to Popular Archwires. Materials, 14(21), 6233. https://doi.org/10.3390/ma14216233