Impact of Induction Furnace Steel Slag as Replacement for Fired Clay Brick Aggregate on Flexural and Durability Performances of RC Beams

Abstract

:1. Introduction

2. Experimental Methodology

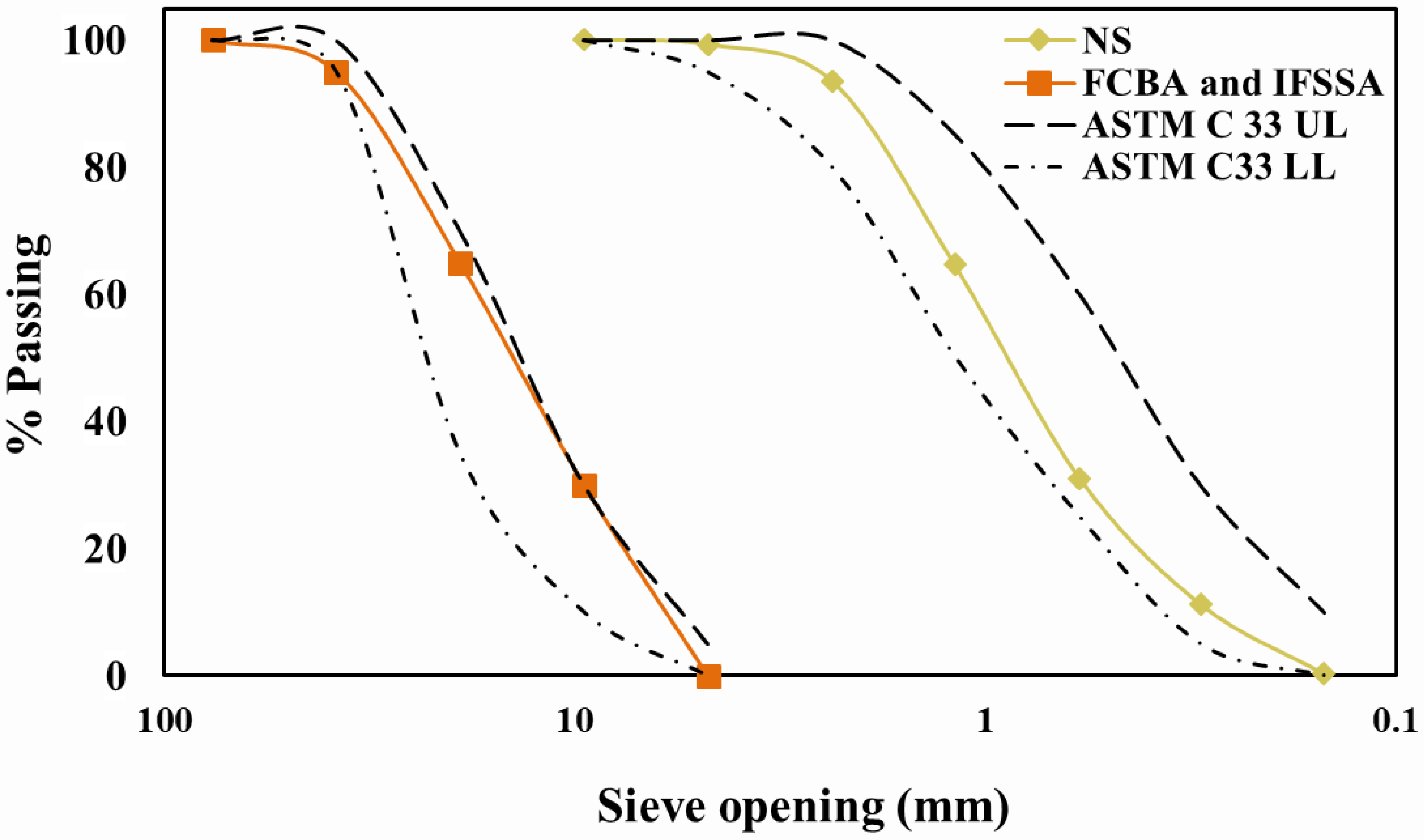

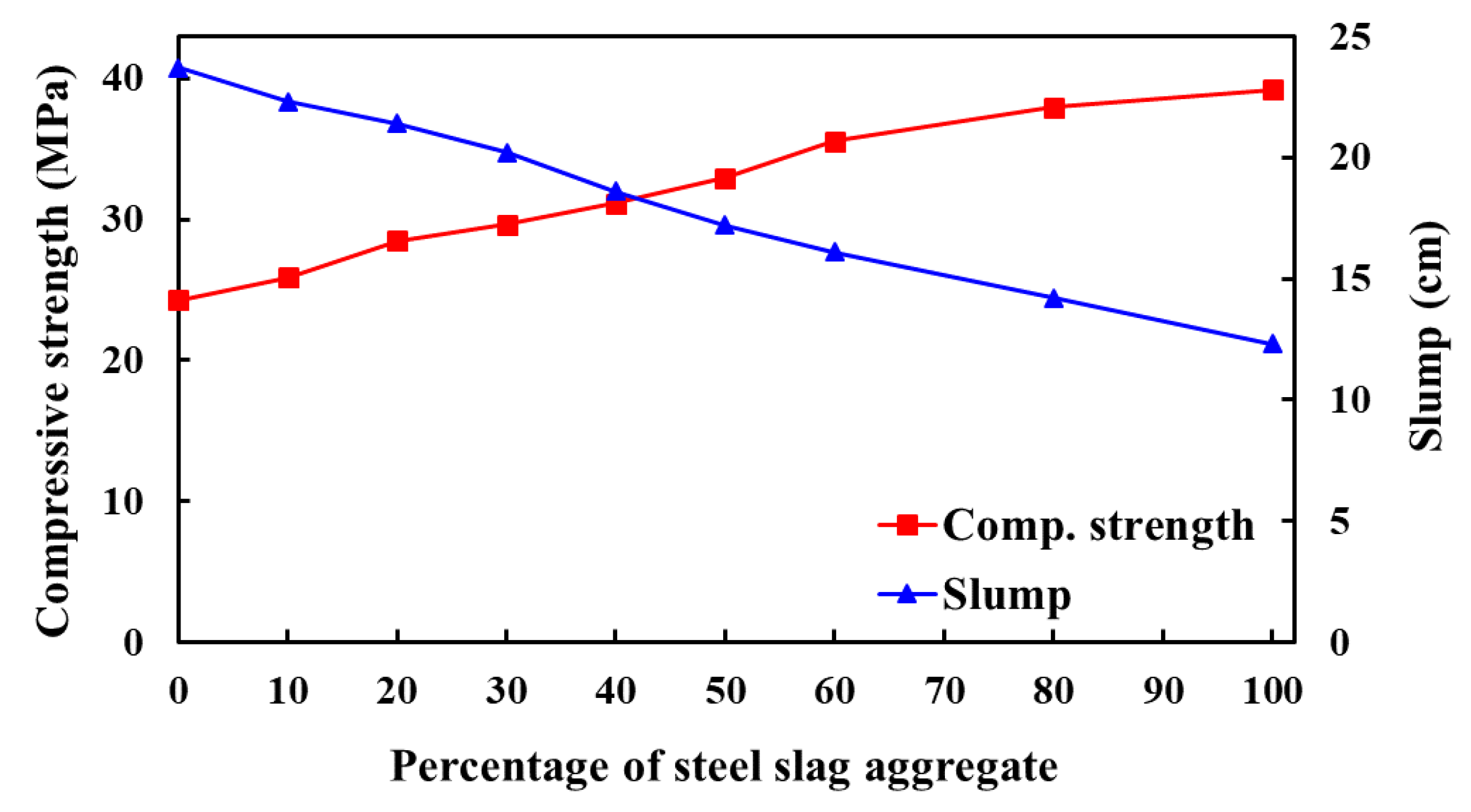

2.1. Materials Properties and Mix Design

2.2. Experimental Program and Test Procedures

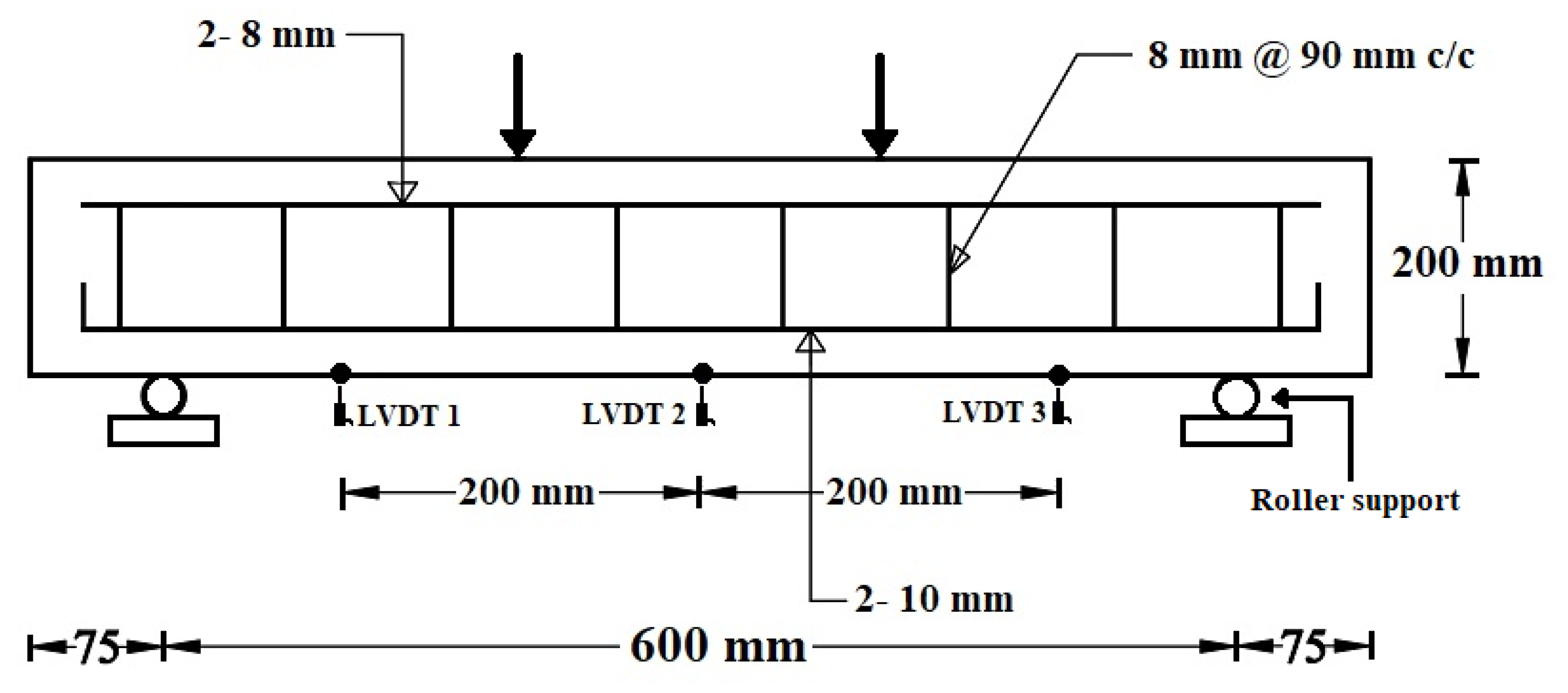

2.2.1. Flexural Performance of RC Beams

2.2.2. Durability of Concrete

3. Results and Discussion

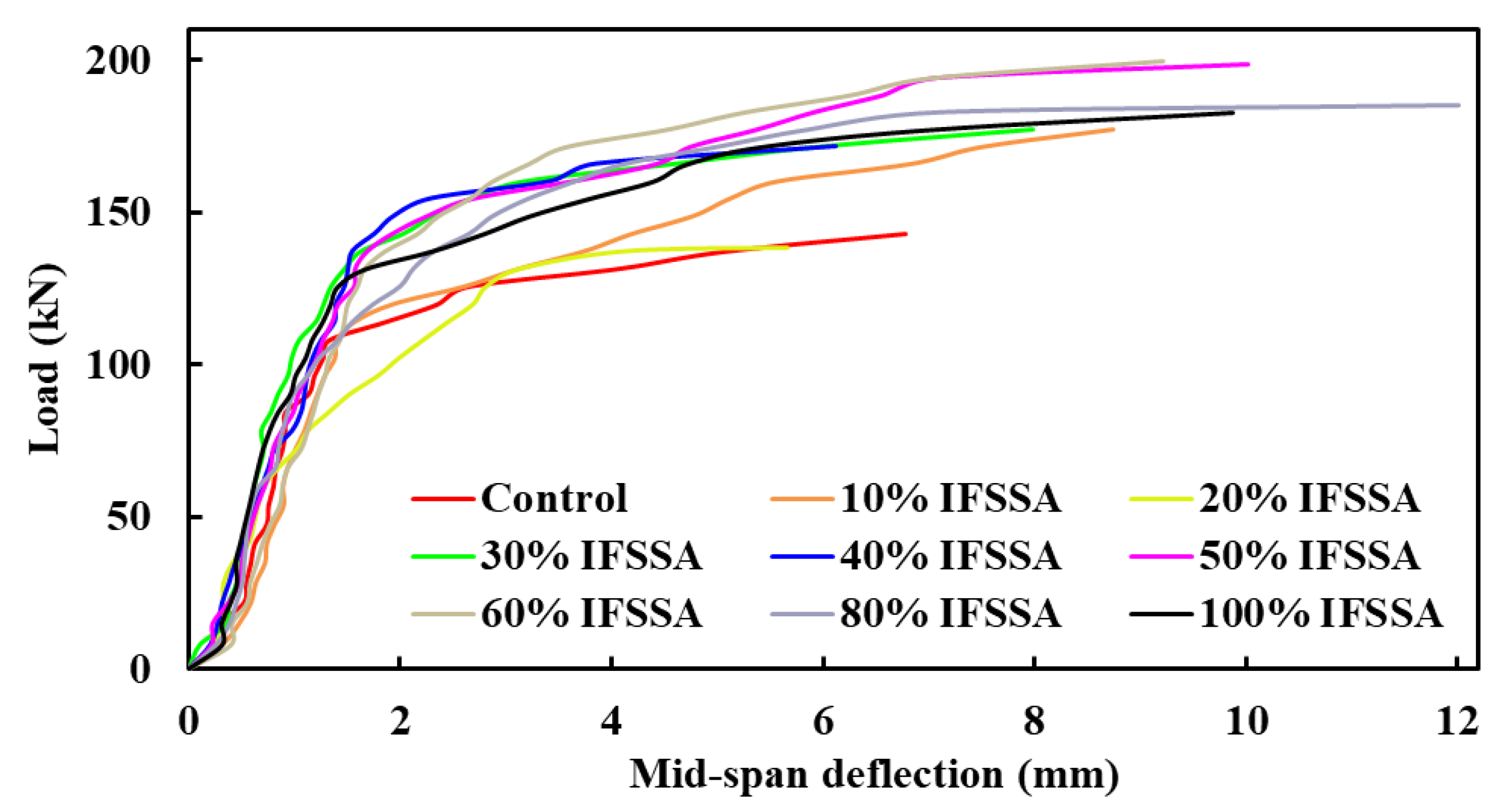

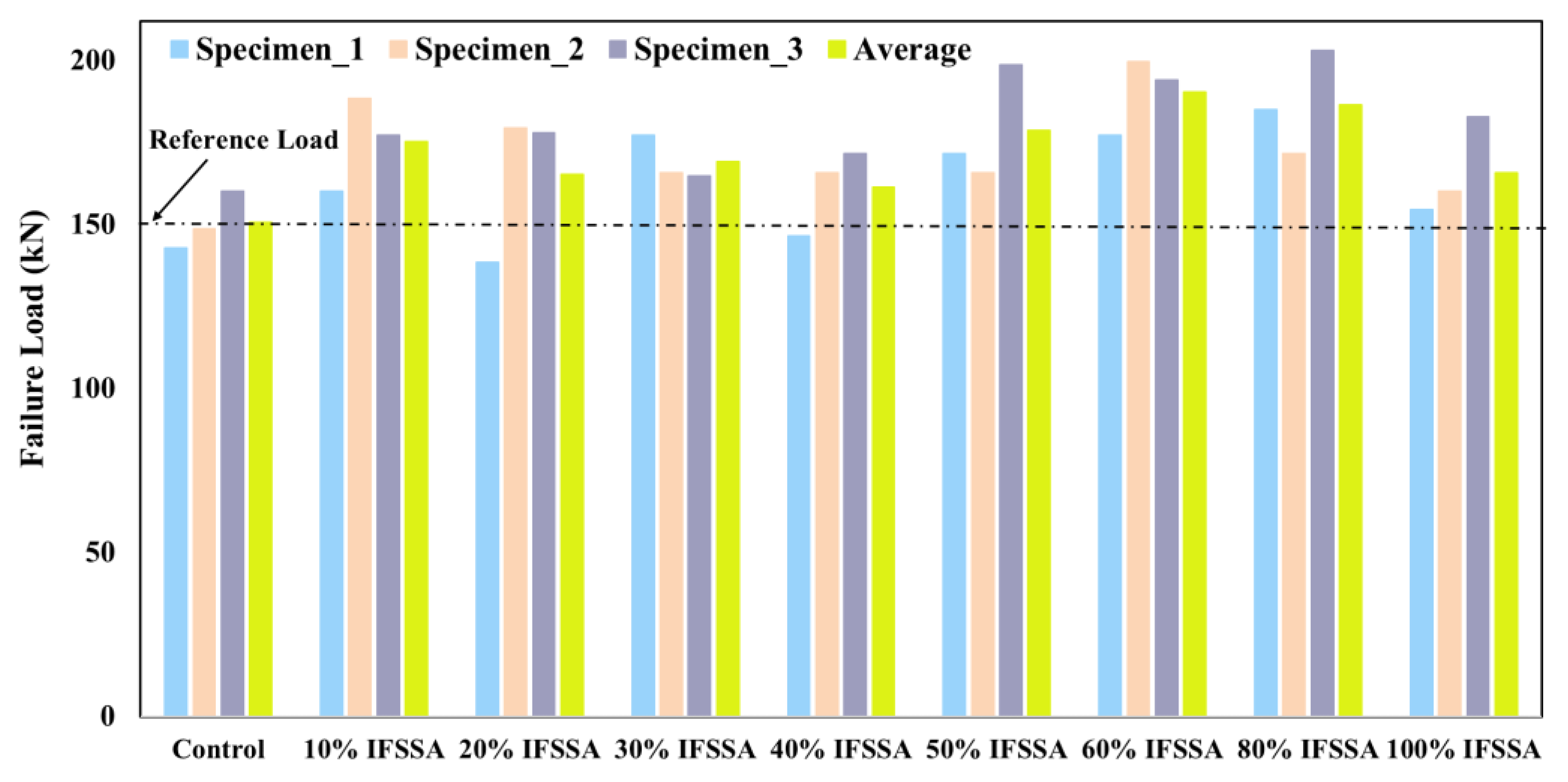

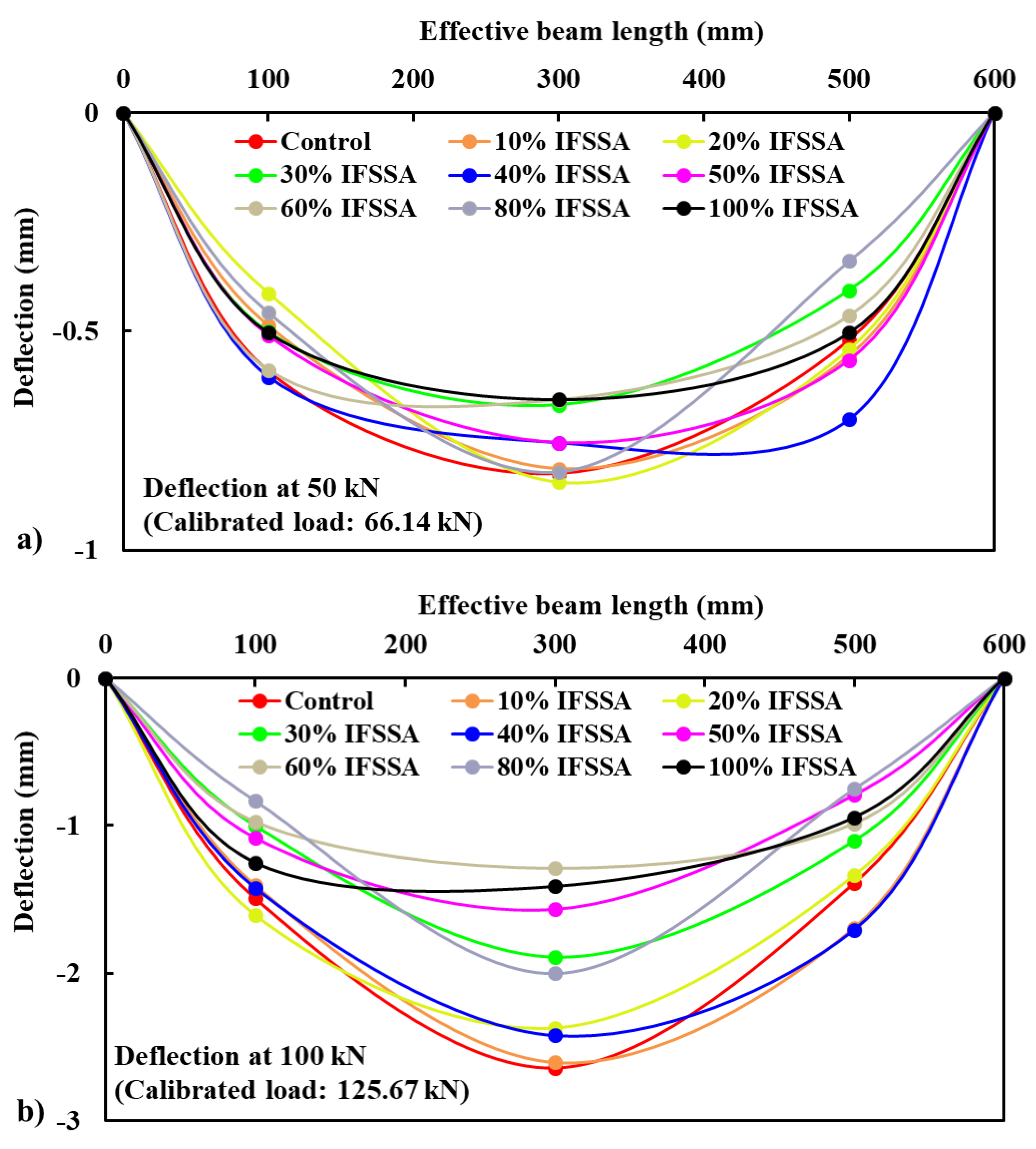

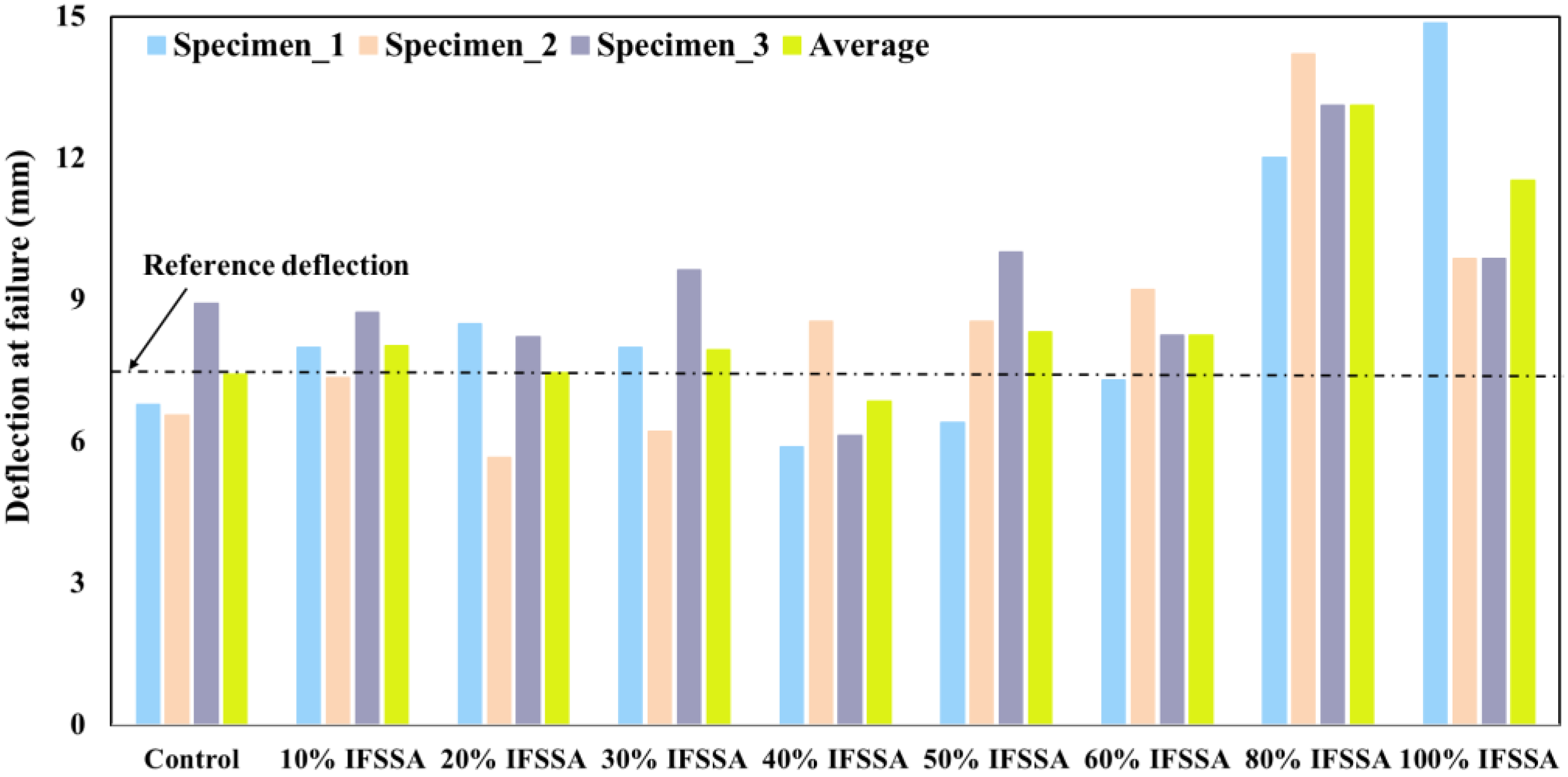

3.1. Load-Deflection Behavior of RC Beams

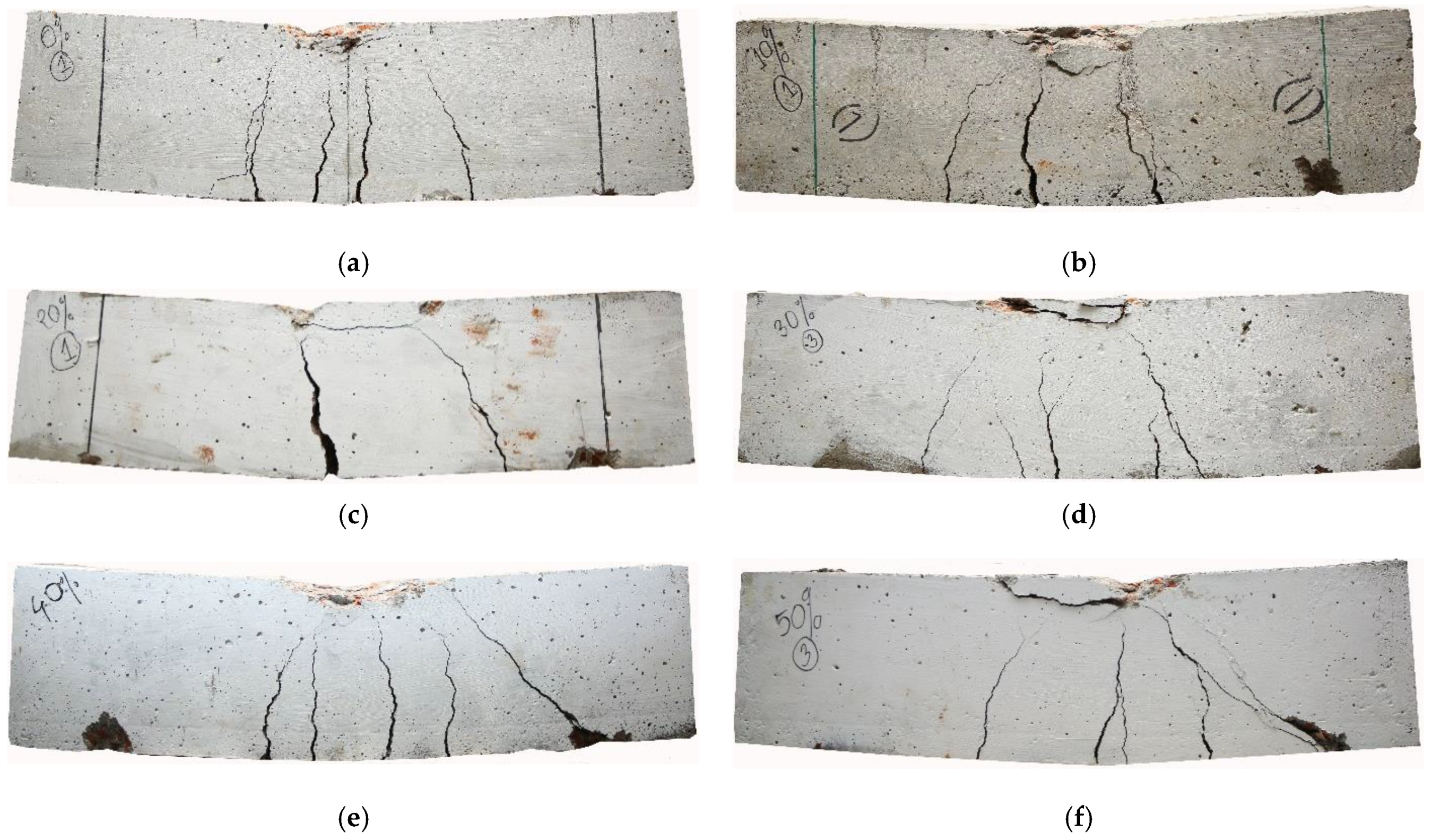

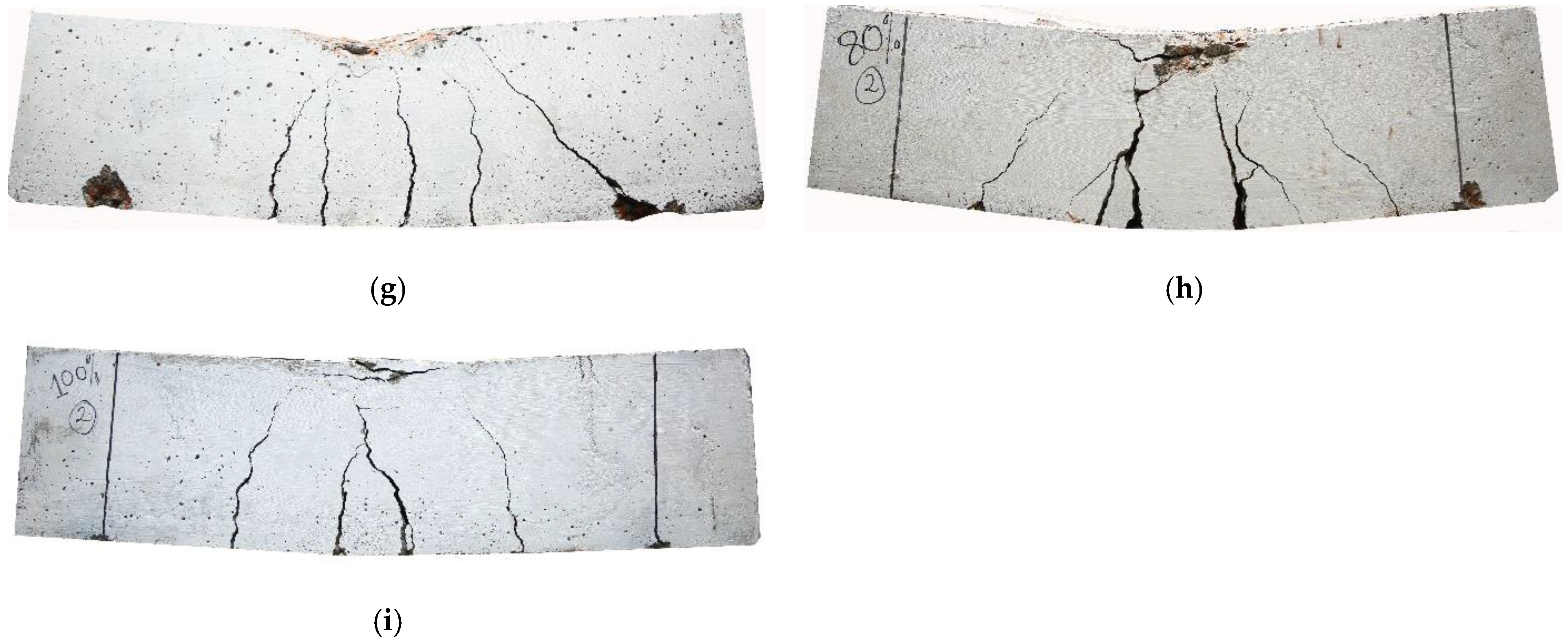

3.2. Failure Behavior of RC Beams

3.3. Durability of RC Beam

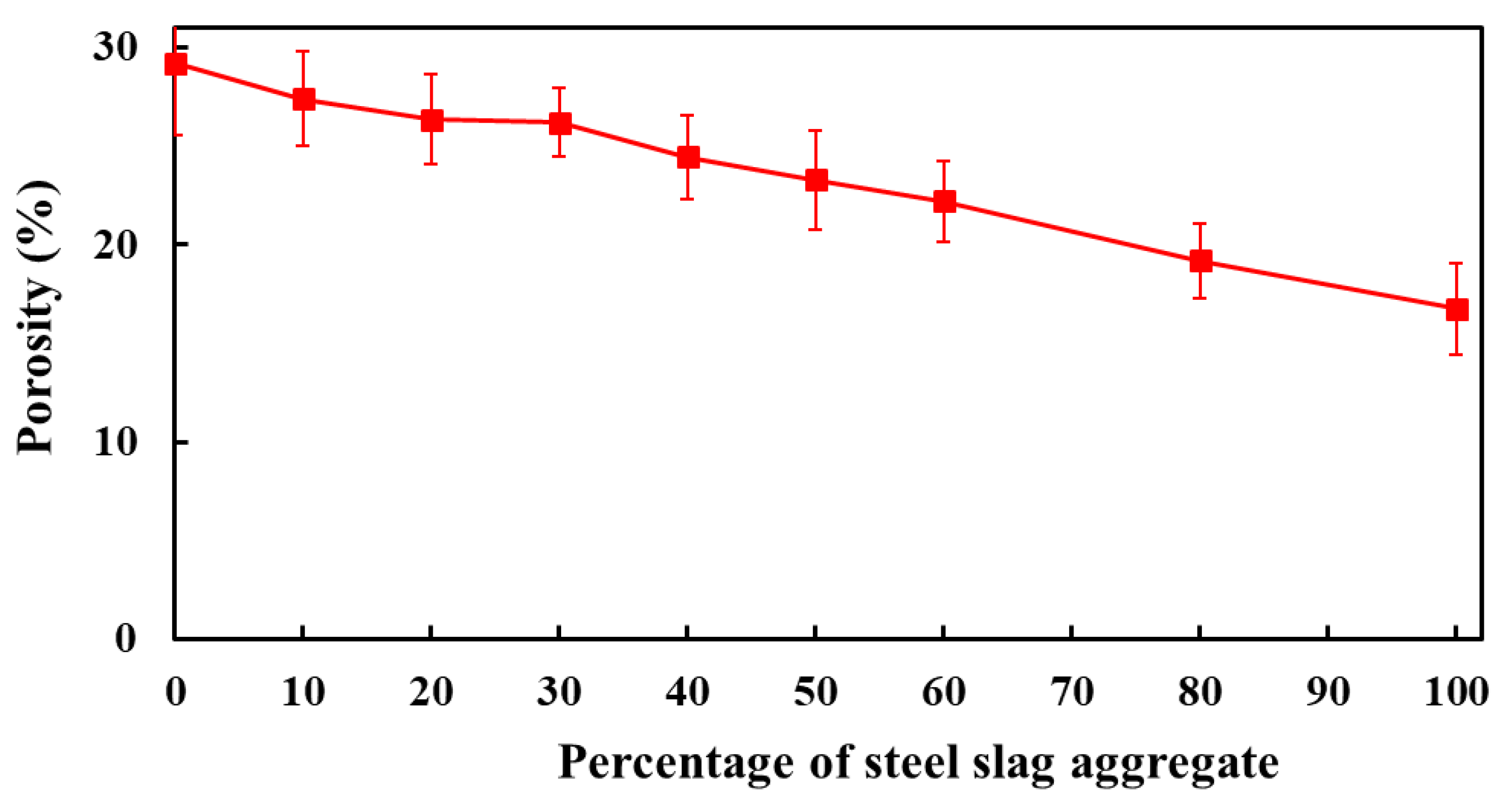

3.3.1. Porosity

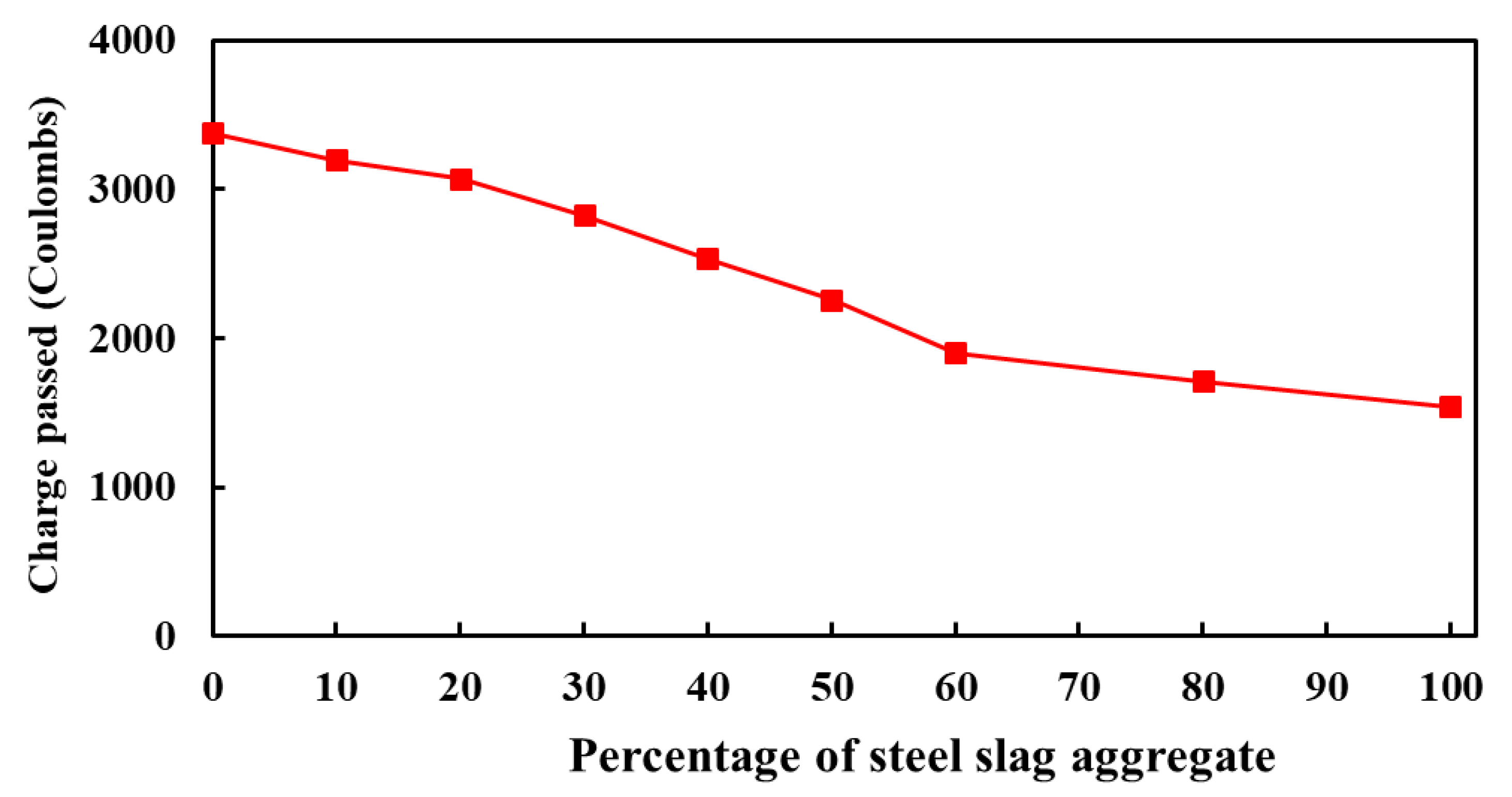

3.3.2. Resistance to Chloride Ion Penetration

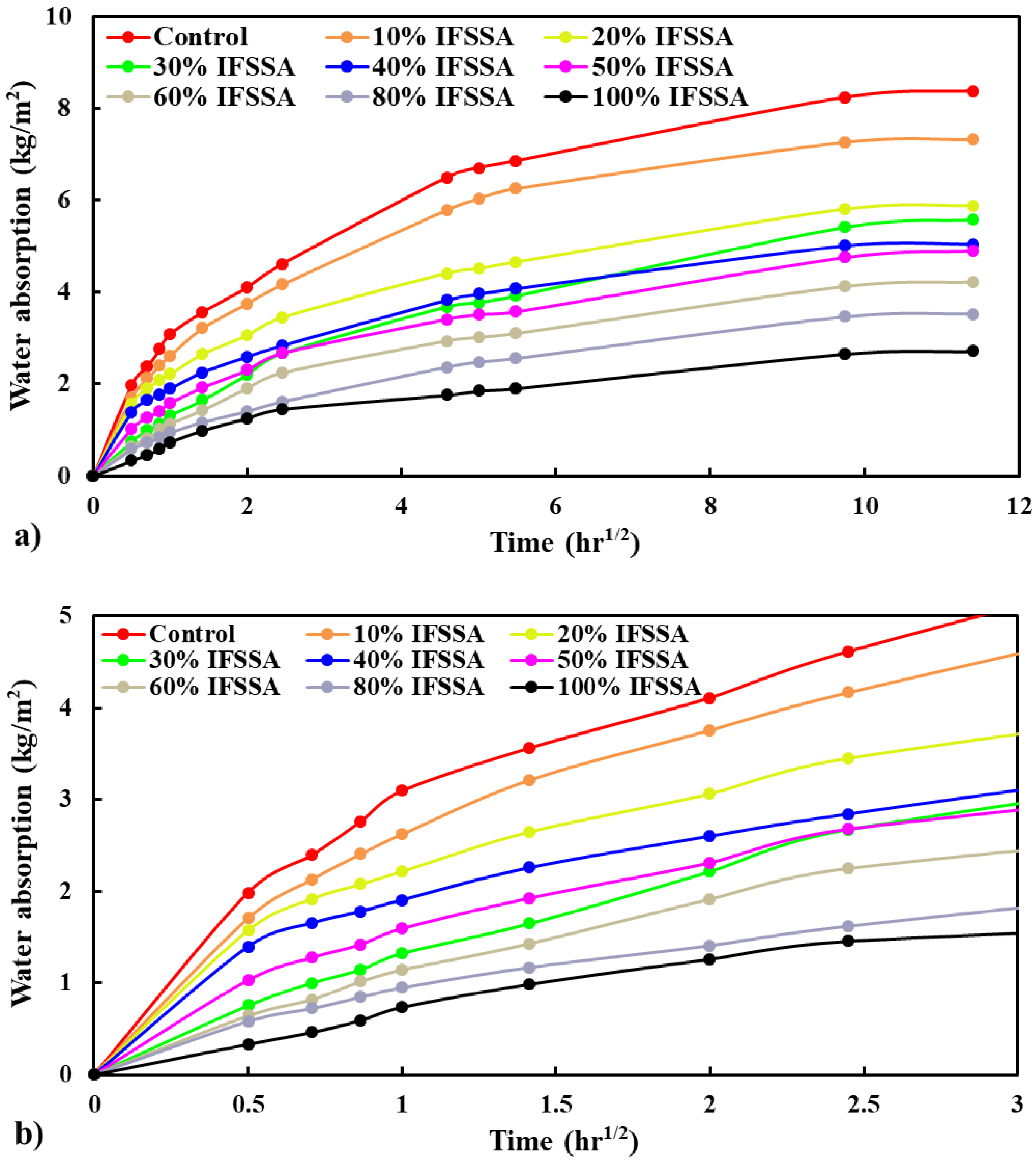

3.3.3. Capillary Water Absorption

3.3.4. Relationship of Durability Properties

4. Conclusions

- i.

- The flexural load increased as the replacement percentage of FCBA by IFSSA increased due to the higher hardness, dense microstructure, surface roughness, and sharp edges of IFSSA and improved ITZ. The flexural load increased by 27% for the beam made with 80% IFSSA compared to the control beam (100% FCBA).

- ii.

- The RC beams made with IFSSA have higher stiffness than the control beam (100% FCBA), probably due to higher modulus of elasticity and higher strength of concrete, delaying and limiting the formation of cracks and micro-cracks. However, the RC beams with IFSSA failed with significantly higher deflection than control beams, 59% for 80% IFSSA and 66% for 100% IFSSA, higher than the control beam.

- iii.

- Porosity, resistance to chloride ion penetration, and capillary water absorption decreased with the increasing replacement of FCBA by IFSSA, which are 43%, 54%, and 68%, respectively, lower when IFSSA entirely replaced FCBA.

- iv.

- Linear relationships between porosity, water absorption, and resistance to chloride penetration of concrete mixes were observed, i.e., as the porosity increases, the capillary water absorption and resistance to chloride penetration of concrete mixes increase.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global Cement Production in 1990, 2000 and 2010, with Forecasts for 2020 and 2030. Available online: https://www.statista.com/statistics/373845/global-cement-production-forecast/ (accessed on 8 June 2021).

- Jiménez, L.F.; Dominguez, J.A.; Vega-Azamar, R.E. Carbon Footprint of Recycled Aggregate Concrete. Adv. Civ. Eng. 2018, 2018, 7949741. [Google Scholar] [CrossRef]

- Quattrone, M.; Angulo, S.C.; John, V.M. Energy and CO2 from high performance recycled aggregate production. Resour. Conserv. Recycl. 2014, 90, 21–33. [Google Scholar] [CrossRef]

- Mobili, A.; Giosuè, C.; Corinaldesi, V.; Tittarelli, F. Bricks and concrete wastes as coarse and fine aggregates in sustainable mortars. Adv. Mater. Sci. Eng. 2018, 2018, 8676708. [Google Scholar] [CrossRef] [Green Version]

- Cachim, P.B. Mechanical properties of brick aggregate concrete. Constr. Build. Mater. 2009, 23, 1292–1297. [Google Scholar] [CrossRef]

- Talukdar, S.; Islam, S.T.; Banthia, N. Development of a lightweight low-carbon footprint concrete containing recycled waste materials. Adv. Civ. Eng. 2011, 2011, 594270. [Google Scholar] [CrossRef] [Green Version]

- Ghadzali, N.S.; Ibrahim, M.H.W.; Sani, M.M.; Jamaludin, N.; Desa, M.S.M.; Misri, Z. Properties of concrete containing different type of waste materials as aggregate replacement exposed to elevated temperature—A review. IOP Conf. Ser. Earth Environ. Sci. 2018, 140, 012139. [Google Scholar] [CrossRef] [Green Version]

- Biskri, Y.; Achoura, D.; Chelghoum, N.; Mouret, M. Mechanical and durability characteristics of High Performance Concrete containing steel slag and crystalized slag as aggregates. Constr. Build. Mater. 2017, 150, 167–178. [Google Scholar] [CrossRef]

- Khern, Y.C.; Paul, S.C.; Kong, S.Y.; Babafemi, A.J.; Anggraini, V.; Miah, M.J.; Šavija, B. Impact of chemically treated waste rubber tire aggregates on mechanical, durability and thermal properties of concrete. Front. Mater. 2020, 7, 90. [Google Scholar] [CrossRef] [Green Version]

- Miah, M.J.; Ali, M.K.; Paul, S.C.; Miah, M.S.; Haque, M.M.; Islam, M.S.; Islam, M.R. Impact of partial replacement of brick coarse aggregate by waste rubber tyre on the fresh and hardened properties of concrete. In Key Engineering Materials; Trans Tech Publications Ltd.: Bangkok, Thailand, 2021; Volume 877, pp. 131–137. [Google Scholar]

- Miah, M.J.; Miah, M.S.; Sultana, A.; Shamim, T.A.; Alom, M.A. The Effect of Steel Slag Coarse Aggregate on the Mechanical and Durability Performances of Concrete. In Key Engineering Materials; Trans Tech Publications Ltd.: Kuala Lumpur, Malaysia, 2020; Volume 833, pp. 228–232. [Google Scholar]

- Khan, M.S.H.; Castel, A.; Akbarnezhad, A.; Foster, S.J.; Smith, M. Utilisation of steel furnace slag coarse aggregate in a low calcium fly ash geopolymer concrete. Cem. Concr. Res. 2016, 89, 220–229. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.C.; Shi, C.; Pan, S.Y. Characteristics of steel slags and their use in cement and concrete—A review. Resour. Conserv. Recycl. 2018, 136, 187–197. [Google Scholar] [CrossRef]

- Pang, B.; Zhou, Z.; Xu, H. Utilization of carbonated and granulated steel slag aggregate in concrete. Constr. Build. Mater. 2015, 84, 454–467. [Google Scholar] [CrossRef]

- Alharbi, Y.R.; Abadel, A.A.; Elsayed, N.; Mayhoub, O.; Kohail, M. Mechanical properties of EAFS concrete after subjected to elevated temperature. Ain Shams Eng. J. 2021, 12, 1305–1311. [Google Scholar] [CrossRef]

- Qasrawi, H. The use of steel slag aggregate to enhance the mechanical properties of recycled aggregate concrete and retain the environment. Constr. Build. Mater. 2014, 54, 298–304. [Google Scholar] [CrossRef]

- Amani, A.; Ramezanianpour, A.M.; Palassi, M. Investigation on the sustainable use of electric arc furnace slag aggregates in eco-friendly alkali-activated low fineness slag concrete as a green construction composite. J. Clean. Prod. 2021, 307, 127257. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J.R. Interfacial transition zone of cement composites with steel furnace slag aggregates. Cem. Concr. Compos. 2018, 86, 117–129. [Google Scholar] [CrossRef]

- Liu, J.; Guo, R. Applications of steel slag powder and steel slag aggregate in ultra-high performance concrete. Adv. Civ. Eng. 2018, 2018, 1426037. [Google Scholar] [CrossRef] [Green Version]

- Dong, Q.; Wang, G.; Chen, X.; Tan, J.; Gu, X. Recycling of Steel Slag Aggregate in Portland Cement Concrete: An overview. J. Clean. Prod. 2021, 282, 124447. [Google Scholar] [CrossRef]

- Chandru, P.; Karthikeyan, J.; Sahu, A.K.; Sharma, K.; Natarajan, C. Some durability characteristics of ternary blended SCC containing crushed stone and induction furnace slag as coarse aggregate. Constr. Build. Mater. 2021, 270, 121483. [Google Scholar] [CrossRef]

- Miah, M.J.; Patoary, M.M.H.; Paul, S.C.; Babafemi, A.H.; Panda, B. Enhancement of Mechanical Properties and Porosity of Concrete Using Steel Slag Coarse Aggregate. Materials 2020, 13, 2865. [Google Scholar] [CrossRef] [PubMed]

- Miah, M.J.; Miah, M.S.; Alam, W.B.; Lo Monte, F.; Li, Y. Strengthening of RC beams by ferrocement made with unconventional concrete. Mag. Civ. Eng. 2019, 89, 94–105. [Google Scholar]

- Khan, H.R.; Rahman, K.; Rouf, A.J.M.A.; Sattar, G.S.; Oki, Y.; Adachi, T. Assessment of degradation of agricultural soils arising from brick burning in selected soil profiles. Int. J. Environ. Sci. Technol. 2007, 4, 471–480. [Google Scholar] [CrossRef] [Green Version]

- Debnath, B.; Sarkar, P.P. Quantification of random pore features of porous concrete mixes prepared with brick aggregate: An application of stereology and mathematical morphology. Constr. Build. Mater. 2021, 294, 123594. [Google Scholar] [CrossRef]

- Debnath, B.; Sarkar, P.P. Characterization of pervious concrete using over burnt brick as coarse aggregate. Constr. Build. Mater. 2020, 242, 118154. [Google Scholar] [CrossRef]

- Miah, M.J.; Sagar, S.U.; Paul, S.C.; Babafemi, A.J. Feasibility of Using Recycled Burnt Clay Brick Waste in Cement-Based Mortar: Mechanical Properties, Durability, and Residual Strength after Exposure to Elevated Temperatures. Int. J. Civ. Eng. 2021, 19, 1055–1069. [Google Scholar] [CrossRef]

- Miah, M.J.; Paul, S.C.; Babafemi, A.J.; Panda, B. Strength Properties of Sustainable Mortar Containing Waste Steel Slag and Waste Clay Brick: Effect of Temperature. Materials 2021, 14, 2113. [Google Scholar] [CrossRef] [PubMed]

- Miah, M.J.; Ali, M.K.; Paul, S.C.; Babafemi, A.J.; Kong, S.Y.; Šavija, B. Effect of recycled iron powder as fine aggregate on the mchanical, durability, and high temperature behavior of mortars. Materials 2020, 13, 1168. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- BDS EN 197–1:2000. Cement. In Composition, Specifications and Conformity Criteria for Common Cements; Dhaka, Bangladesh. 2000. Available online: http://www.puntofocal.gov.ar/notific_otros_miembros/mwi40_t.pdf (accessed on 8 June 2021).

- ASTM. C136/C136M-14. Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM. C33/C33M-18. Standard Specification for Concrete Aggregates; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ASTM. C127-15. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM. C128-15. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM. C29/C29M-17a. Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM. C131/C131M-14. Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- ASTM. C78-15b. Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM. C39/C39M-18. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- NFP. 18-459. Essai Pour Béton Durci-Essai De Porosité et De Masse Volumique; AFNOR: La Plaine, France, 2010. [Google Scholar]

- AFREM, A. Compte-Rendu des Journées Techniques de l’AFPC-AFREM, Groupe de Travail Durabilité des Bétons, MéthodesRecommandées Pour la Mesure Des Grandeurs Associées À la Durabilité; LaboratoireMatériaux et Durabilité des Constructions: Toulouse, France, 1997. [Google Scholar]

- ASTM. C1202-19. Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Miah, M.J. The Effect of Compressive Loading and Cement Type on the Fire Spalling Behaviour of Concrete. Ph.D. Thesis, Université de Pau et des Pays de l’Adour, Pau, France, 19 October 2017. [Google Scholar]

- Miah, M.J.; Kallel, H.; Carré, H.; Pimienta, P.; La Borderie, C. The effect of compressive loading on the residual gas permeability of concrete. Constr. Build. Mater. 2019, 217, 12–19. [Google Scholar] [CrossRef]

- Monte, F.L.; Felicetti, R.; Miah, M.J. The influence of pore pressure on fracture behaviour of Normal-Strength and High-Performance Concretes at high temperature. Cem. Concr. Compos. 2019, 104, 103388. [Google Scholar] [CrossRef]

| FCBA | IFSSA | Sand | |

|---|---|---|---|

| Specific gravity | 2.0 | 3.24 | 2.62 |

| Unit weight (kg/m3) | 1140 | 1810 | 1565 |

| Abrasion resistance (%) | 41.87 | 18.89 | - |

| Absorption capacity (%) | 20.56 | 1.2 | 5.86 |

| CaO (%) | 4.18 | 4.94 | - |

| SiO2 (%) | 60.43 | 26.18 | - |

| Fe2O3 (%) | 14.27 | 44.39 | - |

| Al2O3 (%) | 9.96 | 4.93 | - |

| MgO (%) | 1.69 | 0.46 | - |

| K2O (%) | 5.23 | 0.56 | - |

| TiO2 (%) | 1.81 | 1.73 | - |

| MnO (%) | 0.30 | 12.9 | - |

| Na2O (%) | 0.90 | 0.45 | - |

| ZnO (%) | 0.10 | 2.33 | - |

| SO3 (%) | 0.57 | 0.43 | - |

| P2O5 (%) | 0.24 | 0.08 | - |

| SrO (%) | 0.05 | 0.09 | - |

| ZrO2 (%) | 0.05 | 0.11 | - |

| Mix ID. | % FCBA | % IFSSA | Cement | Coarse Aggregate | NS | Water | |

|---|---|---|---|---|---|---|---|

| FCBA | IFSSA | ||||||

| Control | 100 | 0 | 350 | 781 | 0 | 817 | 158 |

| 10% IFSSA | 90 | 10 | 350 | 703 | 126 | 817 | 158 |

| 20% IFSSA | 80 | 20 | 350 | 624 | 253 | 817 | 158 |

| 30% IFSSA | 70 | 30 | 350 | 546 | 379 | 817 | 158 |

| 40% IFSSA | 60 | 40 | 350 | 468 | 506 | 817 | 158 |

| 50% IFSSA | 50 | 50 | 350 | 390 | 632 | 817 | 158 |

| 60% IFSSA | 40 | 60 | 350 | 312 | 759 | 817 | 158 |

| 80% IFSSA | 20 | 80 | 350 | 156 | 1012 | 817 | 158 |

| 100% IFSSA | 0 | 100 | 350 | 0 | 1265 | 817 | 158 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miah, M.J.; Ali, M.K.; Li, Y.; Babafemi, A.J.; Paul, S.C. Impact of Induction Furnace Steel Slag as Replacement for Fired Clay Brick Aggregate on Flexural and Durability Performances of RC Beams. Materials 2021, 14, 6268. https://doi.org/10.3390/ma14216268

Miah MJ, Ali MK, Li Y, Babafemi AJ, Paul SC. Impact of Induction Furnace Steel Slag as Replacement for Fired Clay Brick Aggregate on Flexural and Durability Performances of RC Beams. Materials. 2021; 14(21):6268. https://doi.org/10.3390/ma14216268

Chicago/Turabian StyleMiah, Md Jihad, Md. Kawsar Ali, Ye Li, Adewumi John Babafemi, and Suvash Chandra Paul. 2021. "Impact of Induction Furnace Steel Slag as Replacement for Fired Clay Brick Aggregate on Flexural and Durability Performances of RC Beams" Materials 14, no. 21: 6268. https://doi.org/10.3390/ma14216268

APA StyleMiah, M. J., Ali, M. K., Li, Y., Babafemi, A. J., & Paul, S. C. (2021). Impact of Induction Furnace Steel Slag as Replacement for Fired Clay Brick Aggregate on Flexural and Durability Performances of RC Beams. Materials, 14(21), 6268. https://doi.org/10.3390/ma14216268