The Low-Cycle Fatigue Behavior, Failure Mechanism and Prediction of SLM Ti-6Al-4V Alloy with Different Heat Treatment Methods

Abstract

:1. Introduction

2. Materials and Methods

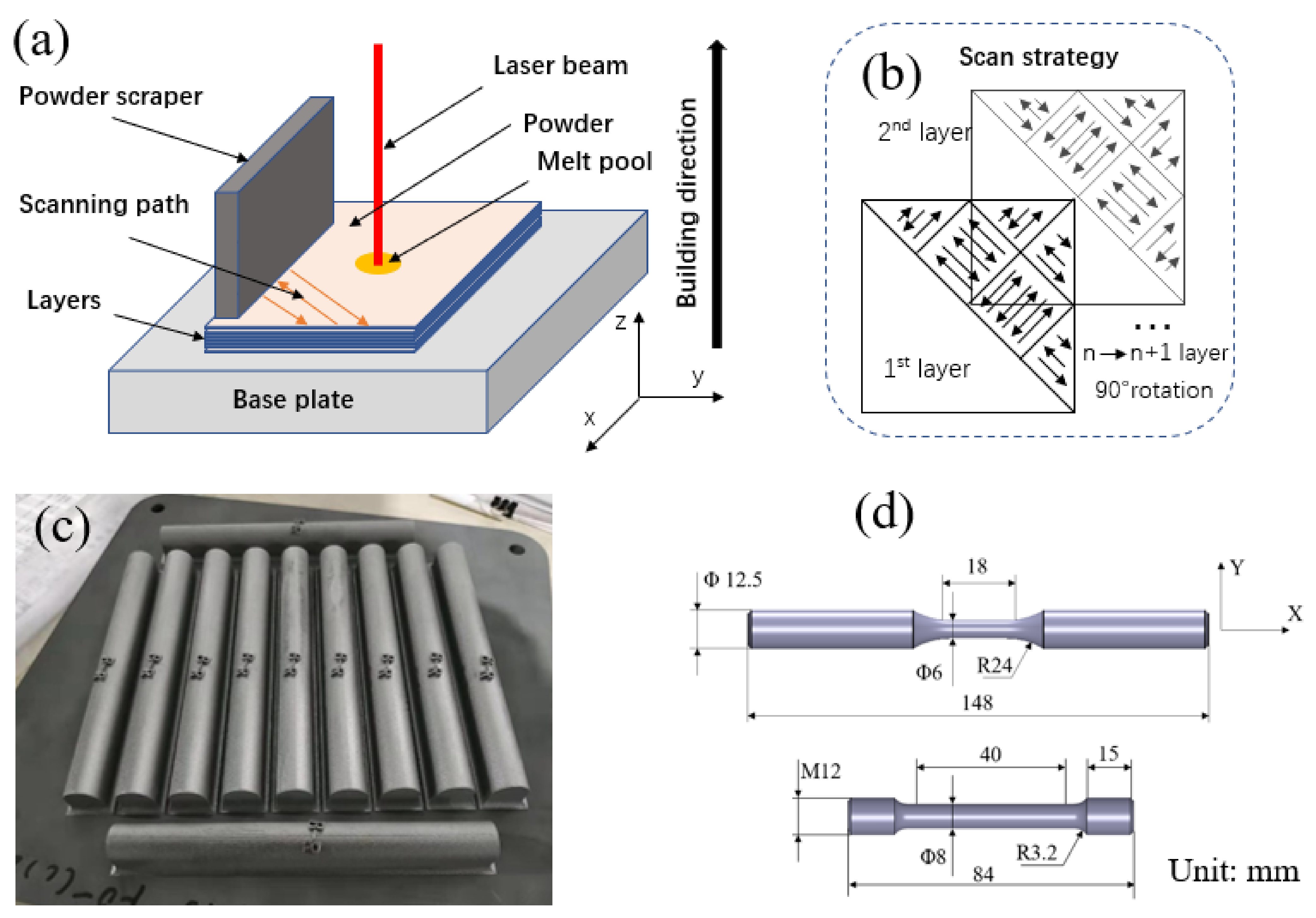

2.1. Materials and Manufacturing

2.2. Heat Treatment

2.3. Tensile and Fatigue Test Methods

2.4. LCF Analysis Model

2.5. Microstructure Analysis

3. Experimental Results

3.1. Microstructure

3.2. Tensile and LCF Performance

3.3. Cyclic Softening Behaviours and LCF Performance

3.4. Fractographic Analysis

4. Discussion

4.1. Investigation of AM Ti-6Al-4V LCF Properties

4.2. The Difference in Failure Mechanism of HT and HIP SLM Ti-6Al-4V

4.3. MSF Fatigue Life Prediction Model Calibration

5. Conclusions

- The static tensile properties of HT- and HIP-treated SLM Ti-6Al-4V were similar and comparable to their wrought counterparts.

- The HT- and HIP-treated SLM Ti-6Al-4V alloys showed higher LCF lives than most AM Ti-6Al-4V samples in the literature and even better LCF properties than the standard wrought samples at lower strain amplitudes.

- The material underwent obvious cyclic strain-softening behavior at all strain levels from 0.8% to 2.0%. When the strain amplitudes increased, the cyclic softening degree also increased.

- The hot isostatic press (HIP) process helps to close the internal defects, and almost no defects were found in the HIP-treated samples. Defects were found on the HT sample fracture surface, indicating that defects were not the dominant factor influencing the LCF properties of SLM Ti-6Al-4V; furthermore, the interior defects were not significantly detrimental to LCF performance.

- Multiple crack initiation sites were found for both HT- and HIP-treated samples. All crack origins were near the surface, and none of them were pores or voids.

- The behaviors of fatigue crack initiation and propagation were investigated for the HT- and HIP-treated samples. In terms of the crack initiation region, HT samples had more branched secondary cracks than HIP-treated samples, and cracks propagated along α + β lath boundaries. The crack paths of HT samples exhibited a more zig-zag pattern than their HIP counterparts. As the crack propagated, intragranular fatigue fracture became the main crack growth phenomenon.

- The LCF prediction life curve of HT- and HIP-treated SLM samples obtained using the microstructure-based multistage fatigue (MSF) model showed good agreement with the experimental results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peguesab, J.W.; Shao, S.; Shamsaei, N.; Sanaei, N.; Fatemi, A.; Warner, D.H.; Li, P.; Phan, N. Fatigue of Additive Manufactured Ti-6Al-4V, Part I: The Effects of Powder Feedstock, Manufacturing, and Post Process Conditions on the Resulting Microstructure and Defects. Int. J. Fatigue 2020, 132, 105358. [Google Scholar] [CrossRef]

- Hitzler, L.; Merkel, M.; Hall, W.; Öchsner, A. A Review of Metal Fabricated with Laser- and Powder-Bed Based Additive Manufacturing Techniques: Process, Nomenclature, Materials, Achievable Properties, and its Utilization in the Medical Sector. Adv. Eng. Mater. 2018, 20, 1700658. [Google Scholar] [CrossRef] [Green Version]

- Qiu, C.; Adkins, N.J.; Attallah, M. Microstructure and tensile properties of selectively laser-melted and of HIPed laser-melted Ti–6Al–4V. Mater. Sci. Eng. A 2013, 578, 230–239. [Google Scholar] [CrossRef]

- Xu, W.; Sun, S.; Elambasseril, J.; Liu, Q.; Brandt, M.; Qian, M. Ti-6Al-4V Additively Manufactured by Selective Laser Melting with Superior Mechanical Properties. Jom 2015, 67, 668–673. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.-D. As-Fabricated and Heat-Treated Microstructures of the Ti-6Al-4V Alloy Processed by Selective Laser Melting. Met. Mater. Trans. A 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Craeghs, T.; Thijs, L.; Verhaeghe, F.; Kruth, J.-P.; Humbeeck, J.V. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater 2010, 58, 3303–3312. [Google Scholar]

- Calleja-ochoa, A.; Gonzalez-barrio, H.; de Lacalle, N.L.; Martínez, S.; Albizuri, J.; Lamikiz, A. A new approach in the de-sign of microstructured ultralight components to achieve maximum functional performance. Materials 2021, 14, 1588. [Google Scholar] [CrossRef]

- Hrabe, N.; Quinn, T. Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti–6Al–4V) fabricated using electron beam melting (EBM), Part 2: Energy input, orientation, and location. Mater. Sci. Eng. A 2013, 573, 271–277. [Google Scholar] [CrossRef]

- Parry, L.; Ashcroft, I.; Wildman, R. Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-mechanical simulation. Addit. Manuf. 2016, 12, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. Improving the fatigue behavior of a selectively laser melted aluminium alloy: Influence of heat treatment and surface quality. Mater. Des. 2016, 104, 174–182. [Google Scholar] [CrossRef]

- Li, P.; Warner, D.H.; Fatemi, A.; Phan, N. Critical assessment of the fatigue performance of additively manufactured Ti-6Al-4V and perspective for future research. Int. J. Fatigue 2016, 85, 130–143. [Google Scholar] [CrossRef]

- Beretta, S.; Romano, S. A comparison of fatigue strength sensitivity to defects for materials manufactured by AM or traditional processes. Int. J. Fatigue 2017, 94, 178–191. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N. Additive manufacturing of fatigue resistant materials: Challenges and opportunities. Int. J. Fatigue 2017, 98, 14–31. [Google Scholar] [CrossRef] [Green Version]

- Shamsaei, N.; Yadollahi, A.; Bian, L.; Thompson, S.M. An overview of Direct Laser Deposition for additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit. Manuf. 2015, 8, 12–35. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Chern, A.H.; Nandwana, P.; Yuan, T.; Kirka, M.M.; Dehoff, R.R.; Liaw, P.K.; Duty, C.E. A review on the fatigue behavior of Ti-6Al-4V fabricated by electron beam melting additive manufacturing. Int. J. Fatigue 2019, 119, 173–184. [Google Scholar] [CrossRef]

- Chastand, V.; Quaegebeur, P.; Maia, W.; Charkaluk, E. Comparative study of fatigue properties of Ti-6Al-4V specimens built by electron beam melting (EBM) and selective laser melting (SLM). Mater. Charact. 2018, 143, 76–81. [Google Scholar] [CrossRef]

- Masuo, H.; Tanaka, Y.; Morokoshi, S.; Yagura, H.; Uchida, T.; Yamamoto, Y.; Murakami, Y. Influence of defects, surface roughness and HIP on the fatigue strength of Ti-6Al-4V manufactured by additive manufacturing. Int. J. Fatigue 2018, 117, 163–179. [Google Scholar] [CrossRef]

- Molaei, R.; Fatemi, A.; Phan, N. Significance of hot isostatic pressing (HIP) on multiaxial deformation and fa-tigue behaviors of additive manufactured Ti-6Al-4V including build orientation and surface roughness effects. Int. J. Fatigue 2018, 117, 352–370. [Google Scholar] [CrossRef]

- McDowell, D.; Gall, K.; Horstemeyer, M.; Fan, J. Microstructure-based fatigue modeling of cast A356-T6 alloy. Eng. Fract. Mech. 2003, 70, 49–80. [Google Scholar] [CrossRef] [Green Version]

- Torries, B.; Sterling, A.J.; Shamsaei, N.; Thompson, S.M.; Daniewicz, S.R. Utilization of a microstructure sensitive fatigue model for additively manufactured Ti-6Al-4V. Rapid Prototyp. J. 2016, 22, 817–825. [Google Scholar] [CrossRef]

- Ren, Y.; Lin, X.; Guo, P.; Yang, H.; Tan, H.; Chen, J.; Li, J.; Zhang, Y.; Huang, W. Low cycle fatigue properties of Ti-6Al-4V alloy fabricated by high-power laser directed energy deposition: Experimental and prediction. Int. J. Fatigue 2019, 127, 58–73. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Strain-Controlled Fatigue Testing; E606/E606M-12; ASTM: West Conshohocken, PA, USA, 2004; Volume 96, pp. 1–16. [Google Scholar]

- Manson, S.S. Fatigue: A Complex Subject-Some Simple Approximations some approximations useful in design are outlined and their application illustrated. Exp. Mech. 1965, 5, 193–226. [Google Scholar] [CrossRef]

- Ricotta, M. Simple expressions to estimate the Manson–Coffin curves of ductile cast irons. Int. J. Fatigue 2015, 78, 38–45. [Google Scholar] [CrossRef]

- Muralidharan, U.; Manson, S.S. A Modified Universal Slopes Equation for Estimation of Fatigue Characteristics of Metals. J. Eng. Mater. Technol. 1988, 110, 55–58. [Google Scholar] [CrossRef]

- Mower, T.M.; Long, M.J. Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng. A 2016, 651, 198–213. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, A.; Wang, X. The influence of building direction on the fatigue crack propagation behavior of Ti6Al4V alloy produced by selective laser melting. Mater. Sci. Eng. A 2019, 767, 138409. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.; Tuck, C. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti–6Al–4V. Mater. Sci. Eng. A 2014, 616, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.A.; Maier, H.J. On the mechanical behavior of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Shunmugavel, M.; Polishetty, A.; Littlefair, G. Microstructure and Mechanical Properties of Wrought and Additive Manufactured Ti-6Al-4V Cylindrical Bars. Procedia Technol. 2015, 20, 231–236. [Google Scholar] [CrossRef] [Green Version]

- Suresh, S. Cyclic deformation in ductile single crystals. Fatigue Mater. 1998, 39–85. [Google Scholar]

- Lee, Y.; Pan, J.; Hathaway, R.; Barkey, M. Fatigue testing and analysis. In Wood Science and Technology; Springer: Berlin/Heidelberg, Germany, 2004; Volume 416, pp. 965–975. [Google Scholar]

- Shao, C.; Zhang, P.; Liu, R.; Zhang, Z.; Pang, J. Low-cycle and extremely-low-cycle fatigue behaviors of high-Mn austenitic TRIP/TWIP alloys: Property evaluation, damage mechanisms and life prediction. Acta Mater. 2016, 103, 781–795. [Google Scholar] [CrossRef]

- Fatemi, A.; Molaei, R.; Simsiriwong, J.; Sanaei, N.; Pegues, J.; Torries, B.; Phan, N.; Shamsaei, N. Fatigue behavior of additive manufactured materials: An overview of some recent experimental studies on Ti-6Al-4V considering various processing and loading direction effects. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 991–1009. [Google Scholar] [CrossRef]

- Sterling, A.; Shamsaei, N.; Torries, B.; Thompson, S.M. Fatigue Behavior of Additively Manufactured Ti-6Al-4V. Procedia Eng. 2015, 133, 576–589. [Google Scholar] [CrossRef] [Green Version]

- Ren, Y.M.; Lin, X.; Fu, X.; Tan, H.; Chen, J.; Huang, W.D. Microstructure and deformation behavior of Ti-6Al-4V alloy by high-power laser solid forming. Acta Mater. 2017, 132, 82–95. [Google Scholar] [CrossRef]

- Benedetti, M.; Fontanari, V.; Bandini, M.; Zanini, F.; Carmignato, S. Low- and high-cycle fatigue resistance of Ti-6Al-4V ELI additively manufactured via selective laser melting: Mean stress and defect sensitivity. Int. J. Fatigue 2018, 107, 96–109. [Google Scholar] [CrossRef]

- Aeronautical China. Materials Handbook. In Titanium alloys and Copper Alloys; Aeronautical China: Beijing, China, 2001; Volume 4, pp. 104–132. [Google Scholar]

- Sterling, A.J.; Torries, B.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Fatigue behavior and failure mechanisms of direct laser deposited Ti–6Al–4V. Mater. Sci. Eng. A 2016, 655, 100–112. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials. Cambridge University Press: Cambridge, UK, 2002. [Google Scholar] [CrossRef]

- Mander, B.J.B.; Kasalanatp, A. Low-Cycle Fatigue Behavior of Reinforcing Steel. J. Mater. Civ. Eng. 1995, 6, 453–468. [Google Scholar] [CrossRef]

- Stephens, R.I.; Fatemi, A.; Stephens, R.R.; Henry, F.O. Metal. Fatigue in Engineering, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2000. [Google Scholar]

- Denti, L.; Bassoli, E.; Gatto, A.; Santecchia, E.; Mengucci, P. Fatigue life and microstructure of additive manufactured Ti6Al4V after different finishing processes. Mater. Sci. Eng. A 2019, 755, 1–9. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, A.; Wang, X.; Liu, B.; Guo, M. Fatigue limit prediction model and fatigue crack growth mechanism for selective laser melting Ti6Al4V samples with inherent defects. Int. J. Fatigue 2021, 143, 106008. [Google Scholar] [CrossRef]

- Ren, Y.M.; Lin, X.; Yang, H.O.; Tan, H.; Chen, J.; Jian, Z.Y.; Li, J.Q.; Huang, W.D. Microstructural features of Ti-6Al-4V manufactured via high power laser directed energy deposition under low-cycle fatigue. J. Mater. Sci. Technol. 2021, 83, 18–33. [Google Scholar] [CrossRef]

- Razavi, S.M.J.; Berto, F. Directed Energy Deposition versus Wrought Ti-6Al-4V: A Comparison of Micro-structure, Fatigue Behavior, and Notch Sensitivity. Adv. Eng. Mater. 2019, 21, 1900220. [Google Scholar] [CrossRef]

- Xue, Y.; McDowell, D.; Horstemeyer, M.; Dale, M.; Jordon, J. Microstructure-based multistage fatigue modeling of aluminum alloy 7075-T651. Eng. Fract. Mech. 2007, 74, 2810–2823. [Google Scholar] [CrossRef]

- Xue, Y.; Pascu, A.; Horstemeyer, M.F.; Wang, L.; Wang, P.T. Microporosity effects on cyclic plasticity and fatigue of LENSTM-processed steel. Acta Mater. 2010, 58, 4029–4038. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

| Al | Y | O | C | V | N | Fe | Ti |

|---|---|---|---|---|---|---|---|

| 6.28 | <0.001 | 0.074 | 0.012 | 3.97 | 0.012 | 0.131 | Balance |

| f/Hz | Load Shape | Strain Ratio | Amount | |

|---|---|---|---|---|

| 0.008 | 0.313 | Triangle | −1 | 3 |

| 0.010 | 0.250 | Triangle | −1 | 3 |

| 0.012 | 0.208 | Triangle | −1 | 3 |

| 0.020 | 0.125 | Triangle | −1 | 1 |

| Properties | HT | HIP | Wrought |

|---|---|---|---|

| Density (g/cm3) | 4.254 | 4.299 | 4.5 |

| Elastic modulus (GPa) | 116.2 | 118.6 | 108.1 |

| Yield stress, (MPa) | 964 | 913 | 904 |

| Ultimate stress, (MPa) | 1115 | 1112 | 1078 |

| Elongation to failure, (%) | 17.1 | 19 | 23.4 |

| Cyclic modulus of elasticity, (GPa) | 114.6 | 114.9 | - |

| Fatigue strength coefficient, (MPa) | 1302 | 1076 | - |

| Fatigue strength exponent, | −0.0509 | −0.0351 | - |

| Fatigue ductility coefficient, | 0.236 | 0.177 | - |

| Fatigue ductility exponent, | −0.582 | −0.453 | - |

| Cyclic strength coefficient, (MPa) | 1311.6 | 1234.2 | - |

| Cyclic strain hardening coefficient, | 0.0695 | 0.0674 | - |

| HT | - | - | - | - | - |

| 0.8 | 0.094 | 0.706 | 832 | −16 | 13,372 |

| 0.8 | 0.074 | 0.726 | 763 | −73 | 9194 |

| 0.8 | 0.094 | 0.706 | 825 | −39 | 15,082 |

| 1.0 | 0.258 | 0.742 | 877 | −27 | 3460 |

| 1.0 | 0.293 | 0.707 | 839 | −34 | 2256 |

| 1.0 | 0.204 | 0.796 | 950 | −42 | 2112 |

| 1.2 | 0.212 | 0.988 | 929 | −39 | 1226 |

| 1.2 | 0.424 | 0.776 | 900 | −10 | 1762 |

| 1.2 | 0.415 | 0.785 | 918 | −29 | 1524 |

| 2.0 | 1.114 | 0.886 | 869 | 10 | 232 |

| HIP | - | - | - | - | - |

| 0.8 | 0.129 | 0.671 | 786 | −10 | 13,636 |

| 0.8 | 0.129 | 0.671 | 787 | −31 | 8860 |

| 0.8 | 0.141 | 0.659 | 781 | −16 | 13,872 |

| 1.0 | 0.299 | 0.701 | 831 | −26 | 2836 |

| 1.0 | 0.293 | 0.707 | 836 | −35 | 2598 |

| 1.0 | 0.245 | 0.755 | 849 | −45 | 1572 |

| 1.2 | 0.489 | 0.711 | 834 | 10 | 1800 |

| 1.2 | 0.476 | 0.724 | 845 | −28 | 1114 |

| 1.2 | 0.431 | 0.769 | 840 | 2 | 1244 |

| 2.0 | 1.246 | 0.754 | 939 | −36 | 180 |

| No. | Specimen | Location of Defects | Cycles to Failure | |

|---|---|---|---|---|

| 1 | HT-5#-0.8% | 14.7, (26.5, 36.8), (27.6, 39.9) | interior | 6686 |

| 2 | HT-3#-1.2% | 17.9, (23.7, 36.5) | interior | 882 |

| 3 | HT-8#-2.0% | 24.6 | interior | 116 |

| Number | Process | Yield Stress (MPa) | Elongation (%) | LCF Properties | Reference | |||

|---|---|---|---|---|---|---|---|---|

| b | c | |||||||

| 1 | HT SLM | 964 | 17.1 | 0.01366 | −0.05085 | 0.23615 | −0.5915 | This work |

| 2 | HIP SLM | 913 | 19 | 0.009358 | −0.03511 | 0.17677 | −0.5208 | |

| 3 | HT lens | 959 | 3.7 | 0.015 | −0.111 | 0.736 | −0.967 | [37] |

| 4 | As-built | 893 | 11 | 0.01177 | −0.07162 | 2.13535 | −1.0007 | [38] |

| 5 | HIP LSF | 872 | 12.3 | 0.1028 | −0.0575 | 0.5899 | −0.78261 | [39] |

| 6 | SLM Ti-6Al-4V ELI | 1015 | 10 | 0.02761 | −0.186 | 15.35 | −1.47 | [40] |

| 7 | Wrought | >825 | >10 | 0.013 | −0.07 | 2.69 | −0.96 | [41] |

| 8 | HT LSF | 791.6 | 18.2 | 0.0097 | −0.05217 | 0.20621 | −0.57527 | [23] |

| 9 | HT LSF | 839.5 | 17.8 | 0.00946 | −0.04474 | 0.21957 | −0.60018 | |

| 10 | As-built DLD | 908 | 3.8 | 0.022 | −0.135 | 0.03 | −0.53 | [42] |

| 11 | HT DLD | 957 | 3.4 | 0.015 | −0.111 | 0.736 | −0.967 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xi, J.; Hu, Y.; Xing, H.; Han, Y.; Zhang, H.; Jiang, J.; Nikbin, K. The Low-Cycle Fatigue Behavior, Failure Mechanism and Prediction of SLM Ti-6Al-4V Alloy with Different Heat Treatment Methods. Materials 2021, 14, 6276. https://doi.org/10.3390/ma14216276

Xi J, Hu Y, Xing H, Han Y, Zhang H, Jiang J, Nikbin K. The Low-Cycle Fatigue Behavior, Failure Mechanism and Prediction of SLM Ti-6Al-4V Alloy with Different Heat Treatment Methods. Materials. 2021; 14(21):6276. https://doi.org/10.3390/ma14216276

Chicago/Turabian StyleXi, Jiangjing, Yun Hu, Hui Xing, Yuanfei Han, Haiying Zhang, Jun Jiang, and Kamran Nikbin. 2021. "The Low-Cycle Fatigue Behavior, Failure Mechanism and Prediction of SLM Ti-6Al-4V Alloy with Different Heat Treatment Methods" Materials 14, no. 21: 6276. https://doi.org/10.3390/ma14216276

APA StyleXi, J., Hu, Y., Xing, H., Han, Y., Zhang, H., Jiang, J., & Nikbin, K. (2021). The Low-Cycle Fatigue Behavior, Failure Mechanism and Prediction of SLM Ti-6Al-4V Alloy with Different Heat Treatment Methods. Materials, 14(21), 6276. https://doi.org/10.3390/ma14216276