Novel Permanent Magnetic Surface Work Hardening Process for 60/40 Brass

Abstract

1. Introduction

2. Experimental Section

2.1. Materials Preparation and Setup

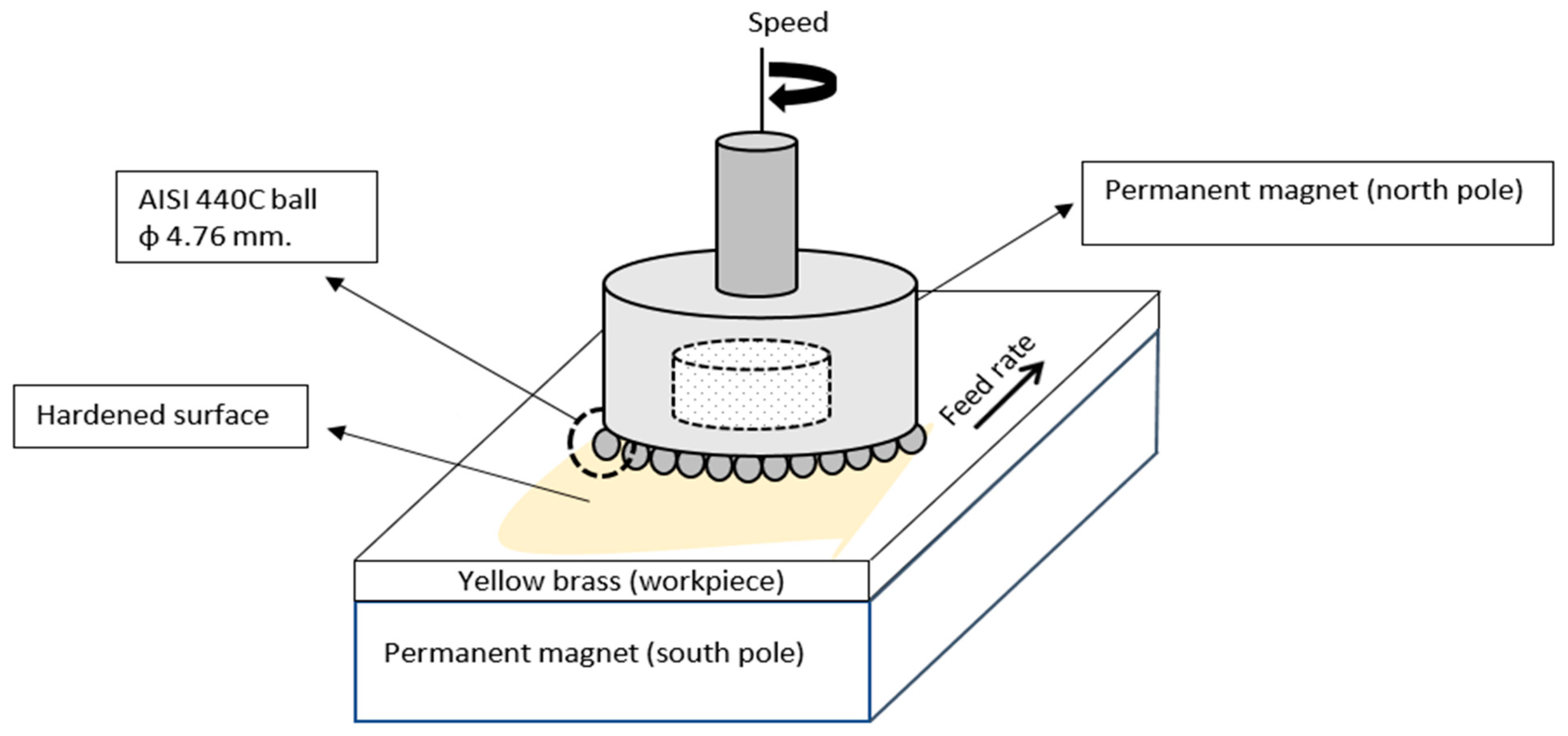

2.2. Permanent Magnetic Surface Hardening Process

2.3. Experimental Tests

3. Results and Discussion

3.1. Optical Microscope

3.2. Microhardness

3.3. Mechanical Properties and Surface Roughness

4. Conclusions

- The MSWH process plastically deforms the brass surface to a depth of 72 µm via the oscillation of balls and friction processes with forces originating from the permanent magnetic field and in the presence of both speed and feed rate.

- The relatively high speed between the stainless steel balls significantly increases the compressive stresses on the surface; therefore, it increases the hardness by 42.7 HV (33%) to 144.3 HV (112.5%) depending on the high speed and primarily the high feed rate. The increment can be improved up to 157.7 HV (123%) with a proper speed–feed rate combination.

- Factorial design was performed using univariate analysis of variance using four levels of hardening speeds and five levels of feed rates, with six repetitions for each case. The results show that hardening speed, feed rate, and their interactions significantly affect microhardness value.

- A nonlinear prediction of microhardness using Equation (1) shows that microhardness increases as speed and feed rate increase, but with more weight in favor of the speed.

- If the balls remain in the magnetic field during the process, the magnetic pressure increases as the relative speed between the stainless steel balls and brass increases. It then increases the plastic deformation on the surface of the brass.

- Both the UTS and ductility remain unchanged, but the yield strength for all processed samples increases by 27.3 MPa (10.8%) regardless of the applied speed and feed rate. The hardened depth of 72 µm, for 1500 rpm and 6 mm min−1, could not contribute to changes in the overall UTS and ductility, while it contributed to increasing the yield strength.

- Using MSWH, Sq and Sa increase because of the high indentation marks of the stainless steel balls on the brass surface in low and high feed rates and their combinations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maleki, E.; Unal, O.; Guagliano, M.; Bagherifard, S. The effects of shot peening, laser shock peening and ultrasonic nanocrystal surface modification on the fatigue strength of Inconel 718. Mater. Sci. Eng. A 2021, 810, 141029. [Google Scholar] [CrossRef]

- Radhi, H.N.; Aljassani, A.M.H.; Mohammed, M.T. Effect of ECAP on microstructure, mechanical and tribological properties of aluminum and brass alloys: A review. Mater. Today Proc. 2020, 26, 2302–2307. [Google Scholar] [CrossRef]

- Schneider, M.J.; Chatterjee, M.S. Introduction to Surface Hardening of Steels, Steel Heat Treating Fundamentals and Processes. In ASM Handbook; Dossett, J.L., Totten, G.E., Eds.; ASM International: Novelty, OH, USA, 2013; Volume 4a, pp. 389–398. [Google Scholar] [CrossRef]

- Soyama, H.; Chighizola, C.R.; Hill, M.R. Effect of compressive residual stress introduced by cavitation peening and shot peening on the improvement of fatigue strength of stainless steel. J. Mater. Process. Technol. 2021, 288, 116877. [Google Scholar] [CrossRef]

- Chen, H.; Guan, Y.; Zhu, L.; Li, Y.; Zhai, J.; Lin, J. Effects of ultrasonic shot peening process parameters on nanocrystalline and mechanical properties of pure copper surface. Mater. Chem. Phys. 2021, 259, 124025. [Google Scholar] [CrossRef]

- Kalisz, J.; Żak, K.; Wojciechowski, S.; Gupta, M.K.; Krolczyk, G.M. Technological and tribological aspects of milling-burnishing process of complex surfaces. Tribol. Int. 2021, 155, 106770. [Google Scholar] [CrossRef]

- Hassan, A.M.; Al-Bsharat, A.S. Influence of burnishing process on surface roughness, hardness, and microstructure of some non-ferrous metals. Wear 1996, 199, 1–8. [Google Scholar] [CrossRef]

- Hassan, A.M.; Al-Jalil, H.F.; Ebied, A.A. Burnishing force and number of ball passes for the optimum surface finish of brass components. J. Mater. Process. Technol. 1998, 83, 176–179. [Google Scholar] [CrossRef]

- Ovali, İ.; Akkurt, A. Comparison of burnishing process with other methods of hole surface finishing processes applied on brass materials. Mater. Manuf. Process. 2011, 26, 1064–1072. [Google Scholar] [CrossRef]

- Luo, H.; Liu, J.; Wang, L.; Zhong, Q. Investigation of the burnishing force during the burnishing process with a cylindrical surfaced tool. J. Eng. 2006, 220, 893–904. [Google Scholar] [CrossRef]

- Hassan, A.M. The effects of ball- and roller-burnishing on the surface roughness and hardness of some non-ferrous metals. J. Mater. Process. Technol. 1997, 72, 385–391. [Google Scholar] [CrossRef]

- Kalpakjian, S. Manufacturing Engineering and Technology, 3rd ed.; Addison-Wesley: New York, NY, USA, 1995. [Google Scholar]

- El-Axir, M.H. An Investigation into Roller Burnishing. Int. J. Mach. Tool. Manuf. 2000, 40, 1603–1617. [Google Scholar] [CrossRef]

- Tripathi, H.; Pungotra, H.; Gandotra, S.; Beri, N.; Kumar, A. Experimental investigation into ball burnishing process of brass using Taguchi approach. Int. J. Sci. Eng. Res. 2013, 4, 66. [Google Scholar]

- Malleswara Rao, J.N.; Chennakesava Reddy, A.; Sumalatha, M. Experimental investigation of the influence of roller burnishing tool passes on surface roughness and hardness of brass specimens. Indian J. Sci. Technol. 2011, 4, 1113–1118. [Google Scholar]

- Morimoto, T. Work hardening and tool surface damage in burnishing. Wear 1988, 127, 149–159. [Google Scholar] [CrossRef]

- Kovács, Z.F.; Viharos, Z.J.; Kodácsy, J. Determination of the working gap and optimal machining parameters for magnetic assisted ball burnishing. Measurement 2018, 118, 172–180. [Google Scholar] [CrossRef]

- Kovács, Z. The Investigation of Tribological Characteristics of Surface Improved by Magnetic Polishing and Roller Burnishing. Procedia Eng. 2016, 149, 183–189. [Google Scholar] [CrossRef][Green Version]

- Kovács, Z.F.; Viharos, Z.J.; Kodácsy, J. Surface flatness and roughness evolution after magnetic assisted ball burnishing of magnetizable and non-magnetizable materials. Measurement 2020, 158, 107750. [Google Scholar] [CrossRef]

- Alaskari, A.; Albannai, A.; Althaqeb, B.; Liptakova, T. Improving the surface quality of 60/40 brass using flexible magnetic burnishing brush formed with permanent magnets. Manuf. Lett. 2020, 24, 113–122. [Google Scholar] [CrossRef]

- Alaskari, A.M.; Albannai, A.I.; Alawadhi, M.Y.; Aloraier, A.S.; Liptakova, T.; Alazemi, A.A. Surface Evaluation of a Multi-Pass Flexible Magnetic Burnishing Brush for Rough and Soft Ground 60/40 Brass. Materials 2020, 13, 4465. [Google Scholar] [CrossRef]

- American Society for Testing Materials International. Test Method for Microindentation Hardness of Materials. J. ASTM Int. 2017. [Google Scholar] [CrossRef]

- American Society for Testing Materials International. Standard Test Methods for Tension Testing of Metallic Materials. J. ASTM Int. 2021. [Google Scholar] [CrossRef]

- Dzierwa, A.; Markopoulos, A.P. Influence of Ball-Burnishing Process on Surface Topography Parameters and Tribological Properties of Hardened Steel. Machines 2019, 7, 11. [Google Scholar] [CrossRef]

- Dai, S.; Zhu, Y.; Huang, Z. Microstructure evolution and strengthening mechanisms of pure titanium with nano-structured surface obtained by high energy shot peening. Vacuum 2016, 125, 215–221. [Google Scholar] [CrossRef]

- Lu, J.Z.; Luo, K.Y.; Zhang, Y.K.; Sun, G.F.; Gu, Y.Y.; Zhou, J.Z.; Ren, X.D.; Zhang, X.C.; Zhang, L.F.; Chen, K.M.; et al. Grain refinement mechanism of multiple laser shock processing impacts on ANSI 304 stainless steel. Acta Mater. 2010, 58, 5354–5362. [Google Scholar] [CrossRef]

- Unal, O.; Varol, R. Surface severe plastic deformation of AISI 304 via conventional shot peening, severe shot peening and repeening. Appl. Surf. Sci. 2015, 351, 289–295. [Google Scholar] [CrossRef]

- Azhari, A.; Schindler, C.; Kerscher, E.; Grad, P. Improving surface hardness of austenitic stainless steel using waterjet peening process. Int. J. Adv. Manuf. Technol. 2012, 63, 1035–1046. [Google Scholar] [CrossRef]

- Ye, L.; Zhu, X.; He, Y.; Song, T.; Hu, W. Surface strengthening and grain refinement of AZ31B magnesium alloy by ultrasonic cavitation modification. Chin. J. Aeronaut. 2021, 34, 508–517. [Google Scholar] [CrossRef]

- Wang, H.B.; Song, G.L.; Tang, G. Evolution of surface mechanical properties and microstructure of Ti–6Al–4V alloy induced by electropulsing-assisted ultrasonic surface rolling process. J. Alloys Compd. 2016, 681, 146–156. [Google Scholar] [CrossRef]

- Ren, C.X.; Wang, Q.; Zhang, Z.J.; Zhu, Y.K. A novel method for achieving gradient microstructure in a Cu–Al alloy: Surface spinning strengthening (3S). Acta Metall. Sin. (Engl. Lett.) 2017, 30, 212–217. [Google Scholar] [CrossRef]

- Ren, C.X.; Wang, Q.; Zhang, Z.J.; Yang, H.J.; Zhang, Z.F. Surface strengthening behaviors of pure Cu with heterogeneous microstructures. Mater. Sci. Eng. A 2018, 727, 192–199. [Google Scholar] [CrossRef]

- Zhang, C.; Fu, T.; Chen, H.; Gao, Y. Microstructure evolution of surface gradient nanocrystalline by shot peening of TA17 titanium alloy. Metall. Mater. Trans. A 2021, 52, 1790–1798. [Google Scholar] [CrossRef]

- Huang, H.W.; Wang, Z.B.; Lu, J.; Lu, K. Fatigue behaviors of AISI 316L stainless steel with a gradient nanostructured surface layer. Acta Mater. 2015, 87, 150–160. [Google Scholar] [CrossRef]

| Material | Fe | Cr | Ni | Mn | Cu | Mo | Zn | C |

|---|---|---|---|---|---|---|---|---|

| C274 (yellow brass) | - | - | 0.13 | - | 60.68 | - | 39.19 | - |

| SS 440C (balls) | 79.15 | 17.05 | - | 0.95 | - | 0.72 | - | 1.09 |

| Tests of Between-Subjects Effects | |||||

|---|---|---|---|---|---|

| Dependent Variable: Microhardness | |||||

| Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

| Corrected Model | 69,754.886 | 19 | 3671.310 | 52.683 | 0.000 |

| Intercept | 6,978,099.677 | 1 | 6,978,099.677 | 100,135.927 | 0.000 |

| Speed | 35,326.914 | 3 | 11,775.638 | 168.981 | 0.000 |

| Feed | 12,969.265 | 4 | 3242.316 | 46.527 | 0.000 |

| Speed × Feed | 21,458.707 | 12 | 1788.226 | 25.661 | 0.000 |

| Error | 6968.627 | 100 | 69.686 | - | - |

| Total | 7,054,823.191 | 120 | - | - | - |

| Corrected Total | 76,723.514 | 119 | - | - | - |

| Iteration History | ||||

| Iteration Number | Residual Sum of Squares | Parameter | ||

| a | b | c | ||

| 1.0 | 7,054,823.191 | 0.000 | 0.000 | 0.000 |

| 1.1 | 6,536,501.331 | 9.129 | 0.000 | 0.000 |

| 2.0 | 6,536,501.331 | 9.129 | 0.000 | 0.000 |

| 2.1 | 322,848.497 | 19.678 | 0.172 | 0.505 |

| 3.0 | 322,848.497 | 19.678 | 0.172 | 0.505 |

| 3.1 | 126,846.409 | 22.166 | 0.190 | 0.480 |

| 4.0 | 126,846.409 | 22.166 | 0.190 | 0.480 |

| 4.1 | 91,876.500 | 25.297 | 0.205 | 0.374 |

| 5.0 | 91,876.500 | 25.297 | 0.205 | 0.374 |

| 5.1 | 79,756.510 | 35.299 | 0.218 | 0.173 |

| 6.0 | 79,756.510 | 35.299 | 0.218 | 0.173 |

| 6.1 | 67,914.867 | 48.136 | 0.190 | 0.123 |

| 7.0 | 67,914.867 | 48.136 | 0.190 | 0.123 |

| 7.1 | 54,908.458 | 61.009 | 0.162 | 0.113 |

| 8.0 | 54,908.458 | 61.009 | 0.162 | 0.113 |

| 8.1 | 49,148.869 | 64.230 | 0.159 | 0.113 |

| 9.0 | 49,148.869 | 64.230 | 0.159 | 0.113 |

| 9.1 | 49,142.959 | 64.283 | 0.159 | 0.113 |

| 10.0 | 49,142.959 | 64.283 | 0.159 | 0.113 |

| 10.1 | 49,142.959 | 64.283 | 0.159 | 0.113 |

| Parameter Estimates | ||||

| 95% Confidence Interval | ||||

| Parameter | Estimate | Std. Error | Lower Bound | Upper Bound |

| a | 64.283 | 10.747 | 42.999 | 85.568 |

| b | 0.159 | 0.023 | 0.113 | 0.204 |

| c | 0.113 | 0.026 | 0.061 | 0.164 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alaskari, A.M.; Albannai, A.I.; Aloraier, A.S.; Alawadhi, M.Y.; Liptáková, T. Novel Permanent Magnetic Surface Work Hardening Process for 60/40 Brass. Materials 2021, 14, 6312. https://doi.org/10.3390/ma14216312

Alaskari AM, Albannai AI, Aloraier AS, Alawadhi MY, Liptáková T. Novel Permanent Magnetic Surface Work Hardening Process for 60/40 Brass. Materials. 2021; 14(21):6312. https://doi.org/10.3390/ma14216312

Chicago/Turabian StyleAlaskari, Ayman M., Abdulaziz I. Albannai, Abdulkareem S. Aloraier, Meshal Y. Alawadhi, and Tatiana Liptáková. 2021. "Novel Permanent Magnetic Surface Work Hardening Process for 60/40 Brass" Materials 14, no. 21: 6312. https://doi.org/10.3390/ma14216312

APA StyleAlaskari, A. M., Albannai, A. I., Aloraier, A. S., Alawadhi, M. Y., & Liptáková, T. (2021). Novel Permanent Magnetic Surface Work Hardening Process for 60/40 Brass. Materials, 14(21), 6312. https://doi.org/10.3390/ma14216312