Study on Dry Sliding Wear and Friction Behaviour of Al7068/Si3N4/BN Hybrid Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composite Fabrication

2.3. Microstructural Analysis and Hardness Test

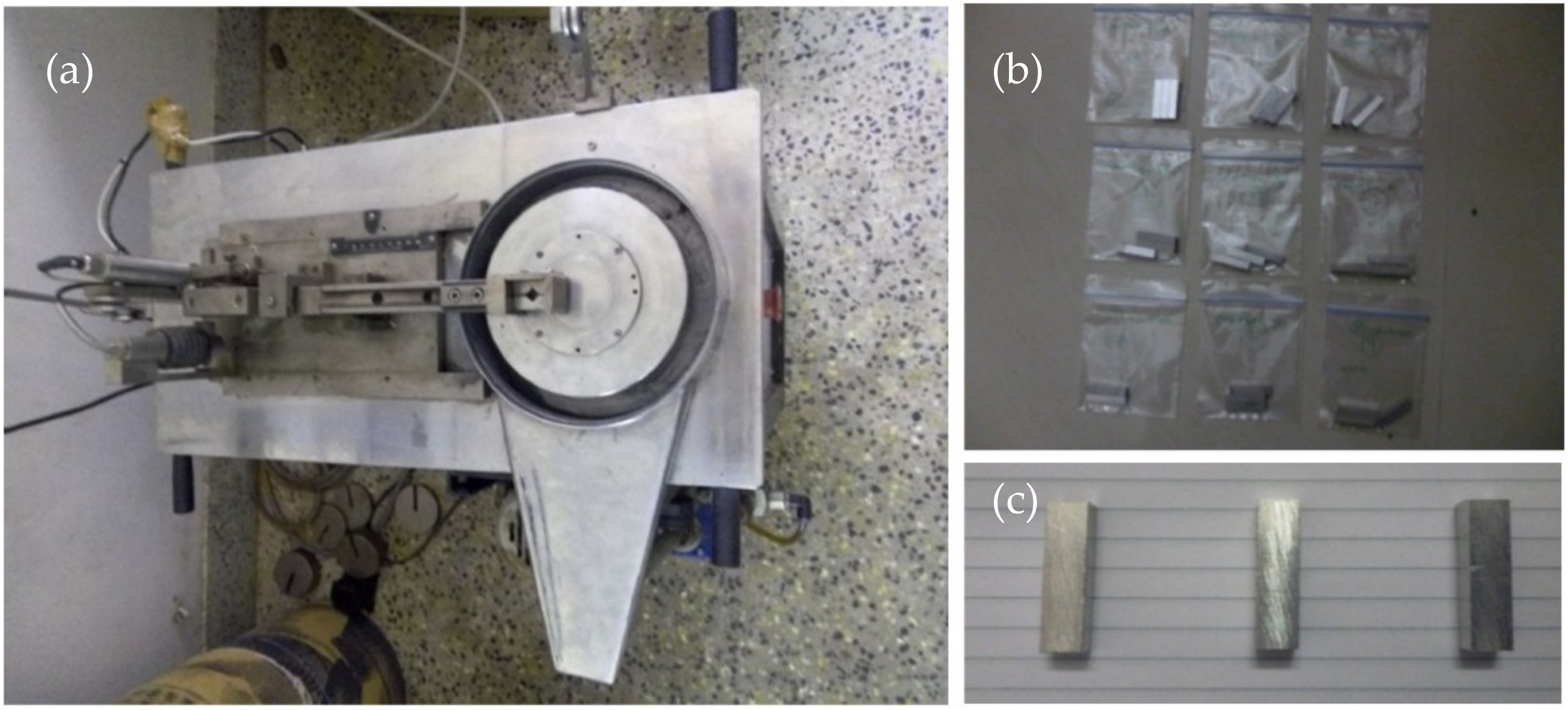

2.4. Dry Sliding Wear Study on AMMCs

2.5. Plan of Wear Experiments

3. Results and Discussion

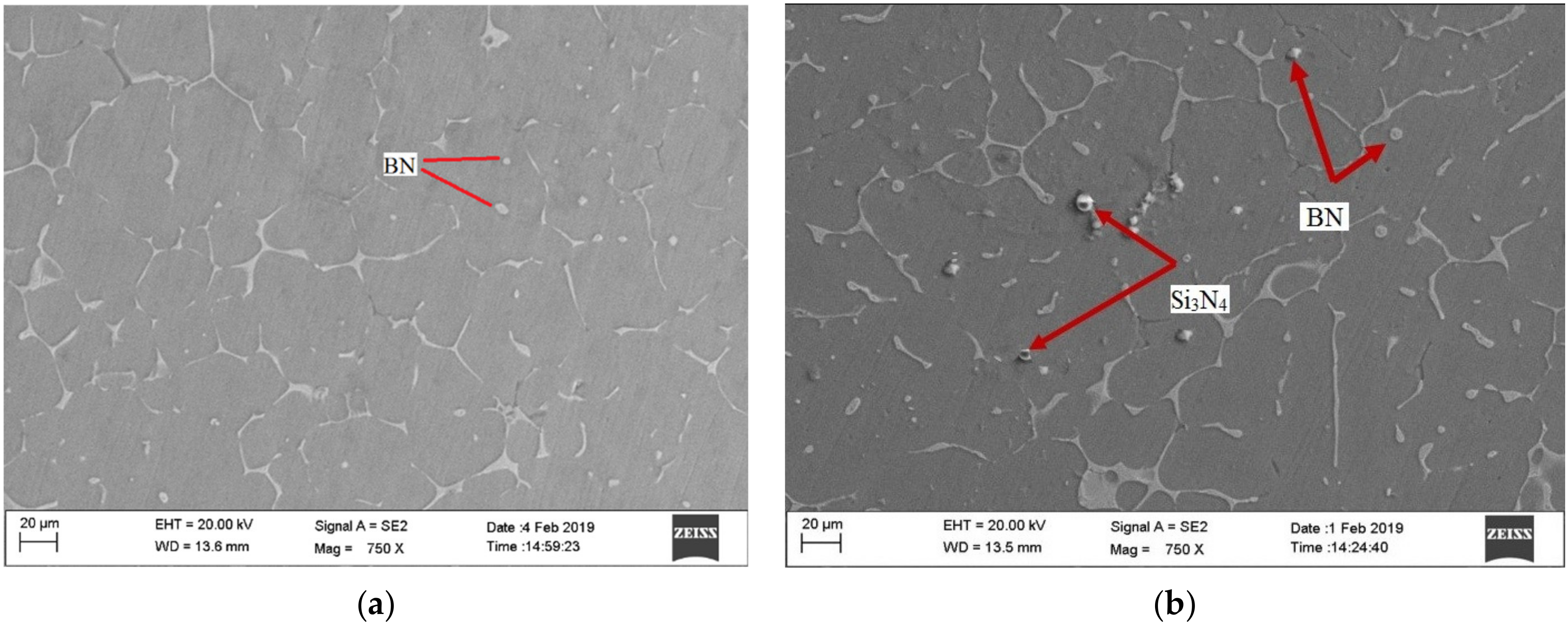

3.1. Microstructural Evolution of AMMCs

3.2. Hardness of AMMCs

3.3. Wear Rate and COF

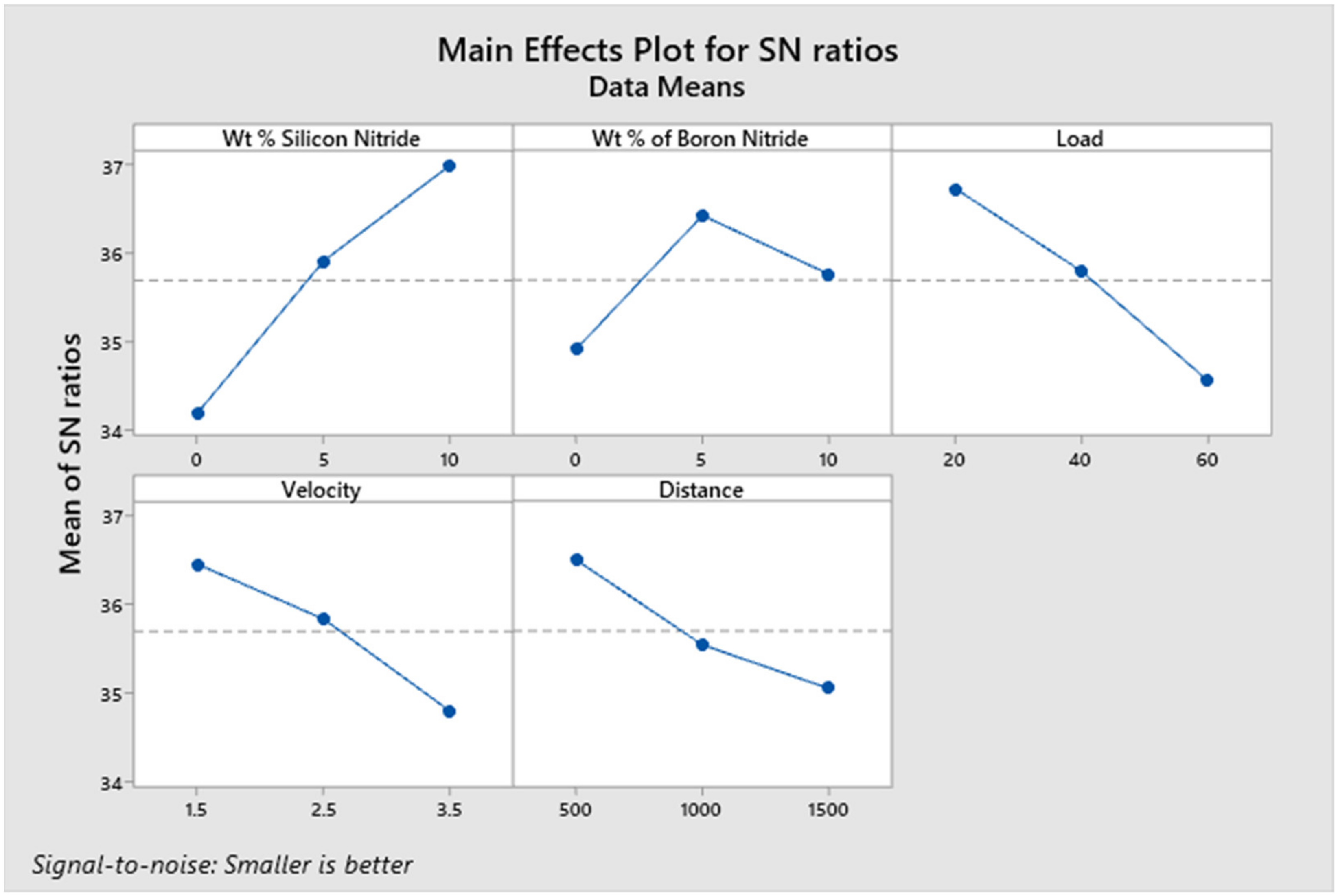

3.4. Effect of Independent Process Parameters on the Wear Rate

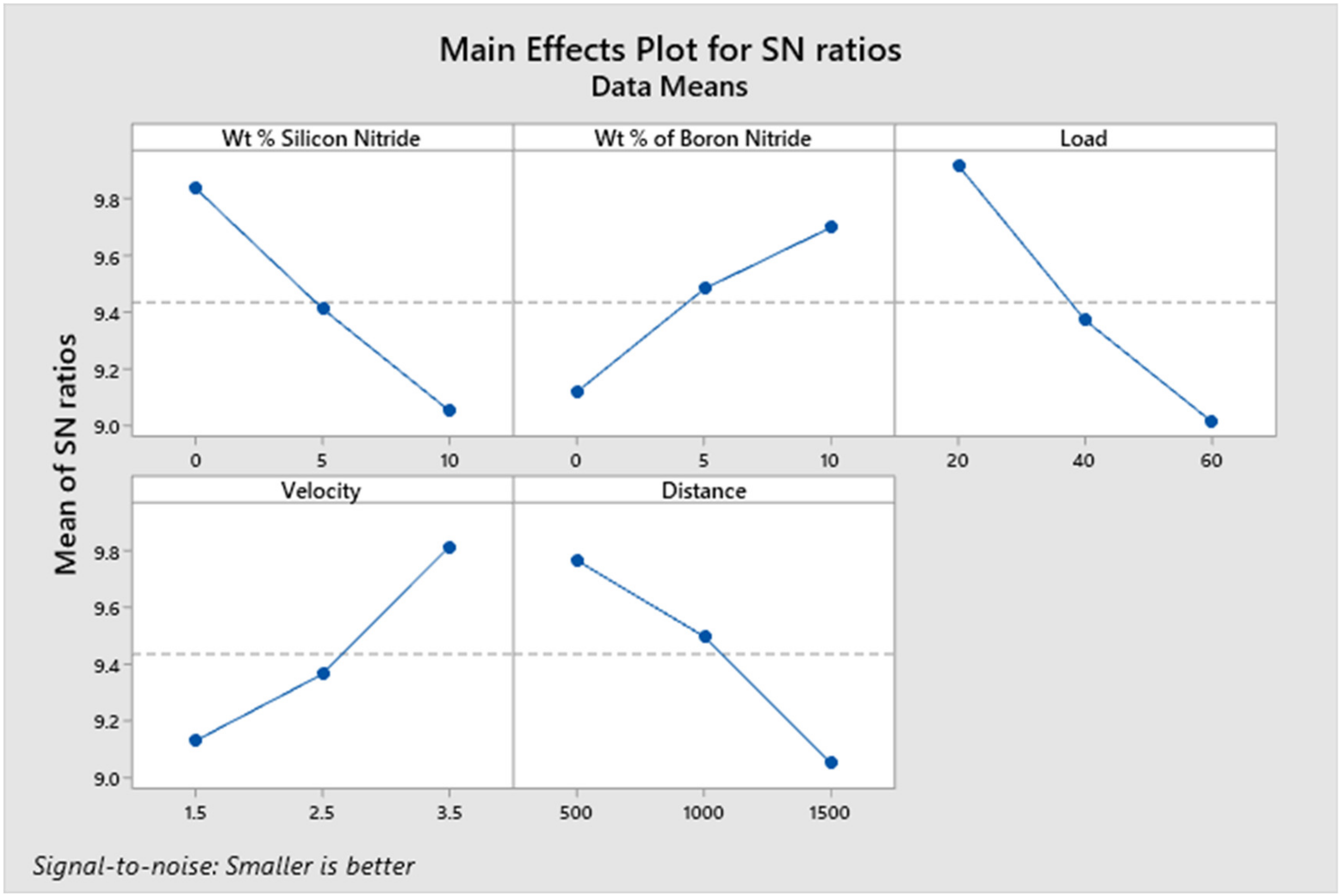

3.5. Effect of Independent Process Parameters on COF

3.6. ANOVA

3.7. Mathematical Modelling

3.8. Confirmation Experimental Runs

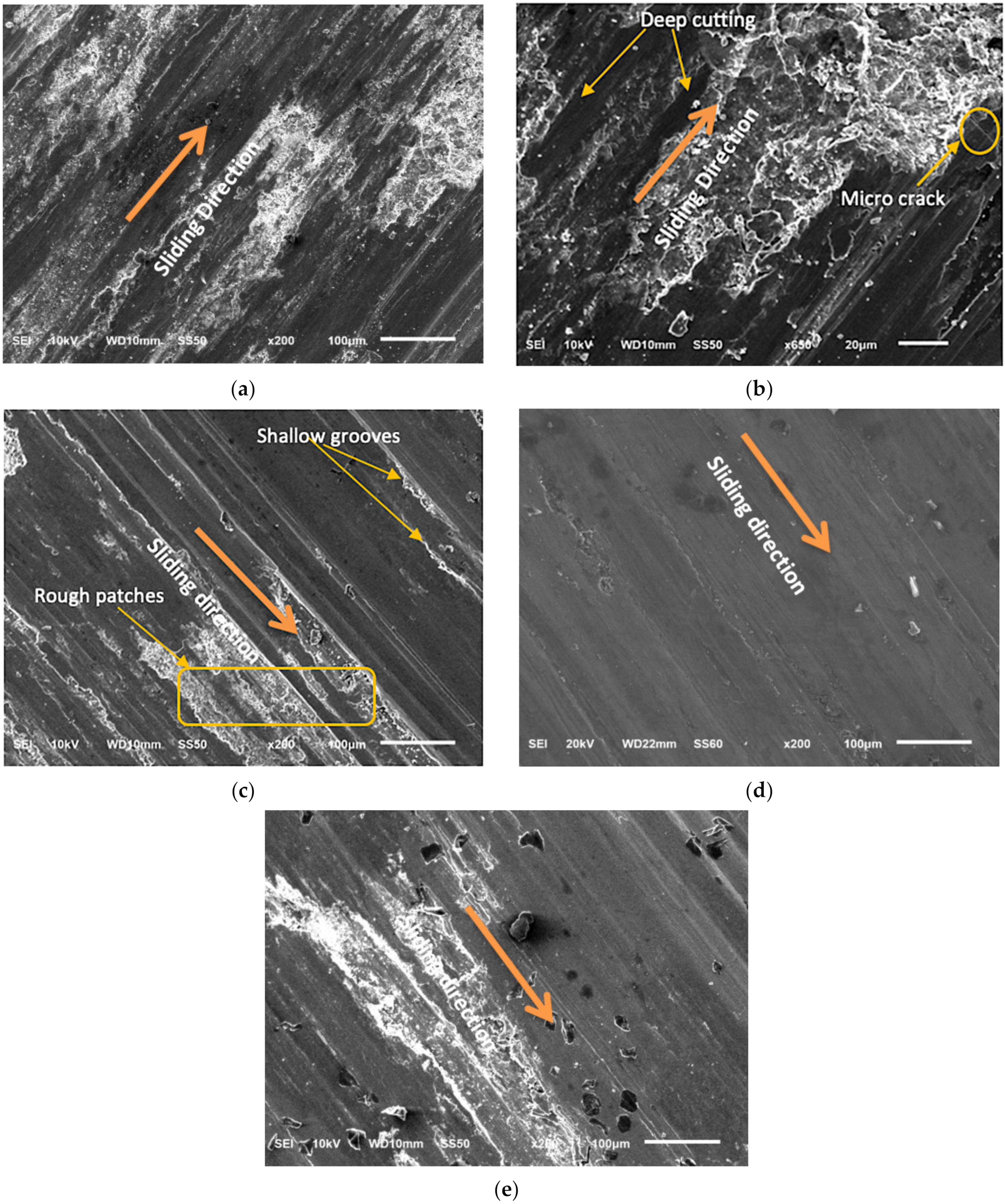

3.9. Analysis of Worn-Out Surface of Wear Specimens

4. Conclusions

- The highest hardness value of the hybrid composite was obtained with the addition of 10 wt. % of Si3N4 and 5 wt. % of BN.

- The wear rate of the fabricated composite materials decreases with the addition of Si3N4 content. However, COF exhibited an increasing trend.

- The increase in BN content leads to a decrease in COF. However, wear rate initially decreases, up to 5 wt. %, and after that, increases.

- The minimum wear rate was found with the composite material reinforced with 10 wt. % of Si3N4 and 5 wt. % of BN.

- COF increases with the increase in applied load and sliding distance. However, an increase in sliding velocity lowers COF.

- ANOVA results conclude that wt. % of Si3N4 (36.60%) has more of a contribution percentage on wear rate followed by load (23.01%).

- In the case of COF, load (29.73%) is the most influencing parameter, followed by wt. % of Si3N4 (22.12%).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dursun, T.; Soutis, C. Recent deveompents in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Janeczek, A.; Tomków, J.; Fydrych, D. The Influence of Tool Shape and Process Parameters on the Mechanical Properties of AW-3004 Aluminium Alloy Friction Stir Welded Joints. Materials 2021, 14, 3244. [Google Scholar] [CrossRef]

- Baradeswaran, A.; Vettivel, S.C.; Perumal, A.E.; Selvakumar, N.; Issac, R.F. Experimental investigation on mechanical behaviour, modelling and optimization of wear parameters of B4C and graphite reinforced aluminium hybrid composites. Mater. Des. 2014, 63, 620–632. [Google Scholar] [CrossRef]

- Daniel, S.A.A.; Sakthivel, M.; Gopal, P.M.; Sudhagar, S. Study on Tribological Behaviour of Al/SiC/MoS2 Hybrid Metal Matrix Composites in High Temperature Environmental Condition. Silicon 2018, 10, 2129–2139. [Google Scholar] [CrossRef]

- Bodunrin, M.O.; Alaneme, K.K.; Chown, L.H. Aluminium matrix hybrid composites: A review of reinforcement philosophies; mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 2015, 4, 434–445. [Google Scholar] [CrossRef] [Green Version]

- Baradeswaran, A.; Elayaperumal, A.; Franklin Issaca, R. A statistical analysis of optimization of wear behaviour of Al-Al2O3 composites using Taguchi technique. Procedia Eng. 2013, 64, 973–982. [Google Scholar] [CrossRef] [Green Version]

- Daniel, A.A.; Murugesan, S.; Sukkasamy, S. Dry Sliding Wear Behaviour of Aluminium 5059/SiC/MoS2 Hybrid Metal Matrix Composites. Mater. Res. 2017, 20, 1697–1706. [Google Scholar] [CrossRef] [Green Version]

- Lotfy, A.; Pozdniakov, A.V.; Zolotorevskiy, V.S.; Abou El-khair, M.T.; Daoud, A.; Mochugovskiy, A.G. Novel preparation of Al-5%Cu / BN and Si3N4 composites with analyzing microstructure, thermal and mechanical properties. Mater. Charact. 2018, 136, 144–151. [Google Scholar] [CrossRef]

- Birari, U.P.; Shelke, R.S. Investigation of Tribological characteristics of Al7068+B4C+Gr Hybrid Composite for Defence application. Int. J. Adv. Res. Innov. Ideas. Educ. 2017, 3, 1012–1021. [Google Scholar]

- Madhusudhan, M.; Naveen, G.J.; Mahesha, K. Mechanical Characterization of AA7068-ZrO2 reinforced Metal Matrix Composites. Mater. Today. Proc. 2017, 4, 3122–3130. [Google Scholar] [CrossRef]

- Alipour, M.; Eslami-Farsani, R. Synthesis and characterization of graphene nanoplatelets reinforced AA7068 matrix nanocomposites produced by liquid metallurgy route. Mater. Sci. Eng. A 2017, 706, 71–82. [Google Scholar] [CrossRef]

- Riley, F.L. Silicon nitride and related materials. J. Am. Ceram. Soc. 2000, 83, 245–265. [Google Scholar] [CrossRef]

- Sharma, N.; Khanna, R.; Singh, G.; Kumar, V. Fabrication of 6061 aluminum alloy reinforced with Si3N4/n-Gr and its wear performance optimization using integrated RSM-GA. Particul. Sci. Technol. 2016, 35, 1–11. [Google Scholar] [CrossRef]

- Suryanarayana, R.C.; Khan, S.; Koppad, P.G.; Khan, Z. Tribological behaviour of hot extruded Al6061-Si3N4 composite. In ASME 2013 International Mechanical Engineering Congress and Exposition; American Society Of Mechanical Engineers: New York, NY, USA, 2013; p. V02ATA050. [Google Scholar]

- Arik, H. Effect of mechanical alloying process on mechanical properties of a-Si3N4 reinforced aluminum-based composite materials. Mater. Des. 2008, 29, 1856–1861. [Google Scholar] [CrossRef]

- Cambronero, L.; Sanchez, E.; Ruiz-Roman, J.; Ruiz-Prieto, J. Mechanical characterization of AA7015 aluminium alloy reinforced with ceramics. J. Mater. Process. Technol. 2003, 143, 378–383. [Google Scholar] [CrossRef]

- Duan, X.; Yang, Z.; Chen, L.; Tian, Z.; Cai, D.; Wang, Y.; Jia, D.; Yu, Z. Review on the properties of hexagonal boron nitride matrix composite ceramics. J. Eur. Ceram. Soc. 2016, 36, 3725–3737. [Google Scholar] [CrossRef]

- Sathish, T.; Mohanavel, V.; Arunkumar, T.; Raja, T.; Rashedi, A.; Alarifi, I.M.; Badruddin, I.A.; Algahtani, A.; Afzal, A. Investigation of Mechanical Properties and Salt Spray Corrosion Test Parameters Optimization for AA8079 with Reinforcement of TiN + ZrO2. Materials 2021, 14, 5260. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Ezatpour, H.; Beygi, H. Microstructure and mechanical properties of Al–Al2O3 micro and nano composites fabricated by stir casting. Mat. Sci. Eng. A Struct. 2011, 528, 8765–8771. [Google Scholar] [CrossRef]

- Omrani, E.; Moghadam, A.D.; Menezes, P.L.; Rohatgi, P.K. Influences of graphite reinforcement on the tribological properties of self-lubricating aluminum matrix composites for green tribology, sustainability, and energy efficiency—A review. Int. J. Adv. Manuf. Technol. 2016, 83, 325–346. [Google Scholar] [CrossRef]

- Khatavkar, R.A.; Mandave, A.K.; Baviskar, D.D.; Shinde, S.L. Influence of Hexagonal Boron Nitride on Tribological Properties of AA2024-hBN Metal Matrix Composite. Int. Res. J. Eng. Tech. 2018, 5, 3792–3798. [Google Scholar]

- Ul Haq, M.I.; Anand, A. Dry Sliding Friction andWear Behavior of AA7075-Si3N4 Composite. Silicon 2018, 10, 1819–1829. [Google Scholar] [CrossRef]

- Ul Haq, M.I.; Anand, A. Dry sliding friction and wear behaviour of Hybrid AA7075/Si3N4 /Gr selflubricating composites. Mater. Res. Express 2018, 5, 066544. [Google Scholar] [CrossRef]

- Radhika, N.; Subramanian, R.; Venkat Prasat, S.; Anandavel, B. Dry sliding wear behaviour of aluminium/alumina/graphite hybrid metal matrix composites. Ind. Lubr. Tribol. 2012, 64, 359–366. [Google Scholar] [CrossRef]

- Mungara, S.R.; Manohar, H.S.; Trishul, M.A. Study of mechanical characteristics of stir cast AA7050-B4C metal matrix ceramic composites. Mater. Today Proc. 2021, 37, 1463–1468. [Google Scholar] [CrossRef]

- Usca, Ü.A.; Uzun, M.; Kuntoğlu, M.; Şap, S.; Giasin, K.; Pimenov, D.Y. Tribological Aspects, Optimization and Analysis of Cu-B-CrC Composites Fabricated by Powder Metallurgy. Materials 2021, 14, 4217. [Google Scholar] [CrossRef]

- Güneş, A.; Şahin, Ö.S.; Düzcükoğlu, H.; Salur, E.; Aslan, A.; Kuntoğlu, M.; Giasin, K.; Pimenov, D.Y. Optimization Study on Surface Roughness and Tribological Behavior of Recycled Cast Iron Reinforced Bronze MMCs Produced by Hot Pressing. Materials 2021, 14, 3364. [Google Scholar] [CrossRef]

- Harichandran, R.; Selvakumar, N.; Venkatachalam, G. High Temperature Wear Behaviour of Nano/Micro B4C Reinforced Aluminium Matrix Composites Fabricated by an Ultrasonic Cavitation-Assisted Solidification Process. Trans. Indian Inst. Met. 2017, 70, 17–29. [Google Scholar] [CrossRef]

- AnandhaKumar, C.J.; Mohan, D.G. Predicting the ultimate tensile strength and wear rate of aluminium hybrid surface composites fabricated via friction stir processing using computational methods. J. Adhes. Sci. Technol. 2021, 1–20. [Google Scholar] [CrossRef]

- Kuldeep, B.; Ravikumar, K.P.; Pradeep, S.; Gopi, K.R. Effect of boron nitride and zirconium dioxide on mechanical behavior of Al7075 metal matrix hybrid composite. Mater. Res. Express 2018, 6, 036509. [Google Scholar] [CrossRef]

- Broniszewski, K.; Woźniak, J.; Czechowski, K.; Orłowski, P.; Olszyna, A. Properties of Al2O3—hBN Composites. Int. J. Mater. Metall. Eng. 2012, 6, 653–656. [Google Scholar]

- Selvakumar, N.; Narayanasamy, P. Optimization and effect of weight fraction of MoS2 on the tribological behavior of Mg-TiC-MoS2 hybrid composites. Tribol.Trans. 2016, 59, 733–747. [Google Scholar] [CrossRef]

- Kumar, S.; Sakthivel, M.; Sudhagar, S.; Nivethan, K. Investigation on Tribological behaviour of Al7068/Si3N4/BN Hybrid Composites under Dry Sliding Condition. Mater. Res. Express 2019, 6, 066502. [Google Scholar] [CrossRef]

- AnandhaKumar, C.J.; Gopi, S.; Shashi Kumar, S.; Mohan, D.G. Mechanical, Metallurgical and Tribological Properties of Friction Stir Processed Aluminium Alloy 6061 Hybrid Surface Composites. Surf. Topogr. Metrol. Prop. 2021, (in press). [Google Scholar] [CrossRef]

- Umanath, K.; Palanikumar, K.; Selvamani, S.T. Analysis of dry sliding wear behaviour of Al6061/SiC/Al2O3 hybrid metal matrix composites. Compos. Part B Eng. 2013, 53, 159–168. [Google Scholar] [CrossRef]

- Ravindran, P.; Manisekar, K.; Narayanasamy, R.; Narayanasamy, P. Tribological behaviour of powder metallurgy-processed aluminium hybrid composites with the addition of graphite solid lubricant. Ceram. Int. 2013, 39, 1169–1182. [Google Scholar] [CrossRef]

- Dolata-Grosz, A.; Wieczorek, J. Tribological properties of hybrid composites containing two carbide phases. Arch. Mater. Sci. Eng. 2007, 28, 149–155. [Google Scholar]

- Carbone, G.; Bottiglione, F. Asperity contact theories: Do they predict linearity between contact area and load? J. Mech. Phys. Solids 2008, 56, 2555–2572. [Google Scholar] [CrossRef]

- Chen, W.W.; Wang, Q.J. Thermomechanical analysis of elastoplastic bodies in a sliding spherical contact and the effects of sliding speed, heat partition, and thermal softening. J. Tribol. 2008, 130, 041402. [Google Scholar] [CrossRef]

- Kim, H.J.; Emge, A.; Karthikeyan, S.; Rigney, D.A. Effects of tribooxidation on sliding behavior of aluminium. Wear 2005, 259, 501–505. [Google Scholar] [CrossRef]

- Rajeev, V.R.; Dwivedi, D.K.; Jain, S.C. Effect of experimental parameters on reciprocating wear behavior of Al-Si-SiCp composites under dry condition. Tribol. Online. 2009, 4, 115–126. [Google Scholar] [CrossRef] [Green Version]

- Tomków, J.; Fydrych, D.; Rogalski, G.; Łabanowski, J. Effect of welding environment and storage time of electrodes on the diffusible hydrogen content in deposited metal. Rev. Metal. 2019, 55, e140. [Google Scholar] [CrossRef] [Green Version]

- Şap, E.; Usca, Ü.A.; Gupta, M.K.; Kuntoğlu, M.; Sarıkaya, M.; Pimenov, D.Y.; Mia, M. Parametric Optimization for Improving the Machining Process of Cu/Mo-SiCP Composites Produced by Powder Metallurgy. Materials 2021, 14, 1921. [Google Scholar] [CrossRef]

- Suresh, S.; Sridhara, B.K. Wear characteristics of hybrid aluminium matrix composites reinforced with graphite and silicon carbide particles. Compos. Sci. Technol. 2010, 70, 1652–1659. [Google Scholar] [CrossRef]

- Güneş, A.; Salur, E.; Aslan, A.; Kuntoğlu, M.; Giasin, K.; Pimenov, D.Y.; Düzcükoğlu, H.; Şahin, Ö.S. Towards Analysis and Optimization for Contact Zone Temperature Changes and Specific Wear Rate of Metal Matrix Composite Materials Produced from Recycled Waste. Materials 2021, 14, 5145. [Google Scholar] [CrossRef]

- Mahdavi, S.; Akhlaghi, F. Effect of the Graphite Content on the Tribological Behavior of Al/Gr and Al/30SiC/Gr Composites Processed by In Situ Powder Metallurgy (IPM) Method. Tribol. Lett. 2011, 44, 1–12. [Google Scholar] [CrossRef]

| Elements | Zn | Mg | Cu | Fe | Zr | Si | Mn | Ti | Cr | Others | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight % | 8.3 | 3.0 | 2.4 | 0.15 | 0.15 | 0.12 | 0.1 | 0.01 | 0.05 | 0.20 | balance |

| Sample Number | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 |

|---|---|---|---|---|---|---|---|---|---|

| Weight percentage of Si3N4 | 0 | 0 | 0 | 5 | 5 | 5 | 10 | 10 | 10 |

| Weight percentage of BN | 0 | 5 | 10 | 0 | 5 | 10 | 0 | 5 | 10 |

| Code | Parameter | Unit | Level | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| A | Weight fraction of Si3N4 | % | 0 | 5 | 10 |

| B | Weight fraction of BN | % | 0 | 5 | 10 |

| C | Load | N | 20 | 40 | 60 |

| D | Sliding velocity | m/s | 1.5 | 2.5 | 3.5 |

| E | Sliding distance | M | 500 | 1000 | 1500 |

| Sample No | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 |

|---|---|---|---|---|---|---|---|---|---|

| Hardness (BHN) | 97.1 | 98.6 | 99.6 | 104.6 | 105 | 107 | 103 | 108 | 107 |

| Sl.No | Weight Fraction of Si3N4 (%) | Weight Fraction of BN (%) | Load (N) | Sliding Velocity (m/s) | Sliding Distance (m) | Wear Rate (mg/m) | S/N Ratio for Wear Rate | COF | S/N Ratio for COF |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 20 | 1.5 | 500 | 0.0158 | 36.0269 | 0.315 | 10.0338 |

| 2 | 0 | 0 | 20 | 1.5 | 1000 | 0.0178 | 34.9916 | 0.324 | 9.7891 |

| 3 | 0 | 0 | 20 | 1.5 | 1500 | 0.0187 | 34.5632 | 0.344 | 9.2688 |

| 4 | 0 | 5 | 40 | 2.5 | 500 | 0.0164 | 35.7031 | 0.309 | 10.2008 |

| 5 | 0 | 5 | 40 | 2.5 | 1000 | 0.0182 | 34.7986 | 0.326 | 9.7356 |

| 6 | 0 | 5 | 40 | 2.5 | 1500 | 0.0179 | 34.9429 | 0.342 | 9.3195 |

| 7 | 0 | 10 | 60 | 3.5 | 500 | 0.0248 | 32.1110 | 0.294 | 10.6331 |

| 8 | 0 | 10 | 60 | 3.5 | 1000 | 0.0232 | 32.6902 | 0.314 | 10.0614 |

| 9 | 0 | 10 | 60 | 3.5 | 1500 | 0.0256 | 31.8352 | 0.335 | 9.4991 |

| 10 | 5 | 0 | 40 | 3.5 | 500 | 0.0175 | 35.1392 | 0.327 | 9.7090 |

| 11 | 5 | 0 | 40 | 3.5 | 1000 | 0.0178 | 34.9916 | 0.334 | 9.5251 |

| 12 | 5 | 0 | 40 | 3.5 | 1500 | 0.0228 | 32.8413 | 0.354 | 9.0199 |

| 13 | 5 | 5 | 60 | 1.5 | 500 | 0.0148 | 36.5948 | 0.356 | 8.9710 |

| 14 | 5 | 5 | 60 | 1.5 | 1000 | 0.0156 | 36.1375 | 0.360 | 8.8739 |

| 15 | 5 | 5 | 60 | 1.5 | 1500 | 0.0158 | 36.0269 | 0.382 | 8.3587 |

| 16 | 5 | 10 | 20 | 2.5 | 500 | 0.0125 | 38.0618 | 0.297 | 10.5449 |

| 17 | 5 | 10 | 20 | 2.5 | 1000 | 0.0147 | 36.6537 | 0.313 | 10.0891 |

| 18 | 5 | 10 | 20 | 2.5 | 1500 | 0.0146 | 36.7129 | 0.330 | 9.6297 |

| 19 | 10 | 0 | 60 | 2.5 | 500 | 0.0153 | 36.3062 | 0.378 | 8.4502 |

| 20 | 10 | 0 | 60 | 2.5 | 1000 | 0.0185 | 34.6566 | 0.381 | 8.3815 |

| 21 | 10 | 0 | 60 | 2.5 | 1500 | 0.0185 | 34.6566 | 0.402 | 7.9155 |

| 22 | 10 | 5 | 20 | 3.5 | 500 | 0.0109 | 39.2515 | 0.309 | 10.2008 |

| 23 | 10 | 5 | 20 | 3.5 | 1000 | 0.0135 | 37.3933 | 0.316 | 10.0063 |

| 24 | 10 | 5 | 20 | 3.5 | 1500 | 0.0143 | 36.8933 | 0.328 | 9.6825 |

| 25 | 10 | 10 | 40 | 1.5 | 500 | 0.0109 | 39.2515 | 0.349 | 9.1435 |

| 26 | 10 | 10 | 40 | 1.5 | 1000 | 0.0133 | 37.5230 | 0.355 | 8.9954 |

| 27 | 10 | 10 | 40 | 1.5 | 1500 | 0.0142 | 36.9542 | 0.367 | 8.7067 |

| Source | Degree of Freedom | Sum of Squares | Mean Square | F-Value | p-Value | Percent Contribution (%) |

|---|---|---|---|---|---|---|

| wt. % of Si3N4 | 2 | 0.000138 | 0.000069 | 59.21 | 0.000 | 36.60 |

| wt. % of BN | 2 | 0.000037 | 0.000018 | 15.72 | 0.000 | 9.71 |

| Load | 2 | 0.000087 | 0.000043 | 37.22 | 0.000 | 23.01 |

| Sliding velocity | 2 | 0.000066 | 0.000033 | 28.35 | 0.000 | 17.52 |

| Sliding distance | 2 | 0.000031 | 0.000015 | 13.29 | 0.000 | 8.22 |

| Error | 16 | 0.000019 | 0.000001 | 4.94 | ||

| Total | 26 | 0.000377 | 100 |

| Source | Degree of Freedom | Sum of Squares | Mean Square | F-Value | p-Value | Percent Contribution (%) |

|---|---|---|---|---|---|---|

| wt. % of Si3N4 | 2 | 0.004424 | 0.002212 | 125.60 | 0.000 | 22.12 |

| wt. % of BN | 2 | 0.002395 | 0.001197 | 67.99 | 0.000 | 11.97 |

| Load | 2 | 0.005947 | 0.002973 | 168.84 | 0.000 | 29.73 |

| Sliding velocity | 2 | 0.003387 | 0.001693 | 96.16 | 0.000 | 16.93 |

| Sliding distance | 2 | 0.003568 | 0.001784 | 101.31 | 0.000 | 17.84 |

| Error | 16 | 0.000282 | 0.000018 | 1.41 | ||

| Total | 26 | 0.020003 | 100 |

| Ex. No. | Wt. % of Si3N4 | Wt. % of BN | Load (N) | Sliding Velocity (m/s) | Sliding Distance (m) |

|---|---|---|---|---|---|

| 1 | 5 | 10 | 30 | 2.0 | 600 |

| 2 | 10 | 5 | 50 | 3.0 | 1200 |

| Ex. No. | Confirmation Test Wear Rate (mg/m) | Computed Wear Rate (mg/m) | Error (%) | Confirmation Test COF | Computed COF | Error (%) |

|---|---|---|---|---|---|---|

| 1 | 0.0131 | 0.01348 | 2.82 | 0.321 | 0.31384 | 2.28 |

| 2 | 0.0164 | 0.01710 | 4.09 | 0.374 | 0.36242 | 3.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Subramanian, K.; Murugesan, S.; Mohan, D.G.; Tomków, J. Study on Dry Sliding Wear and Friction Behaviour of Al7068/Si3N4/BN Hybrid Composites. Materials 2021, 14, 6560. https://doi.org/10.3390/ma14216560

Subramanian K, Murugesan S, Mohan DG, Tomków J. Study on Dry Sliding Wear and Friction Behaviour of Al7068/Si3N4/BN Hybrid Composites. Materials. 2021; 14(21):6560. https://doi.org/10.3390/ma14216560

Chicago/Turabian StyleSubramanian, Kumar, Sakthivel Murugesan, Dhanesh G. Mohan, and Jacek Tomków. 2021. "Study on Dry Sliding Wear and Friction Behaviour of Al7068/Si3N4/BN Hybrid Composites" Materials 14, no. 21: 6560. https://doi.org/10.3390/ma14216560

APA StyleSubramanian, K., Murugesan, S., Mohan, D. G., & Tomków, J. (2021). Study on Dry Sliding Wear and Friction Behaviour of Al7068/Si3N4/BN Hybrid Composites. Materials, 14(21), 6560. https://doi.org/10.3390/ma14216560