Preparation of Nano/Micro Bimodal Aluminum Powder by Electrical Explosion of Wires

Abstract

:1. Introduction

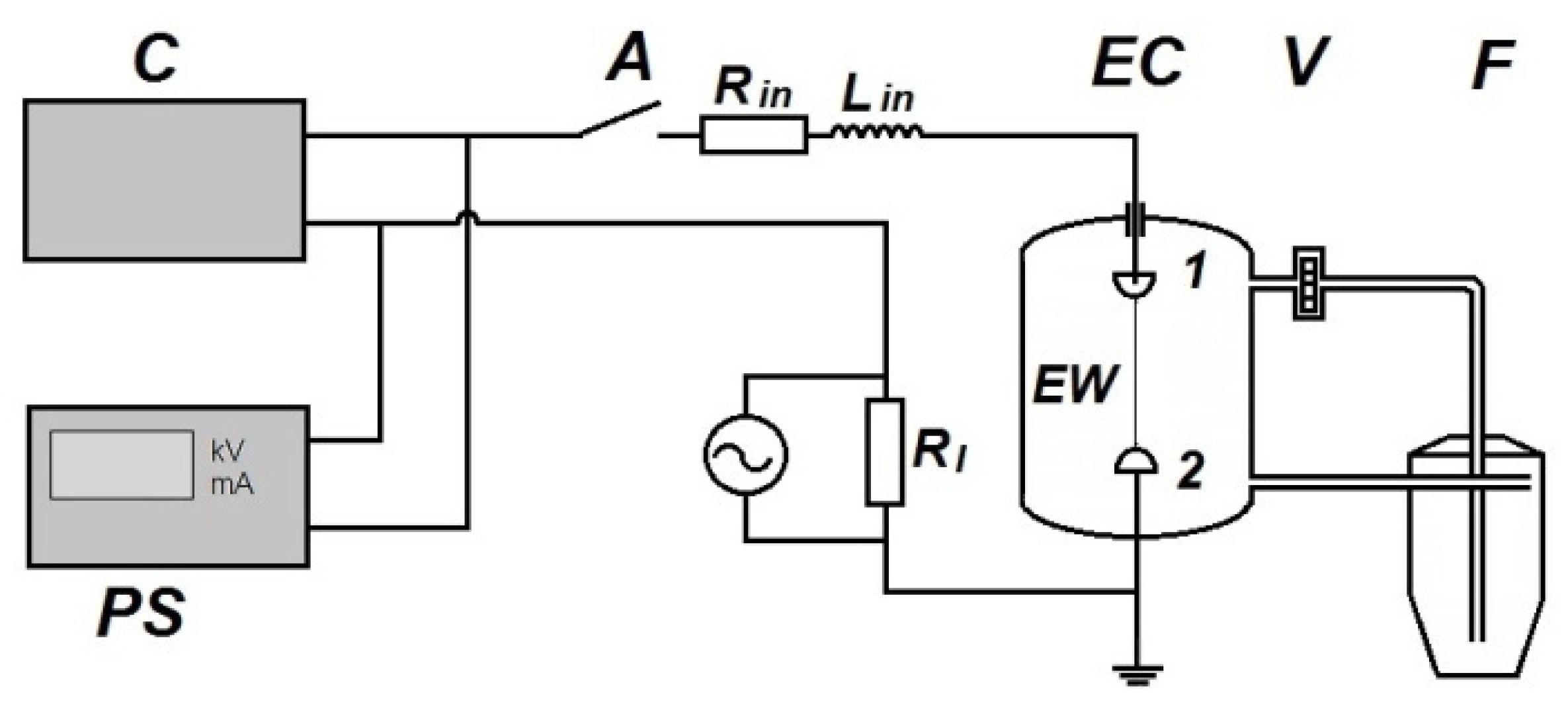

2. Experimental Procedure

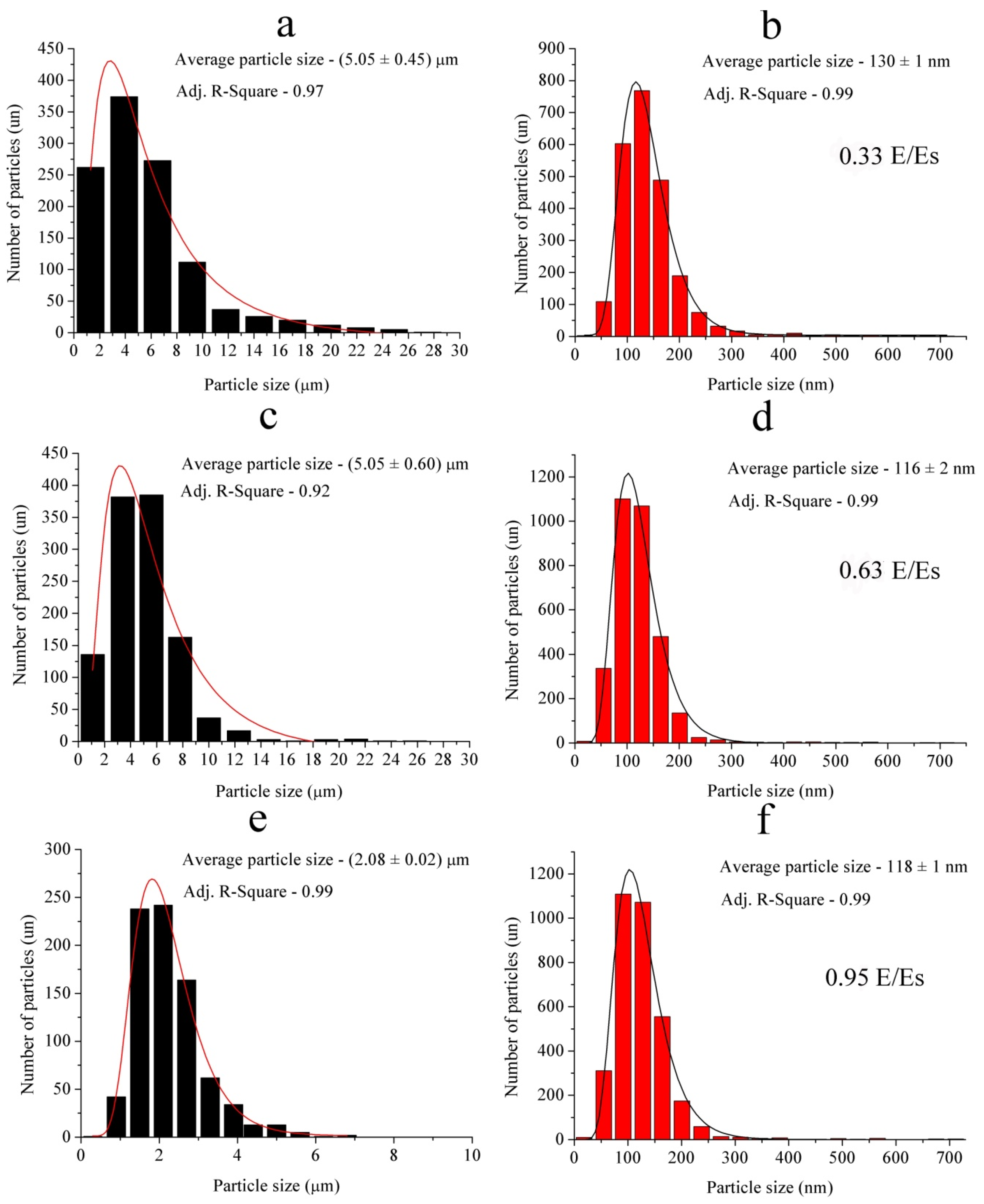

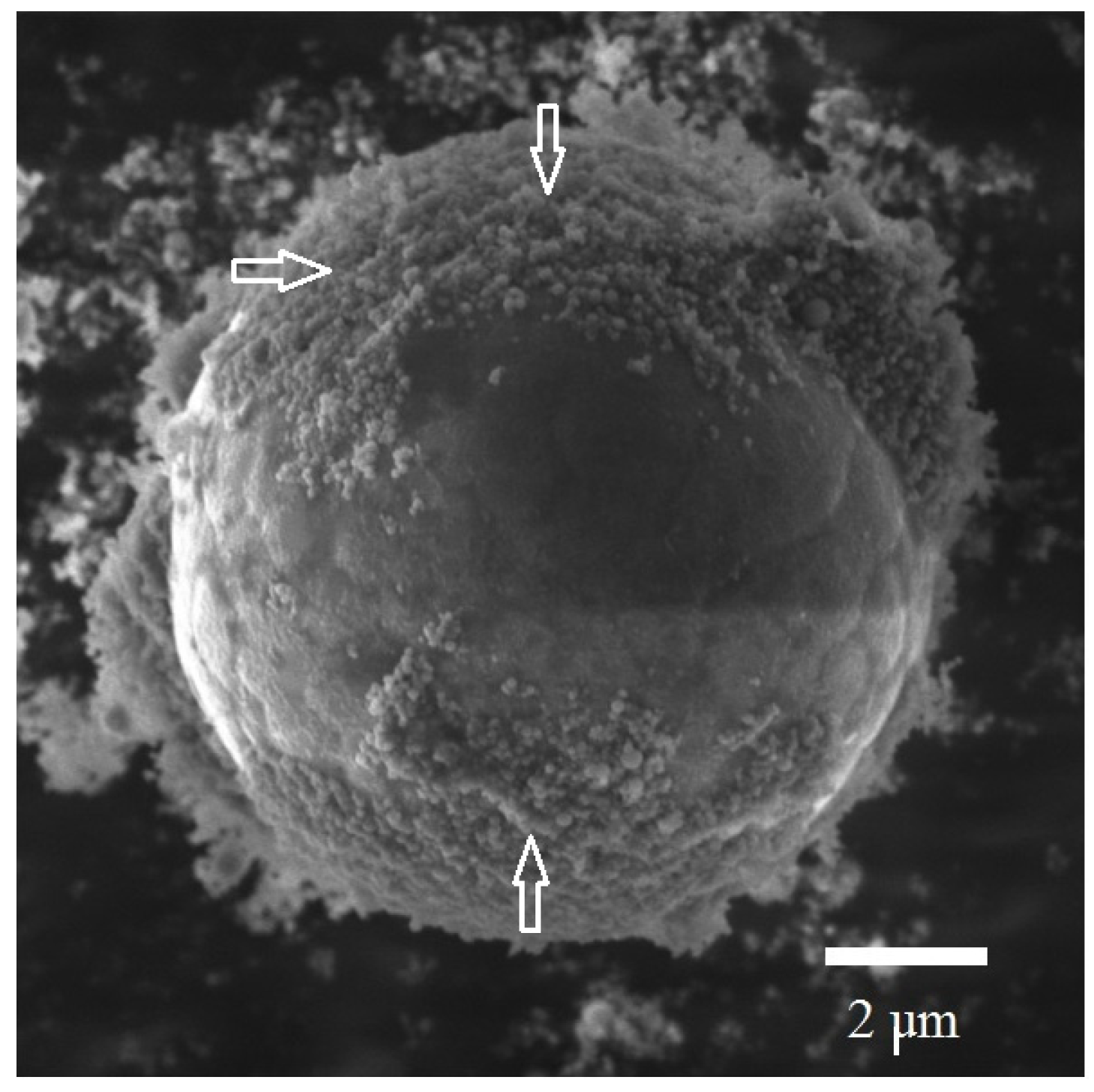

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, Q.; Tuck, C.; Wildman, R.; Hague, R. Application of Nanoparticles in Manufacturing. In Handbook of Nanoparticles; Aliofkhazraei, M., Ed.; Springer: Cham, Switzerland, 2016; pp. 1219–1278. [Google Scholar] [CrossRef]

- Koch, C.C. Nanostructured Materials: Processing, Properties, and Potential Applications, 2nd ed.; Andrew, W., Ed.; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Son, S.J.; Cho, Y.S.; Choi, C.J. Advanced micromanufacturing for high-precision microbearing by nanopowder metallurgy and LIGA processing. Rev. Adv. Mater. Sci. 2011, 28, 190–195. [Google Scholar]

- Rajabi, J.; Muhamad, N.; Sulong, A.B. Effect of nano-sized powders on powder injection molding: A review. Microsyst. Technol. 2012, 18, 1941–1961. [Google Scholar] [CrossRef]

- Kim, K.H.; Lee, B.T.; Choi, C.J. Fabrication and evaluation of powder injection moulded Fe-Ni sintered bodies using nano Fe-50%Ni powder. J. Alloys Compd. 2010, 491, 391–394. [Google Scholar] [CrossRef]

- Ferkel, H.; Hellmig, R.J. Effect of nanopowder deagglomeration on the densities of nanocrystalline ceramic green bodies and their sintering behavior. Nanostruct. Mater. 1999, 11, 617–622. [Google Scholar] [CrossRef]

- Mutsuddy, B.C.; Ford, R.G. Ceramic Injection Molding; Chapmman & Hall: London, UK, 1995. [Google Scholar]

- Oh, J.W.; Bollina, R.; Lee, W.S.; Park, S.J. Effect of nanopowder ratio in bimodal powder mixture on powder injection molding. Powder Technol. 2016, 302, 168–176. [Google Scholar] [CrossRef]

- Wei, D.; Dave, R.; Pfeffer, R. Mixing and characterization of nanosized powders: An assessment of different techniques. J. Nanopart. Res. 2002, 4, 21–41. [Google Scholar] [CrossRef]

- McGeary, R.K. Mechanical packing of spherical particles. J. Am. Ceram. Soc. 1961, 44, 513–522. [Google Scholar] [CrossRef]

- German, R.M.; Bulger, M. A model for densification by sintering of bimodal particle size distributions. Int. J. Powder Metall. 1992, 28, 301–311. [Google Scholar]

- Zheng, J.; Carlson, W.B.; Reed, J.S. The packing density of binary powder mixtures. J. Eur. Ceram. Soc. 1995, 15, 479–483. [Google Scholar] [CrossRef]

- Bai, Y.; Wagner, G.; Williams, C.B. Effect of Particle Size Distribution on Powder Packing and Sintering in Binder Jetting Additive Manufacturing of Metals. J. Manuf. Sci. Eng. 2017, 139, 081019. [Google Scholar] [CrossRef] [Green Version]

- Du, W.; Ren, X.; Ma, C.; Pei, Z. Binder Jetting Additive Manufacturing of Ceramics: A Literature Review. In Proceedings of the ASME 2017 International Mechanical Engineering Congress and Exposition, Emerging Technologies, Materials Genetics to Structures, Safety Engineering and Risk Analysis, Tampa, FL, USA, 3–9 November 2017; Volume 14. V014T07A006. [Google Scholar] [CrossRef]

- Du, W.; Ren, X.; Chen, Y.; Ma, C.; Radovic, M.; Pei, Z. Model Guided Mixing of Ceramic Powders with Graded Particle Sizes in Binder Jetting Additive Manufacturing. In Proceedings of the ASME 2018 13th International Manufacturing Science and Engineering Conference, Additive Manufacturing, Bio and Sustainable Manufacturing, College Station, TX, USA, 18–22 June 2018; Volume 1. V001T01A014. [Google Scholar] [CrossRef]

- Gonzalez, J.A.; Mireles, J.; Lin, Y.; Wicker, R.B. Characterization of ceramic components fabricated using binder jetting additive manufacturing technology. Ceram. Int. 2016, 42, 10559–10564. [Google Scholar] [CrossRef] [Green Version]

- Solis, D.M.; Silva, A.V.; Volpato, N.; Berti, L.F. Reaction-bonding of aluminum oxide processed by binder jetting. J. Manuf. Process. 2019, 41, 267–272. [Google Scholar] [CrossRef]

- Sun, C.; Tian, X.; Wang, L.; Liu, Y.; Wirth, C.M.; Günster, J.; Li, D.; Jin, Z. Effect of particle size gradation on the performance of glass-ceramic 3D printing process. Ceram. Int. 2017, 43, 578–584. [Google Scholar] [CrossRef]

- Du, W.; Singh, M.; Singh, D. Binder jetting additive manufacturing of silicon carbide ceramics: Development of bimodal powder feedstocks by modeling and experimental methods. Ceram. Int. 2020, 46, 19701–19707. [Google Scholar] [CrossRef]

- Vock, S.; Klöden, B.; Kirchner, A.; Weibgarber, T.; Kieback, B. Powders for powder bed fusion: A review. Prog. Addit. Manuf. 2019, 4, 383–397. [Google Scholar] [CrossRef] [Green Version]

- Farzadfar, S.A.; Murtagh, M.J.; Venugopal, N. Impact of IN718 bimodal powder size distribution on the performance and productivity of laser powder bed fusion additive manufacturing process. Powder Technol. 2020, 375, 60–80. [Google Scholar] [CrossRef]

- Spierings, A.B.; Herres, N.; Levy, G. Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp. J. 2011, 17, 195–202. [Google Scholar] [CrossRef] [Green Version]

- Oh, J.W.; Ryu, S.K.; Lee, W.S.; Park, S.J. Analysis of compaction and sintering behavior of 316L stainless steel nano/micro bimodal powder. Powder Technol. 2017, 322, 1–8. [Google Scholar] [CrossRef]

- Oh, J.W.; Seong, Y.; Shin, D.S.; Park, S.J. Investigation and two-stage modeling of sintering behavior of nano/micro-bimodal powders. Powder Technol. 2019, 352, 42–52. [Google Scholar] [CrossRef]

- Rajabi, J.; Fayyaz, A. Effects of Nanopowder Addition on Rheological Properties of Feedstock for Micropowder Injection Moulding Process. J. Kejuruter. 2019, 31, 229–241. [Google Scholar] [CrossRef]

- Lu, H.; Tang, S.Y.; Yun, G.; Li, H.; Zhang, Y.; Qiao, R.; Li, W. Modular and Integrated Systems for Nanoparticle and Microparticle Synthesis—A Review. Biosensors 2020, 10, 165. [Google Scholar] [CrossRef]

- Lerner, M.I.; Svarovskaya, N.V.; Psakhie, S.G.; Bakina, O.V. Production Technology, Characteristics, and Some Applications of Electric-Explosion Nanopowders of Metals. Nanotechnol. Russ. 2009, 4, 741–757. [Google Scholar] [CrossRef]

- Rodkevich, N.G.; Pervikov, A.V.; Glazkova, E.A.; Apkaryan, A.S.; Lerner, M.I. Sintering of 316L stainless steel bimodal powder produced by electrical explosion of wires. AIP Conf. Proc. 2018, 2053, 040081. [Google Scholar] [CrossRef]

- Lerner, M.; Pervikov, A.; Rodkevich, N.; Glazkova, E. Sintering of Cr-60Ni-W and Cr-70Ni-Al alloys bimodal powders prepared by electric explosion of wires. Mater. Res. Express. 2019, 6, 126524. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Rometsch, P.; Jia, Q.; Yang, K.V.; Wu, X. Aluminum alloys for selective laser melting—Towards improved performance. Addit. Manuf. Aerosp. Ind. 2019, 301–325. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of aluminium alloys: Additive manufacturing of aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Sedoi, V.S.; Ivanov, Y.F. Particles and crystallites under electrical explosion of wires. Nanotechnology 2008, 19, 145710. [Google Scholar] [CrossRef] [PubMed]

- Kotov, Y.A. Electric explosion of wires as a method for preparation of nanopowders. J. Nanopart. Res. 2003, 5, 539–550. [Google Scholar] [CrossRef]

- Sedoi, V.S.; Mesyats, G.A.; Oreshkin, V.I.; Valevich, V.V.; Chemezova, L.I. The Current Density and the Specific Energy Input in Fast Electrical Explosion. IEEE Trans. Plasma Sci. 1999, 27, 845–850. [Google Scholar] [CrossRef]

- Pervikov, A.V. Metal, Metal Composite, and Composited Nanoparticles Obtained by Electrical Explosion of Wires. Nanobiotechnol. Rep. 2021, 16, 401–420. [Google Scholar] [CrossRef]

- Abramova, K.B.; Zlatin, N.A.; Peregud, B.P. Magnetohydrodynamic instability of liquid and solid conductors. Destruction of conductors by an electric current. JETP 1975, 42, 1019–1026. [Google Scholar]

- Chace, W.G.; Levine, M.A. Classification of wire explosions. J. Appl. Phys. 1960, 31, 1298. [Google Scholar] [CrossRef]

- Apollonov, V.V.; Pletnev, N.V. Formation of Extended Directional Breakdown Channels Produced by a Copper Wire Exploding in the Atmosphere. Tech. Phys. 2013, 58, 1770–1782. [Google Scholar] [CrossRef]

- Pervikov, A.V.; Lerner, M.I.; Glazkova, E.A.; Domashenko, V.V. Phase State of Matter during Metal and Binary Alloy Conductor Dispersion by a Pulse of Current. AIP Conf. Proc. 2014, 1623, 483. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kukla, C.; Gonzalez-Gutierrez, J.; Duretek, I.; Schuschnigg, S.; Holzer, C. Effect of particle size on the properties of highly-filled polymers for fused filament fabrication. AIP Conf. Proc. 2017, 1914, 190006. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez-Gutierrez, J.; Stringari, G.; Emri, I. Powder Injection Molding of Metal and Ceramic Parts. In Some Critical Issues for Injection Molding; Wang, J., Ed.; IntechOpen: Rijeka, Croatia, 2012; pp. 65–86. [Google Scholar] [CrossRef] [Green Version]

- Nishiyabu, K. Micro metal powder injection molding. In Some Critical Issues for Injection Molding; Wang, J., Ed.; IntechOpen: Rijeka, Croatia, 2012; pp. 105–130. [Google Scholar] [CrossRef] [Green Version]

- Oh, J.W.; Seong, Y.; Park, S.J. Effect of nanoparticles in bimodal powder on physical and mechanical properties of powder injection molded parts. J. Mater. Process. Technol. 2018, 262, 503–510. [Google Scholar] [CrossRef]

- Farr, R.S.; Groot, R.D. Close packing density of polydisperse hard spheres. J. Chem. Phys. 2009, 131, 244104. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Sample | d, mm | l, mm | C, µF | Lin, µH | U0, kV |

|---|---|---|---|---|---|

| 1 | 0.35 | 90 | 1.6 | 0.73 | 13 |

| 2 | 0.35 | 90 | 1.6 | 0.73 | 17 |

| 3 | 0.35 | 90 | 1.6 | 0.73 | 20 |

| Sample | I, kA | S, cm2 | I/S, A/cm2 | E/Es |

|---|---|---|---|---|

| 1 | 15.5 | 9.6 × 10−4 | 1.6 × 107 | 0.33 |

| 2 | 19.5 | 9.6 × 10−4 | 2.0 × 107 | 0.63 |

| 3 | 22.5 | 9.6 × 10−4 | 2.34 × 107 | 0.95 |

| Sample | Average Size of Fine Fraction, nm | Average Microparticle Size, μm | Microparticle-to-Nanoparticle Diameter Ratio |

|---|---|---|---|

| 1 | 130 ± 1 | 5.05 ± 0.45 | 38.8 |

| 2 | 116 ± 2 | 5.05 ± 0.60 | 43.5 |

| 3 | 118 ± 1 | 2.08 ± 0.02 | 17.6 |

| Feedstock | MFI, g/10 min |

|---|---|

| 1 | 53.0 |

| 2 | 42.3 |

| 3 | 18.0 |

| 4 ** | 16.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pervikov, A.; Toropkov, N.; Kazantsev, S.; Bakina, O.V.; Glazkova, E.; Lerner, M. Preparation of Nano/Micro Bimodal Aluminum Powder by Electrical Explosion of Wires. Materials 2021, 14, 6602. https://doi.org/10.3390/ma14216602

Pervikov A, Toropkov N, Kazantsev S, Bakina OV, Glazkova E, Lerner M. Preparation of Nano/Micro Bimodal Aluminum Powder by Electrical Explosion of Wires. Materials. 2021; 14(21):6602. https://doi.org/10.3390/ma14216602

Chicago/Turabian StylePervikov, Alexander, Nikita Toropkov, Sergey Kazantsev, Olga V. Bakina, Elena Glazkova, and Marat Lerner. 2021. "Preparation of Nano/Micro Bimodal Aluminum Powder by Electrical Explosion of Wires" Materials 14, no. 21: 6602. https://doi.org/10.3390/ma14216602

APA StylePervikov, A., Toropkov, N., Kazantsev, S., Bakina, O. V., Glazkova, E., & Lerner, M. (2021). Preparation of Nano/Micro Bimodal Aluminum Powder by Electrical Explosion of Wires. Materials, 14(21), 6602. https://doi.org/10.3390/ma14216602