Recycled Aggregates from Construction and Demolition Waste in the Manufacture of Urban Pavements

Abstract

:1. Introduction

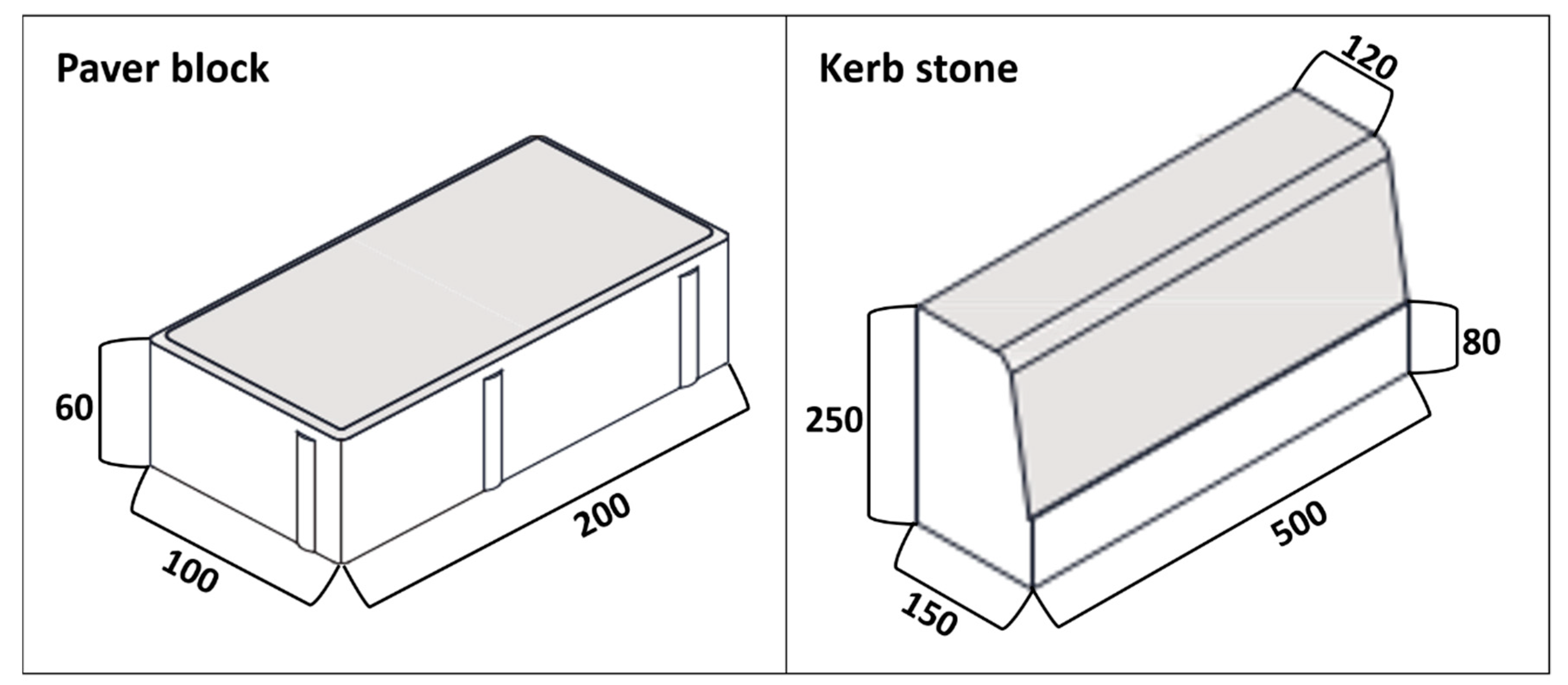

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Characterisation Techniques

3. Results and Discussion

3.1. Raw Materials Characterisation

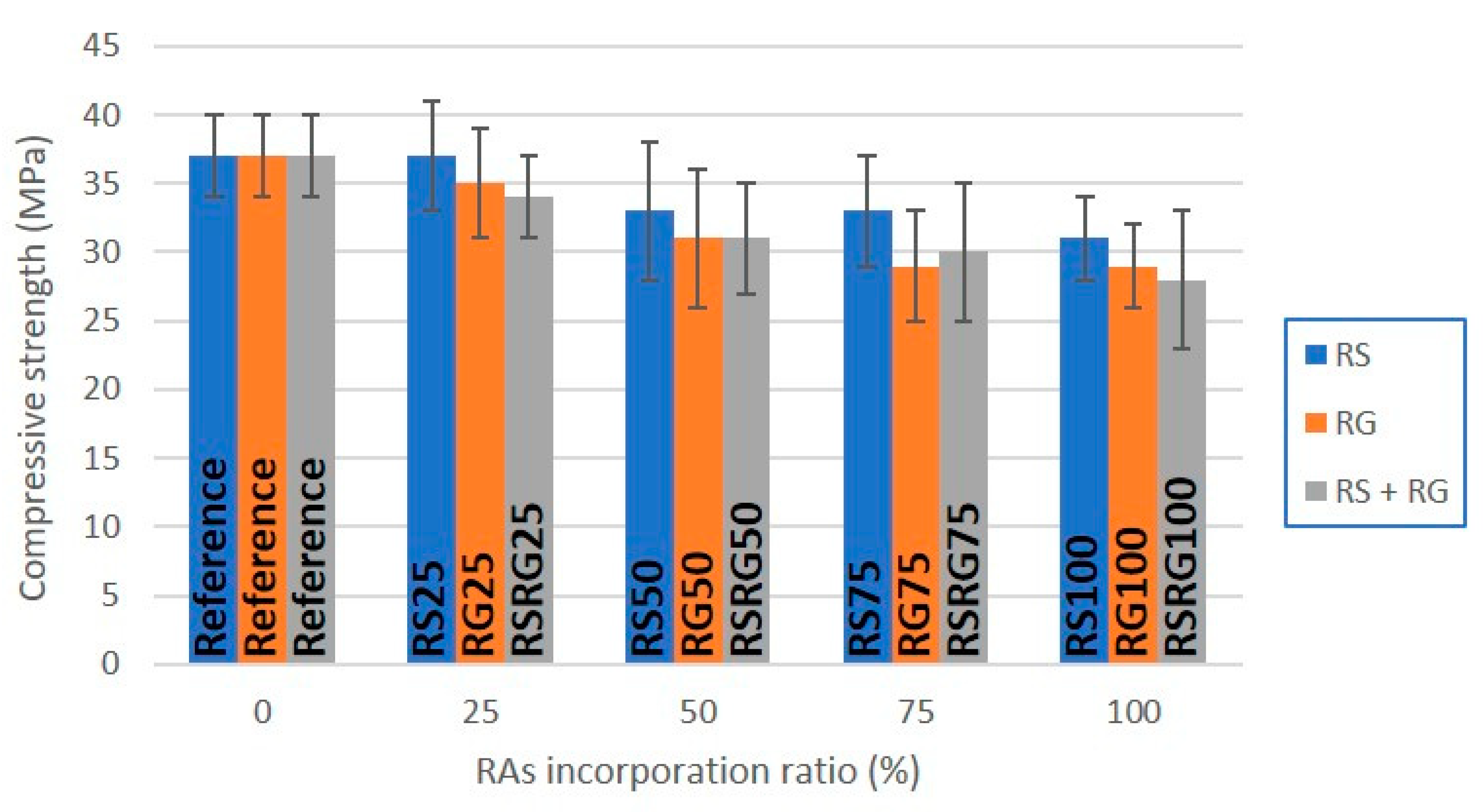

3.2. Concrete Test Characterisation

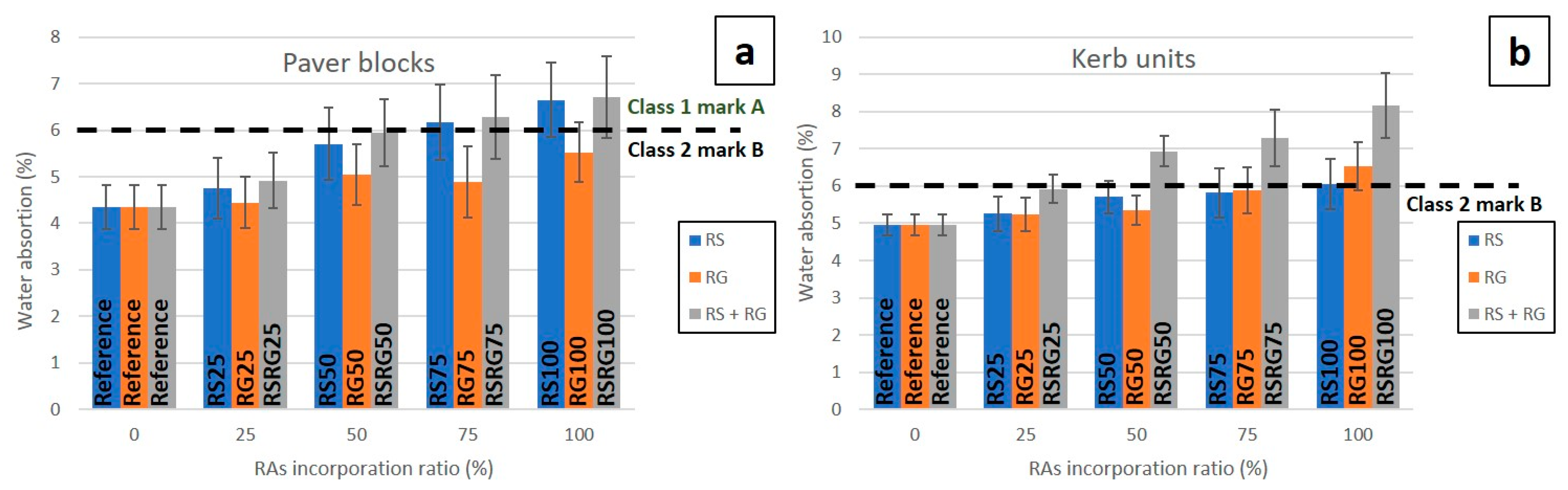

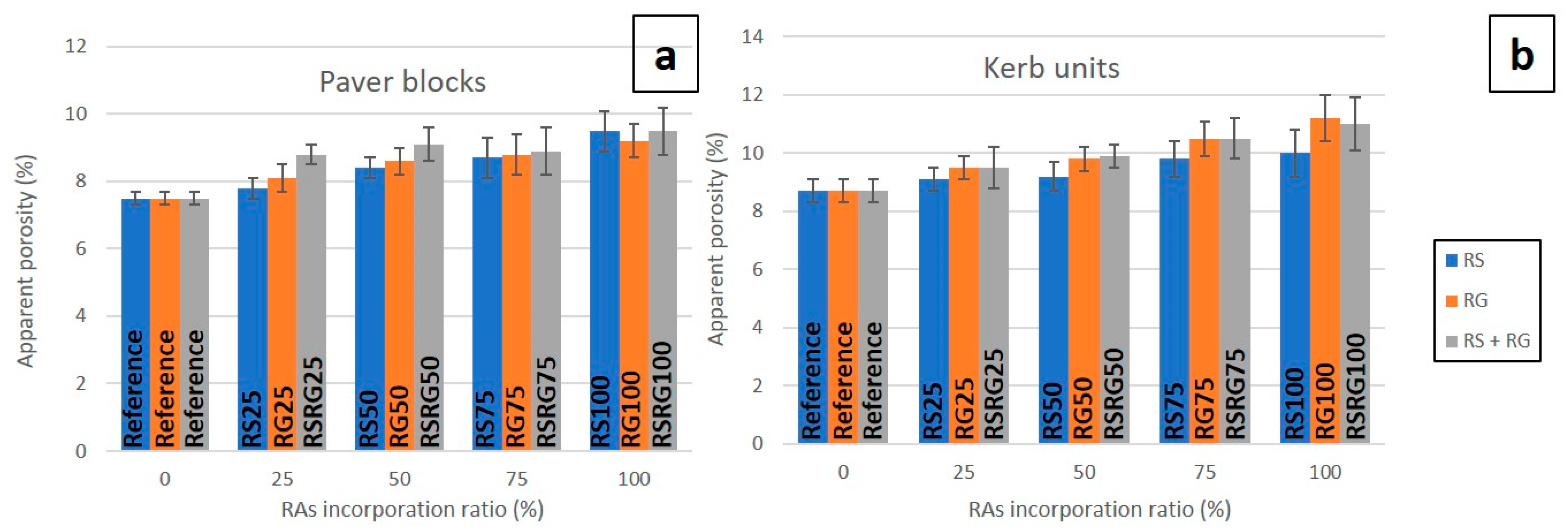

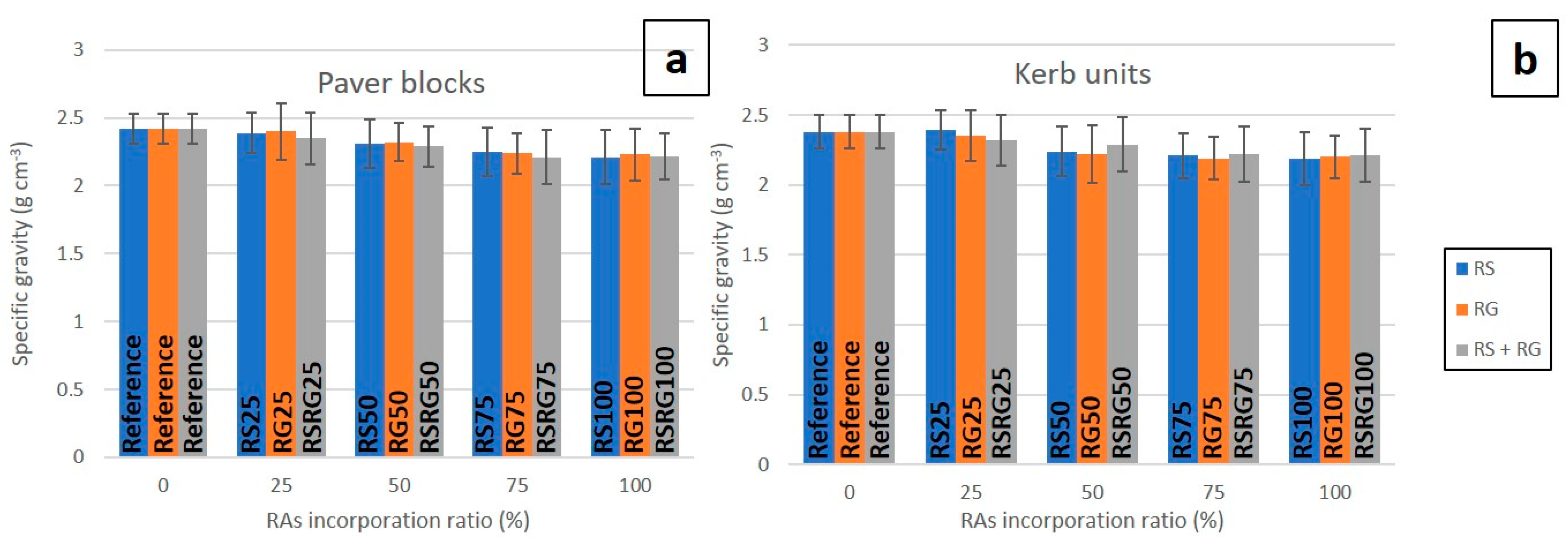

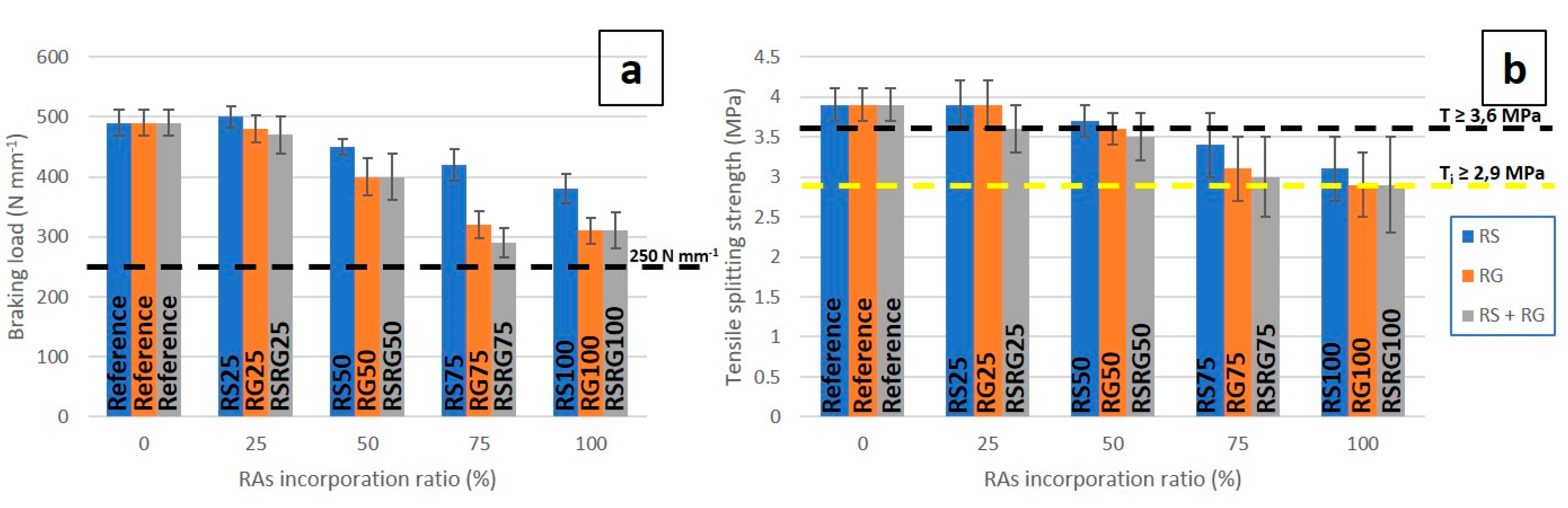

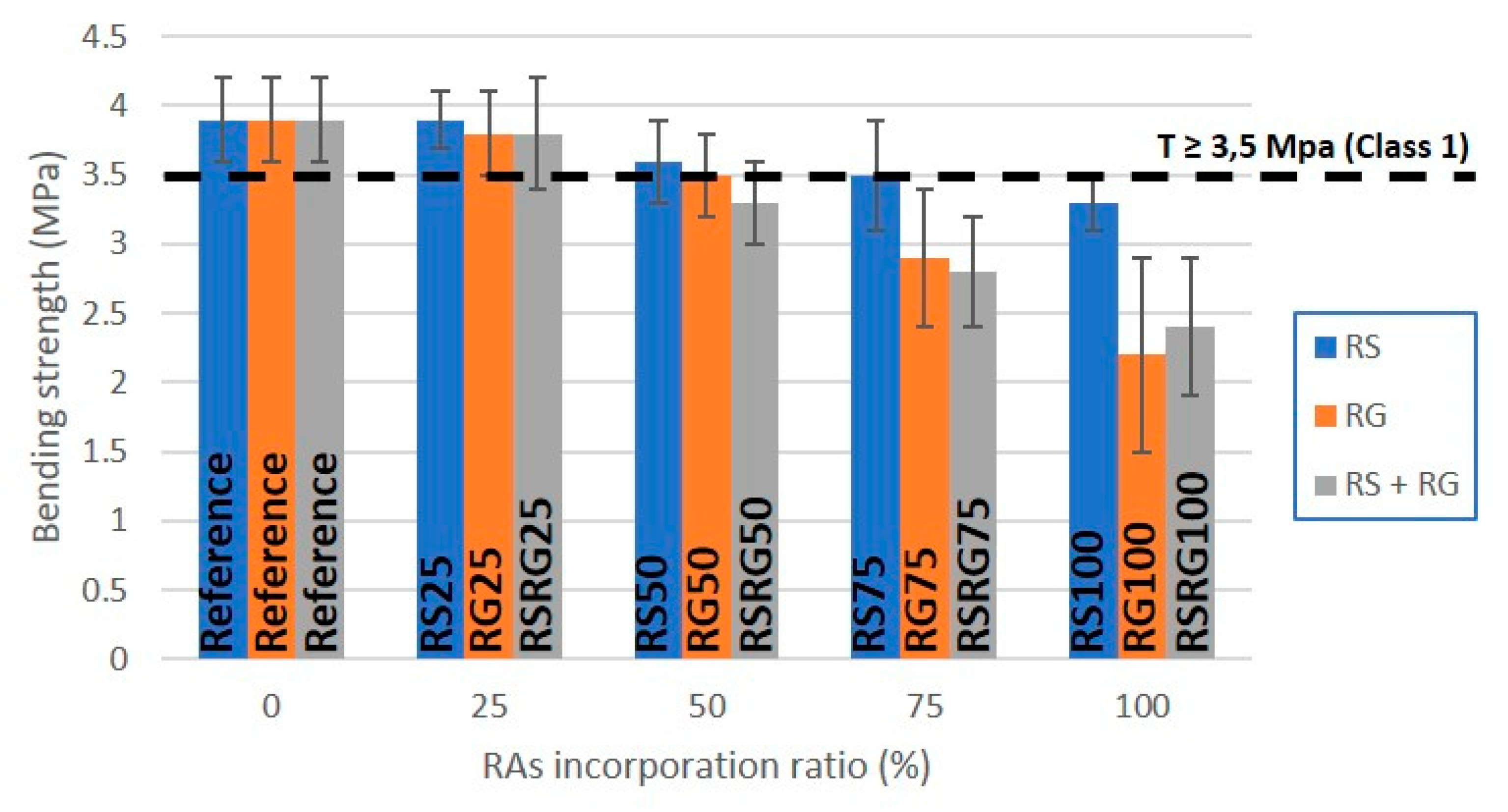

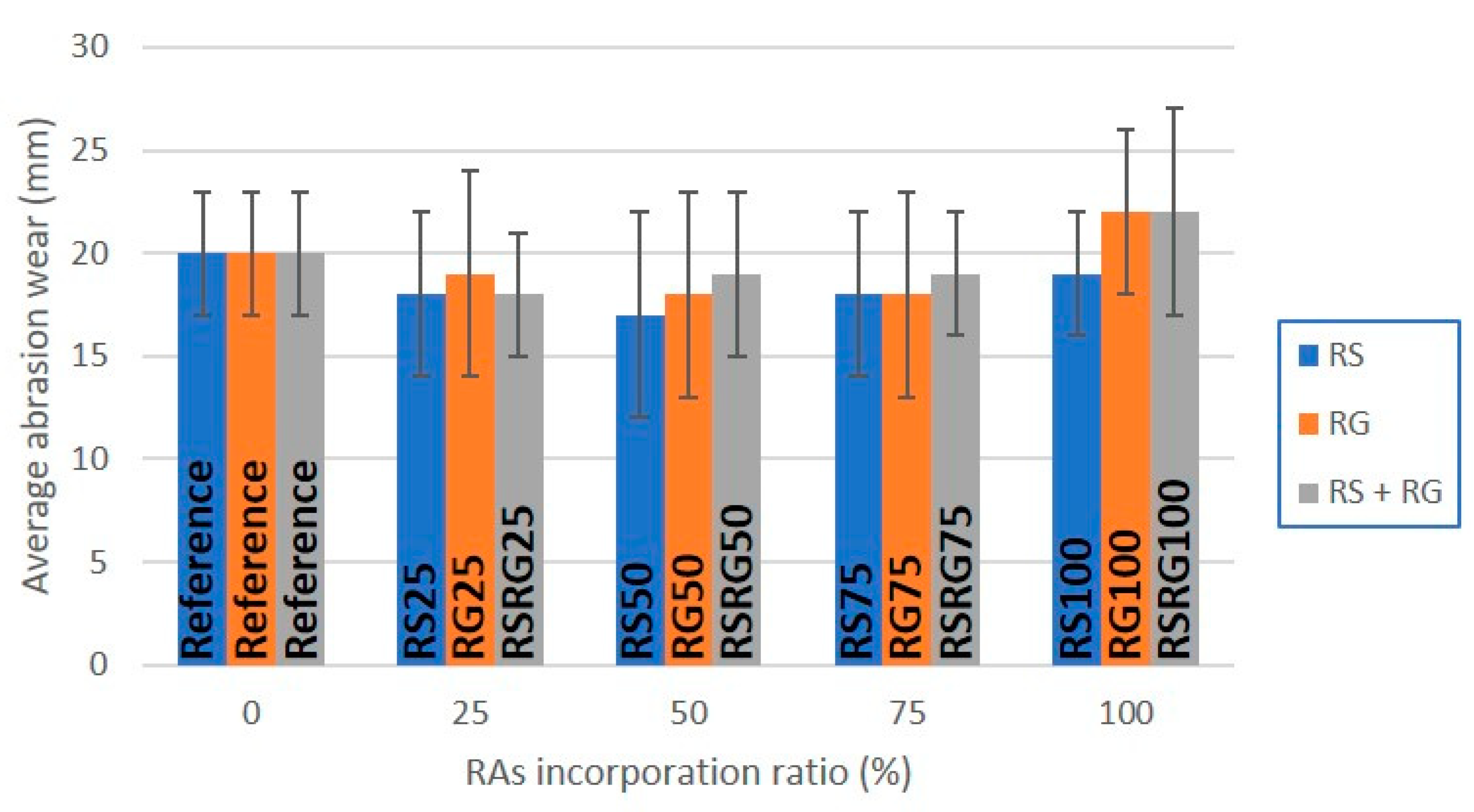

3.3. Paving Unit Characterisation

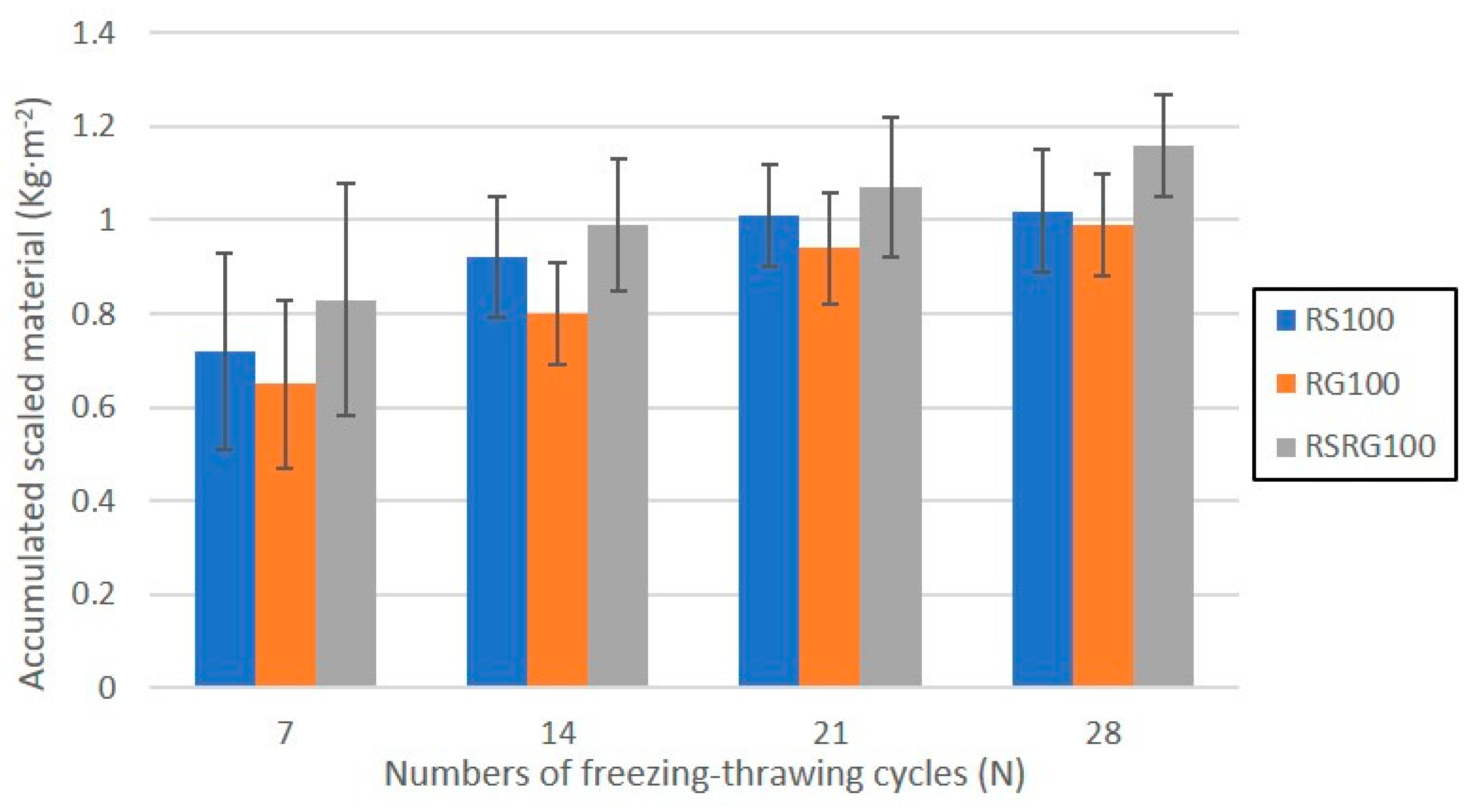

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Environment Agency (EEA). Circular Economy in Europe—Developing the Knowledge Base; Publication Office of the European Union: Copenhagen, Denmark, 2016; Available online: https://ec.europa.eu/environment/ecoap/policies-and-practices-eco-innovation-uptake-and-circular-economy-transition_en (accessed on 24 August 2021).

- European Builders Confederation (EBC). Annual 2017–2018—the Voice of Construction Crafts and Smes in Europe; European Builders Confederation (EBC): Brussels, Belgium, 2018; Available online: https://ebc-construction.eu/wp-content/uploads/EBC-RA2017-2018-EN_BD.pdf (accessed on 4 September 2021).

- Jain, M.S. A mini review on generation, handling, and initiatives to tackle construction and demolition waste in India. Environ. Technol. Innov. 2021, 22, 101490. [Google Scholar] [CrossRef]

- Wahlström, M.; Bergmans, J.; Teittinen, T.; Bachér, J.; Smeets, A.; Paduart, A. Construction and Demolition Waste: Challenges and Opportunities in a Circular Economy; European Enviroment Agency_European Topic Centre Waste and Materials in a Green Economy. Eionet Report—ETC/WMGE 2020/1; European Environment Agency (EEA): Copenhagen, Denmark, 2020; Available online: https://www.eionet.europa.eu/etcs/etc-wmge/products/etc-reports/construction-and-demolition-waste-challenges-and-opportunities-in-a-circular-economy/@@download/file/Clean%20Version_CDW%20and%20CE%20Report%20version%20January%2010%202020_final.pdf (accessed on 8 September 2021).

- European Commission. The European Construction Sector: A Global Partner. European Commission; Joint Research Centre (JRC): Brussels, Belgium, 2016. Available online: https://ec.europa.eu/growth/content/european-construction-sector-global-partner-0_en (accessed on 4 September 2021).

- US EPA. Advancing Sustainable Materials Management: Facts and Figures Report; US EPA: Washington, DC, USA, 2020. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/advancing-sustainable-materials-management (accessed on 12 September 2021).

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Mingxue, M. Prevailing Construction and Demolition Waste Management Practices: A China Study. Master’s Thesis, Western Sidney University, Sidney, Australia, February 2020. Available online: https://researchdirect.westernsydney.edu.au/islandora/object/uws%3A56559/datastream/PDF/download/citation.pdf (accessed on 24 September 2021).

- Leite, F.D.C.; Motta, R.D.S.; Vasconcelos, K.L.; Bernucci, L. Laboratory evaluation of recycled construction and demolition waste for pavements. Constr. Build. Mater. 2011, 25, 2972–2979. [Google Scholar] [CrossRef]

- Juan-Valdés, A.; Rodríguez-Robles, D.; García-González, J.; Guerra-Romero, M.I.; Morán-del Pozo, J.M. Mechanical and microstructural characterization of non-structural precast concrete made with recycled mixed ceramic aggregates from construction and demolition wastes. J. Clean. Prod. 2018, 180, 482–493. [Google Scholar] [CrossRef]

- Patil, A.R.; Sathe, S.B. Feasibility of sustainable construction materials for concrete paving blocks: A review on waste foundry sand and other materials. Mater. Today Proc. 2021, 43, 1552–1561. [Google Scholar] [CrossRef]

- López-Gayarre, F.; López-Colina, C.; Serrano, M.A.; López-Martínez, A. Manufacture of concrete kerbs and floor blocks with recycled aggregate from C&DW. Constr. Build. Mater. 2013, 40, 1193–1199. [Google Scholar]

- Soutsos, M.N.; Tang, K.; Millard, S.G. The use of recycled demolition aggregate in precast concrete products—Phase III: Concrete pavement flags. Constr. Build. Mater. 2021, 36, 674–680. [Google Scholar] [CrossRef]

- Pourkhorshidi, S.; Sangiorgi, C.; Torreggiani, D.; Tassinari, P. Using Recycled Aggregates from Construction and Demolition Waste in Unbound Layers of Pavements. Sustainability 2020, 12, 9386. [Google Scholar] [CrossRef]

- Jankovic, K.; Nikolic, D.; Bojovic, D. Concrete paving blocks and flags made with crushed brick as aggregate. Constr. Build. Mater. 2012, 28, 659–663. [Google Scholar] [CrossRef]

- Sabai, M.M.; Cox, M.G.D.M.; Mato, R.R.; Egmond, E.L.C.; Lichtenberg, J.J.N. Concrete block production from construction and demolition waste in Tanzania. Resour. Conserv. Recycl. 2013, 72, 9–19. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.-L.; Tang, Y.; Meng, T.; Zhan, L.-T. Transportation Geotechnics Evaluating the crushing characteristics of recycled construction and demolition waste for use in road bases. Transp. Geotech. 2021, 28, 100543. [Google Scholar] [CrossRef]

- Beja, I.A.; Motta, R.; Bernucci, L.B. Application of recycled aggregates from construction and demolition waste with Portland cement and hydrated lime as pavement subbase in Brazil. Constr. Build. Mater. 2020, 258, 119520. [Google Scholar] [CrossRef]

- Xuan, D.X.; Molenaar, A.A.A.; Houben, L.J.M. Evaluation of cement treatment of reclaimed construction and demolition waste as road bases. J. Clean. Prod. 2015, 100, 77–83. [Google Scholar] [CrossRef]

- Kumar, G.; Shrivastava, S.; Gupta, R.C. Materials Today: Proceedings Paver blocks manufactured from construction & demolition waste. Mater. Today Proc. 2020, 27, 311–317. [Google Scholar]

- Özalp, F.; Yilmaz, H.D.; Kara, M.; Kaya, Ö.; Şahin, A. Effects of recycled aggregates from construction and demolition wastes on mechanical and permeability properties of paving stone, kerb and concrete pipes. Constr. Build. Mater. 2016, 110, 17–23. [Google Scholar] [CrossRef]

- Arenas, C.; Leiva, C.; Vilches, L.F.; Arroyo, F.; Villegas, R. Development of a fly ash-based geopolymeric concrete with construction and demolition wastes as aggregates in acoustic barriers. Constr. Build. Mater. 2017, 134, 433–442. [Google Scholar] [CrossRef]

- Kumar, S.; Shrivastava, S. A study on the viability of fly ash and construction and demolition waste as geopolymerized masonry mortar and their comparative analysis. Mater. Today Proc. 2020, 32, 574–583. [Google Scholar]

- Ulugöl, H.; Günal, M.F.; Yaman, İ.Ö.; Yıldırım, G.; Şahmaran, M. Effects of self-healing on the microstructure, transport, and electrical properties of 100% construction- and demolition-waste-based geopolymer composites. Cem. Concr. Compos. 2021, 121, 104081. [Google Scholar] [CrossRef]

- Contreras-Llanes, M.; Romero-Pérez, M.; Gázquez-González, M.J.; Bolívar-Raya, J.P. Construction and demolition waste as recycled aggregate for environmentally friendly concrete paving. Environ. Sci. Pollut. Res. 2021, 1–15. [Google Scholar] [CrossRef]

- Poon, C.S.; Chan, D. Feasible use of recycled concrete aggregates and crushed clay brick as unbound road sub-base. Constr. Build. Mater. 2006, 20, 578–585. [Google Scholar] [CrossRef]

- Poon, C.S.; Chan, D. Paving blocks made with recycled concrete aggregate and crushed clay brick. Constr. Build. Mater. 2006, 20, 569–577. [Google Scholar] [CrossRef]

- Yang, J.; Du, Q.; Bao, Y. Concrete with recycled concrete aggregate and crushed clay bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Contreras, M.; Teixeira, S.R.; Lucas, M.C.; Lima, L.C.N.; Cardoso, D.S.L.; da Silva, G.A.C.; Gregório, G.C.; de Souza, A.E.; dos Santos, A. Recycling of construction and demolition waste for producing new construction material (Brazil case-study). Constr. Build. Mater. 2016, 123, 594–600. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, L.; de Brito, J.; Barra, M. Influence of the pre-saturation of recycled coarse concrete aggregates on concrete properties. Mag. Concr. Res. 2011, 63, 617–627. [Google Scholar] [CrossRef]

- García-González, J.; Rodríguez-Robles, D.; Juan-Valdés, A.; Morán-del Pozo, J.; Guerra-Romero, M.I. Pre-Saturation Technique of the Recycled Aggregates: Solution to the Water Absorption Drawback in the Recycled Concrete Manufacture. Materials 2014, 7, 6224–6236. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- European Standards. EN 12390-1:2001/AC:2005. Testing Hardened Concrete—Part 1: Shape, Dimensions and Other Requirements for Specimens and Moulds; European Comission: Brussels, Belgium, 2005.

- European Standards. EN 12620 + A1:2009. Aggregates for Concrete; European Comission: Brussels, Belgium, 2009.

- European Standards. EN 1097-6:2001. Tests for Mechanical and Physical Properties of Aggregates. Part 6: Determination of Particle Density and Water Absorption; European Comission: Brussels, Belgium, 2001.

- The International Organization for Standardization (ISO). ISO 5016:1997. Shaped Insulating Refractory Products—Determination of Bulk Density and True Porosity; The International Organization for Standardization (ISO): Geneva, Switzerland, 1997. [Google Scholar]

- European Standards. EN 1097-2:2021. Tests for Mechanical and Physical Properties of Aggregates—Part 2: Methods for the Determination of Resistance to Fragmentation; European Comission: Brussels, Belgium, 2021.

- European Standards. EN 12390-3:2020. Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; European Comission: Brussels, Belgium, 2020.

- European Standards. EN 12390-7:2020. Testing Hardened Concrete—Part 7: Density of Hardened Concrete; European Comission: Brussels, Belgium, 2020.

- European Standards. EN 12390-8:2020. Testing Hardened Concrete—Part 8: Depth of Penetration of Water Under Pressure; European Comission: Brussels, Belgiums, 2020.

- European Standards. EN 12390-4:2020. Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines; European Comission: Brussels, Belgium, 2020.

- European Standards. EN 1338:2004. Concrete Paving Blocks—Requirements and Test Methods; European Comission: Brussels, Belgium, 2004.

- European Standards. EN 1340:2004. Concrete Kerb Units—Requirements and Test Methods; European Comission: Brussels, Belgium, 2004.

- Government of Spain. Royal Decree 1247/2008 Of 18 July, Which Approves: The Statement Of Structural Concrete (EHE-08); Government of Spain: Madrid, Spain, 2008.

- Tam, V.W.Y.; Tam, C.M.; Le, K.N. Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef] [Green Version]

- Shi, C.; Li, Y.; Zhang, J.; Li, W.; Chong, L.; Xie, Z. Performance enhancement of recycled concrete aggregate—A review. J. Clean. Prod. 2016, 112, 466–472. [Google Scholar] [CrossRef]

- Ibrahim, H.A.; Goh, Y.; Ng, Z.A.; Yap, S.P.; Mo, K.H.; Yuen, C.W.; Abutaha, F. Hydraulic and strength characteristics of pervious concrete containing a high volume of construction and demolition waste as aggregates. Constr. Build. Mater. 2020, 253, 119251. [Google Scholar] [CrossRef]

- Idagu, F.O. The Effects of Recycled Aggregates on Compressive Strength of Concrete. Int. J. Adv. Res. Eng. Appl. Sci. 2017, 4, 250–258. [Google Scholar]

- Azevedo, A.R.G.; Cecchin, D.; Carmo, D.F.; Silva, F.C.; Campos, C.M.O.; Shtrucka, T.G.; Marvila, M.T.; Monteiro, S.N. Analysis of the compactness and properties of the hardened state of mortars with recycling of construction and demolition waste (CDW). J. Mater. Res. Technol. 2020, 9, 5942–5952. [Google Scholar] [CrossRef]

- Attri, G.K.; Gupta, R.C.; Shrivastava, S. Impact of recycled concrete aggregate on mechanical and durability properties of concrete paver blocks. Mater. Today Proc. 2021, 42, 975–981. [Google Scholar] [CrossRef]

- Nandi, S.; Ransinchung, G.D.R.N. Performance evaluation and sustainability assessment of precast concrete paver blocks containing coarse and fine RAP fractions: A comprehensive comparative study. Constr. Build. Mater. 2021, 300, 124042. [Google Scholar] [CrossRef]

- Gonzalez-Corominas, A.; Etxeberria, M. Properties of high performance concrete made with recycled fine ceramic and coarse mixed aggregates. Constr. Build. Mater. 2014, 68, 618–626. [Google Scholar] [CrossRef]

- Ferreira, R.L.S.; Anjos, M.A.S.; Nóbrega, A.K.C.; Pereira, J.E.S.; Ledesma, E.F. The role of powder content of the recycled aggregates of CDW in the behaviour of rendering mortars. Constr. Build. Mater. 2019, 208, 601–612. [Google Scholar] [CrossRef]

- Rahul, S.D.; Reddy, S.V.; Tarun, N.; Basutkar, S.M.; Wali, R.S.; Renukadevi, M.V. Influence of brick waste and brick waste fines as fine aggregate on the properties of paver blocks—Preliminary investigation. Mater. Today Proc. 2021, 43, 1496–1502. [Google Scholar] [CrossRef]

- Poon, C.S.; Chan, D. Effects of contaminants on the properties of concrete paving blocks prepared with recycled concrete aggregates. Constr. Build. Mater. 2007, 21, 164–175. [Google Scholar] [CrossRef]

- Vo, D.-H.; Hwang, C.-L.; Thi, K.-D.T.; Yehualaw, M.D.; Liao, M.-C.; Chao, Y.-F. HPC produced with CDW as a partial replacement for fine and coarse aggregates using the Densified Mixture Design Algorithm (DMDA) method: Mechanical properties and stability in development. Constr. Build. Mater. 2021, 270, 121441. [Google Scholar] [CrossRef]

| Natural Aggregates | Recycled Aggregates | |||||||

|---|---|---|---|---|---|---|---|---|

| Sample | Water Content | Cement Content | W/C Ratio | Superplasticiser | Gravel (NG) | Sand (NS) | Gravel * (RG) | Sand * (RS) |

| Reference | 3.02 | 6.76 | 0.45 | 0.05 | 36.07 | 54.10 | - | - |

| RS25 | 3.02 | 6.76 | 0.45 | 0.05 | 36.07 | 40.58 | - | 13.53 |

| RS50 | 3.02 | 6.76 | 0.45 | 0.05 | 36.07 | 27.05 | - | 27.05 |

| RS75 | 3.02 | 6.76 | 0.45 | 0.05 | 36.07 | 13.53 | - | 40.58 |

| RS100 | 3.02 | 6.76 | 0.45 | 0.05 | 36.07 | - | - | 54.10 |

| RG25 | 3.02 | 6.76 | 0.45 | 0.05 | 27.06 | 54.10 | 9.02 | - |

| RG50 | 3.02 | 6.76 | 0.45 | 0.05 | 18.04 | 54.10 | 18.04 | - |

| RG75 | 3.02 | 6.76 | 0.45 | 0.05 | 9.02 | 54.10 | 27.06 | - |

| RG100 | 3.02 | 6.76 | 0.45 | 0.05 | - | 54.10 | 36.07 | - |

| RSRG25 | 3.02 | 6.76 | 0.45 | 0.05 | 27.06 | 40.58 | 9.02 | 13.53 |

| RSRG50 | 3.02 | 6.76 | 0.45 | 0.05 | 18.04 | 27.05 | 18.04 | 27.05 |

| RSRG75 | 3.02 | 6.76 | 0.45 | 0.05 | 9.02 | 13.53 | 27.06 | 40.58 |

| RSRG100 | 3.02 | 6.76 | 0.45 | 0.05 | - | - | 36.07 | 54.10 |

| BD * (kg m−3) | BD ** (kg m−3) | SG (kg m−3) | WA (%) | LA (%) | |

|---|---|---|---|---|---|

| NS | 1450 ± 70 | 1660 ± 40 | 2450 ± 180 | 1.1 ± 0.2 | - |

| NG | 1520 ± 40 | 1620 ± 90 | 2650 ± 110 | 1.7 ± 0.5 | 25 ± 1 |

| CDW | 1390 ± 180 | 1610 ± 190 | 2200 ± 340 | 7.1 ± 1.9 | - |

| RS | 1410 ± 120 | 1590 ± 100 | 2280 ± 290 | 5.0 ± 0.9 | - |

| RG | 1490 ± 190 | 1530 ± 90 | 2390 ± 210 | 4.5 ± 1.1 | 33 ± 3 |

| AP (%) | SG (g cm−3) | WA (%) | σ (MPa) | |

|---|---|---|---|---|

| Reference | 8.7 ± 0.7 | 2.39 ± 0.22 | 4.8 ± 0.8 | 37 ± 3 |

| RS25 | 9.1 ± 0.4 | 2.28 ± 0.20 | 5.1 ± 0.5 | 37 ± 4 |

| RS50 | 9.2 ± 0.5 | 2.19 ± 0.18 | 5.7 ± 0.9 | 33 ± 5 |

| RS75 | 9.8 ± 0.6 | 2.17 ± 0.23 | 5.8 ± 0.4 | 33 ± 4 |

| RS100 | 10.0 ± 0.5 | 2.17 ± 0.20 | 6.1 ± 0.7 | 31 ± 3 |

| RG25 | 9.5 ± 0.4 | 2.32 ± 0.10 | 5.0 ± 0.5 | 35 ± 4 |

| RG50 | 9.9 ± 0.4 | 2.28 ± 0.24 | 5.4 ± 0.7 | 31 ± 5 |

| RG75 | 10.5 ± 0.6 | 2.17 ± 0.19 | 5.9 ± 0.4 | 29 ± 4 |

| RG100 | 11.2 ± 0.5 | 2.14 ± 0.22 | 6.5 ± 0.6 | 29 ± 3 |

| RSRG25 | 9.5 ± 0.7 | 2.37 ± 0.25 | 5.9 ± 0.4 | 34 ± 3 |

| RSRG50 | 10.1 ± 0.4 | 2.24 ± 0.15 | 6.9 ± 0.6 | 31 ± 4 |

| RSRG75 | 10.5 ± 0.7 | 2.16 ± 0.31 | 7.3 ± 0.4 | 30 ± 5 |

| RSRG100 | 11.0 ± 0.5 | 2.21 ± 0.21 | 8.2 ± 0.3 | 28 ± 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Contreras-Llanes, M.; Romero, M.; Gázquez, M.J.; Bolívar, J.P. Recycled Aggregates from Construction and Demolition Waste in the Manufacture of Urban Pavements. Materials 2021, 14, 6605. https://doi.org/10.3390/ma14216605

Contreras-Llanes M, Romero M, Gázquez MJ, Bolívar JP. Recycled Aggregates from Construction and Demolition Waste in the Manufacture of Urban Pavements. Materials. 2021; 14(21):6605. https://doi.org/10.3390/ma14216605

Chicago/Turabian StyleContreras-Llanes, Manuel, Maximina Romero, Manuel Jesús Gázquez, and Juan Pedro Bolívar. 2021. "Recycled Aggregates from Construction and Demolition Waste in the Manufacture of Urban Pavements" Materials 14, no. 21: 6605. https://doi.org/10.3390/ma14216605

APA StyleContreras-Llanes, M., Romero, M., Gázquez, M. J., & Bolívar, J. P. (2021). Recycled Aggregates from Construction and Demolition Waste in the Manufacture of Urban Pavements. Materials, 14(21), 6605. https://doi.org/10.3390/ma14216605