Effects of He-D Interaction on Irradiation-Induced Swelling in Fe9Cr Alloys

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

4. Conclusions

- In the lower dose He-irradiated samples, a large number of small dislocations and vacancies are generated and form helium-vacancy clusters with the helium atoms.

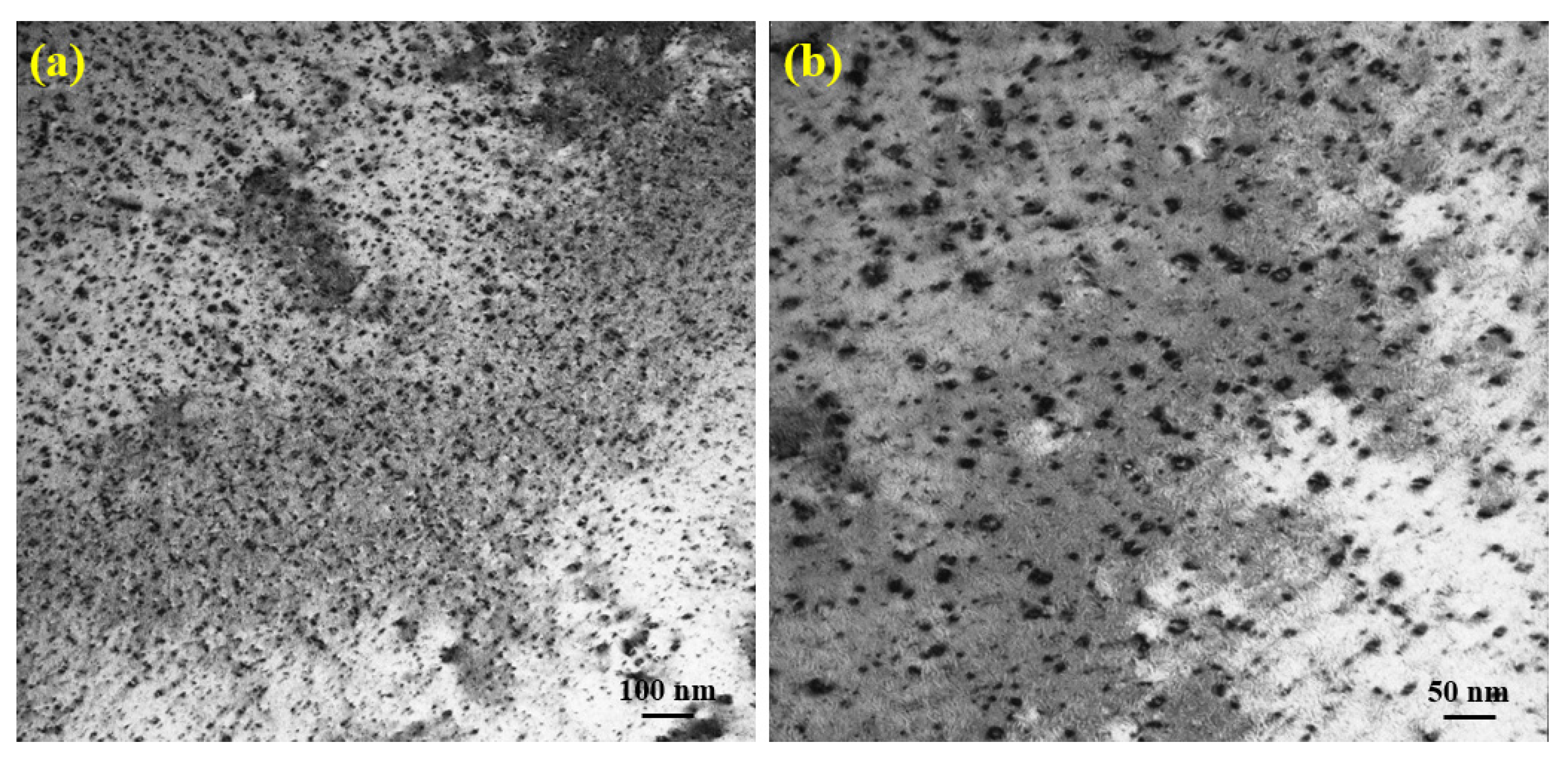

- Only a few small radiation-induced defects appeared as black spots in the alloy irradiated with a dose of 1 × 1015 He+/cm2. As the dose increases, the black spot defects (small dislocation loops) become more visible and show a three-dimensional grain shape.

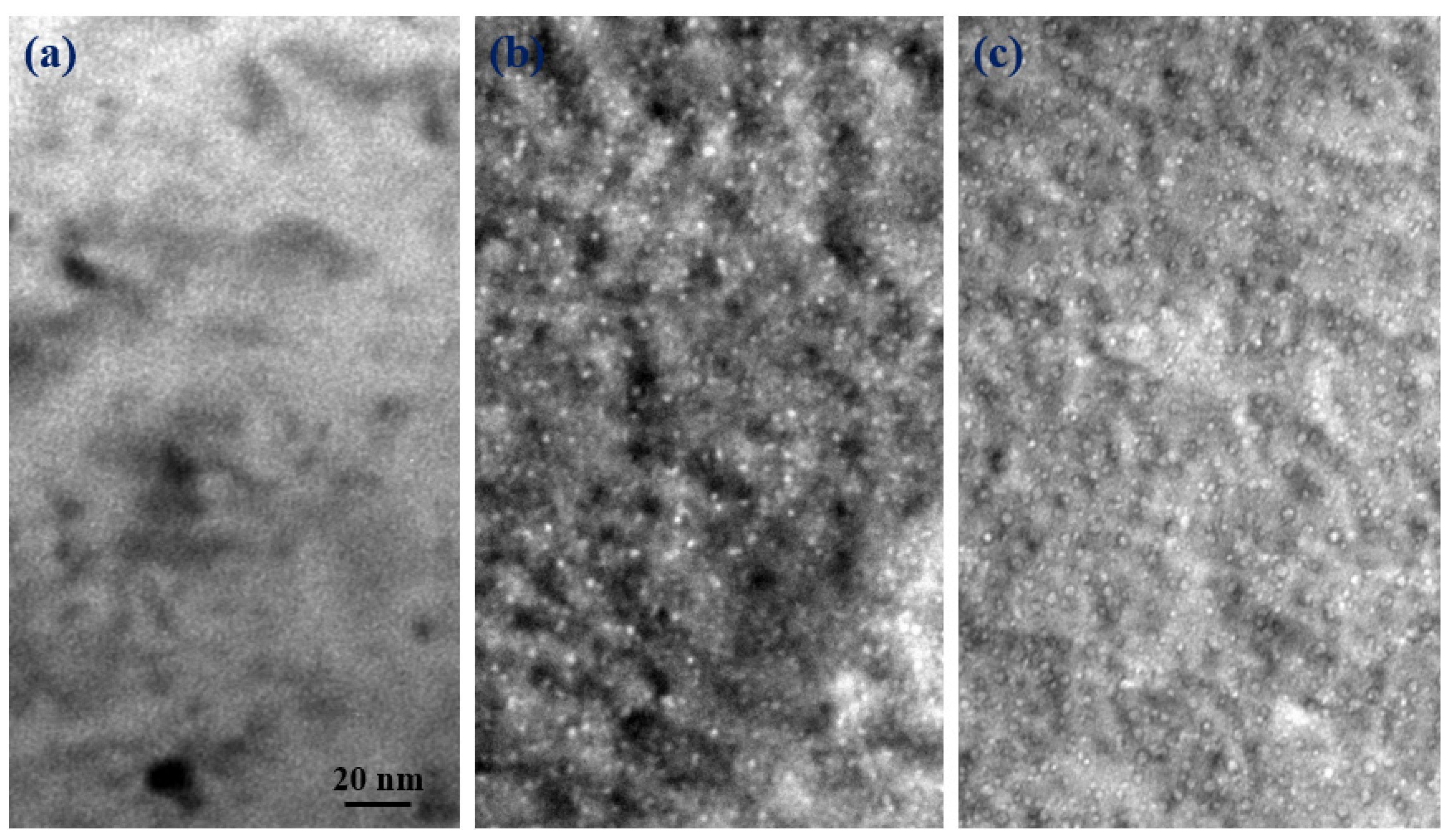

- The microstructure in the specimen after D-ions irradiation at room temperature consisted of a high density of small dislocation loops and networks, but no bubbles were observed in the sample.

- The size of the dislocation loop formed in helium/deuterium sequential-ion irradiated sample was larger than that of helium single-ion irradiated specimen, which indicates that the subsequent D-ions irradiation promotes the growth of the dislocation loops.

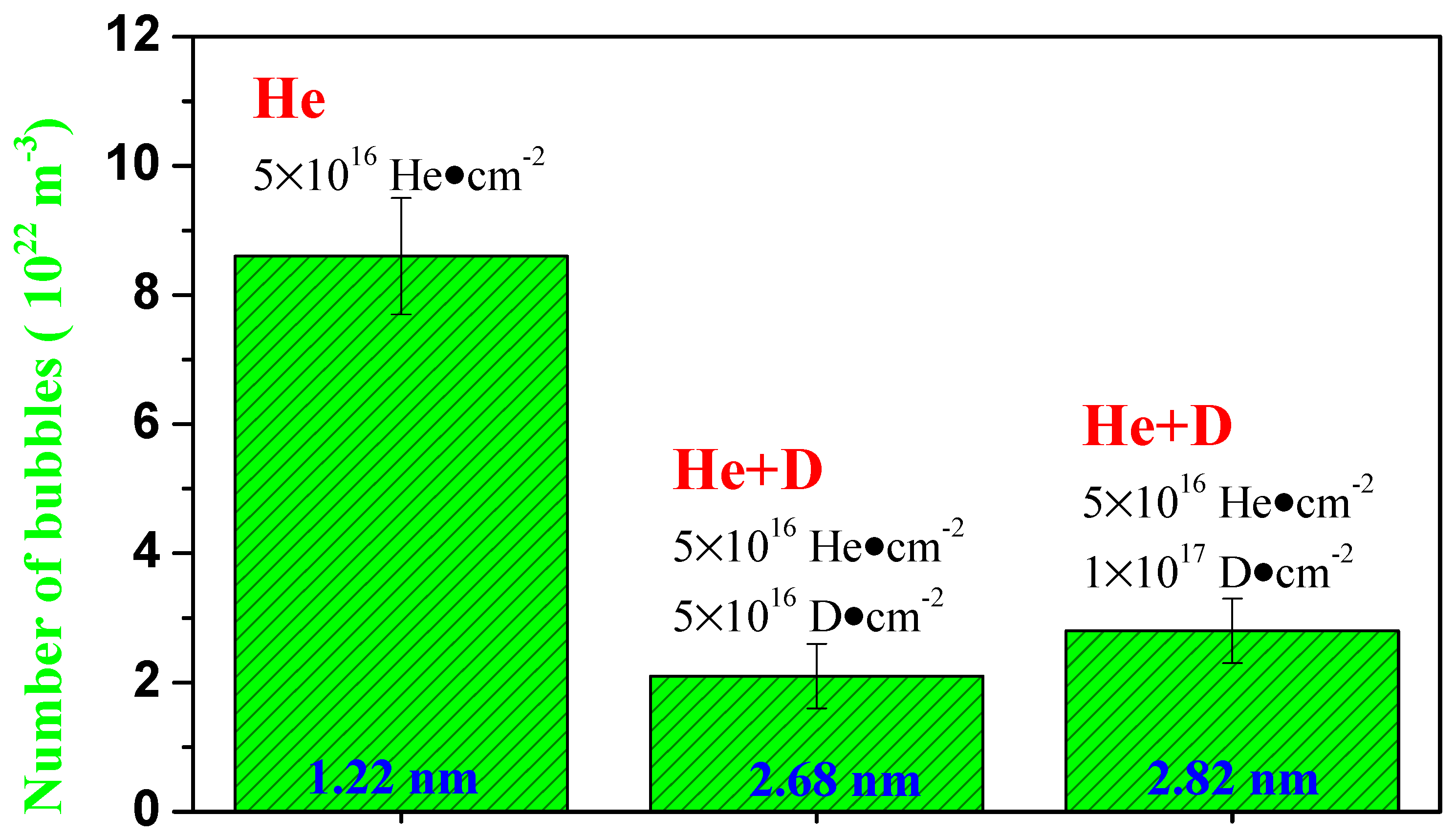

- Nanosized bubbles are formed in the specimen irradiated with high-dose He-ions, and the subsequent implanted D-ions contribute to the growth of these helium bubbles. This is most likely because the previously formed helium bubbles in the sample captured the subsequently injected deuterium, causing the bubbles to grow.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jitsukawa, S.; Tamura, M.; van der Schaaf, B.; Klueh, R.L.; Alamo, A.; Petersen, C.; Schirra, M.; Spaetig, P.; Odette, G.R.; Tavassoli, A.A.; et al. Development of an extensive database of mechanical and physical properties for reduced-activation martensitic steel F82H. J. Nucl. Mater. 2002, 307–311, 179–186. [Google Scholar] [CrossRef]

- Kimura, A.; Kasada, R.; Kohyama, A.; Tanigawa, H.; Hirose, T.; Shiba, K.; Jitsukawa, S.; Ohtsuka, S.; Ukai, S.; Sokolov, M.A.; et al. Recent progress in US–Japan collaborative research on ferritic steels R&D. J. Nucl. Mater. 2007, 367–370, 60–67. [Google Scholar]

- Huang, Q.; Li, J.; Chen, Y. Study of irradiation effects in China low activation martensitic steel CLAM. J. Nucl. Mater. 2004, 329–333, 268–272. [Google Scholar] [CrossRef]

- Klueh, R.L.; Alexander, D.J.; Kenik, E.A. Development of low-chromium, chromium-tungsten steels for fusion. J. Nucl. Mater. 1995, 227, 11–23. [Google Scholar] [CrossRef]

- Huang, Q.; Li, C.; Li, Y.; Chen, M.; Zhang, M.; Peng, L.; Zhu, Z.; Song, Y.; Gao, S. Progress in development of China Low Activation Martensitic steel for fusion application. J. Nucl. Mater. 2007, 367–370, 142–146. [Google Scholar] [CrossRef]

- Kaminsky, M.; Das, S.K. Surface damage of 316 stainless steel irradiated with 4He+ to high doses. J. Nucl. Mater. 1978, 76–77, 256–257. [Google Scholar] [CrossRef]

- Stoller, R.E. The influence of helium on microstructural evolution: Implications for DT fusion reactors. J. Nucl. Mater. 1990, 174, 289–310. [Google Scholar] [CrossRef]

- Chernikov, V.N.; Zakharov, A.P.; Kazansky, P.R. Relation between swelling and embrittlement during post-irradiation annealing and instability of helium-vacancy complexes in nickel. J. Nucl. Mater. 1988, 155–157, 1142–1145. [Google Scholar] [CrossRef]

- Klaver, P.; Haddeman, E.; Thijsse, B. Atomic-scale effects of sub-keV ions during growth and subsequent ion-beam analysis of molybdenum thin films. Nucl. Instrum. Methods B 1999, 153, 228–235. [Google Scholar] [CrossRef]

- Wilson, W.D.; Johnson, R.A. Rare gases in metals. In Interactomic Potentials and Simulation of Lattice Defects—Part 3; Gehlen, P.C., Beeler, J.R., Jaffee, R.I., Eds.; Plenum: New York, NY, USA, 1972. [Google Scholar]

- Lee, E.H.; Hunn, J.D.; Rao, G.R.; Klueh, R.L.; Mansur, L.K. Triple ion beam studies of radiation damage in 9Cr-2WVTa ferritic/martensitic steel for a high power spallation neutron source. J. Nucl. Mater. 1999, 271–272, 385–390. [Google Scholar] [CrossRef] [Green Version]

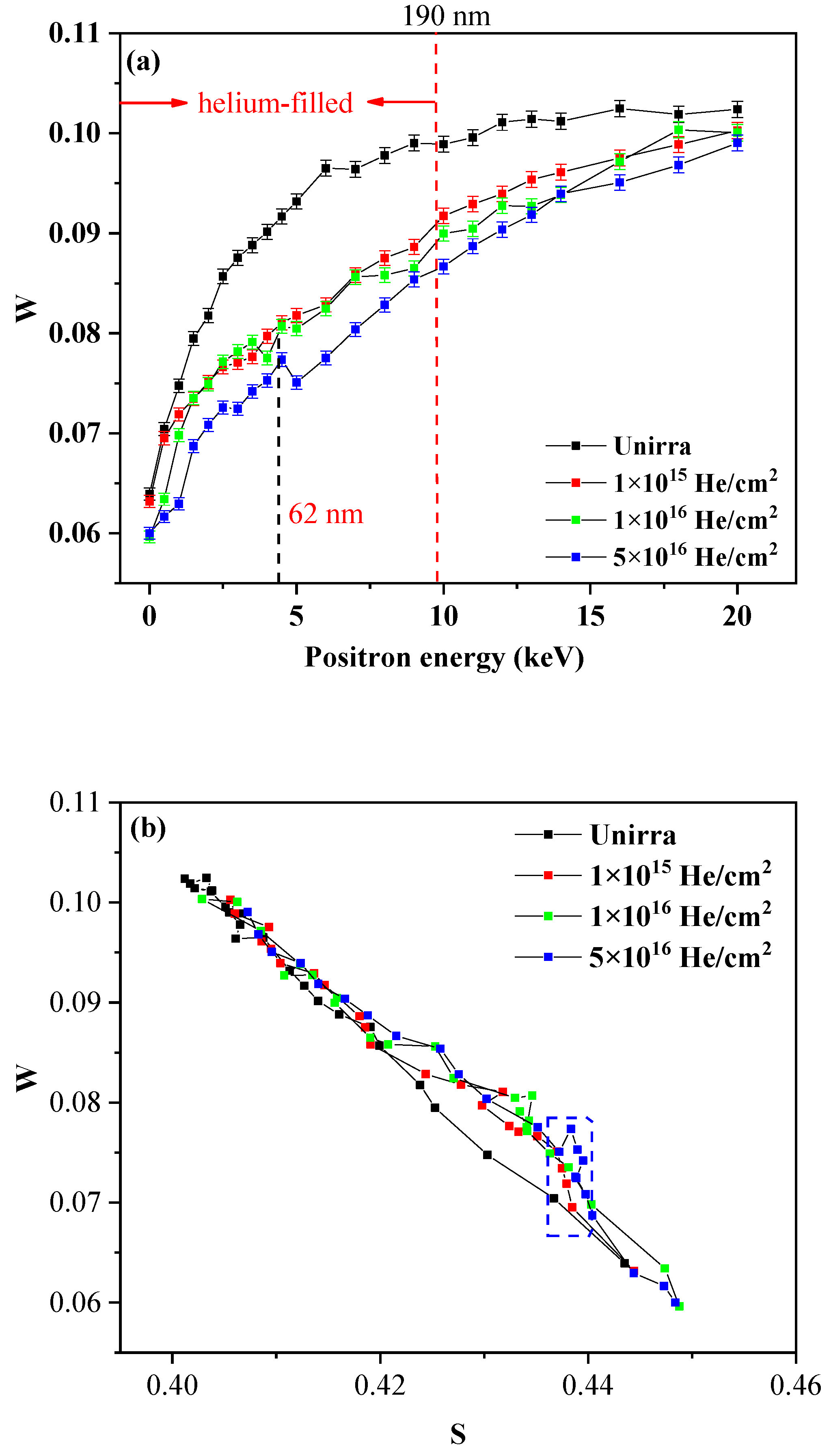

- Xin, Y.; Ju, X.; Qiu, J.; Guo, L.; Li, T.; Luo, F.; Zhang, P.; Cao, X.; Wang, B. Vacancy-type defect production in CLAM steel after the co-implantation of He and H ion beams studied by positron-annihilation spectroscopy. J. Nucl. Mater. 2013, 432, 120–126. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, Y.; Liu, H.-D.; Lyu, Y.-M.; Liu, F.; Cao, X.; Wang, B.; Zhu, T.; Ding, F.; Luo, G. Reexamination of D retention behavior in He ion irradiated RAFMs. Nucl. Fusion 2018, 58, 056017. [Google Scholar] [CrossRef]

- Kesternich, W.; Ullmaier, H. Mechanical properties and microstructure of helium-implanted beryllium. J. Nucl. Mater. 2003, 312, 212–223. [Google Scholar] [CrossRef]

- Karwasz, G.P.; Zecca, A.; Brusa, R.S.; Pliszka, D. Application of positron annihilation techniques for semiconductor studies. J. Alloys Compd. 2004, 382, 244–251. [Google Scholar] [CrossRef]

- Subrahmanyam, V.S.; Nambissan, P.M.G.; Sen, P. Helium bubbles in tungsten studied by positron annihilation. Solid State Commun. 1994, 89, 523–527. [Google Scholar] [CrossRef]

- Xu, Q.; Ishizaki, T.; Sato, K.; Yoshiie, T.; Nagata, S. Coincidence doppler broadening of positron annihilation radiation for detection of helium in irradiated Ni and Cu. Mater. Trans. 2006, 47, 2885–2887. [Google Scholar] [CrossRef] [Green Version]

- Zhu, T.; Cao, X.Z.; Jin, S.X.; Wu, J.P.; Gong, Y.H.; Lu, E.Y.; Wang, B.Y.; Yu, R.S.; Wei, L. Helium retention and thermal desorption from defects in Fe9Cr binary alloys. J. Nucl. Mater. 2015, 466, 522–525. [Google Scholar] [CrossRef]

- Labrim, H.; Barthe, M.-F.; Desgardin, P.; Sauvage, T.; Blondiau, G.; Corbe, C.; Piron, J.P. Vacancy defects induced in sintered polished UO2 disks by helium implantation. Appl. Surf. Sci. 2016, 252, 3256–3261. [Google Scholar] [CrossRef]

- Cao, X.Z.; Xu, Q.; Sato, K.; Yoshiie, T. Thermal desorption of helium from defects in nickel. J. Nucl. Mater. 2011, 412, 165–169. [Google Scholar] [CrossRef] [Green Version]

- Garner, F.A.; Perrin, J.S. Effects of Radiation on Materials: Twelfth International Symposium; ASTM International: Philadelphia, PA, USA, 1984. [Google Scholar]

- Zhu, T.; Jin, S.; Guo, L.; Hu, Y.; Lu, E.; Wu, J.; Wang, B.; Wei, L.; Cao, X. Helium/hydrogen synergistic effect in reduced activation ferritic/martensitic steel investigated by slow positron beam. Philos. Mag. 2016, 96, 253–260. [Google Scholar] [CrossRef]

- Zhu, T.; Cao, X.; Wang, B.; Xu, Q.; Jin, S.; Zhang, P.; Lu, E.; Kuang, P.; Gong, Y.; Guo, L. Thermal evolution of irradiation defects in ferritic/martensitic steel during isochronal annealing. Nucl. Instrum. Methods B 2018, 436, 35–39. [Google Scholar] [CrossRef]

- Zhu, T.; Jin, S.; Zhang, P.; Song, L.; Cao, X.; Wang, B.; Xu, Q.; Yu, R.S.; Fan, P.; Lian, X.; et al. Characterization of helium-vacancy complexes in He-ions implanted Fe9Cr by using positron annihilation spectroscopy. J. Nucl. Mater. 2018, 505, 69–72. [Google Scholar] [CrossRef]

- Cao, X.-Z.; Song, L.-G.; Jin, S.-X.; Zhang, R.-G.; Wang, B.-Y.; Wei, L. Advances in applications of positron annihilation spectroscopy to investigating semiconductor microstructures. Acta Phys. Sin. 2017, 66, 027801. [Google Scholar]

- Nambissan, P.M.G.; Sen, P. Positron-annihilation study of the annealing behavior of alpha-induced defects in tungsten. Radiat. Eff. Defects Solids 1992, 124, 215–221. [Google Scholar] [CrossRef]

- Ogorodnikova, O.; Dubov, L.Y.; Stepanov, S.; Terentyev, D.; Funtikov, Y.; Shtotsky, Y.; Stolbunov, V.; Efimov, V.; Gutorov, K. Annealing of radiation-induced defects in tungsten: Positron annihilation spectroscopy study. J. Nucl. Mater. 2019, 517, 148–151. [Google Scholar] [CrossRef]

- Cao, X.; Zhu, T.; Jin, S.; Kuang, P.; Zhang, P.; Lu, E.; Gong, Y.; Guo, L.; Wang, B. Detection of helium in irradiated Fe9Cr alloys by coincidence Doppler broadening of slow positron annihilation. Appl. Phys. A 2017, 123, 177. [Google Scholar] [CrossRef]

- Zhu, T.; Wang, B.; Lian, X.; Jin, S.; Yu, R.; Cao, X.; Xu, Q. Positron annihilation spectroscopy characterization of formation of helium/hydrogen-vacancy nano-clusters in FeCr alloy. Acta Phys. Pol. A 2020, 137, 235–237. [Google Scholar] [CrossRef]

- Lu, E.; Cao, X.; Jin, S.; Zhang, C.; Zhang, P.; Guo, L.; Zhu, T.; Gong, Y.; Wang, B. The evolution of micro defects in He+ irradiated FeCrNi alloy during isochronal annealing. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2015, 356-357, 94–98. [Google Scholar] [CrossRef]

- Jin, S.; Zhang, P.; Lu, E.; Guo, L.; Wang, B.; Cao, X. Correlation between Cu precipitates and irradiation defects in Fe–Cu model alloys investigated by positron annihilation spectroscopy. Acta Mater. 2016, 103, 658–664. [Google Scholar] [CrossRef]

- Luo, F.; Guo, L.; Chen, J.; Li, T.; Zheng, Z.; Yao, Z.; Suo, J. Damage behavior in helium-irradiated reduced-activation martensitic steels at elevated temperatures. J. Nucl. Mater. 2014, 455, 339–342. [Google Scholar] [CrossRef]

- Liu, P.; Yu, R.; Zhu, Y.; Zhao, M.Z.; Bai, J.W.; Wan, F.R.; Zhan, W. Deuterium ion irradiation induced precipitation in Fe-Cr alloy: Characterization and effects on irradiation behavior. J. Nucl. Mater. 2015, 459, 81–89. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Wang, Z.; Zhu, T.; Xu, Q.; Wang, B.; Xiao, D.; Cao, X. Effects of He-D Interaction on Irradiation-Induced Swelling in Fe9Cr Alloys. Materials 2021, 14, 6669. https://doi.org/10.3390/ma14216669

Wu H, Wang Z, Zhu T, Xu Q, Wang B, Xiao D, Cao X. Effects of He-D Interaction on Irradiation-Induced Swelling in Fe9Cr Alloys. Materials. 2021; 14(21):6669. https://doi.org/10.3390/ma14216669

Chicago/Turabian StyleWu, Haibiao, Zhen Wang, Te Zhu, Qiu Xu, Baoyi Wang, Detao Xiao, and Xingzhong Cao. 2021. "Effects of He-D Interaction on Irradiation-Induced Swelling in Fe9Cr Alloys" Materials 14, no. 21: 6669. https://doi.org/10.3390/ma14216669