Transparency- and Repellency-Enhanced Acrylic-Based Binder for Stimuli-Responsive Road Paint Safety Improvement Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials of Stimuli-Responsive Acrylic Polymer Binder

2.2. Characterization

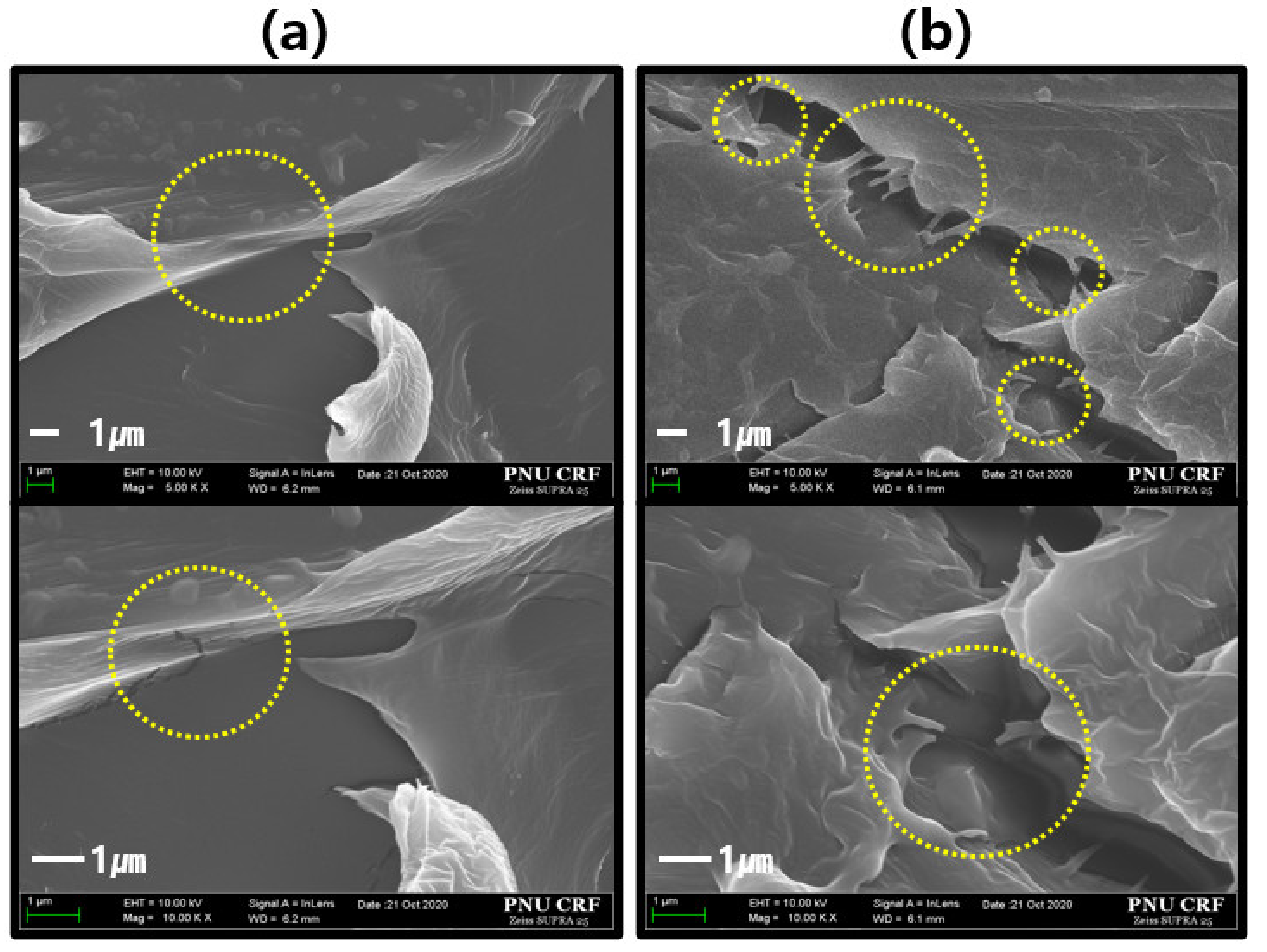

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Browarzik, D. A new thermodynamic model of volume changes in temperature-sensitive polymer gels. J. Mol. Liq. 2014, 198, 149–156. [Google Scholar] [CrossRef]

- Kinner, L.; List-Kratochvil, E.J.W.; Dimopoulos, T. Gentle plasma process for embedded silver-nanowire flexible trans-parent electrodes on temperature-sensitive polymer substrates. Nanotechnology 2020, 31, 365303. [Google Scholar] [CrossRef] [PubMed]

- Huynh, C.T.; Nguyen, M.K.; Jeong, I.K.; Kim, S.W.; Lee, D.S. Synthesis, characteristics and potential application of poly (β-Amino Ester Urethane)-based multiblock co-polymers as an injectable, biodegradable and pH/temperature-sensitive hydrogel System. J. Biomater. Sci. 2012, 23, 1091–1106. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Shim, M.S.; Levinson, N.S.; Sung, H.-W.; Xia, Y. Stimuli-responsive materials for controlled release of theranostic agents. Adv. Funct. Mater. 2014, 24, 4206–4220. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shu, T.; Hu, L.; Shen, Q.; Jiang, L.; Zhang, Q.; Serpe, M.J. Stimuli-responsive polymer-based systems for diagnostic applications. J. Mater. Chem. B 2020, 8, 7042–7061. [Google Scholar] [CrossRef]

- Verkoyen, P.; Frey, H. Amino-functional polyethers: Versatile, stimuli-responsive polymers. Polym. Chem. 2020, 11, 3940–3950. [Google Scholar] [CrossRef]

- Su, Z.; Jiang, X. Multi-stimuli responsive amine-containing polyethers: Novel building blocks for smart assemblies. Polymer 2016, 93, 221–239. [Google Scholar] [CrossRef]

- Gil, E.; Hudson, S. Stimuli-reponsive polymers and their bioconjugates. Prog. Polym. Sci. 2004, 29, 1173–1222. [Google Scholar] [CrossRef]

- Petropoulou, A.; Gibson, T.J.; Themistou, E.; Pispas, S.; Riziotis, C. Development of amphiphilic block copolymers as silica optical fiber overlayers for BSA protein detection. Mater. Chem. Phys. 2018, 216, 421–428. [Google Scholar] [CrossRef] [Green Version]

- Lakard, B. Electrochemical biosensors based on conducting polymers: A review. Appl. Sci. 2020, 10, 6614. [Google Scholar] [CrossRef]

- Bawa, P.; Pillay, V.; Choonara, Y.; Du Toit, L. Stimuli-responsive polymers and their applications in drug delivery. Biomed. Mater. 2009, 4, 022001. [Google Scholar] [CrossRef] [PubMed]

- Vodišek, N.; Šuligoj, A.; Korte, D.; Štangar, U.L. Transparent photocatalytic thin films on flexible polymer substrates. Materials 2018, 11, 1945. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rozman, M.; Cetin, N.; Bren, U.; Lukšič, M. Use of different metal oxide coatings in stainless steel based ECDs for smart textiles. Electronics 2021, 10, 2529. [Google Scholar] [CrossRef]

- Stumpel, J.E.; Broer, D.J.; Schenning, A.P.H.J. Stimuli-responsive photonic polymer coatings. Chem. Commun. 2014, 50, 15839–15848. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abdollahi, A.; Roghani-Mamaqani, H.; Razavi, B.; Salami-Kalajahi, M. The light-controlling of temperature-responsivity in stimuli-responsive polymers. Polym. Chem. 2019, 10, 5686–5720. [Google Scholar] [CrossRef]

- Torres-Pierna, H.; Ruiz-Molina, D.; Roscini, C. Highly transparent photochromic films with a tunable and fast solution-like response. Mater. Horiz. 2020, 7, 2749–2759. [Google Scholar] [CrossRef]

- Bae, J.-H.; Won, J.; Lim, W.; Kim, B.; Lee, J.; Min, J.; Seo, M.; Mo, Y.; Huh, P. Tacky-free polyurethanes pressure-sensitive adhesives by molecular-weight and HDI trimer design. Materials 2021, 14, 2164. [Google Scholar] [CrossRef] [PubMed]

- Sirirat, T.; Vatanatham, T.; Hansupalak, N.; Rempel, G.L.; Arayapranee, W. Kinetic study of styrene and methyl meth-acrylate emulsion polymerization induced by cumene hydroperoxide/tetraethylenepentamine. J. Polym. Res. 2015, 22, 1–11. [Google Scholar] [CrossRef]

- Kohut-Svelko, N.; Pirri, R.; Asua, J.M.; Leiza, J.R. Redox initiator systems for emulsion polymerization of acrylates. J. Polym. Sci. Part A Polym. Chem. 2009, 47, 2917–2927. [Google Scholar] [CrossRef]

- Kochthongrasamee, T.; Prasassarakich, P.; Kiatkamjornwong, S. Effects of redox initiator on graft copolymerization of methyl methacrylate onto natural rubber. J. Appl. Polym. Sci. 2006, 101, 2587–2601. [Google Scholar] [CrossRef]

- Zhang, S.; Shi, Z.; Xu, H.; Ma, X.; Yin, J.; Tian, M. Revisiting the mechanism of redox-polymerization to build the hydrogel with excellent properties using a novel initiator. Soft Matter 2016, 12, 2575–2582. [Google Scholar] [CrossRef] [PubMed]

- Studer, K.; Decker, C.; Beck, E.; Schwalm, R.; Gruber, N. Redox and photoinitiated crosslinking polymerization. Prog. Org. Coat. 2005, 53, 134–136. [Google Scholar] [CrossRef]

- Garra, P.; Morlet-Savary, F.; Dietlin, C.; Fouassier, J.P.; Lalevée, J. On-demand visible light activated amine/benzoyl peroxide redox initiating systems: A unique tool to overcome the shadow areas in photopolymerization processes. Macromolecules 2016, 49, 9371–9381. [Google Scholar] [CrossRef]

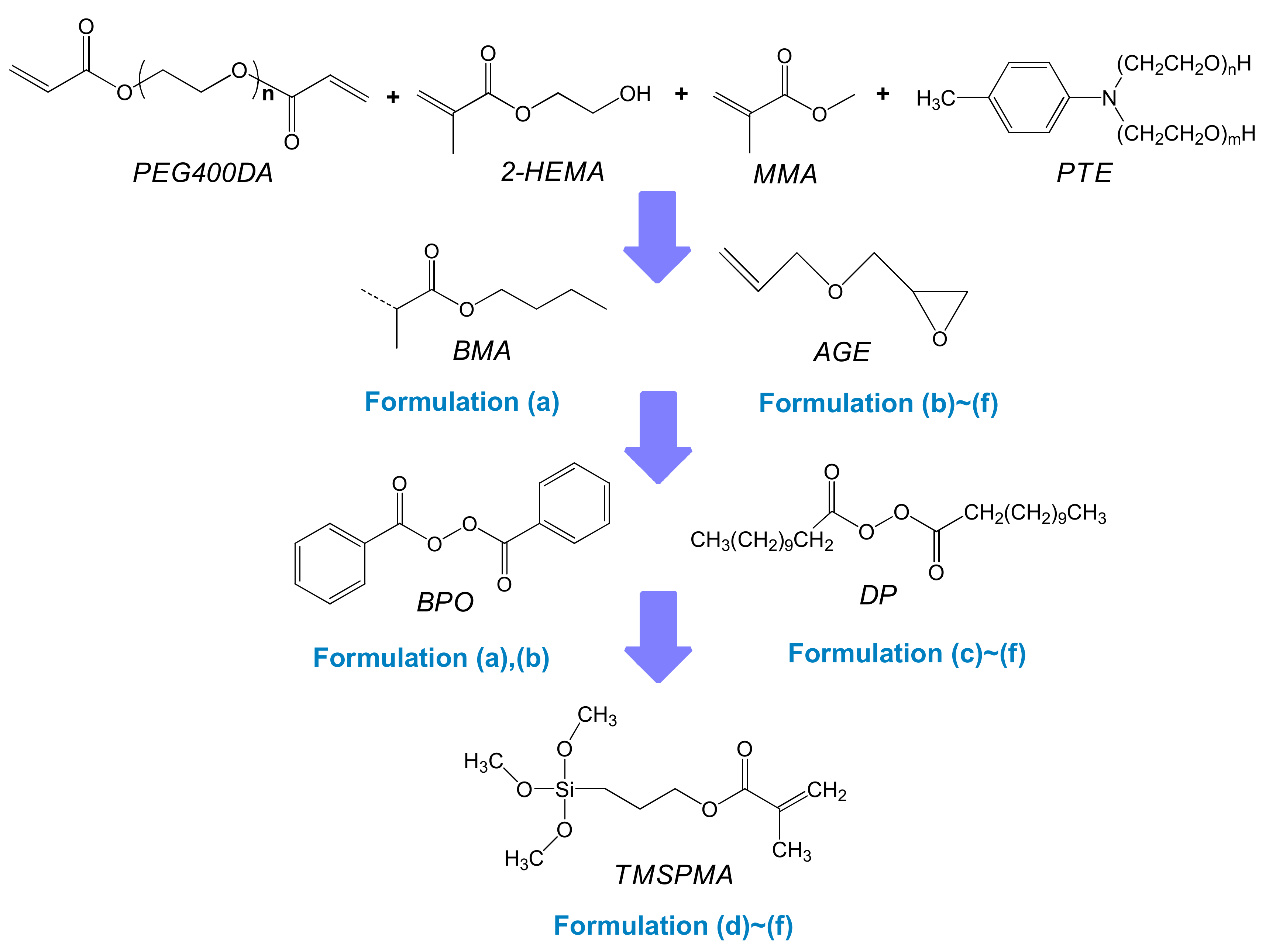

| Functionality | Component | Contents (wt%) | |||||

|---|---|---|---|---|---|---|---|

| (a) | (b) | (c) | (d) | (e) | (f) | ||

| Acrylic monomer | PEG400DA | 2.3 | 2.3 | 2.3 | 2.3 | 2.3 | 2.3 |

| 2-HEMA | 11.59 | 11.59 | 11.59 | 11.59 | 11.59 | 11.59 | |

| AGE | 36.8 | 36.8 | 36.8 | 36.8 | 36.8 | ||

| BMA | 16.8 | ||||||

| MMA | 66.4 | 46.4 | 46.4 | 41.4 | 31.4 | 21.4 | |

| Catalyst | PTE | 2.91 | 2.91 | 2.91 | 2.91 | 2.91 | 2.91 |

| Trivalent acrylate | TMSPMA | 5 | 15 | 25 | |||

| Curing agent | BPO | 2 | 2 | ||||

| DP | 2 | 2 | 2 | 2 | |||

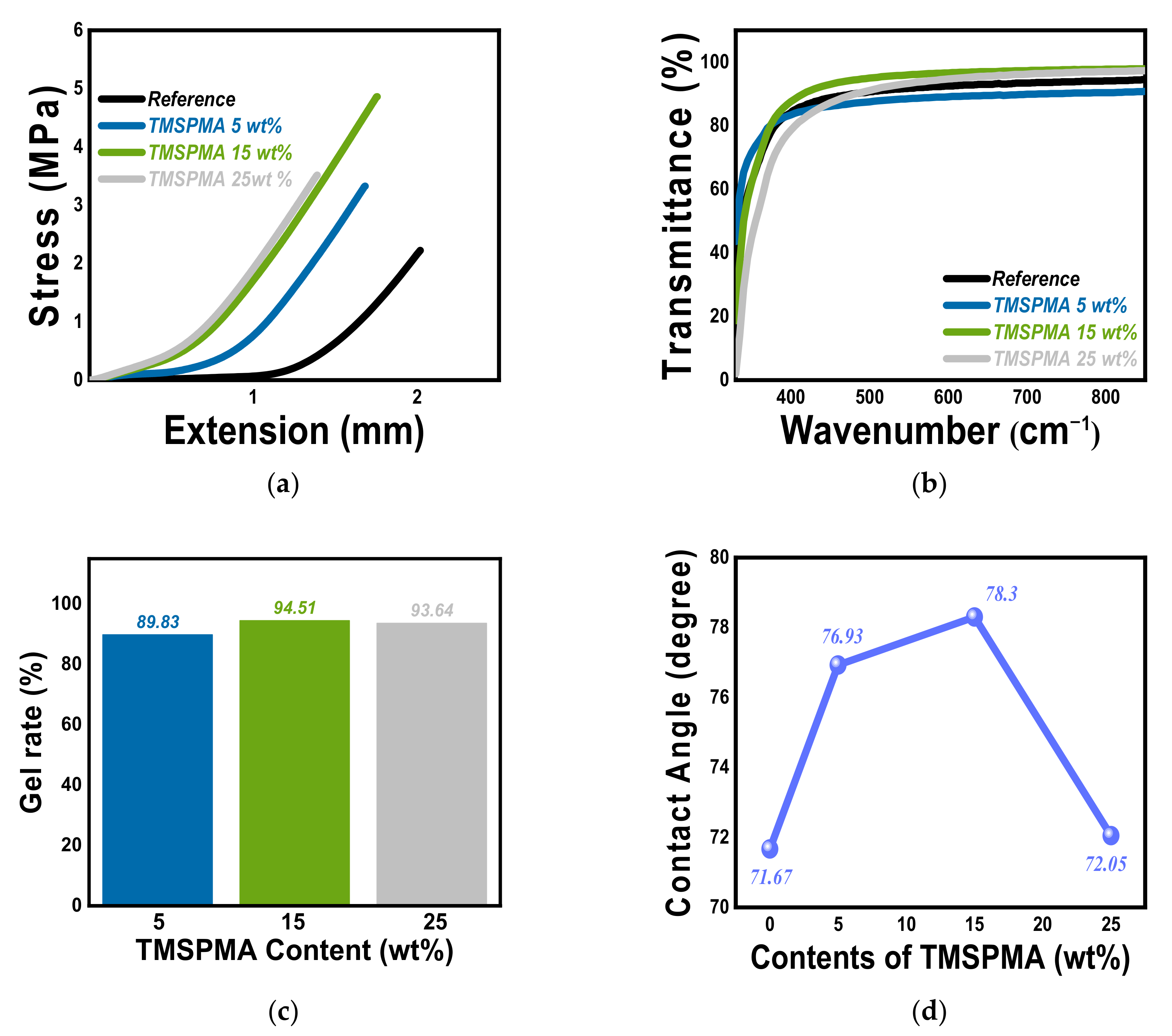

| Stress (MPa) | Transmittance 420 nm (%) | Gel Rate (%) | Contact Angle (Degree) | |

|---|---|---|---|---|

| 0 wt% | 2.22 | 86.7 | - | 71.67 |

| 5 wt% | 3.33 | 84.8 | 89.83 | 76.93 |

| 15 wt% | 4.86 | 90.6 | 94.51 | 78.3 |

| 25 wt% | 3.52 | 83 | 93.64 | 72.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, W.-B.; Bae, J.-H.; Lee, G.-H.; Lee, J.-H.; Min, J.-G.; Huh, P. Transparency- and Repellency-Enhanced Acrylic-Based Binder for Stimuli-Responsive Road Paint Safety Improvement Technology. Materials 2021, 14, 6829. https://doi.org/10.3390/ma14226829

Lim W-B, Bae J-H, Lee G-H, Lee J-H, Min J-G, Huh P. Transparency- and Repellency-Enhanced Acrylic-Based Binder for Stimuli-Responsive Road Paint Safety Improvement Technology. Materials. 2021; 14(22):6829. https://doi.org/10.3390/ma14226829

Chicago/Turabian StyleLim, Won-Bin, Ji-Hong Bae, Gyu-Hyeok Lee, Ju-Hong Lee, Jin-Gyu Min, and PilHo Huh. 2021. "Transparency- and Repellency-Enhanced Acrylic-Based Binder for Stimuli-Responsive Road Paint Safety Improvement Technology" Materials 14, no. 22: 6829. https://doi.org/10.3390/ma14226829