Thermo-Physiological Comfort Properties of Sportswear with Different Combination of Inner and Outer Layers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Fabric Thickness

2.2.2. Thermal Resistance

2.2.3. Thermal Conductivity

2.2.4. Thermal Absorptivity

2.2.5. Water Vapor Resistance

3. Results and Discussion

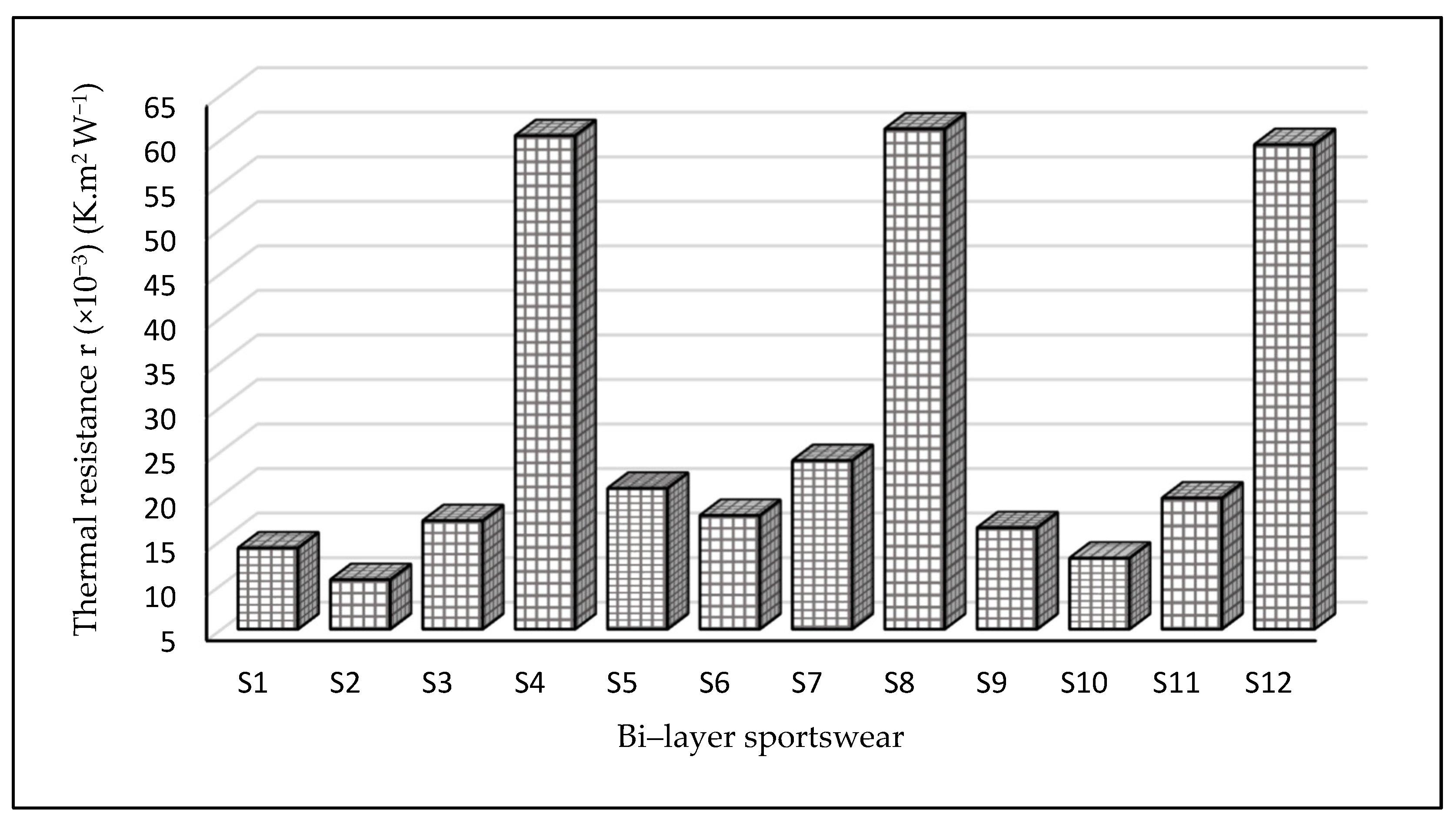

3.1. Thermal Resistance

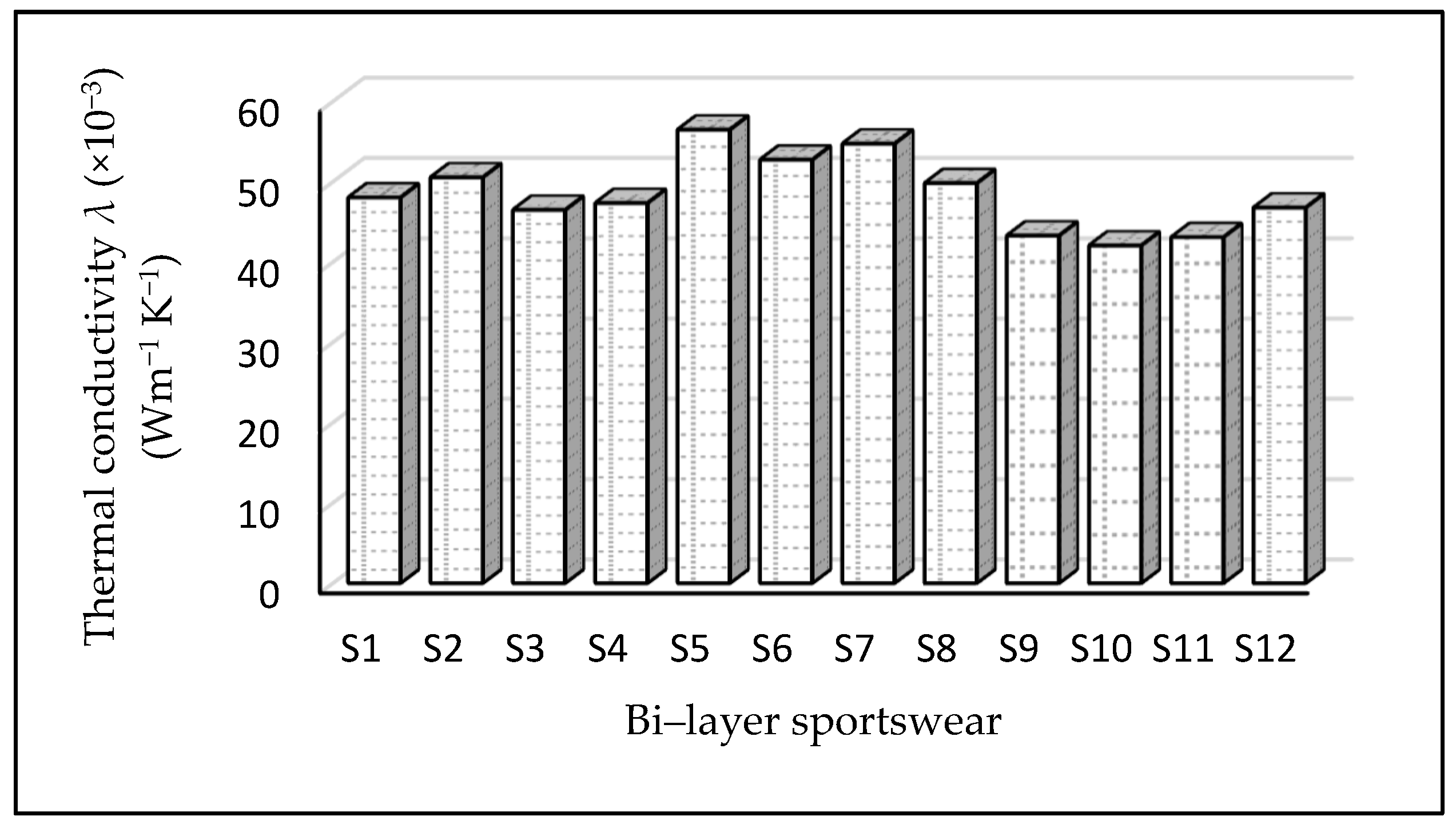

3.2. Thermal Conductivity

3.3. Thermal Absorptivity

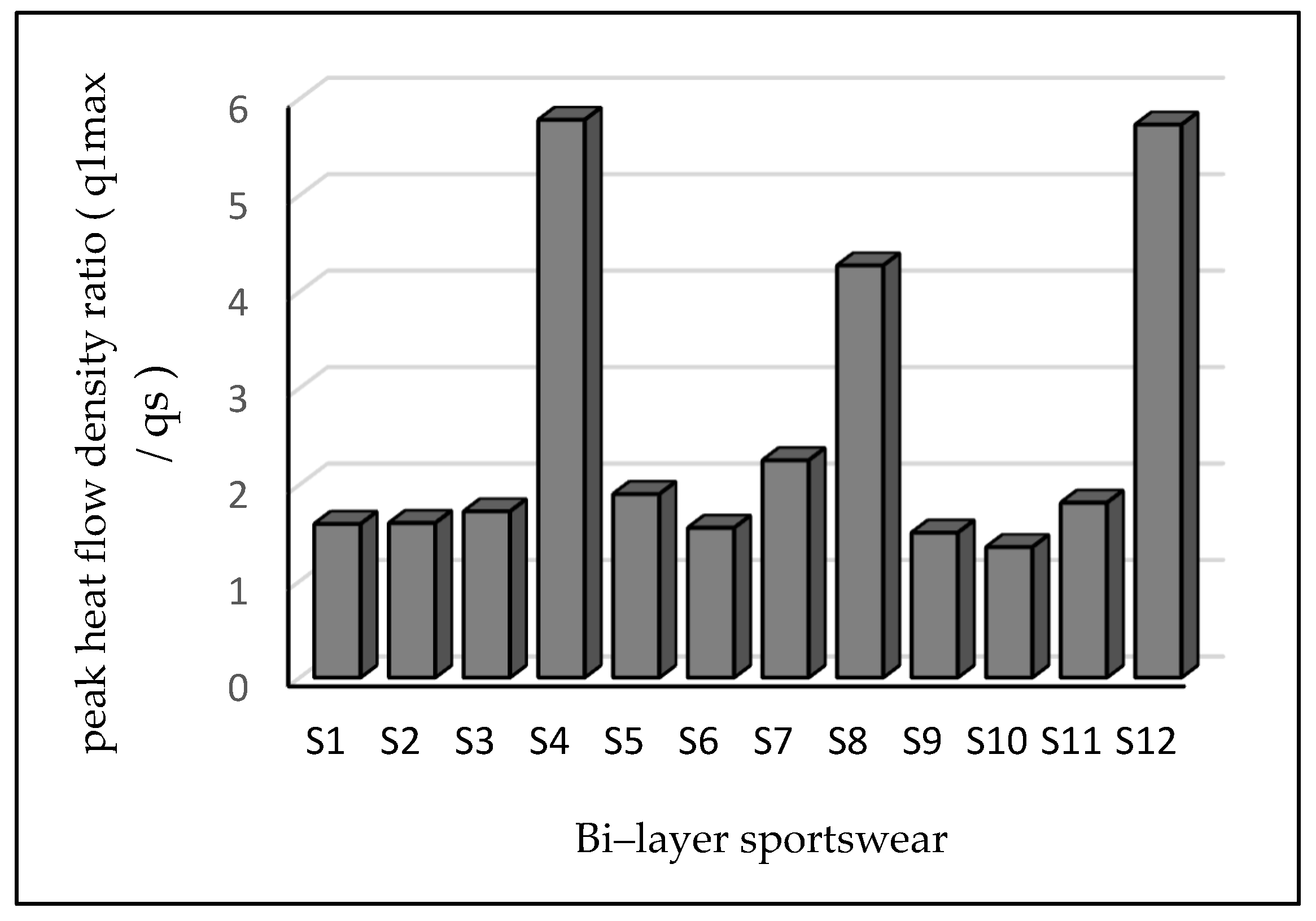

3.4. Ratio of Maximum and Stationary Heat Flow Density

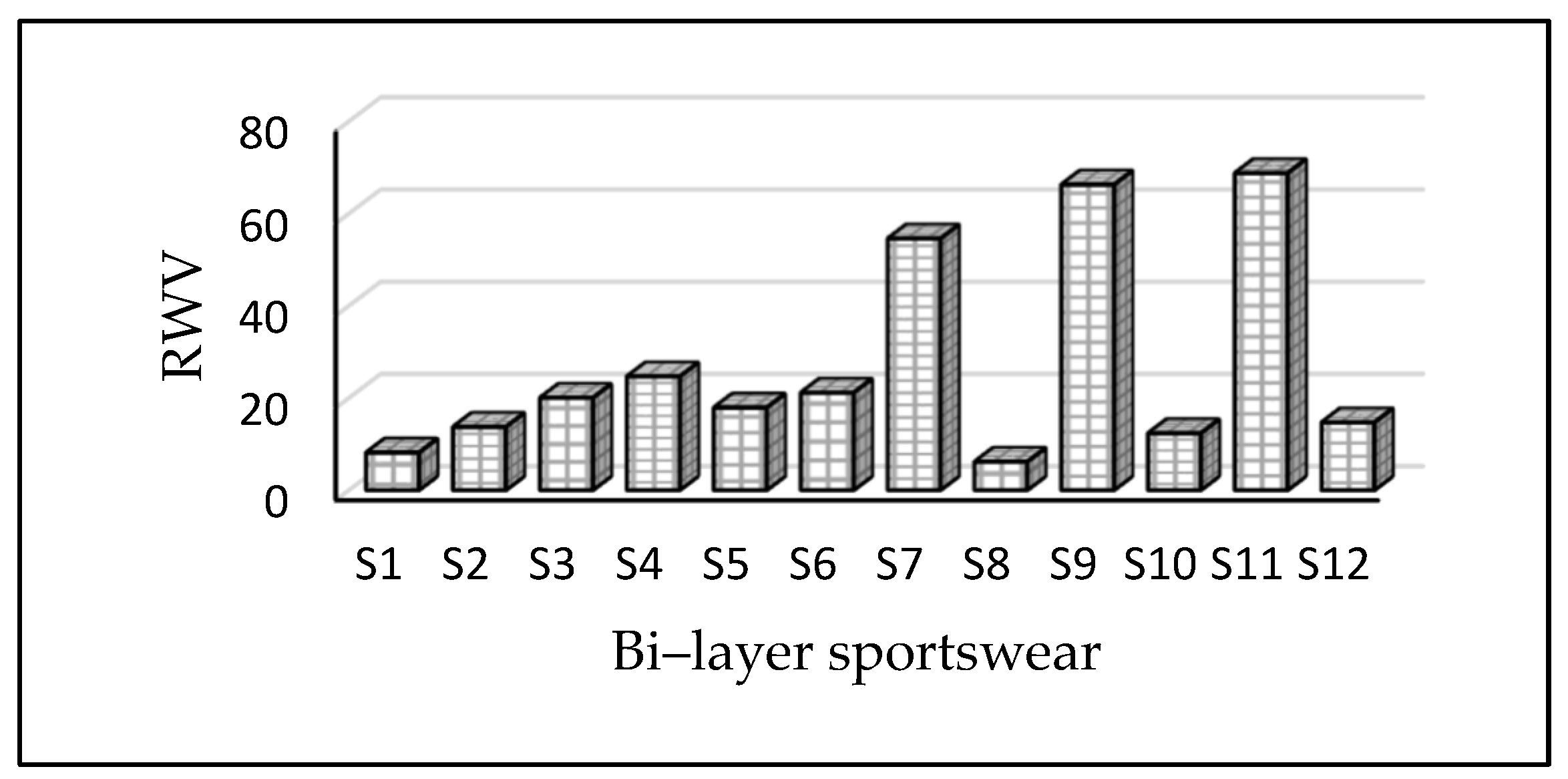

3.5. Stationary Heat Flow

3.6. Water Vapor Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kanat, Z.E. Sportswear. In Waterproof and Water Repellent Textiles and Clothing; Elsevier: Amsterdam, The Netherlands, 2018; pp. 367–390. [Google Scholar]

- Uttam, D. Active sportswear fabrics. Int. J. Res. Appl. Sci. Eng. Technol. 2013, 2, 34–40. [Google Scholar]

- Shishoo, R. Textiles in Sport; Woodhead Publishing: Sawston, UK, 2005. [Google Scholar]

- Rossi, R.M. Cold weather sports clothing. In Textiles for Sportswear; Elsevier: Amsterdam, The Netherlands, 2015; pp. 197–212. [Google Scholar]

- Harnett, P.R.; Mehta, P.N. A survey and comparison of laboratory test methods for measuring wicking. Text. Res. J. 1984, 54, 471–478. [Google Scholar] [CrossRef]

- Suganthi, T.; Senthilkumar, P.; Dipika, V. Thermal comfort properties of a bi-layer knitted fabric structure for volleyball sportswear. Fibres Text. East. Eur. 2017, 25, 75–80. [Google Scholar] [CrossRef]

- Krithika, S.M.U.; Sampath, M.B.; Rajwin, A.J.; Prakash, C.; Kumar, M.S.; Kumar, P.S. Moisture management properties of bi-layer knitted fabrics. Fibres Text. East. Eur. 2021, 29, 81–86. [Google Scholar] [CrossRef]

- Mbise, E.; Dias, T.; Hurley, W.; Morris, R. The study of applying heat to enhance moisture transfer in knitted spacer structures. J. Ind. Text. 2018, 47, 1584–1608. [Google Scholar] [CrossRef]

- Kumar, S.T.; Kumar, R.M.; Kumar, S.B. The effect of raw material combination, yarn count, fabric structure and loop length on the thermal properties of Eri-silk bi-layer knitted fabrics. Indu. Text 2021, 72, 331–339. [Google Scholar] [CrossRef]

- Babu, B.S.; Senthilkumar, P.; Senthilkumar, M. Effect of yarn linear density on moisture management characteristics of cotton/polypropylene double layer knitted fabrics. Ind. Text. 2015, 66, 123–130. [Google Scholar]

- Laing, R.M.; MacRae, B.A.; Wilson, C.A.; Niven, B.E. Layering of fabrics in laboratory tests to reflect combinations as outdoor apparel. Text. Res. J. 2011, 81, 1828–1842. [Google Scholar] [CrossRef]

- Choudhury, A.K.R.; Majumdar, P.K.; Datta, C. Factors affecting comfort: Human physiology and the role of clothing. In Improving Comfort in Clothing; Elsevier: Amsterdam, The Netherlands, 2011; pp. 3–60. [Google Scholar]

- Atalie, D.; Gideon, R.; Melesse, G.; Ferede, E.; Getnet, F.; Nibret, A. Thermo-physiological comfort of half bleached woven fabrics made from different cotton yarns parameters. J. Nat. Fibers 2021, 1–16. [Google Scholar] [CrossRef]

- Abbasi, S.A.; Marmaral, A.; Ertekin, G. Thermal comfort properties of weft knitted quilted fabrics. Int. J. Cloth. Sci. Technol. 2020, 32, 837–847. [Google Scholar] [CrossRef]

- Atalie, D.; Rotich, G.K. Impact of cotton parameters on sensorial comfort of woven fabrics. Res. J. Text. Appar. 2020, 24, 281–302. [Google Scholar] [CrossRef]

- Varshney, R.K.; Kothari, V.K.; Dhamija, S. A study on thermophysiological comfort properties of fabrics in relation to constituent fibre fineness and cross-sectional shapes. J. Text. Inst. 2010, 101, 495–505. [Google Scholar] [CrossRef]

- Nazir, M.U.; Shaker, K.; Nawab, Y.; Fazal, M.Z.; Khan, M.I.; Umair, M. Investigating the effect of material and weave design on comfort properties of bilayer-woven fabrics. J. Text. Inst. 2017, 108, 1319–1326. [Google Scholar] [CrossRef]

- Atalie, D.; Tesema, A.F.; Rotich, G.K. Effect of weft yarn twist level on thermal comfort of 100 per cent cotton woven fabrics. Res. J. Text. Appar. 2018, 22, 180–194. [Google Scholar] [CrossRef]

- Babu, B.S.; Kumar, P.S.; Kumar, M.S. Effect of yarn type on moisture transfer characteristics of double-face knitted fabrics for active sportswear. J. Ind. Text. 2020, 49, 1078–1099. [Google Scholar] [CrossRef]

- Nayak, R.; Kanesalingam, S.; Houshyar, S.; Wang, L.; Padhye, R.; Vijayan, A. Evaluation of thermal, moisture management and sensorial comfort properties of superabsorbent polyacrylate fabrics for the next-to-skin layer in firefighters’ protective clothing. Text. Res. J. 2018, 88, 1077–1088. [Google Scholar] [CrossRef]

- Manshahia, M.; Das, A. Comfort characteristics of knitted active sportswear: Liquid water transportation. Res. J. Text. Appar. 2013, 17, 38–49. [Google Scholar] [CrossRef]

- Awais, M.; Krzywinski, S.; Wölfling, B.; Classen, E. Thermal simulation of close-fitting sportswear. Energies 2020, 13, 2419. [Google Scholar] [CrossRef]

- Kamal, M.S.; Mahmoud, E.R.; Hassabo, A.G.; Eid, M.M. Effect of some construction factors of bi-layer knitted fabrics produced for sports wear on resisting ultraviolet radiation. Egypt. J. Chem. 2020, 63, 4369–4378. [Google Scholar] [CrossRef]

- Cho, S.; Cho, G.; Kim, C. Fabric sound depends on fiber and stitch types in weft knitted fabrics. Text. Res. J. 2009, 79, 761–767. [Google Scholar] [CrossRef]

- Niles, N.; Fernando, S.; Rathnayake, N.; Hewamalavi, A.; Weerasinghe, S. Two-layer fabrics for moisture management. Res. J. Text. Appar. 2021, 25, 64–74. [Google Scholar] [CrossRef]

- Karthik, T.; Senthilkumar, P.; Murugan, R. Analysis of comfort and moisture management properties of polyester/milkweed blended plated knitted fabrics for active wear applications. J. Ind. Text. 2018, 47, 897–920. [Google Scholar] [CrossRef]

- Gadkari, R.R.; Ali, S.W.; Joshi, M.; Rajendran, S.; Das, A.; Alagirusamy, R. Leveraging antibacterial efficacy of silver loaded chitosan nanoparticles on layer-by-layer self-assembled coated cotton fabric. Int. J. Biol. Macromol. 2020, 162, 548–560. [Google Scholar] [CrossRef]

- Suganthi, T.; Senthilkumar, P. Development of tri-layer knitted fabrics for shuttle badminton players. J. Ind. Text. 2018, 48, 738–760. [Google Scholar] [CrossRef]

- Huang, J. Review of heat and water vapor transfer through multilayer fabrics. Text. Res. J. 2016, 86, 325–336. [Google Scholar] [CrossRef]

- Troynikov, O.; Wardiningsih, W. Moisture management properties of wool/polyester and wool/bamboo knitted fabrics for the sportswear base layer. Text. Res. J. 2011, 81, 621–631. [Google Scholar] [CrossRef]

- Korger, M.; Glogowsky, A.; Sanduloff, S.; Steinem, C.; Huysman, S.; Horn, B.; Ernst, M.; Rabe, M. Testing thermoplastic elastomers selected as flexible three-dimensional printing materials for functional garment and technical textile applications. J. Eng. Fiber. Fabr. 2020, 15. [Google Scholar] [CrossRef]

- Lokhande, N.B.; Patil, P.L.G.; Awasare, P.A.U. Suitability of bi-layer knitted fabric for sportswear application. Int. J. Eng. Res. Technol. 2014, 3, 429–436. [Google Scholar]

- Nayak, R.; Kanessalingam, S.; Vijayan, A.; Wang, L.; Padhye, R.; Arnold, L. Impact resistance and comfort properties of textile structures for sportswear. Fibers Polym. 2020, 21, 2147–2159. [Google Scholar] [CrossRef]

- Mccann, J. Material requirements for the design of performance sportswear. Text. Sport 2005, 44–69. [Google Scholar] [CrossRef]

- Zhu, L.; Naebe, M.; Blanchonette, I.; Wang, X. Moisture transfer properties of bifacial fabrics. Text. Res. J. 2017, 87, 1096–1106. [Google Scholar] [CrossRef]

- Yang, Y.; Yu, X.; Chen, L.; Zhang, P. Effect of knitting structure and yarn composition on thermal comfort properties of bi-layer knitted fabrics. Text. Res. J. 2021, 91, 3–17. [Google Scholar] [CrossRef]

- Kumar, S.; Boominathan, S.K.; Raj, D.V.K. Comparative analysis on thermo-physiological behavior of eri silk, wool and bamboo knitted fabrics toward sportswear. J. Nat. Fibers 2021, 1–12. [Google Scholar] [CrossRef]

- Kumar, C.B.S.; Kumar, B.S. Study on thermal comfort properties of eri silk knitted fabrics for sportswear application. J. Nat. Fibers 2021, 1–12. [Google Scholar] [CrossRef]

- Mikalauskaitė, G.V.D. Investigation of the influence of bonding and thermal ageing duration on the peeling strength of knitted materials’ bonds. Mater. Sci. 2020, 26, 225–232. [Google Scholar] [CrossRef] [Green Version]

- Suganthi, P.S.T. Thermo-physiological comfort of layered knitted fabrics for sportswear. Tekstil ve Konfeksiyon 2017, 27, 352–360. [Google Scholar]

- Manshahia, M.; Das, A. High active sportswear—A critical review. Indian J. Fibre Text. Res. 2014, 39, 441–449. [Google Scholar]

- Bivainyte, A.; Mikučioniene, D. Investigation on the dynamic water absorption of double-layered weft knitted fabrics. Fibres Text. East. Eur. 2011, 19, 64–70. [Google Scholar]

- Özdil, N.; Anand, S. Recent developments in textile materials and products used for activewear and sportswear. Electron. J. Veh. Technol. 2014, 8, 68–83. [Google Scholar]

- Tadesse, M.G.; Nagy, L.; Nierstrasz, V.; Loghin, C.; Chen, Y.; Wang, L. Low-stress mechanical property study of various functional fabrics for tactile property evaluation. Materials 2018, 11, 2466. [Google Scholar] [CrossRef] [Green Version]

- Özdil, N.; Marmarali, A.; Kretzschmar, S.D. Effect of yarn properties on thermal comfort of knitted fabrics. Int. J. Therm. Sci. 2007, 46, 1318–1322. [Google Scholar] [CrossRef]

- Raj, A.E.N.; Yamunadevi, S. Application of textile fibres for technical and performance enhancements in sports. Int. J. Multidiscip. Res. Dev. 2016, 3, 40–45. [Google Scholar]

| Layers | Single Layer Code | Type of Material | Pattern/Printed | Thread Density/Cm | Fabric Weight (g/m2) | Fabric Structure | |

|---|---|---|---|---|---|---|---|

| Warp/Wales | Weft/Course | ||||||

| Inner layer | IL1 | 90% polyester 10% elastane | dyed | 30 | 17 | 177 | Woven ripstop |

| IL2 | 60% cotton 30% polyester 10% elastane | bleached | 29 | 16 | 198 | Woven ripstop | |

| IL3 | 100% elastane | white | 21 | 10 | 167 | Woven ripstop | |

| Outer layer | OL1 | 100% polyamide | dyed | 14 | 22 | 126 | Plain knitted PU coated |

| OL2 | 100% polyamide | dyed | 24 | 48 | 59 | Plain knitted PU coated | |

| OL3 | 95% polyester 5% elastane | dyed | 15 | 22 | 160 | Plain knitted | |

| OL4 | 100% polyester | printed | 26 | 18 | 361 | Plain woven | |

| Single Layer Code | Thickness (mm) | Thermal Resistance | Thermal Conductivity | Thermal Absorptivity | Peak Heat | Water Vapor Resistance |

| IL1 | 53.12 | 7.25 | 51.12 | 168 | 0.52 | 1.87 |

| IL2 | 40.35 | 13.58 | 44.46 | 141 | 0.39 | 3.48 |

| IL3 | 40.13 | 9.11 | 40.26 | 135 | 0.43 | 1.86 |

| OL1 | 30.63 | 6.17 | 30.67 | 11 | 0.51 | 73.35 |

| OL2 | 21.12 | 2.87 | 20.26 | 181 | 0.67 | 15.58 |

| OL3 | 31.45 | 8.98 | 31.45 | 131 | 0.41 | 3.39 |

| OL4 | 40.76 | 49.51 | 40.78 | 71 | 0.15 | 86.26 |

| Combined Fabric Code | Prepared from Inner Layer (IL) and Outer Layer (OL) | Combined Fabric Code | Prepared from Inner Layer (IL) and Outer Layer (OL) | |||

| S1 | IL1 + OL1 | S7 | IL2 + OL3 | |||

| S2 | IL1 + OL2 | S8 | IL2 + OL4 | |||

| S3 | IL1 + OL3 | S9 | IL3 + OL1 | |||

| S4 | IL1 + OL4 | S10 | IL3 + OL2 | |||

| S5 | IL2 + OL1 | S11 | IL3 + OL3 | |||

| S6 | IL2 + OL2 | S12 | IL3 + OL4 |

| Properties | Source of Variation | SS | df | MS | F | p-Value | F Crit |

|---|---|---|---|---|---|---|---|

| Thermal resistance | Between Groups | 43,649.33 | 11 | 3968.121 | 9766.801 | 0.000 | 1.8784 |

| Within Groups | 43.87896 | 108 | 0.406287 | ||||

| Thermal conductivity | Between Groups | 2329.853 | 11 | 211.8048 | 57,187,299 | 0.000 | 1.8783 |

| Within Groups | 0.0004 | 108 | 0.0000 | ||||

| Thermal absorptivity | Between Groups | 286,145.4 | 11 | 26,013.22 | 2.590388 | 0.011 | 1.8784 |

| Within Groups | 1,766,504 | 108 | 16,356.52 | ||||

| Peak heat flow density (q1max) | Between Groups | 0.175427 | 11 | 0.015948 | 83.12601 | 0.000 | 1.8784 |

| Within Groups | 0.02072 | 108 | 0.000192 | ||||

| Peak heat flow density ratio (q1max/qs) | Between Groups | 305.8382 | 11 | 27.80348 | 236,625.3 | 0.000 | 1.8783 |

| Within Groups | 0.01269 | 108 | 0.000118 | ||||

| Water vapor resistance | Between Groups | 49,967.29 | 11 | 4542.481 | 70,776.33 | 0.000 | 1.8898 |

| Within Groups | 6.161356 | 108 | 0.064181 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atalie, D.; Tesinova, P.; Tadesse, M.G.; Ferede, E.; Dulgheriu, I.; Loghin, E. Thermo-Physiological Comfort Properties of Sportswear with Different Combination of Inner and Outer Layers. Materials 2021, 14, 6863. https://doi.org/10.3390/ma14226863

Atalie D, Tesinova P, Tadesse MG, Ferede E, Dulgheriu I, Loghin E. Thermo-Physiological Comfort Properties of Sportswear with Different Combination of Inner and Outer Layers. Materials. 2021; 14(22):6863. https://doi.org/10.3390/ma14226863

Chicago/Turabian StyleAtalie, Desalegn, Pavla Tesinova, Melkie Getnet Tadesse, Eyasu Ferede, Ionuț Dulgheriu, and Emil Loghin. 2021. "Thermo-Physiological Comfort Properties of Sportswear with Different Combination of Inner and Outer Layers" Materials 14, no. 22: 6863. https://doi.org/10.3390/ma14226863