Application of Smart Materials in the Actuation System of a Gas Injector

Abstract

1. Introduction

2. Materials and Methods

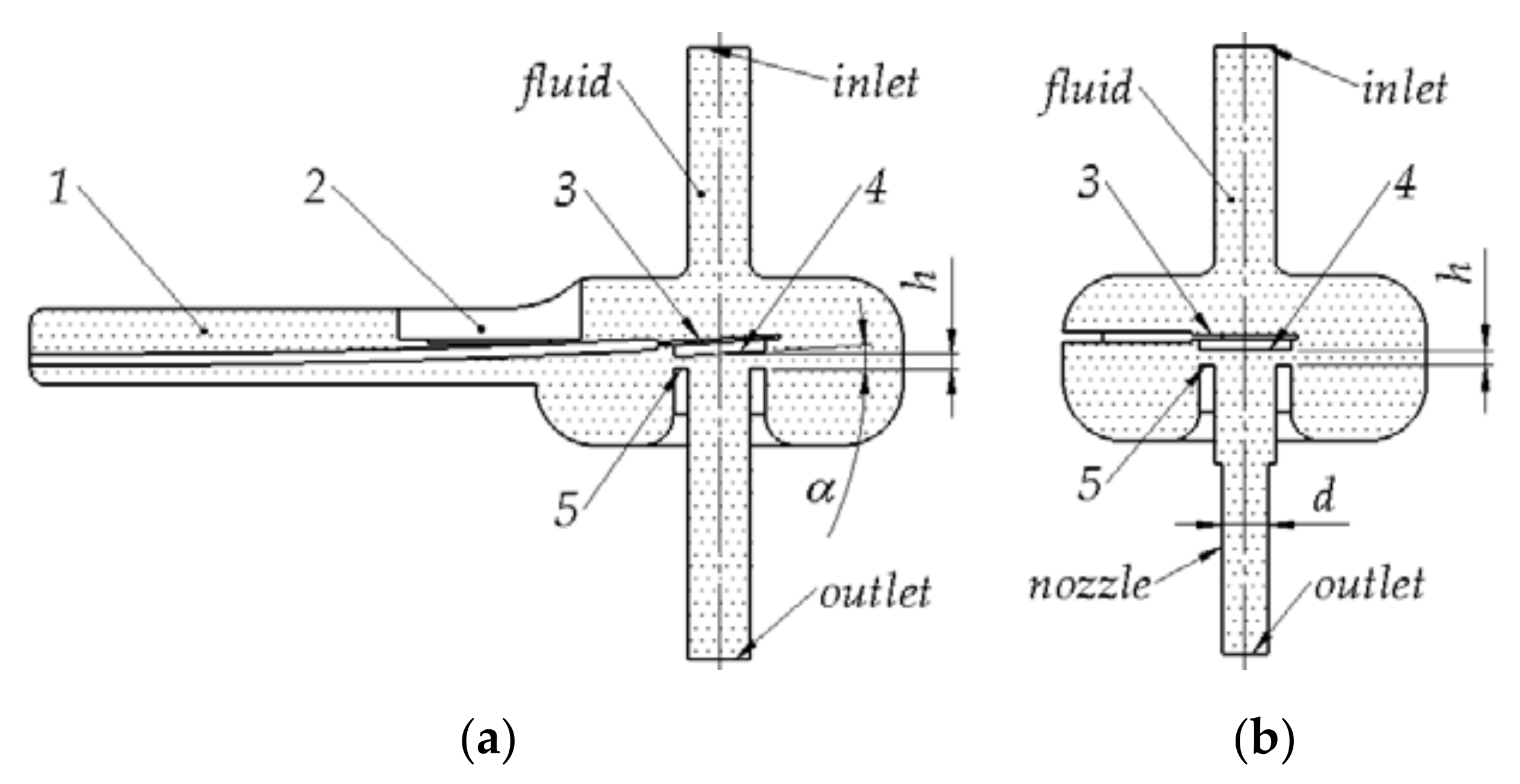

2.1. Research Object

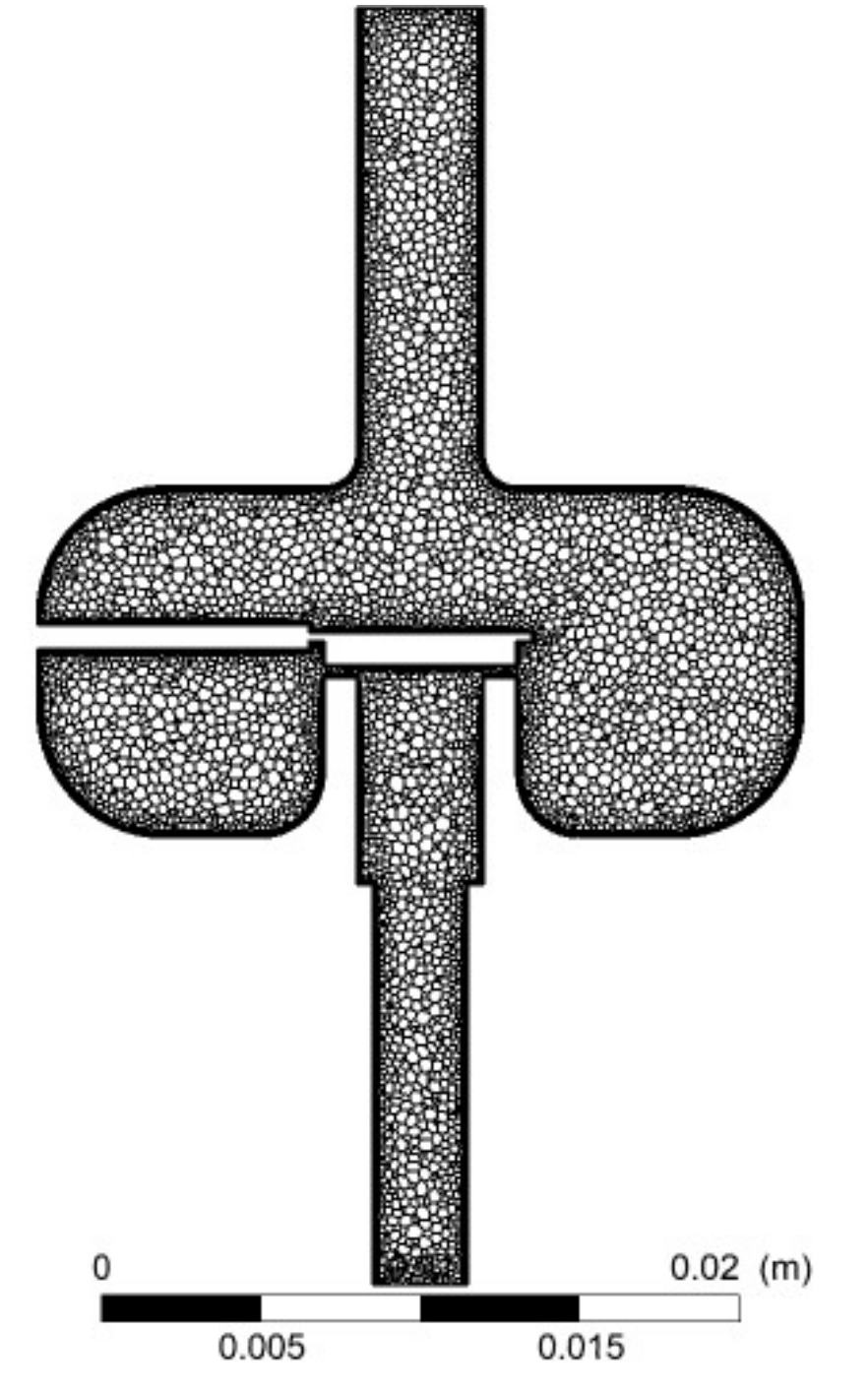

2.2. Flow Characteristics of the Injector

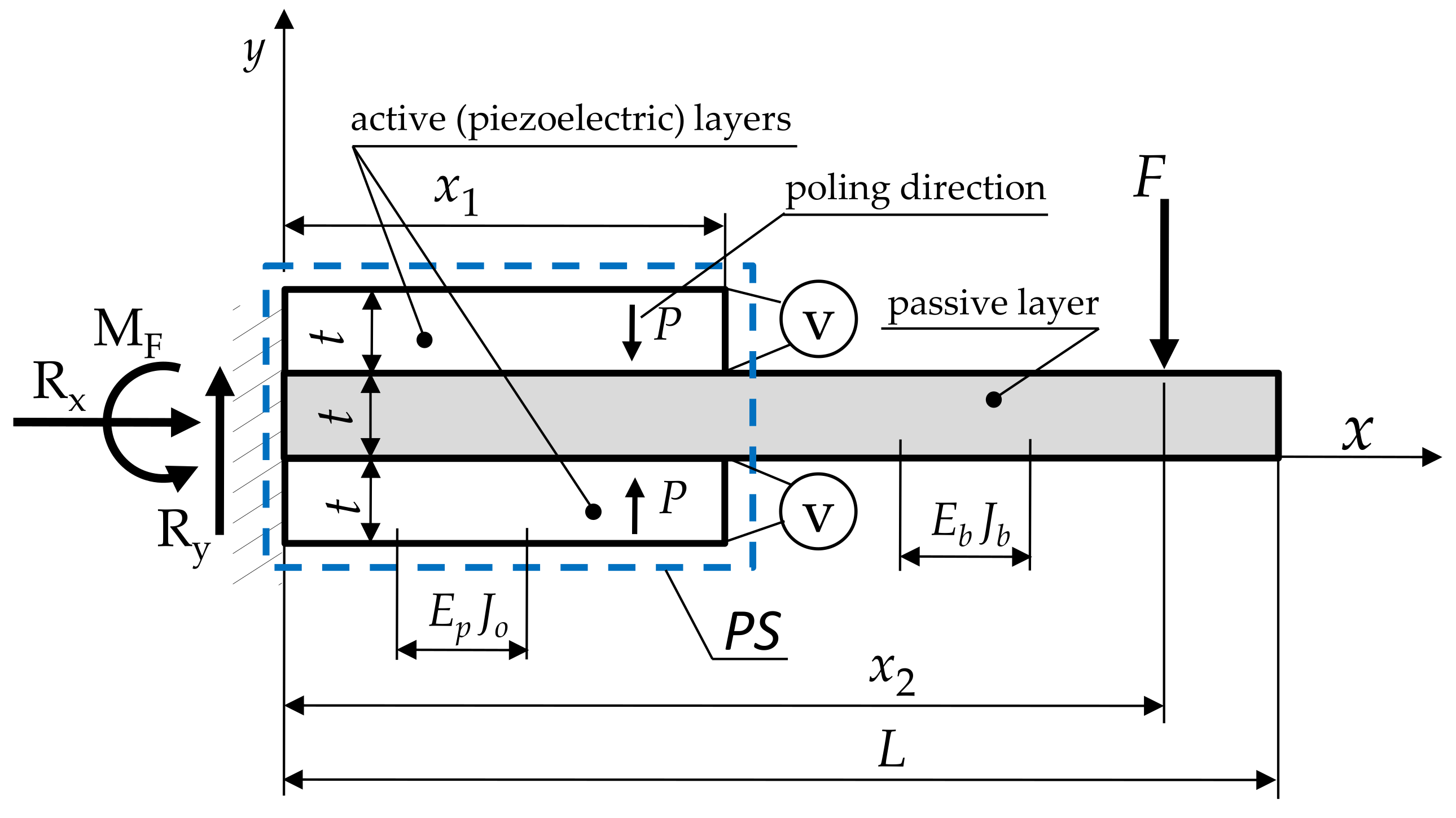

2.3. The Electromechanical Characteristics of a Piezoelectric Transducer

- The thicknesses of the beam and the piezoelectric segment are identical.

- The heights of the beam and the passive layer are the same.

- There is no intermediate layer at the interface between the components and there is no slippage.

- Bending of the transducer occurs according to Euler’s hypothesis with equal radii of curvature of the deformed components.

- There is a transverse piezoelectric effect 1-3 in the active layer, resulting in pure bending.

- Then, the constitutive equations were developed:

- —Heaviside’s function [50];

- —a coefficient to take account of the change in stiffness at the location of the PS;

- Ep, Eb—Young’s moduli of piezoelectric and passive elements;

- —moment of inertia of the beam element;

- —moment of inertia of PS segment [49];

- —bending moment due to mechanical load;

- —bending moment due to electric load [49];

- d31—piezoelectric constant.

2.4. Geometric and Material Features of a Piezoelectric Transducer

- Passive layer length L = 46 mm;

- Passive/active layer width b = 15 mm;

- Active layer length x1 = 41 mm;

- Layer thickness t = 0.25 mm;

- Coordinate of the point at which the force F is applied x2 = 44.5 mm.

3. Results and Discussion

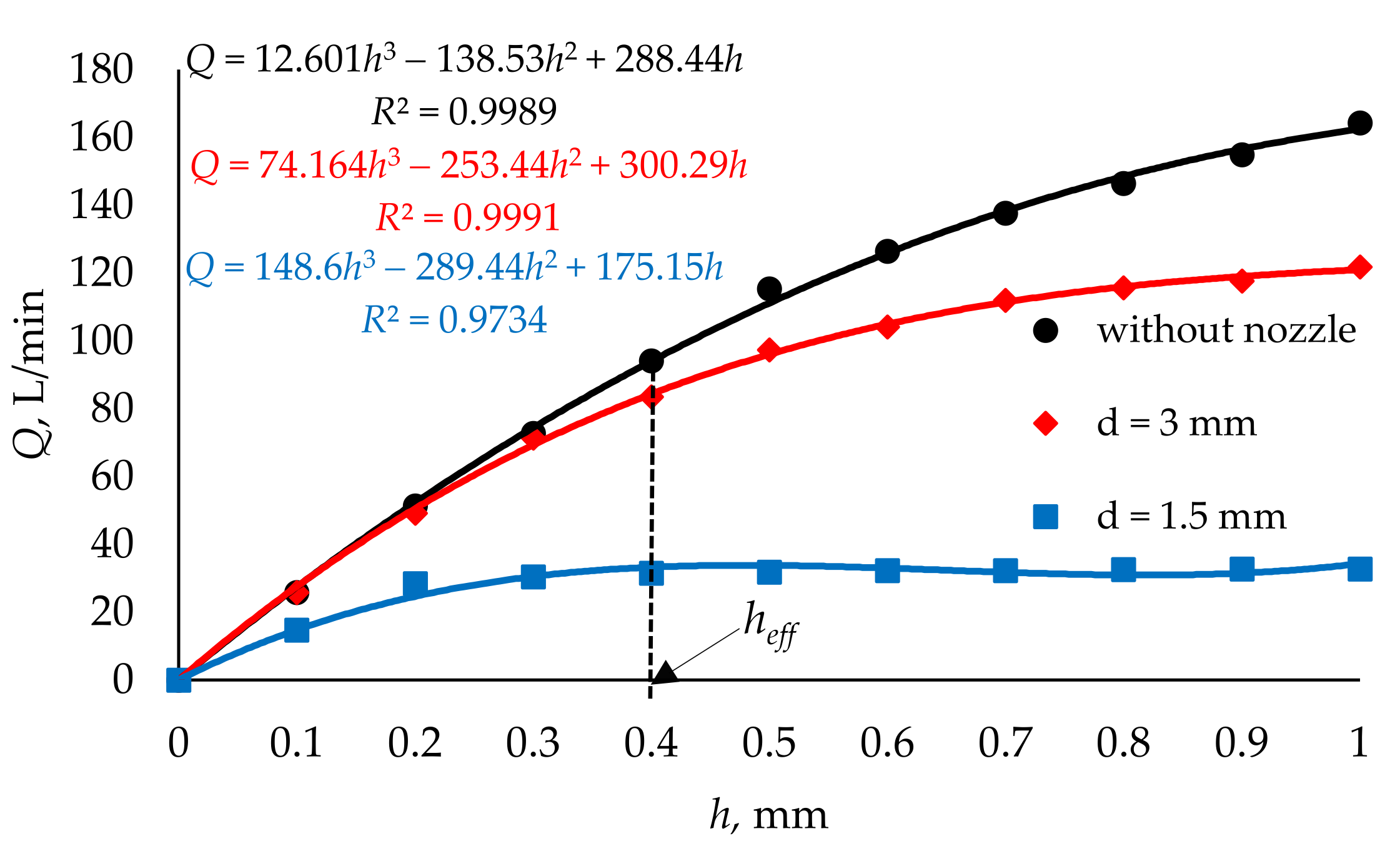

3.1. The Results of the Flow Test

3.2. Electromechanical Studies Results

4. Conclusions

- The initial tetrahedral mesh used each time had about 2 million elements; the skewness was about 0.21 and the orthogonal quality was close to 0.88. The Ansys Fluent software used for the calculations converted the tetrahedral mesh into a polyhedral mesh. In a further step using the in-solver SIMPLE scheme, significant flow parameters were determined with control values of all residuals being 1 × 10−4.

- The distributions of the pressure fields in the longitudinal section of the low-pressure gas-phase injector obtained from the flow tests showed a significant influence of the opening stage. The pressure difference in the areas upstream and downstream of the injector valve and the local vacuum zones were thus identified. The streamlines presented for the three cases of injector valve opening stages correlated with the pressure fields.

- CFD tests enabled the determination of flow characteristics of the low-pressure gas-phase injector. Three variants of the injector outlet diameter significantly differentiated the characteristics in question. Maximum values of volumetric flow rate in the examined range (0–1 mm) were as follows: d = 1.5 mm—Q = 32.82 L/min; d = 3 mm—Q = 121.93 L/min; without nozzle (d = 4 mm)—Q = 164.31 L/min

- Analysis of the flow characteristics made it possible to determine the effective degree of valve opening at heff = 0.4 mm. This was based on the volumetric flow rate variation.

- All material combinations, except those containing PVDF polymer, can be used in the actuator.

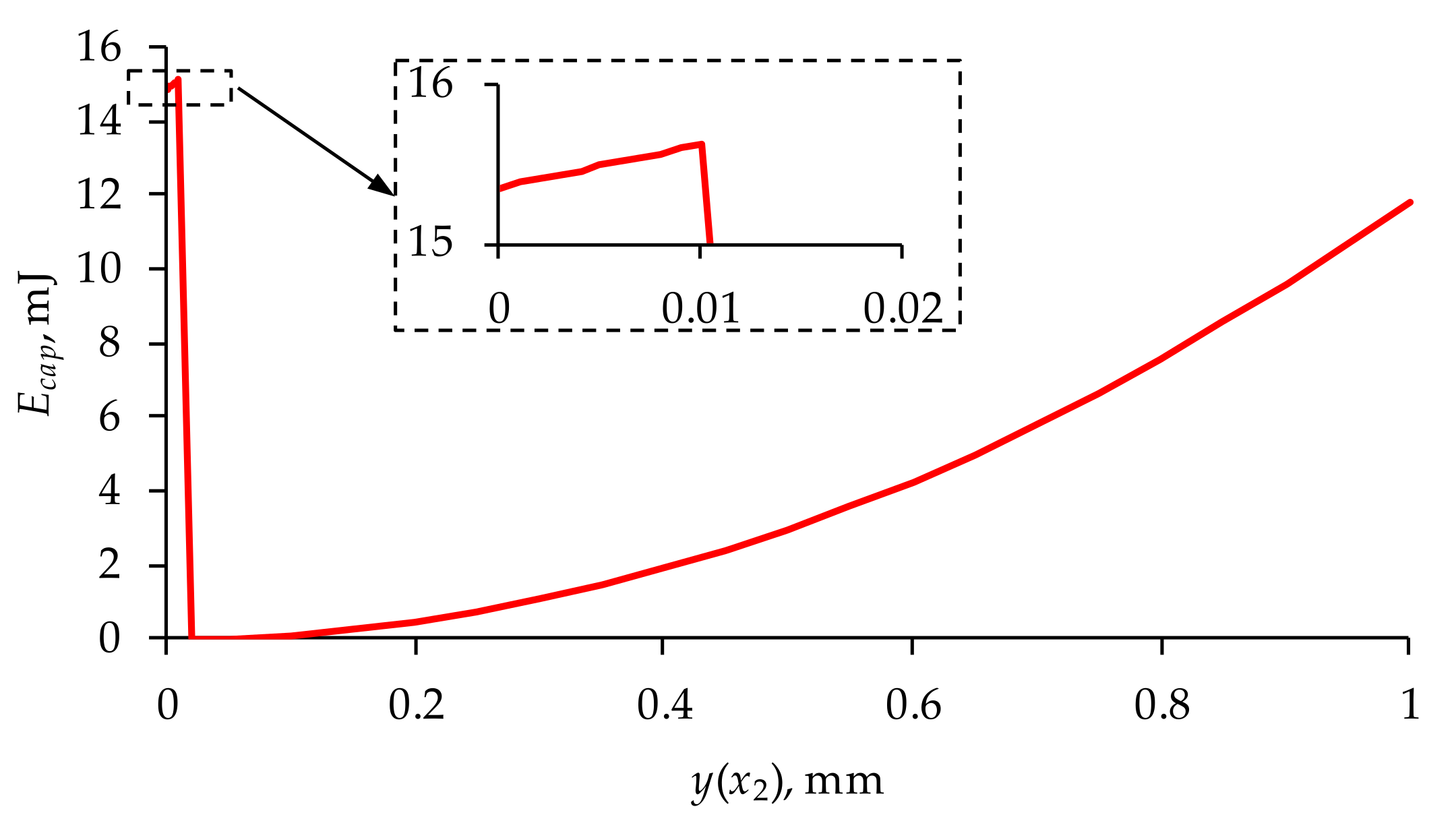

- The energy consumption is influenced by the material parameters of all transducer components. Generalizing, it can be said that it increases as the absolute value of the piezoelectric constant d31 decreases and the relative stiffness increases.

- The least energy-consuming design was the variant in which the active element of the transducer is made of PTZH5 and the passive element is made of silicon oxide.

- The energy consumption during valve unsealing is greater than that required to achieve effective valve opening.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Frigione, M.; Aguiar, J.L.B. Innovative Materials for Construction. Materials 2020, 13, 5448. [Google Scholar] [CrossRef]

- Bruni, A.; Serra, F.G.; Deregibus, A.; Castroflorio, T. Shape-Memory Polymers in Dentistry: Systematic Review and Patent Landscape Report. Materials 2019, 12, 2216. [Google Scholar] [CrossRef] [PubMed]

- Rogers, C.A. Smart Materials, Structures, and Mathematical Issues: Selected Papers Presented at the U.S. Army Research Office Workshop on Smart Materials, Structures, and Mathematical Issues; Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 15–16 September 1988. Available online: https://apps.dtic.mil/sti/pdfs/ADA218528.pdf (accessed on 1 October 2021).

- Zhao, Q.; Wang, L.; Zhao, K.; Yang, H. Development of a Novel Piezoelectric Sensing System for Pavement Dynamic Load Identification. Sensors 2019, 19, 4668. [Google Scholar] [CrossRef]

- Chen, N.; Yan, P.; Ouyang, J. A generalized approach on bending and stress analysis of beams with piezoelectric material bonded. Sens. Actuators A Phys. 2019, 290, 54–61. [Google Scholar] [CrossRef]

- Busch-Vishniac, I.J. Electromechanical Sensors and Actuators; Springer: New York, NY, USA, 1999; ISBN 978-0-387-98495-7. [Google Scholar]

- Liu, Z.; Chen, J.; Zou, X. Modeling the piezoelectric cantilever resonator with different width layers. Sensors 2021, 21, 87. [Google Scholar] [CrossRef]

- Asadi Dereshgi, H.; Dal, H.; Yildiz, M.Z. Piezoelectric micropumps: State of the art review. Microsyst. Technol. 2021, 27, 4127–4155. [Google Scholar] [CrossRef]

- Zaszczyńska, A.; Gradys, A.; Sajkiewicz, P. Progress in the applications of smart piezoelectric materials for medical devices. Polymers 2020, 12, 2754. [Google Scholar] [CrossRef]

- Makowski, M.; Knap, L. Study of a controlled piezoelectric damper. Sensors 2021, 21, 3509. [Google Scholar] [CrossRef]

- Kulkarni, H.; Zohaib, K.; Khusru, A.; Shravan Aiyappa, K. Application of piezoelectric technology in automotive systems. Mater. Today Proc. 2018, 5, 21299–21304. [Google Scholar] [CrossRef]

- Caban, J. Technologies of using energy harvesting systems in motor vehicles—Energy from suspension system. Eng. Rural Dev. 2021, 20, 1470–1477. [Google Scholar]

- Clairotte, M.; Suarez-Bertoa, R.; Zardini, A.A.; Giechaskiel, B.; Pavlovic, J.; Valverde, V.; Ciuffo, B.; Astorga, C. Exhaust emission factors of greenhouse gases (GHGs) from European road vehicles. Environ. Sci. Eur. 2020, 32, 125. [Google Scholar] [CrossRef]

- Leduc, P.; Dubar, B.; Ranini, A.; Monnier, G. Downsizing of gasoline engine: An efficient way to reduce CO2 emissions. Oil Gas. Sci. Technol. 2003, 58, 115–127. [Google Scholar] [CrossRef]

- Raslavičius, L.; Keršys, A.; Mockus, S.; Keršiene, N.; Starevičius, M. Liquefied petroleum gas (LPG) as a medium-term option in the transition to sustainable fuels and transport. Renew. Sustain. Energy Rev. 2014, 32, 513–525. [Google Scholar] [CrossRef]

- Raslavičius, L.; Keršys, A.; Makaras, R. Management of hybrid powertrain dynamics and energy consumption for 2WD, 4WD, and HMMWV vehicles. Renew. Sustain. Energy Rev. 2017, 68, 380–396. [Google Scholar] [CrossRef]

- Bielaczyc, P.; Woodburn, J. Trends in Automotive Emission Legislation: Impact on LD Engine Development, Fuels, Lubricants and Test Methods: A Global View, with a Focus on WLTP and RDE Regulations. Emiss. Control. Sci. Technol. 2019, 5, 86–98. [Google Scholar] [CrossRef]

- Jemni, M.A.; Kassem, S.H.; Driss, Z.; Abid, M.S. Effects of hydrogen enrichment and injection location on in-cylinder flow characteristics, performance and emissions of gaseous LPG engine. Energy 2018, 150, 92–108. [Google Scholar] [CrossRef]

- Khan, M.I.; Yasmeen, T.; Khan, M.I.; Farooq, M.; Wakeel, M. Research progress in the development of natural gas as fuel for road vehicles: A bibliographic review (1991–2016). Renew. Sustain. Energy Rev. 2016, 66, 702–741. [Google Scholar] [CrossRef]

- Wendeker, M.; Jakliński, P.; Czarnigowski, J.; Boulet, P.; Breaban, F. Operational Parameters of LPG Fueled si Engine—Comparison of Simultaneous and Sequential Port Injection; SAE Technical Paper 2007-01–2051; SAE International: Pittsburgh, PA, USA, 2007. [Google Scholar] [CrossRef]

- Borawski, A. Modification of a fourth generation LPG installation improving the power supply to a spark ignition engine. Eksploat. Niezawodn. 2015, 17, 1. [Google Scholar] [CrossRef]

- Szpica, D. Coefficient of Engine Flexibility as a Basis for the Assessment of Vehicle Tractive Performance. Chin. J. Mech. Eng. 2019, 32, 39. [Google Scholar] [CrossRef]

- Anandarajah, G.; McDowall, W.; Ekins, P. Decarbonising road transport with hydrogen and electricity: Long term global technology learning scenarios. Int. J. Hydrog. Energy 2013, 38, 3419–3432. [Google Scholar] [CrossRef]

- Johnson, E. LPG: A secure, cleaner transport fuel? A policy recommendation for Europe. Energy Policy 2003, 31, 1573–1577. [Google Scholar] [CrossRef]

- Mock, R.; Lubitz, K. Piezoelectric Injection Systems. In Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2008; Volume 114. [Google Scholar]

- Yu, W.; Yang, W.; Zhao, F. Investigation of internal nozzle flow, spray and combustion characteristics fueled with diesel, gasoline and wide distillation fuel (WDF) based on a piezoelectric injector and a direct injection compression ignition engine. Appl. Therm. Eng. 2017, 114, 905–920. [Google Scholar] [CrossRef]

- Payri, R.; Salvador, F.J.; Gimeno, J.; Montiel, T. Aging of a Multi-Hole Diesel Injector and Its Effect on the Rate of Injection; SAE Technical Papers 2020-01-0829; SAE International: Pittsburgh, PA, USA, 2020. [Google Scholar]

- Caika, V.; Kammerdiener, T.; Dörr, N. Operation of Piezoelectric Common Rail Injector with Diesel and FT-Kerosene; SAE Technical Papers 2007-24-0070; SAE International: Pittsburgh, PA, USA, 2007. [Google Scholar]

- Yu, W.; Yang, W.; Tay, K.; Mohan, B.; Zhao, F.; Zhang, Y. Macroscopic spray characteristics of kerosene and diesel based on two different piezoelectric and solenoid injectors. Exp. Therm. Fluid Sci. 2016, 76, 12–23. [Google Scholar] [CrossRef]

- Magno, A.; Mancaruso, E.; Vaglieco, B.M. Experimental investigation in an optically accessible diesel engine of a fouled piezoelectric injector. Energy 2014, 64, 842–852. [Google Scholar] [CrossRef]

- D’Ambrosio, S.; Ferrari, A.; Mancarella, A.; Mancò, S.; Mittica, A. Comparison of the emissions, noise, and fuel consumption comparison of direct and indirect piezoelectric and solenoid injectors in a low-compression-ratio diesel engine. Energies 2019, 12, 4023. [Google Scholar] [CrossRef]

- Skogsberg, M.; Dahlander, P.; Denbratt, I. Spray Shape and Atomization Quality of an Outward-Opening Piezo Gasoline di Injector; SAE Technical Papers; SAE International: Pittsburgh, PA, USA, 2007. [Google Scholar]

- Anzinger, C.; Schmid, U.; Kroetz, G.; Klein, M. A Piezoelectric Driven Microinjector for Dl-Gasoline Applications. In Advanced Microsystems for Automotive Applications Yearbook 2002; Krueger, S., Gessner, W., Eds.; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Wang, X.; Zhao, H. Understanding of closely spaced split injections of an outward-opening piezoelectric gasoline injector by large eddy simulations. In Proceedings of the International Conference on Liquid Atomization and Spray Systems (ICLASS), Edinburgh, UK, 29 August–2 September 2021; Volume 1. [Google Scholar]

- Wu, Z.; Wang, L.; Badra, J.A.; Roberts, W.L.; Fang, T. GDI fuel sprays of light naphtha, PRF95 and gasoline using a piezoelectric injector under different ambient pressures. Fuel 2018, 223, 294–311. [Google Scholar] [CrossRef]

- Kuensch, Z.A.; Schlatter, S.; Keskinen, K.; Hulkkonen, T.; Larmi, M.; Boulouchos, K. Experimental Investigation on the Gas Jet Behavior for a Hollow Cone Piezoelectric Injector; SAE Technical Papers; SAE International: Pittsburgh, PA, USA, 2014. [Google Scholar]

- Altieri, L.; Tonoli, A. Piezoelectric injectors for automotive applications: Modeling and experimental validation of hysteretic behavior and temperature effects. J. Dyn. Syst. Meas. Control. Trans. ASME 2013, 135, 011005. [Google Scholar] [CrossRef]

- Taş, İ.; Karamangil, M.İ. Numerical Investigation of the Spray Characteristics in an Outwardly-Opening Piezoelectric Gasoline Injector for Different Ambient Conditions. Uludağ Univ. J. Fac. Eng. 2019, 24, 185–202. [Google Scholar] [CrossRef]

- Peiner, E.; Doering, L. Characterization of diesel injectors using piezoresistive sensors. In Proceedings of the IEEE Sensors, Waikoloa, HI, USA, 1–4 November 2010. [Google Scholar]

- Czarnigowski, J. Teoretyczno-Empiryczne Studium Modelowania Impulsowego Wtryskiwacza Gazu; Wydawnictwo Politechniki Lubelskiej: Lublin, Poland, 2012; ISBN PL 978-83-63569-09-9. [Google Scholar]

- D’ambrosio, S.; Ferrari, A. Diesel engines equipped with piezoelectric and solenoid injectors: Hydraulic performance of the injectors and comparison of the emissions, noise and fuel consumption. Appl. Energy 2018, 211, 1324–1342. [Google Scholar]

- Le, D.; Pietrzak, B.W.; Shaver, G.M. Dynamic surface control of a piezoelectric fuel injector during rate shaping. Control. Eng. Pract. 2014, 30, 12–26. [Google Scholar] [CrossRef]

- Mikulski, M.; Bekdemir, C. Understanding the role of low reactivity fuel stratification in a dual fuel RCCI engine—A simulation study. Appl. Energy 2017, 191, 689–708. [Google Scholar] [CrossRef]

- Szpica, D.; Mieczkowski, G.; Borawski, A. Iniettore di gas piezoelettrico, specialmente per i sistemi di alimentazione di motori a combustione. IT Patent N. 102019000005520, 24 February 2021. [Google Scholar]

- Yang, Z.; Cheng, X.; Zheng, X.; Chen, H. Reynolds-Averaged Navier-Stokes Equations Describing Turbulent Flow and Heat Transfer Behavior for Supercritical Fluid. J. Therm. Sci. 2021, 30, 191–200. [Google Scholar] [CrossRef]

- Matyushenko, A.A.; Garbaruk, A.V. Adjustment of the k-ω SST turbulence model for prediction of airfoil characteristics near stall. J. Phys. Conf. Ser. 2016, 769, 012082. [Google Scholar] [CrossRef]

- ANSYS Fluent Tutorial Guide, 18.0 ed; ANSYS, Inc.: Canonsburg, PA, USA, 2018; Available online: http://users.abo.fi/rzevenho/ansys%20fluent%2018%20tutorial%20guide.pdf (accessed on 1 October 2021).

- Mieczkowski, G. Electromechanical characteristics of piezoelectric converters with freely defined boundary conditions and geometry. Mechanika 2016, 22, 265–272. [Google Scholar] [CrossRef][Green Version]

- Mieczkowski, G. The constituent equations of piezoelectric cantilevered three-layer actuators with various external loads and geometry. J. Theor. Appl. Mech. 2017, 55, 69–86. [Google Scholar] [CrossRef]

- Smith, J.J. An analogy between pure mathematics and the operational mathematics of Heaviside by means of the theory of H-functions. J. Franklin Inst. 1925, 200, 519–534. [Google Scholar] [CrossRef]

- Spearing, S.M. Materials issues in microelectromechanical systems (MEMS). Acta Mater. 2000, 48, 179–196. [Google Scholar] [CrossRef]

- Tichý, J.; Erhart, J.; Kittinger, E.; Přívratská, J. Fundamentals of Piezoelectric Sensorics: Mechanical, Dielectric, and Thermodynamical Properties of Piezoelectric Materials; Springer: Berlin/Heidelberg, Germany, 2010; pp. 1–207. [Google Scholar]

- Szpica, D. Validation of indirect methods used in the operational assessment of LPG vapor phase pulse injectors. Meas. J. Int. Meas. Confed. 2018, 118, 253–261. [Google Scholar] [CrossRef]

- Szpica, D. The determination of the flow characteristics of a low-pressure vapor-phase injector with a dynamic method. Flow Meas. Instrum. 2018, 62, 44–55. [Google Scholar] [CrossRef]

- Gautschi, G. Piezoelectric Sensorics; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Latalski, J. Modelling of macro fiber composite piezoelectric active elements in ABAQUS system. Maint. Reliab. 2011, 4, 72–78. [Google Scholar]

| Passive Materials | ||||||||

|---|---|---|---|---|---|---|---|---|

| Aluminum | Silicon Oxide | Silicon | Copper | Nickel | Silicon Nitride | Aluminum Oxide | Silicon Carbide | |

| Eb (GPa) | 69 | 73 | 129 | 135 | 207 | 304 | 393 | 430 |

| Piezoelectric Materials | |||||

|---|---|---|---|---|---|

| Polymer | Ceramic | ||||

| Soft | Hard | ||||

| PVDF | PTZ5H | APC856 | APC841 | PTZ8 | |

| Ep (GPa) | 3 | 62.1 | 66.6 | 85.4 | 86.9 |

| d31 (pC/N) | 23 | −320 | −260 | −109 | −97 |

| εr | 12 | 3400 | 4100 | 1350 | 1100 |

| Piezoelectric Materials | ||||||

|---|---|---|---|---|---|---|

| PVDF | PTZ5H | APC856 | APC841 | PTZ8 | ||

| Passive MEMS materials | Aluminum | 4.87 * | 1.88 * | 3.41 * | 6.26 * | 6.44 * |

| 4142.36 ** | 152.91 ** | 187.65 ** | 443.02 ** | 497.52 ** | ||

| Silicon Oxide | 5.16 * | 1.89 * | 3.43 * | 6.29 * | 6.46 * | |

| 4265.10 ** | 153.34 ** | 188.07 ** | 443.93 ** | 498.53 ** | ||

| Silicon | 10.16 * | 2.04 * | 3.68 * | 6.66 * | 6.83 | |

| 5983.42 ** | 159.30 ** | 194.92 ** | 456.67 ** | 512.59 | ||

| Copper | 10.79 * | 2.06 * | 3.71 | 6.70 * | 6.87 * | |

| 6167.52 ** | 159.94 ** | 195.65 ** | 458.03 ** | 514.10 ** | ||

| Nickel | 19.91 * | 2.26 | 4.05 * | 7.18 * | 7.37 ** | |

| 8376.78 ** | 167.61 ** | 204.46 ** | 474.41 ** | 532.18 ** | ||

| Silicon Nitride | 36.57 * | 2.55 | 4.54 * | 7.87 * | 8.05 * | |

| 11,353.15 ** | 177.95 ** | 216.32 ** | 496.47 ** | 556.55 ** | ||

| Aluminum Oxide | 56.27 * | 2.83 * | 5.00 * | 8.52 * | 8.74 * | |

| 14,084.04 ** | 187.75 ** | 227.20 ** | 516.71 ** | 579.66 ** | ||

| Silicon Carbide | 68.39 | 2.94 * | 5.20 * | 8.80 * | 9.00 * | |

| 15,526.20 ** | 191.37 ** | 231.72 ** | 525.13 ** | 588.20 ** | ||

| Piezoelectric Materials | ||||||

|---|---|---|---|---|---|---|

| PVDF | PTZ5H | APC856 | APC841 | PTZ8 | ||

| Passive MEMS materials | Aluminum | 4949.24 * | 15.13 * | 24.07 * | 27.67 * | 27.51 * |

| 132,083.49 ** | 433.80 ** | 498.29 ** | 931.07 ** | 1028.59 ** | ||

| Silicon Oxide | 4972.49 * | 15.12 | 24.06 * | 27.64 * | 27.48 * | |

| 132,393.35 ** | 433.73 | 498.18 ** | 930.60 ** | 1028.05 | ||

| Silicon | 5208.23 * | 15.16 * | 24.08 * | 27.54 * | 27.37 * | |

| 135,495.35 ** | 434.26 ** | 498.47 ** | 928.91 ** | 1026.00 ** | ||

| Copper | 5226.50 * | 15.17 * | 24.10 * | 27.54 * | 27.38 * | |

| 135,732.80 ** | 434.41 ** | 498.61 ** | 929.00 ** | 1026.09 ** | ||

| Nickel | 5388.43 * | 15.32 * | 24.31 * | 27.69 * | 27.52 * | |

| 137,819.44 ** | 436.54 ** | 500.81 * | 931.48 ** | 1028.70 ** | ||

| Silicon Nitride | 5514.44 * | 15.54 * | 24.64 * | 27.98 * | 27.80 * | |

| 139,421.67 ** | 439.73 ** | 504.22 ** | 936.29 ** | 1033.89 ** | ||

| Aluminum Oxide | 5587.22 * | 15.75 * | 24.95 * | 28.26 * | 28.08 * | |

| 140,338.68 ** | 442.67 ** | 507.33 ** | 940.97 ** | 1039.16 ** | ||

| Silicon Carbide | 5616.46 * | 15.83 * | 25.07 | 28.38 * | 28.19 * | |

| 140,705.35 ** | 443.72 ** | 508.58 ** | 942.91 | 1041.10 ** | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mieczkowski, G.; Szpica, D.; Borawski, A.; Diliunas, S.; Pilkaite, T.; Leisis, V. Application of Smart Materials in the Actuation System of a Gas Injector. Materials 2021, 14, 6984. https://doi.org/10.3390/ma14226984

Mieczkowski G, Szpica D, Borawski A, Diliunas S, Pilkaite T, Leisis V. Application of Smart Materials in the Actuation System of a Gas Injector. Materials. 2021; 14(22):6984. https://doi.org/10.3390/ma14226984

Chicago/Turabian StyleMieczkowski, Grzegorz, Dariusz Szpica, Andrzej Borawski, Saulius Diliunas, Tilmute Pilkaite, and Vitalis Leisis. 2021. "Application of Smart Materials in the Actuation System of a Gas Injector" Materials 14, no. 22: 6984. https://doi.org/10.3390/ma14226984

APA StyleMieczkowski, G., Szpica, D., Borawski, A., Diliunas, S., Pilkaite, T., & Leisis, V. (2021). Application of Smart Materials in the Actuation System of a Gas Injector. Materials, 14(22), 6984. https://doi.org/10.3390/ma14226984