Investigation of Adhesive Joining Strategies for the Application of a Multi-Material Light Rail Vehicle

Abstract

:1. Introduction

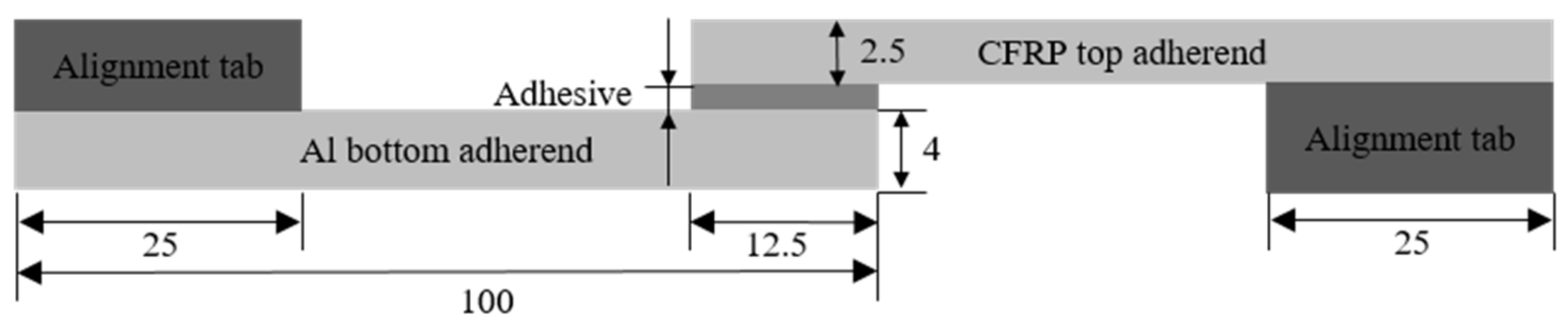

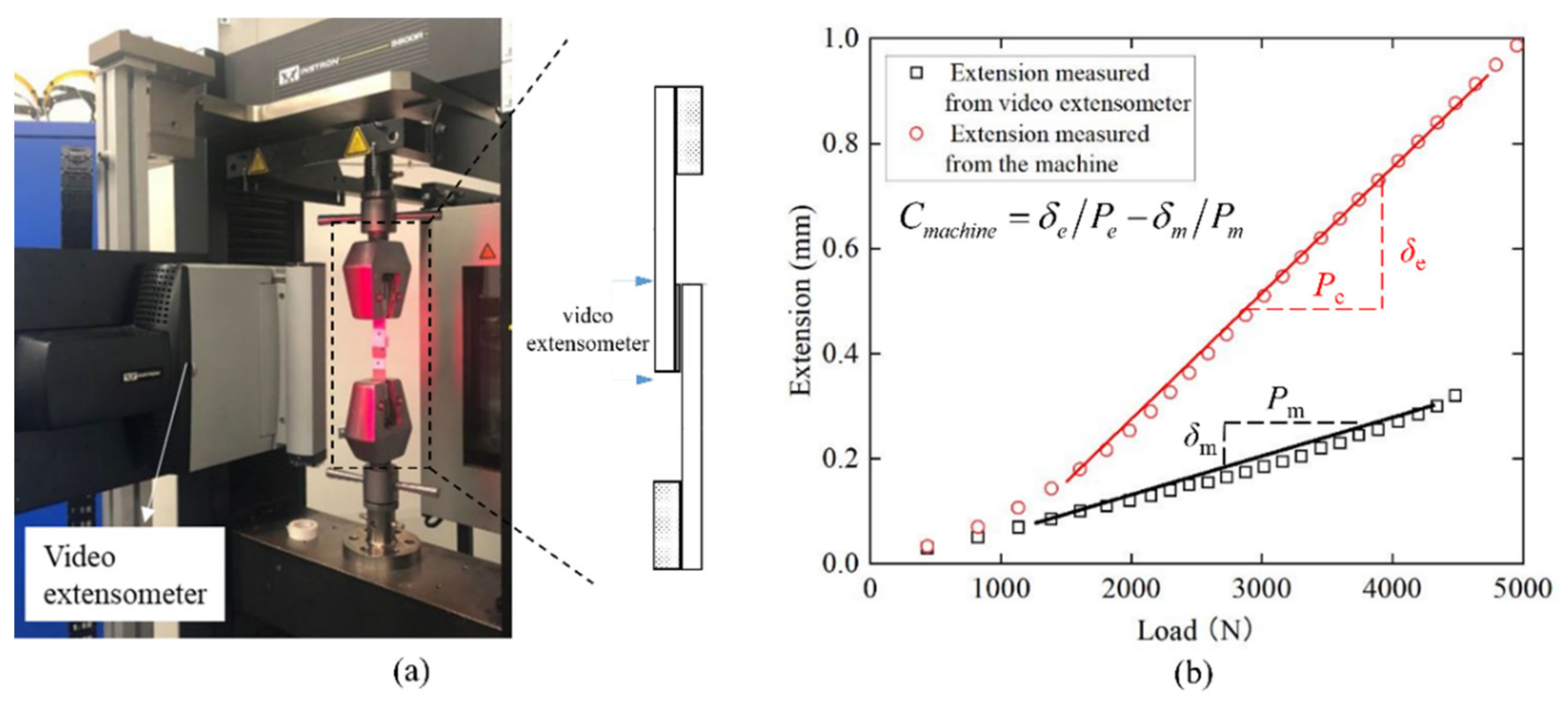

2. Single Lap Joint Tests to Characterise Different Adhesives

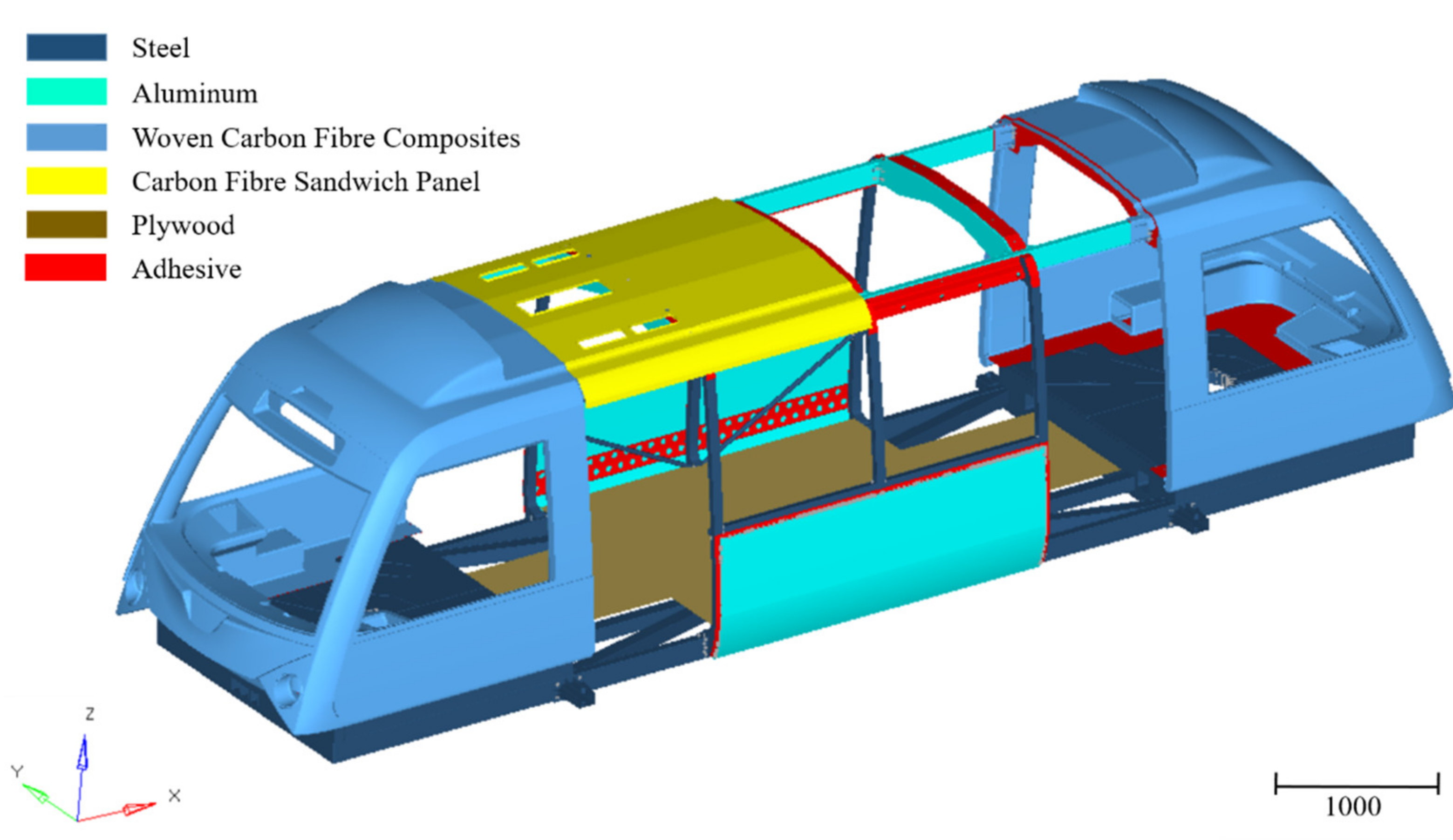

3. Test Results

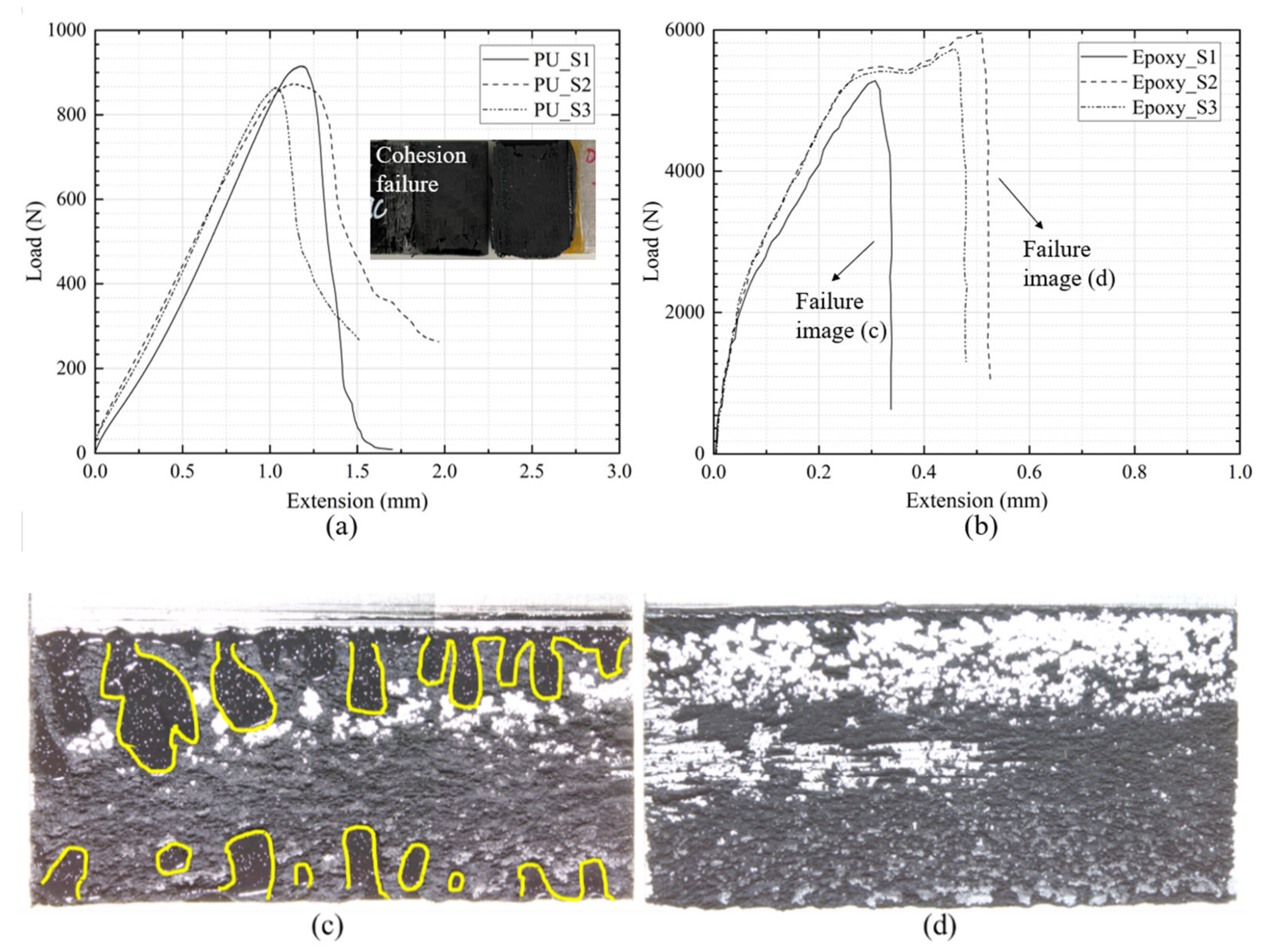

3.1. Load-Displacement Curves

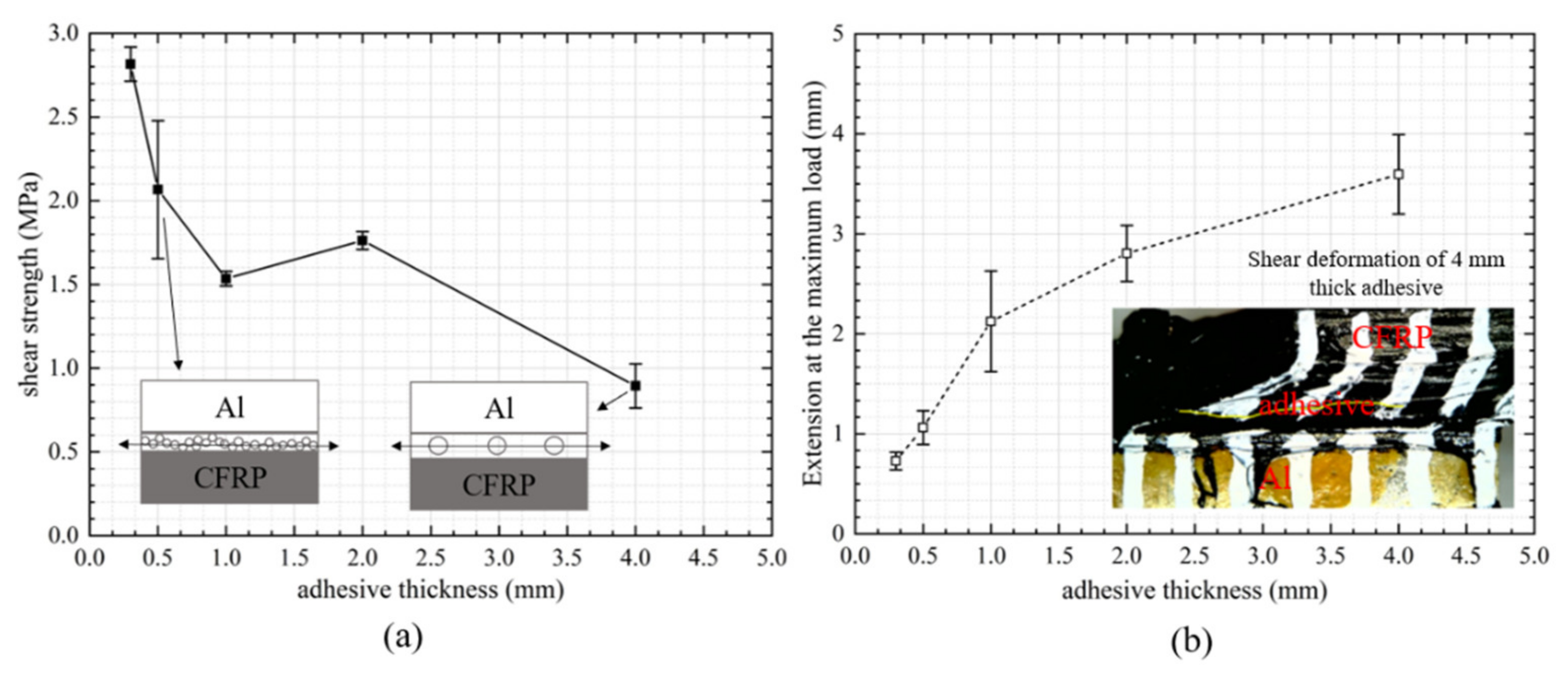

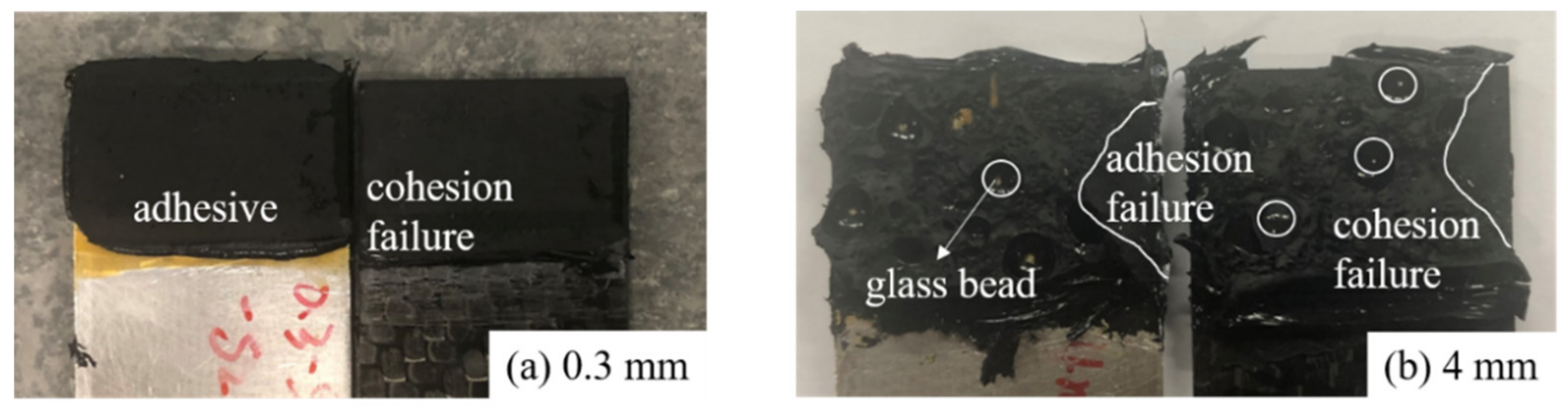

3.2. Failure Strength and Extension of Polyurethane Adhesive Joints with Respect to Bond Gap

3.3. Failure Strength and Extension of Epoxy Adhesive Joints with Respect to Bond Gap

3.4. Stiffness of the Joints

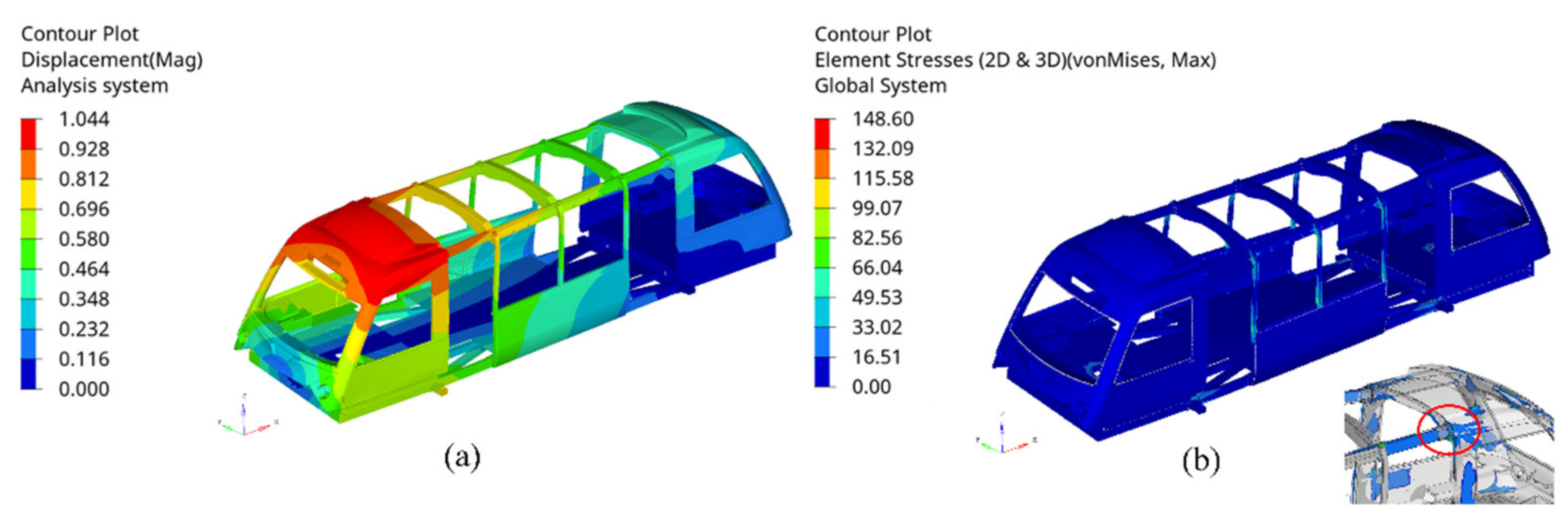

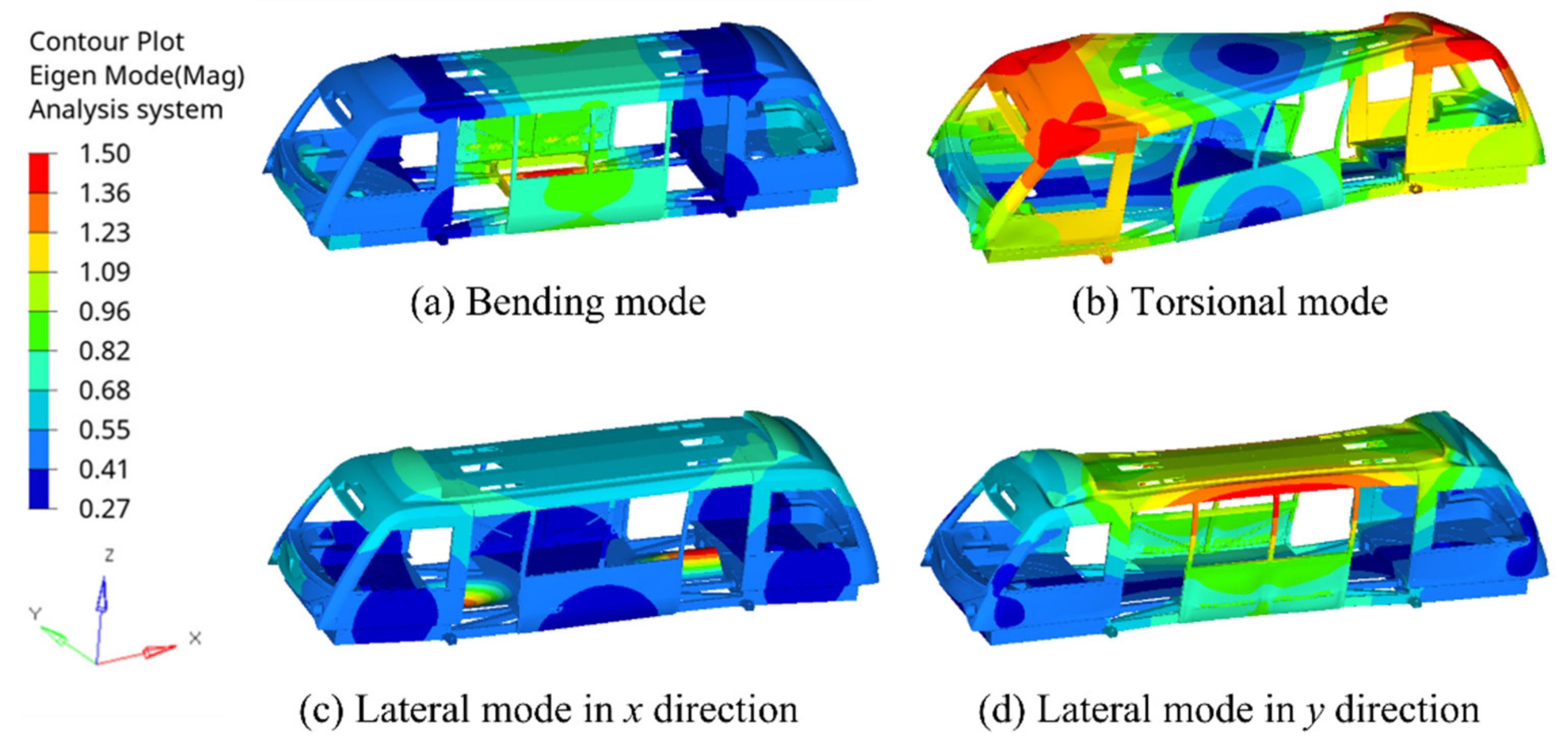

4. Vehicle Finite Element Model

5. Effect of Various Adhesives and Their Thicknesses on the Global Behavior

6. Conclusions

- For joints with polyurethane adhesive, the shear strength decreased significantly in terms of adhesive thickness. The joints with thick polyurethane adhesive experienced a relatively large shear deformation, leading to fracture and final failure. The shear strength of the joints with epoxy adhesive presented the highest value for a 1 mm bond, although the mechanical performance was far less sensitive to the bond gap compared to the polyurethane adhesive. At a high load, the aluminium substrates bonded with epoxy experience a large bending moment, leading to a concentrated peel stress at the interface, resulting in final fracture failure.

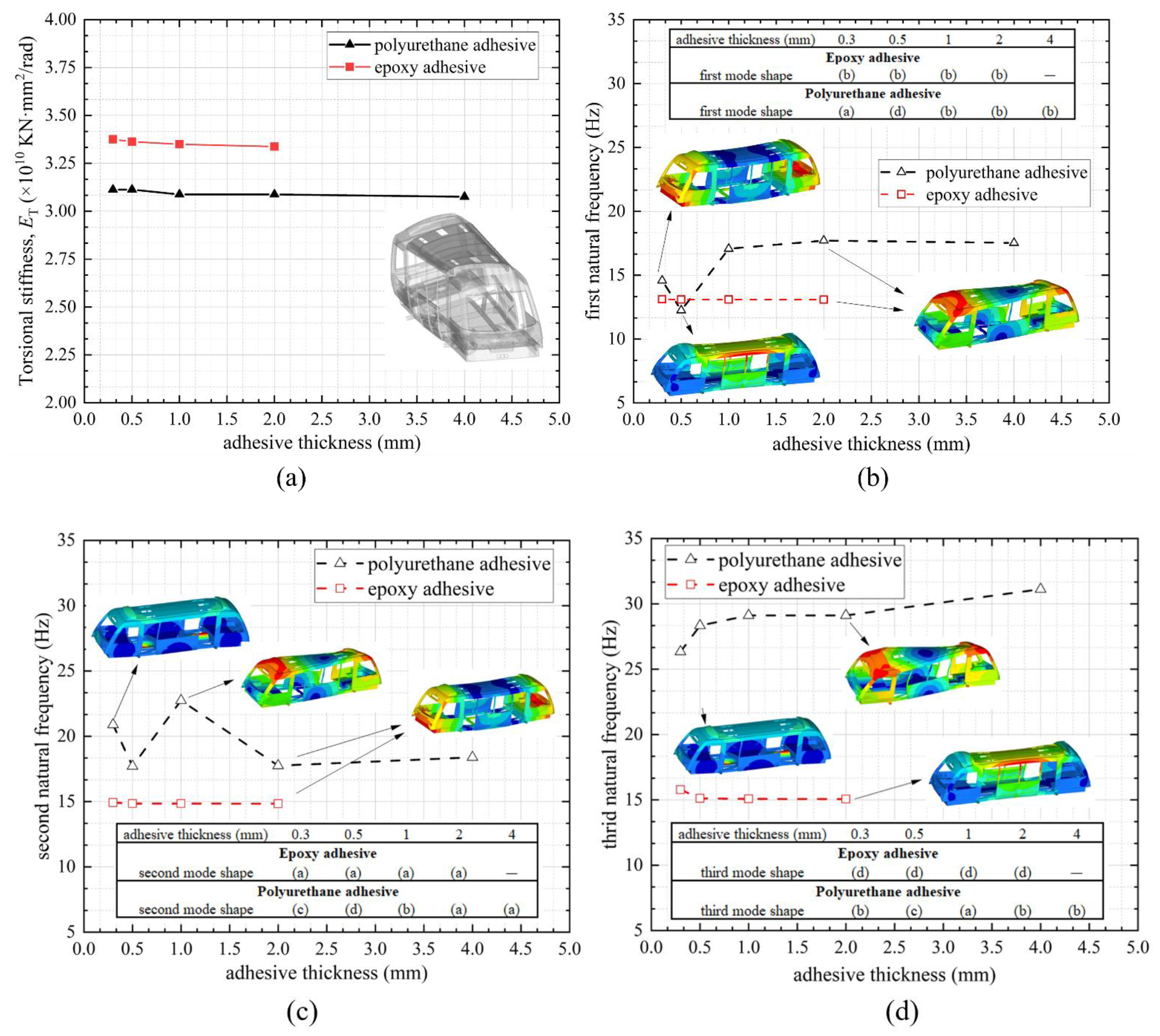

- The vehicle using epoxy adhesive behaved on average 10% stiffer than that using the polyurethane adhesive in sustaining torsional load; however, the torsional stiffness of the vehicle was largely not sensitive to the adhesive thickness; The vehicle with polyurethane adhesive had higher modal frequencies compared with that with epoxy adhesive, and the modal shapes also switched with increasing adhesive thickness.

- The polyurethane adhesive was more flexible and could bear large deformation, resulting in more energy absorption and a higher modal frequency. Therefore, the results indicated that an optimum thickness of approximately 1 mm of polyurethane adhesive is suggested for the current vehicle to optimise the structural performance. During the design phase of a vehicle, it is recommended that consideration be given to the effect of variation in fit-up during manufacturing, as this is likely to influence the vehicle’s vibrational response.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Robinson, M.; Matsika, E.; Peng, Q. Application of composites in rail vehicles. ICCM Int. Conf. Compos. Mater. 2017, 2017, 20–25. [Google Scholar] [CrossRef]

- Dewulf, W.; Skerlos, S.; Kara, S.; Hauschild, M.; Herrmann, C.; Kaluza, A. Life cycle engineering of lightweight structures. CIRP Ann. 2018, 67, 651–672. [Google Scholar] [CrossRef]

- Dost, I.; Khan, S.A.; Aziz, M. Mechanical evaluation of joining methodologies in multi material car body. Int. J. Adv. Eng. Technol. 2012, 5, 259–268. [Google Scholar]

- Suzuki, Y. Adhesive bonding for railway application. Handb. Adhes. Technol. Second Ed. 2018, 2, 1367–1390. [Google Scholar] [CrossRef]

- Budhe, S.; Banea, M.D.; De Barros, S.; Da Silva, L.F.M. An updated review of adhesively bonded joints in composite materials. Int. J. Adhes. Adhes. 2016, 72, 30–42. [Google Scholar] [CrossRef]

- Banea, M.; da Silva, L. Adhesively bonded joints in composite materials: An overview. J. Mater. Des. Appl. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- He, X. A review of finite element analysis of adhesively bonded joints. Int. J. Adhes. Adhes. 2011, 31, 248–264. [Google Scholar] [CrossRef]

- Bogue, R. Recent developments in adhesive technology: A review. Assem. Autom. 2011, 31, 207–211. [Google Scholar] [CrossRef]

- Hazimeh, R.; Challita, G.; Khalil, K.; Othman, R. Experimental investigation of the influence of substrates’ fibers orientations on the impact response of composite double-lap joints. Compos. Struct. 2015, 134, 82–89. [Google Scholar] [CrossRef]

- Mahi, B.E.; Benrahou, K.H.; Belakhdar, K.; Tounsi, A.; Bedia, E.A.A. Effect of the tapered end of a FRP plate on the interfacial stresses in a strengthened beam used in civil engineering applications. Mech. Compos. Mater. 2014, 50, 467–476. [Google Scholar] [CrossRef]

- Neto, J.A.B.P.; Campilho, R.D.S.G.; da Silva, L.F.M. Parametric study of adhesive joints with composites. Int. J. Adhes. Adhes. 2012, 37, 96–101. [Google Scholar] [CrossRef]

- Liao, L.; Huang, C.; Sawa, T. Effect of adhesive thickness, adhesive type and scarf angle on the mechanical properties of scarf adhesive joints. Int. J. Solids Struct. 2013, 50, 4333–4340. [Google Scholar] [CrossRef] [Green Version]

- Gu, Z.; Liu, Y.; Hughes, D.; Ye, J.; Hou, X. A parametric study of adhesive bonded joints with composite material using black-box and grey-box machine learning methods: Deep neuron networks and genetic programming. Compos. Part B Eng. 2021, 217, 108894. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Soares, J.R.L.; Pereira, A.M.; Ferreira, J.A.M. Effect of adherends and environment on static and transverse impact response of adhesive lap joints. Theor. Appl. Fract. Mech. 2015, 80, 79–86. [Google Scholar] [CrossRef]

- Saldanha, D.F.S.; Canto, C.; da Silva, L.F.M.; Carbas, R.J.C.; Chaves, F.J.P.; Nomura, K.; Ueda, T. Mechanical characterization of a high elongation and high toughness epoxy adhesive. Int. J. Adhes. Adhes. 2013, 47, 91–98. [Google Scholar] [CrossRef]

- Ozel, A.; Yazici, B.; Akpinar, S.; Aydin, M.D.; Temiz, Ş. A study on the strength of adhesively bonded joints with different adherends. Compos. Part B Eng. 2014, 62, 167–174. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, X.; Lemanski, S.; Nezhad, H.Y.; Ayre, D. Experimental and numerical study of process-induced defects and their effect on fatigue debonding in composite joints. Int. J. Fatigue 2019, 125, 47–57. [Google Scholar] [CrossRef] [Green Version]

- Cavezza, F.; Boehm, M.; Terryn, H.; Hauffman, T. A review on adhesively bonded aluminium joints in the automotive industry. Metals (Basel) 2020, 10, 1–32. [Google Scholar] [CrossRef]

- Xu, Y.; Li, H.; Shen, Y.; Liu, S.; Wang, W.; Tao, J. Improvement of adhesion performance between aluminum alloy sheet and epoxy based on anodizing technique. Int. J. Adhes. Adhes. 2016, 70, 74–80. [Google Scholar] [CrossRef] [Green Version]

- Da Silva, L.F.M.; Rodrigues, T.N.S.S.; Figueiredo, M.A.V.; de Moura, M.F.S.F.; Chousal, J.A.G. Effect of adhesive type and thickness on the lap shear strength. J. Adhes. 2006, 82, 1091–1115. [Google Scholar] [CrossRef]

- Arenas, J.M.; Narbón, J.J.; Alía, C. Optimum adhesive thickness in structural adhesives joints using statistical techniques based on Weibull distribution. Int. J. Adhes. Adhes. 2010, 30, 160–165. [Google Scholar] [CrossRef] [Green Version]

- Banea, M.; da Silva, L.; Campilho, R. The effect of adhesive thickness on the mechanical behavior of a structural polyurethane adhesive. J. Adhes. 2014, 91, 331–346. [Google Scholar] [CrossRef]

- Sun, W.; Zhou, J.; Gong, D.; You, T. Analysis of modal frequency optimization of railway vehicle car body. Adv. Mech. Eng. 2016, 8, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Du, S.; Micallef, C.; Jia, Y.; Shi, Y.; Hughes, D.J. Optimisation and management of energy generated by a multifunctional MFC-integrated composite chassis for rail vehicles. Energies 2020, 13, 1–18. [Google Scholar] [CrossRef]

- Adams, R.D. Vibration Damping of Adhesively Bonded Joints. In Handbook of Adhesion Technology; Springer: Berlin/Heidelbery, Germany, 2011; ISBN 9783642011696. [Google Scholar]

- Galvez, P.; Quesada, A.; Martinez, M.A.; Abenojar, J.; Boada, M.J.L.; Diaz, V. Study of the behaviour of adhesive joints of steel with CFRP for its application in bus structures. Compos. Part B Eng. 2017, 129, 41–46. [Google Scholar] [CrossRef]

- Sika Company. Sikaflex-265 Direct Glazing and UV Resistant Joint Sealant for Buses, Trucks and Rail Vehicles; Sika Company: Hertfordshire, UK, 2007. [Google Scholar]

- 3M 3MTM Scotch-WeldTM EPXTM Epoxy Adhesive DP490; Manchester, UK. 1996. Available online: https://www.selfadhesive.co.uk/3m-scotch-weld-epx-high-performance-epoxy-adhesive-dp490-50ml.html (accessed on 21 October 2021).

- BS EN 1465:2009. Adhesives: Determination of Tensile Lap-Shear Strength of Bonded Assemblies; British Standards Institute: London, UK, 2009. [Google Scholar] [CrossRef]

- Boutar, Y.; Naïmi, S.; Mezlini, S.; Silva, L.F.M.; Ben, M.; Ali, S.; Boutar, Y.; Naïmi, S.; Mezlini, S.; Silva, L.F.M. Effect of adhesive thickness and surface roughness on the shear strength of aluminium one-component polyurethane adhesive single-lap joints for automotive applications. J. Adhes. Sci. Technol. 2016, 30, 1913–1929. [Google Scholar] [CrossRef]

- Han, X.; Jin, Y.; da Silva, L.F.M.; Costa, M.; Wu, C. On the effect of adhesive thickness on mode I fracture energy—An experimental and modelling study using a trapezoidal cohesive zone model. J. Adhes. 2020, 96, 490–514. [Google Scholar] [CrossRef]

- ASTM-American Society for Testing and Materials ASTM D3039/D3039M: Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. Annu. B. ASTM Stand. 2014, 1–13. [CrossRef]

- European Committee for Standardization EN 12663-1:2010+A1:2014 Railway applications—Structural requirements of railway vehicle bodies—Part 1: Locomotives and passenger rolling stock (and alternative method for freight wagons); Dublin, Germany. 2010. Available online: https://standards.iteh.ai/catalog/standards/cen/a8987a5b-f383-47b4-9943-bc311ed86d52/en-12663-1-2010a1-2014 (accessed on 21 October 2021).

- Altair University. Learn Dynamic Analysis with Altair Optistruct; Online; 2018. Available online: https://altairuniversity.com/free-ebook-learn-dynamic-analysis-with-altair-optistruct/ (accessed on 21 October 2021).

| Elastic Modulus (MPa) | Poisson’s Ratio | Density (kg/m3) | |

|---|---|---|---|

| Steel Aluminium Woven CFRP a | 210,000 | 0.29 | 7850 |

| 69,000 | 0.3 | 2700 | |

| E1 = 76385 E2 = 69685 | 0.51 | 1400 | |

| Phenolic foam core Plywood | 90 | 0.27 | 120 |

| 4500 | 0.2 | 700 | |

| Sikaflex 265 adhesive [27] | 2.7 | 0.48 | 1200 |

| DP490 adhesive [28] | 1442 | 0.38 | 1370 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Carnegie, C.; Ascroft, H.; Li, W.; Han, X.; Guo, H.; Hughes, D.J. Investigation of Adhesive Joining Strategies for the Application of a Multi-Material Light Rail Vehicle. Materials 2021, 14, 6991. https://doi.org/10.3390/ma14226991

Liu Y, Carnegie C, Ascroft H, Li W, Han X, Guo H, Hughes DJ. Investigation of Adhesive Joining Strategies for the Application of a Multi-Material Light Rail Vehicle. Materials. 2021; 14(22):6991. https://doi.org/10.3390/ma14226991

Chicago/Turabian StyleLiu, Yiding, Craig Carnegie, Helen Ascroft, Wenhao Li, Xiao Han, Hua Guo, and Darren J. Hughes. 2021. "Investigation of Adhesive Joining Strategies for the Application of a Multi-Material Light Rail Vehicle" Materials 14, no. 22: 6991. https://doi.org/10.3390/ma14226991

APA StyleLiu, Y., Carnegie, C., Ascroft, H., Li, W., Han, X., Guo, H., & Hughes, D. J. (2021). Investigation of Adhesive Joining Strategies for the Application of a Multi-Material Light Rail Vehicle. Materials, 14(22), 6991. https://doi.org/10.3390/ma14226991