Light-Actuated Liquid Crystal Elastomer Prepared by Projection Display

Abstract

:1. Introduction

2. Experiment Results

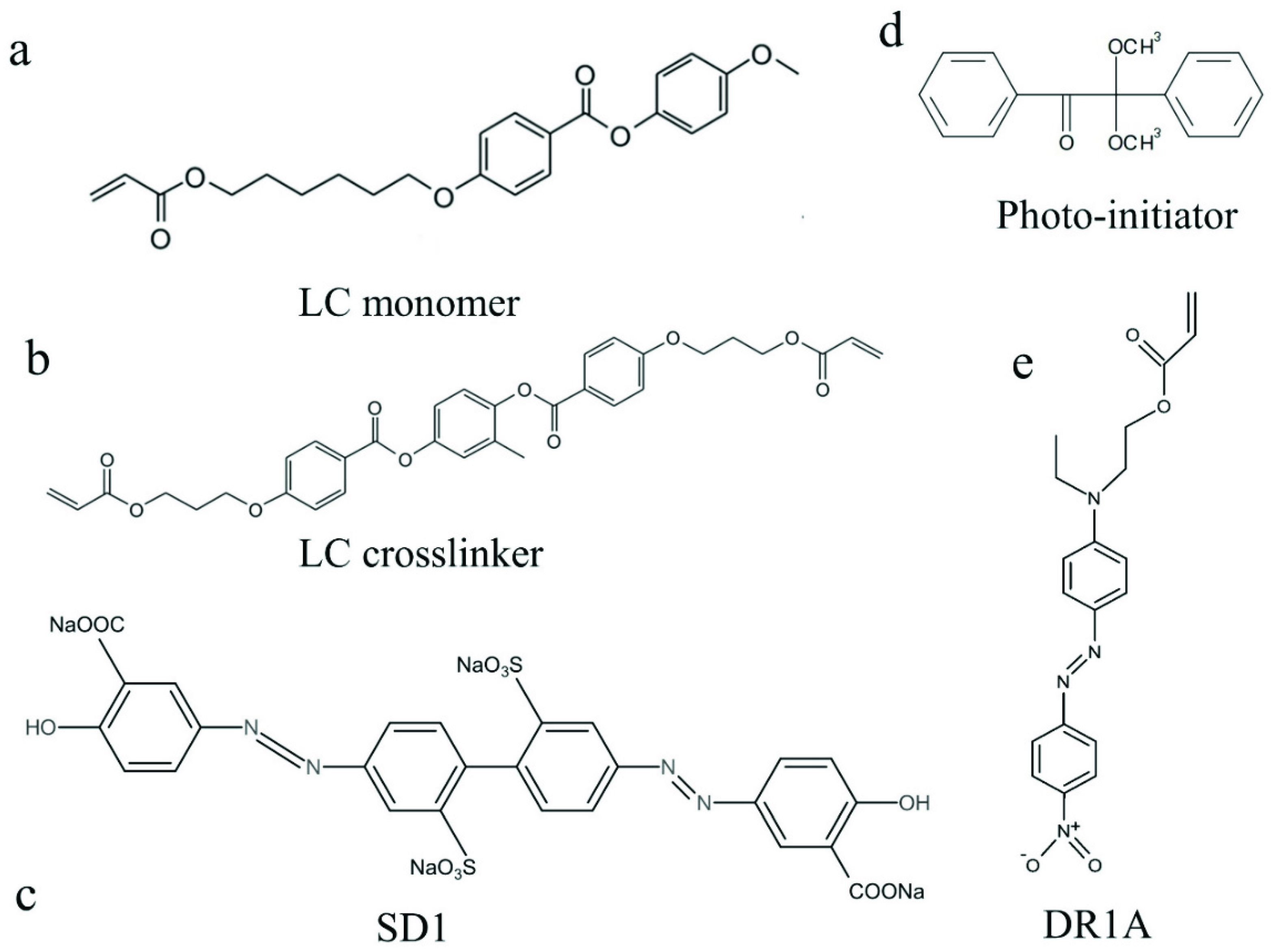

2.1. Sample Preparation

2.2. Photopatterned Substrates Preparation

2.3. Light Actuated LCE Film with a Cone

2.4. The Morphing of LCE Film with a Truncated Pyramid Shape

2.5. Biomimetic Actuation of LCE Device

3. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, X.; Kim, J.; Cezar, C.A.; Huebsch, N.; Lee, K.; Bouhadir, K.; Mooney, D.J. Active scaffolds for on-demand drug and cell delivery. Proc. Natl. Acad. Sci. USA 2011, 108, 67–72. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Z.; Calvert, P. Multilayer Hydrogels as Muscle-Like Actuators. Adv. Mater. 2000, 12, 288–291. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Khademhosseini, A. Advances in engineering hydrogels. Science 2017, 356, 3627. [Google Scholar] [CrossRef] [PubMed]

- Ma, M.; Guo, L.; Anderson, D.G.; Langer, R. Bio-Inspired Polymer Composite Actuator and Generator Driven by Water Gradients. Science 2013, 339, 186. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zarek, M.; Layani, M.; Cooperstein, I.; Sachyani, E.; Cohn, D.; Magdassi, S. 3D Printing of Shape Memory Polymers for Flexible Electronic Devices. Adv. Mater. 2016, 28, 4449. [Google Scholar] [CrossRef]

- Webber, M.J.; Appel, E.A.; Meijer, E.W.; Langer, R. Supramolecular biomaterials. Nat. Mater. 2016, 15, 13. [Google Scholar] [CrossRef]

- Warner, M.; Terentjev, E.M. Liquid Crystal Elastomers; Oxford University Press: New York, NY, USA, 2007; Volume 120. [Google Scholar]

- Gelebart, A.A.H.; Mulder, D.J.; Varga, M.; Konya, A.; Vantomme, G.; Meijer, E.B.; Selinger, R.; Broer, D.J. Making waves in a photoactive polymer film. Nature 2017, 546, 632. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- McConney, M.E.; Martinez, A.; Tondiglia, V.P.; Lee, K.M.; Langley, D.; Smalyukh, I.I.; White, T.J. Topography from Topology: Photoinduced Surface Features Generated in Liquid Crystal Polymer Networks. Adv. Mater. 2013, 25, 5880. [Google Scholar] [CrossRef] [PubMed]

- Wani, O.M.; Verpaalen, R.; Zeng, H.; Priimagi, A.; Schenning, A.P.H.J. An Artificial Nocturnal Flower via Humidity-Gated Photoactuation in Liquid Crystal Networks. Adv. Mater. 2019, 31, 1805985. [Google Scholar] [CrossRef]

- Zhu, C.; Lu, Y.; Jiang, L.; Yu, Y. Liquid Crystal Soft Actuators and Robots toward Mixed Reality. Adv. Funct. Mater. 2021, 1, 2009835. [Google Scholar] [CrossRef]

- Xiao, Y.-Y.; Jiang, Z.-C.; Zhao, Y. Liquid Crystal Polymer-Based Soft Robots. Adv. Intell. Syst. 2020, 2, 2000148. [Google Scholar] [CrossRef]

- Tan, L.; Davis, A.C.; Cappelleri, D.J. Smart Polymers for Microscale Machines. Adv. Funct. Mater. 2021, 31, 2007125. [Google Scholar] [CrossRef]

- Ware, T.H.; McConney, M.E.; Wie, J.J.; Tondiglia, V.P.; White, T.J. Voxelated liquid crystal elastomers. Science 2015, 347, 982. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aharoni, H.; Xia, Y.; Zhang, X.; Kamien, R.D.; Yang, S. Universal inverse design of surfaces with thin nematic elastomer sheets. Proc. Natl. Acad. Sci. USA 2018, 115, 7206. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Herbert, K.M.; Fowler, H.E.; McCracken, J.M.; Schlafmann, K.R.; Koch, J.A.; White, T.J. Synthesis and alignment of liquid crystalline elastomers. Nat. Rev. Mater. 2021, 1–16. [Google Scholar] [CrossRef]

- White, T.J.; Broer, D.J. Programmable and Adaptive Mechanics with Liquid Crystal Polymer Networks and Elastomers. Nat. Mater. 2015, 14, 1087. [Google Scholar] [CrossRef] [PubMed]

- Murray, B.S.; Pelcovits, R.A.; Rosenblatt, C. Creating arbitrary arrays of two-dimensional topological defects. Phys. Rev. E 2014, 90, 052501. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Harkai, S.; Murray, B.S.; Rosenblatt, C.; Kralj, S. Electric field driven reconfigurable multistable topological defect patterns. Phys. Rev. Res. 2020, 2, 013176. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xia, Y.; Cedillo-Servin, G.; Kamien, R.D.; Yang, S. Guided Folding of Nematic Liquid Crystal Elastomer Sheets into 3D via Patterned 1D Microchannels. Adv. Mater. 2016, 28, 9637. [Google Scholar] [CrossRef]

- Guo, Y.; Shahsavan, H.; Davidson, Z.; Sitti, M. Precise Control of Lyotropic Chromonic Liquid Crystals Alignment through Surface Topography. ACS Appl. Mater. Interfaces 2019, 11, 36110. [Google Scholar] [CrossRef] [Green Version]

- del Pozo, M.; Sol, J.A.H.P.; Schenning, A.P.H.J.; Debije, M.G. 4D Printing of Liquid Crystals: What’s Right for Me? Adv. Mater. 2021, 2104390. [Google Scholar] [CrossRef] [PubMed]

- Yaroshchuk, O.; Reznikov, Y. Photoalignment of liquid crystals: Basics and current trends. J. Mater. Chem. 2012, 22, 286. [Google Scholar] [CrossRef]

- Peng, C.; Guo, Y.; Turiv, T.; Jiang, M.; Wei, Q.; Lavrentovich, O.D. Patterning of Lyotropic Chromonic Liquid Crystals by Photoalignment with Photonic Metamasks. Adv. Mater. 2017, 29, 1606112. [Google Scholar] [CrossRef] [PubMed]

- Culbreath, C.; Glazar, N.; Yokoyama, H. Note: Automated maskless micro-multidomain photoalignment. Rev. Sci. Instrum. 2011, 82, 126107. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, Y.; Jiang, M.; Peng, C.; Sun, K.; Yaroshchuk, O.; Lavrentovich, O.; Wei, Q.H. High-Resolution and High-Throughput Plasmonic Photopatterning of Complex Molecular Orientations in Liquid Crystals. Adv. Mater. 2016, 28, 2353. [Google Scholar] [CrossRef] [PubMed]

- Peng, C.; Turiv, T.; Guo, Y.; Wei, Q.-H.; Lavrentovich, O.D. Command of Active Matter by Topological Defects and Patterns. Science 2016, 354, 882. [Google Scholar] [CrossRef] [Green Version]

- Nersisyan, S.; Tabiryan, N.; Steeves, D.M.; Kimball, B.R. Fabrication of liquid crystal polymer axial waveplates for UV-IR wavelengths. Opt. Express 2009, 17, 11926. [Google Scholar] [CrossRef]

- Slussarenko, S.; Murauski, A.; Du, T.; Chigrinov, V.; Marrucci, L.; Santamato, E. Tunable liquid crystal q-plates with arbitrary topological charge. Opt. Express 2011, 19, 4085. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Haan, L.T.; Sánchez-Somolinos, C.; Bastiaansen, C.M.W.; Schenning, A.P.H.J.; Broer, D.J. Engineering of complex order and the macroscopic deformation of liquid crystal polymer networks. Angew. Chem. 2012, 124, 12637. [Google Scholar] [CrossRef]

- Ahn, S.K.; Ware, T.H.; Lee, K.M.; Tondiglia, V.P.; White, T.J. Photoinduced Topographical Feature Development in Blueprinted Azobenzene-Functionalized Liquid Crystalline Elastomers. Adv. Funct. Mater. 2016, 26, 5819. [Google Scholar] [CrossRef]

- Modes, C.D.; Bhattacharya, K.; Warner, M. Disclination-mediated thermo-optical response in nematic glass sheets. Phys. Rev. E 2010, 81, 060701. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Modes, C.D.; Bhattacharya, K.; Warner, M. Gaussian curvature from flat elastica sheets. Proc. R. Soc. A Math. Phys. Eng. Sci. 2011, 467, 1121. [Google Scholar] [CrossRef] [Green Version]

- Modes, C.D.; Warner, M. Blueprinting nematic glass: Systematically constructing and combining active points of curvature for emergent morphology. Phys. Rev. E 2011, 84, 021711. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kowalski, B.A.; Mostajeran, C.; Godman, N.P.; Warner, M.; White, T.J. Curvature by design and on demand in liquid crystal elastomers. Phys. Rev. E 2018, 97, 012504. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gimenez-Pinto, V.; Ye, F.; Mbanga, B.; Selinger, J.; Selinger, R. Modeling out-of-plane actuation in thin-film nematic polymer networks: From chiral ribbons to auto-origami boxes via twist and topology. Sci. Rep. 2017, 7, 45370. [Google Scholar] [CrossRef] [Green Version]

- Lavrentovich, O.D. Prepatterned liquid crystal elastomers as a step toward artificial morphogenesis. Proc. Natl. Acad. Sci. USA 2018, 115, 7171. [Google Scholar] [CrossRef] [Green Version]

- Pei, Z.; Yang, Y.; Chen, Q.; Terentjev, E.; Wei, Y.; Ji, Y. Mouldable liquid-crystalline elastomer actuators with exchangeable covalent bonds. Nat. Mater. 2013, 13, 36. [Google Scholar] [CrossRef] [PubMed]

- Mihai, L.A.; Wang, H.; Guilleminot, J.; Goriely, A. Nematic liquid crystalline elastomers are aeolotropic materials. Proc. R. Soc. A Math. Phys. Eng. Sci. 2021, 477, 20210259. [Google Scholar] [CrossRef]

- Duffy, D.; Biggins, J.S. Defective nematogenesis: Gauss curvature in programmable shape-responsive sheets with topological defects. Soft Matter. 2020, 16, 10935. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Akomolafe, O.I.; Jiang, J.; Peng, C. Light-Actuated Liquid Crystal Elastomer Prepared by Projection Display. Materials 2021, 14, 7245. https://doi.org/10.3390/ma14237245

Chen J, Akomolafe OI, Jiang J, Peng C. Light-Actuated Liquid Crystal Elastomer Prepared by Projection Display. Materials. 2021; 14(23):7245. https://doi.org/10.3390/ma14237245

Chicago/Turabian StyleChen, Juan, Oluwafemi Isaac Akomolafe, Jinghua Jiang, and Chenhui Peng. 2021. "Light-Actuated Liquid Crystal Elastomer Prepared by Projection Display" Materials 14, no. 23: 7245. https://doi.org/10.3390/ma14237245