Influence of the Size of the Fiber Filler of Corn Stalks in the Polylactide Matrix Composite on the Mechanical and Thermomechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

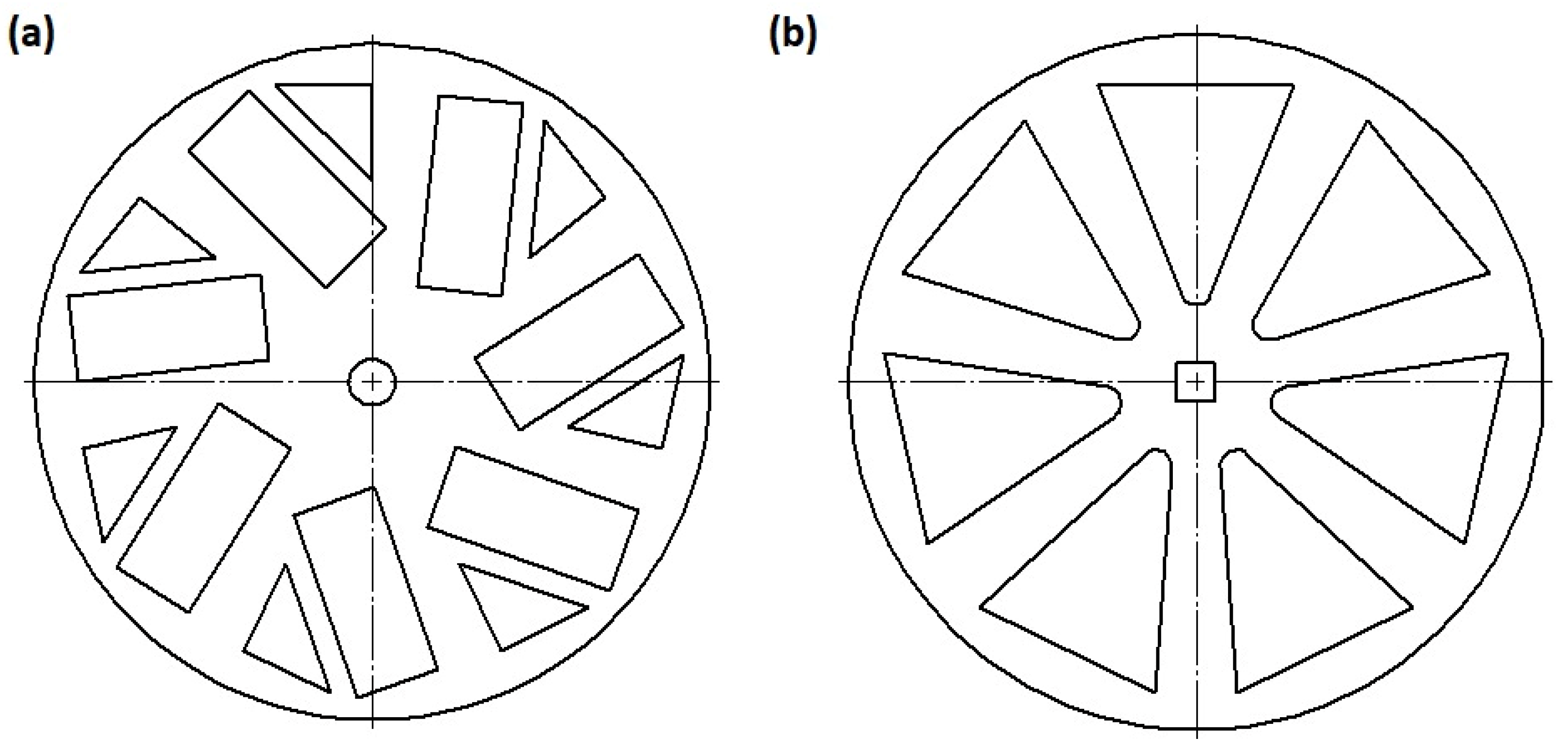

2.2. Shredding and Screening of the Corn Stalk

2.3. Preparation of Samples

2.4. Characteristics of PLA and Composites

3. Results

3.1. Density

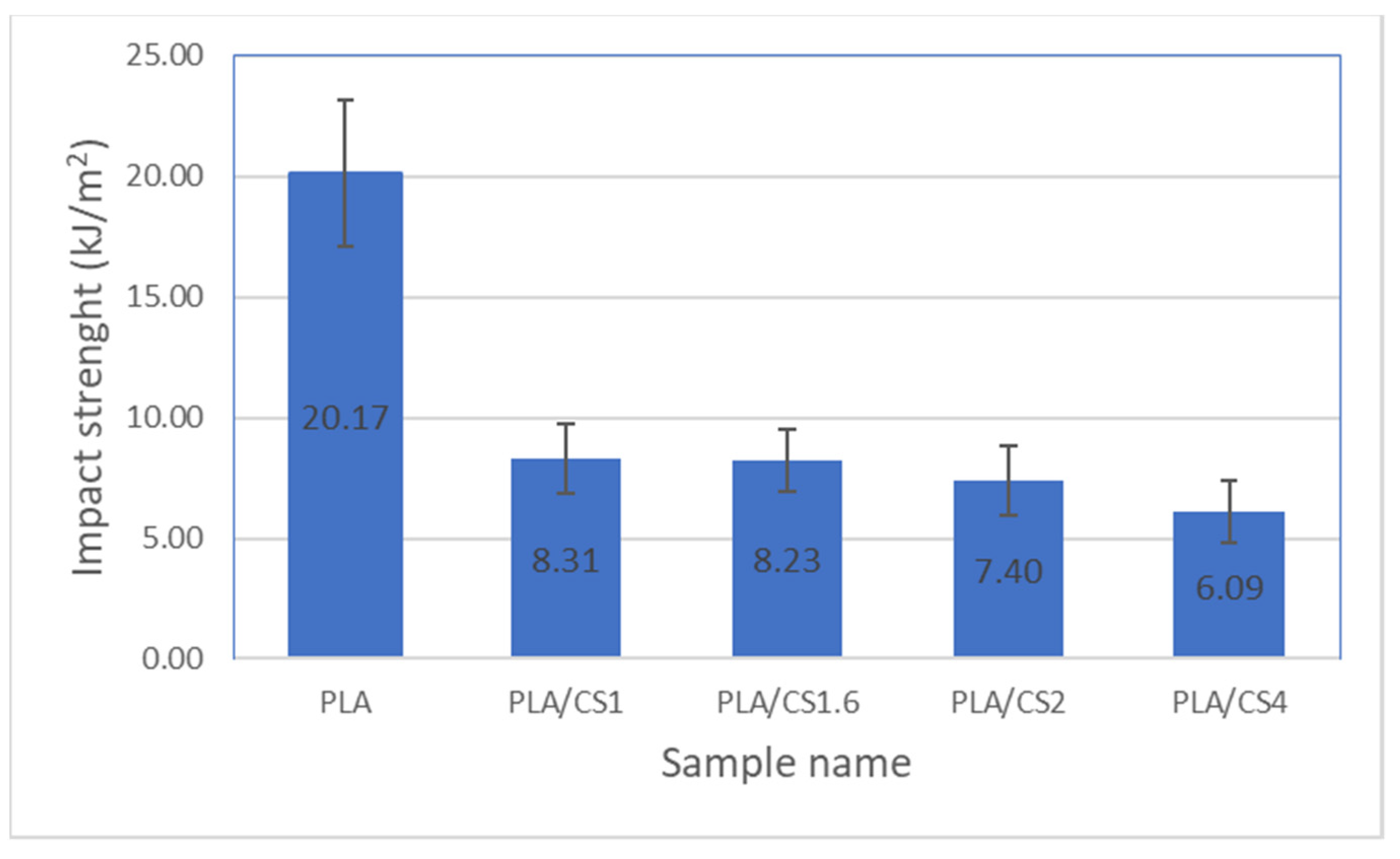

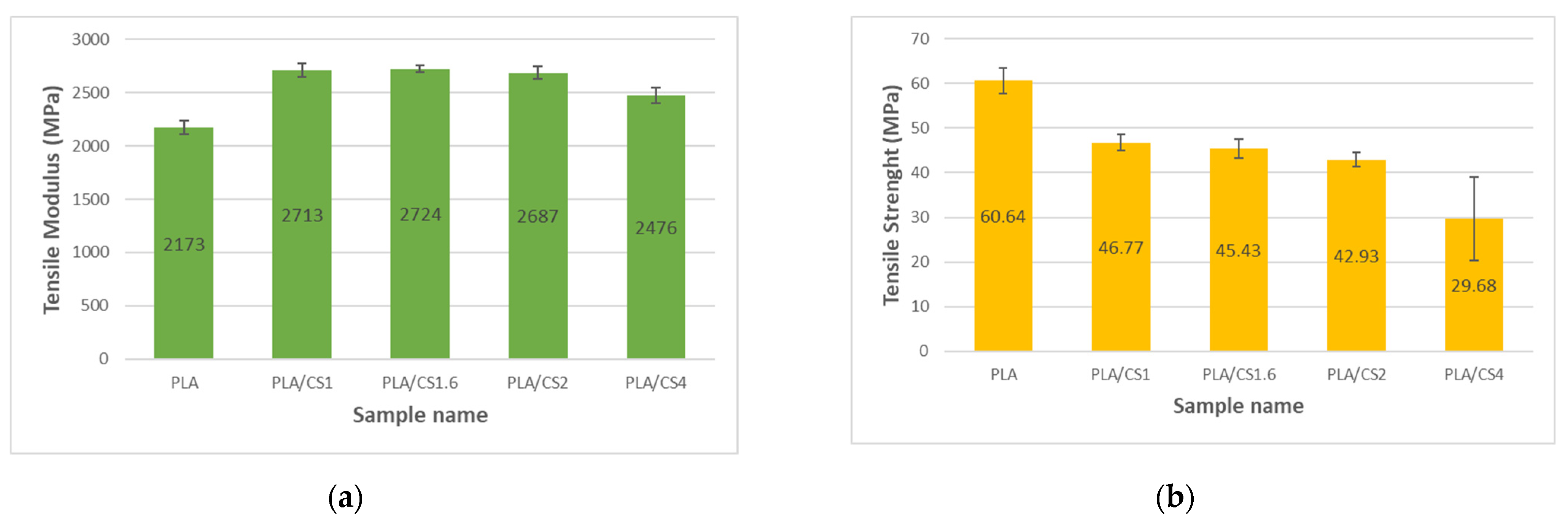

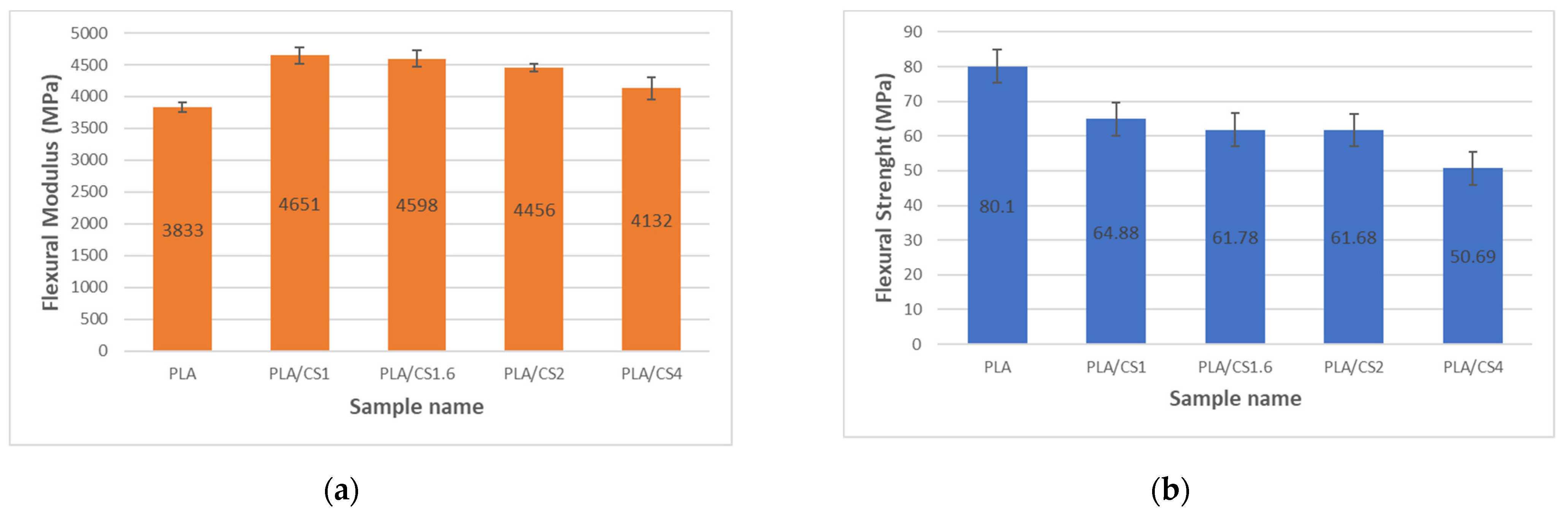

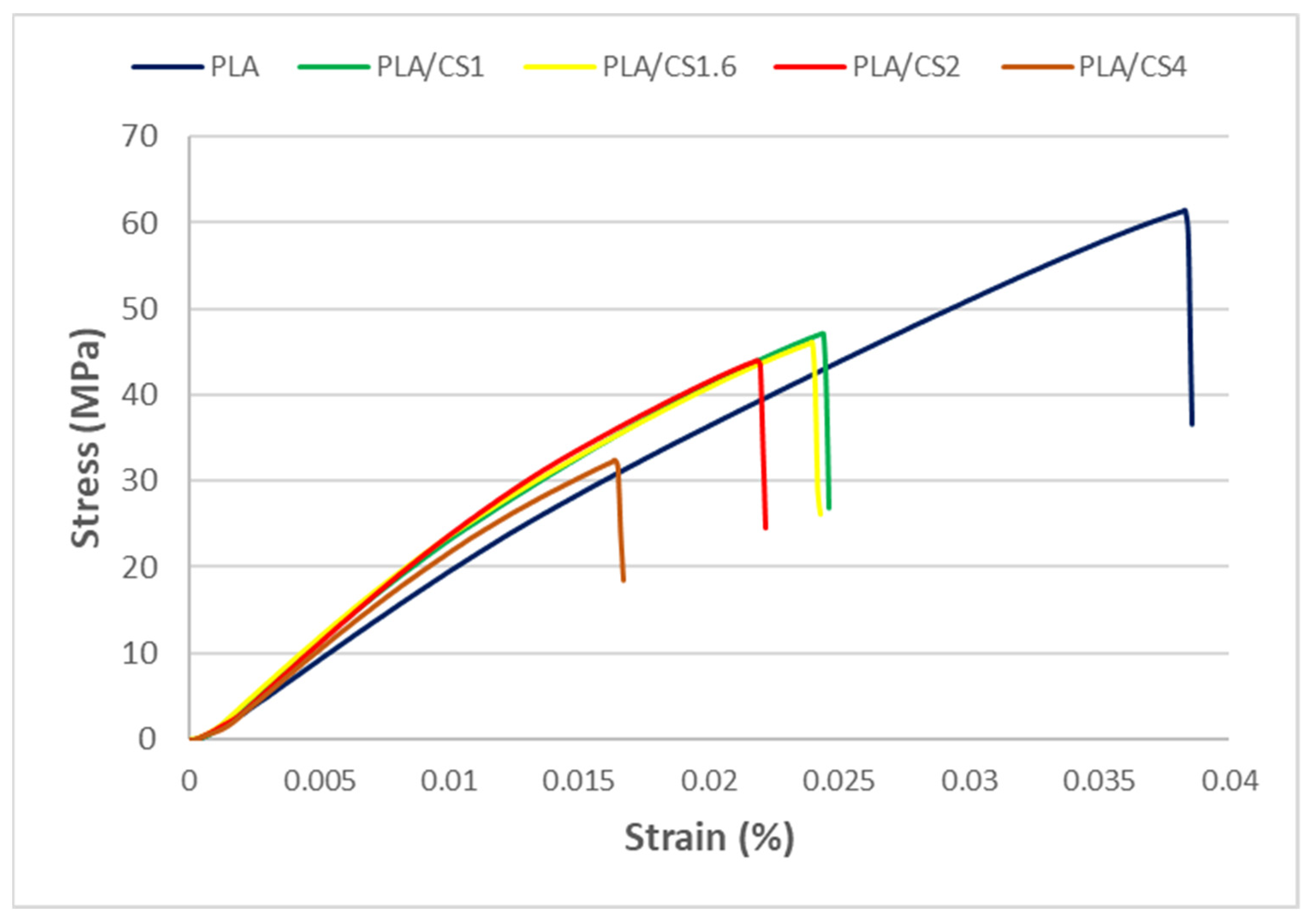

3.2. Characteristics of Mechanical Properties

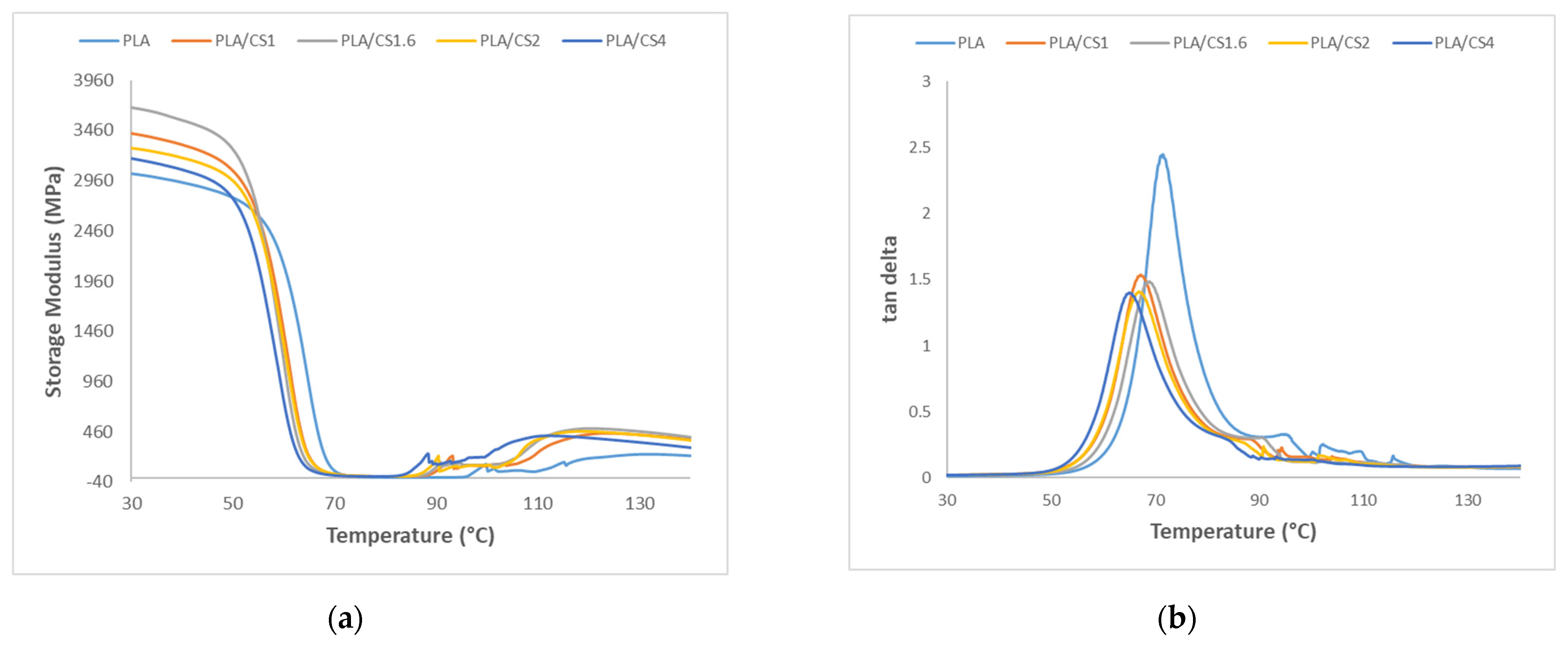

3.3. Characteristics of Thermomechanical Properties

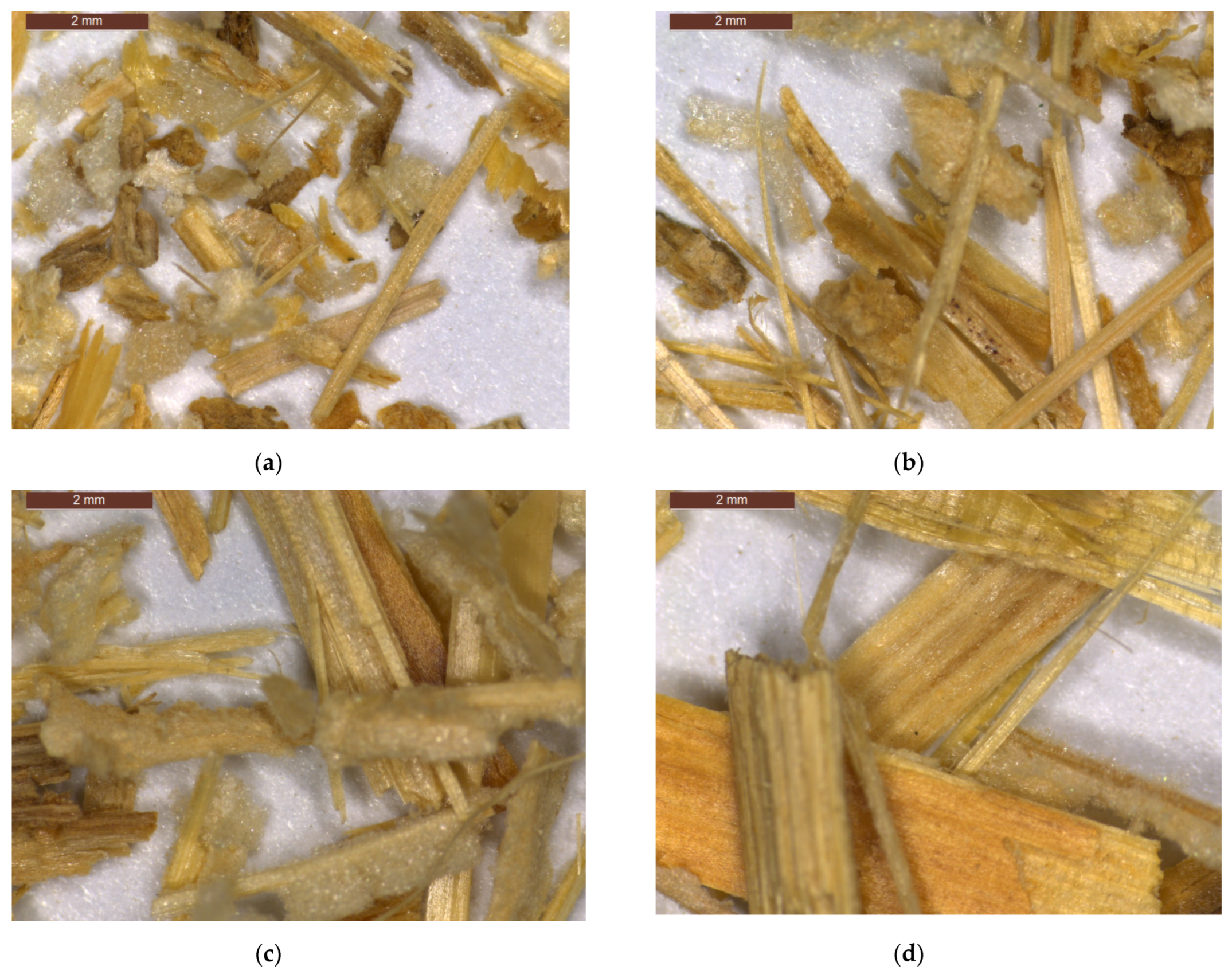

3.4. Characteristics of Corn Stalk Fiber Length before Processings

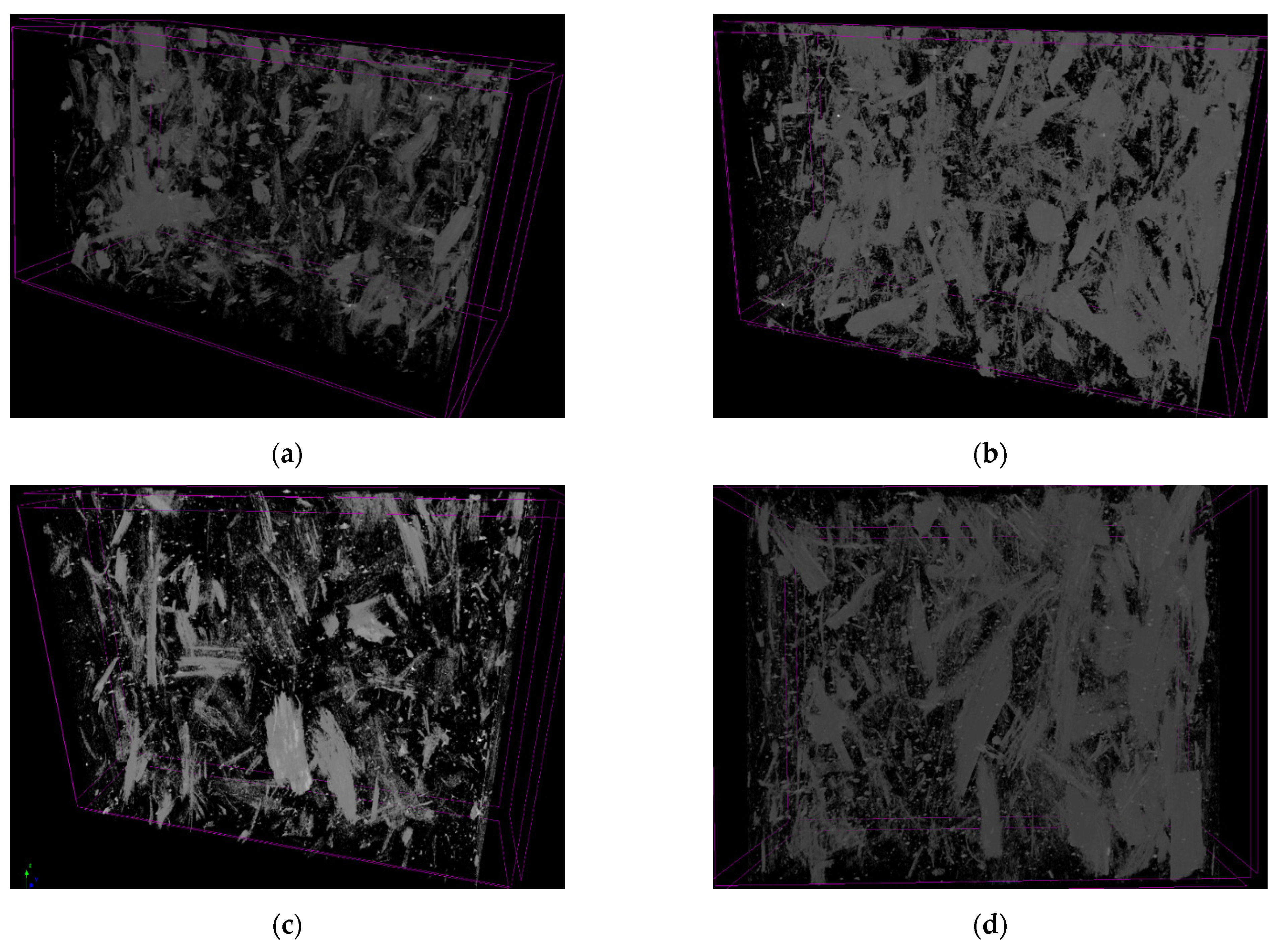

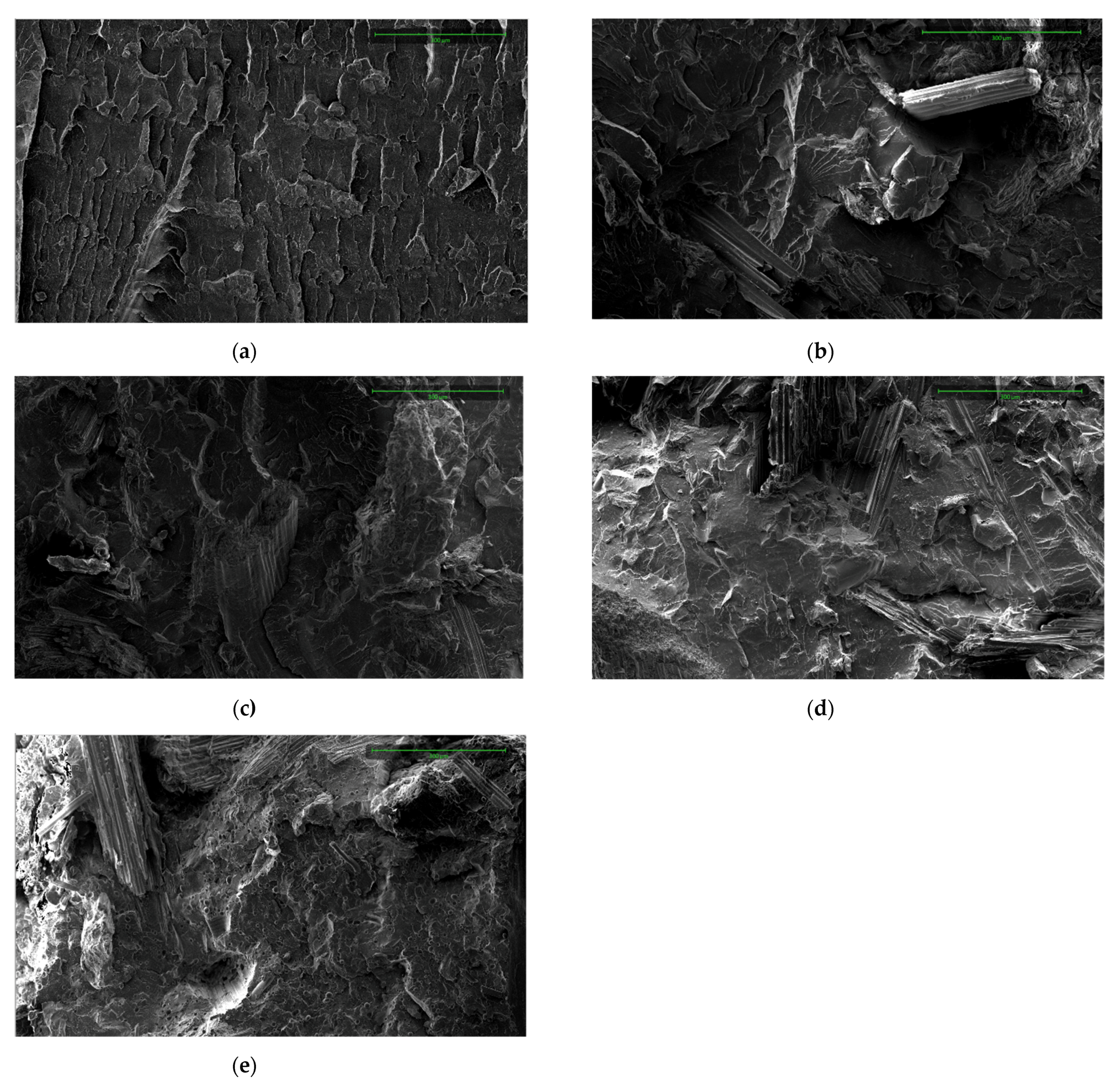

3.5. Analysis of Fiber Orientation and Size in the Composite

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khoo, H.H.; Tan, R.B.H.; Chng, K.W.L. Environmental impacts of conventional plastic and bio-based carrier bags. Int. J. Life Cycle Assess. 2010, 15, 284–293. [Google Scholar] [CrossRef]

- Gholami, F.; Pakzad, L.; Behzadfar, E. Morphological, interfacial and rheological properties in multilayer polymers: A review. Polymer 2020, 208, 122950. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, Y.; Wang, Y.; Li, X. Humidity-Enabled Ionic Conductive Trace Carbon Dioxide Sensing of Nitrogen-Doped Ti3C2Tx MXene/Polyethyleneimine Composite Films Decorated with Reduced Graphene Oxide Nanosheets. Anal. Chem. 2020, 92, 16033–16042. [Google Scholar] [CrossRef]

- Plastics Europe. Plastics–The Facts 2020; An Analysis of European Plastics Production, Demand and Waste Data. Available online: https://www.plasticseurope.org/application/files/5716/0752/4286/AF_Plastics_the_facts-WEB-2020-ING_FINAL.pdf (accessed on 10 March 2021).

- Akil, H.M.; Omar, M.F.; Mazuki, A.A.M.; Safiee, S.; Ishak, Z.A.M.; Abu Bakar, A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Jiménez, A.M.; Delgado-Aguilar, M.; Tarrés, Q.; Quintana, G.; Fullana-i-Palmer, P.; Mutjè, P.; Espinach, F.X. Sugarcane bagasse reinforced composites: Studies on the young’s modulus and macro and micro-mechanics. Bioresources 2017, 12, 3618–3629. [Google Scholar] [CrossRef] [Green Version]

- Stefaniak, K.; Masek, A. Green Copolymers Based on Poly(Lactic Acid)—Short Review. Materials 2021, 14, 5254. [Google Scholar] [CrossRef]

- Wu, W.; Cao, X.; Zhang, Y.; He, G. Polylactide/halloysite nanotube nanocomposites: Thermal, mechanical properties, and foam processing. J. Appl. Polym. Sci. 2013, 130, 443–452. [Google Scholar] [CrossRef]

- Interreg Europe. Sustainable Waste Management in a Circular Economy. A Policy Brief from the Policy Learning Platform on Environment and Resource Efficiency. Available online: https://www.interregeurope.eu/fileadmin/user_upload/plp_uploads/policy_briefs/Policy_brief_on_waste_management.pdf (accessed on 16 March 2021).

- Carbonell-Verdu, A.; Boronat, T.; Quiles-Carrillo, L.; Fenollar, O.; Dominici, F.; Torre, L. Valorization of Cotton Industry Byproducts in Green Composites with Polylactide. J. Polym. Environ. 2020, 28, 2039–2053. [Google Scholar] [CrossRef]

- Zini, E.; Scandola, M. Green composites: An overview. Polym Compos. 2011, 32, 1905–1915. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Gulino, E.F.; Alaimo, G.; Morreale, M. Green Composites Based on PLA and Agricultural or Marine Waste Prepared by FDM. Polymers 2021, 13, 1361. [Google Scholar] [CrossRef]

- Abhiram, Y.; Das, A.; Sharma, K.K. Green composites for structural and non-structural applications: A review. Mater. Today Proc. 2021, 44, 2658–2664. [Google Scholar] [CrossRef]

- Ghanbarzadeh, B.; Almasi, H. Biodegradable polymers. In Biodegradation-Life of Science; Chamy, R., Rosenkranz, F., Eds.; InTech Publications: Rijeka, Croatia, 2013; pp. 141–186. [Google Scholar]

- Haider, T.P.; Volker, C.; Kramm, J.; Landfester, K.; Wurm, F.R. Plastics of the future? The impact of biodegradable polymers on the environment and on society. Angew. Chem. 2019, 58, 50–62. [Google Scholar] [CrossRef] [Green Version]

- Rasal, R.M.; Janorkar, A.V.; Hirt, D.E. Poly(lactic acid) modifications. Prog. Polym. Sci. 2010, 35, 338–356. [Google Scholar] [CrossRef]

- Kumar Bajpai, P.; Singh, I.; Madaan, J. Development and characterization of PLA-based green composites: A review. J. Themoplast. Compos. Mater. 2014, 27, 52–81. [Google Scholar] [CrossRef]

- Zenkiewicz, M.; Richert, J.; Rytlewski, P.; Moraczewski, K.; Stepczyńska, M.; Karasiewicz, T. Characterisation of multi-extruded poly (lactic acid). Polym. Test. 2009, 28, 412–418. [Google Scholar] [CrossRef]

- Gross, R.A.; Kalra, B. Biodegradable Polymers for the Environment. Science 2002, 297, 803–807. [Google Scholar] [CrossRef] [Green Version]

- Cao, X.; Chi, X.; Deng, X.; Sun, Q.; Gong, X.; Yu, B.; Yuen, A.C.Y.; Wu, W.; Li, R.K.Y. Facile Synthesis of Phosphorus and Cobalt Co-Doped Graphitic Carbon Nitride for Fire and Smoke Suppressions of Polylactide Composite. Polymers 2020, 12, 1106. [Google Scholar] [CrossRef]

- Wang, F.; Zhou, S.; Yang, M.; Chen, Z.; Ran, S. Thermo-Mechanical Performance of Polylactide Composites Reinforced with Alkali-Treated Bamboo Fibers. Polymers 2018, 10, 401. [Google Scholar] [CrossRef] [Green Version]

- Scaffaro, R.; Maio, A.; Gulino, E.F.; Megna, B. Structure-property relationship of PLA-Opuntia Ficus Indica biocomposites. Compos. Part B 2019, 167, 199–206. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Misra, M.; Mohanty, A.K. Wood-fiber-reinforced poly(lactic acid) composites: Evaluation of the physicomechanical and morphological properties. J. Appl. Polym. Sci. 2006, 102, 4856–4869. [Google Scholar] [CrossRef]

- Hu, R.; Lim, J.K. Fabrication and Mechanical Properties of Completely Biodegradable Hemp Fiber Reinforced Polylactic Acid Composites. J. Compos. Mater. 2007, 41, 1655–1669. [Google Scholar] [CrossRef]

- Espinach, F.X. Advances in Natural Fibers and Polymers. Materials 2021, 14, 2607. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Navaneethakrishnan, P.; Shankar, S.; Rajasekar, R.; Rajini, N. Characterization of natural fibre and composites—A review. J. Reinf. Plast. Compos. 2013, 32, 1457–1476. [Google Scholar] [CrossRef]

- Gupta, M.K.; Bharti, A. Natural fiber reinforced polymercomposites: A review on dynamic mechanical properties. Curr. Trends Fash. Technol. Text. Eng. 2017, 1, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Wei, L.; McDonald, A.G. A review on grafting of biofibers for biocomposites. Materials 2016, 9, 303. [Google Scholar] [CrossRef] [PubMed]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Natural rubber composites filled with cereals straw modified with acetic and maleic anhydride: Preparation and properties. J. Polym. Environ. 2018, 26, 4141–4157. [Google Scholar] [CrossRef] [Green Version]

- Miedzianowska, J.; Masłowski, M.; Rybiński, P.; Strzelec, K. Properties of chemically modified (selected silanes) lignocellulosic filler and its application in natural rubber biocomposites. Materials 2020, 13, 4163. [Google Scholar] [CrossRef] [PubMed]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef] [Green Version]

- Muscat, A.; de Olde, E.; Kovacic, Z.; de Boer, I.; Ripoll-Bosch, R. Food, energy or biomaterials? Policy coherence across agro-food and bioeconomy policy domains in the EU. Environ. Sci. Policy 2021, 123, 21–30. [Google Scholar] [CrossRef]

- Chhabra, N.; Kaur, A. Studies on Physical and Engineering Characteristics of Maize, Pearl Millet and Soybean. J. Pharmacogn. Phytochem. 2017, 6, 1–5. [Google Scholar]

- Bank PKO World and Domestic Cereal Market in the 2019/20. Available online: https://www.pkobp.pl/media_files/738e5a0e-0dc9-4577-94ed-9871ea36b9fe.pdf (accessed on 18 March 2021).

- Hong, J.; Ren, L.; Hong, J.; Xu, C. Environmental impact assessment of corn straw utilization in China. J. Clean. Prod. 2016, 112, 1700–1708. [Google Scholar] [CrossRef]

- Sokhansanj, S.; Mani, S.; Tagore, S.; Turhollow, A.F. Techno-economic analysis of using corn stover to supply heat and power to a corn ethanol plant–Part 1: Cost of feedstock supply logistics. Biomass Bioenergy 2010, 34, 75–81. [Google Scholar] [CrossRef]

- Kovács, Á.; Kerényi, G. Physical Characteristics and Mechanical Behaviour of Maize Stalks for Machine Development. Int. Agrophysics 2019, 33, 427–436. [Google Scholar] [CrossRef]

- Czajkowski, Ł.; Wojcieszak, D.; Olek, W.; Przybył, J. Thermal properties of fractions of corn stover. Constr. Build. Mater. 2019, 210, 709–712. [Google Scholar] [CrossRef]

- Yuan, X.; Li, P.; Wang, H.; Wang, X.; Cheng, X.; Cui, Z. Enhancing the anaerobic digestion of corn stalks using composite microbial pretreatment. J. Microbiol. Biotechnol. 2011, 21, 746–752. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kadam, K.L.; McMillan, J.D. Availability of corn stover as a sustainable feedstock for bioethanol production. Bioresour. Technol. 2003, 88, 17–25. [Google Scholar] [CrossRef]

- Menardo, S.; Airoldi, G.; Cacciatore, V.; Balsari, P. Potential biogas and methane yield of maize stover fractions and evaluation of some possible stover harvest chains. Biosyst. Eng. 2015, 129, 352–359. [Google Scholar] [CrossRef]

- Wu, T.; Wang, X.; Kito, K. Effects of pressures on the mechanical properties of corn straw bio-board. Eng. Agric. Environ. Food 2015, 8, 123–129. [Google Scholar] [CrossRef] [Green Version]

- Mayer-Laigle, C.; Haurie Ibarra, L.; Breysse, A.; Palumbo, M.; Mabille, F.; Lacasta Palacio, A.M.; Barron, C. Preserving the Cellular Tissue Structure of Maize Pith Though Dry Fractionation Processes: A Key Point to Use as Insulating Agro-Materials. Materials 2021, 14, 5350. [Google Scholar] [CrossRef]

- Ma, Y.; Wu, S.; Zhuang, J.; Tong, J.; Xiao, Y.; Qi, H. The Evaluation of Physio-Mechanical and Tribological Characterization of Friction Composites Reinforced by Waste Corn Stalk. Materials 2018, 11, 901. [Google Scholar] [CrossRef] [Green Version]

- Luo, H.; Xiong, G.; Ma, C.; Chang, P.; Yao, F.; Zhu, Y.; Zhang, C.; Wan, Y. Mechanical and thermo-mechanical behaviors of sizingtreated corn fiber/polylactide composites. Polym. Test. 2014, 32, 45–52. [Google Scholar] [CrossRef]

- Łączny, D.; Macko, M.; Moraczewski, K. Mechanical properties of polylactide matrix composite reinforced with long maize stalk fibers. Adv. Sci. Technol. Res. J. 2021, (in press). [Google Scholar]

- Nyambo, C.; Mohanty, A.K.; Misra, M. Polylactide-Based Renewable Green Composites from Agricultural Residues and Their Hybrids. Biomacromolecules 2010, 11, 1654–1660. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Injection Molded Wheat Straw and Corn Stem Filled Polypropylene Composites. J. Polym. Environ. 2006, 14, 265–272. [Google Scholar] [CrossRef]

- Jiang, D.; Wang, Y.; Li, B.; Sun, C.; Guo, Z. Environmentally Friendly Alternative to Polyester Polyol by Corn Straw on Preparation of Rigid Polyurethane Composite. Compos. Commun. 2020, 17, 109–114. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, B.; Gao, D.; Wen, L. The Study on the Mechanical Properties of Poly(lactic acid)/Straw Fiber Composites. Appl. Mech. Mater. 2012, 200, 312–315. [Google Scholar] [CrossRef]

- PN-EN ISO 1183-3:2003. Plastics–Methods for Determining the Density of Non-porous Plastics–Part 3: Gas Pycnometer Method; Polish Committee for Standardization: Warsaw, Poland, 2003. [Google Scholar]

- PN-EN ISO 527-1:2020-01. Plastics–Determination of Mechanical Properties under Static Stretching–Part 1: General Principles; Polish Committee for Standardization: Warsaw, Poland, 2020. [Google Scholar]

- PN-EN ISO 14125:2001/A1:2011. Plastic Composites Reinforced Fiber–Determination of Bending Properties; Polish Committee for Standardization: Warsaw, Poland, 2011. [Google Scholar]

- PN-EN ISO 179-2:2020-12. Plastics–Determination of Charpy Impact–Part 2: Instrumental Impact Test; Polish Committee for Standardization: Warsaw, Poland, 2020. [Google Scholar]

- PN-EN ISO 6721-1:2019-07. Plastics–Determination of Dynamic Mechanical Properties–Part 1: General Principles; Polish Committee for Standardization: Warsaw, Poland, 2019. [Google Scholar]

- NatureWorks LLC. Ingeo Biopolymer 3251D Technical Data Sheet. Available online: https://www.natureworksllc.com/~/media/Files/NatureWorks/Technical-Documents/Technical-Data-Sheets/TechnicalDataSheet_3251D_injection-molding_pdf.pdf?la=en (accessed on 1 November 2021).

- Golmakani, M.E.; Wiczenbach, T.; Malikan, M.; Aliakbari, R.; Eremeyev, V.A. Investigation of Wood Flour Size, Aspect Ratios, and Injection Molding Temperature on Mechanical Properties of Wood Flour/Polyethylene Composites. Materials 2021, 14, 3406. [Google Scholar] [CrossRef]

- Omrani, E.; Menezes, P.L.; Rohatgi, P.K. State of the art on tribological behavior of polymer matrix composites reinforced with natural fibers in the green materials world. Eng. Sci. Technol. Int. J. 2016, 19, 717–736. [Google Scholar] [CrossRef] [Green Version]

- Stanciu, M.D.; Teodorescu Draghicescu, H.; Tamas, F.; Terciu, O.M. Mechanical and Rheological Behaviour of Composites Reinforced with Natural Fibres. Polymers 2020, 12, 1402. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M.; Kloziński, A. The Influence of Sub-Zero Conditions on the Mechanical Properties of Polylactide-Based Composites. Materials 2020, 13, 5789. [Google Scholar] [CrossRef]

- Luo, H.; Zhang, C.; Xiong, G.; Wan, Y. Effects of alkali and alkali/silane treatments of corn fibers on mechanical and thermal properties of its composites with polylactic acid. Polym. Compos. 2015, 32, 3499–3507. [Google Scholar] [CrossRef]

- Nourbakhsh, A.; Ashori, A. Fundamental Studies on Wood–Plastic Composites: Effects of Fiber Concentration and Mixing Temperature on the Mechanical Properties of Poplar/PP Composite. Polym. Compos. 2008, 29, 569–573. [Google Scholar] [CrossRef]

- Nourbakhsh, A.; Karegarfard, A.; Ashori, A.; Nourbakhsh, A. Effects of Particle Size and Coupling Agent Concentration on Mechanical Properties of Particulate-Filled Polymer Composites. J. Compos. Mater. 2010, 23, 169–174. [Google Scholar] [CrossRef]

- Cui, Y.; Lee, S.; Noruziaan, B.; Cheung, M.; Tao, J. Fabrication and Interfacial Modification of Wood/Recycled Plastic Composite Materials. Compos. Part A Appl. Sci. Manuf. 2008, 39, 655–661. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind. Crop. Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Aguero, A.; Quiles-Carrillo, L.; Jorda-Vilaplana, A.; Fenollar, O.; Montanes, N. Effect of different compatibilizers on environmentally friendly composites from poly(lactic acid) and diatomaceous earth. Polym. Int. 2019, 68, 893–903. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Montanes, N.; Fenollar, O.; García-Sanoguera, D.; Balart, R. Development and optimization of renewable vinyl plastisol/wood flour composites exposed to ultraviolet radiation. Mater. Des. 2016, 108, 648–658. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Abdan, K.; Ishak, M.R. Effect of Alkali and silane treatments on mechanical and fibre-matrix bond strength of kenaf and pineapple leaf fibres. J. Bionic Eng. 2016, 13, 426–435. [Google Scholar] [CrossRef]

- Lopattananon, N.; Panawarangkul, K.; Sahakaro, K.; Ellis, B. Performance of pineapple leaf fiber–natural rubber composites: The effect of fiber surface treatments. J. Appl. Polym. Sci. 2006, 102, 1974–1984. [Google Scholar] [CrossRef]

| Sample Name | Density (g/cm3) |

|---|---|

| PLA | 1.2562 ± 0.0013 |

| PLA/CS1 | 1.2318 ± 0.0025 |

| PLA/CS1.6 | 1.2134 ± 0.0021 |

| PLA/CS2 | 1.2489 ± 0.0011 |

| PLA/CS4 | 1.1995 ± 0.0026 |

| Sample Name | Modulus of Elasticity (MPa) | Tensile Strength (MPa) | Strain at Break (%) |

|---|---|---|---|

| PLA | 2173 ± 65 | 60.64 ± 2.82 | 4 ± 0.7 |

| PLA/CS1 | 2713 ± 66 | 46.77 ± 1.73 | 2.34 ± 0.13 |

| PLA/CS1.6 | 2724 ± 34 | 45.43 ± 2.19 | 2.30 ± 0.17 |

| PLA/CS2 | 2687 ± 60 | 42.93 ± 1.66 | 2.17 ± 0.15 |

| PLA/CS4 | 2476 ± 74 | 29.68 ± 9.33 | 1.53 ± 0.55 |

| Sample Name | Modulus of Elasticity (MPa) | Flexural Strength (MPa) | Flexural Break (%) |

|---|---|---|---|

| PLA | 3833 ± 71 | 80.01 ± 10.3 | 2.24 ± 0.42 |

| PLA/CS1 | 4651 ± 129 | 64.88 ± 2.5 | 1.79 ± 0.19 |

| PLA/CS1.6 | 4598 ± 136 | 61.78 ± 3.3 | 1.76 ± 0.25 |

| PLA/CS2 | 4456 ± 56 | 61.68 ± 2.9 | 1.71 ± 0.15 |

| PLA/CS4 | 4132 ± 171 | 50.69 ± 5.3 | 1.60 ± 0.06 |

| Sample Name | E′30 °C (MPa) | E′50 °C (MPa) | E′75 °C (MPa) | E′130 °C (MPa) | tan δ/Temperature (°C) |

|---|---|---|---|---|---|

| PLA | 3028 | 2789 | 11.98 | 194.4 | 2.419/71.65 |

| PLA/CS1 | 3446 | 3148 | 25.2 | 440.7 | 1.536/69.74 |

| PLA/CS1.6 | 3712 | 3446 | 32.67 | 485.6 | 1.488/70.54 |

| PLA/CS2 | 3306 | 3029 | 35.89 | 466.4 | 1.406/71.17 |

| PLA/CS4 | 3208 | 2966 | 28.12 | 404.1 | 1.398/69.92 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Łączny, D.; Macko, M.; Moraczewski, K.; Szczepański, Z.; Trafarski, A. Influence of the Size of the Fiber Filler of Corn Stalks in the Polylactide Matrix Composite on the Mechanical and Thermomechanical Properties. Materials 2021, 14, 7281. https://doi.org/10.3390/ma14237281

Łączny D, Macko M, Moraczewski K, Szczepański Z, Trafarski A. Influence of the Size of the Fiber Filler of Corn Stalks in the Polylactide Matrix Composite on the Mechanical and Thermomechanical Properties. Materials. 2021; 14(23):7281. https://doi.org/10.3390/ma14237281

Chicago/Turabian StyleŁączny, Daniel, Marek Macko, Krzysztof Moraczewski, Zbigniew Szczepański, and Andrzej Trafarski. 2021. "Influence of the Size of the Fiber Filler of Corn Stalks in the Polylactide Matrix Composite on the Mechanical and Thermomechanical Properties" Materials 14, no. 23: 7281. https://doi.org/10.3390/ma14237281