Preliminary Study of the Rhenium Addition on the Structure and Mechanical Properties of Tungsten Heavy Alloy

Abstract

:1. Introduction

2. Experimental Procedure

3. Results

3.1. Results of Density Measurements

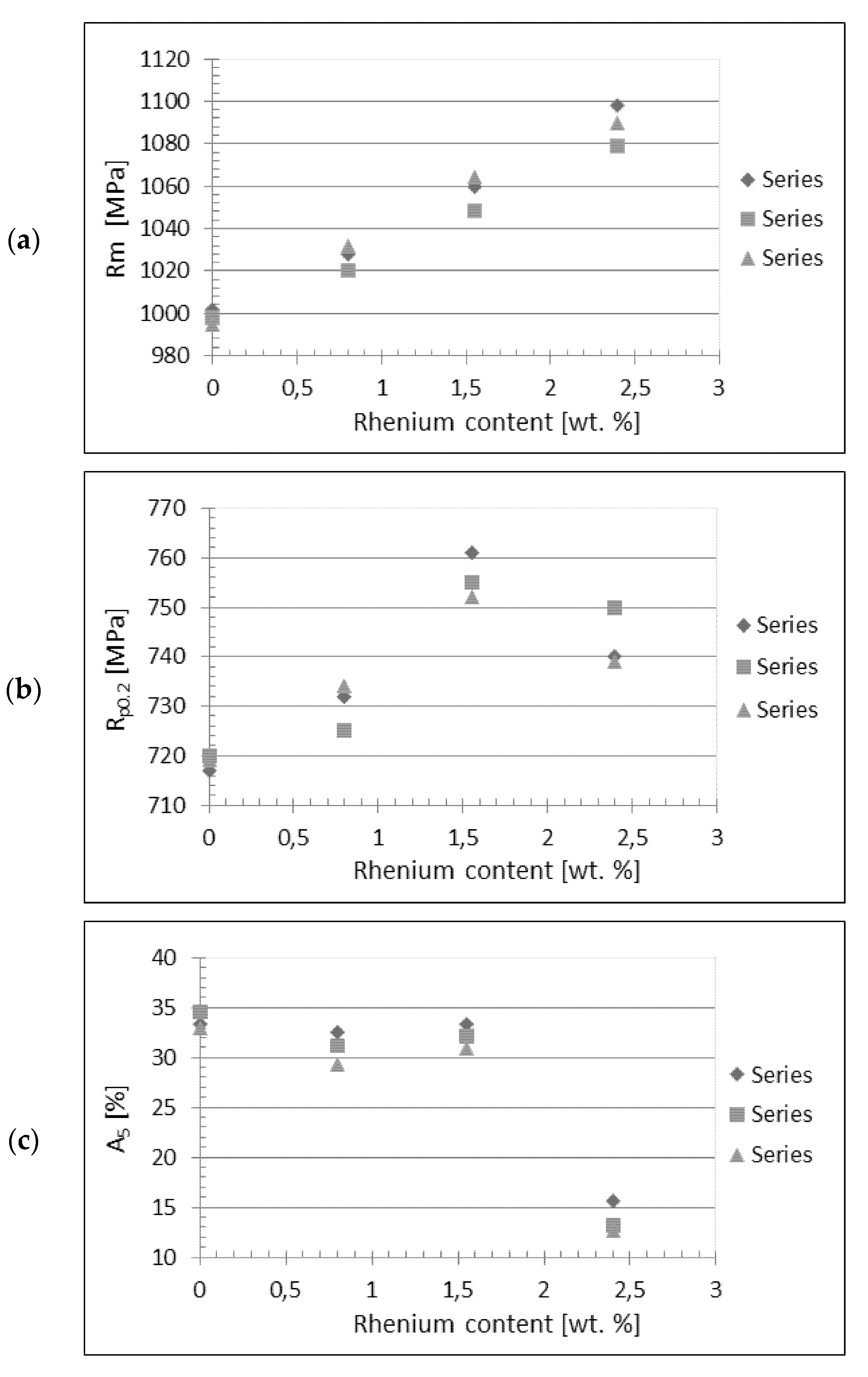

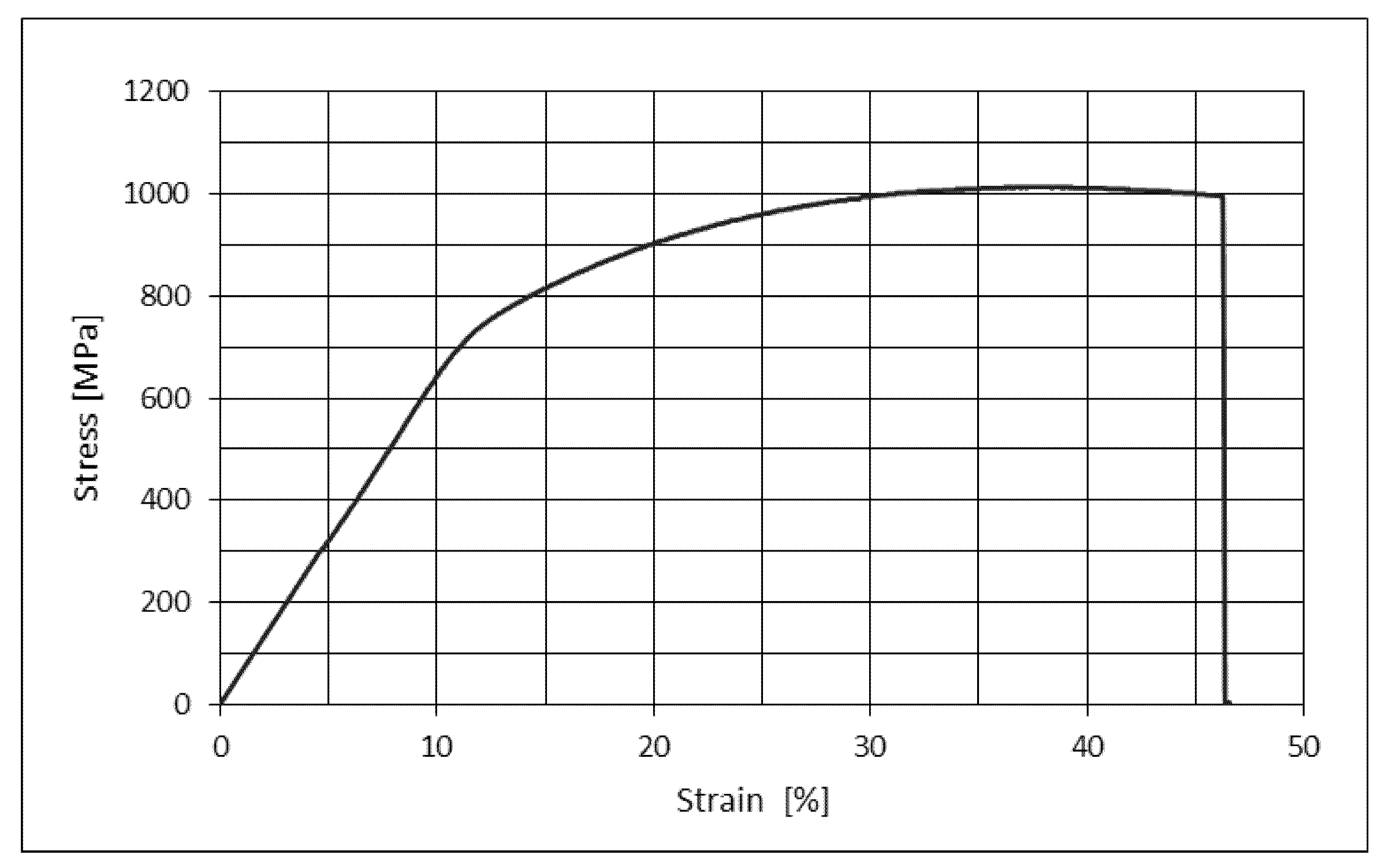

3.2. Results of Mechanical Testing

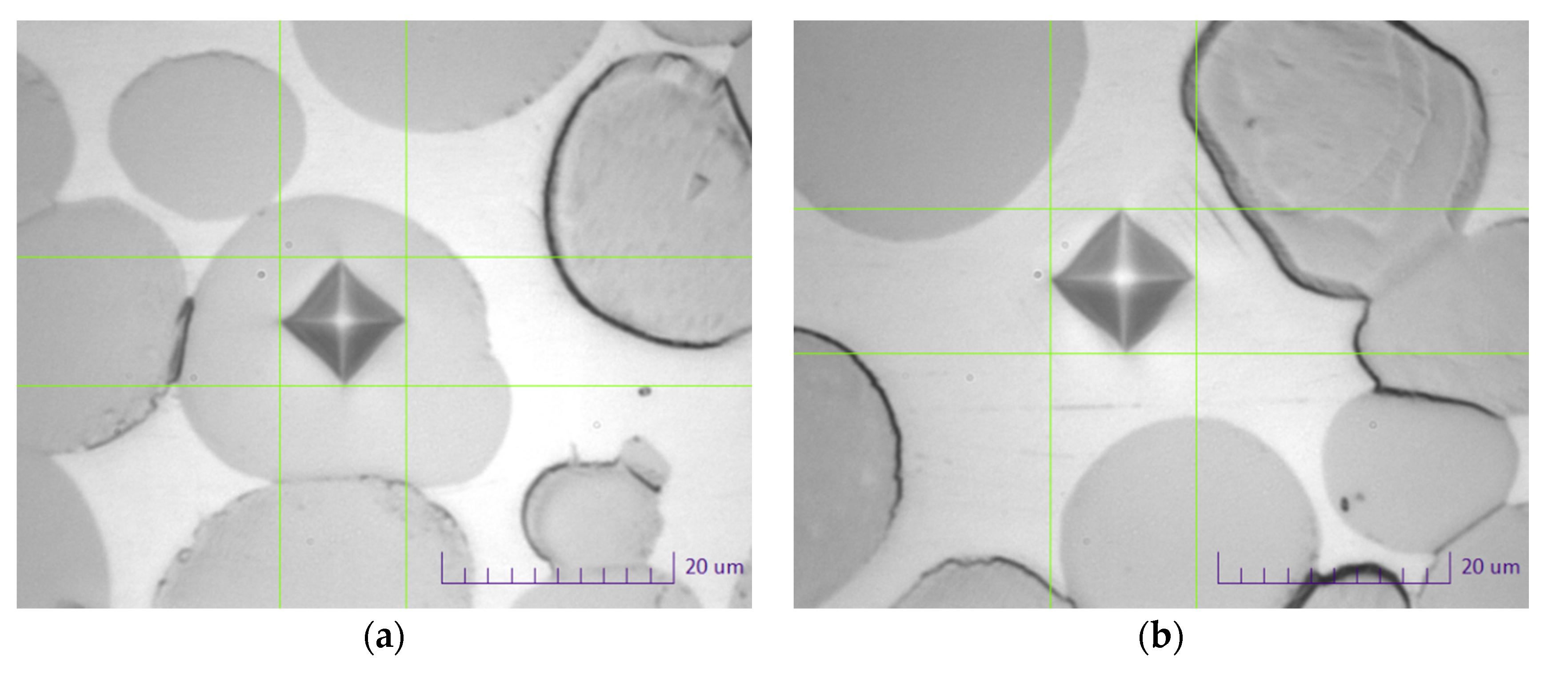

3.3. Results of Microhardness Measurement

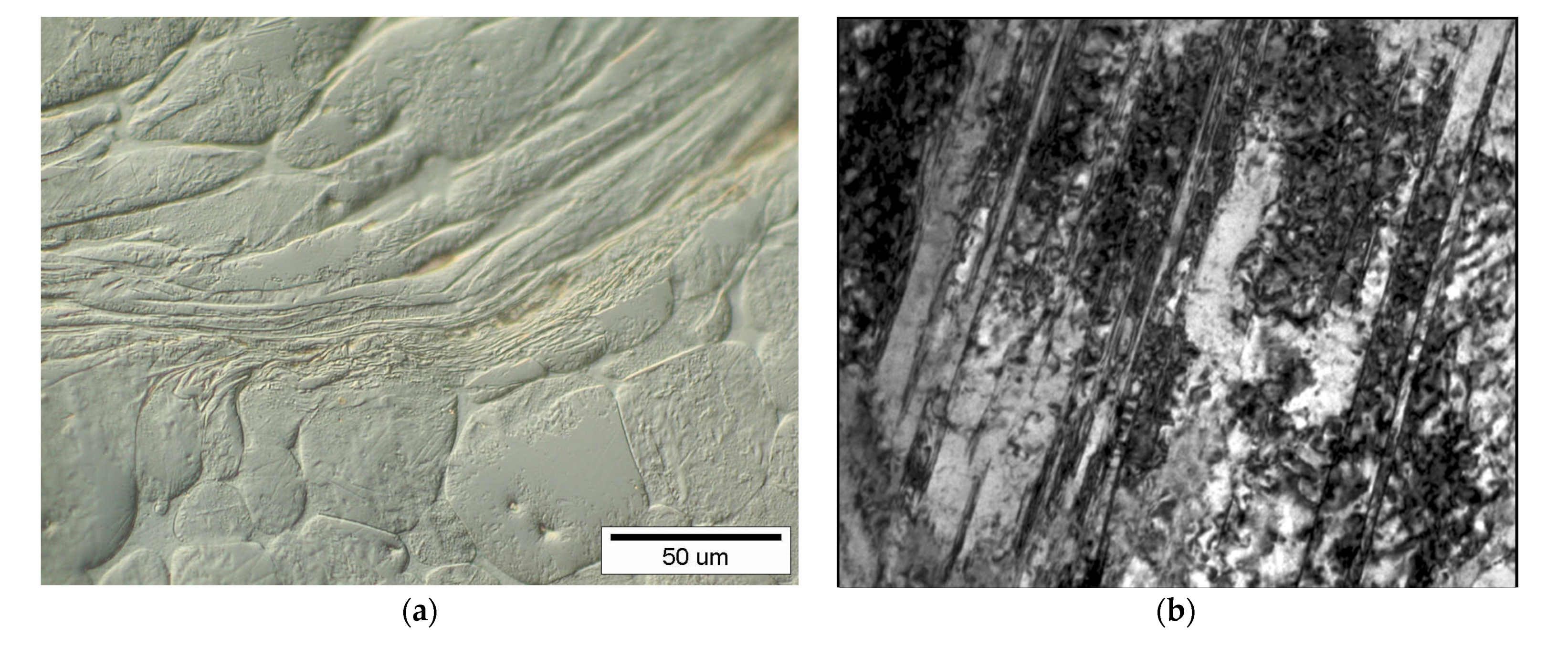

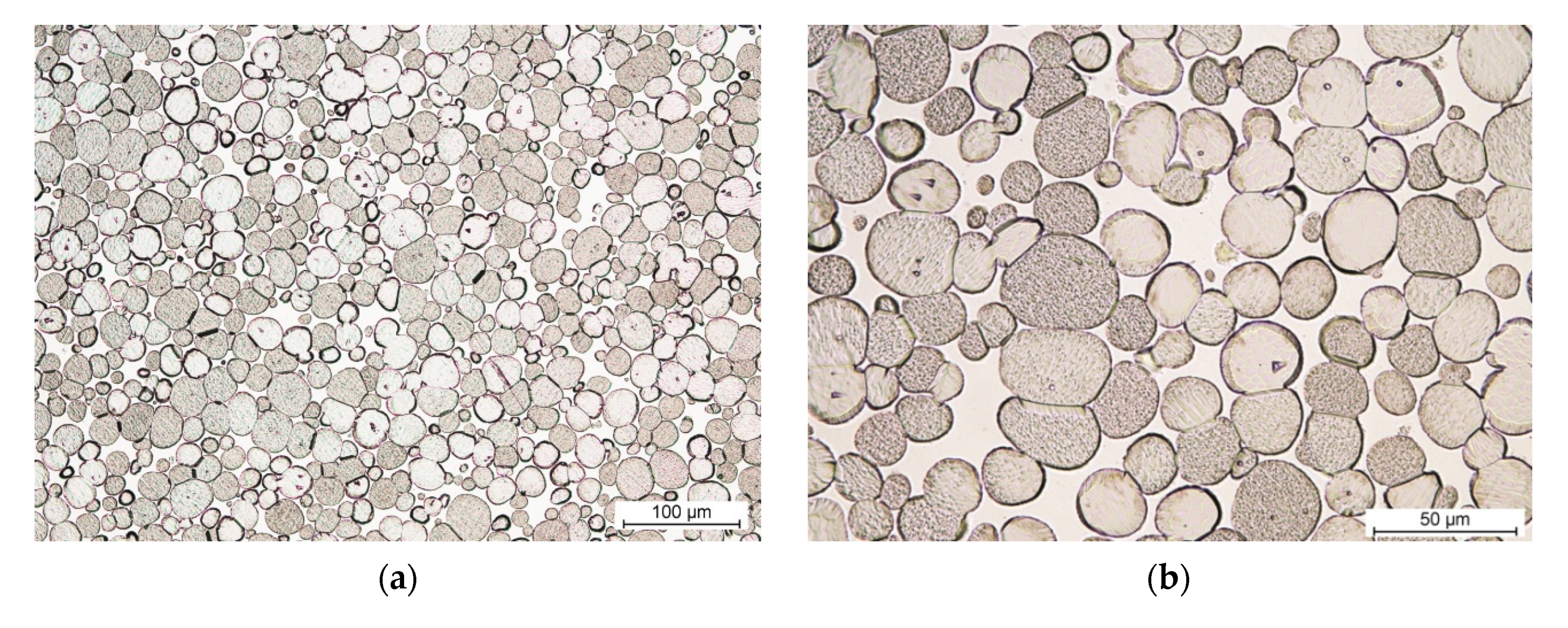

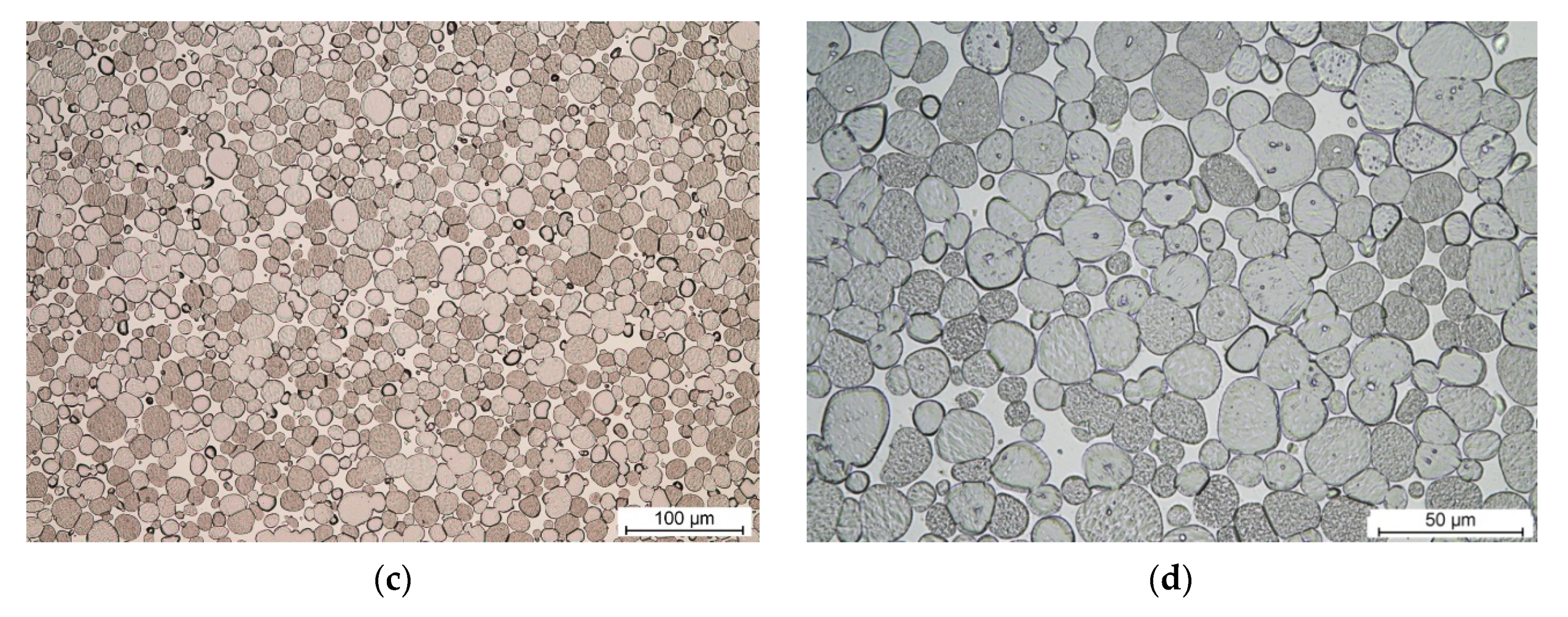

3.4. Microstructure Observations

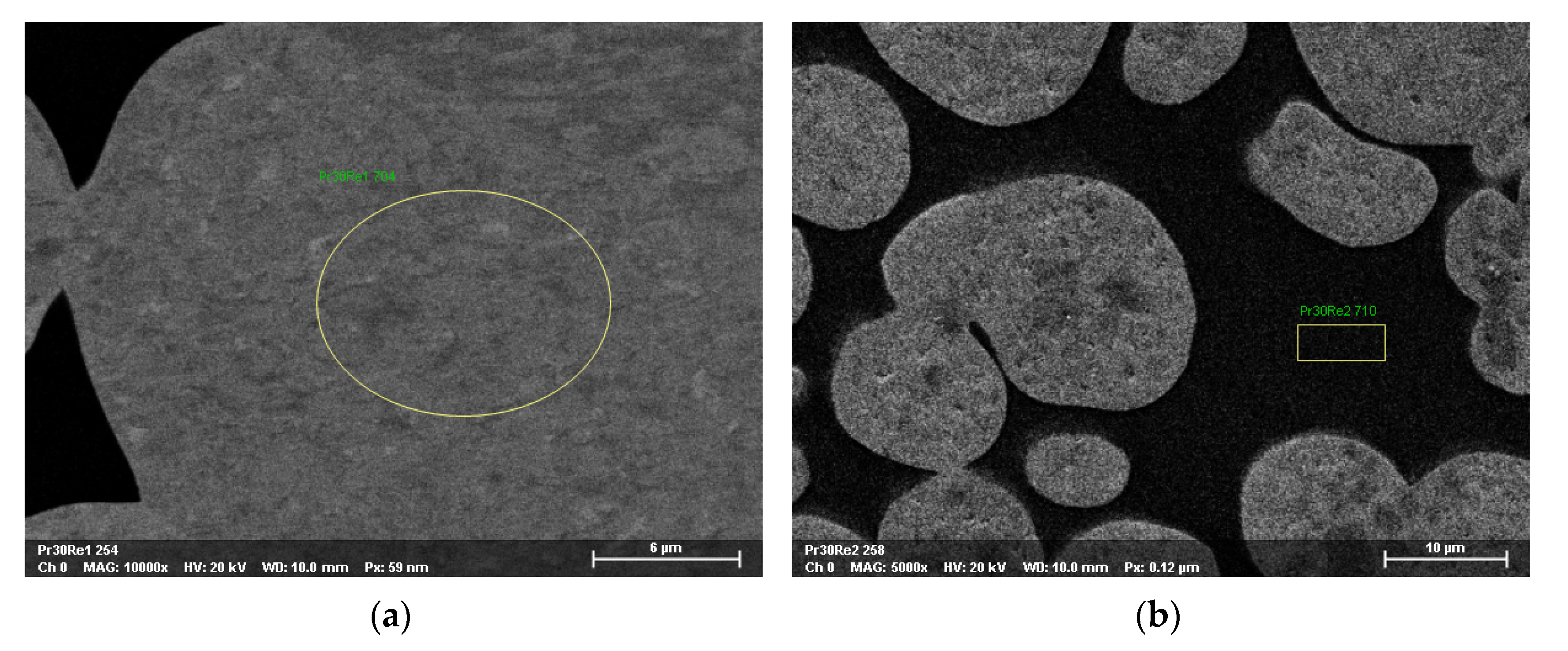

3.5. Chemical Microanalysis Tungsten Grains and Matrix

4. Discussion of Results

5. Conclusions

- Rhenium is dissolved in the tungsten grains to a content of at least 2.4% by mass.

- Rhenium promotes the grinding of tungsten grains. With 1.5 wt.%, changes in the microstructure are visible; there is a marked reduction in the size of the tungsten grains. With the increase in the rhenium content in the alloy, the size distribution of the measured grains decreases.

- Addition of Re has a relatively small influence on tungsten grain hardness (~7%), but causes a visible increase of matrix hardness (~15%).

- The increase of rhenium content increases the porosity. It can be suggested that increased porosity decreases plasticity by increasing the matrix sensitivity on the stress concentration factor. This in turn could explain the drop in elongation in cases with higher (2.4 wt.%) Re content.

- The addition of rhenium increases the strength properties of WHA. The value of tensile strength and proof strength increases with increasing shares of rhenium in WHA.

- The addition of rhenium reduces the plasticity of the WHA. As the rhenium content in WHA increases, the elongation decreases. Initially, for the lower amount of rhenium in WHA (0.8 and 1.55% by weight), the reduction in plasticity is slight—4% for the alloy without the addition of Re. With a higher rhenium content in WHA (2.4%), the decrease in plasticity is significant—nearly 60%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- German, R.M. Liquid Phase Sintering; Plenum Press: Seoul, Korea, 1985. [Google Scholar]

- Skoczylas, P.; Goroch, O.; Gulbinowicz, Z.; Barcz, K.; Kaczorowski, M. Research into the Production of Tungsten Heavy Alloys with Specific Mechanical Properties, Problems of Mechatronics. Armament Aviat. Saf. Eng. 2019, 10, 23–36. [Google Scholar]

- Lassner, E.; Schubert, W.D. Tungsten: Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds; Springer: Boston, MA, USA, 1999. [Google Scholar]

- Kunčická, L.; Kocich, R.; Klečková, Z. Effects of Sintering Conditions on Structures and Properties of Sintered Tungsten Heavy Alloy. Materials 2020, 13, 2338. [Google Scholar] [CrossRef]

- Das, J.; Ravi Kiran, U.; Chakraborty, A.; Eswara, N. Hardness and tensile properties of tungsten based heavy alloys prepared by liquid phase sintering technique. Int. J. Refract. Met. Hard Mater. 2009, 27, 577–583. [Google Scholar] [CrossRef]

- Skoczylas, P.; Kaczorowski, M. The influence of cyclic sintering on the structure and mechanical properties of Tungsten Heavy Alloy. Arch. Foundry Eng. 2016, 16, 131–136. [Google Scholar] [CrossRef] [Green Version]

- Skoczylas, P.; Gulbinowicz, Z.; Goroch, O. Microstructure and Properties of Tungsten Heavy Alloy Connections Formed during Sintering with the Participation of the Liquid Phase. Materials 2020, 13, 4965. [Google Scholar] [CrossRef]

- Lu, Y.; Qiu, X.; Ruan, Y.; Luo, C.; Xing, F. Effect of Ti on Microstructure and Properties of Tungsten Heavy Alloy Joint Brazed by CuAgTi Filler Metal. Materials 2019, 12, 1057. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, Y.; Er-de, W. Microstructure and properties of liquid phase sintered tungsten heavy alloys by using ultra-fine tungsten powders. Trans. Nonferrous Met. Soc. China 2004, 14, 912–917. [Google Scholar]

- Kaczorowski, M.; Skoczylas, P.; Krzyńska, A.; Kaniewski, J. The strengthening of weight heavy alloys during heat treatment. Arch. Foundry Eng. 2012, 12, 75–80. [Google Scholar] [CrossRef]

- Hyung, B.W.; Hee, H.M.; Pyo, K.E. Heat treatment behavior of tungsten heavy alloy. Solid State Phenom. 2006, 118, 35–40. [Google Scholar]

- Katavić, B.; Odanović, Z.; Burzi, M. Investigation of the rotary swaging and heat treatment on the behavior of W- and γ- phase in PM 92.5W-%-Ni-2.5Fe-0.26Co heavy alloy. Mater. Sci. Eng. A 2008, 492, 337–345. [Google Scholar] [CrossRef]

- Katavić, B.; Nikaćević, M.; Odanović, Z. Effect of cold swaging and heat treatment on properties of the P/M 91W-6Ni-3Co heavy alloy. Sci. Sinter. 2008, 40, 319–331. [Google Scholar] [CrossRef]

- Sunwoo, A.; Groves, S.; Goto, D. Effect of matrix alloy and cold swaging on micro-tensile properties of tungsten heavy alloys. Mater. Lett. 2006, 60, 321–325. [Google Scholar] [CrossRef]

- Edmonds, D.V. Structure-property relationships in sintered heavy alloys. Refract. Met. Hard Mater. 1991, 10, 15–26. [Google Scholar] [CrossRef]

- Durlu, N.; Çalişkan, N.K.; Bor, Ş. Effect of swaging on microstructure and tensile properties of W–Ni–Fe alloys. Int. J. Refract. Met. Hard Mater. 2014, 42, 126–131. [Google Scholar] [CrossRef]

- German, R.M. Critical developments in tungsten heavy alloys. In Proceedings of the 1th International Conference on Tungsten Tungsten Alloys, Arlington, VA, USA, 15–18 November 1992; pp. 3–13. [Google Scholar]

- Magness, L.S.; Kapoor, D. Flow-softening tungsten composites for kinetic energy penetrator applications. In Proceedings of the 2nd International Conference on Tungsten and Refractory Metals, McLean, VA, USA, 17–19 October 1994. [Google Scholar]

- Lanz, W.; Odermatt, W.; Weihrauch, G. Kinetic energy projectiles: Development history, state of the art, trends. In Proceedings of the 19th International Symposium of Ballistics, Interlaken, Switzerland, 7–11 May 2001. [Google Scholar]

- Kumbhar, K.; Senthil, P.P.; Gogia, A.K. Microstructural observations on the terminal penetration of long rod projectile. Def. Technol. 2017, 6, 413–421. [Google Scholar] [CrossRef]

- Kruszka, L.; Janiszewski, J.; Grązka, M. Experimental and Numerical Analysis of Al6063 Duralumin Using Taylor Impact Test, EPJ Web of Conference; EDP Sciences: Les Ulis, France, 2012; Volume 26, p. 201201062. [Google Scholar]

- Kennedy, C.; Murr, L.E. Comparison of tungsten heavy-alloy rod penetration into ductile and hard metal targets: Microstructural analysis and computer simulations. Mater. Sci. Eng. A 2002, 325, 131–143. [Google Scholar] [CrossRef]

- Hauver, G.E.; Melani, A. Behavior of Segmented Rods during Penetration, Technical Report BRL-TR-3129; Army Ballistic Research Lab Aberdeen Proving Ground: Aberdeen, MD, USA, 1990. [Google Scholar]

- Arnold, W. Tungsten heavy alloys for multiple impact applications. In AIP Conference Proceedings; AIP: College Park, MA, USA, 2004; pp. 1319–1322. [Google Scholar]

- Rabin, B.H.; Bose, A.; German, R.M. Characteristics of Liquid Phase Sintered Tungsten Heavy Alloys. Int. J. Powder Metall. 1989, 25, 21–27. [Google Scholar]

- Bose, A.; German, R.M. Sintering atmosphere effects on tensile properties of heavy alloys. Metall. Trans. A Phys. Metall. Mater. Sci. 1988, 19, 66–77. [Google Scholar] [CrossRef]

- Kaczorowski, M.; Skoczylas, P.; Krzyńska, A. The influence of Fe content on spreading ability of tungsten heavy alloys matrix on tungsten surface. Arch. Foundry Eng. 2011, 11, 103–106. [Google Scholar]

- Majewski, T. Technologiczne Uwarunkowania Właściwości Użytkowych Spieków Ciężkich W-(Fe, Ni, Re); Wojskowa Akademia Techniczna: Warszawa, Poland, 2013. [Google Scholar]

- Motyl, K.; Magier, M.; Borkowski, J.; Zygmunt, B. Theoretical and experimental research of anti-Tank kinetic penetrator ballistics. Bull. Pol. Acad. Sci. Tech. Sci. 2017, 65, 399–404. [Google Scholar] [CrossRef]

- Magier, M. The role of adiabatic shear bands effect in penetration process. Probl. Tech. Uzbroj. 2018, 147, 7–17. [Google Scholar] [CrossRef]

- Kaczorowski, M.; Nowak, W.; Skoczylas, P.; Rafalski, M. Zjawiska występujące w rdzeniach pocisków podczas penetracji płyty, Materiały konferencyjne, wydanie specjalne XVI konferencji naukowo-technicznej. Uzbrojenie 2007, 2007, 213–219. [Google Scholar]

- Yadav, S.; Ramesh, K.T. The dynamic behavior of a tungsten-hafnium composite for kinetic energy penetrator applications. In Proceedings of the 4th International Conference on Tungsten Refractory Metals and Alloys, Lake Buena Vista, FL, USA, 17–19 November 1997; pp. 111–117. [Google Scholar]

- Kaczorowski, M.; Skoczylas, P. Kształtowanie struktury i właściwości wolframowych stopów ciężkich o przeznaczeniu specjalnym", Problemy Mechatroniki. Uzbroj. Lot. Inżynieria Bezpieczeństwa 2015, 6, 27–40. [Google Scholar]

- Ravi Kiran, U.; Panchal, A.; Prem Kumar, M.; Sankaranarayana, M.; Nageswara Rao, G.V.S.; Nandy, T.K. Refractory metal alloying: A new method for improving mechanical properties of tungsten heavy alloys. J. Alloys Compd. 2017, 709, 609–619. [Google Scholar] [CrossRef]

- Natarajan, S.; Gopalan, V.; Rajan, R.A.A.; Jen, C.-P. Effect of Rare Earth Metals (Y, La) and Refractory Metals (Mo, Ta, Re) to Improve the Mechanical Properties of W–Ni–Fe Alloy—A Review. Materials 2021, 14, 1660. [Google Scholar] [CrossRef]

- Annamalai, A.R.; Muthuchamy, A.; Srikanth, M.; Natarajan, S.; Acharya, S.; Khisti, A.; Jen, C.-P. Powder Metallurgical Processing and Characterization of Molybdenum Addition to Tungsten Heavy Alloys by Spark Plasma Sintering. Materials 2021, 14, 5756. [Google Scholar] [CrossRef]

- German, R.M.; Bose, A.; Kemp, P.B.; Zhang, H. Additive Effect on the Microstructure and Properties of Tungsten Heavy Alloy Composites. In Advances in Powder Metallurgy; Basbarre, T.G., Jandeska, W.F., Eds.; Metal Powder Industries Federation: Princeton, NJ, USA, 1989; Volume 2, pp. 401–414. [Google Scholar]

- Liu, W.; Ma, Y.; Huang, B. Influence of minor elements additions on microstructure and properties of 93W–4⋅9Ni–2⋅1Fe alloys. Bull. Mater. Sci. 2008, 31, 1–6. [Google Scholar] [CrossRef]

- Bose, A.; Sadangi, R.; German, R.M. A review on alloying in tungsten heavy alloys. Suppl. Proc. Mater. Process. Interfaces 2012, 1, 453–465. [Google Scholar]

- Tan, X.; Leng, B.; Qiu, S. Influences of sub-micrometer Ta and Co dopants on microstructure and properties of tungsten heavy alloys. Trans. Nonferrous Met. Soc. China 2004, 14, 747–750. [Google Scholar]

- Zhang, Y.; Huang, Y.; Liu, W.; Ma, Y.; Liu, J.; Liang, C. Effect of tungsten tantalum pre-alloying on the sintering structure of 90(W-Ta)-Ni-Fe alloy. J. Alloys Compd. 2022, 891, 161881. [Google Scholar] [CrossRef]

- Annamalai, A.R.; Lakshmi, B.S. Effect of Rhenium addition on tungsten heavy alloys processed through spark plasma sintering. Ain Shams Eng. J. 2021, 12, 2957–2963. [Google Scholar]

- Bose, A.; Jerman, G.; German, R.M. Rhenium alloying of tungsten heavy alloys. Powder Metall. Int. 1989, 21, 9–13. [Google Scholar]

- James, R.S.; James, A.M. Fine Grain Tungsten Heavy Alloys Containing Additives. EP0323628A1, 12 July 1989. [Google Scholar]

- Okamoto, H.; Massalski, T.B. Binary Alloy Phase Diagrams; ASM International: Materials Park, OH, USA, 1990. [Google Scholar]

- Murray, J.L.; Bennett, L.H.; Baker, H.; Massalski, T.B. Binary Alloy Phase Diagrams; American Society for Metals: Metals Park, OH, USA, 1986. [Google Scholar]

| Alloy Designation | Chemical Composition (wt.%) | ||||

|---|---|---|---|---|---|

| W | Ni | Fe | Co | Re | |

| PR-100 | 90.80 | 6.2 | 1.2 | 1.8 | - |

| Re-1 | 90.00 | 0.80 | |||

| Re-2 | 89.25 | 1.55 | |||

| Re-3 | 88.40 | 2.40 | |||

| Alloy Designation | Density (Mg/m3) | |

|---|---|---|

| Calculated | Measured | |

| PR-100 | 17.37 | 17.35 |

| Re-1 | 17.38 | 17.37 |

| Re-2 | 17.39 | 17.35 |

| Re-3 | 17.40 | 17.35 |

| Alloy Type | Mechanical Properties | ||

|---|---|---|---|

| Rp0.2 (MPa) | Rm (MPa) | A5 (%) | |

| Pr-100 | 717 | 1002 | 33.4 |

| 720 | 998 | 34.5 | |

| 719 | 995 | 32.9 | |

| Average values | 719 ± 2 | 998 ± 4 | 33.6 ± 0.8 |

| Re-1 | 732 | 1028 | 32.5 |

| 725 | 1020 | 31.2 | |

| 734 | 1032 | 29.3 | |

| Average values | 730 ± 5 | 1027 ± 6 | 31.0 ± 1.6 |

| Re-2 | 761 | 1060 | 33.4 |

| 755 | 1048 | 32.1 | |

| 752 | 1064 | 30.9 | |

| Average values | 756 ± 5 | 1057 ± 8 | 32.1 ± 1.3 |

| Re-3 | 740 | 1098 | 15.6 |

| 750 | 1079 | 13.2 | |

| 739 | 1090 | 12.6 | |

| Average values | 743 ± 6 | 1089 ± 10 | 13.8 ± 1.6 |

| Alloy Designation | HV 0.025 | |

|---|---|---|

| Matrix | Tungsten Grain | |

| PR-100 | 345 ± 15 | 440 ± 12 |

| Re-1 | 340 ± 15 | 398 ± 18 |

| Re-2 | 380 ± 21 | 455 ± 13 |

| Re-3 | 398 ± 23 | 470 ± 12 |

| Alloy Designation | Re Content (wt.%) | Tungsten Grain Size (μm) |

|---|---|---|

| PR-100 | 33.1 ± 4.6 | |

| Re-1 | 0.80 | 32.8 ± 4.6 |

| Re-2 | 1.55 | 26.1 ± 3.1 |

| Re-3 | 2.40 | 20.6 ± 3.4 |

| Alloy Designation | Re Content Mass Norm. (%) | Chemical Composition (wt.%) | |

|---|---|---|---|

| Tungsten Grains | Matrix | ||

| Re-1 | 0.82 | 0.73 | 0.80 |

| Re-2 | 1.85 | 0.49 | 1.55 |

| Re-3 | 2.46 | 0.82 | 2.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skoczylas, P.; Kaczorowski, M. Preliminary Study of the Rhenium Addition on the Structure and Mechanical Properties of Tungsten Heavy Alloy. Materials 2021, 14, 7365. https://doi.org/10.3390/ma14237365

Skoczylas P, Kaczorowski M. Preliminary Study of the Rhenium Addition on the Structure and Mechanical Properties of Tungsten Heavy Alloy. Materials. 2021; 14(23):7365. https://doi.org/10.3390/ma14237365

Chicago/Turabian StyleSkoczylas, Paweł, and Mieczysław Kaczorowski. 2021. "Preliminary Study of the Rhenium Addition on the Structure and Mechanical Properties of Tungsten Heavy Alloy" Materials 14, no. 23: 7365. https://doi.org/10.3390/ma14237365

APA StyleSkoczylas, P., & Kaczorowski, M. (2021). Preliminary Study of the Rhenium Addition on the Structure and Mechanical Properties of Tungsten Heavy Alloy. Materials, 14(23), 7365. https://doi.org/10.3390/ma14237365