1. Introduction

Intensive research is currently being carried out to reduce the CO

2 footprint of concrete construction. In addition to the reduction and substitution of the CO

2 intense cementitious binder, there is the option of building with a lower material intensity, while maintaining the required mechanical and structural properties. Research has been carried out on textile-reinforced concrete for years [

1,

2,

3]. Here, steel reinforcement is replaced by textiles impregnated with polymers, e.g., made of glass or carbon. Due to their significantly higher tensile strength and better alkali resistance, the minimum concrete cover can be reduced and, significantly, filigree components can be produced. The strength of the textile concrete is largely dependent on the impregnation selected. Thus, the maximum textile stresses when using glass reinforcement can be up to 1500 MPa [

4], and with carbon up to 3500 Mpa, during the uniaxial tension test [

5,

6]. Normally, textile concrete is produced by the casting, laminating or shotcrete methods [

5,

7].

Extensive research is also being carried out into topic of digitalisation and additive manufacturing in the industry to reduce material consumption [

8,

9]. Additive manufacturing in the construction industry has developed rapidly, especially in 3D concrete printing, in recent years [

10,

11,

12]. This multitude of processes cannot always be clearly separated from one another. In the context of this paper, a distinction is therefore made between processes by means of extrusion or extrusion molding and robot-assisted processes. Extrusion or extrusion-molding is a production process in which solid to viscous, hardening materials are continuously pressed through a shaping mouthpiece, giving the product its final shape. Robot-assisted processes are generally distinguished between those based on extrusion by means of a nozzle [

13,

14] selective bonding [

15], layer-by-layer concrete placement [

16] and adaptive slip-forming [

8,

12,

17,

18]. The aim of these robot-assisted processes is to produce the desired products through a targeted layer build-up.

One key research direction within the 3D concrete printing community is the integration of reinforcement [

19,

20,

21]. Microfibers are added to the mixture during mixing or continuous fibers are integrated into the printed strand. In addition, the reinforcement can be inserted between or through the layers [

22], or printed around a reinforcement [

23,

24]. Nevertheless, the integration of classic reinforcement concepts into the 3D concrete printing process is still very difficult.

Classic extrusion is also used in the construction sector [

25,

26]. Currently, hollow slabs, roof tiles or window sills made of concrete are already being successfully extruded [

27]. In [

28], an overview of the basics of extruding cement-based mixes is presented.

The use of extrudable fiber concretes has been the subject of several investigations in the past. The results of the investigations on different types of short fibers, such as glass fibers and PVA (polyvinyl alcohol) fibers, show that PVA fibers give reinforced slabs a higher toughness and a correspondingly more ductile behavior. In addition, it was shown that strength and toughness could be further improved by combining both types of fibers [

29]. Comparative test specimens of extruded and differently cast fiber-reinforced concrete have shown that the extruded materials showed higher strength and stiffness. Scanning electron microscope images show that the fiber orientation in the extruded fiber-reinforced concrete slab was in the direction of extrusion, whereas the fibers in the conventionally produced slab were distributed randomly and without a defined direction in the concrete cross-section [

30].

For the extrusion of unreinforced and fiber-reinforced concrete, the first successful investigations have already been published for a laboratory mortar extruder (LabMorTex) by RWTH Aachen University in 2012 [

31] and 2019 [

32]. It was shown that extrusion is possible with different types of fibers such as PVA, basalt and glass. The fiber-reinforced concrete could be extruded from the extruder′s mouthpiece with an almost constant volume flow, while maintaining the desired geometry. Thus, it is possible to produce test specimens of cement-bonded concrete with different geometries [

31,

32,

33,

34]. In contrast, aramid fibers can cause a non-defect-free extrusion of the fiber-reinforced concrete, as the high water absorption of the fibers has a negative influence on the fine concrete mixture [

32]. Carbon short fibers were also not suitable for the extrusion process, as they were broken up during the mixing process due to their brittle material behavior in the intensive concrete mixer [

32]. However, the currently used concrete mixes still have a high binder content and are not yet practical and robust enough for plant scale to compensate for fluctuations in the raw materials.

In initial preliminary tests at ibac (Institute of Building Materials Research), textile reinforcement was successfully integrated into the extrusion process, which significantly increased the performance of the construction [

32]. The tests showed that flexible impregnated textiles were better suited for the feeding process than uncoated textiles due to their higher stiffness, as the latter either contracted during the extrusion or was pushed together by the concrete. The concrete could be extruded without defects and without strand expansion, and a uniform surface finish of the extruded strand could be guaranteed [

32,

33]. To produce a high-performance textile-reinforced concrete component by extrusion, stiff impregnated textiles must be used in which as many fibers as possible are involved in the loading transfer. The flexible impregnations used so far for the textiles are flexible but have the disadvantage that not all fibers are activated during the loading transfer, and so have an insufficient reinforcing effect [

32].

At present, there is a lack of test results and suitable structure with which stiffly impregnated textiles can be used in the concrete extrusion process.

2. Materials

Within the scope of this work, three different mortars with strength classes were developed for the mortar extrusion process with textile reinforcement. The mix designs are given in

Table 1. Mixture 1 was a modification of the basic mixture from [

32]. To be able to use compounds with a better CO

2 footprint, two further compounds were developed. In Mixture 2, the binder content was significantly reduced and replaced by quartz powder. The blastfurnace cement CEM III/A used in Mixture 3 consisted of 44.9 wt.% blastfurnace slag in addition to Portland cement clinker. According to [

35], mortar Mix 1 has a global warming potential (GWP) of 728/m

3. By adjusting the binder, the GWP of Mix 2 (592 GWP/m

3) could be reduced by 18.7% compared to Mix 1 and of Mix 3 (369 GWP/m

3) by 49.3% compared to Mix 1. Thus, compounds were developed that are extrudable and have a reduced CO

2 footprint.

Methyl cellulose was added to the mix in powder form to influence the consistency of the mortar mix. The methyl cellulose ensured that the mortar had a stiff consistency and at the same time bound the water in the mix and formed a gel. This gel ensured that the mixture was transportable in the extruder and that the mortar did not change its geometric shape after leaving the mouthpiece.

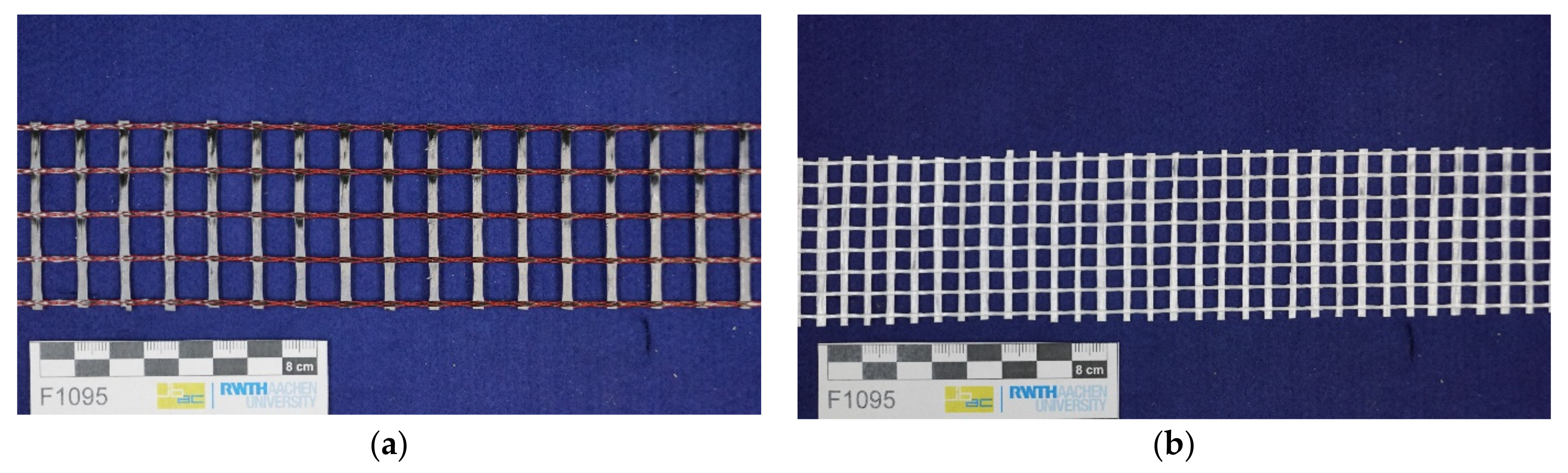

Two different textiles were examined as reinforcement materials for the extrusion process. Textile 1 was the carbon textile SITgrid044 VL from Wilhelm Kneitz Solutions in Textile GmbH (Hof, Germany), which is already being used successfully in masonry construction [

36]. Textile 2 was the glass textile AR 240 manufactured by Kelteks d.o.o.—tvornice tekstila (Karlovac, Croatia). These textiles also differ in their thickness, fineness, grid spacing and impregnation. The pre-cut carbon textile and glass textile can be seen in

Figure 1a,b.