Characterization of Cobalt-Based Stellite 6 Alloy Coating Fabricated by Laser-Engineered Net Shaping (LENS)

Abstract

:1. Introduction

2. Materials and Methods

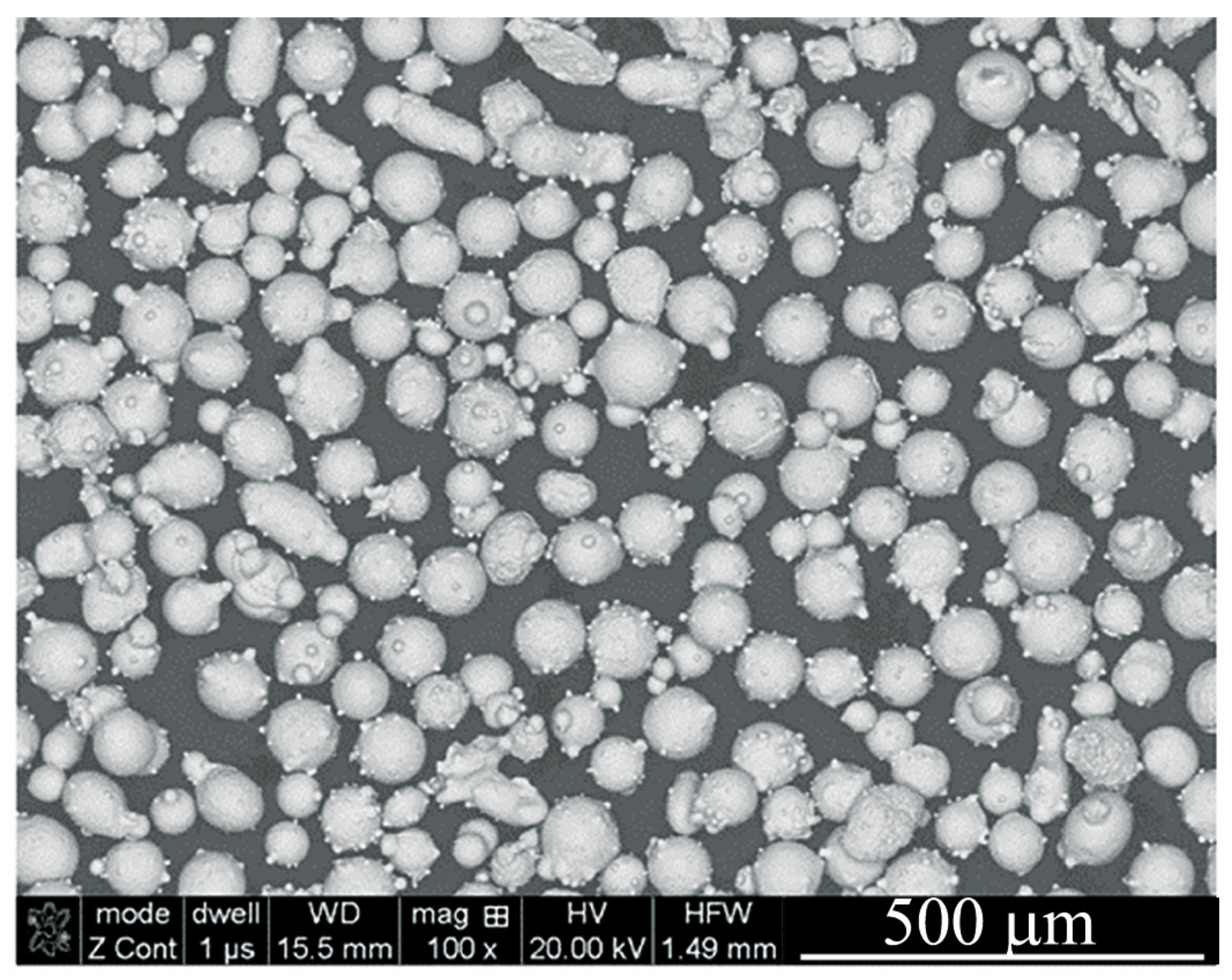

2.1. Materials

2.2. The LENS Process

2.3. The Characterization Techniques of Coatings

2.4. The Mechanical Properties Tests

- -

- A deflection at the maximum bending strength;

- -

- A maximum bending force;

- -

- Bending strength;

- -

- Deformation.

3. Results and Discussion

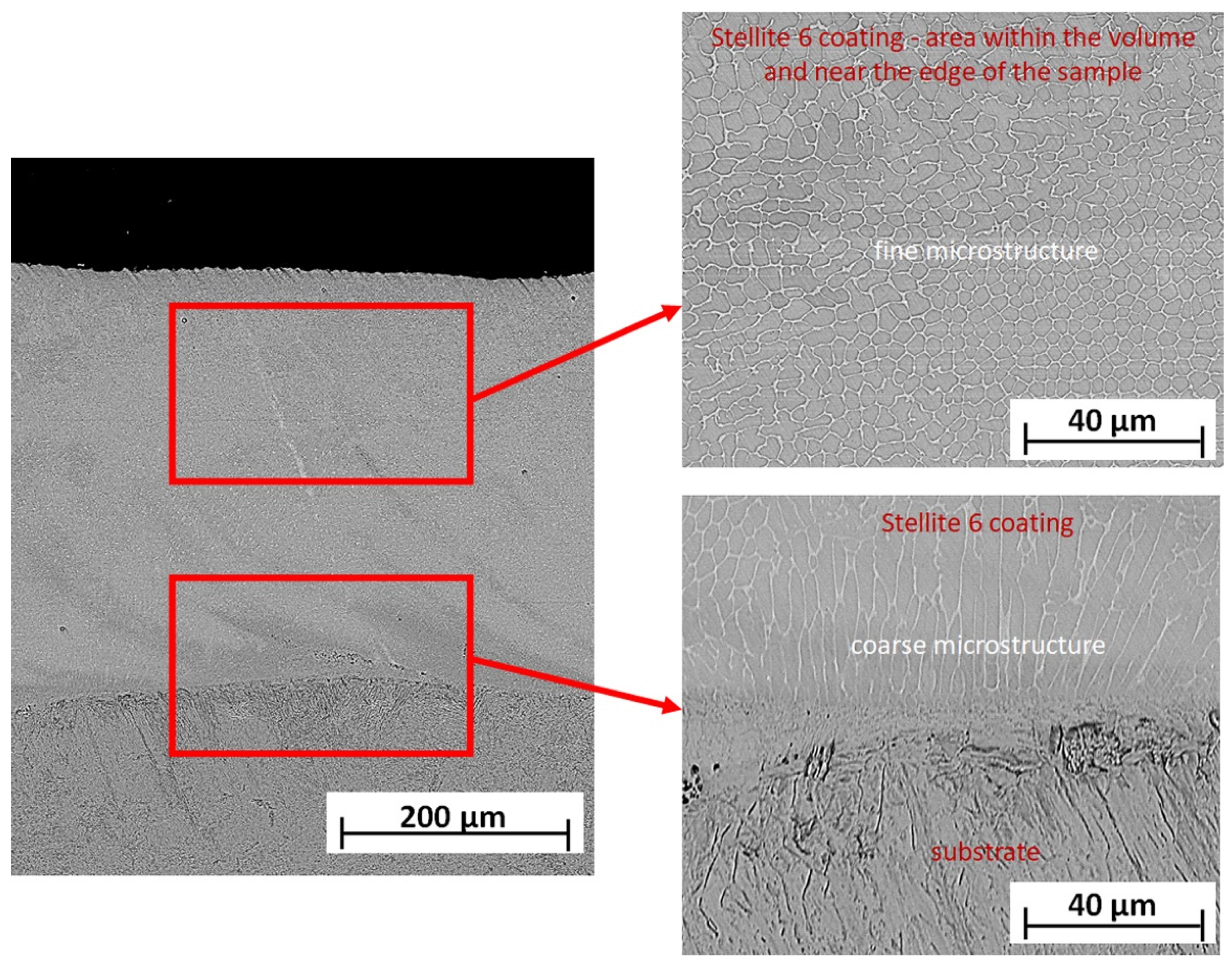

3.1. Microstructure of Co-6 Coatings

3.2. EBSD and XRD Phase Analysis

3.3. Microhardness

3.4. Three-Point Bending Tests

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, Y.; Tiandong, X.; Yanling, H. Microstructures Comparison of Stellite 6 Alloy by Self-Propagating High-Temperature Synthesis and Cast HS111 Alloy. Rare Metal Mat. Eng. 2009, 38, 1333–1337. [Google Scholar] [CrossRef] [Green Version]

- Jeshvaghani, R.A.; Shamanian, M.; Jaberzadeh, M. Enhancement of wear resistance of ductile iron surface alloyed by stellite 6. Mater. Des. 2011, 32, 2028–2033. [Google Scholar] [CrossRef]

- Sidhu, T.S.; Prakash, S.; Agrawal, R.D. Studies of the metallurgical and mechanical properties of high velocity oxy-fuel sprayed stellite-6 coatings on Ni- and Fe-based superalloys. Surf. Coat. Technol. 2006, 201, 273–281. [Google Scholar] [CrossRef]

- Pilehrood, A.E.; Mashhuriazar, A.; Baghdadi, A.H.; Sajuri, Z.; Omidvar, H. Effect of Laser Metal Deposition Parameters on the Characteristics of Stellite 6 Deposited Layers on Precipitation-Hardened Stainless Steel. Materials 2021, 14, 5662. [Google Scholar] [CrossRef] [PubMed]

- Davis, J.R. Nickel, Cobalt, and Their Alloys. In ASM Specialty Handbook; ASM International: Materials Park, OH, USA, 2000; ISBN 978-0-87170-685-0. [Google Scholar]

- Hattori, S.; Mikami, N. Cavitation erosion resistance of stellite alloy weld overlays. Wear 2009, 267, 1954–1960. [Google Scholar] [CrossRef]

- Erickson, L.C.; Westergård, R.; Wiklund, U.; Axén, N.; Hawthorne, H.M.; Hogmark, S. Cohesion in plasma-sprayed coatings—a comparison between evaluation methods. Wear 1998, 214, 30–37. [Google Scholar] [CrossRef]

- Cinca, N.; López, E.; Dosta, S.; Guilemany, J.M. Study of stellite-6 deposition by cold gas spraying. Surf. Coat. Technol. 2013, 232, 891–898. [Google Scholar] [CrossRef]

- Kong, G.; Zhang, D.; Brown, P.D.; McCartney, D.G.; Harris, S.J. Microstructural characterisation of high velocity oxyfuel thermally sprayed Stellite 6. Mater. Sci. Technol. 2003, 19, 1003–1011. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, D.; Mishra, S.K.; Tiwari, S.K. Laser cladding of Stellite 6 on stainless steel to enhance solid particle erosion and cavitation resistance. Surf. Coat. Technol. 2014, 251, 87–97. [Google Scholar] [CrossRef]

- Gholipour, A.; Shamanian, M.; Ashrafizadeh, F. Microstructure and wear behavior of stellite 6 cladding on 17–4 PH stainless steel. J. Alloys Compd. 2011, 509, 4905–4909. [Google Scholar] [CrossRef]

- Ciubotariu, C.R.; Frunzăverde, D.; Mărginean, G.; Șerban, V.A.; Bîrdeanu, A.-V. Optimization of the laser remelting process for HVOF-sprayed Stellite 6 wear resistant coatings. Opt. Laser Technol. 2016, 77, 98–103. [Google Scholar] [CrossRef]

- Sobolev, V.V.; Guilemany, J.M. Analysis of Coating Gas Porosity Development During Thermal Spraying. Surf. Coat. Technol. 1994, 70, 57. [Google Scholar] [CrossRef]

- Thawari, N.; Gullipalli, C.; Katiyar, J.K.; Gupta, T.V.K. Influence of buffer layer on surface and tribomechanical properties of laser cladded Stellite 6. Mater. Sci. Eng. B 2021, 263, 114799. [Google Scholar] [CrossRef]

- Smolina, I.; Kobiela, K. Characterization of Wear and Corrosion Resistance of Stellite 6 Laser Surfaced Alloyed (LSA) with Rhenium. Coatings 2021, 11, 292. [Google Scholar] [CrossRef]

- Schubert, E.; Seefeld, T.; Rinn, A.; Sepold, G. Laser beam cladding: A flexible tool for local surface treatment and repair. J. Therm. Spray Technol. 1999, 8, 590–596, e-ISSN: 15441016. [Google Scholar] [CrossRef]

- Sun, S.; Durandet, Y.; Brandt, M. Parametric investigation of pulsed Nd: YAG laser cladding of stellite 6 on stainless steel. Surf. Coat. Technol. 2005, 194, 225–231. [Google Scholar] [CrossRef]

- D’Oliveiraa, A.S.C.M.; Sérgio, P.; da Silvaa, C.P.; Vilarc, R.M.C. Microstructural features of consecutive layers of Stellite 6 deposited by laser cladding. Surf. Coat. Technol. 2002, 153, 203–209. [Google Scholar] [CrossRef]

- Luo, F.; Cockburn, A.; Lupoi, R.; Sparkes, M.; O’Neill, W. Performance comparison of Stellite 6® deposited on steel using supersonic laser deposition and laser cladding. Surf. Coat. Technol. 2012, 212, 119–127. [Google Scholar] [CrossRef]

- Chen, J.; Wang, S.-H.; Xue, L. On the development of microstructures and residual stresses during laser cladding and post-heat treatments. J. Mater. Sci. 2012, 47, 779–792. [Google Scholar] [CrossRef]

- Farnia, A.; Malek Ghaini, F.; Ocelík, V.; De Hosson, J.T.M. Microstructural characterization of Co-based coating deposited by low power pulse laser cladding. J. Mater. Sci. 2013, 48, 2714–2723. [Google Scholar] [CrossRef]

- Traxel, K.D.; Bandyopadhyay, A. Diamond-reinforced cutting tools using laser-based additive manufacturing. Addit. Manuf. 2021, 37, 101602. [Google Scholar] [CrossRef] [PubMed]

- Mudge, R.P.; Wald, N.R. Laser Engineered Net Shaping Advances Additive Manufacturing and Repair. Weld. J. 2007, 86, 44–48. [Google Scholar]

- Wang, L.; Felicelli, S.; Gooroochurn, Y.; Wang, P.T.; Horstemeyer, M.F. Optimization of the LENS process for steady molten pool size. Mater. Sci. Eng. A 2008, 474, 148–156. [Google Scholar] [CrossRef]

- Yin, H.; Felicelli, S.D. Dendrite growth simulation during solidification in the LENS process. Acta Mater. 2010, 58, 1455–1465. [Google Scholar] [CrossRef]

- Griffith, M.L.; Ensz, M.T.; Puskar, J.D.; Robino, C.V.; Brooks, J.A.; Philliber, J.A.; Smugeresky, J.E.; Hofmeister, W.H. Understanding the Microstructure and Properties of Components Fabricated by Laser Engineered Net Shaping (LENS). MRS Proc. 2000, 625, 9. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Kruth, J.P. Composites by rapid prototyping technology. Mater. Des. 2010, 31, 850–856. [Google Scholar] [CrossRef]

- Sahasrabudhea, H.; Harrisona, R.; Carpenterb, C.; Bandyopadhyay, A. Stainless steel to titanium bimetallic structure using LENSTM. Addit. Manuf. 2015, 5, 1–8. [Google Scholar] [CrossRef]

- Ziętala, M.; Durejko, T.; Polański, M.; Kunce, I.; Płociński, T.; Zieliński, W.; Łazińska, M.; Stępniowski, W.; Czujko, T.; Kurzydłowski, K.J.; et al. The microstructure, mechanical properties and corrosion resistance of 316L stainless steel fabricated using laser engineered net shaping. Mater. Sci. Eng. A 2016, 667, 1–10. [Google Scholar] [CrossRef]

- Wołosz, P.; Baran, A.; Polański, M. The influence of laser engineered net shaping (LENS™) technological parameters on the laser deposition efficiency and properties of H13 (AISI) steel. J. Alloys Compd. 2020, 823, 153840. [Google Scholar] [CrossRef]

- Xiong, Y.; Smugeresky, J.E.; Ajdelsztajn, L.; Schoenung, J.M. Fabrication of WC–Co cermets by laser engineered net shaping. Mater. Sci. Eng. A 2008, 493, 261–266. [Google Scholar] [CrossRef]

- Liu, D.; Lippold, J.C.; Li, J.; Rohklin, S.R.; Vollbrecht, J.; Grylls, R. Laser Engineered Net Shape (LENS) Technology for the Repair of Ni-Base Superalloy Turbine. Metall. Mater. Trans. A 2014, 45, 4454–4469. [Google Scholar] [CrossRef]

- Dutkiewicz, J.; Rogal, Ł.; Kalita, D.; Berent, K.; Antoszewski, B.; Danielewski, H.; Węglowski, M.; Łazińska, M.; Durejko, T.; Czujko, T. Microstructure and Properties of Inconel 625 Fabricated Using Two Types of Laser Metal Deposition Methods. Materials 2020, 13, 5050. [Google Scholar] [CrossRef]

- Onuike, B.; Heer, B.; Bandyopadhyay, A. Additive manufacturing of Inconel 718—Copper alloy bimetallic structure using laser engineered net shaping (LENS™). Addit. Manuf. 2018, 21, 133–140. [Google Scholar] [CrossRef]

- Antolak-Dudka, A.; Płatek, P.; Durejko, T.; Baranowski, P.; Małachowski, J.; Sarzyński, M.; Czujko, T. Static and Dynamic Loading Behavior of Ti6Al4V Honeycomb Structures Manufactured by Laser Engineered Net Shaping (LENSTM) Technology. Materials 2019, 12, 1225. [Google Scholar] [CrossRef] [Green Version]

- Durejko, T.; Ziętala, M.; Łazińska, M.; Lipiński, S.; Polkowski, W.; Czujko, T.; Varin, R.A. Structure and properties of the Fe3Al-type intermetallic alloy fabricated by laser engineered net shaping (LENS). Mater. Sci. Eng. A 2016, 650, 374–381. [Google Scholar] [CrossRef]

- Karczewski, K.; Pęska, M.; Ziętala, M.; Polański, M. Fe-Al thin walls manufactured by Laser Engineered Net Shaping. J. Alloys Compd. 2017, 696, 1105–1112. [Google Scholar] [CrossRef]

- Durejko, T.; Ziętala, M.; Polkowski, W.; Czujko, T. Thin wall tubes with Fe3Al/SS316L graded structure obtained by using laser engineered net shaping technology. Mater. Des. 2014, 63C, 766–774. [Google Scholar] [CrossRef]

- Bandyopadhyay, P.P.; Balla, V.K.; Bose, S.; Bandyopadhyay, A. Compositionally Graded Aluminum Oxide Coatings on Stainless Steel Using Laser Processing. J. Am. Ceram. Soc. 2007, 90, 1989–1991. [Google Scholar] [CrossRef]

- Li, L. Repair of directionally solidified superalloy GTD-111 by laser-engineered net shaping. J. Mater. Sci. 2006, 41, 7886–7893. [Google Scholar] [CrossRef]

- Roy, M.; Krishna, B.V.; Bandyopadhyay, A.; Bose, S. Laser processing of bioactive tricalcium phosphate coating on titanium for load-bearing implants. Acta Biomater. 2008, 4, 324–333. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, R.; Yao, J.; Zhang, Q.; Wang, L. Stellite alloy mixture hardfacing via laser cladding for control valve seat sealing surfaces. Surf. Coat. Technol. 2017, 329, 97–108. [Google Scholar] [CrossRef]

- Traxel, K.D.; Bandyopadhyay, A. First Demonstration of Additive Manufacturing of Cutting Tools using Directed Energy Deposition System: Stellite™-Based Cutting Tools. Addit. Manuf. 2019, 25, 460–468. [Google Scholar] [CrossRef]

- Li, Z.; Cui, Y.; Wang, J.; Liu, C.; Wang, J.; Xu, T.; Lu, T.; Zhang, H.; Lu, J.; Ma, S.; et al. Characterization of Microstructure and Mechanical Properties of Stellite 6 Part Fabricated by Wire Arc. Additive Manufacturing. Metals 2019, 9, 474. [Google Scholar] [CrossRef] [Green Version]

- Mostafaei, A.; De Vecchis, P.R.; Buckenmeyer, M.J.; Wasule, S.R.; Bryan, N.; Brown, B.N.; Chmielus, M. Microstructural evolution and resulting properties of differently sintered and heat-treated binder-jet 3D-printed Stellite 6. Mater. Sci. Eng. C 2019, 102, 276–288. [Google Scholar] [CrossRef] [PubMed]

- Luo, F.; Lupoi, R.; Cockburn, A.; Sparkers, M.; O’neill, W.; Yao, J. Characteristics of Stellite 6 Deposited by supersonic laser deposition under optimized parameters. Iron Steel Res. Int. 2013, 20, 52–57. [Google Scholar] [CrossRef]

- Moradi, M.; Ashoori, A.; Hasani, A. Additive manufacturing of stellite 6 superalloy by direct laser metal deposition—Part 1: Effects of laser power and focal plane position. Opt. Laser Technol. 2020, 131, 106328. [Google Scholar] [CrossRef]

- Balla, V.K.; Bose, S.; Bandyopadhyay, A. Processing of Bulk Alumina Ceramics Using Laser Engineered Net Shaping. Int. J. Appl. Ceram. Technol. 2008, 5, 234–242. [Google Scholar] [CrossRef]

- Łazińska, M.; Durejko, T.; Polkowski, W. The effect of nanometric α-Al2O3 addition on structure and mechanical properties of FeAl alloys fabricated by LENS technique. Arch. Metall. Mater. 2017, 62, 1703–1712. [Google Scholar] [CrossRef] [Green Version]

- Moradi, M.; Hasani, A.; Beiranvand, Z.M.; Ashoori, A. Additive manufacturing of stellite 6 superalloy by direct laser metal deposition—Part 2: Effects of scanning pattern and laser power reduction in differrent layers. Opt. Laser Technol. 2020, 131, 106455. [Google Scholar] [CrossRef]

- Liu, R.; Yao, J.H.; Zhang, Q.L.; Yao, M.X.; Collier, R. Relations of chemical composition to solidification behavior and associated microstructure of stellite alloys. Metallogr. Microstruct. Anal. 2015, 4, 146–157. [Google Scholar] [CrossRef]

- Caoa, R.; Zhanga, H.Y.; Liub, G.H.; Cheb, H.Y.; Chena, J.H. Effect of thermal cycle shocking on microstructure and mechanical properties of Stellite 12 (Co-29Cr-2.3C-3W) cobalt based alloy. Mater. Sci. Eng. A 2018, 714, 68–74. [Google Scholar] [CrossRef]

- Ganesh, P.; Moitra, A.; Tiwari, P.; Sathyanarayanan, S.; Kumar, H.; Rai, S.K.; Kaul, R.; Paul, C.P.; Prasad, R.C.; Kukreja, L.M. Fracture behavior of laser-clad joint of Stellite 21 on AISI 316L stainless steel. Mater. Sci. Eng. A 2010, 527, 3748–3756. [Google Scholar] [CrossRef]

| No. | Laser Power [W] | Powder Flow Rate [g/min] | Feed Rate (Contour) [mm/s] | Feed Rate (Hatch) [mm/s] | Thickness of Obtained Coating [mm] | Porosity [%] |

|---|---|---|---|---|---|---|

| #1 | 600 | 9.5 | 10 | 8 | 0.94 | 1.5 |

| #2 | 600 | 3.5 | 10 | 8 | 0.55 | 0.02 |

| #3 | 400 | 3.5 | 10 | 8 | 0.25 | 0.02 |

| #4 | 400 | 5.5 | 10 | 8 | 0.40 | 0.01 |

| #5 | 400 | 8.5 | 10 | 8 | 0.44 | 1.0 |

| #6 | 800 | 8.5 | 10 | 8 | 1.10 | 0.5 |

| Sample Number | Diamensions of Sample [mm] | Bending Force F [kN] | Deflection [mm] | Bending Strength [MPa] | Deformation [%] | ||

|---|---|---|---|---|---|---|---|

| l0 | b | H | |||||

| #0 | 50 | 7 | 3.5 | 2.07 ± 0.8 | 7.13 ± 0.21 | 1726 ± 69 | 6.13 ± 0.18 |

| #4 | 50 | 7 | 3.5 | 1.87 ± 0.37 | 5.27 ± 1.16 | 1669 ± 34 | 4.39 ± 0.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durejko, T.; Łazińska, M. Characterization of Cobalt-Based Stellite 6 Alloy Coating Fabricated by Laser-Engineered Net Shaping (LENS). Materials 2021, 14, 7442. https://doi.org/10.3390/ma14237442

Durejko T, Łazińska M. Characterization of Cobalt-Based Stellite 6 Alloy Coating Fabricated by Laser-Engineered Net Shaping (LENS). Materials. 2021; 14(23):7442. https://doi.org/10.3390/ma14237442

Chicago/Turabian StyleDurejko, Tomasz, and Magdalena Łazińska. 2021. "Characterization of Cobalt-Based Stellite 6 Alloy Coating Fabricated by Laser-Engineered Net Shaping (LENS)" Materials 14, no. 23: 7442. https://doi.org/10.3390/ma14237442

APA StyleDurejko, T., & Łazińska, M. (2021). Characterization of Cobalt-Based Stellite 6 Alloy Coating Fabricated by Laser-Engineered Net Shaping (LENS). Materials, 14(23), 7442. https://doi.org/10.3390/ma14237442