Design and Simulation Study of the Induction Heated Injection Mold with Sliders

Abstract

:1. Introduction

2. Materials and Methods

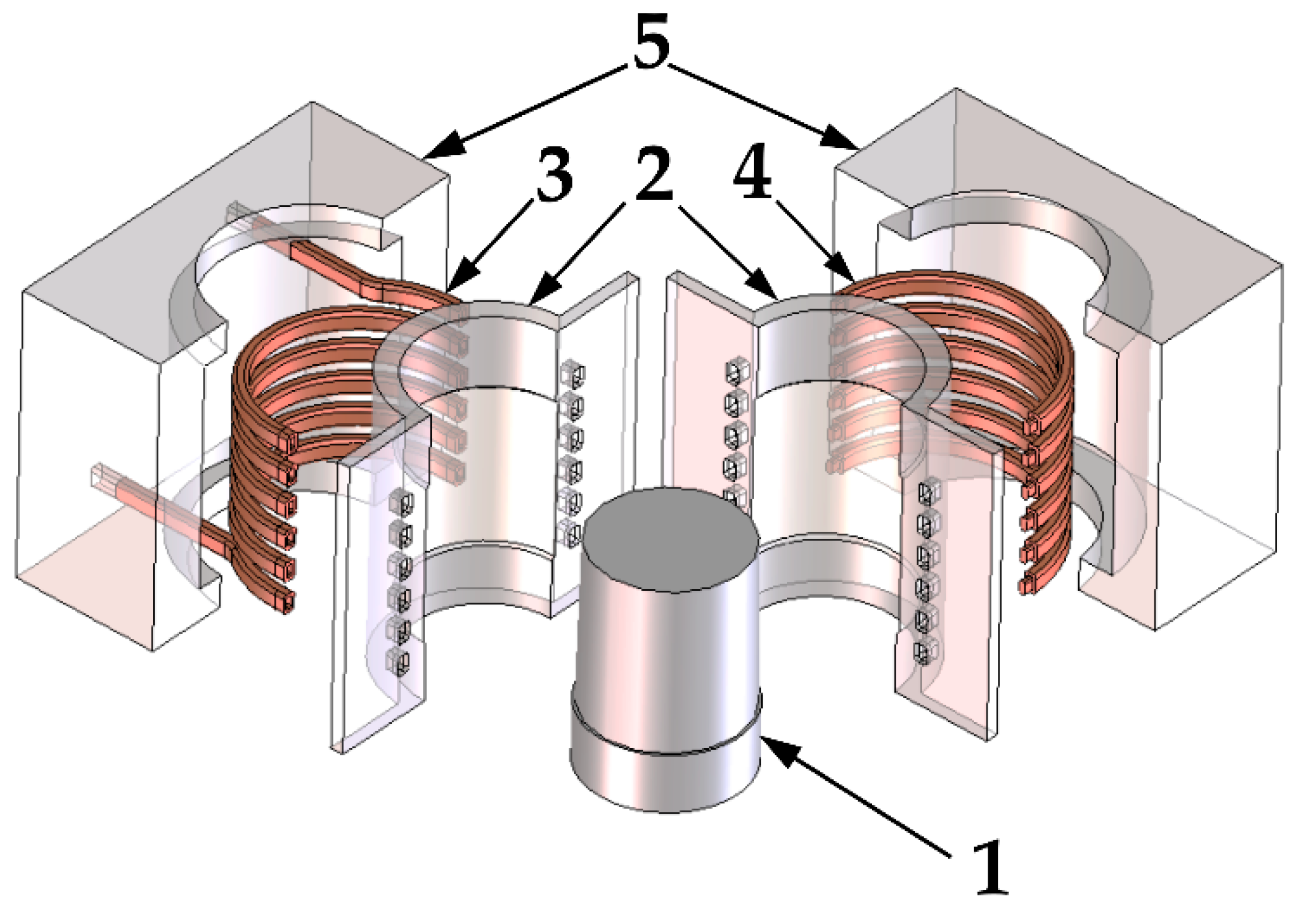

2.1. Detachable Inductor Integrated with Sliders

2.2. Theoretical Model

2.3. Experimental Procedure

3. Results

3.1. Investigation of the Influence of the Magnetic Concentrator Shape on the Heating Process of the Forming Insert

3.2. Investigation of the Influence of Process Parameters on the Heating of the Forming Insert

3.3. Selection of Process Parameters

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kalwik, A.; Postawa, P.; Nabialek, M. Analysis of Ageing Processes of Semi-Crystalline Materials. Mater. Plast. 2020, 57, 41–51. [Google Scholar] [CrossRef]

- Sykutera, D.; Czyżewski, P.; Kościuszko, A.; Szewczykowski, P.; Wajer, Ł.; Bieliński, M. Monitoring of the Injection and Holding Phases by Using a Modular Injection Mold. J. Polym. Eng. 2018, 38, 63–71. [Google Scholar] [CrossRef]

- Mohd Hanid, M.H.; Abd Rahim, S.Z.; Gondro, J.; Sharif, S.; Al Bakri Abdullah, M.M.; Zain, A.M.; El-hadj Abdellah, A.; Mat Saad, M.N.; Wysłocki, J.J.; Nabiałek, M. Warpage Optimisation on the Moulded Part with Straight Drilled and Conformal Cooling Channels Using Response Surface Methodology (RSM), Glowworm Swarm Optimisation (GSO) and Genetic Algorithm (GA) Optimisation Approaches. Materials 2021, 14, 1326. [Google Scholar] [CrossRef]

- Wang, J.; Hopmann, C.; Kahve, C.; Hohlweck, T.; Alms, J. Measurement of Specific Volume of Polymers under Simulated Injection Molding Processes. Mater. Des. 2020, 196, 109136. [Google Scholar] [CrossRef]

- Fiorio, R.; Villanueva Díez, S.; Sánchez, A.; D’hooge, D.R.; Cardon, L. Influence of Different Stabilization Systems and Multiple Ultraviolet A (UVA) Aging/Recycling Steps on Physicochemical, Mechanical, Colorimetric, and Thermal-Oxidative Properties of ABS. Materials 2020, 13, 212. [Google Scholar] [CrossRef] [Green Version]

- Białasz, S.; Klepka, T. Simulation of the Medical Syringe Injection Moulding Process. MATEC Web Conf. 2019, 252, 05016. [Google Scholar] [CrossRef]

- Zhao, P.; Ji, K.; Zhang, J.; Chen, Y.; Dong, Z.; Zheng, J.; Fu, J. In-Situ Ultrasonic Measurement of Molten Polymers during Injection Molding. J. Mater. Process. Technol. 2021, 293, 117081. [Google Scholar] [CrossRef]

- Srithep, Y.; Turng, L.-S. Microcellular Injection Molding of Recycled Poly(Ethylene Terephthalate) Blends with Chain Extenders and Nanoclay. J. Polym. Eng. 2014, 34, 5–13. [Google Scholar] [CrossRef]

- Mrozek, K.; Chen, S.-C. Selective Induction Heating to Eliminate the Fundamental Defects of Thin-Walled Moldings Used in Electrical Industry. J. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Bula, K.; Sterzyński, T.; Piasecka, M.; Różański, L. Deformation Mechanism in Mechanically Coupled Polymer–Metal Hybrid Joints. Materials 2020, 13, 2512. [Google Scholar] [CrossRef]

- Postawa, P.; Stachowiak, T. Mould Temperature Control during Injection Moulding Process. AIP Conf. Proc. 2015, 1664, 110012. [Google Scholar] [CrossRef] [Green Version]

- Bociąga, E.; Kaptacz, S.; Duda, P.; Rudawska, A. The Influence of the Type of Polypropylene and the Length of the Flow Path on the Structure and Properties of Injection Molded Parts with the Weld Lines. Polym. Eng. Sci. 2019, 59, 1710–1718. [Google Scholar] [CrossRef]

- Mrozek, K.; Poszwa, P.; Muszyński, P. Numerical Study on the Influence of Rapid Temperature Cycling (RTC) on Polymer Flow at Maximum Injection Pressure. Numer. Heat Transf. Part A Appl. 2020, 77, 821–839. [Google Scholar] [CrossRef]

- Sánchez, R.; Martinez, A.; Mercado, D.; Carbonel, A.; Aisa, J. Rapid Heating Injection Moulding: An Experimental Surface Temperature Study. Polym. Test. 2021, 93, 106928. [Google Scholar] [CrossRef]

- Liparoti, S.; Sorrentino, A.; Titomanlio, G. Temperature and pressure evolution in fast heat cycle injection molding. Mater. Manuf. Process. 2019, 34, 422–430. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, G.; Guan, Y.; Wu, X.; Hui, Y. Effect of Rapid Heating Cycle Injection Mold Temperature on Crystal Structures, Morphology of Polypropylene and Surface Quality of Plastic Parts. J. Polym. Res. 2015, 22, 84. [Google Scholar] [CrossRef]

- Croitoru, E.-I.; Magurian, D.; Oancea, G. Finite Element Analysis of Heating-Cooling Systems Used for Laminating Tools. Trans. FAMENA 2016, 40, 111–128. [Google Scholar]

- Lucchetta, G.; Fiorotto, M. Influence of Rapid Mould Temperature Variation on the Appearance of Injection-Moulded Parts. SV-JME 2013, 59, 683–688. [Google Scholar] [CrossRef] [Green Version]

- Moritzer, E.; Seidel, S. Numerical Analysis and Evaluation of Process and Geometry Specific Transient Temperature Fields for a New Variation of Gas-Assisted Injection Molding. Int. Polym. Process. 2015, 30, 265–275. [Google Scholar] [CrossRef]

- Su, Q.; Zhang, N.; Gilchrist, M.D. The Use of Variotherm Systems for Microinjection Molding. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.-C.; Jong, W.-R.; Chang, J.-A. Dynamic Mold Surface Temperature Control Using Induction Heating and Its Effects on the Surface Appearance of Weld Line. J. Appl. Polym. Sci. 2006, 101, 1174–1180. [Google Scholar] [CrossRef]

- Chen, S.-C.; Minh, P.S.; Chang, J.-A.; Huang, S.-W.; Huang, C.-H. Mold Temperature Control Using High-Frequency Proximity Effect Induced Heating. Int. Commun. Heat Mass Transf. 2012, 39, 216–223. [Google Scholar] [CrossRef]

- Chen, S.C.; Peng, H.S.; Chang, J.A.; Jong, W.R. Simulations and verifications of induction heating on a mold plate. Int. Commun. Heat Mass Transf. 2004, 31, 971–980. [Google Scholar] [CrossRef]

- Chen, S.-C.; Lin, Y.-W.; Chien, R.-D.; Li, H.-M. Variable Mold Temperature to Improve Surface Quality of Microcellular Injection Molded Parts Using Induction Heating Technology. Adv. Polym. Technol. 2008, 27, 224–232. [Google Scholar] [CrossRef]

- Shih, S.-Y.; Nian, S.-C.; Huang, M.-S. Comparison between Single- and Multiple-Zone Induction Heating of Largely Curved Mold Surfaces. Int. Commun. Heat Mass Transf. 2016, 75, 24–35. [Google Scholar] [CrossRef]

- Nian, S.-C.; Huang, M.-S.; Tsai, T.-H. Enhancement of Induction Heating Efficiency on Injection Mold Surface Using a Novel Magnetic Shielding Method. Int. Commun. Heat Mass Transf. 2014, 50, 52–60. [Google Scholar] [CrossRef]

- Mrozek, K. Simulation Study of Induction Heating of Multi-Metallic Injection Moulds. Int. J. Simul. Model. 2018, 17, 220–230. [Google Scholar] [CrossRef]

- Mrozek, K.; Muszyński, P.; Poszwa, P. Influence of Induction Heating of Injection Molds on Reliability of Electrical Connectors. Eksploat. Niezawodn. 2020, 22, 676–683. [Google Scholar] [CrossRef]

- Tang, P.T.; Ravn, C.; Menotti, S.; Bissacco, G.; Hansen, H.N. Characterization Methods of Nano-Patterned Surfaces Generated by Induction Heating Assisted Injection Molding. Int. J. Autom. Technol. 2015, 9, 349–355. [Google Scholar]

- Lee, H.-J.; Jang, N.-H.; Park, K. High-Frequency Induction Heating for Increase of Flow Length in Polymer/Metal Hybrid Molding. J. Mech. Sci. Technol. 2019, 33, 5375–5382. [Google Scholar] [CrossRef]

- Giang, N.T.; Minh, P.S.; Son, T.A.; Uyen, T.M.T.; Nguyen, T.-H.; Dang, H.-S. Study on External Gas-Assisted Mold Temperature Control with the Assistance of a Flow Focusing Device in the Injection Molding Process. Materials 2021, 14, 965. [Google Scholar] [CrossRef]

- Huang, P.-W.; Peng, H.-S.; Choong, W.-H. Mold-Face Heating Mechanism, Overflow-Well Design, and Their Effect on Surface Weldline and Tensile Strength of Long-Glass-Fiber-Reinforced Polypropylene Injection Molding. Polymers 2020, 12, 2474. [Google Scholar] [CrossRef] [PubMed]

- Xie, P.; Yang, H.; Zhao, Y.; Yu, W.; Cheng, L.; Yang, W.; Yan, H.; Tan, J. Carbide-Bonded Graphene Coating of Mold Insert for Rapid Thermal Cycling in Injection Molding. Appl. Therm. Eng. 2017, 122, 19–26. [Google Scholar] [CrossRef]

- Fluxtrol. Available online: www.fluxtrol.com (accessed on 29 September 2021).

- Ko, D.-C.; Min, G.-S.; Kim, B.-M.; Choi, J.-C. Finite Element Analysis for the Semi-Solid State Forming of Aluminium Alloy Considering Induction Heating. J. Mater. Process. Technol. 2000, 100, 95–104. [Google Scholar] [CrossRef]

- Alonso-González, M.; Felix, M.; Guerrero, A.; Romero, A. Effects of Mould Temperature on Rice Bran-Based Bioplastics Obtained by Injection Moulding. Polymers 2021, 13, 398. [Google Scholar] [CrossRef]

- Golmakani, M.E.; Wiczenbach, T.; Malikan, M.; Aliakbari, R.; Eremeyev, V.A. Investigation of Wood Flour Size, Aspect Ratios, and Injection Molding Temperature on Mechanical Properties of Wood Flour/Polyethylene Composites. Materials 2021, 14, 3406. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Liu, K.; Zhao, D.; Wang, M.; Li, Q.; Hou, J. Multi-Objective Optimizations for Microinjection Molding Process Parameters of Biodegradable Polymer Stent. Materials 2018, 11, 2322. [Google Scholar] [CrossRef] [Green Version]

- Muszyński, P.; Poszwa, P.; Gessner, A.; Mrozek, K. Application of Selective Induction Heating for Improvement of Mechanical Properties of Elastic Hinges. Materials 2021, 14, 2543. [Google Scholar] [CrossRef]

- Gim, J.; Han, E.; Rhee, B.; Friesenbichler, W.; Gruber, D.P. Causes of the Gloss Transition Defect on High-Gloss Injection-Molded Surfaces. Polymers 2020, 12, 2100. [Google Scholar] [CrossRef] [PubMed]

- Liparoti, S.; Pantani, R.; Sorrentino, A.; Speranza, V.; Titomanlio, G. Hydrophobicity Tuning by the Fast Evolution of Mold Temperature during Injection Molding. Polymers 2018, 10, 322. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zuorro, A.; Cassiani-Cassiani, D.; Meza-González, D.A.; Moreno-Sader, K.A.; González-Delgado, Á.D. Evaluation of Shrimp Waste Valorization Combining Computer-Aided Simulation and Numerical Descriptive Inherent Safety Technique (NuDIST). Appl. Sci. 2020, 10, 5339. [Google Scholar] [CrossRef]

- Zuorro, A. Optimization of Polyphenol Recovery from Espresso Coffee Residues Using Factorial Design and Response Surface Methodology. Sep. Purif. Technol. 2015, 152, 64–69. [Google Scholar] [CrossRef]

| Material | μ [-] | ||||

|---|---|---|---|---|---|

| Steel 1.2343 | 60 | 107 | 45 | 460 | 7800 |

| Copper | 1 | 5.6 × 107 | 370 | 385 | 8700 |

| Fluxtrol A | 130 | 5 × 10−5 | 23 | 430 | 6600 |

| Air | 1 | 0 | 0.025 | 1005 | 1 |

| Time t [s] | Electric Current I [A] | Average Value [°C] | Median Value [°C] | Standard Deviation [°C] |

|---|---|---|---|---|

| 1 | 500 | 39.416 | 39.499 | 0.858 |

| 600 | 47.960 | 48.079 | 1.235 | |

| 700 | 58.056 | 58.218 | 1.681 | |

| 800 | 69.706 | 69.918 | 2.196 | |

| 900 | 82.909 | 83.177 | 2.779 | |

| 1000 | 97.666 | 97.996 | 3.431 | |

| 2 | 500 | 66.226 | 66.247 | 2.660 |

| 600 | 86.565 | 87.718 | 3.830 | |

| 700 | 110.602 | 112.172 | 5.213 | |

| 800 | 138.338 | 140.388 | 6.808 | |

| 900 | 169.771 | 172.366 | 8.617 | |

| 1000 | 204.903 | 208.107 | 10.638 | |

| 3 | 500 | 94.367 | 96.638 | 5.304 |

| 600 | 127.089 | 130.359 | 7.637 | |

| 700 | 165.760 | 170.211 | 10.395 | |

| 800 | 210.381 | 216.194 | 13.577 | |

| 900 | 260.950 | 268.308 | 17.184 | |

| 1000 | 317.470 | 326.553 | 21.214 | |

| 4 | 500 | 122.134 | 126.629 | 8.591 |

| 600 | 167.074 | 173.546 | 12.371 | |

| 700 | 220.184 | 228.993 | 16.838 | |

| 800 | 281.464 | 292.971 | 21.992 | |

| 900 | 350.916 | 365.479 | 27.834 | |

| 1000 | 428.538 | 446.517 | 34.363 |

| Time t [s] | Electric Current I [A] | Average Value [°C] | Standard Deviation [°C] | Distance with the Desired Temperature [mm] |

|---|---|---|---|---|

| 2 | 1000 | 204.903 | 10.638 | 42.2 |

| 3 | 800 | 210.381 | 13.577 | 42.4 |

| 4 | 700 | 220.184 | 16.838 | 43.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muszyński, P.; Poszwa, P.; Mrozek, K.; Zielinski, M.; Dalewski, P.; Kowal, M. Design and Simulation Study of the Induction Heated Injection Mold with Sliders. Materials 2021, 14, 7476. https://doi.org/10.3390/ma14237476

Muszyński P, Poszwa P, Mrozek K, Zielinski M, Dalewski P, Kowal M. Design and Simulation Study of the Induction Heated Injection Mold with Sliders. Materials. 2021; 14(23):7476. https://doi.org/10.3390/ma14237476

Chicago/Turabian StyleMuszyński, Paweł, Przemysław Poszwa, Krzysztof Mrozek, Michał Zielinski, Piotr Dalewski, and Michał Kowal. 2021. "Design and Simulation Study of the Induction Heated Injection Mold with Sliders" Materials 14, no. 23: 7476. https://doi.org/10.3390/ma14237476

APA StyleMuszyński, P., Poszwa, P., Mrozek, K., Zielinski, M., Dalewski, P., & Kowal, M. (2021). Design and Simulation Study of the Induction Heated Injection Mold with Sliders. Materials, 14(23), 7476. https://doi.org/10.3390/ma14237476