Anomalies in the Geometric Surface Structure of Shaped Elements Composed of Inconel 718 Alloy

Abstract

:1. Introduction

2. Materials and Methods

- Rzi—measured height of surface roughness;

- Rzto—theoretical surface roughness, which depends on the minimum uncut chip thickness value, condition of the cutting edge, and the dynamics of the machining process.

- Rio—foreseen (theoretical) component of the machined surface roughness, Ri, as a result of the so-called efficient kinematic-geometrical projection of the cutting insert in the material;

- ΔRid—component of the Ri parameter resulting from the dynamic and tribological effects (vibrations) in the zone of the cutting insert’s contact with the material, varying during machining in a permanent, periodical, or random mode.

- f—feed;

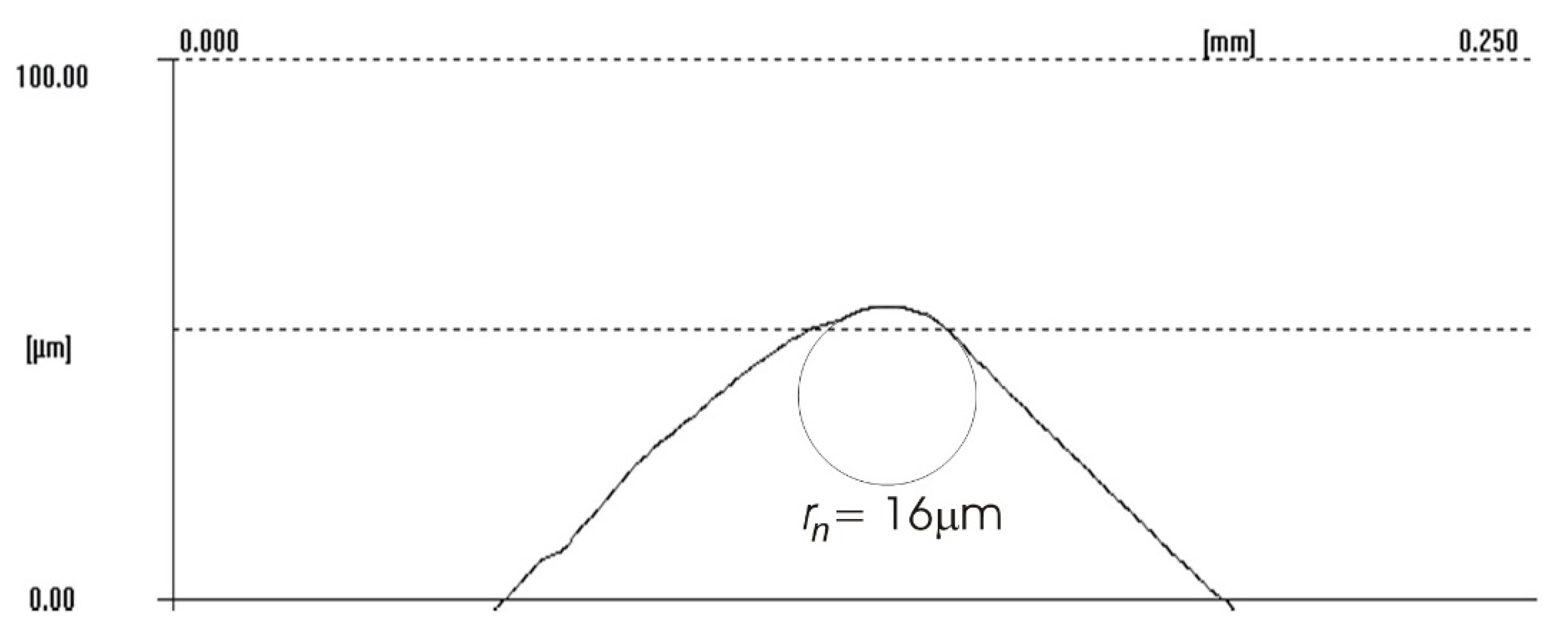

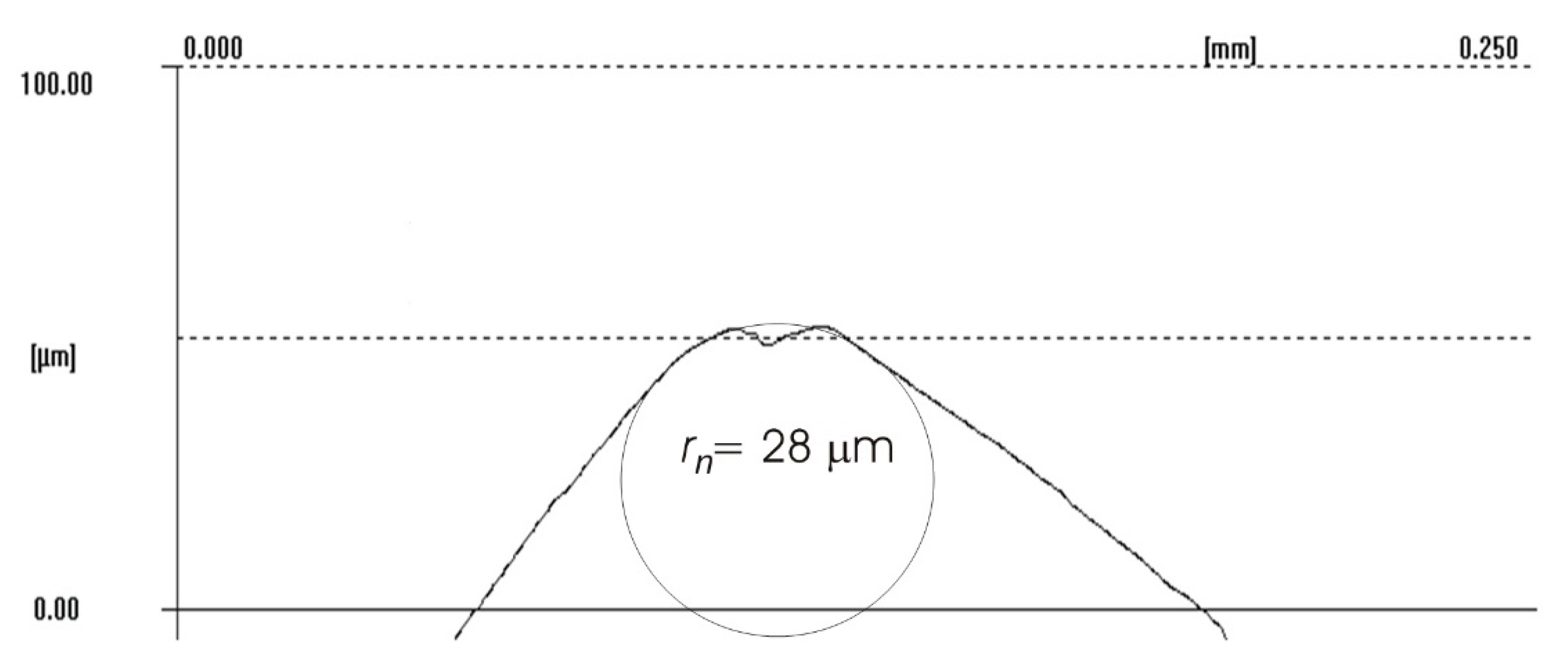

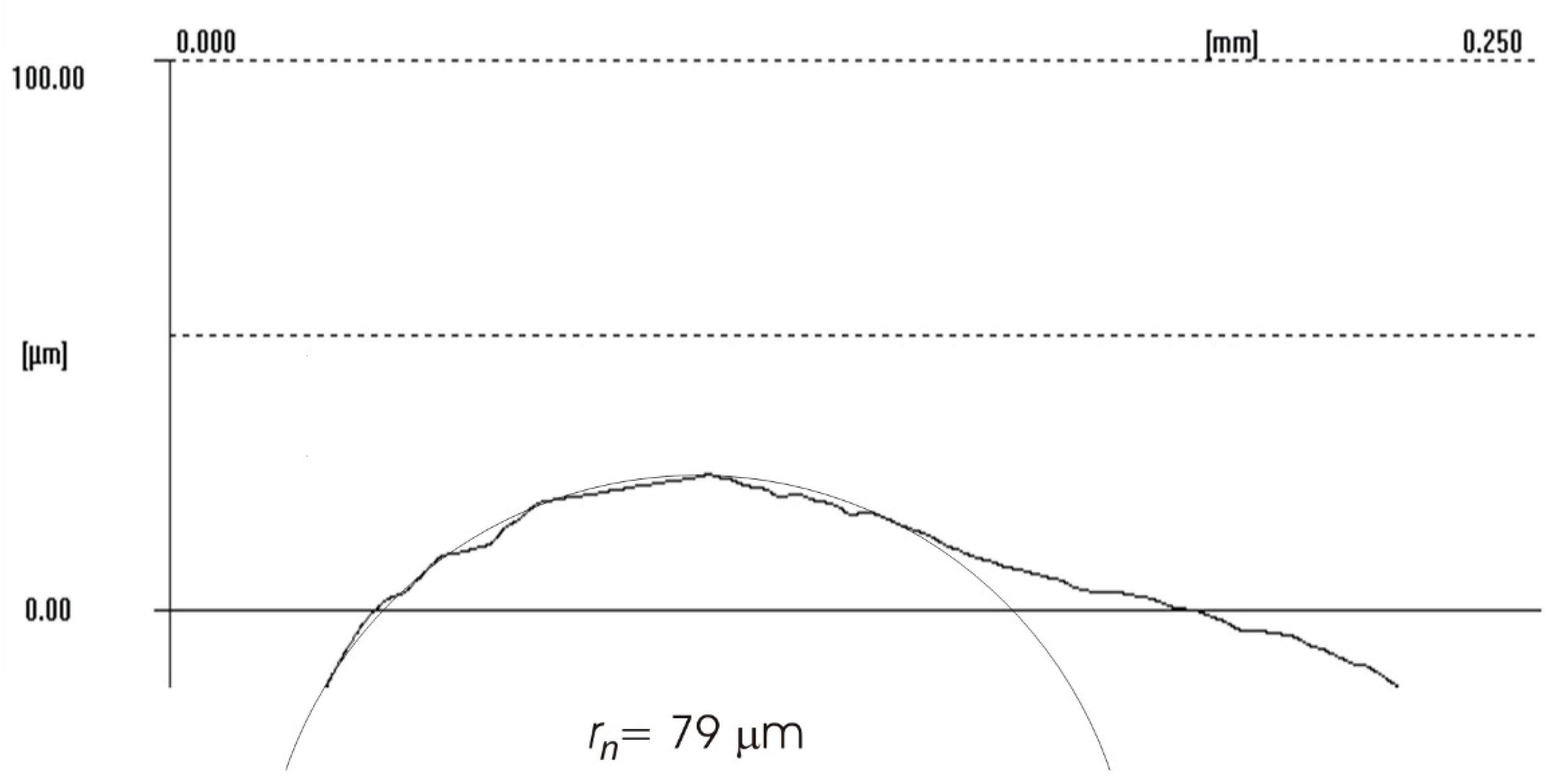

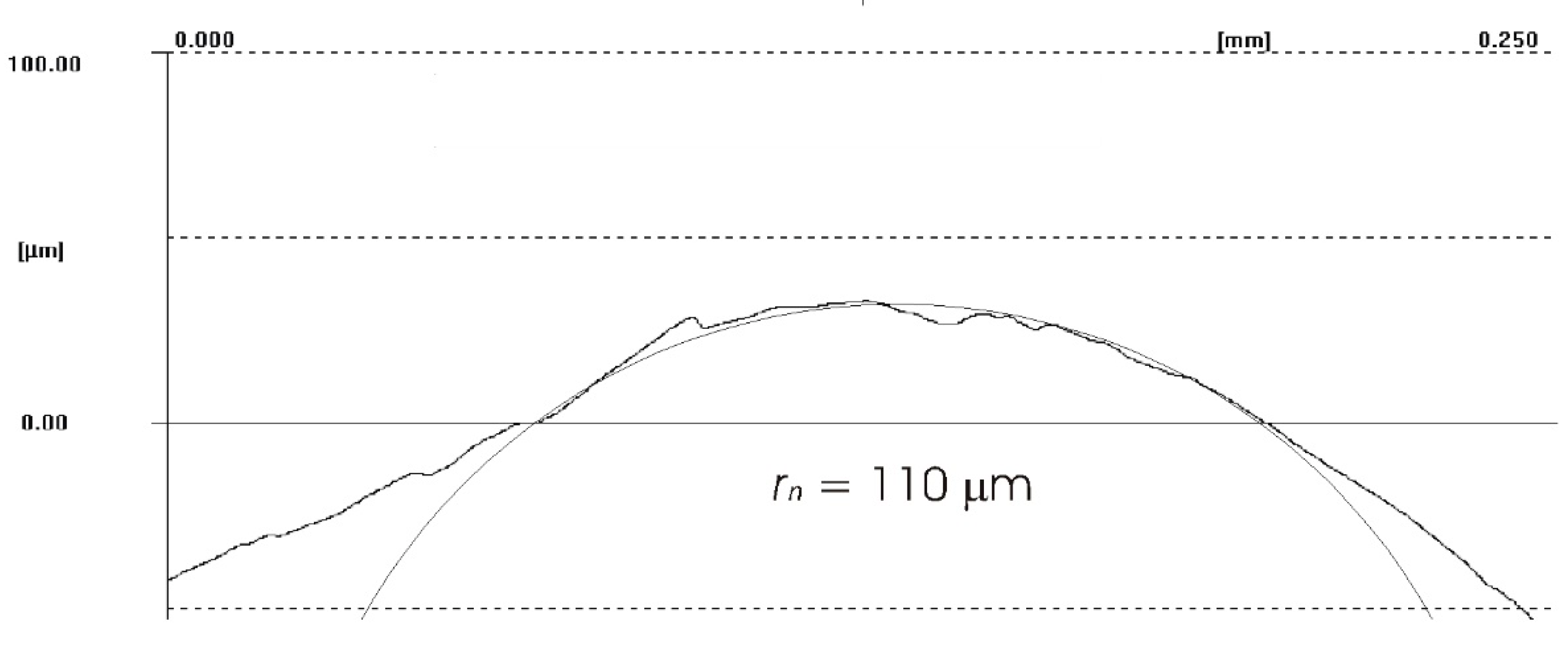

- rn—cutting edge radius;

- rε—nose radius;

- k—(hmin/rn); factor (k ≈ 0.1 ÷ 0.6).

3. Results and Discussion

4. Conclusions

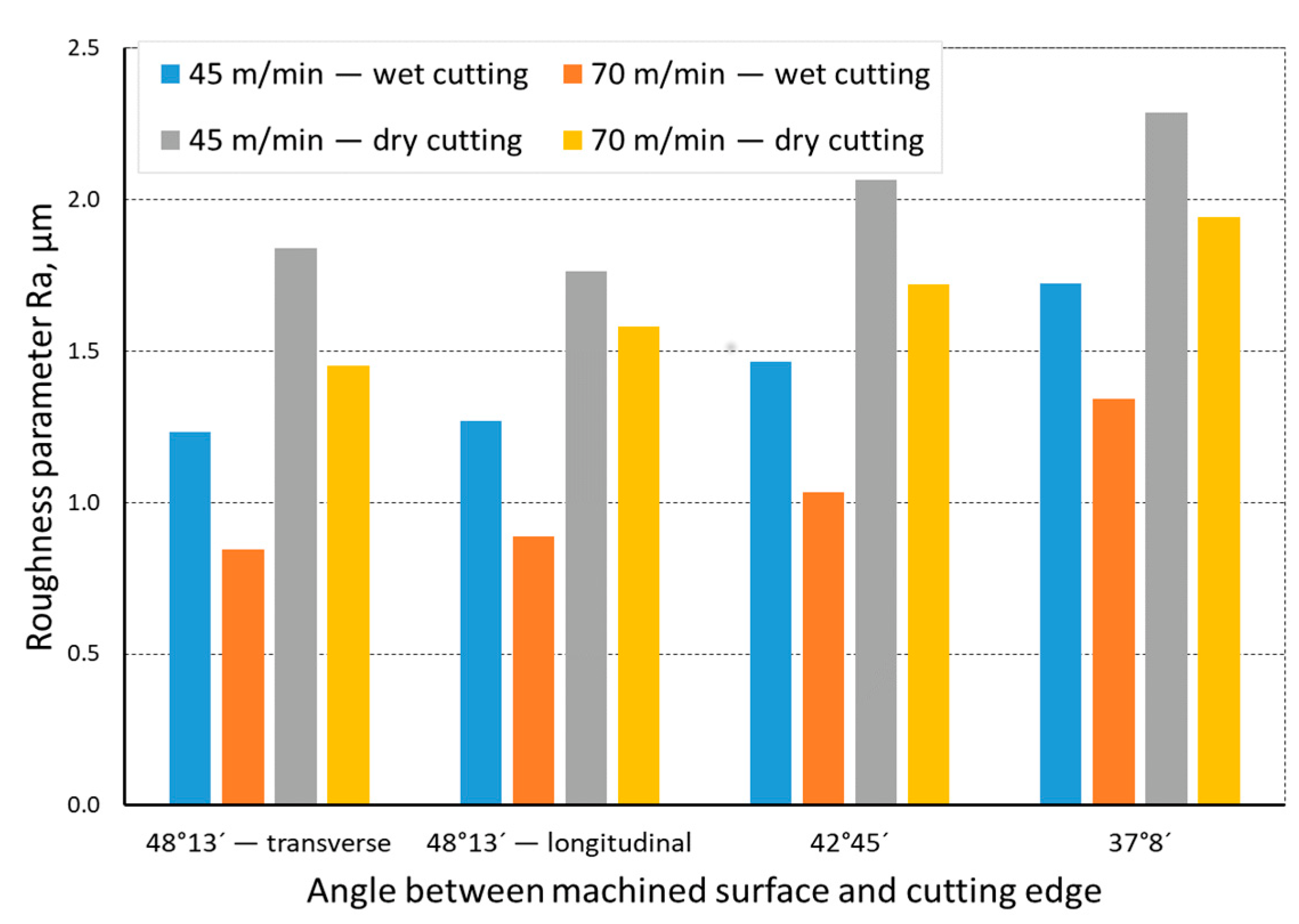

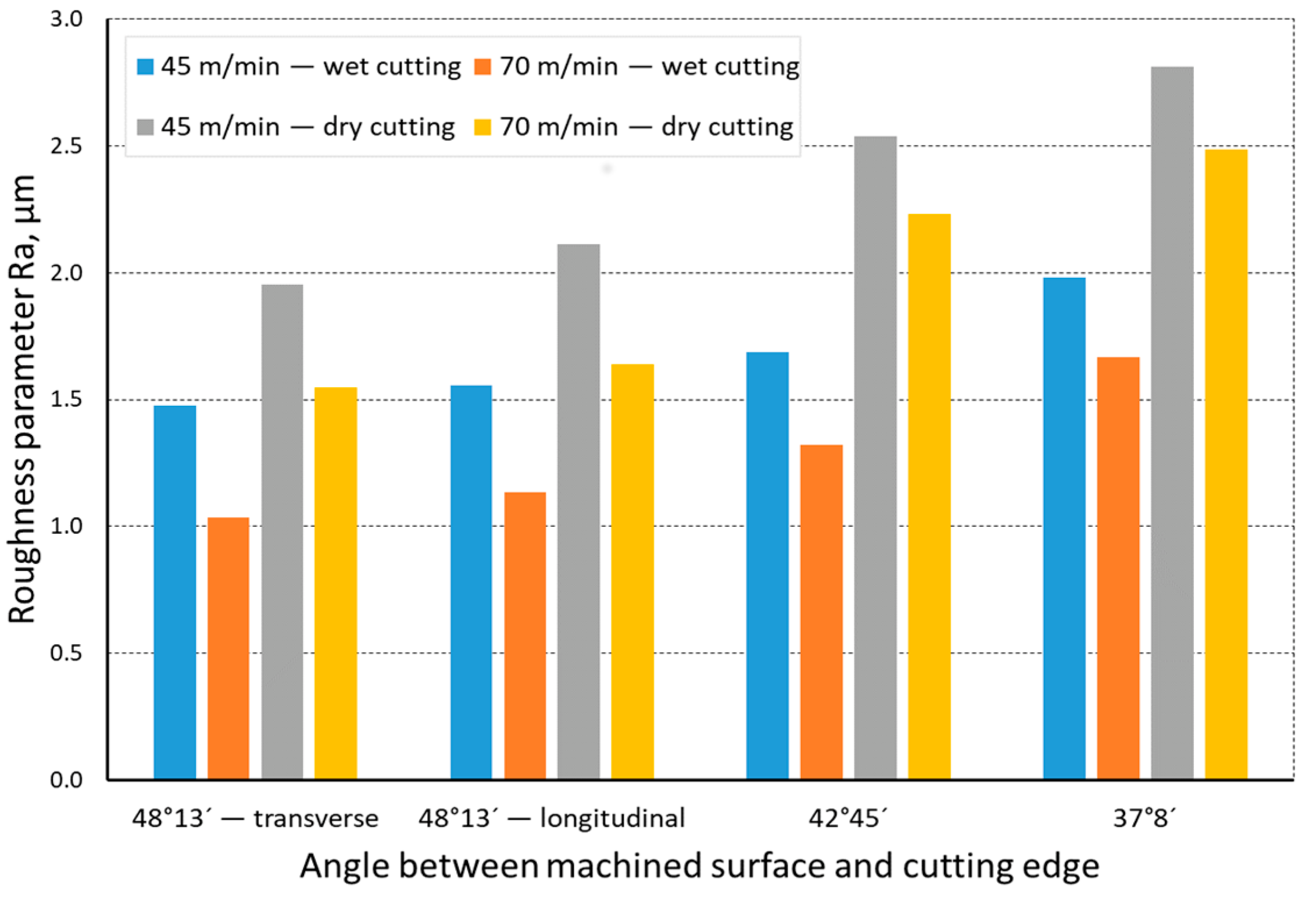

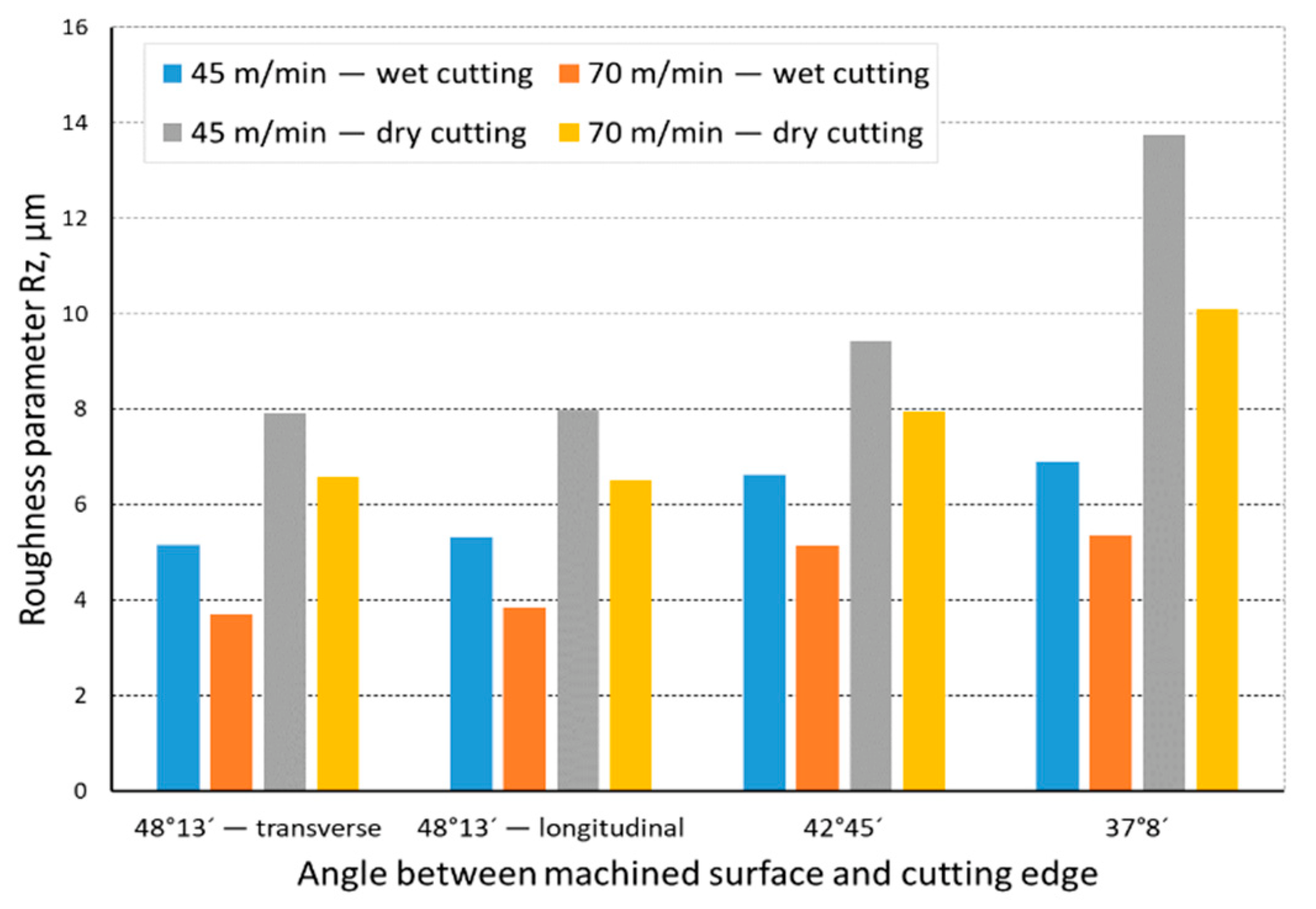

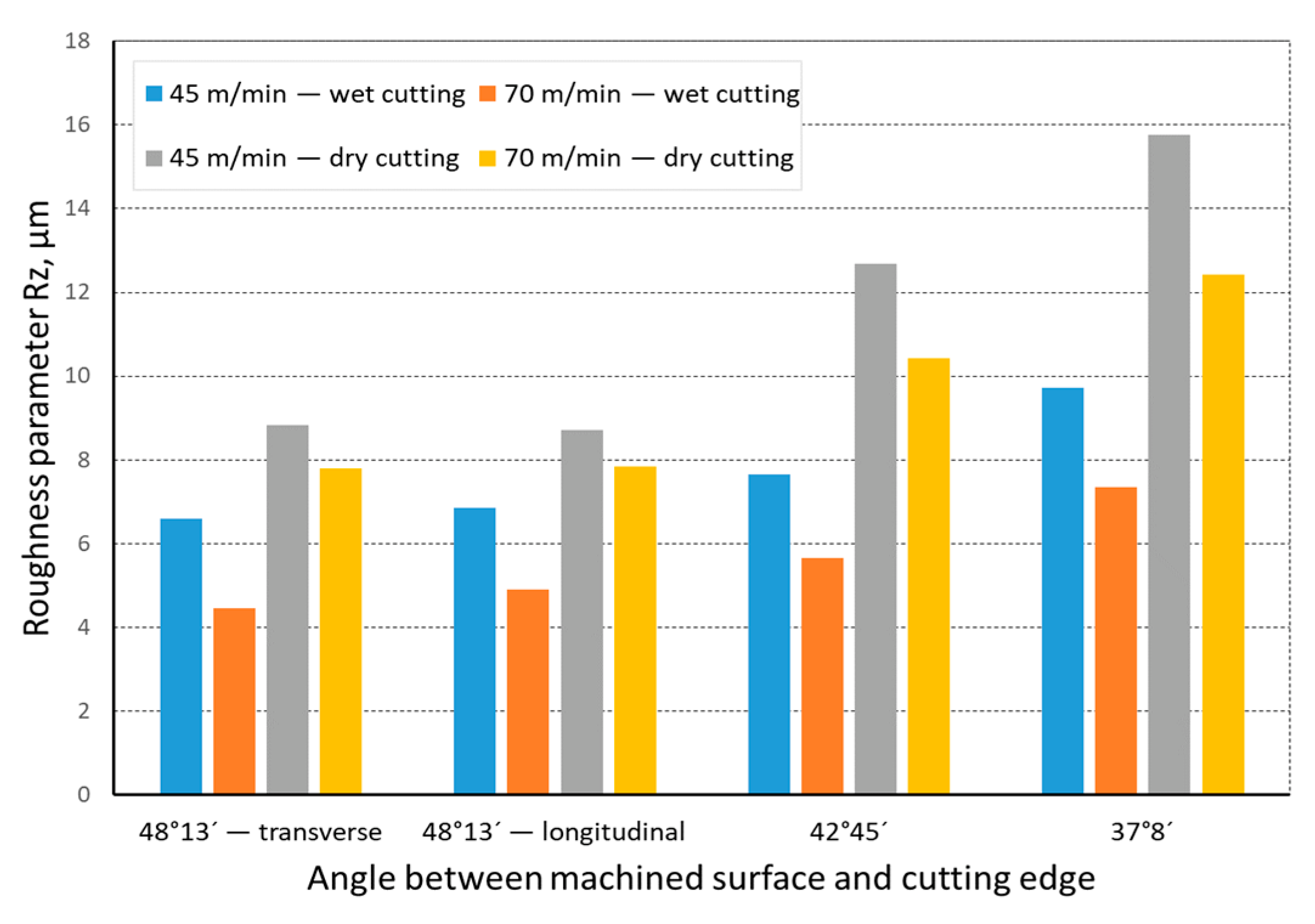

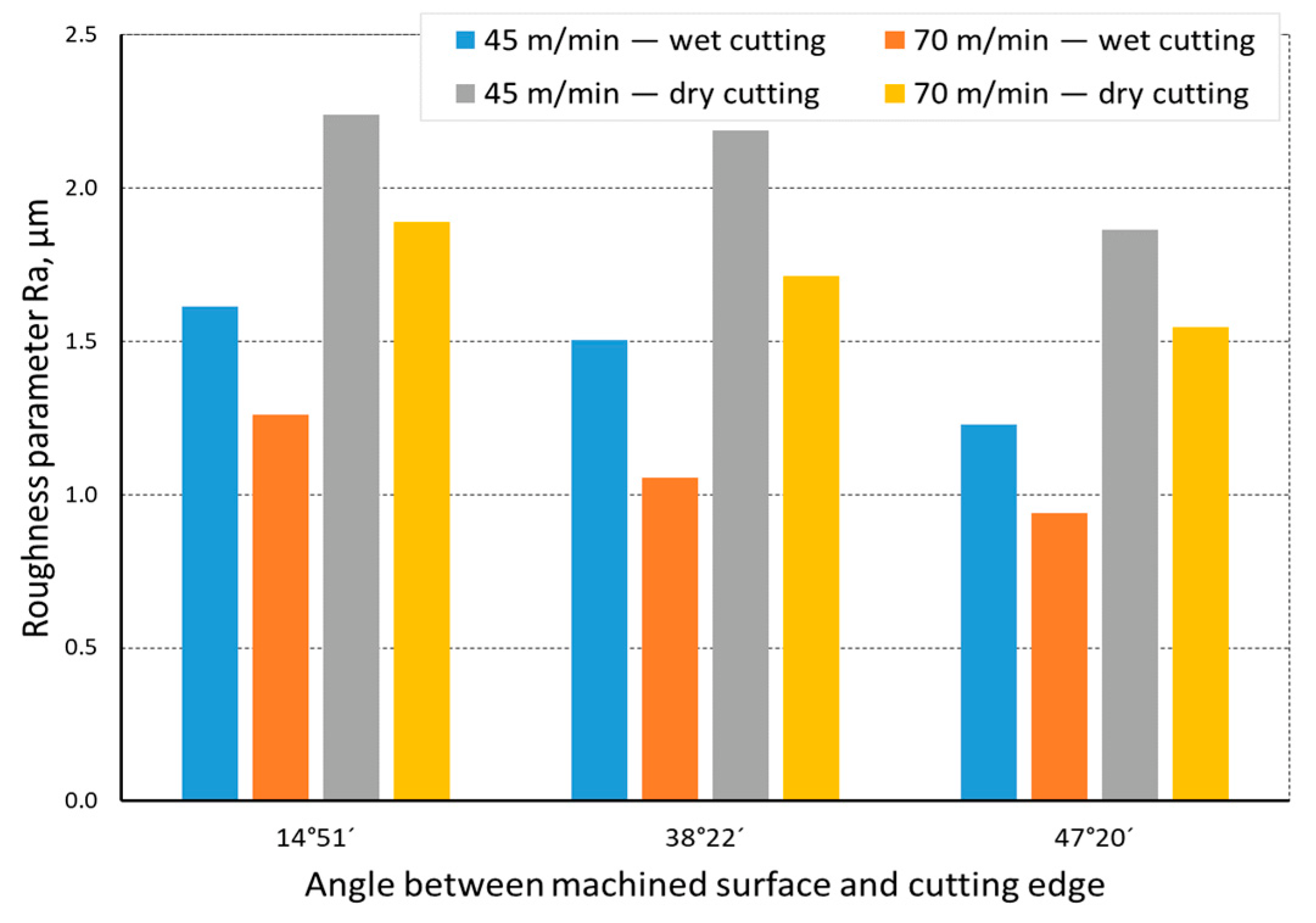

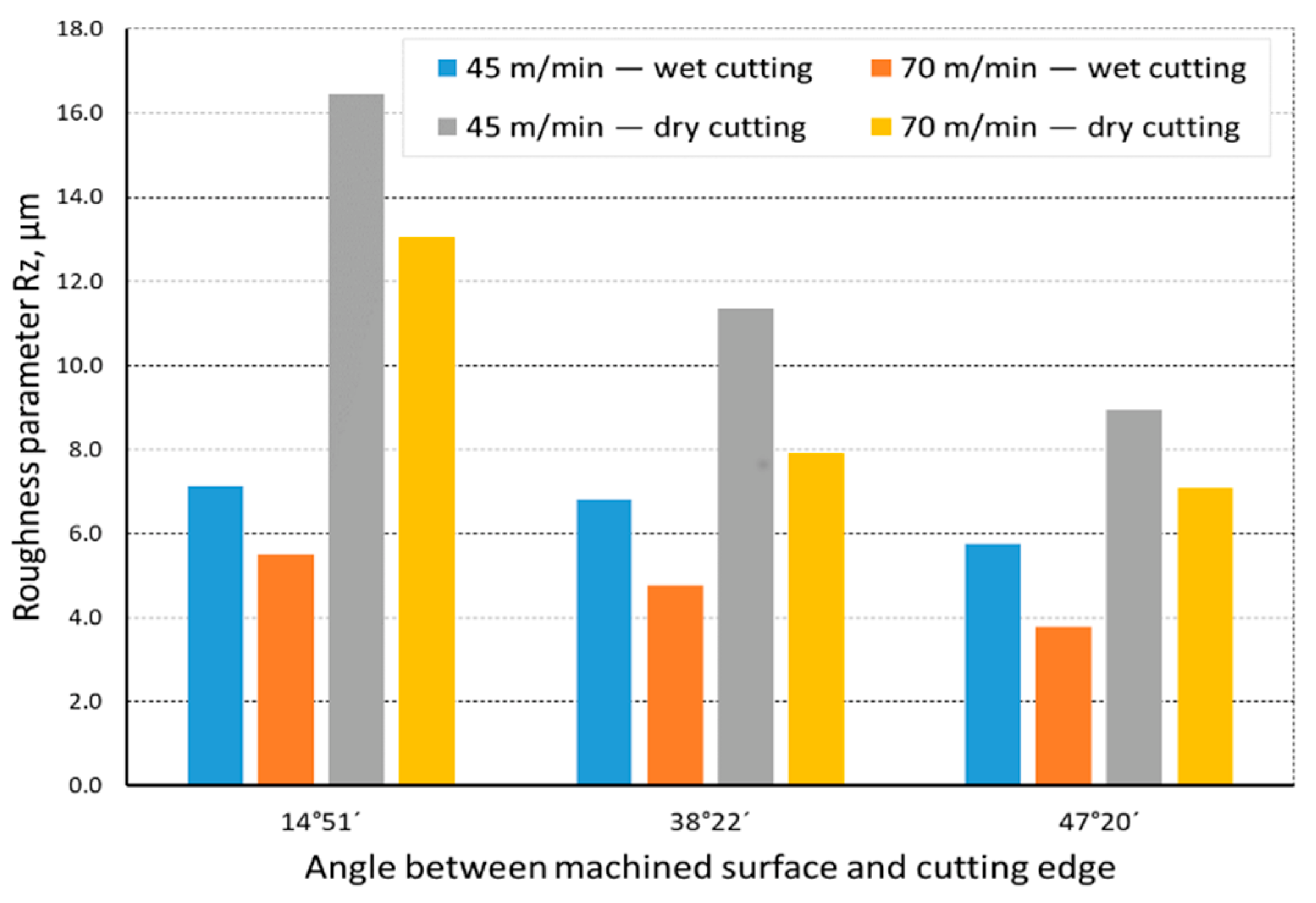

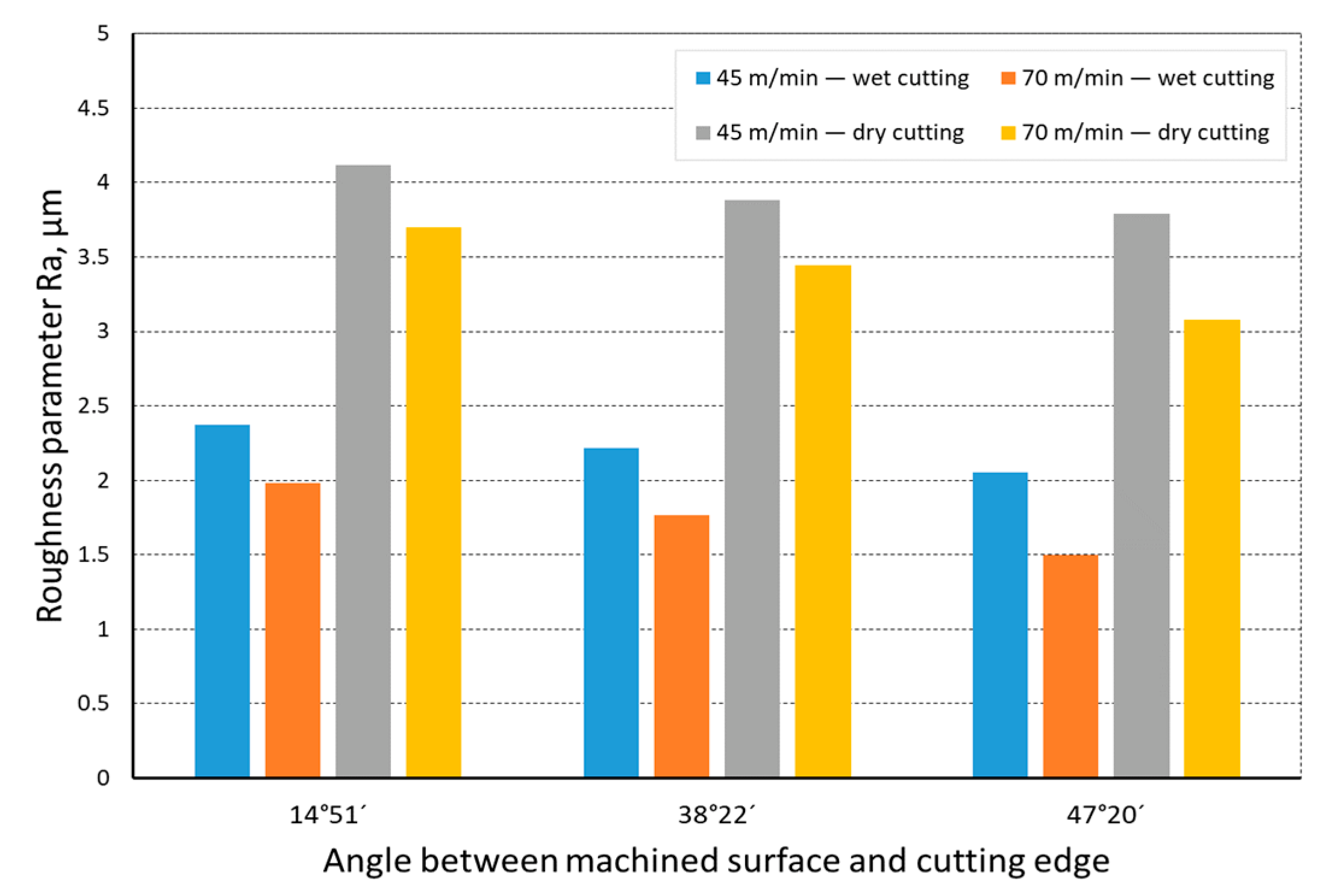

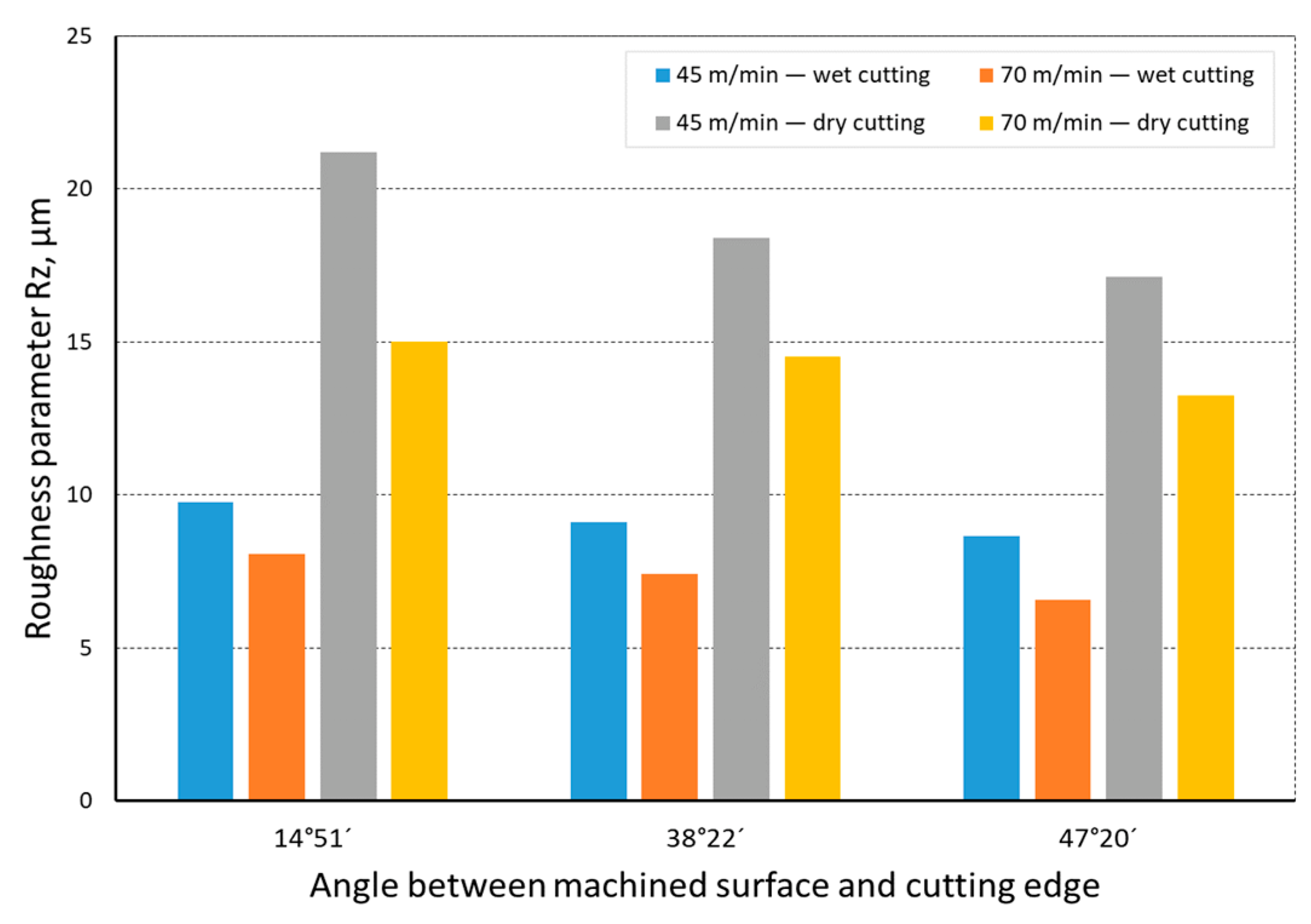

- It was found that a higher cutting speed, with the other machining conditions being kept the same, allowed us to obtain a better surface quality as assessed by the roughness parameters, Ra and Rz. The least average values of those parameters, for a cutting speed of vc = 45 m/min, were: Ra = 1.233 µm and Rz = 5.154 µm for the 23 HRC material; and Ra = 1.475 µm, Rz = 6.592 µm for the 36 HRC material. For a cutting speed of vc = 70 m/min, the least average roughness parameters were Ra = 0.843 µm and Rz = 3.697 µm for the 23 HRC material

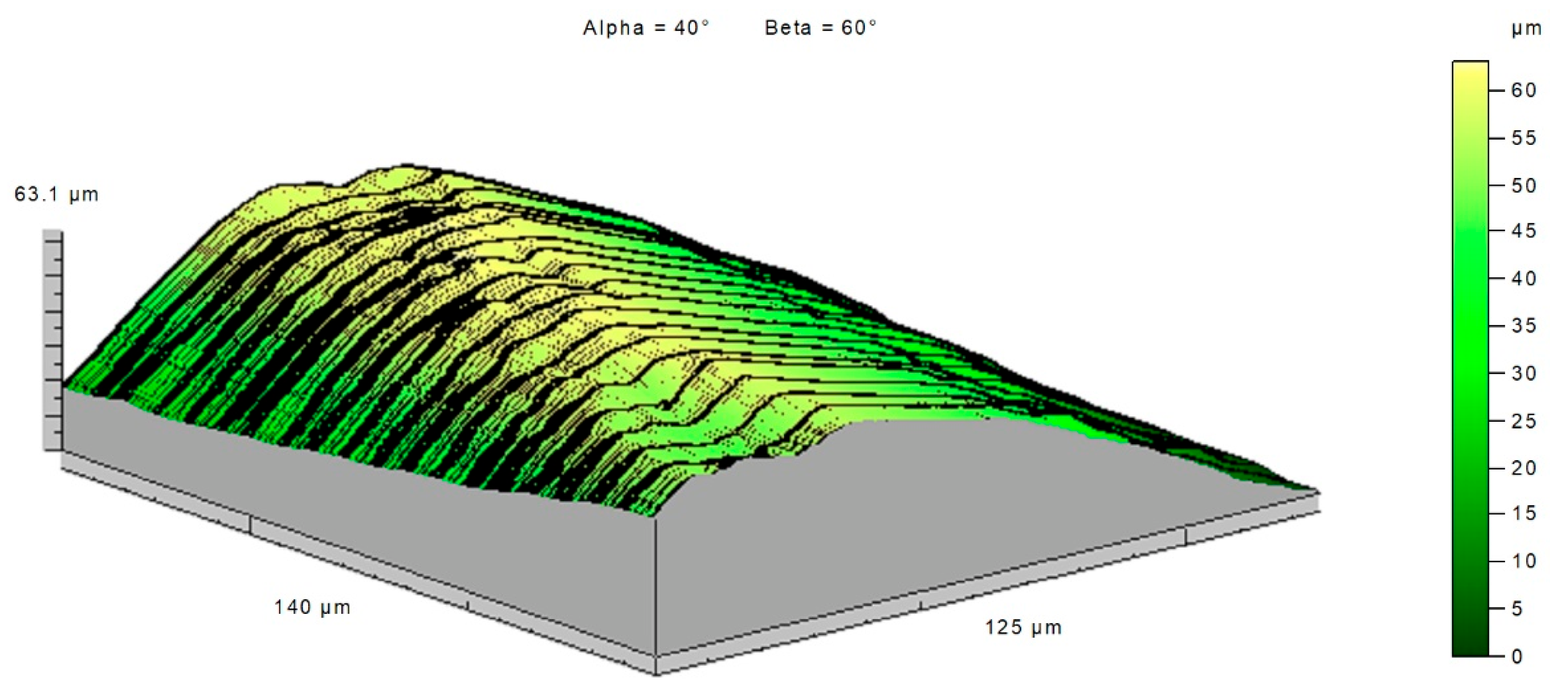

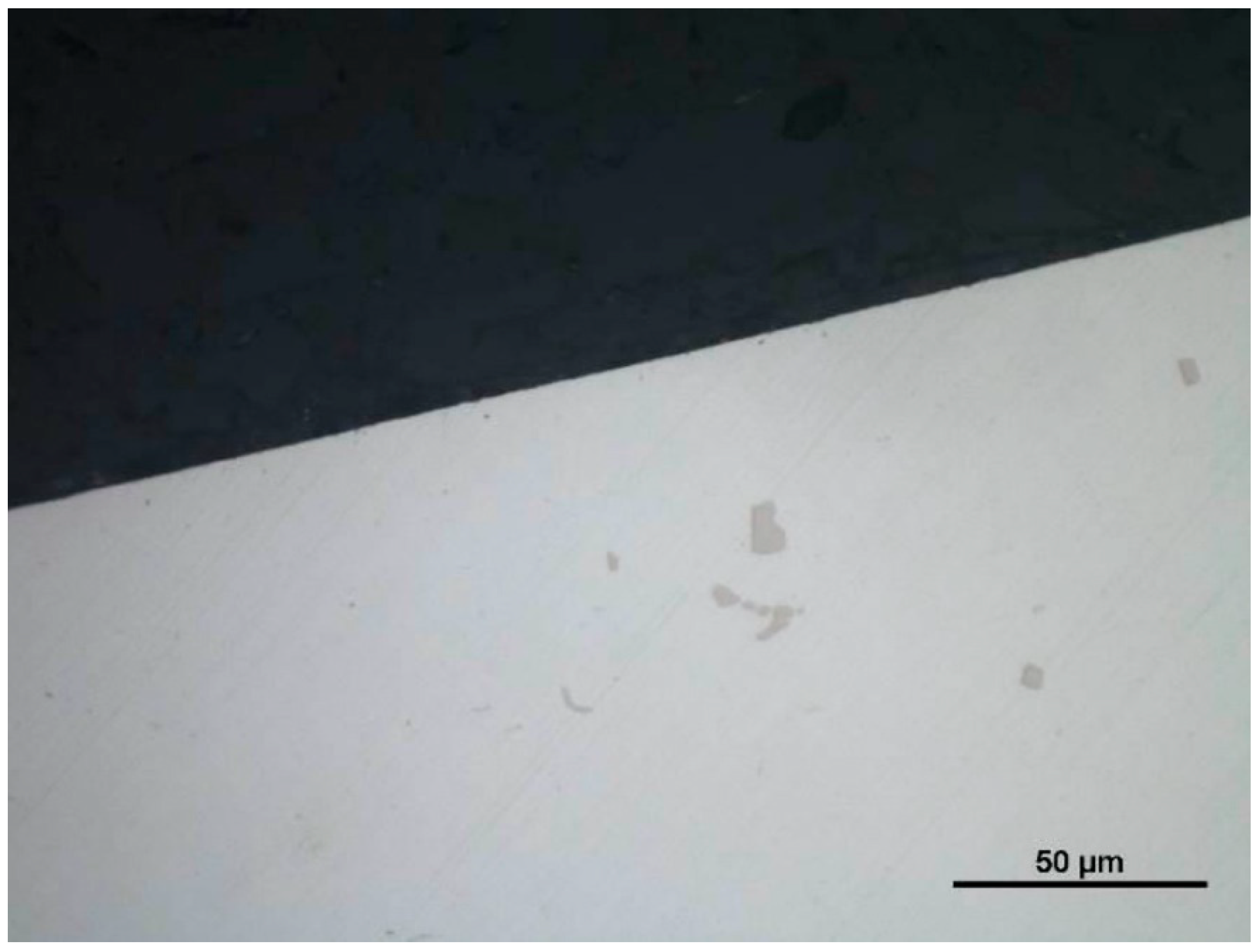

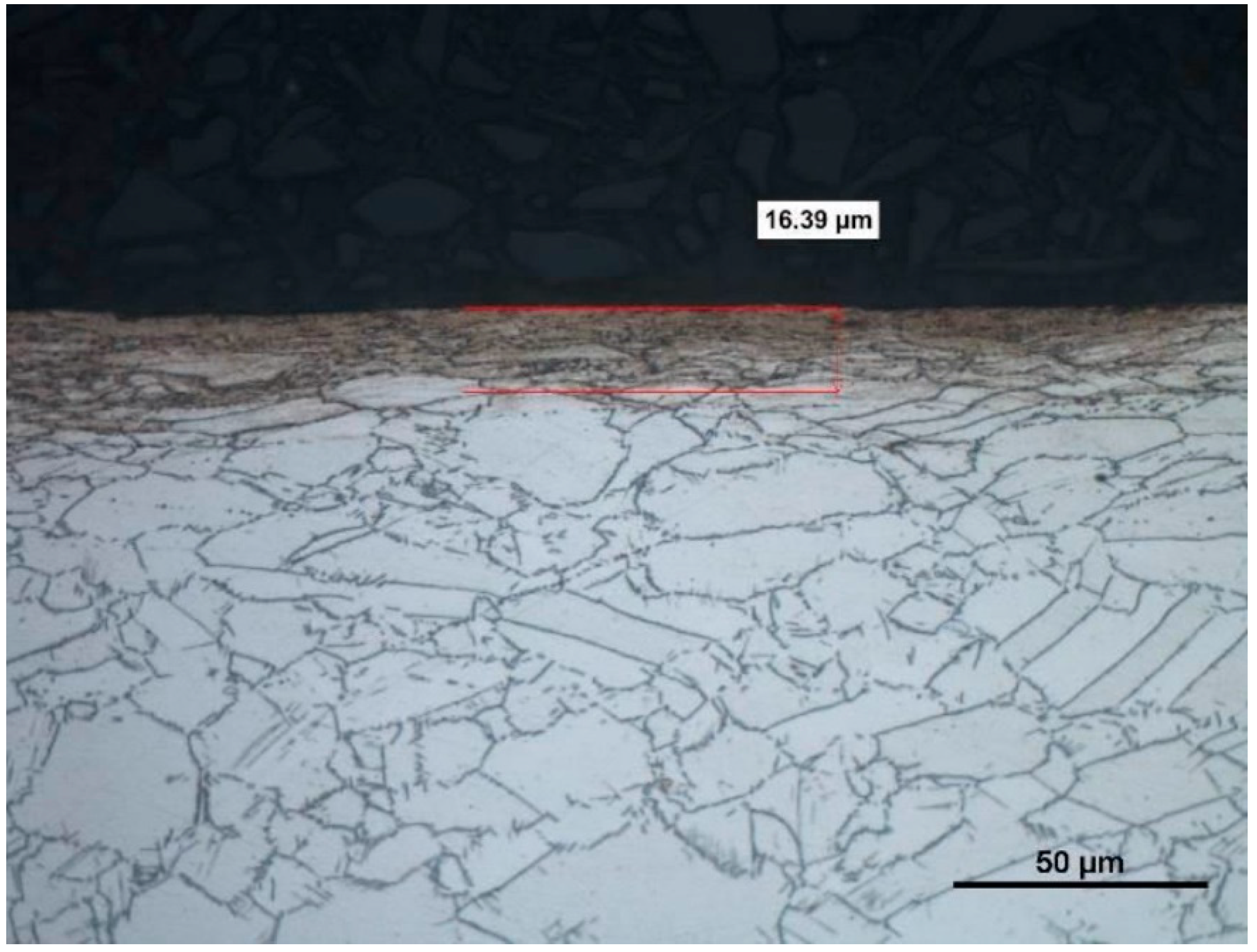

- Dry turning of the Inconel 718 alloy, regardless of its hardness, influenced the character and size of the wear of the cutting edge. No use of coolant resulted in an increase in the radius of the cutting edge rounding, and consequently, an increase in the amount of heat generated in the cutting zone, a symptom of which was changes in microstructure and quality deterioration of the machined surface.

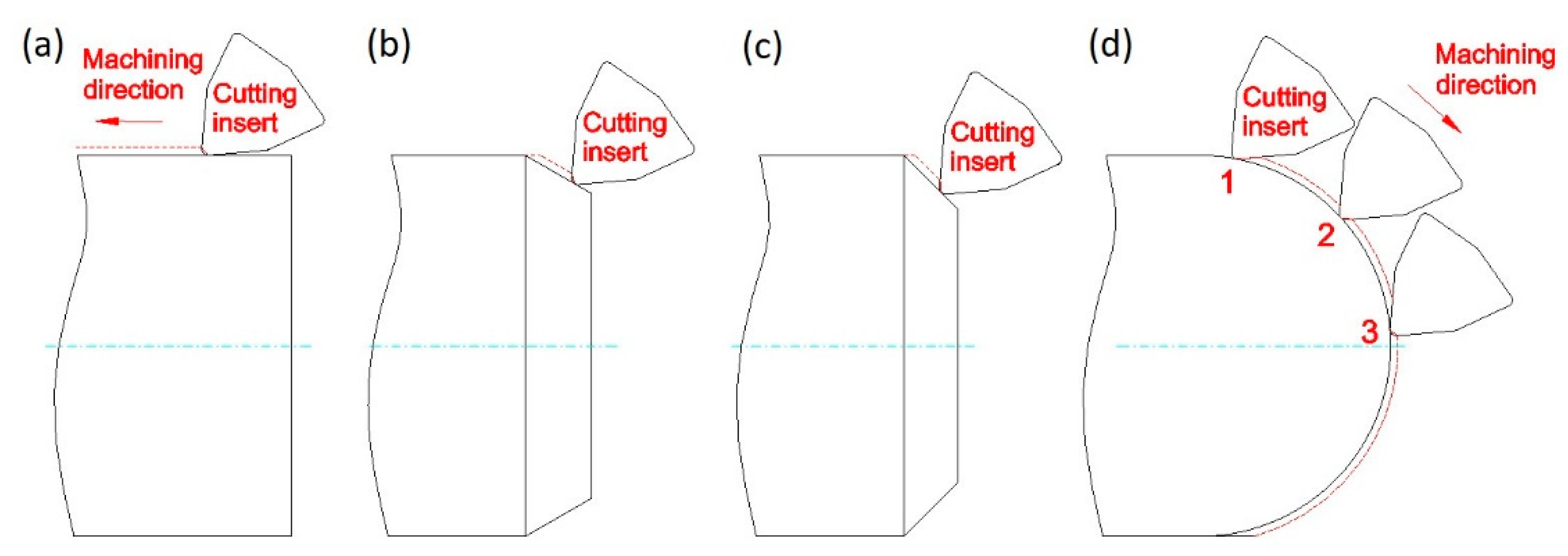

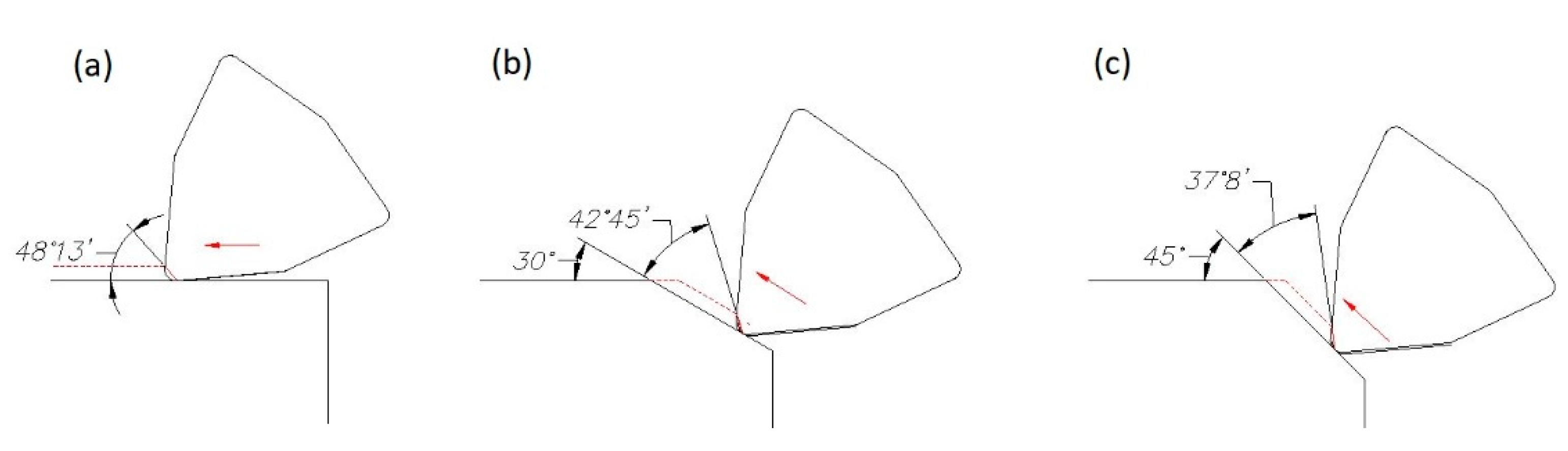

- The investigation results proved the influence of the angle between the cutting edge and the machined surface on the roughness parameters, Ra and Rz. Reduction in that angle caused an increase in the active length of the cutting edge, as a result of which higher cutting resistances were generated, manifested by vibrations that negatively influenced the surface roughness.

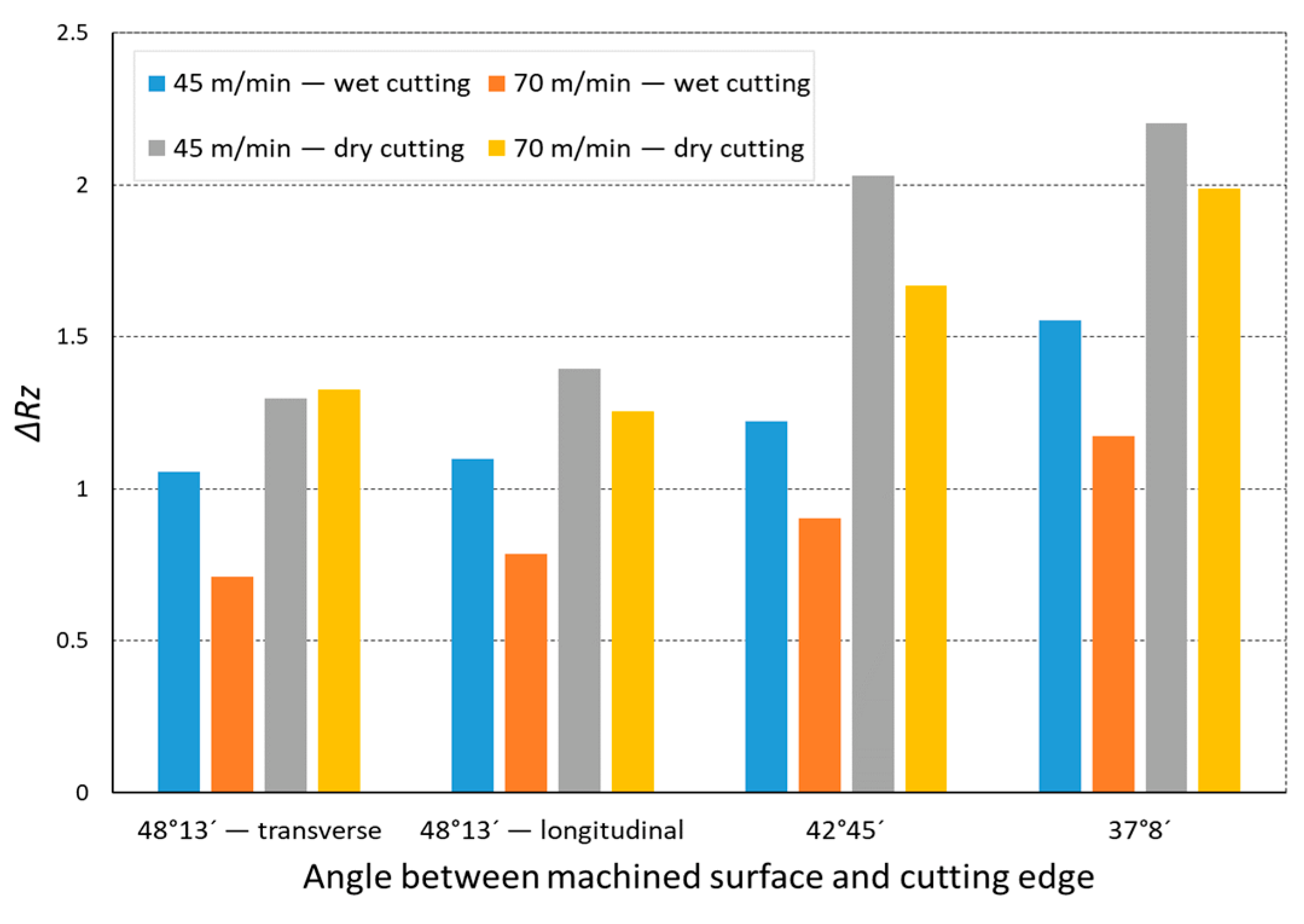

- The accuracy of the application of Formula (5) to predict the value of parameter Rzto was sufficient in stable conditions of the machining process. Disturbance of that stability by the lack of coolant application, increase of the active length of the cutting edge, and change of the cutting speed influenced the dynamics of the machining process; i.e., the value of ΔRzd. Analysis of the ΔRz coefficient indicated that the largest influence on value of ΔRz was that of the lack of coolant application in turning, and consequently, the lack of lubrication between the cutting insert and the machined surface. The ΔRz coefficient analysis also showed that the cutting speed had a significant influence on the surface roughness when cutting the Inconel 718 alloy. The use of a cutting speed of 70 m/min during cooling turning allowed us to obtain a ΔRz value below 1.

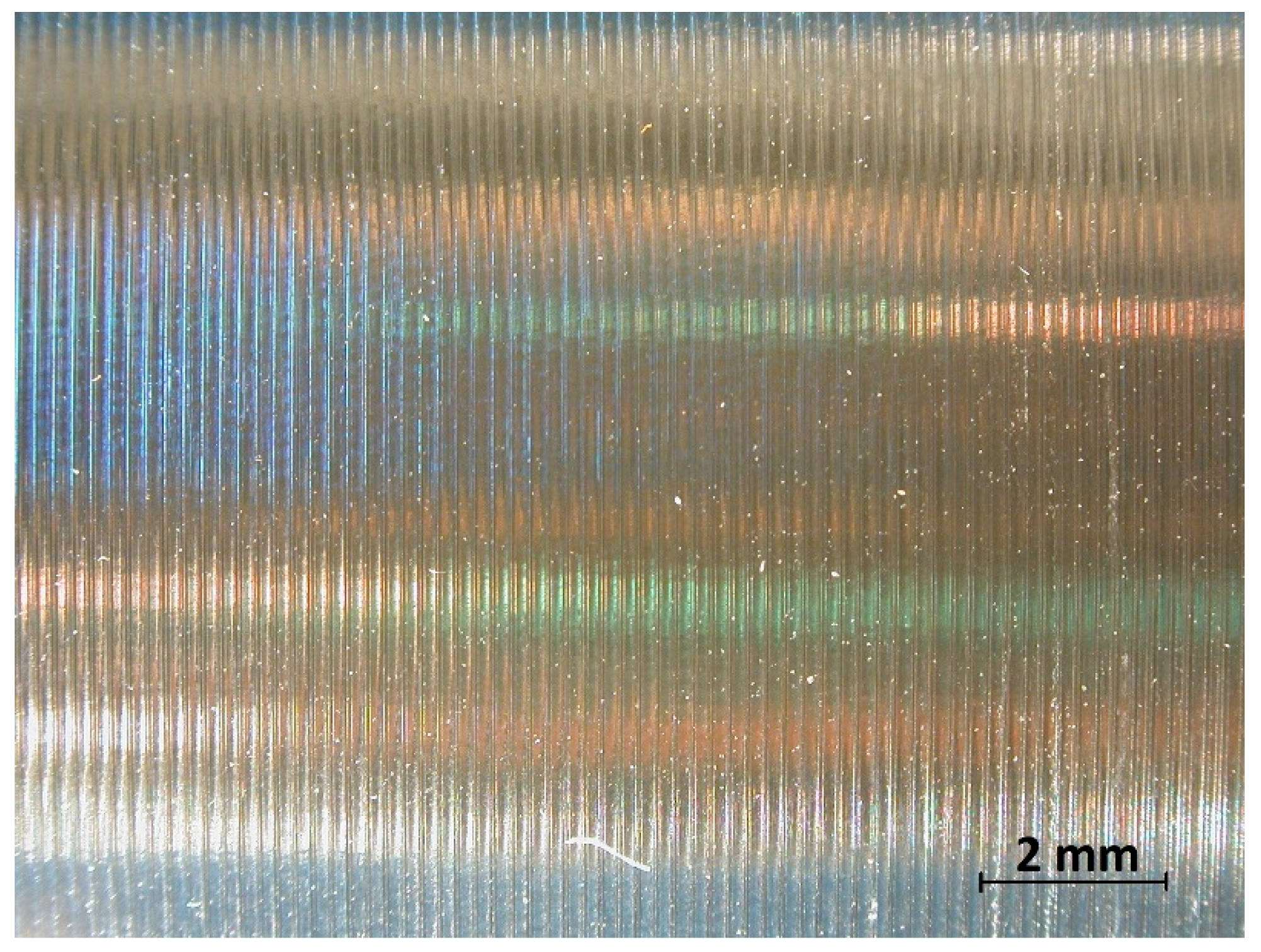

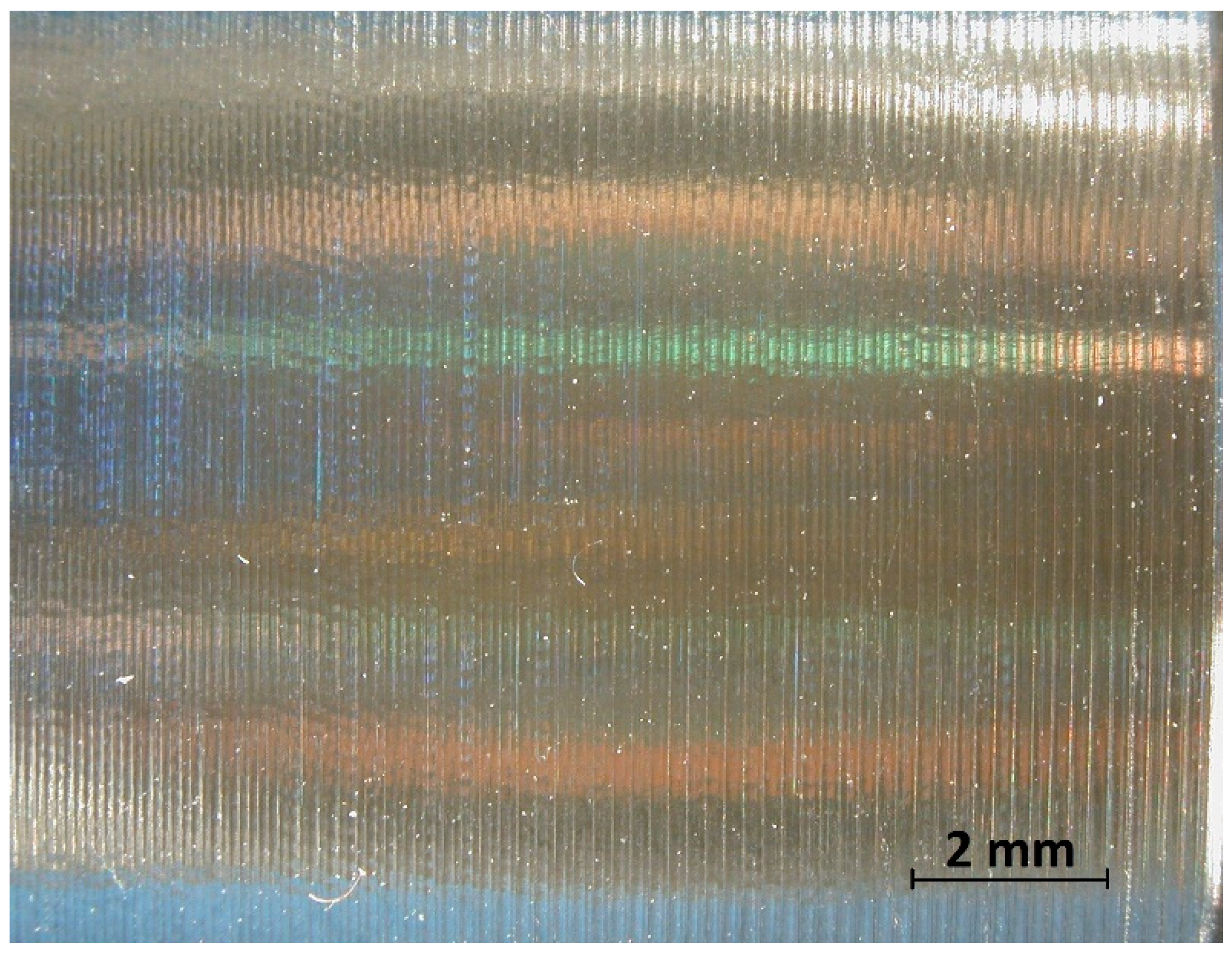

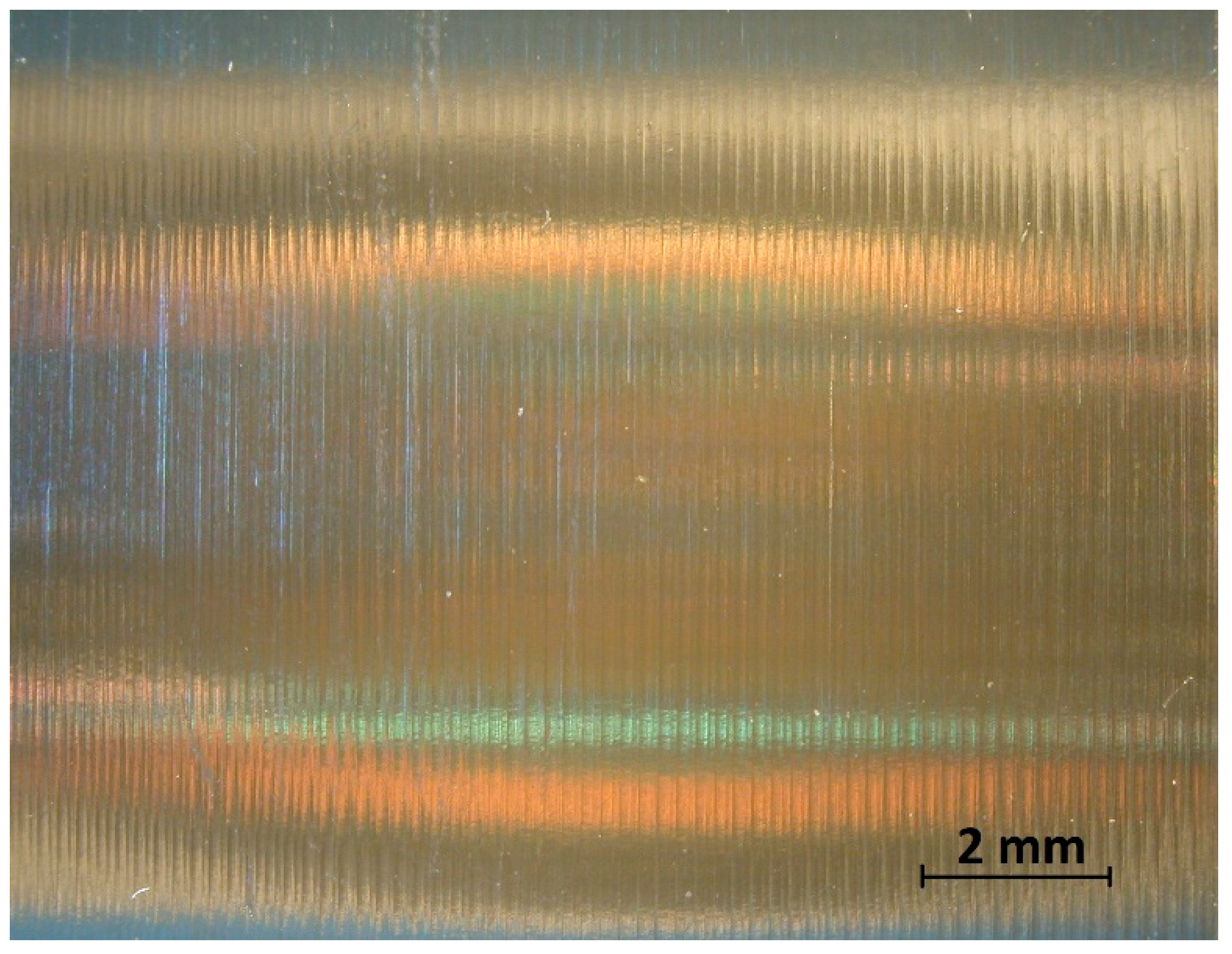

- The process of dry turning of the Inconel 718 alloy resulted in the formation of stickings on the machined surface. This phenomenon was not observed in machining with cooling. Therefore, the material could not be dry machined in the process of finish turning.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aronson, R.B. What’s different about manufacturing for Aerospace? Manuf. Eng. 2002, 126, 36–38. [Google Scholar]

- Ahmed, N.; Mitrofanov, A.V.; Babitsky, V.I.; Silberschmidt, V.V. Analysis of material response to ultrasonic vibration loading in turning Inconel 718. Mater. Sci. Eng. 2006, 424, 318–325. [Google Scholar] [CrossRef]

- Cano Salinas, L.; Moussaoui, K.; Hejjaji, A.; Salem, M.; Hor, A.; Zitoune, R. Influence of abrasive water jet parameters on the surface integrity of Inconel 718. Int. J. Adv. Manuf. Technol. 2021, 114, 997–1009. [Google Scholar] [CrossRef]

- Marinescu, I.; Axinte, D.; Herbert, C.; McGourlay, J.; Withers, P.J. Assessment of thread-cutting strategies to enable damage-tolerant surfaces on an advanced Ni-based aerospace superalloy. J. Eng. Manuf. 2010, 225, 12–24. [Google Scholar] [CrossRef]

- Pawade, R.S.; Joshi, S.; Brahmankar, P.K.; Rahman, M. An investigation of cutting forces and surface damage in high-speed turning of Inconel 718. J. Mater. Process. Technol. 2007, 192, 139–146. [Google Scholar] [CrossRef]

- Pereira, W.H.; Delijaicov, S. Surface integrity of INCONEL 718 turned under cryogenic conditions at high cutting speeds. Int. J. Adv. Manuf. Technol. 2019, 104, 2163–2177. [Google Scholar] [CrossRef]

- Çakıroğlu, R. Machinability analysis of Inconel 718 superalloy with AlTiN coated carbide tool under different cutting environments. Arab. J. Sci. Eng. 2021, 46, 8055–8073. [Google Scholar] [CrossRef]

- Rahman, M.; Seah, W.K.H.; Teom, T.T. The machinability of Inconel 718. J. Mater. Process. Technol. 1997, 63, 199–204. [Google Scholar] [CrossRef]

- He, Y.; Zhou, Z.; Zou, P.; Gao, X.; Ehmann, K.F. Study of ultrasonic vibration–assisted thread turning of Inconel 718 superalloy. Adv. Mech. Eng. 2019, 11, 1–12. [Google Scholar] [CrossRef]

- Tebassia, H.; Athmane Yallesea, M.; Belhadia, S.; Girardinb, F.; Mabroukic, T. Quality-productivity decision making when turning of Inconel 718 aerospace alloy: A response surface methodology approach. Int. J. Ind. Eng. Comput. 2017, 8, 347–362. [Google Scholar] [CrossRef]

- Yin, Q.; Liu, Z.; Wang, B. Machinability improvement of Inconel 718 through mechanochemical and heat transfer effects of coated surface-active thermal conductive mediums. J. Alloys Compd. 2021, 876, 160186. [Google Scholar] [CrossRef]

- Zhou, J.; Bushlya, V.; Avdovic, P.; Stahl, J.E. Study of surface quality in high speed turning of Inconel 718 with uncoated and coated CBN tools. Int. J. Adv. Manuf. Technol. 2012, 58, 141–151. [Google Scholar] [CrossRef]

- Khanna, N.; Agrawal, C.; Dogra, M.; Pruncu, C.I. Evaluation of tool wear, energy consumption, and surface roughness during turning of inconel 718 using sustainable machining technique. J. Matter. Res. Techol. 2020, 9, 5794–5804. [Google Scholar] [CrossRef]

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. Some investigations on high speed dry machining of aerospace material Inconel 718 using multicoated carbide inserts. Mater. Manuf. Process. 2012, 27, 1066–1072. [Google Scholar] [CrossRef]

- Deshpande, Y.; Andhare, A.; Sahu, N.K. Estimation of surface roughness using cutting parameters, force, sound, and vibration in turning of Inconel 718. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 5087–5096. [Google Scholar] [CrossRef]

- Krolczyk, G.; Legutko, S.; Nieslony, P.; Gajek, M. Study of the surface integrity microhardness of austenitic stainless steel after turning. Tech. Gaz. 2014, 21, 1307–1311. [Google Scholar]

- Maruda, R.W.; Feldshtein, E.E.; Legutko, S.; Krolczyk, G.M. Improving the efficiency of running-in for a bronze–stainless steel friction pair. J. Frict. Wear 2015, 36, 548–553. [Google Scholar] [CrossRef]

- Wieczorowski, M.; Cellary, A.; Majchrowski, R. The analysis of credibility and reproducibility of surface roughness measurement results. Wear 2010, 269, 480–484. [Google Scholar] [CrossRef]

- Coelho, R.T.; Silva, L.R.; Braghini, A.; Bezerra, A.A. Some effects of cutting edge preparation and geometric modifications when turning Inconel 718 at high cutting speeds. J. Mater. Process. Technol. 2004, 148, 147–153. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Tang, S.H. Surface abuse when machining cast iron (G-17) and nickel-base superalloy (Inconel 718) with ceramic tools. J. Mater. Process. Technol. 1995, 55, 63–69. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, Z. Effects of cutting parameters and tool nose radius on surface roughness and work hardening during dry turning Inconel 718. Int. J. Adv. Manuf. Technol. 2018, 96, 2421–2430. [Google Scholar] [CrossRef]

- D’Addona, D.M.; Raykar, S.J.; Narke, M.M. High speed machining of Inconel 718: Tool wear and surface roughness analysis. Procedia CIRP 2017, 62, 269–274. [Google Scholar] [CrossRef]

- Jafarian, F.; Umbrello, D.; Golpayegani, S.; Darake, Z. Experimental investigation to optimize tool life and surface roughness in Inconel 718 machining. Mater. Manuf. Process. 2016, 31, 1683–1691. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, D.; Kalsi, N.S. Experimental investigations of surface roughness of Inconel 718 under different machining conditions. Mater. Today: Proc. 2017, 4, 1179–1185. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Nieslony, P.; Krolczyk, J.B.; Legutko, S. Chip formation zone analysis during the turning of austenitic stainless steel 316L under MQCL cooling condition. Procedia Eng. 2016, 149, 297–304. [Google Scholar] [CrossRef] [Green Version]

- Mehta, A.; Hemakumar, S.; Patil, A.; Khandke, S.P.; Kuppan, P.; Oyyaravelu, R.; Balan, A.S.S. Influence of sustainable cutting environments on cutting forces, surface roughness and tool wear in turning of Inconel 718. Mater. Today Proc. 2018, 5, 6746–6754. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, X.; Zhang, D. Integration of finishing and surface treatment of Inconel 718 alloy using high-speed ultrasonic vibration cutting. Surf. Coat. Technol. 2021, 413, 127088. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, X.; Zhang, D. Performance evaluation of high-speed ultrasonic vibration cutting for improving machinability of Inconel 718 with coated carbide tools. Tribol. Int. 2021, 155, 106766. [Google Scholar] [CrossRef]

- Colwell, L. Predicting the angle of chip flow for single-point cutting tools. Trans. Am. Soc. Mech. Eng. 1954, 76, 199–204. [Google Scholar]

- Brammertz, P.H. Die Entstechung der Oberflachenrauheit beim Feindrehen. Ind. Anz. 1961, 83, 25–32. [Google Scholar]

- Szablewski, P.; Kawalec, M. Mikronierówności powierzchni obrobionej stopu Inconel 718 po procesie toczenia. Zesz. Nauk. Politech. Poznańskiej 2005, 2, 93–102. [Google Scholar]

- Grzesik, W.; Wanat, T. Comparative assessment of surface roughness produced by hard machining with mixed ceramic tools including 2D and 3D analysis. J. Mater. Process. Technol. 2005, 169, 364–371. [Google Scholar] [CrossRef]

- Klocke, F.; Helbig, J. Kein Leichter Job. Hochpräzisions—Hartdrehen von Hartmetallen ist wirtschaftliche Alternative zum Feinschleifen. Maschinenmarkt 2004, 17, 42–46. [Google Scholar]

- Arunachalam, R.M.; Mannan, M.A.; Spowage, A.C. Residual stress and surface roughness when fading age hardened Inconel 718 with CBN and ceramic cutting tools. Int. J. Mach. Tools Manuf. 2004, 44, 879–887. [Google Scholar] [CrossRef]

- Salio, M.; Berruti, T.; De Poli, G. Prediction of residual stress distribution after turning in turbine disks. Int. J. Mech. Sci. 2006, 28, 976–984. [Google Scholar] [CrossRef]

- Pawade, R.S.; Joshi, S.S.; Brahmankar, P.K. Effect of machining parameters and cutting edge geometry of surface integrity of high-speed turned Inconel 718. Int. J. Mach. Tools Manuf. 2008, 48, 15–28. [Google Scholar] [CrossRef]

- Sharman, A.R.C.; Hughes, J.I.; Ridgway, K. An analysis of the residual stresses generated in Inconel 718 when turning. J. Mater. Process. Technol. 2006, 173, 359–367. [Google Scholar] [CrossRef]

- Connoley, T.; Starink, M.J.; Reed, P.A.S. Effect of broaching on high-temperature fatigue behavior in notched specimens of INCONEL 718. Metall. Mater. Trans. A 2004, 35, 771–783. [Google Scholar] [CrossRef] [Green Version]

- Devillez, A.; Schneider, F.; Dominiak, S.; Dudzinski, D.; Larrouquere, D. Cutting forces and wear in dry machining of Inconel 718 with coated carbide tools. Wear 2007, 262, 931–942. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krawczyk, B.; Szablewski, P.; Legutko, S.; Smak, K.; Gapiński, B. Anomalies in the Geometric Surface Structure of Shaped Elements Composed of Inconel 718 Alloy. Materials 2021, 14, 7524. https://doi.org/10.3390/ma14247524

Krawczyk B, Szablewski P, Legutko S, Smak K, Gapiński B. Anomalies in the Geometric Surface Structure of Shaped Elements Composed of Inconel 718 Alloy. Materials. 2021; 14(24):7524. https://doi.org/10.3390/ma14247524

Chicago/Turabian StyleKrawczyk, Bartłomiej, Piotr Szablewski, Stanisław Legutko, Krzysztof Smak, and Bartosz Gapiński. 2021. "Anomalies in the Geometric Surface Structure of Shaped Elements Composed of Inconel 718 Alloy" Materials 14, no. 24: 7524. https://doi.org/10.3390/ma14247524