Bondline Thickness Effects on Damage Tolerance of Adhesive Joints Subjected to Localized Impact Damages: Application to Leading Edge of Wind Turbine Blades

Abstract

:1. Introduction

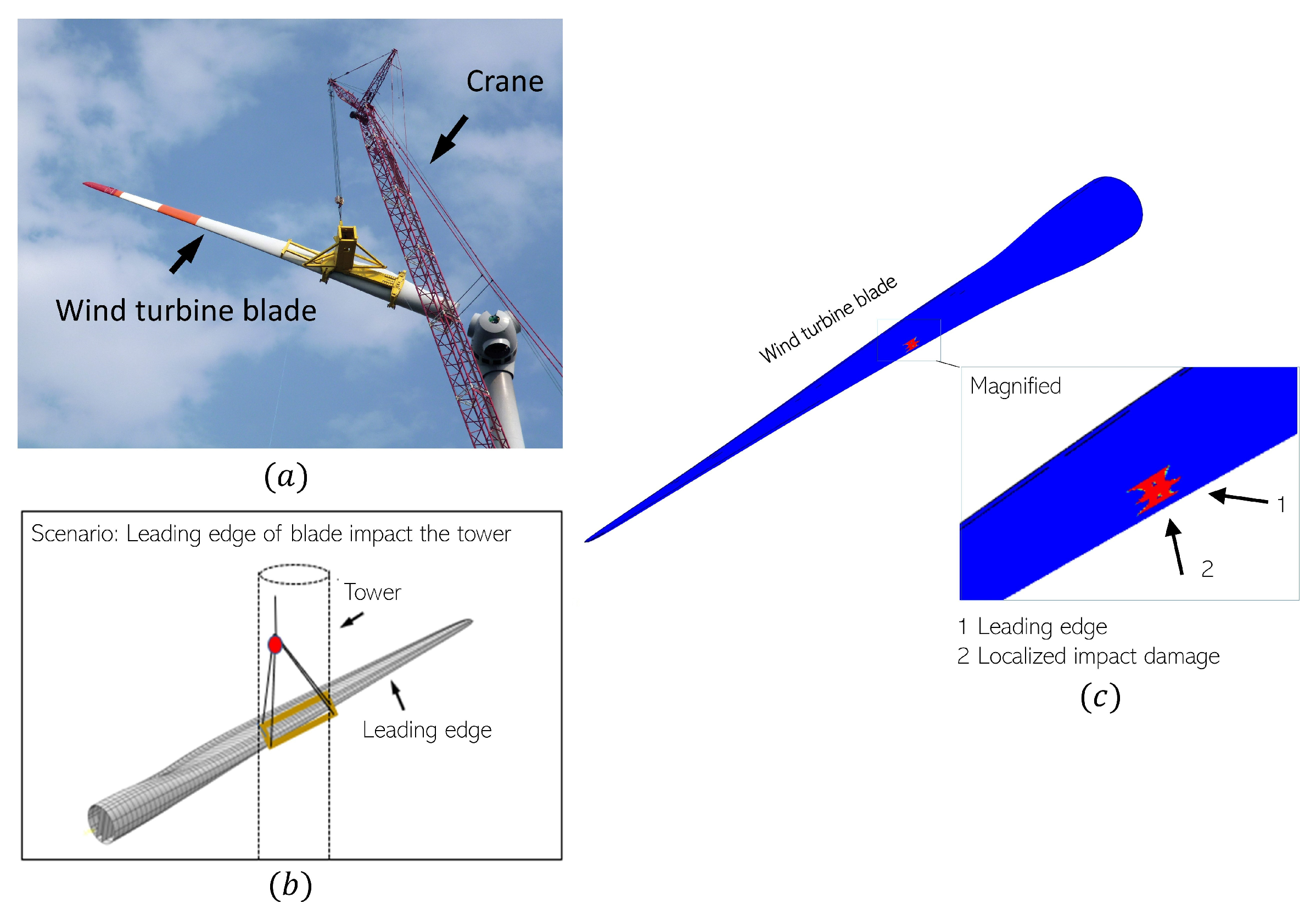

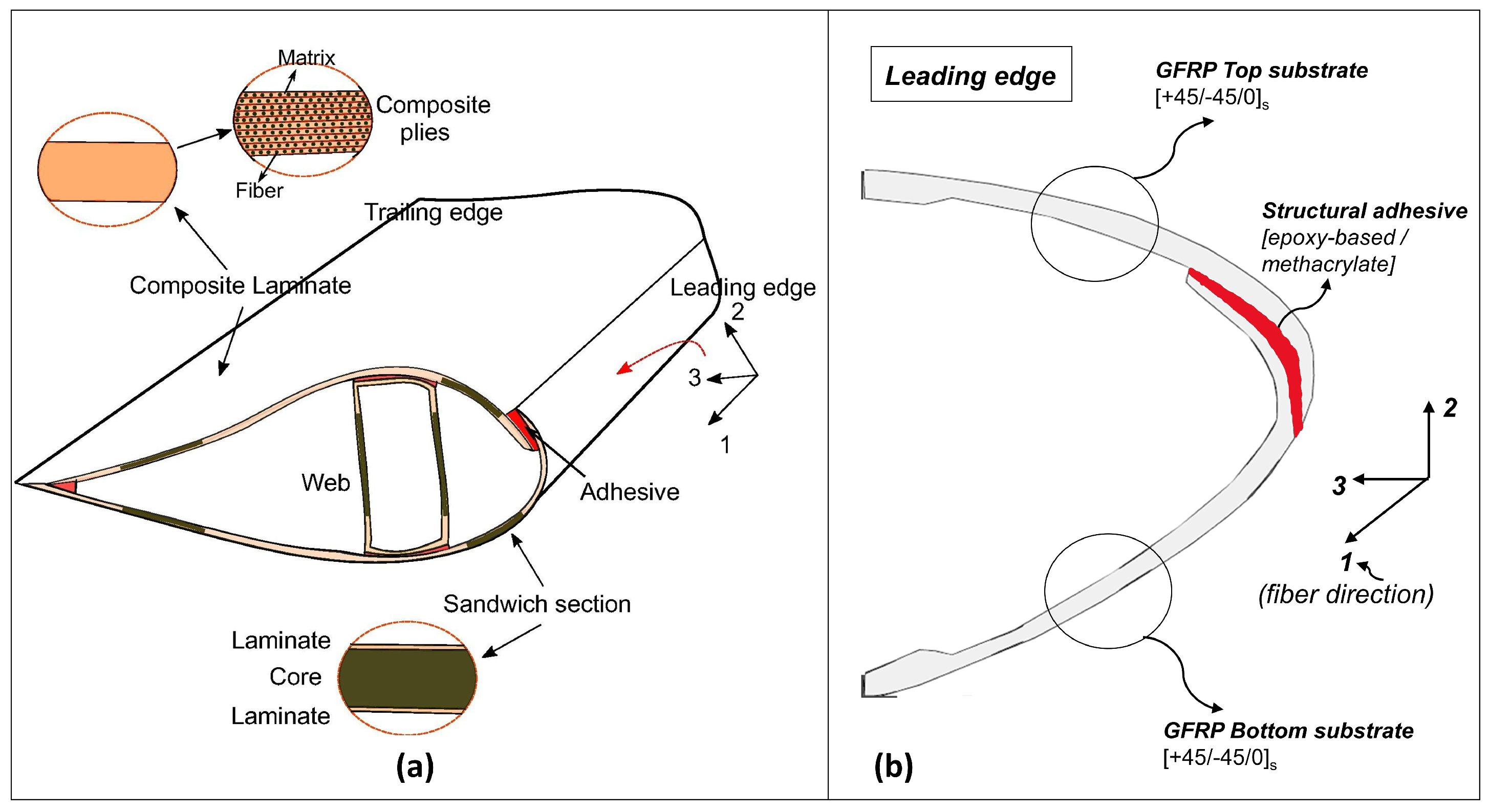

1.1. Background

1.2. Literature Review: Wind Turbine Blades, Impact Loads, and Damage Tolerance Investigations

2. Experimental Design

2.1. Coupon Scale Representation of Leading Edge and Benchmark Testing

2.2. Test Setup for Generating Localised Impact Damage

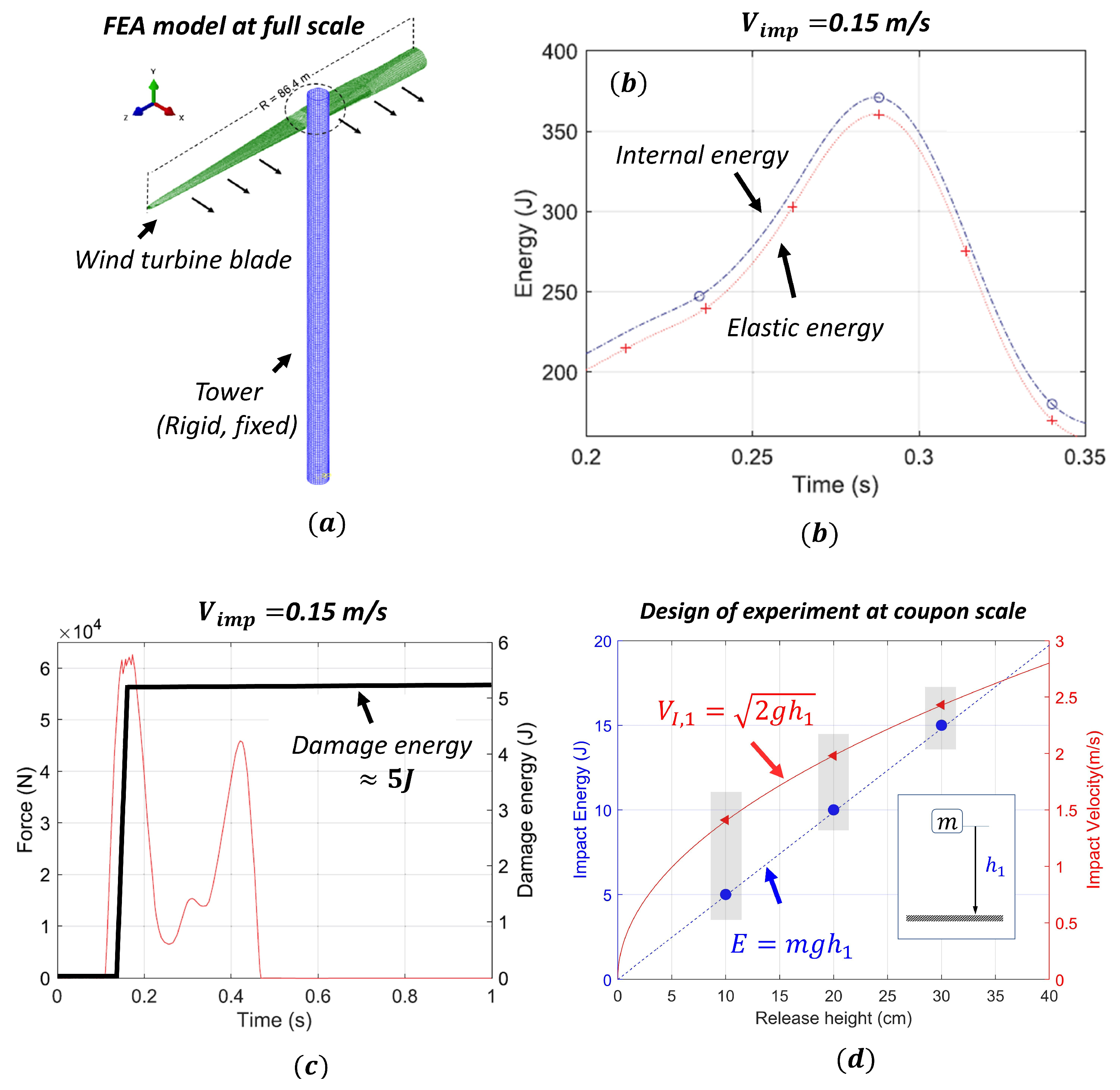

2.3. Choice of Impact Energy at Coupon Scale

3. Materials and Methods

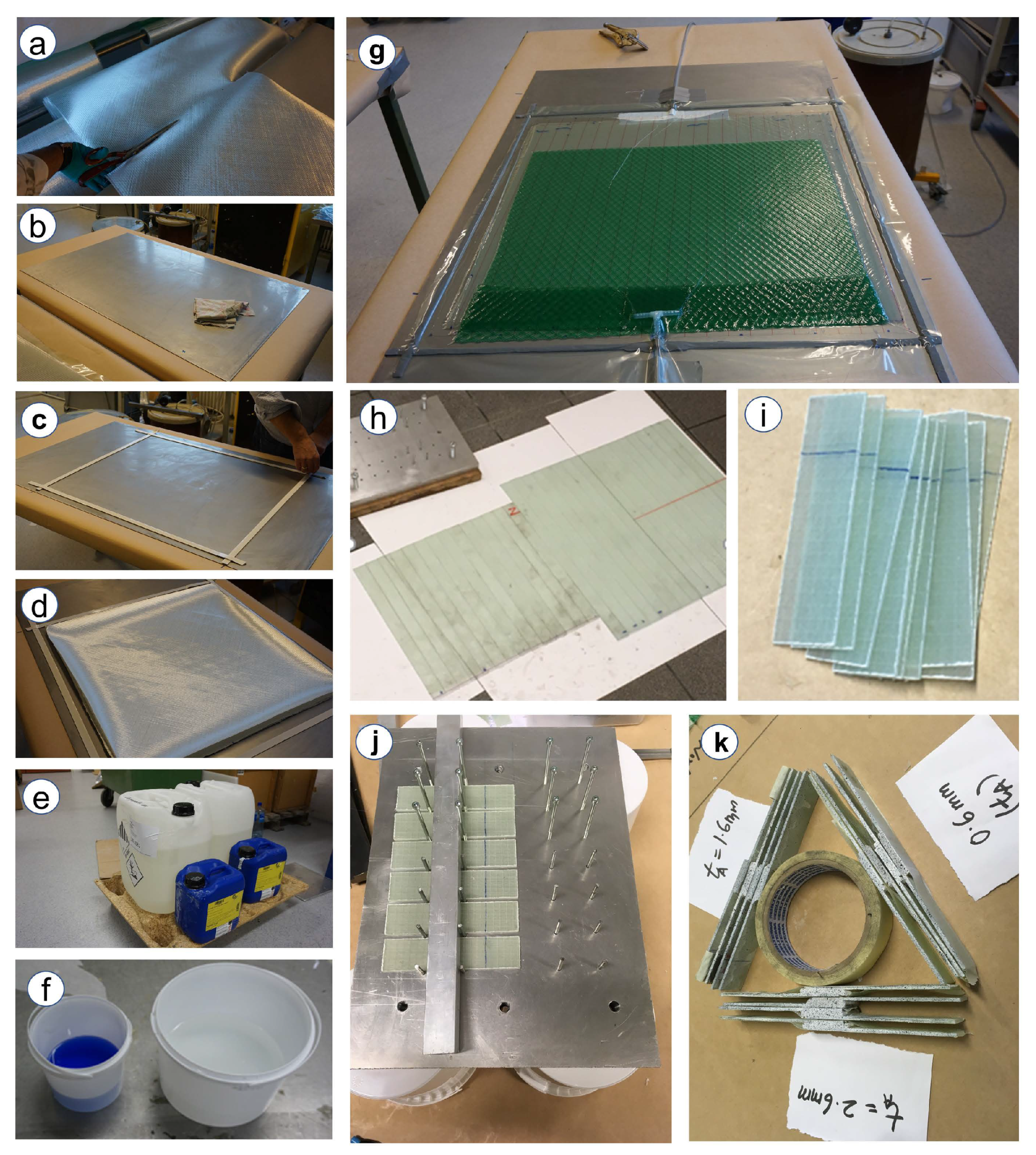

3.1. Preparation of Composite Substrates

3.2. Preparation of Single Lap Adhesive Joints

3.3. Lap Shear Tests of Intact Samples

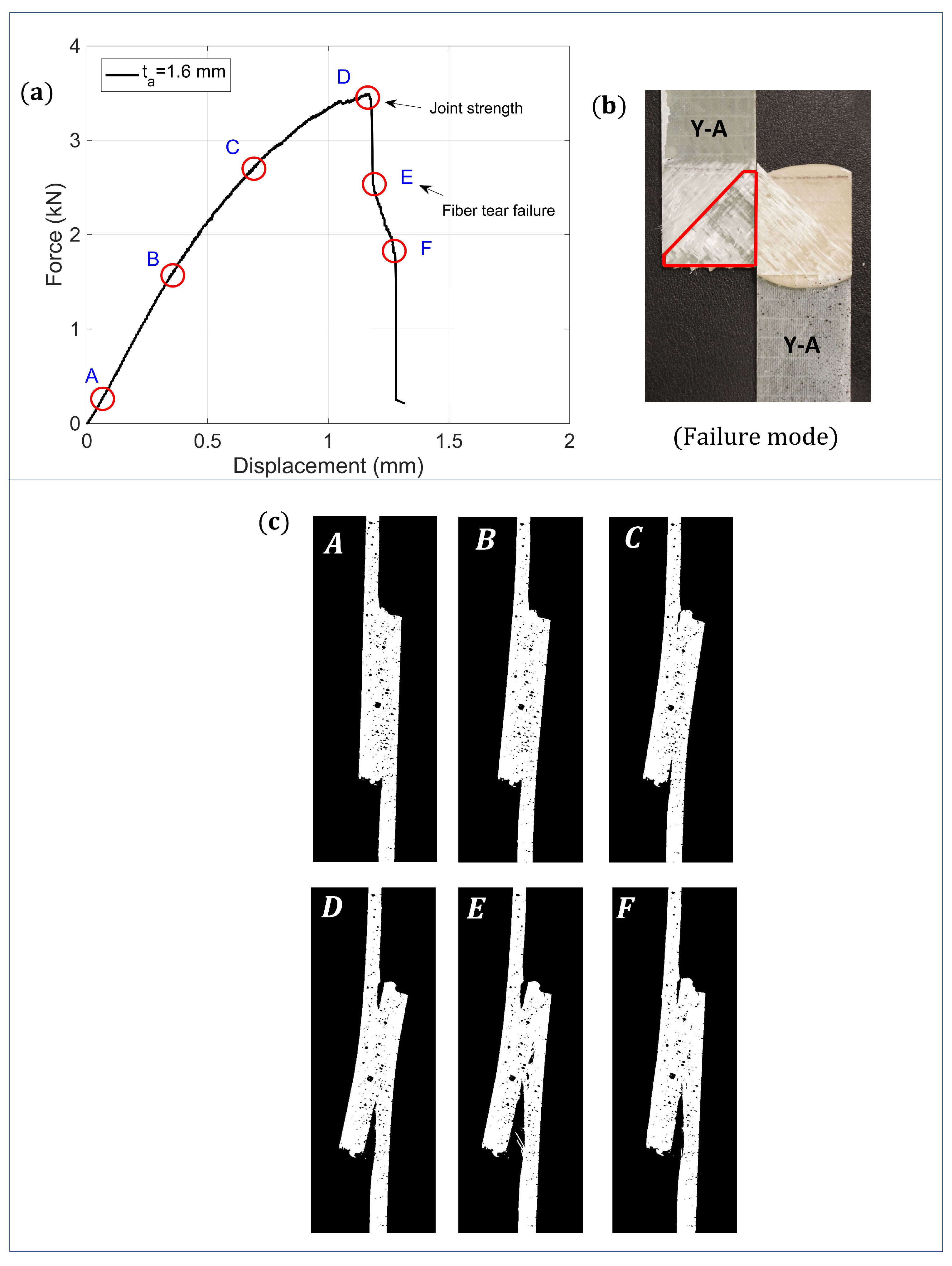

3.4. Impact Testing of Single Lap Joints (SLJs)

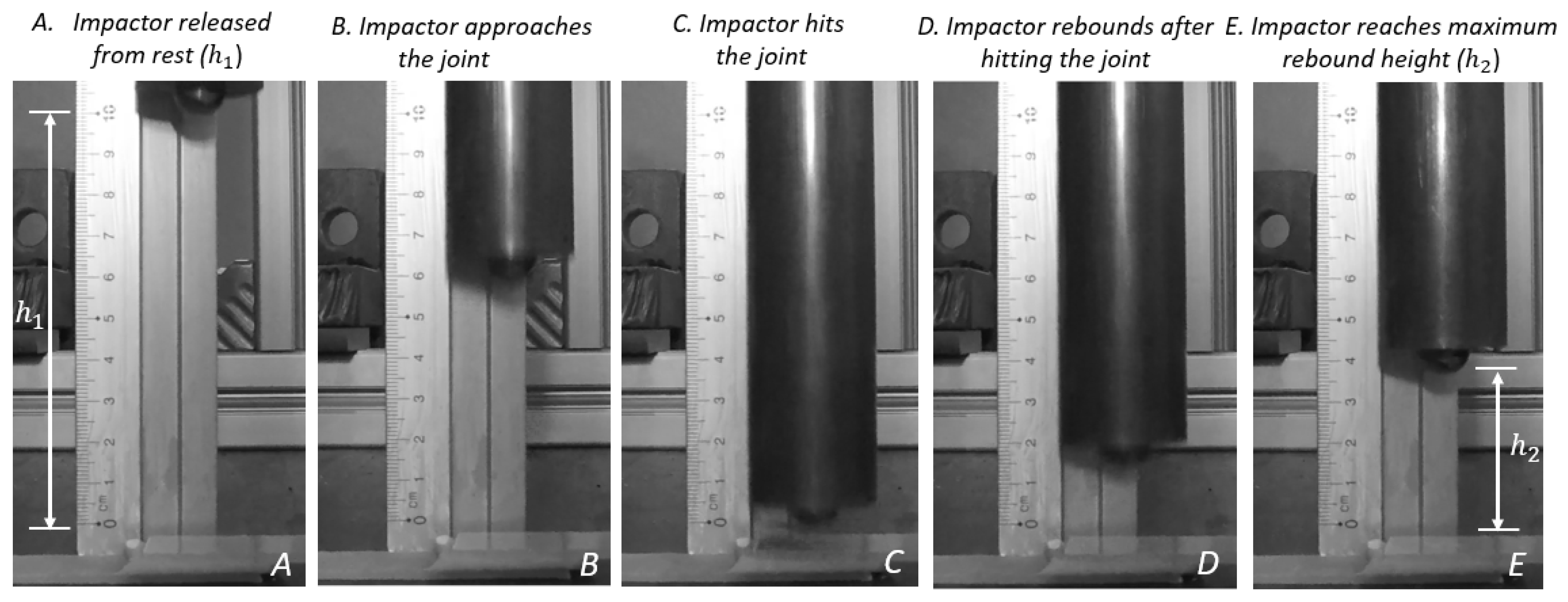

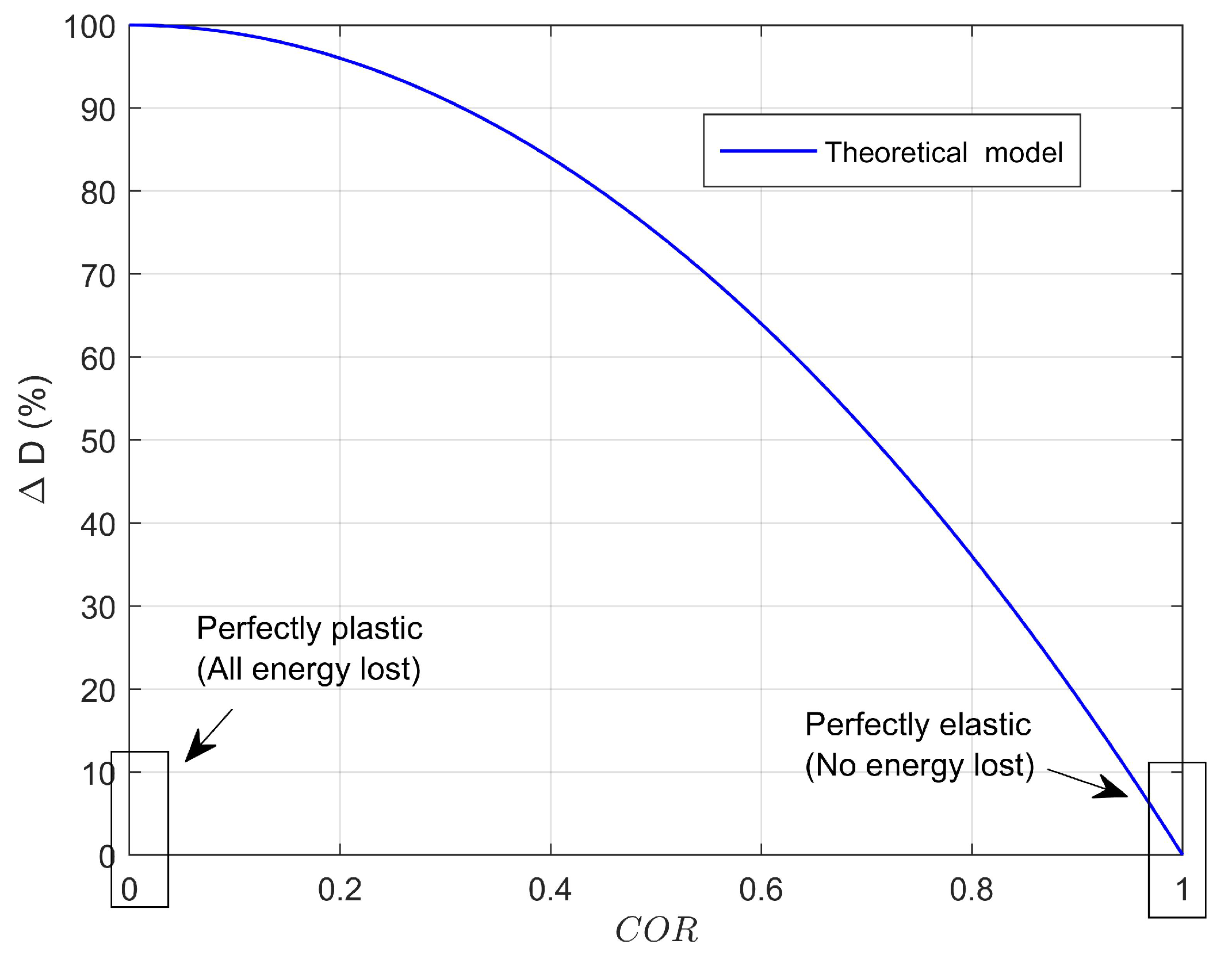

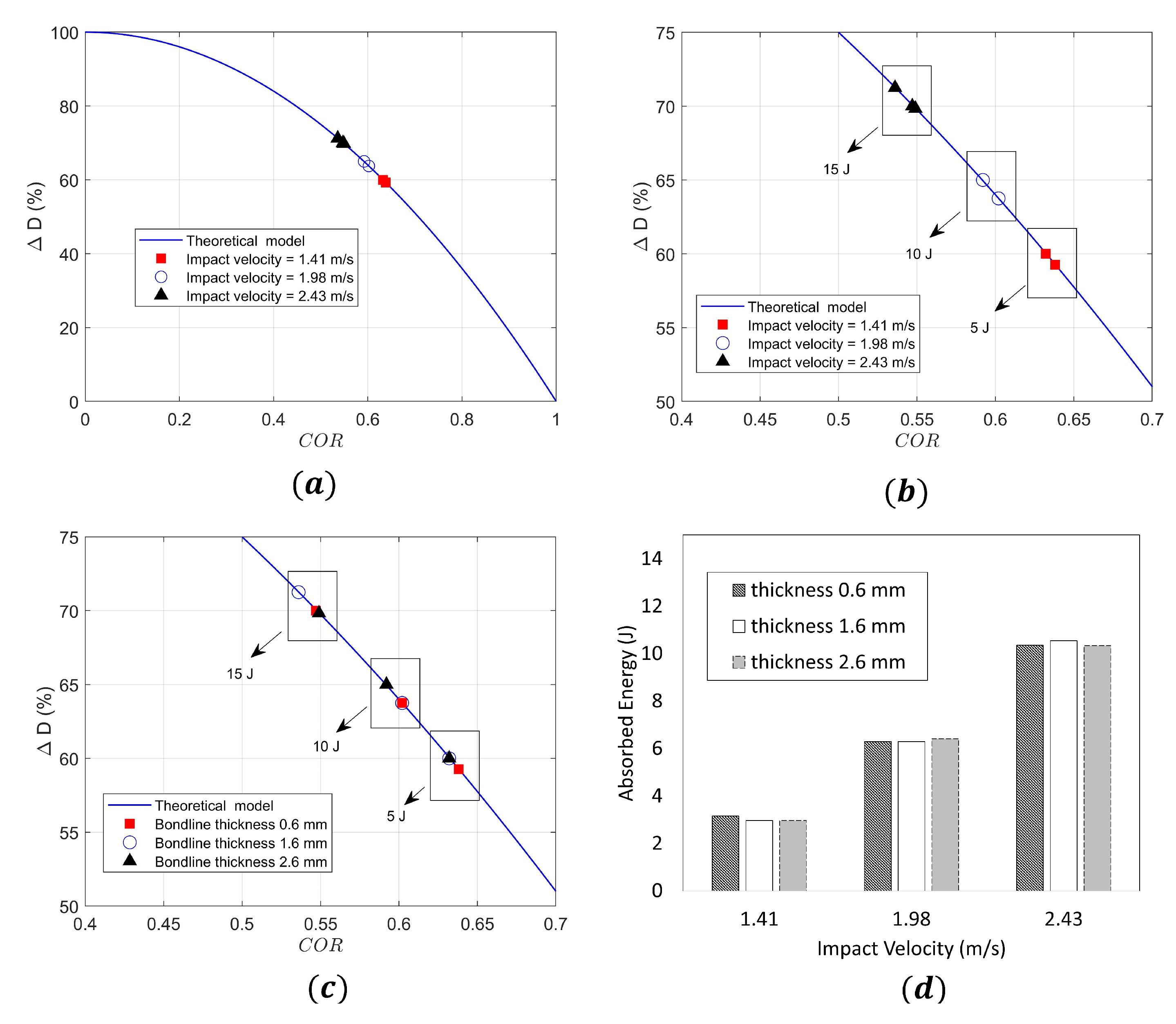

Analysis of Impact Kinematics

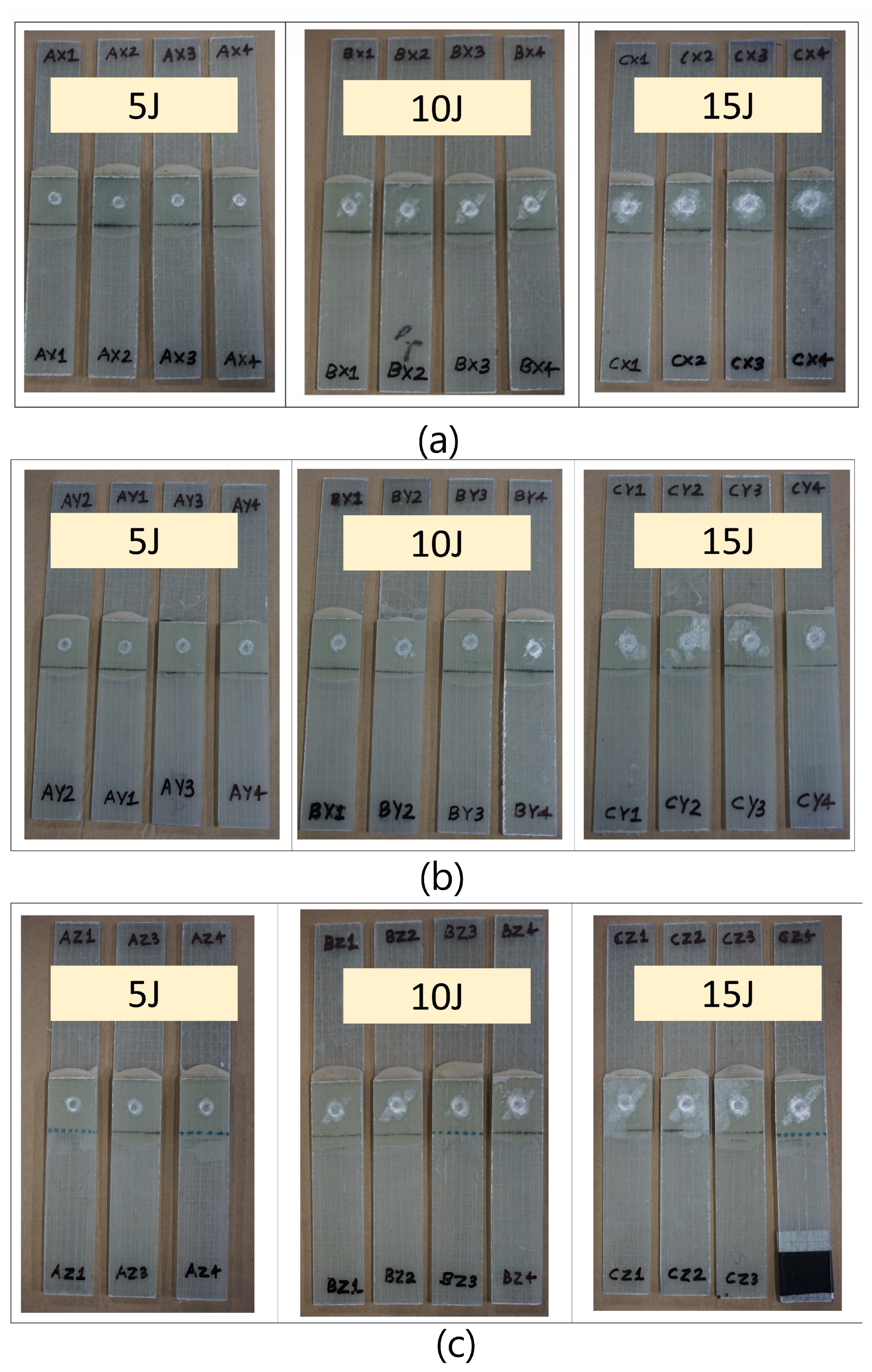

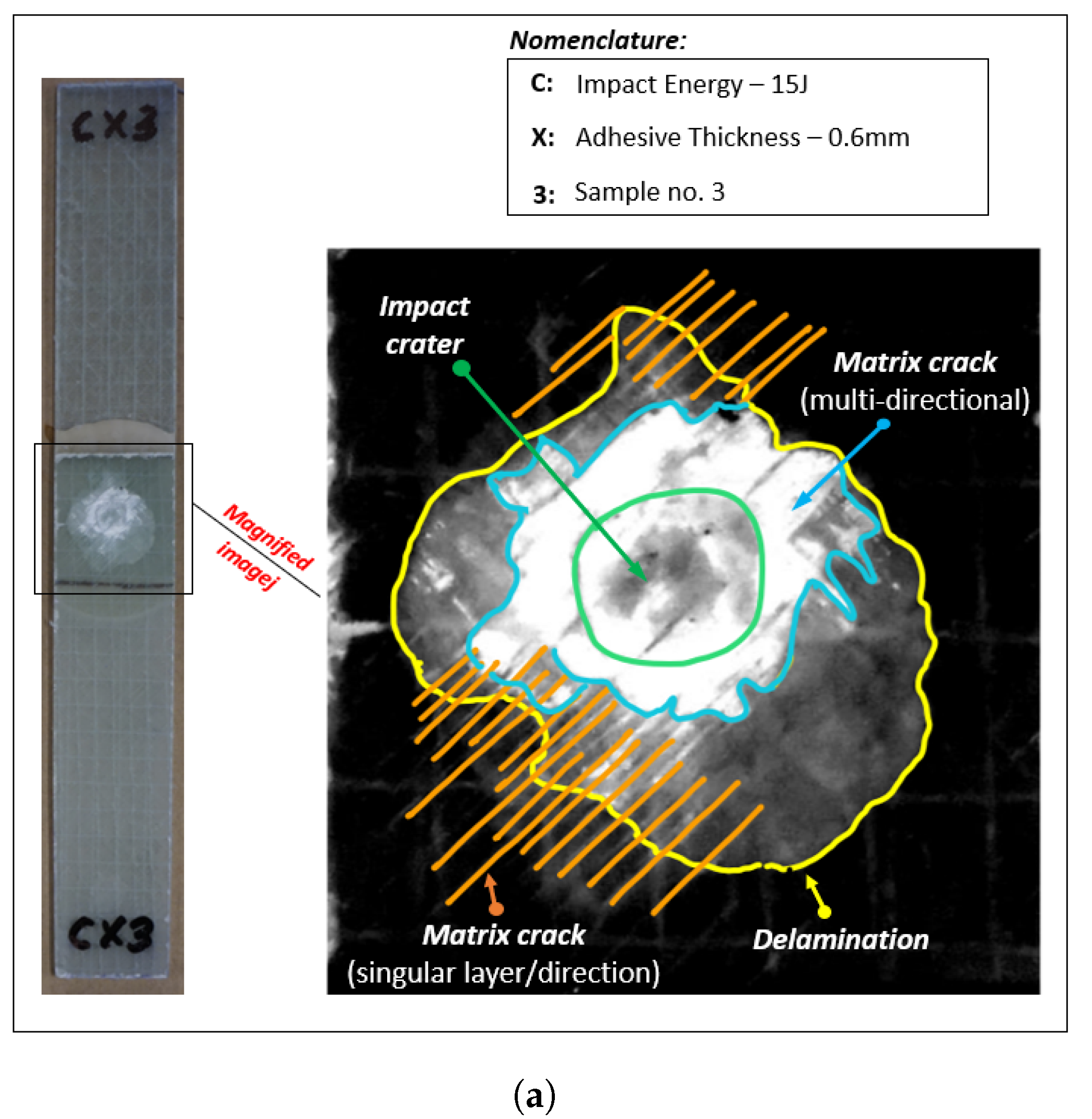

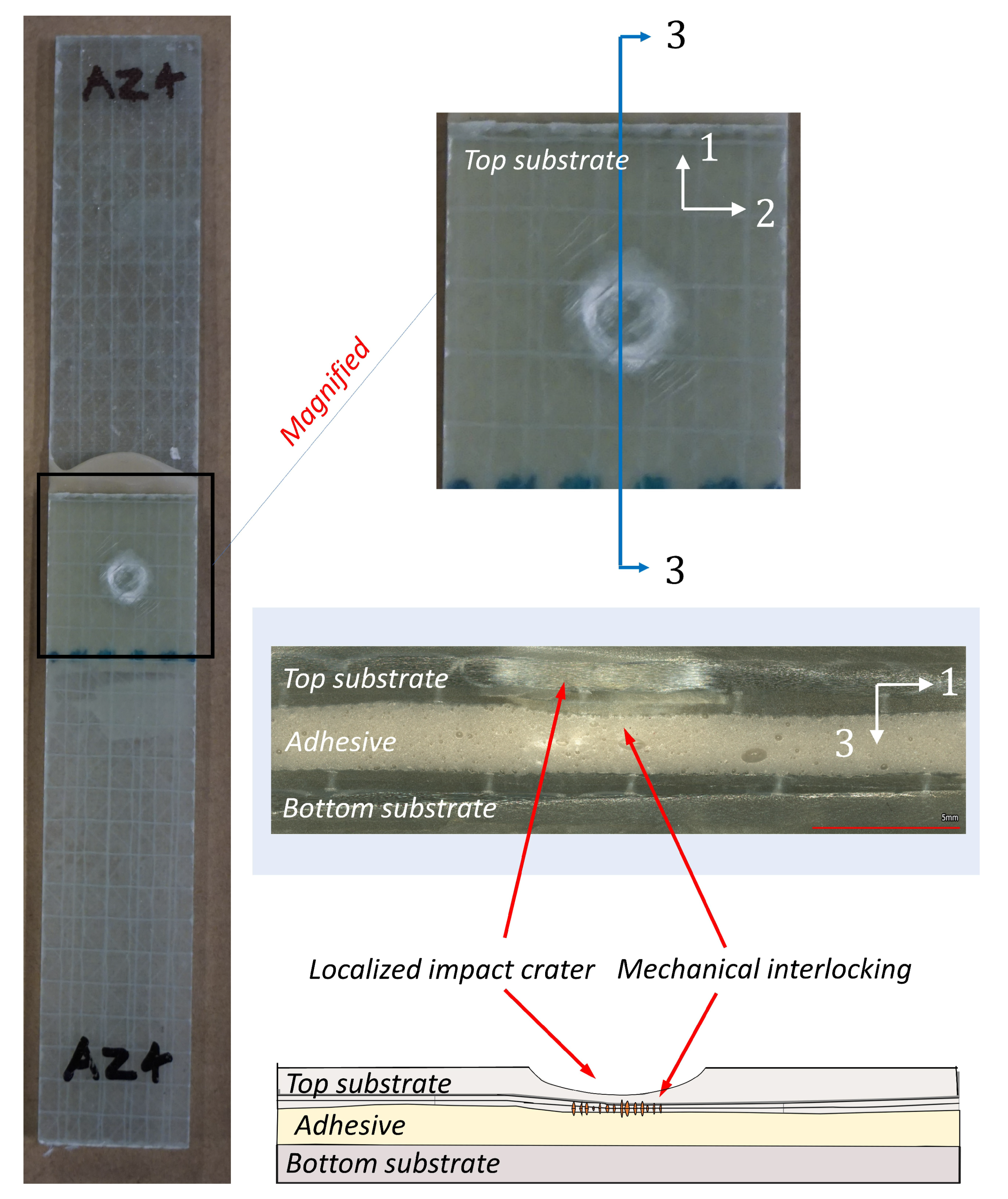

3.5. Post Impact Assessment

4. Results and Discussion

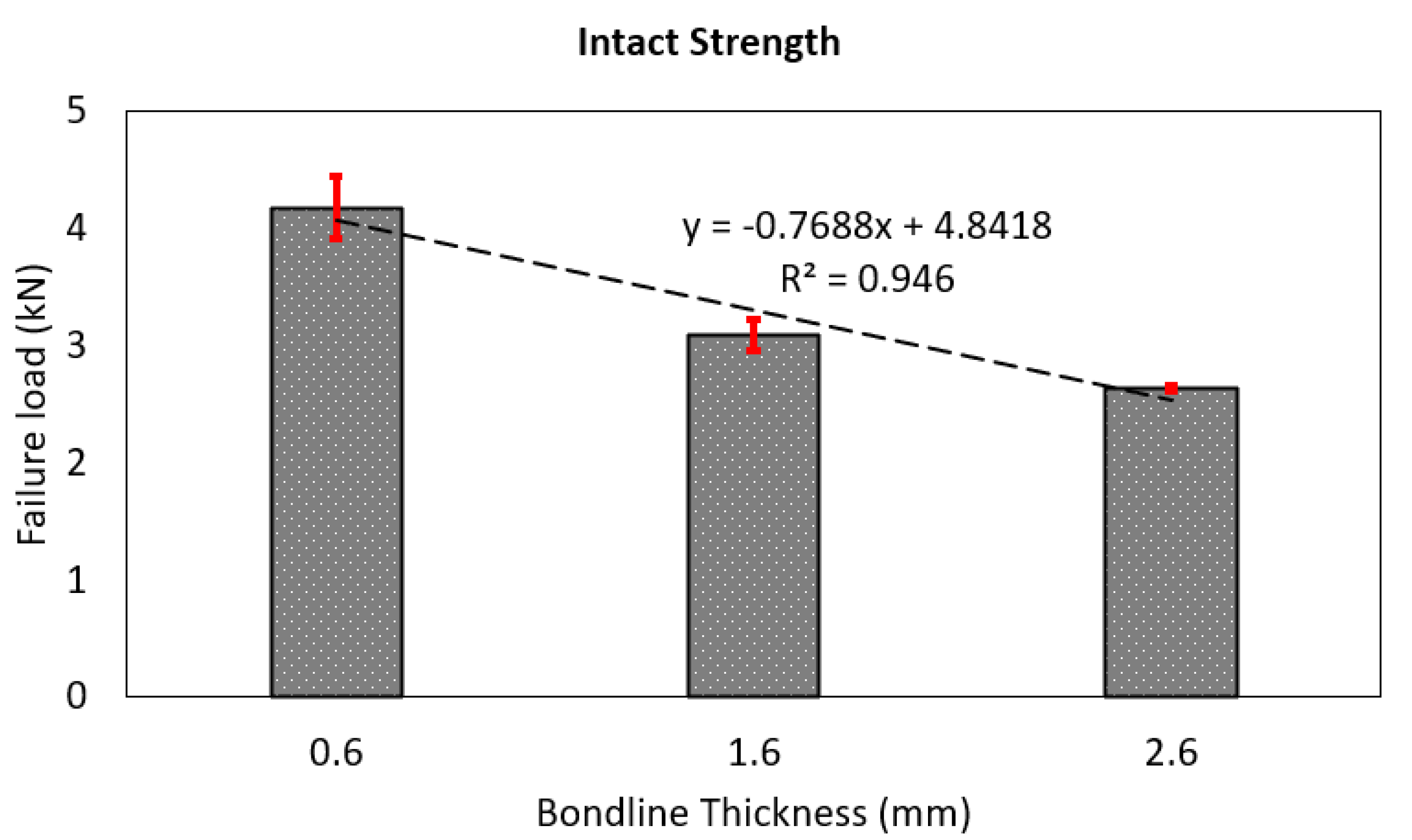

4.1. Assessment of Intact Failure Loads of Adhesive Joints with Different Bondline Thicknesses

4.2. Impact Damage Assessment and Impact Kinematics

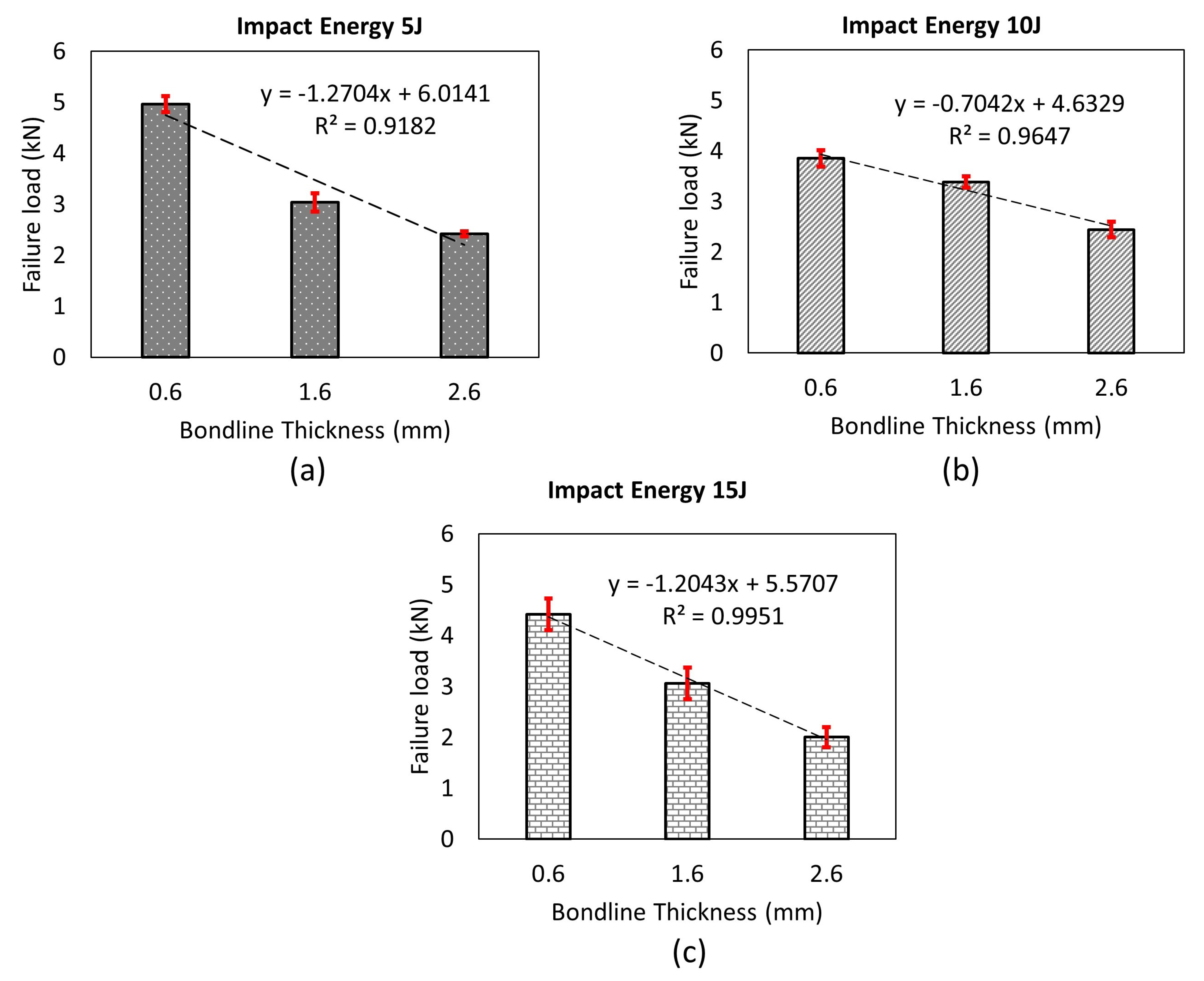

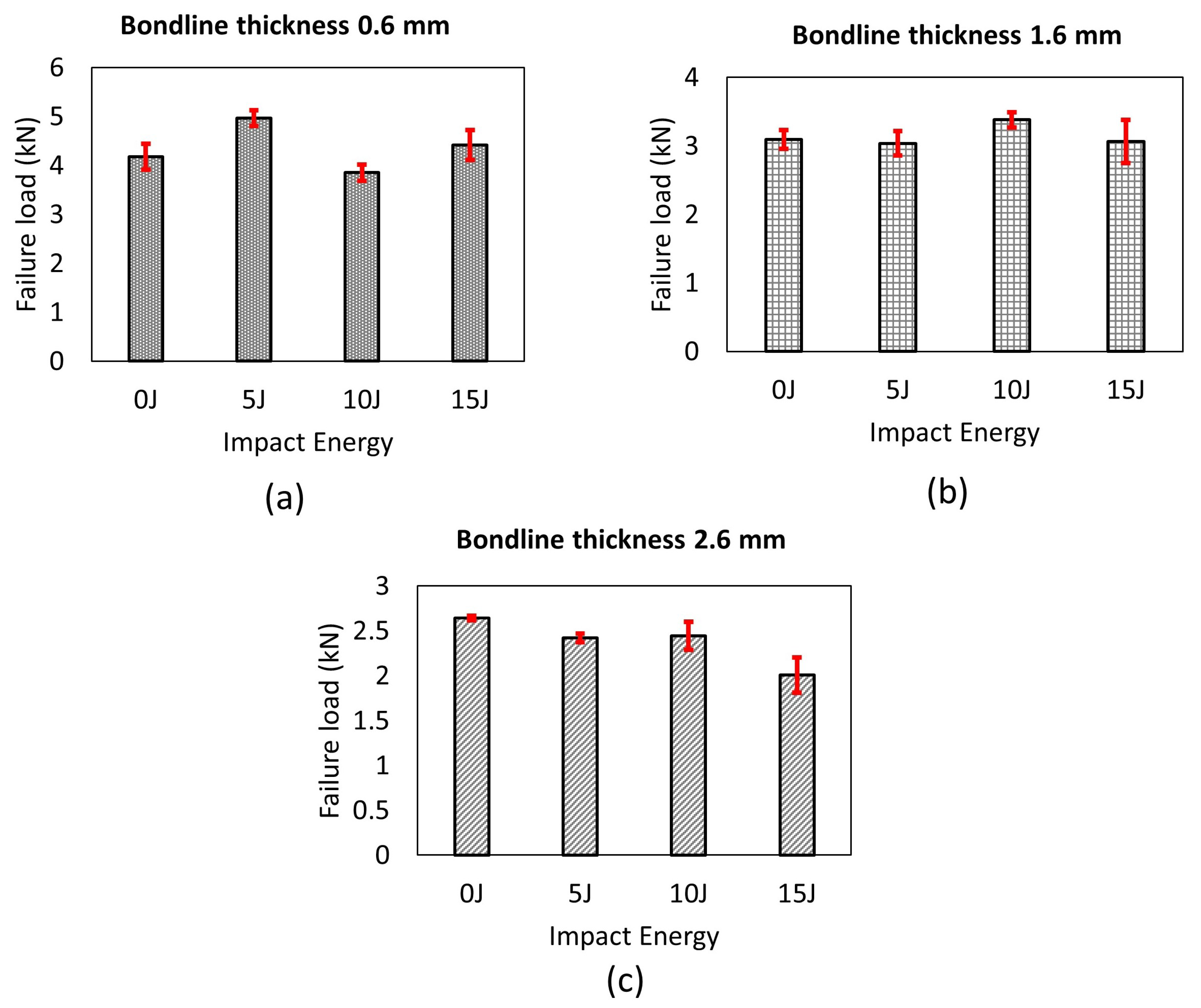

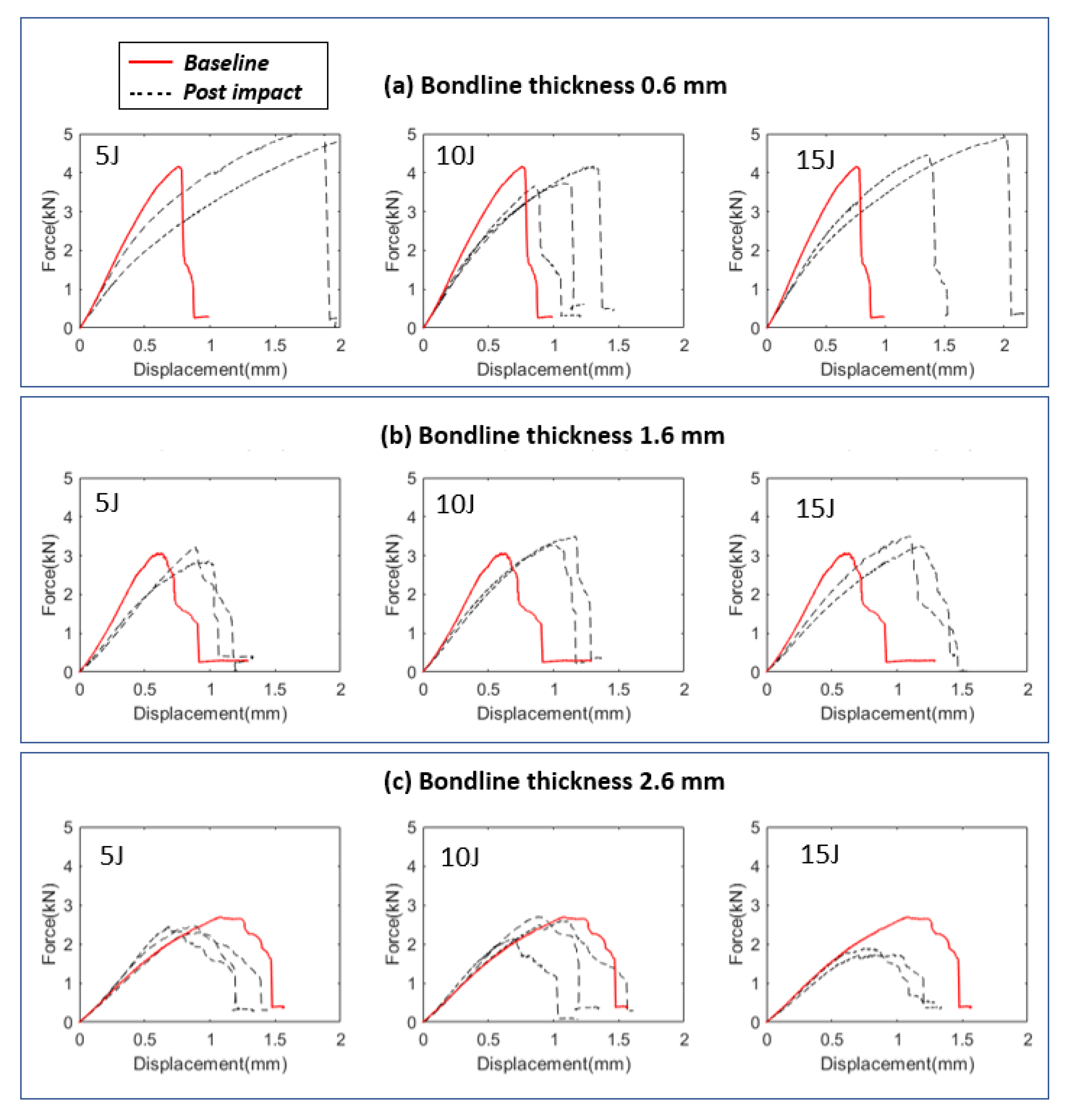

4.3. Damage Tolerance Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Acero, W.I.G. Assessment of Marine Operations for Offshore Wind Turbine Installation with Emphasis on Response-Based Operational Limits. Ph.D. Thesis, Norwegian University of Science and Technology (NTNU), Trondheim, Norway, 2016. [Google Scholar]

- Verma, A.S.; Vedvik, N.P.; Gao, Z. A comprehensive numerical investigation of the impact behaviour of an offshore wind turbine blade due to impact loads during installation. Ocean Eng. 2019, 172, 127–145. [Google Scholar] [CrossRef] [Green Version]

- Verma, A.S.; Jiang, Z.; Vedvik, N.P.; Gao, Z.; Ren, Z. Impact assessment of a wind turbine blade root during an offshore mating process. Eng. Struct. 2019, 180, 205–222. [Google Scholar] [CrossRef]

- Verma, A.S.; Zhao, Y.; Vedvik, N.P.; Gao, Z. Explicit structural response-based methodology for assessment of operational limits for single blade installation for offshore wind turbines. In Proceedings of the Fourth International Conference in Ocean Engineering (ICOE2018); Springer: Singapore, 2018. [Google Scholar]

- Ad-liftra—Own Work, CC BY-SA 3.0. Available online: https://commons.wikimedia.org/w/index.php?curid=23253956 (accessed on 11 October 2021).

- Pinto, T.H.L.; Gul, W.; Torres, L.A.G.; Cimini, C.A.; Ha, S.K. Experimental and Numerical Comparison of Impact Behavior between Thermoplastic and Thermoset Composite for Wind Turbine Blades. Materials 2021, 14, 6377. [Google Scholar] [CrossRef]

- Verma, A.S.; Haselbach, P.U.; Vedvik, N.P.; Gao, Z. A global-local damage assessment methodology for impact damage on offshore wind turbine blades during lifting operations. In Proceedings of the ASME 2018 37th International Conference on Ocean, Offshore and Arctic Engineering, Madrid, Spain, 17–22 June 2018; p. V010T09A064. [Google Scholar]

- Hunter-Alarcon, R.; Leyrer, J.; Leal, E.; Vizan, A.; Perez, J.; da Silva, L. Influence of dissimilar composite adherends on the mechanical adhesion of bonded joints for small blade wind turbine applications. Int. J. Adhes. Adhes. 2018, 83, 178–183. [Google Scholar] [CrossRef]

- Verma, A.S.; Vedvik, N.P.; Haselbach, P.U.; Gao, Z.; Jiang, Z. Comparison of numerical modelling techniques for impact investigation on a wind turbine blade. Compos. Struct. 2019, 209, 856–878. [Google Scholar] [CrossRef]

- Subrahmanian, K.; Dubouloz, F. Adhesives for bonding wind turbine blades. Reinf. Plast. 2009, 53, 26–29. [Google Scholar] [CrossRef]

- Jørgensen, J.B. Adhesive Joints in Wind Turbine Blades. Ph.D Thesis, DTU Wind Energy, Roskilde, Denmark, 2017. [Google Scholar]

- Perillo, G.; Jørgensen, J.K.; Cristiano, R.; Riccio, A. A Numerical/Experimental Study on the Impact and CAI Behaviour of Glass Reinforced Compsite Plates. Appl. Compos. Mater. 2018, 25, 425–447. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, K.K.; Sarkar, P. Impact damage on fibre-reinforced polymer matrix composite–a review. J. Compos. Mater. 2014, 48, 317–332. [Google Scholar] [CrossRef]

- Nanami, N.; Ochoa, O. Bird impact study of a preloaded composite wind turbine blade. Energy 2013, 15, 2. [Google Scholar]

- Keegan, M.H.; Nash, D.; Stack, M. Numerical Modelling of Hailstone Impact on the Leading Edge of a Wind Turbine Blade. Available online: https://strathprints.strath.ac.uk/42830/1/Nash_DH_Stack_MM_Pure_Numerical_modelling_of_hailstone_impact_on_the_leading_edge_of_a_wind_turbine_blade_Feb_2013.pdf (accessed on 11 October 2021).

- Verma, A.S.; Castro, S.G.; Jiang, Z.; Teuwen, J.J. Numerical investigation of rain droplet impact on offshore wind turbine blades under different rainfall conditions: A parametric study. Compos. Struct. 2020, 241, 112096. [Google Scholar] [CrossRef]

- Verma, A.S.; Jiang, Z.; Ren, Z.; Gao, Z.; Vedvik, N.P. Effects of wind-wave misalignment on a wind turbine blade mating process. J. Mar. Sci. Appl. 2020, 19, 218–233. [Google Scholar] [CrossRef]

- Boudounit, H.; Tarfaoui, M.; Saifaoui, D.; Qureshi, Y. Parametric Study of Accidental Impacts on an Offshore Wind Turbine Composite Blade. J. Bio-Tribo-Corros. 2021, 7, 1–21. [Google Scholar] [CrossRef]

- Haselbach, P.; Bitsche, R.; Branner, K. The effect of delaminations on local buckling in wind turbine blades. Renew. Energy 2016, 85, 295–305. [Google Scholar] [CrossRef]

- Nielsen, J.S.; Sørensen, J.D. Bayesian estimation of remaining useful life for wind turbine blades. Energies 2017, 10, 664. [Google Scholar] [CrossRef] [Green Version]

- Valeti, B.; Pakzad, S.N. Estimation of remaining useful life of a fatigue damaged wind turbine blade with particle filters. In Dynamics of Civil Structures; Springer: Berlin/Heidelberg, Germany, 2019; Volume 2, pp. 319–328. [Google Scholar]

- Sellitto, A.; Russo, A.; Riccio, A.; Damiano, M. Fibreglass wind turbine blades: Damage tolerant design and verification. AIP Conf. Proc. 2020, 2309, 020032. [Google Scholar]

- Chen, X.; Semenov, S.; McGugan, M.; Madsen, S.H.; Yeniceli, S.C.; Berring, P.; Branner, K. Fatigue testing of a 14.3 m composite blade embedded with artificial defects–damage growth and structural health monitoring. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106189. [Google Scholar] [CrossRef]

- Li, J.; Wang, J.; Zhang, L.; Huang, X.; Yu, Y. Study on the Effect of Different Delamination Defects on Buckling Behavior of Spar Cap in Wind Turbine Blade. Adv. Mater. Sci. Eng. 2020, 2020, 6979636. [Google Scholar] [CrossRef]

- Standard Test method for compressive residual strength properties of damaged polymer matrix composite plates. In Annual Book of ASTM Standards; ASTM D7137; ASTM: West Conshohocken, PA, USA, 2012.

- BOEING, B. 7260: Advanced Composite Compression Test; The Boeing Company: Seattle, WA, USA, 1988. [Google Scholar]

- Li, N.; Chen, P. Experimental investigation on edge impact damage and Compression-After-Impact (CAI) behavior of stiffened composite panels. Compos. Struct. 2016, 138, 134–150. [Google Scholar] [CrossRef]

- Greenhalgh, E.; Meeks, C.; Clarke, A.; Thatcher, J. The effect of defects on the performance of post-buckled CFRP stringer-stiffened panels. Compos. Part A Appl. Sci. Manuf. 2003, 34, 623–633. [Google Scholar] [CrossRef]

- Dávila, C.G.; Bisagni, C. Fatigue life and damage tolerance of postbuckled composite stiffened structures with indentation damage. J. Compos. Mater. 2018, 52, 931–943. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kubiak, T.; Borkowski, L.; Wiacek, N. Experimental investigations of impact damage influence on behavior of thin-walled composite beam subjected to pure bending. Materials 2019, 12, 1127. [Google Scholar] [CrossRef] [Green Version]

- Kubiak, T.; Gliszczynski, A.; Krygier, M. Impact damage tolerance of laminate short columns subjected to uniform compression–Experimental investigation. Compos. Struct. 2019, 226, 111222. [Google Scholar] [CrossRef]

- Rozylo, P.; Debski, H.; Kubiak, T. A model of low-velocity impact damage of composite plates subjected to Compression-After-Impact (CAI) testing. Compos. Struct. 2017, 181, 158–170. [Google Scholar] [CrossRef]

- Gliszczynski, A.; Bogenfeld, R.; Degenhardt, R.; Kubiak, T. Corner impact and compression after impact (CAI) of thin-walled composite profile–An experimental study. Compos. Struct. 2020, 248, 112502. [Google Scholar] [CrossRef]

- Sayer, F.; Antoniou, A.; van Wingerde, A. Investigation of structural bond lines in wind turbine blades by sub-component tests. Int. J. Adhes. Adhes. 2012, 37, 129–135. [Google Scholar] [CrossRef]

- Ji, Y.M.; Han, K. Fracture mechanics approach for failure of adhesive joints in wind turbine blades. Renew. Energy 2014, 65, 23–28. [Google Scholar] [CrossRef]

- Jensen, F.; Falzon, B.; Ankersen, J.; Stang, H. Structural testing and numerical simulation of a 34 m composite wind turbine blade. Compos. Struct. 2006, 76, 52–61. [Google Scholar] [CrossRef]

- Yang, J.; Peng, C.; Xiao, J.; Zeng, J.; Xing, S.; Jin, J.; Deng, H. Structural investigation of composite wind turbine blade considering structural collapse in full-scale static tests. Compos. Struct. 2013, 97, 15–29. [Google Scholar] [CrossRef]

- Veritas, D.N. Design and Manufacture of Wind Turbine Blades, Offshore and Onshore Wind Turbines; DNV Standard DNV-DS-J102. Available online: https://rules.dnv.com/docs/pdf/dnvpm/codes/docs/2010-11/DS-J102.pdf (accessed on 11 October 2021).

- Budhe, S.; Banea, M.; De Barros, S.; Da Silva, L. An updated review of adhesively bonded joints in composite materials. Int. J. Adhes. Adhes. 2017, 72, 30–42. [Google Scholar] [CrossRef]

- Machado, J.; Marques, E.; da Silva, L.F. Adhesives and adhesive joints under impact loadings: An overview. J. Adhes. 2018, 94, 421–452. [Google Scholar] [CrossRef]

- Redmann, A.; Damodaran, V.; Tischer, F.; Prabhakar, P.; Osswald, T.A. Evaluation of Single-Lap and Block Shear Test Methods in Adhesively Bonded Composite Joints. J. Compos. Sci. 2021, 5, 27. [Google Scholar] [CrossRef]

- Attaf, B. Ecobonding of composite wind turbine blade structural parts using eco-friendly adhesives. Adv. Mater. Sci. Appl. (AMSA) 2013, 3, 31–37. [Google Scholar] [CrossRef]

- Droubi, M.; Fosbrooke, C.; McConnachie, J.; Faisal, N. Indentation based strength analysis of adhesively bonded leading-edge composite joints in wind turbine blades. SN Appl. Sci. 2019, 1, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Avendaño, R.; Carbas, R.; Chaves, F.; Costa, M.; da Silva, L.; Fernandes, A. Impact loading of single lap joints of dissimilar lightweight adherends bonded with a crash-resistant epoxy adhesive. J. Eng. Mater. Technol. 2016, 138, 041019. [Google Scholar] [CrossRef]

- Varajão, J.F.D. Impact of CFRP Adhesive Joints for the Automotive Industry. 2015. Available online: https://repositorio-aberto.up.pt/bitstream/10216/79488/2/35651.pdf (accessed on 11 October 2021).

- Machado, J.; Nunes, P.; Marques, E.; da Silva, L.F. Adhesive joints using aluminium and CFRP substrates tested at low and high temperatures under quasi-static and impact conditions for the automotive industry. Compos. Part B Eng. 2019, 158, 102–116. [Google Scholar] [CrossRef]

- Silva, M.; Marques, E.; Silva, L. Behaviour under impact of mixed adhesive joints for the automotive industry. Lat. Am. J. Solids Struct. 2016, 13, 835–853. [Google Scholar] [CrossRef] [Green Version]

- Higuchi, I.; Sawa, T.; Suga, H. Three-dimensional finite element analysis of single-lap adhesive joints under impact loads. J. Adhes. Sci. Technol. 2002, 16, 1585–1601. [Google Scholar] [CrossRef]

- Liao, L.; Kobayashi, T.; Sawa, T.; Goda, Y. 3-D FEM stress analysis and strength evaluation of single-lap adhesive joints subjected to impact tensile loads. Int. J. Adhes. Adhes. 2011, 31, 612–619. [Google Scholar] [CrossRef]

- Liao, L.; Sawa, T.; Huang, C. Experimental and FEM studies on mechanical properties of single-lap adhesive joint with dissimilar adherends subjected to impact tensile loadings. Int. J. Adhes. Adhes. 2013, 44, 91–98. [Google Scholar] [CrossRef] [Green Version]

- Vaidya, U.K.; Gautam, A.R.; Hosur, M.; Dutta, P. Experimental–numerical studies of transverse impact response of adhesively bonded lap joints in composite structures. Int. J. Adhes. Adhes. 2006, 26, 184–198. [Google Scholar] [CrossRef]

- Kim, H.; Kayir, T.; Mousseau, S.L. Mechanisms of damage formation in transversely impacted glass-epoxy bonded lap joints. J. Compos. Mater. 2005, 39, 2039–2052. [Google Scholar] [CrossRef]

- Choudhry, R.S.; Hassan, S.F.; Li, S.; Day, R. Damage in single lap joints of woven fabric reinforced polymeric composites subjected to transverse impact loading. Int. J. Impact Eng. 2015, 80, 76–93. [Google Scholar] [CrossRef] [Green Version]

- Galliot, C.; Rousseau, J.; Verchery, G. Drop weight tensile impact testing of adhesively bonded carbon/epoxy laminate joints. Int. J. Adhes. Adhes. 2012, 35, 68–75. [Google Scholar] [CrossRef]

- Boling, H.; Dongyun, G. Dynamic analysis of single-lap, adhesively bonded composite-titanium joints subjected to solid projectile impact. J. Adhes. Sci. Technol. 2018, 32, 1176–1199. [Google Scholar] [CrossRef]

- Akderya, T.; Kemiklioğlu, U.; Sayman, O. Effects of thermal ageing and impact loading on tensile properties of adhesively bonded fibre/epoxy composite joints. Compos. Part B Eng. 2016, 95, 117–122. [Google Scholar] [CrossRef]

- Sayman, O.; Arikan, V.; Dogan, A.; Soykok, I.F.; Dogan, T. Failure analysis of adhesively bonded composite joints under transverse impact and different temperatures. Compos. Part B Eng. 2013, 54, 409–414. [Google Scholar] [CrossRef]

- Hu, C.; Huang, G.; Li, C. Experimental and Numerical Study of Low-Velocity Impact and Tensile after Impact for CFRP Laminates Single-Lap Joints Adhesively Bonded Structure. Materials 2021, 14, 1016. [Google Scholar] [CrossRef]

- Machado, J.; Gamarra, P.R.; Marques, E.; da Silva, L.F. Improvement in impact strength of composite joints for the automotive industry. Compos. Part B Eng. 2018, 138, 243–255. [Google Scholar] [CrossRef]

- Bak, C.; Zahle, F.; Bitsche, R.; Kim, T.; Yde, A.; Henriksen, L.C.; Hansen, M.H.; Natarajan, A. Description of the DTU 10 MW Reference Wind Turbine; Progress Report-I-0092, DTU Wind Energy; DTU Library: Kongens Lyngby, Denmark, 2013. [Google Scholar]

- Araldite 2015-1 Structural Adhesives Data Sheet. Available online: http://www.huntsman.com (accessed on 20 October 2021).

- Standard, A. D1002-01, 2001. In Standard Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension Loading (Metal-to-Metal); ASTM International: West Conshohocken, PA, USA, 2001. [Google Scholar]

- Standard, A. ASTM D2093-03. In Standard Practice for Preparation of Surfaces of Plastics Prior to Adhesive Bonding; ASTM International: West Conshohocken, PA, USA, 2003; Volume 3. [Google Scholar]

- Bosch Rexroth AG Strut Profiles and Connections. Available online: https://www.boschrexroth.com/en/xc/products/product-groups/assembly-technology/topics/aluminum-profiles-solutions-components/aluminum-profiles-products/connections/index (accessed on 6 October 2021).

- Hibbeler, R.C. Engineering Mechanics: Dynamics; Pearson Educación: London, UK, 2004. [Google Scholar]

- Sandeep, C.S.; Senetakis, K.; Cheung, D.; Choi, C.E.; Wang, Y.; Coop, M.; Ng, C.W.W. Experimental study on the coefficient of restitution of grain against block interfaces for natural and engineered materials. Can. Geotech. J. 2021, 58, 35–48. [Google Scholar] [CrossRef]

- Skórski, W.W.; Obszański, M.; Zawisza, M. Experimental Determination of the Coefficient of Restitution for Selected Modern Hybrid Composites. Materials 2021, 14, 5638. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Li, J.; Wang, B.; Liao, Y. Experimental-numerical analysis of failure of adhesively bonded lap joints under transverse impact and different temperatures. Int. J. Impact Eng. 2020, 140, 103541. [Google Scholar] [CrossRef]

- Abràmoff, M.D.; Magalhães, P.J.; Ram, S.J. Image processing with ImageJ. Biophotonics Int. 2004, 11, 36–42. [Google Scholar]

- Kumar, A.; Ghosh, P.; Yadav, K.; Kumar, K. Thermo-mechanical and anti-corrosive properties of MWCNT/epoxy nanocomposite fabricated by innovative dispersion technique. Compos. Part B Eng. 2017, 113, 291–299. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, K.; Ghosh, P.; Rathi, A.; Yadav, K. MWCNTs toward superior strength of epoxy adhesive joint on mild steel adherent. Compos. Part B Eng. 2018, 143, 207–216. [Google Scholar] [CrossRef]

- Azari, S.; Papini, M.; Spelt, J. Effect of adhesive thickness on fatigue and fracture of toughened epoxy joints–Part I: Experiments. Eng. Fract. Mech. 2011, 78, 153–162. [Google Scholar] [CrossRef]

- Bortz, D.R.; Heras, E.G.; Martin-Gullon, I. Impressive fatigue life and fracture toughness improvements in graphene oxide/epoxy composites. Macromolecules 2012, 45, 238–245. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Verma, A.S.; Vedvik, N.P.; Gao, Z.; Castro, S.G.P.; Teuwen, J.J.E. Bondline Thickness Effects on Damage Tolerance of Adhesive Joints Subjected to Localized Impact Damages: Application to Leading Edge of Wind Turbine Blades. Materials 2021, 14, 7526. https://doi.org/10.3390/ma14247526

Verma AS, Vedvik NP, Gao Z, Castro SGP, Teuwen JJE. Bondline Thickness Effects on Damage Tolerance of Adhesive Joints Subjected to Localized Impact Damages: Application to Leading Edge of Wind Turbine Blades. Materials. 2021; 14(24):7526. https://doi.org/10.3390/ma14247526

Chicago/Turabian StyleVerma, Amrit Shankar, Nils Petter Vedvik, Zhen Gao, Saullo G. P. Castro, and Julie J. E. Teuwen. 2021. "Bondline Thickness Effects on Damage Tolerance of Adhesive Joints Subjected to Localized Impact Damages: Application to Leading Edge of Wind Turbine Blades" Materials 14, no. 24: 7526. https://doi.org/10.3390/ma14247526

APA StyleVerma, A. S., Vedvik, N. P., Gao, Z., Castro, S. G. P., & Teuwen, J. J. E. (2021). Bondline Thickness Effects on Damage Tolerance of Adhesive Joints Subjected to Localized Impact Damages: Application to Leading Edge of Wind Turbine Blades. Materials, 14(24), 7526. https://doi.org/10.3390/ma14247526