Microstructure and Fatigue Damage of 316L Stainless Steel Manufactured by Selective Laser Melting (SLM)

Abstract

:1. Introduction

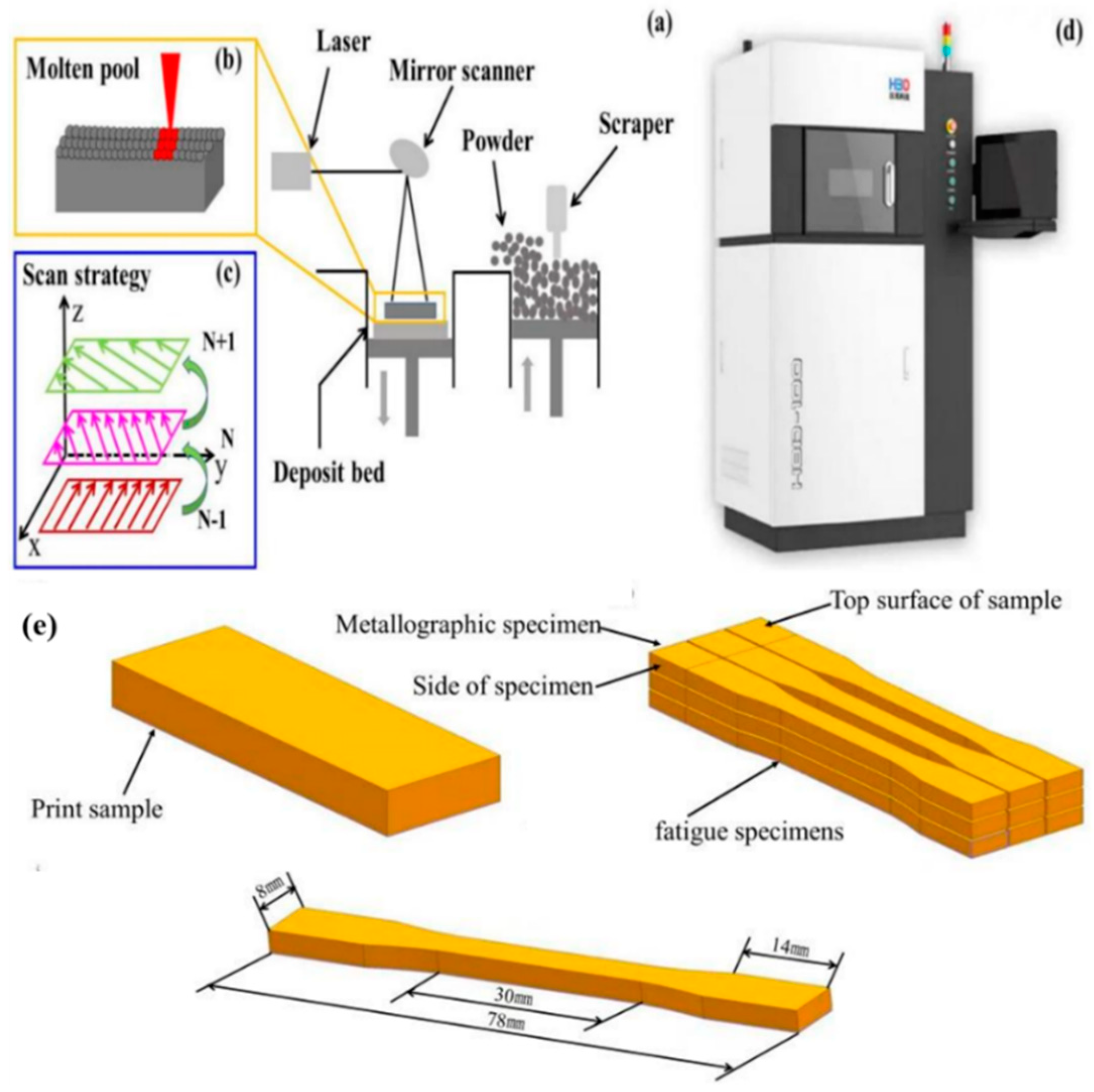

2. Test Materials and Methods

3. Results and Discussion

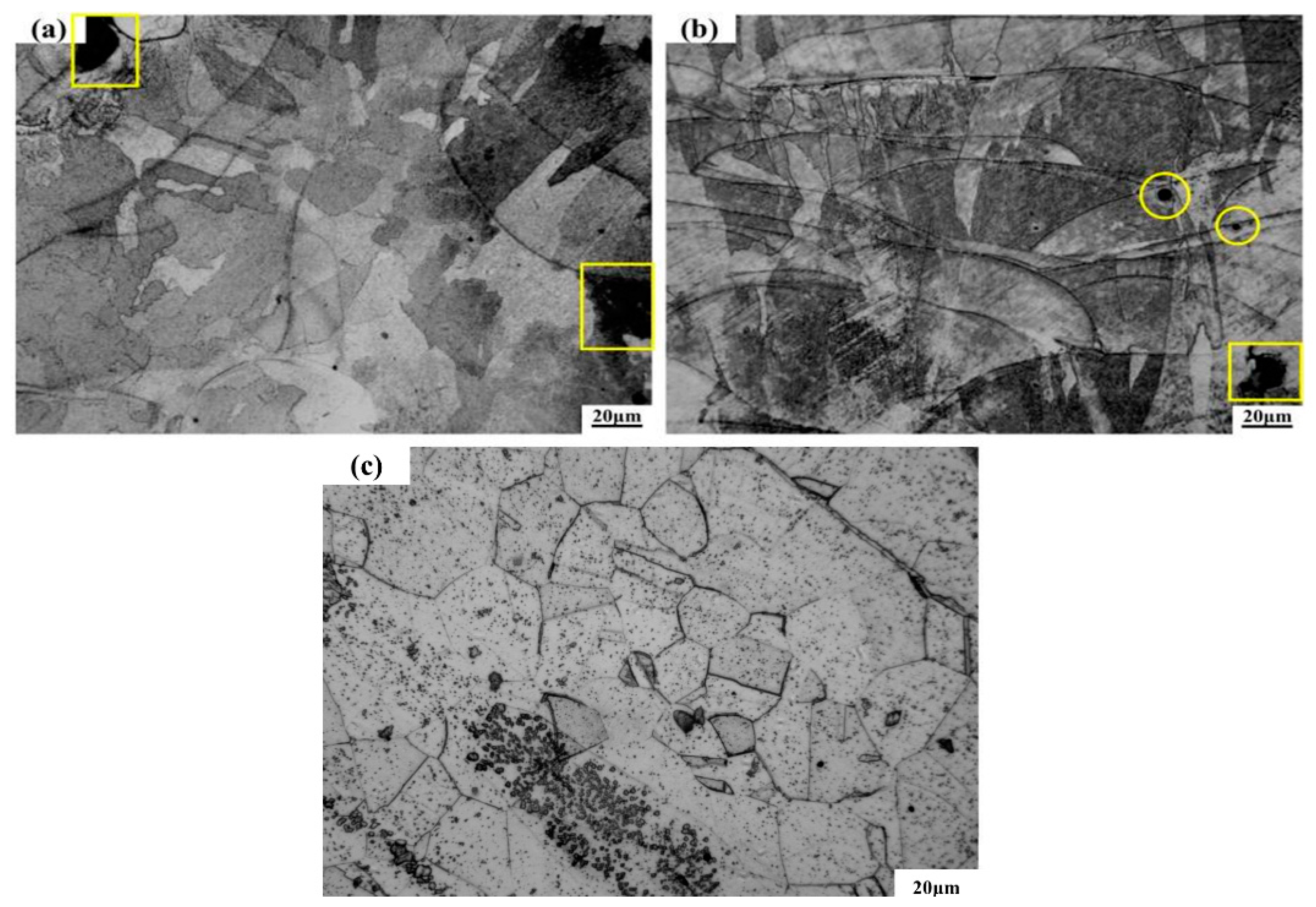

3.1. Microstructure and Defect Analysis

3.2. Fatigue Test Analysis

3.3. Surface Fatigue Damage Analysis

4. Discuss

4.1. Fatigue Crack Initiation Mechanism

4.2. Characteristics of Fatigue Crack Growth

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Song, Y.; Sun, Q.; Guo, K.; Wang, X.; Sun, J. Effect of scanning strategies on the microstructure and mechanical behavior of 316L stainless steel fabricated by selective laser melting. Mater. Sci. Eng. A 2020, 793, 139879. [Google Scholar] [CrossRef]

- Zhao, X.; Wei, Q.S.; Gao, N.; Zheng, E.L.; Shi, Y.S.; Yang, S.F. Rapid fabrication of TiN/AISI 420 stainless steel composite by selective laser melting additive manufacturing. J. Mater. Process. Technol. 2019, 270, 8–19. [Google Scholar] [CrossRef]

- Jeon, J.M.; Park, J.M.; Yu, J.H.; Kim, J.G.; Seong, Y.; Park, S.H.; Kim, H.S. Effects of microstructure and internal defects on mechanical anisotropy and asymmetry of selective laser-melted 316L austenitic stainless steel. Mater. Sci. Eng. A 2019, 763, 138152. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 2018, 17, 63–71. [Google Scholar] [CrossRef] [Green Version]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Mechanical behavior of selective laser melted 316L stainless steel. Mater. Sci. Eng. A 2017, 696, 113–121. [Google Scholar] [CrossRef]

- Huang, Y.B.; Yang, S.L.; Gu, J.X.; Xiong, Q.; Duan, C.; Meng, X.; Fang, Y. Microstructure and wear properties of selective laser melting 316L. Mater. Chem. Phys. 2020, 254, 123487. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.; Vedani, M. Microstructure and Fracture Behavior of 316L Austenitic Stainless Steel Produced by Selective Laser Melting. J. Mater. Sci. Technol. 2016, 32, 738–744. [Google Scholar] [CrossRef]

- Shang, Y.T.; Yuan, Y.P.; Li, D.F.; Li, Y.; Chen, J. Effects of scanning speed on in vitro biocompatibility of 316L stainless steel parts elaborated by selective laser melting. Int. J. Adv. Manuf. Technol. 2017, 92, 4379–4385. [Google Scholar] [CrossRef]

- Antony, K.; Arivazhagan, N.; Senthilkumaran, K. Numerical and experimental investigations on laser melting of stainless steel 316L metal powders. J. Manuf. Process. 2014, 16, 345–355. [Google Scholar] [CrossRef]

- Santos, E.C.; Shiomi, M.; Osakada, K.; Laoui, T. Rapid manufacturing of metal components by laser forming. Int. J. Mach. Tools Manuf. 2006, 46, 1459–1468. [Google Scholar] [CrossRef]

- Xia, M.J.; Gu, D.D.; Yu, G.Q.; Dai, D.; Chen, H.; Shi, Q. Porosity evolution and its thermodynamic mechanism of randomly packed powder-bed during selective laser melting of Inconel 718 alloy. Int. J. Mach. Tools Manuf. 2017, 116, 96–106. [Google Scholar] [CrossRef]

- Zhang, H.Z.; Xu, M.T.; Liu, Z.D.; Li, C.; Kumar, P.; Liu, Z.; Zhang, Y. Microstructure, surface quality, residual stress, fatigue behavior and damage mechanisms of selective laser melted 304L stainless steel considering building direction. Addit. Manuf. 2021, 46, 102147. [Google Scholar] [CrossRef]

- Qiu, C.L.; Panwisawas, C.; Ward, M.; Basoalto, H.C.; Brooks, J.W.; Attallah, M.M. On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater. 2015, 96, 72–79. [Google Scholar] [CrossRef] [Green Version]

- Kamath, C.; El-Dasher, B.; Gallegos, G.F.; King, W.E.; Sisto, A. Density of additively-manufactured, 316L SS parts using laser powder-bed fusion at powers up to 400W. Int. J. Adv. Manuf. Technol. 2014, 74, 65–78. [Google Scholar] [CrossRef] [Green Version]

- Lima, M.; Sankare, S. Microstructure and mechanical behavior of laser additive manufactured AISI 316 stainless steel stringers. Mater. Des. 2014, 55, 526–532. [Google Scholar] [CrossRef]

- Hanzl, P.; Zetek, M.; Baksa, T.; Kroupa, T. The Influence of Processing Parameters on the Mechanical Properties of SLM Parts. Procedia Eng. 2015, 100, 1405–1413. [Google Scholar] [CrossRef] [Green Version]

- Uhlmann, E.; Fleck, C.; Gerlitzky, G.; Faltin, F. Dynamical Fatigue Behavior of Additive Manufactured Products for a Fundamental Life Cycle Approach. Procedia CIRP 2017, 61, 588–593. [Google Scholar] [CrossRef]

- Zhang, C.; Cao, D.; You, W.; Wei, D.; Wu, C.; Yang, G. Fatigue failure of welded details in steel bridge pylons. Eng. Fail. Anal. 2021, 127, 105530. [Google Scholar] [CrossRef]

- Sajith, S.; Shukla, S.S.; Murthy, K.; Robi, P.S. Mixed mode fatigue crack growth studies in AISI 316 stainless steel-ScienceDirect. Eur. J. Mech. A/Solids 2020, 80, 103898. [Google Scholar] [CrossRef]

- He, L.; Akebono, H.; Sugeta, A. Effect of high-amplitude loading on accumulated fatigue damage under variable-amplitude loading in 316 stainless steel. Int. J. Fatigue 2018, 116, 388–395. [Google Scholar] [CrossRef]

- Riemer, A.; Leuders, S.; Thöne, M.; Richard, A.; Tröster, T.; Niendorf, T. On the fatigue crack growth behavior in 316L stainless steel manufactured by selective laser melting. Eng. Fract. Mech. 2014, 120, 15–25. [Google Scholar] [CrossRef]

- Sarkar, S.; Kumar, C.S.; Nath, A.K. Effect of mean stresses on mode of failures and fatigue life of selective laser melted stainless steel. Mater. Sci. Eng. A 2017, 700, 92–106. [Google Scholar] [CrossRef]

- Pegues, J.W.; Roach, M.D.; Shamsaei, N. Additive Manufacturing of Fatigue Resistant Austenitic Stainless Steels by Establishing the Process-Structure-Property Relationships. Mater. Res. Lett. 2020, 8, 8–15. [Google Scholar] [CrossRef] [Green Version]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I.; Johansson, S.; Smurov, I. Energy input effect on morphology and microstructure of selective laser melting single track from metallic powder. J. Mater. Process. Technol. 2013, 213, 606–613. [Google Scholar] [CrossRef]

- Das, S. Physical Aspects of Process Control in Selective Laser Sintering of Metals. Adv. Eng. Mater. 2003, 5, 701–711. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, D.; Liu, X.; Zhang, D.D.; Qu, S.; Ma, J.; London, G.; Shen, Z.; Liu, W. 3D-imaging of selective laser melting defects in a Co-Cr-Mo alloy by synchrotron radiation micro-CT. Acta Mater. 2015, 98, 1–16. [Google Scholar] [CrossRef]

- Phung, N.L.; Favier, V.; Ranc, N.; Vales, F.; Mughrabi, H. Very high cycle fatigue of copper: Evolution, morphology and locations of surface slip markings. Int. J. Fatigue 2014, 63, 68–77. [Google Scholar] [CrossRef] [Green Version]

- Meng, L.X.; Ben, D.D.; Yang, H.J.; Ji, H.B.; Lian, D.L.; Zhu, Y.K.; Chen, J.; Yi, J.L.; Wang, L.; Yang, J.B.; et al. Effects of embedded spherical pore on the tensile properties of a selective laser melted Ti6Al4V alloy. Mater. Sci. Eng. A 2021, 815, 141254. [Google Scholar] [CrossRef]

- Beachem, C.D.; Yoder, G.R. Elastic-plastic fracture by homogeneous microvoid coalescence tearing along alternating shear planes. Metall. Trans. 1973, 4, 1145–1153. [Google Scholar] [CrossRef]

| Composion | Cr | Mn | Ni | Mo | Cu | C | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 316L powder | 16.97 | 0.8 | 12.2 | 2.89 | 0.01 | 0.003 | 0.002 | 0.006 | Bal. |

| Rolled 316L | 16–18 | ≤2.0 | 10–14 | 2.0–3.0 | ---- | ≤0.03 | ≤0.045 | ≤0.03 | Bal. |

| Materials | Scanning Distance (mm) | Laser Power (W) | Scanning Speed (mm/s) | Layer Thickness (μm) | Spot Distance (μm) |

|---|---|---|---|---|---|

| 316L | 0.07 | 160 | 1000 | 30 | 70 |

| Type | Sample No. | Maximum Stress (Smax/Mpa) | Stress Amplitude (Sa/Mpa) | Life Cycle |

|---|---|---|---|---|

| Rolled | B-1 | 460 | 207 | 241,870 |

| Rolled | B-2 | 440 | 198 | 262,350 |

| Rolled | B-3 | 420 | 189 | 354,397 |

| Rolled | B-4 | 400 | 180 | 461,752 |

| Rolled | B-5 | 380 | 171 | 600,691 |

| Rolled | B-6 | 370 | 166.5 | 1,000,000 |

| Rolled | B-7 | 360 | 162 | 1,000,000 |

| SLM | S-1 | 300 | 135 | 421,906 |

| SLM | S-2 | 280 | 126 | 399,303 |

| SLM | S-3 | 260 | 117 | 465,199 |

| SLM | S-4 | 240 | 108 | 454,712 |

| SLM | S-5 | 220 | 99 | 530,287 |

| SLM | S-6 | 210 | 94.5 | 580,493 |

| SLM | S-7 | 200 | 90 | 1,000,000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Yang, S.; Huang, Y.; Fan, C.; Peng, Z.; Gao, Z. Microstructure and Fatigue Damage of 316L Stainless Steel Manufactured by Selective Laser Melting (SLM). Materials 2021, 14, 7544. https://doi.org/10.3390/ma14247544

Wang Z, Yang S, Huang Y, Fan C, Peng Z, Gao Z. Microstructure and Fatigue Damage of 316L Stainless Steel Manufactured by Selective Laser Melting (SLM). Materials. 2021; 14(24):7544. https://doi.org/10.3390/ma14247544

Chicago/Turabian StyleWang, Zhentao, Shanglei Yang, Yubao Huang, Cong Fan, Zeng Peng, and Zihao Gao. 2021. "Microstructure and Fatigue Damage of 316L Stainless Steel Manufactured by Selective Laser Melting (SLM)" Materials 14, no. 24: 7544. https://doi.org/10.3390/ma14247544