Microstructural Evolution, Hardness, and Strengthening Mechanisms in SLM AlSi10Mg Alloy Subjected to Equal-Channel Angular Pressing (ECAP)

Abstract

:1. Introduction

2. Materials and Methods

2.1. SLM Process

2.2. Heat Treatment

- Time—8 min;

- Temperature—300 °C.

2.3. ECAP Process

2.4. Porosity and Microstructural Characterization

- Temperature of polishing solution—30°;

- Polishing solution flow rate = 12;

- Voltage = 20 V.

2.5. Hardness

3. Results

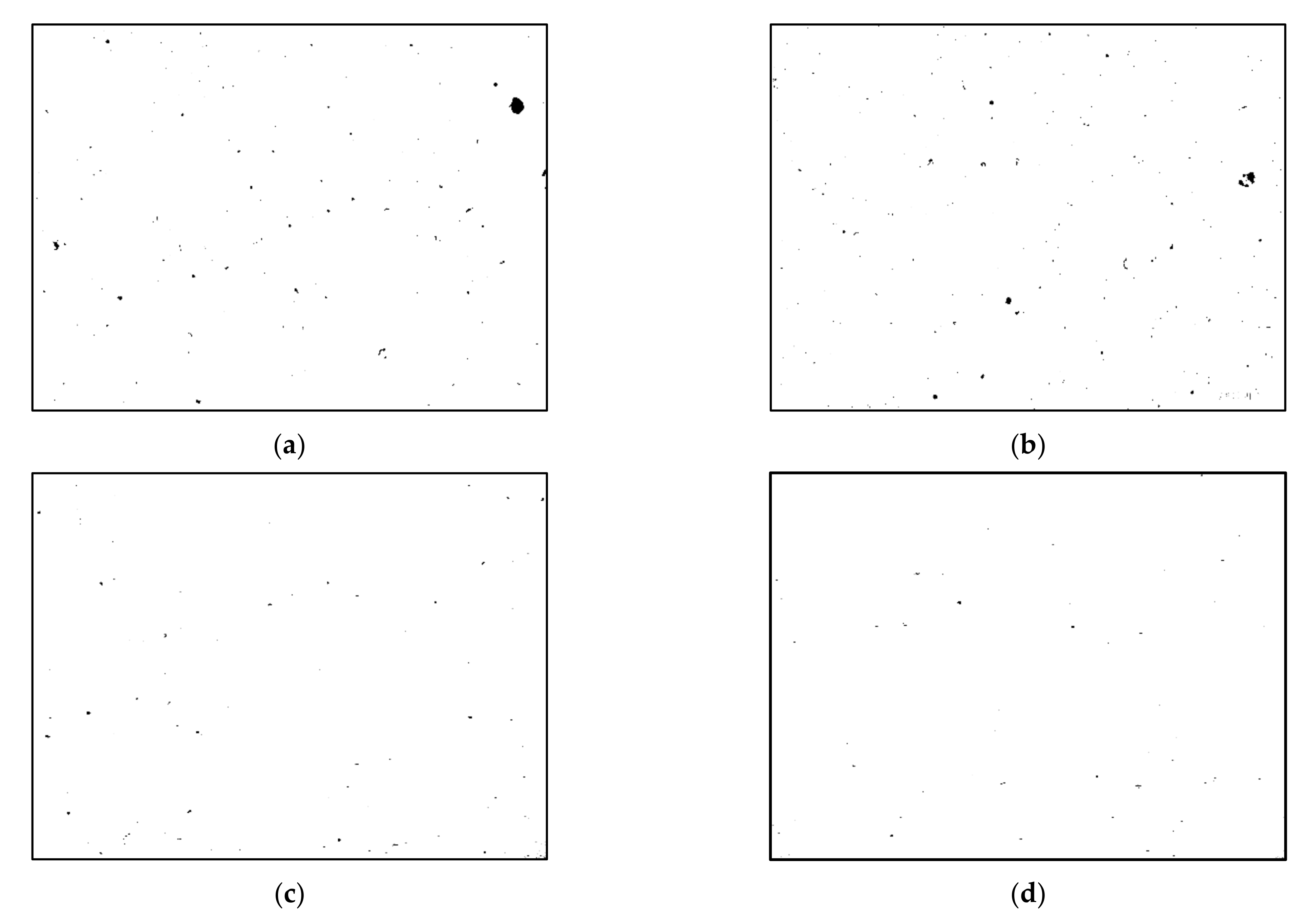

3.1. Effects of Heat Treatment and ECAP on Porosity

3.2. Microstructure

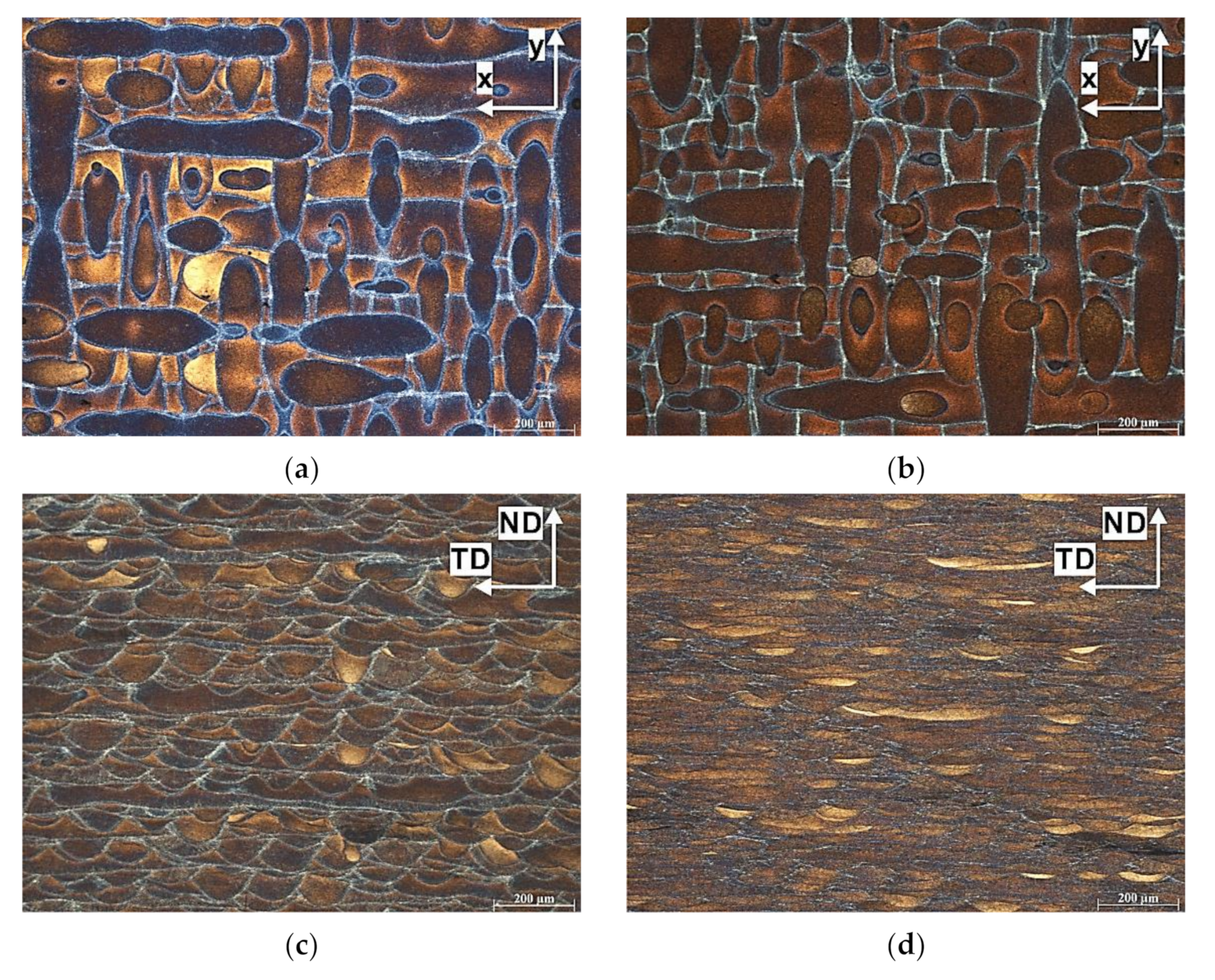

3.2.1. Light Microscopy

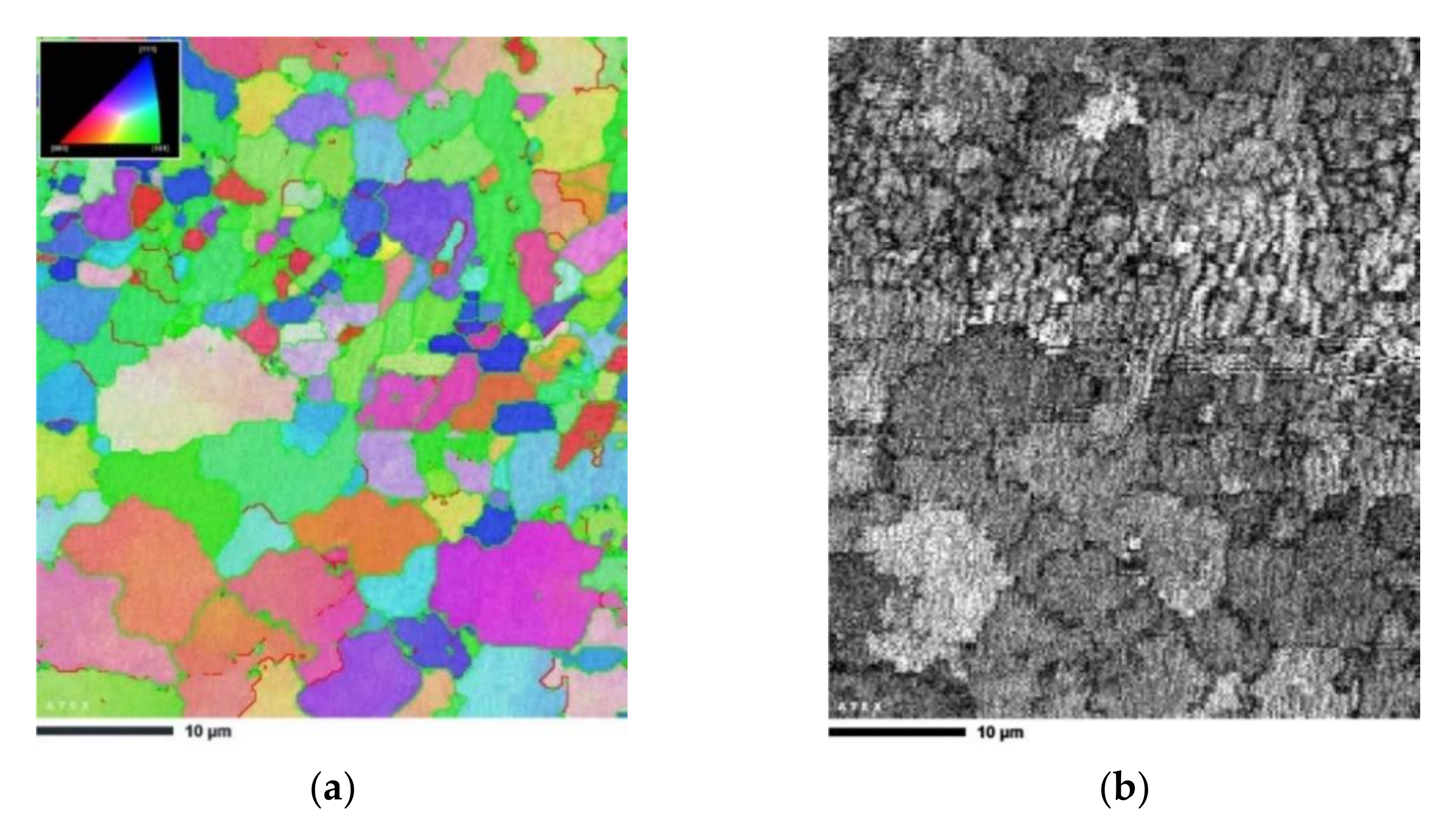

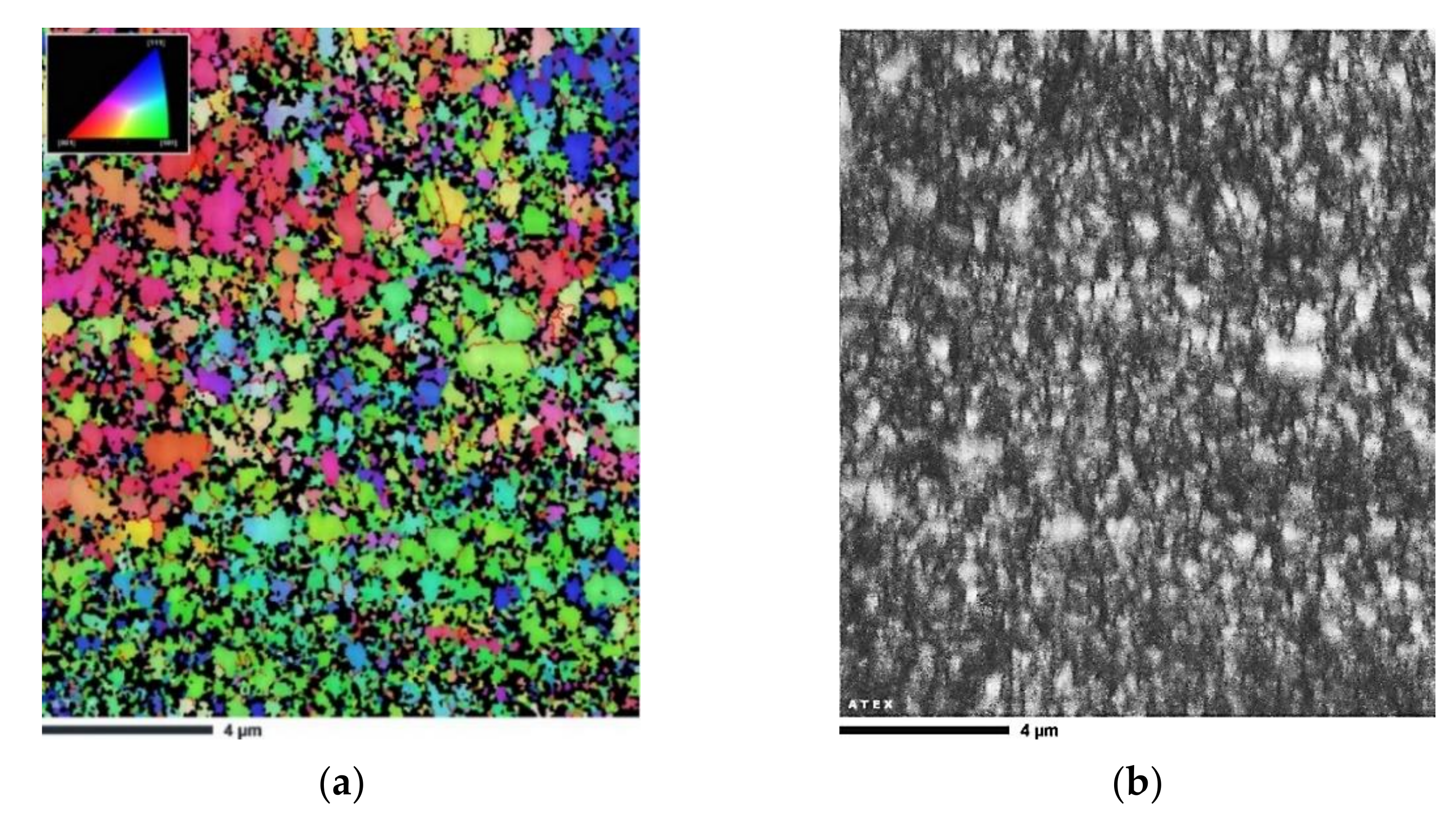

3.2.2. EBSD

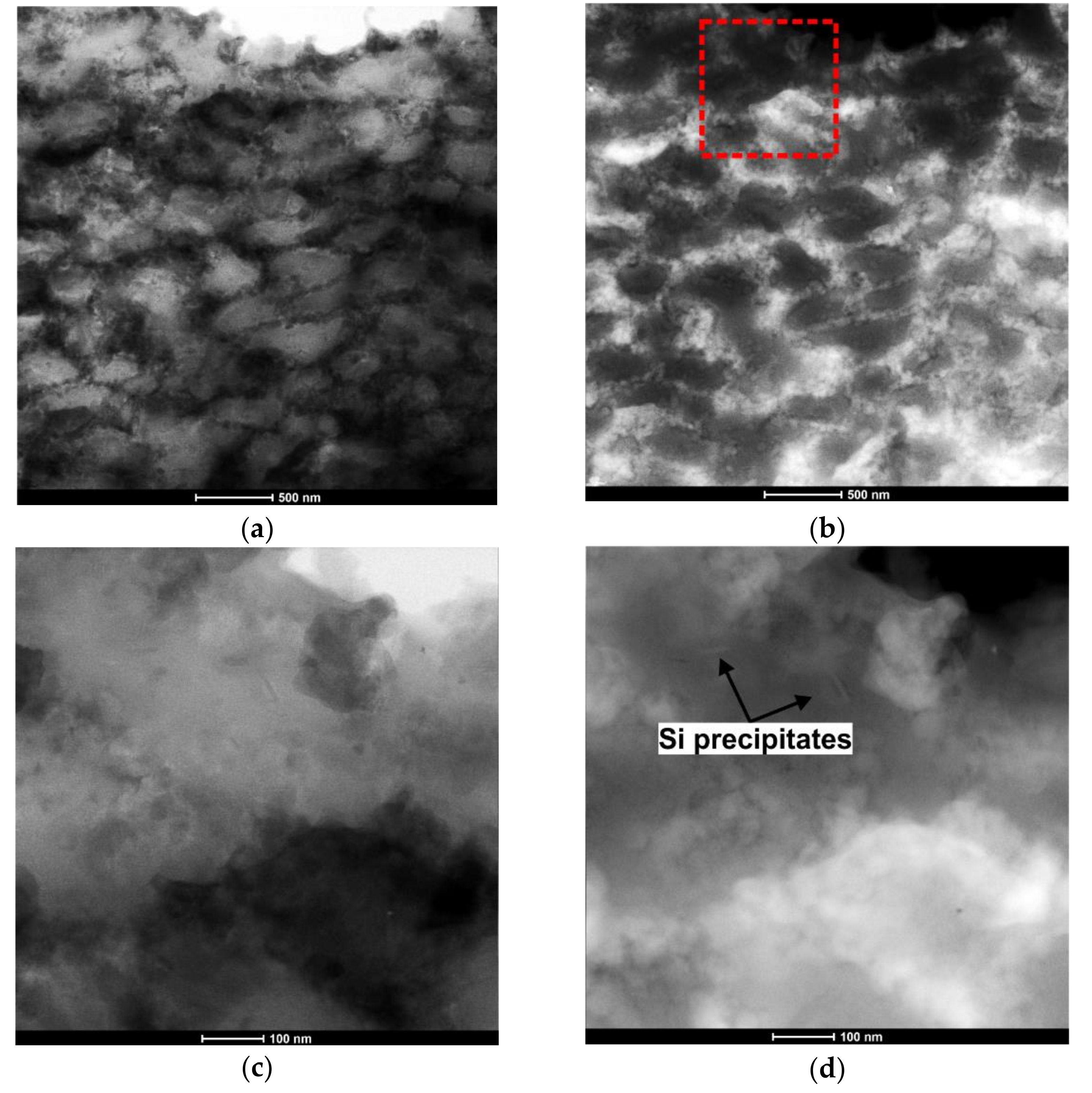

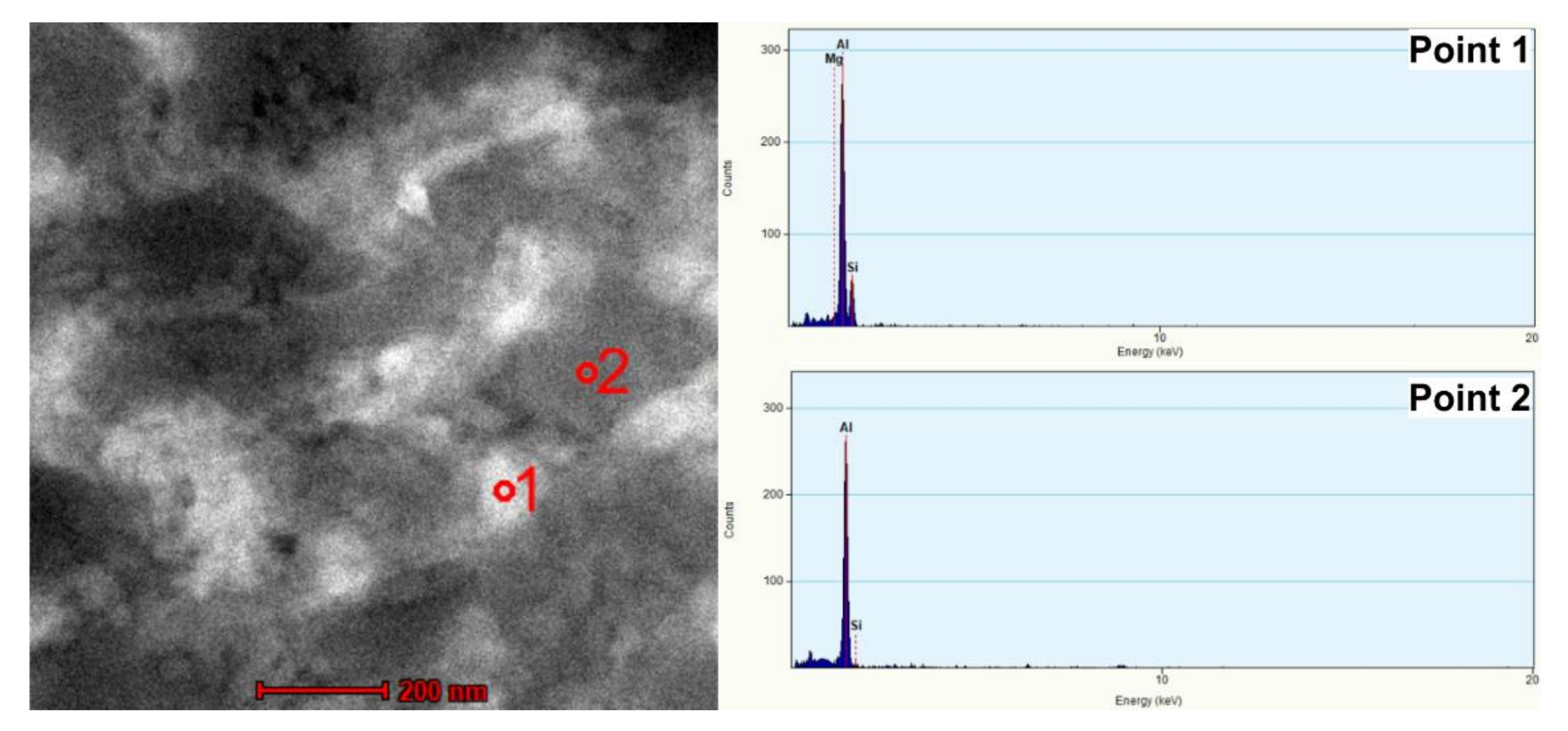

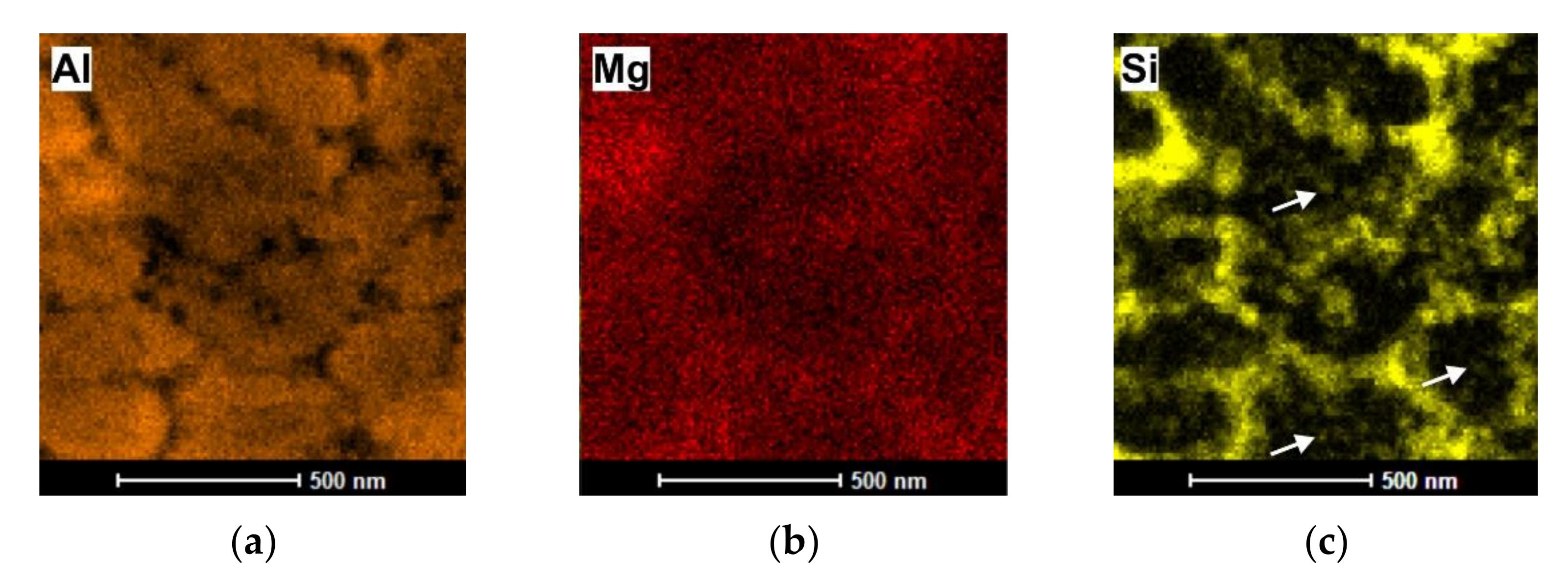

3.2.3. TEM

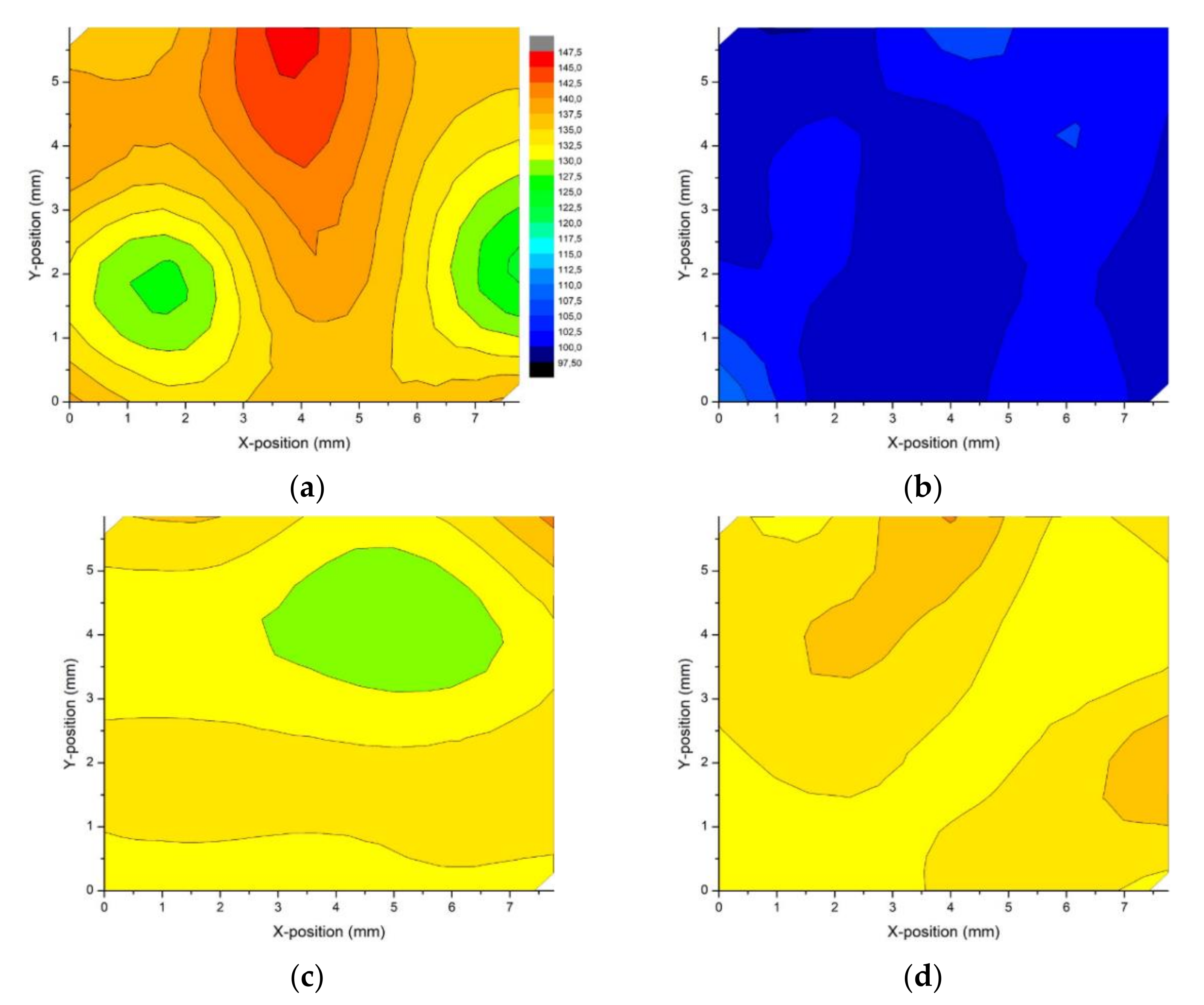

3.3. Hardness Distribution

3.4. Analysis of Strengthening Mechanisms of the ECAP-Processed Sample

4. Conclusions

- The image analysis revealed that the ECAP led to a reduction in the porosity of the selectively laser-melted AlSi10Mg samples. It was found that the fraction of porosity defects decreased with an increase in the number of ECAP pressings.

- ECAP eliminated the pores of the SLM-AlSi10Mg alloy; therefore, the density increased from 2.51 to 2.65 g/cm3.

- Heat treatment had a negligible effect on the microstructure of the AlSi10Mg alloy. ECAP processing promoted the formation of a novel layered structure that comprised semi-circular patterns and multiple melt pool boundaries, whose fraction increased by increasing the number of ECAP pressings.

- The EBSD analysis revealed that the mean size of grains decreased from 3.5 μm to 0.24 μm after two pressings of ECAP.

- Heat treatment caused a decrease in the mean microhardness value from ~135 to ~101 HV. After ECAP processing, the hardness increased to ~133 HV.

- Based on the strengthening mechanism analysis, it can be concluded that the increment in the σy value of the AlSi10Mg alloy after ECAP resulted from the Orowan mechanism, the grain boundary (Hall–petch), the solid solution, and dislocation strengthening. The greatest contribution to the overall σy came from the exceptional grain refinement (grain boundary) and dislocation strengthening.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bai, S.; Perevoshchikova, N.; Sha, Y.; Wu, X. The Effects of Selective Laser Melting Process Parameters on Relative Density of the AlSi10Mg Parts and Suitable Procedures of the Archimedes Method. Appl. Sci. 2019, 9, 583. [Google Scholar] [CrossRef] [Green Version]

- Prashanth, K.; Eckert, J. Formation of metastable cellular microstructures in selective laser melted alloys. J. Alloys Compd. 2017, 707, 27–34. [Google Scholar] [CrossRef]

- Mfusi, B.J.; Mathe, N.R.; Tshabalala, L.C.; Popoola, P.A. The Effect of Stress Relief on the Mechanical and Fatigue Properties of Additively Manufactured AlSi10Mg Parts. Metals 2019, 9, 1216. [Google Scholar] [CrossRef] [Green Version]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.; Babu, S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Dong, Z.; Zhang, X.; Shi, W.; Zhou, H.; Lei, H.; Liang, J. Study of Size Effect on Microstructure and Mechanical Properties of AlSi10Mg Samples Made by Selective Laser Melting. Materials 2018, 11, 2463. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Wang, S.; Hao, Y.; Pu, J.; Jiang, X.; Huang, L.-F.; Wang, L. Friction and Wear Behavior of CrN Coating on 316L Stainless Steel in Liquid Sodium at Elevated Temperature. Tribol. Int. 2020, 143, 106079. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Baxter, C.; Amirkhiz, B.S.; Mohammadi, M. Strengthening mechanisms in direct metal laser sintered AlSi10Mg: Comparison between virgin and recycled powders. Addit. Manuf. 2018, 23, 108–120. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.; Tan, Z.; Xiong, D.-B.; Guo, Q. Stress relaxation and the cellular structure-dependence of plastic deformation in additively manufactured AlSi10Mg alloys. Int. J. Plast. 2020, 127, 102640. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, Y.; Lu, K. Ductility and strain hardening in gradient and lamellar structured materials. Scr. Mater. 2020, 186, 321–325. [Google Scholar] [CrossRef]

- Rafieazad, M.; Mohammadi, M.; Gerlich, A.; Nasiri, A. Enhancing the corrosion properties of additively manufactured AlSi10Mg using friction stir processing. Corros. Sci. 2021, 178, 109073. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Tuck, C.; Ashcroft, I.; Maskery, I.; Everitt, N. On the Precipitation Hardening of Selective Laser Melted AlSi10Mg. Met. Mater. Trans. A 2015, 46, 3337–3341. [Google Scholar] [CrossRef]

- Park, T.-H.; Baek, M.-S.; Hyer, H.; Sohn, Y.; Lee, K.-A. Effect of direct aging on the microstructure and tensile properties of AlSi10Mg alloy manufactured by selective laser melting process. Mater. Charact. 2021, 176, 111113. [Google Scholar] [CrossRef]

- Gu, D.; Wang, H.; Chang, F.; Dai, D.; Yuan, P.; Hagedorn, Y.-C.; Meiners, W. Selective Laser Melting Additive Manufacturing of TiC/AlSi10Mg Bulk-form Nanocomposites with Tailored Microstructures and Properties. Phys. Procedia 2014, 56, 108–116. [Google Scholar] [CrossRef]

- Gao, C.; Wang, Z.; Xiao, Z.; You, D.; Wong, K.; Akbarzadeh, A. Selective laser melting of TiN nanoparticle-reinforced AlSi10Mg composite: Microstructural, interfacial, and mechanical properties. J. Mater. Process. Technol. 2020, 281, 116618. [Google Scholar] [CrossRef]

- Li, X.; Ji, G.; Chen, Z.; Addad, A.; Wu, Y.; Wang, H.; Vleugels, J.; Van Humbeeck, J.; Kruth, J. Selective laser melting of nano-TiB 2 decorated AlSi10Mg alloy with high fracture strength and ductility. Acta Mater. 2017, 129, 183–193. [Google Scholar] [CrossRef]

- Chang, F.; Gu, D.; Dai, D.; Yuan, P. Selective laser melting of in-situ Al4SiC4 + SiC hybrid reinforced Al matrix composites: Influence of starting SiC particle size. Surf. Coat. Technol. 2015, 272, 15–24. [Google Scholar] [CrossRef]

- Han, Q.; Setchi, R.; Lacan, F.; Gu, D.; Evans, S. Selective laser melting of advanced Al-Al2O3 nanocomposites: Simulation, microstructure and mechanical properties. Mater. Sci. Eng. A 2017, 698, 162–173. [Google Scholar] [CrossRef]

- Gao, C.; Xiao, Z.; Liu, Z.; Zhu, Q.; Zhang, W. Selective laser melting of nano-TiN modified AlSi10Mg composite powder with low laser reflectivity. Mater. Lett. 2019, 236, 362–365. [Google Scholar] [CrossRef]

- Finfrock, C.; Exil, A.; Carroll, J.D.; Deibler, L. Effect of Hot Isostatic Pressing and Powder Feedstock on Porosity, Microstructure, and Mechanical Properties of Selective Laser Melted AlSi10Mg. Met. Microstruct. Anal. 2018, 7, 443–456. [Google Scholar] [CrossRef] [Green Version]

- Rosenthal, I.; Tiferet, E.; Ganor, M.; Stern, A. Post-processing of AM-SLM AlSi10Mg specimens: Mechanical properties and fracture behaviour. Weld. Equip. Technol. 2015, 26, 33–38. [Google Scholar]

- Bonneric, M.; Brugger, C.; Saintier, N. Effect of hot isostatic pressing on the critical defect size distribution in AlSi7Mg0.6 alloy obtained by selective laser melting. Int. J. Fatigue 2020, 140, 105797. [Google Scholar] [CrossRef]

- Hirata, T.; Kimura, T.; Nakamoto, T. Effects of hot isostatic pressing and internal porosity on the performance of selective laser melted AlSi10Mg alloys. Mater. Sci. Eng. A 2020, 772, 138713. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Hoegden, M.; Gao, N. Effect of sample orientation on the microstructure and microhardness of additively manufactured AlSi10Mg processed by high-pressure torsion. Int. J. Adv. Manuf. Technol. 2020, 106, 4321–4337. [Google Scholar] [CrossRef] [Green Version]

- Hosseinzadeh, A.; Radi, A.; Richter, J.; Wegener, T.; Sajadifar, S.V.; Niendorf, T.; Yapici, G.G. Severe plastic deformation as a processing tool for strengthening of additive manufactured alloys. J. Manuf. Process. 2021, 68, 788–795. [Google Scholar] [CrossRef]

- Snopiński, P.; Król, M.; Pagáč, M.; Petrů, J.; Hajnyš, J.; Mikuszewski, T.; Tański, T. Effects of equal channel angular pressing and heat treatments on the microstructures and mechanical properties of selective laser melted and cast AlSi10Mg alloys. Arch. Civ. Mech. Eng. 2021, 21, 1–18. [Google Scholar] [CrossRef]

- Furukawa, M.; Horita, Z.; Langdon, T.G. Factors influencing the shearing patterns in equal-channel angular pressing. Mater. Sci. Eng. A 2002, 332, 97–109. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Amirkhiz, B.S.; Mohammadi, M. Contribution of Mg2Si precipitates to the strength of direct metal laser sintered AlSi10Mg. Mater. Sci. Eng. A 2019, 739, 295–300. [Google Scholar] [CrossRef]

- Arechabaleta, Z.; van Liempt, P.; Sietsma, J. Unravelling dislocation networks in metals. Mater. Sci. Eng. A 2018, 710, 329–333. [Google Scholar] [CrossRef]

- Urrutia, I.G.; Muñoz-Morris, M.; Morris, D. Contribution of microstructural parameters to strengthening in an ultrafine-grained Al–7% Si alloy processed by severe deformation. Acta Mater. 2007, 55, 1319–1330. [Google Scholar] [CrossRef] [Green Version]

- Snopiński, P.; Król, M. Microstructure, Mechanical Properties and Strengthening Mechanism Analysis in an AlMg5 Aluminium Alloy Processed by ECAP and Subsequent Ageing. Metals 2018, 8, 969. [Google Scholar] [CrossRef] [Green Version]

- Snopiński, P.; Tanski, T.; Matus, K.; Rusz, S. Microstructure, grain refinement and hardness of Al–3%Mg aluminium alloy processed by ECAP with helical die. Arch. Civ. Mech. Eng. 2018, 19, 287–296. [Google Scholar] [CrossRef]

| Element, wt. (%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Si | Mg | Fe | Ti | Zn | Mn | Ni | Co | Al |

| 9–11 | 0.25–0.45 | <0.25 | <0.15 | <0.10 | <0.10 | <0.05 | <0.05 | Balance |

| Measured Laser Power, W | Layer Thickness, μm | Laser Beam Diameter, μm | Scan Speed, mm·s−1 |

|---|---|---|---|

| 175 | 20 | 55 | 1400 |

| Sample | As-Built | Heat-Treated | Heat-Treated + 1 ECAP Pass | Heat-Treated + 2 ECAP Passes |

|---|---|---|---|---|

| Density (g/cm3) | 2.51 ± 0.18 | 2.52 ± 0.18 | 2.61 ± 0.04 | 2.65 ± 0.04 |

| Point | Element | Wt, % | At, % |

|---|---|---|---|

| 1 | Al | 82.8 | 83.2 |

| Si | 15.9 | 15.4 | |

| Mg | 1.3 | 1.4 | |

| 2 | Al | 98.4 | 98.5 |

| Si | 1.2 | 1.1 | |

| Mg | 0.4 | 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Snopiński, P.; Woźniak, A.; Pagáč, M. Microstructural Evolution, Hardness, and Strengthening Mechanisms in SLM AlSi10Mg Alloy Subjected to Equal-Channel Angular Pressing (ECAP). Materials 2021, 14, 7598. https://doi.org/10.3390/ma14247598

Snopiński P, Woźniak A, Pagáč M. Microstructural Evolution, Hardness, and Strengthening Mechanisms in SLM AlSi10Mg Alloy Subjected to Equal-Channel Angular Pressing (ECAP). Materials. 2021; 14(24):7598. https://doi.org/10.3390/ma14247598

Chicago/Turabian StyleSnopiński, Przemysław, Anna Woźniak, and Marek Pagáč. 2021. "Microstructural Evolution, Hardness, and Strengthening Mechanisms in SLM AlSi10Mg Alloy Subjected to Equal-Channel Angular Pressing (ECAP)" Materials 14, no. 24: 7598. https://doi.org/10.3390/ma14247598

APA StyleSnopiński, P., Woźniak, A., & Pagáč, M. (2021). Microstructural Evolution, Hardness, and Strengthening Mechanisms in SLM AlSi10Mg Alloy Subjected to Equal-Channel Angular Pressing (ECAP). Materials, 14(24), 7598. https://doi.org/10.3390/ma14247598