Evaluating the Technology Readiness of a Ribbon-Blade Wind Turbine Using NASA’s TRL Method

Abstract

:1. Introduction

2. Solving the Task

- Will the use of an innovative ribbon-blade wind turbine contribute to efficiency gains and to a reduction in the energy used in the innovative process?

- Will the use of said ribbon-blade turbine improve the effectiveness and quality of the product: power and electricity?

3. The Innovation Readiness Method

4. Results, Discussions and Analysis of a Technology Readiness Assessment

4.1. TRL 1: Identifying Basic Operating Principles

4.2. TRL 2: Formulating the Concept of the Solution

4.3. TRL 3: Validating the Proof-of-Concept Experimentally

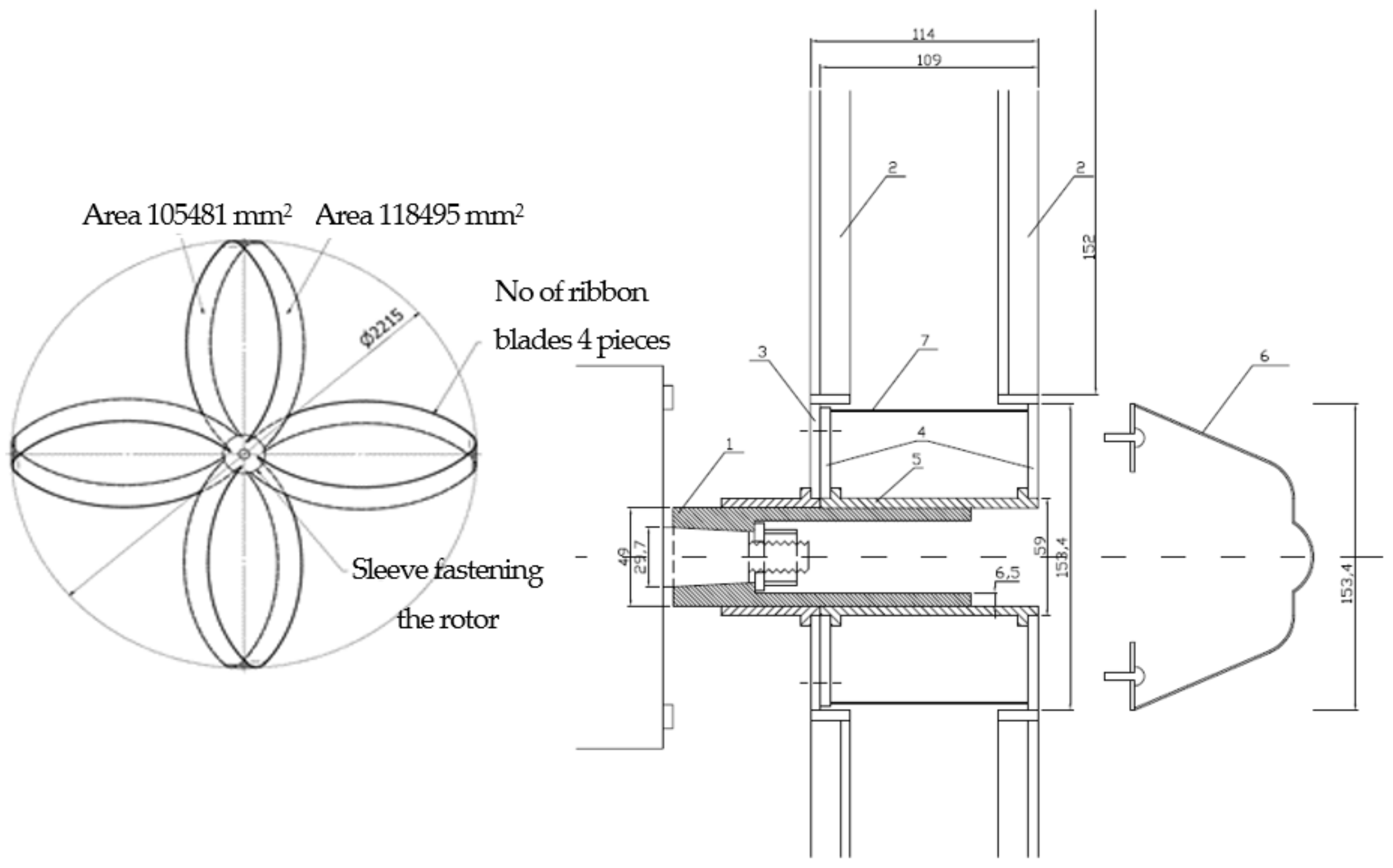

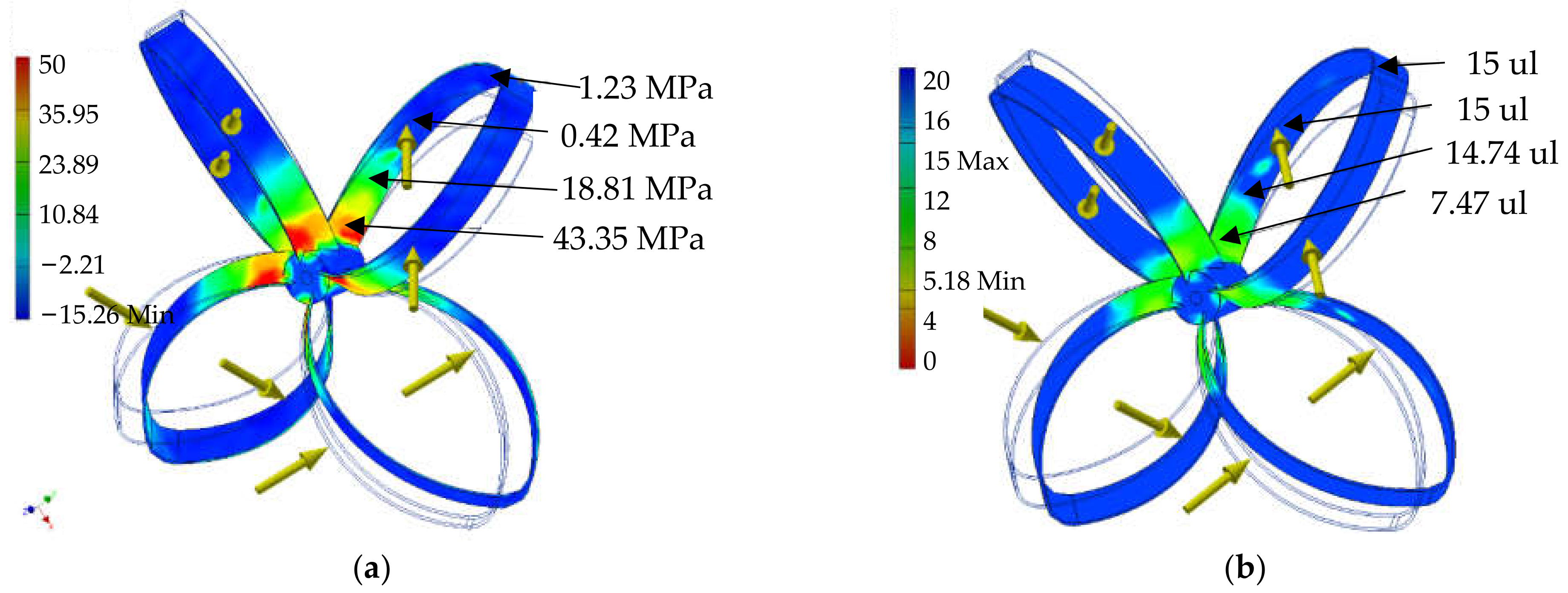

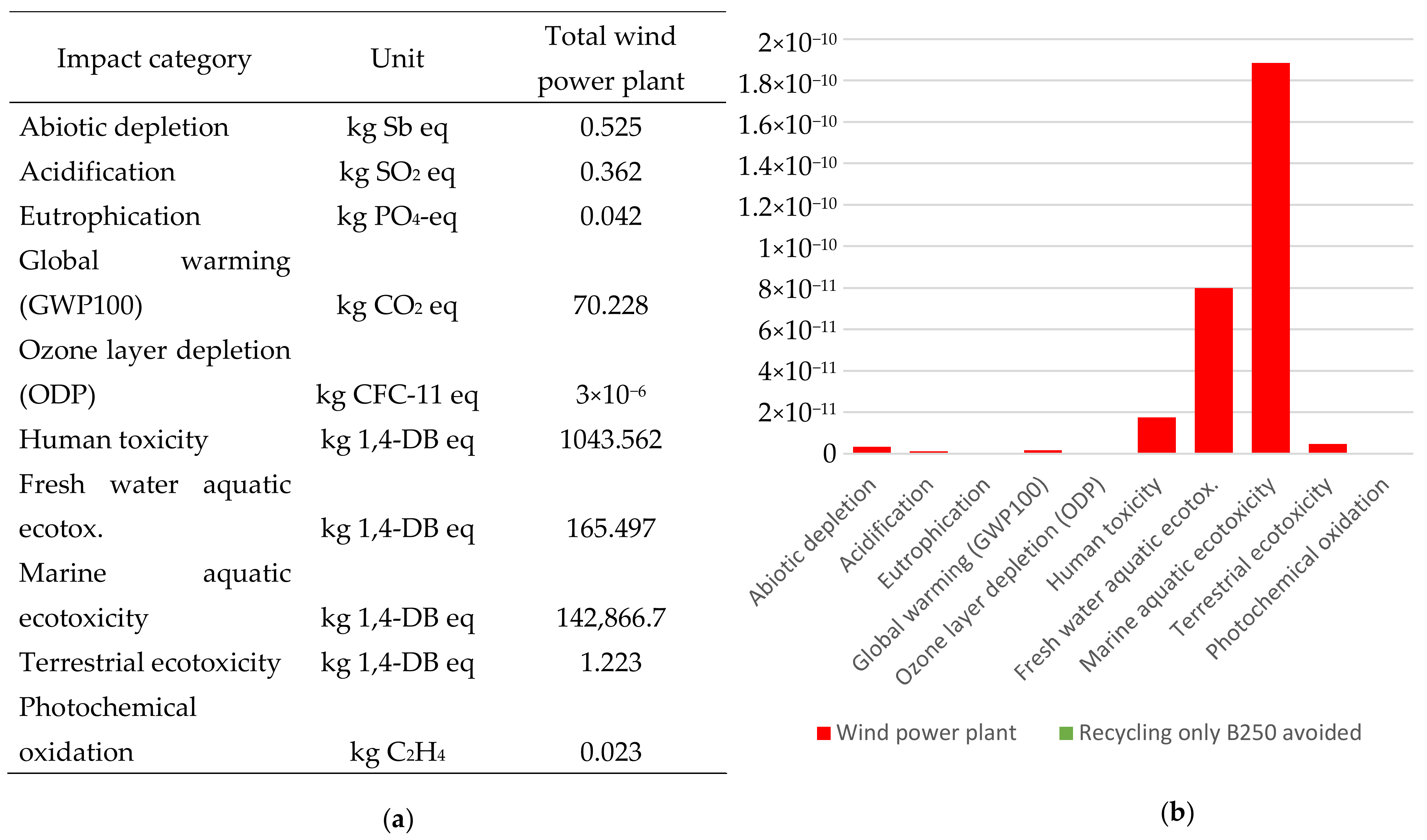

4.4. TRL 4: Validating the Technology in Laboratory Conditions; TRL 5: Validating the Technology in Simulated Operational Conditions

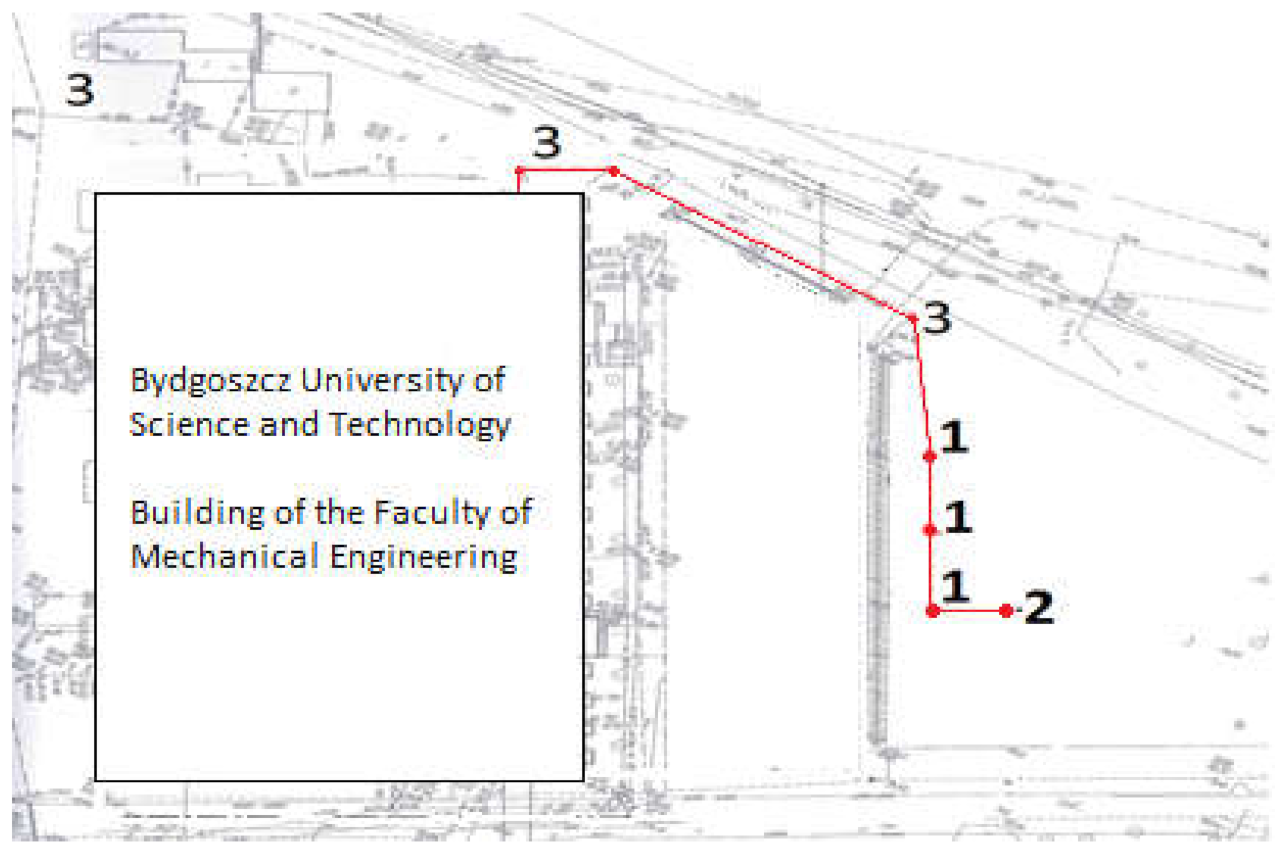

4.5. TRL 6: Production and Demonstration of a Prototype in a Simulated Environment Similar to the Target One; TRL 7: Prototype Demonstration in the Target Environment

- −

- −

- Designing and obtaining administrative decisions for measurement-verification stations for wind turbines in target conditions (Figure 8),

- −

4.6. TRL 8: Producing the Final Version of the Product; TRL 9: Completion of a Test Series and Obtaining Product Conformity Certificates and Approvals for Use

- NU—effective power on the shaft of the turbine’s rotor, W,

- NT—theoretical wind power acting on the ribbon-blade turbine, W.

5. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baranowski, A. Wind Farms: Threats to Humans and the Environment; University of Science and Technology in Bydgoszcz: Bydgoszcz, Poland, 2014; Volume 1, pp. 58–62. [Google Scholar]

- Kasner, R.; Kruszelnicka, W.; Bałdowska-Witos, P.; Flizikowski, J.; Tomporowski, A. Sustainable Wind Power Plant Modernization. Energies 2020, 13, 1461. [Google Scholar] [CrossRef] [Green Version]

- Boczar, T. The Use of Wind Energy; Wydawnictwo Poznańska Księgarnia Akademicka: Krakow, Poland, 2010; p. 225. [Google Scholar]

- Burton, T.; Sharpe, D.; Jenkins, N.; Bossanyi, E. Wind Energy, Handbook; John Wiley & Sons: Hoboken, NJ, USA, 2001; pp. 4–6. [Google Scholar]

- Bałdowska-Witos, P.; Doerffer, K.; Pysz, M.; Doerffer, P.; Tomporowski, A.; Opielak, M. Manufacturing and Recycling Impact on Environmental Life Cycle Assessment of Innovative Wind Power Plant Part 2/2. Materials 2021, 14, 204. [Google Scholar] [CrossRef]

- Flaga, A. Inżynieria Wiatrowa: Podstawy i Zastosowania; Wydawnictwo Arkady: Warsaw, Poland, 2008; pp. 661–669. [Google Scholar]

- Flizikowski, J.; Tomporowski, A.; Flizikowski, A. Siłownia, Elektrownia Wiatrowa z Turbiną o Łopatach Wstęgowych; Polish Patent Office: Warsaw, Poland, 2011; p. 397301. [Google Scholar]

- Flizikowski, J. Dissertation on Innovation; University of Science and Technology in Bydgoszcz: Bydgoszcz, Poland, 2021. [Google Scholar]

- Flizikowski, J.; Bielinski, K. Technology and Energy Sources Monitoring: Control, Efficiency and Optimization; IGI Global: Hershey, PA, USA, 2013; p. 248. [Google Scholar]

- Matyka, M.; Kołodziej, B. Odnawialne źródła Energii. Rolnicze Surowce Energetyczne; Wydawnictwo Powszechne Wydawnictwo Rolnicze i Lesne: Lublin, Poland, 2013; pp. 144–161. [Google Scholar]

- Mężyk, A.; Jureczko, M. Optymalizacja Wielokryterialna łopat Elektrowni Wiatrowej ze Względu na Minimalizację Drgań; Wydawnictwo Politechniki Slaskiej: Gliwice, Poland, 2006; pp. 42–55. [Google Scholar]

- Tomporowski, A.; Flizikowski, J.; Kruszelnicka, W.; Piasecka, I.; Kasner, R.; Mrozinski, A.; Kovalyshyn, S. Destructiveness of profits and outlays associated with operation of offshore wind electric power plant. Part 1: Identification of a model and its components. Pol. Marit. Res. 2018, 25, 132–139. [Google Scholar] [CrossRef] [Green Version]

- Kasner, R.; Flizikowski, J.; Tomporowski, A.; Kruszelnicka, W.; Idzikowski, A. Ecological efficiency Assessment Model for Environmental Safety Management of Wind Power Plant. Syst. Saf. Hum. Tech. Facil. Environ. 2019, 1, 371–377. [Google Scholar] [CrossRef] [Green Version]

- Wolańczyk, F. Elektrownie wiatrowe. Wydaw. i Handel Ksiaz. KaBe 2009, 1, 50–96. [Google Scholar]

- Zmarzył, D. Badania jakości energii w wybranej farmie wiatrowej. Politech. Opol. Oficyna Wydaw. 2014, 1, 171. [Google Scholar]

- Kasner, R. The Fundamentals of the Eco-Development of Wind Power Plant Design; University of Science and Technology in Bydgoszcz: Bydgoszcz, Poland, 2020; Volume 1. [Google Scholar]

- Badania, Forum Małych Elektrowni Wiatrowych 2011—Pierwsze Wyniki Badań nad Sektorem Małej Energetyki Wiatrowej. Available online: www.ieo.pl (accessed on 2 April 2021).

- Piasecka, I.; Tomporowski, A.; Flizikowski, J.; Kruszelnicka, W.; Kasner, R.; Mrozinski, A. Life Cycle Analysis of Ecological Impacts of an Offshore and a Land-Based Wind Power Plant. Appl. Sci. 2019, 9, 231. [Google Scholar] [CrossRef] [Green Version]

- Kasner, R. Badania Innowacyjnych Turbin Wiatrowych; Projekty CTT UTP: Bydgoszcz, Poland, 2019. [Google Scholar]

- Kieć, J. Odnawialne Źródła Energii; Wydawnictwo Akademii Rolniczej: Poznań, Poland, 2007; Volume 1. [Google Scholar]

- Lubośny, Z. Elektrownie wiatrowe w systemie elektroenergetycznym. Wydaw. Nauk. Tech. 2007, 1, 56–58. [Google Scholar]

- Malczyk, T. Antropopresja Ekoenergetyczna w Procesie Zmiany Krajobrazu na Przykładzie Wybranych Farm Wiatrowych w Polsce; Wydawnictwo Uniwersytetu Przyrodniczego we Wrocławiu: Wrocław, Poland, 2013; pp. 186–188. [Google Scholar]

- Maroński, R. Siłownie wiatrowe. Oficyna Wydawnicza Politech. Warsz. Warsaw, Poland 2016, 1, 109–128. [Google Scholar]

- IEO. Raport, Wizja Rozwoju Energetyki Wiatrowej w Polsce do 2020 r. Available online: www.ieo.pl (accessed on 24 September 2021).

- IEO. Raport, Krajowy Plan Rozwoju Mikroinstalacji Odnawialnych Źródeł Energii. Available online: www.ieo.pl (accessed on 24 September 2021).

- Biuletyn Energii Odnawialnej 2015—Energetyka Wiatrowa—EurObserv’ER. Available online: www.eurobserv-er.org (accessed on 20 June 2021).

- Kruszlenicka, W.; Marczuk, A.; Kasner, R.; Baldowska-Witos, P.; Piotrowska, K.; Flizikowski, J.; Tomporowski, A. Mechanical and Processing Properties of Rice Grains. Sustainability 2020, 12, 552. [Google Scholar] [CrossRef] [Green Version]

- IEO. Energetyka Wiatrowa—Stan Aktualny i Perspektywy Rozwoju w Polsce. Available online: www.ieo.pl (accessed on 18 April 2021).

- Obliczanie Parametrów Małej Elektrowni Wiatrowej. Available online: http://www.elektro.info.pl/artykul/id6049,obliczanie-parametrow-malej-elektrowni-wiatrowej?print=1 (accessed on 6 April 2021).

- Laboratorium Inżynierii Wiatrowej. Available online: https://www.windlab.pl/ (accessed on 25 June 2021).

- Odnawialne Firmy. Available online: https://www.odnawialne-firmy.pl/wiadomosci/pokaz/3,turbiny-o-poziomej-osi-obrotu-hawt (accessed on 14 May 2021).

- Szarek, M. Projekt i Badania Elektrowni Wiatrowej z Turbiną o Łopatach Wstęgowych; University of Science and Technology in Bydgoszcz: Bydgoszcz, Poland, 2016. [Google Scholar]

- Wind Energy Solution. Available online: https://windenergysolutions.nl/ (accessed on 16 February 2021).

- Wind Power. Available online: https://www.windpowermonthly.com/ (accessed on 18 April 2021).

- Elektrownie Wiatrowe. Available online: https://www.elektrownie-wiatrowe.org.pl/ (accessed on 10 March 2021).

- Piasecka, I.; Bałdowska-Witos, P.; Flizikowski, J.; Piotrowska, K.; Tomporowski, A. Control the System and Environment of Post-Production Wind Turbine Blade Waste Using Life Cycle Models. Part 1: Environmental Transformation Models. Polymers 2020, 12, 1828. [Google Scholar] [CrossRef] [PubMed]

- Bałdowska-Witos, P.; Piotrowska, K.; Kruszelnicka, W.; Błaszczak, M.; Tomporowski, A.; Opielak, M.; Kasner, R.; Flizikowski, J. Managing the Uncertainty and Accuracy of Life Cycle Assessment Results for the Process of Beverage Bottle Moulding. Polymers 2020, 12, 1320. [Google Scholar] [CrossRef] [PubMed]

| TRL Level | Characteristics |

|---|---|

| TRL 1 | Identifying basic operating principles |

| TRL 2 | Formulating technology concept |

| TRL 3 | Proof-of-concept via experimentation |

| TRL 4 | Validating the technology in laboratory conditions |

| TRL 5 | Validating the technology in relevant environment |

| TRL 6 | Prototype demonstration in simulated environment similar to the target one |

| TRL 7 | Prototype demonstration in the target environment |

| TRL 8 | Producing the final version of the product |

| TRL 9 | Completing a test series and obtaining product conformity certificates and approvals for use |

| TRL 1 | Identifying basic operating principles | Positive assessment of mechanical operating principles |

| Dependence | Description | |

|---|---|---|

| (1) | where: qk—pressure of the wind speed —wind speed in a given climate zone, ρ—air density 1.23 kg/m3. | |

| After calculating the pressure of the wind speed we can calculate the characteristic load caused by wind effects with the following formula: | ||

| [Pa] | (2) | where: pk—characteristic load caused by wind effects, β—coefficient of wind gust action. |

| The design load applied when determining the ultimate limit states of the construction are derived from the formula: | ||

| [Pa] | (3) | where: pk—characteristic load caused by wind effects, γf—load coefficient. |

| After determining the design load and surface area designated from the rotor’s ribbon we can compute the force applied to the relevant surface. The calculated force will be directed perpendicular to the surface from the calculations. This force can be derived from the following formula: | ||

| [N] | (4) | where: Pw—unit resultant force applied perpendicular to the surface, p—design load, Aj—unit surface area of a part of the rotor’s ribbon [m2]. |

| Knowing the resultant force on the unit area of the blade we can calculate the circumferential force needed to define the power of the turbine. To this end, we will use the following formula: | ||

| [N] | (5) | where: α—angle between force Pw and the frontal plane of the rotor Pw—unit resultant force on the rotor. |

| The next step is to calculate the rotor power for different rotational speeds, which will be determined on the basis of wind speed variation. First, we derive the rotor speed from the formula: | ||

| [rpm] | (6) | where: Vn—wind speed, δ—specific speed, D—rotor diameter. |

| Next we may proceed to calculate the theoretical power of the rotor: | ||

| [kW] | (7) | where: —total circumferential forces occurring on particular planes of the rotor, R—active radius of the rotor, nti—given rotational speed of the rotor. |

| Finally, when taking the assumed efficiency of the system into account, the power output will be calculated: | ||

| (8) | where: —efficiency of the system —theoretical power which in practice is the wind power acting on the ribbon-blade turbine. | |

| TRL 2 | Formulating the solution concept | Positive assessment of the mechanical concept of the solution |

| TRL 3 | Validating the proof-of-concept experimentally | Positive assessment, concept experimentally valid |

| The Chemical Composition of Steel AISI 304 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Element | Iron | Chrome | Nickel | Manganese | Silicon | Coal | Potassium | Sulfur |

| Participation, % | 66–74 | 18–20 | 8–10.5 | Max 2 | Max 1 | 0.08 | 0.045 | 0.03 |

| Properties of steel AISI 304 | ||||||||

| Properties | The value of the metric unit | |||||||

| Density | 7.9 × 103 | kg·m−3 | ||||||

| Modulus of elasticity | 193 | GPa | ||||||

| Thermal expansion (20 °C) | 17.2 × 10−6 | °C −1 | ||||||

| Specific heat capacity | 502 | J·(kg·K)−1 | ||||||

| Thermal conductivity | 16.2 | W· (m·K) −1 | ||||||

| Electrical resistance | 7.2 × 10−7 | Ohm·m | ||||||

| Tensile strength | 520 | MPa | ||||||

| Yield point | 210 | MPa | ||||||

| Elongation | 45 | % | ||||||

| Hardness | <215 | HB | ||||||

| Melting temperature | 1400–1450 | °C | ||||||

| TRL 4 | Validating the technology in laboratory conditions | Positive assessment, elements of technology verified in laboratory conditions |

| TRL 5 | Validating the technology in simulated operational conditions | Positive assessment in laboratory conditions as simulated operational conditions |

| Wind Power Plant | Global Warming (GWP100), kg CO2 eq | Renewable Wind Energy, MJ |

|---|---|---|

| Double Bladed | 70.2 | 3.76 |

| Three Bladed | 77.8 | 4.7 |

| Four bladed | 93.3 | 5.64 |

| Five Bladed | 109 | 6.58 |

| Six Bladed | 124 | 7.52 |

| TRL 6 | Production and demonstration of a prototype in a simulated environment similar to the target one | Assessment positive, prototype produced by professional wind turbine producer |

| TRL 7 | Demonstration of the prototype in target operational conditions | Assessment positive, Prototype demonstrated in the target conditions of a laboratory |

| Lp. | Area A [m2] | Speed VK [m·s−1] | Wind Speed Pressure qk [Pa] | Characteristic Load pk [Pa] | Design Load p [Pa] |

|---|---|---|---|---|---|

| 1 | 0.105481 | 6 | 22 | 40 | 52 |

| 2 | 0.118495 | 12 | 89 | 159 | 207 |

| 3 | 0.105481 | 18 | 199 | 359 | 466 |

| 4 | 0.118495 | 24 | 354 | 638 | 829 |

| 5 | 0.105481 | 29 * | 517 | 931 | 1210 |

| 6 | 0.118495 | 35 | 753 | 1356 | 1763 |

| 7 | 0.105481 | 41 | 1034 | 1861 | 2419 |

| 8 | 0.118495 | 47 | 1359 | 2445 | 3179 |

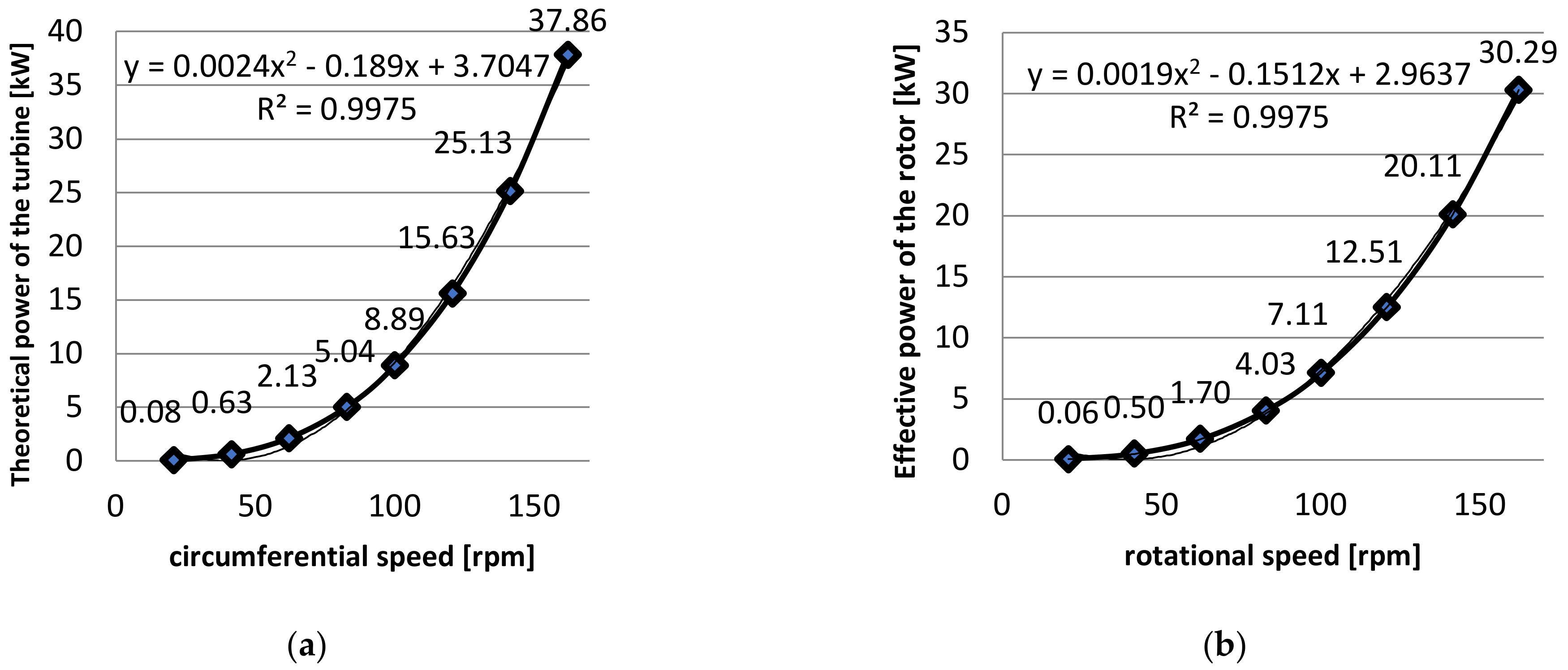

| Lp. | Speed VK [m·s−1] | Resultant Force [N] | Circumferential Force [N] | Revolutions nt [rpm] | Theoretical Power NT [kW] |

|---|---|---|---|---|---|

| 1 | 6 | 46 | 33 | 21 | 0.08 |

| 2 | 12 | 186 | 131 | 41 | 0.63 |

| 3 | 18 | 418 | 295 | 62 | 2.13 |

| 4 | 24 | 743 | 525 | 83 | 5.04 |

| 5 | 29 * | 1084 | 767 | 100 | 8.89 |

| 6 | 35 | 1579 | 1117 | 121 | 15.63 |

| 7 | 41 | 2167 | 1533 | 141 | 25.13 |

| 8 | 47 | 2848 | 2014 | 162 | 37.86 |

| Lp. | Speed VK·[m·s−1] | Circumferential Force [N] | Revolutions nt [rpm] | Theoretical Power NT [kW] |

|---|---|---|---|---|

| 1 | 6 | 26 | 21 | 0.06 |

| 2 | 12 | 105 | 41 | 0.50 |

| 3 | 18 | 236 | 62 | 1.70 |

| 4 | 24 | 420 | 83 | 4.03 |

| 5 | 29 * | 613 | 100 | 7.11 |

| 6 | 35 | 893 | 121 | 12.1 |

| 7 | 41 | 1226 | 141 | 20.1 |

| 8 | 47 | 1611 | 162 | 30.9 |

| TRL 8 | Producing the final version of the product | Assessment conditionally positive, a final version of the product was completed |

| TRL 9 | Completion of a test series and obtaining product conformity certificates and approvals for use | No assessment |

| TRL Level | Characteristics | Evaluation |

|---|---|---|

| TRL 1 | Identifying basic operating principles | Positive, high |

| TRL 2 | Formulating the solution concept | Positive, high |

| TRL 3 | Validating the proof-of-concept experimentally | Positive, high |

| TRL 4 | Validating the technology in laboratory conditions | Positive, high |

| TRL 5 | Validating the technology in simulated operational conditions | Positive, high |

| TRL 6 | Production and demonstration of a prototype in a simulated environment similar to the target one | Positive, high |

| TRL 7 | Demonstration of the prototype in target operational conditions | Positive, high |

| TRL 8 | Producing the final version of the product | Assessment conditionally positive, a final version of the product was completed |

| TRL 9 | Completion of a test series and obtaining product conformity certificates and approvals for use | No assessment |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kasner, R.; Bałdowska-Witos, P. Evaluating the Technology Readiness of a Ribbon-Blade Wind Turbine Using NASA’s TRL Method. Materials 2021, 14, 7709. https://doi.org/10.3390/ma14247709

Kasner R, Bałdowska-Witos P. Evaluating the Technology Readiness of a Ribbon-Blade Wind Turbine Using NASA’s TRL Method. Materials. 2021; 14(24):7709. https://doi.org/10.3390/ma14247709

Chicago/Turabian StyleKasner, Robert, and Patrycja Bałdowska-Witos. 2021. "Evaluating the Technology Readiness of a Ribbon-Blade Wind Turbine Using NASA’s TRL Method" Materials 14, no. 24: 7709. https://doi.org/10.3390/ma14247709

APA StyleKasner, R., & Bałdowska-Witos, P. (2021). Evaluating the Technology Readiness of a Ribbon-Blade Wind Turbine Using NASA’s TRL Method. Materials, 14(24), 7709. https://doi.org/10.3390/ma14247709