Shielding Effectiveness and Impact Resistance of Concrete Walls Strengthened by High-Strength High-Ductility Concrete

Abstract

:1. Introduction

2. Experimental Program

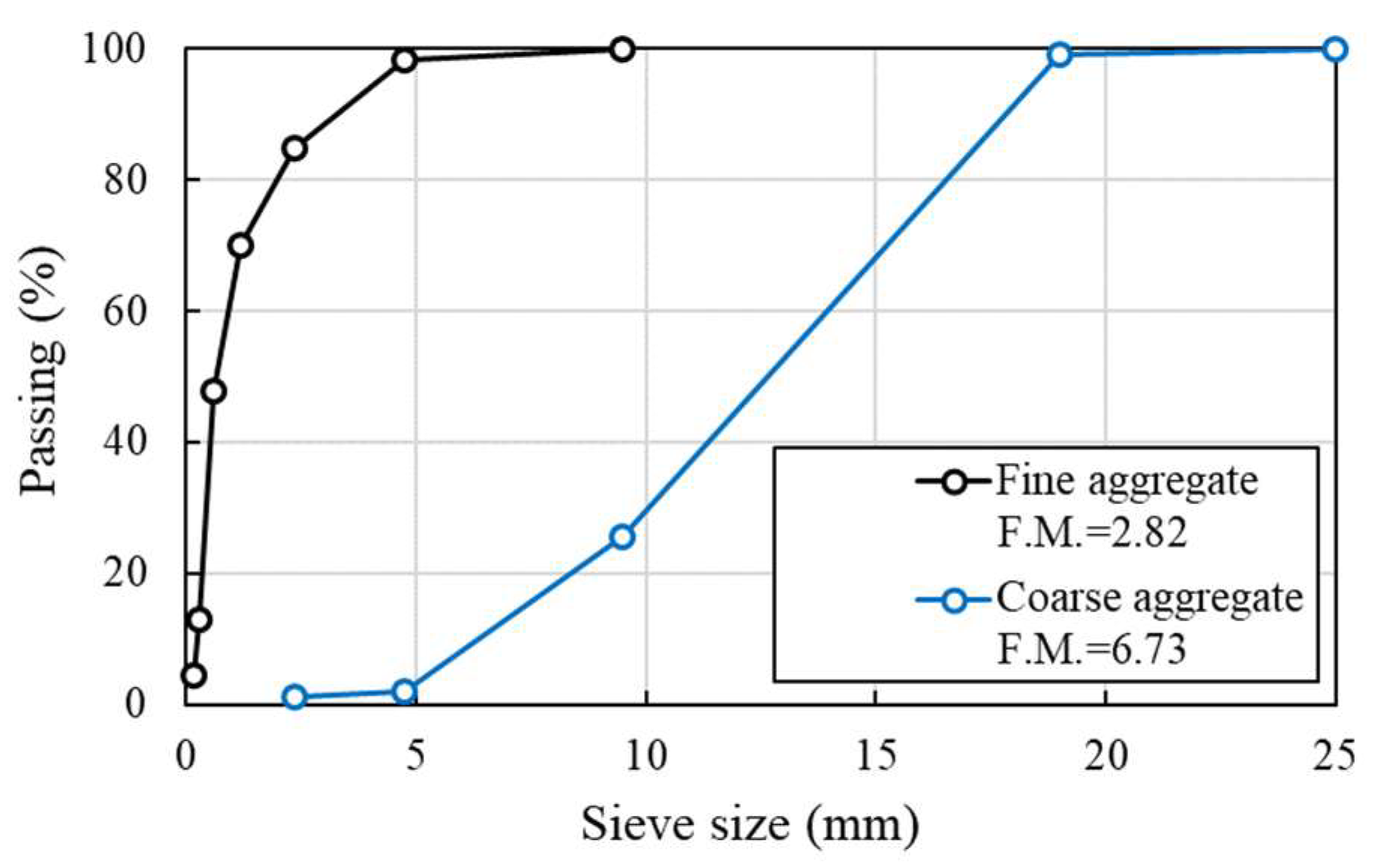

2.1. Details of Materials and Specimen Fabrication

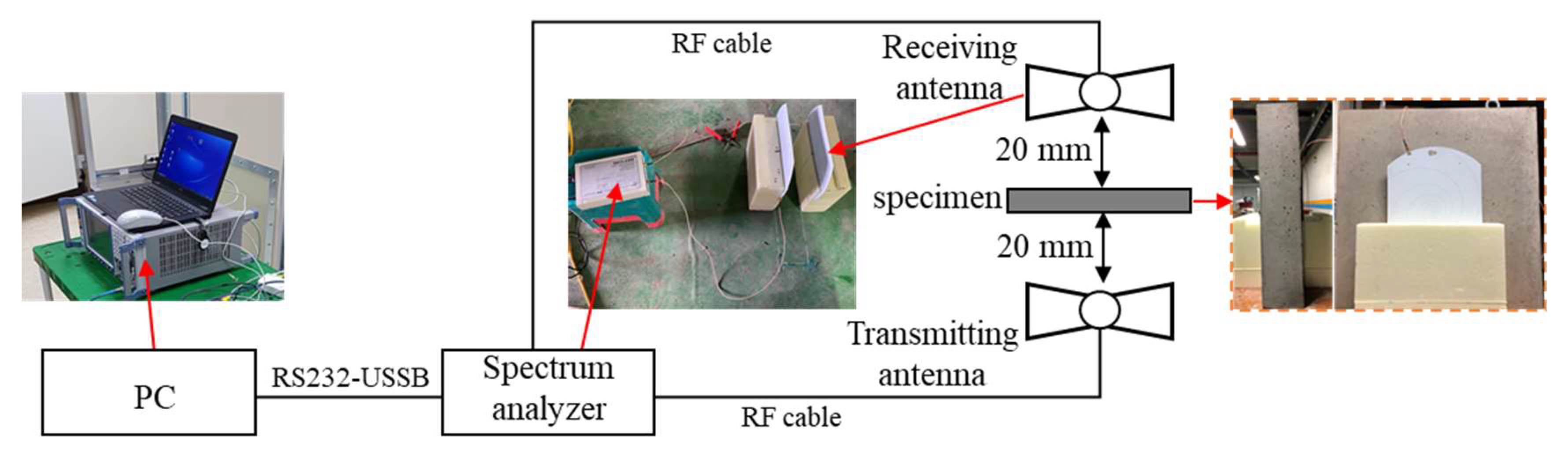

2.2. Details of Setup of Electromagnetic Interference Shielding Test

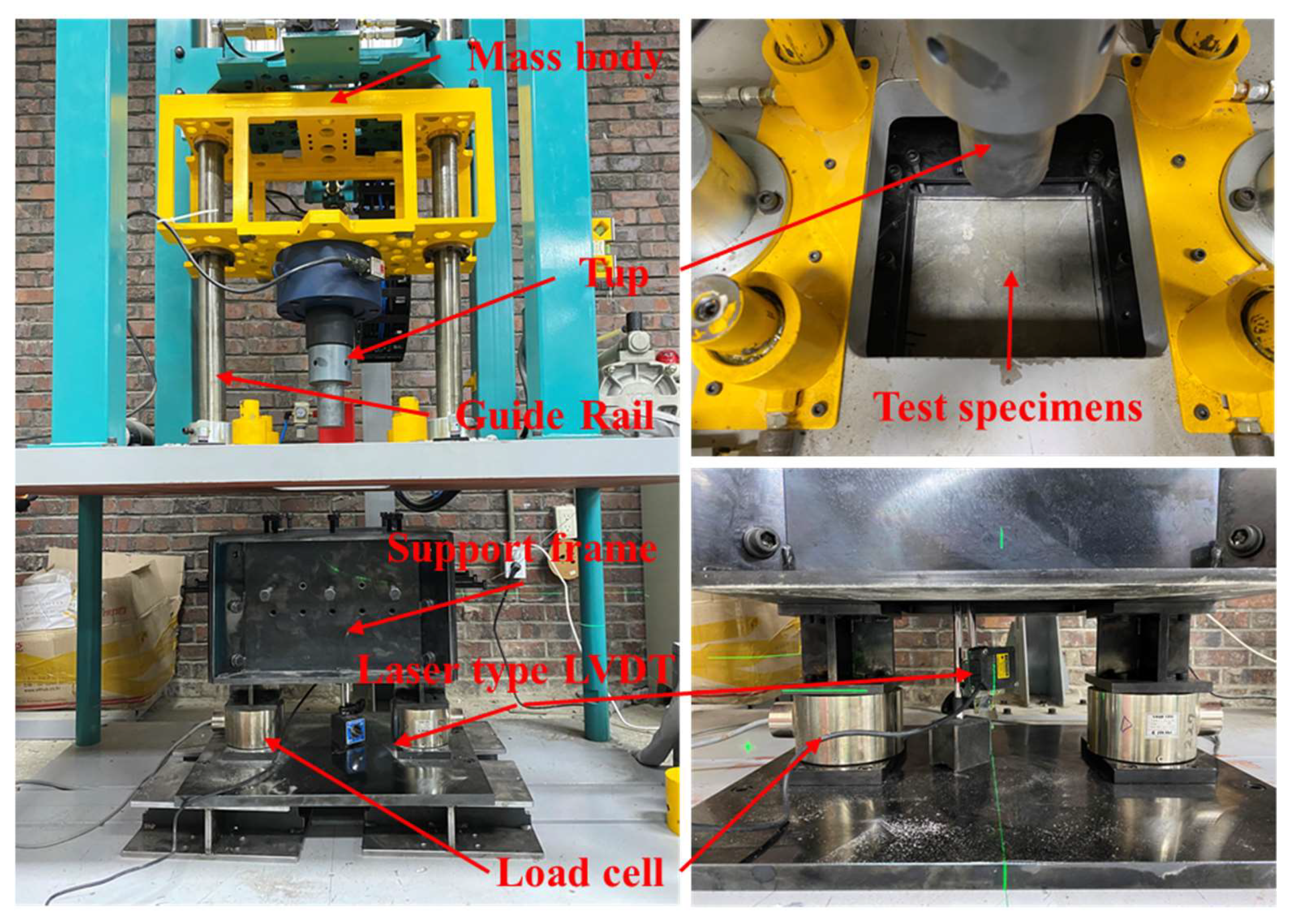

2.3. Detail Setup of Impact Test

3. Experimental Results and Discussion

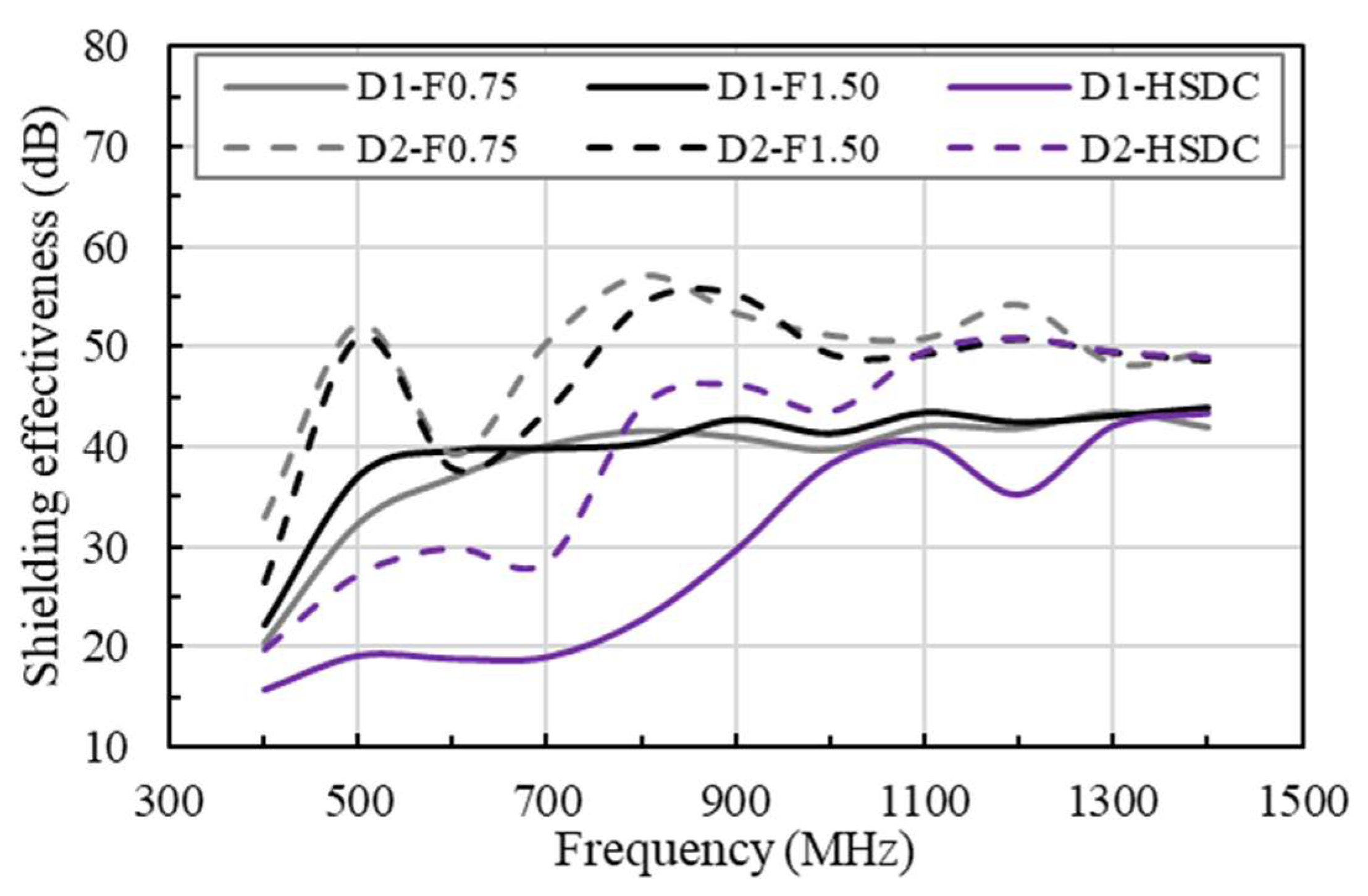

3.1. Shielding Effectiveness of HSDC-Strengthened Specimen

3.2. Shielding Effectiveness of Impact-Damaged Specimen

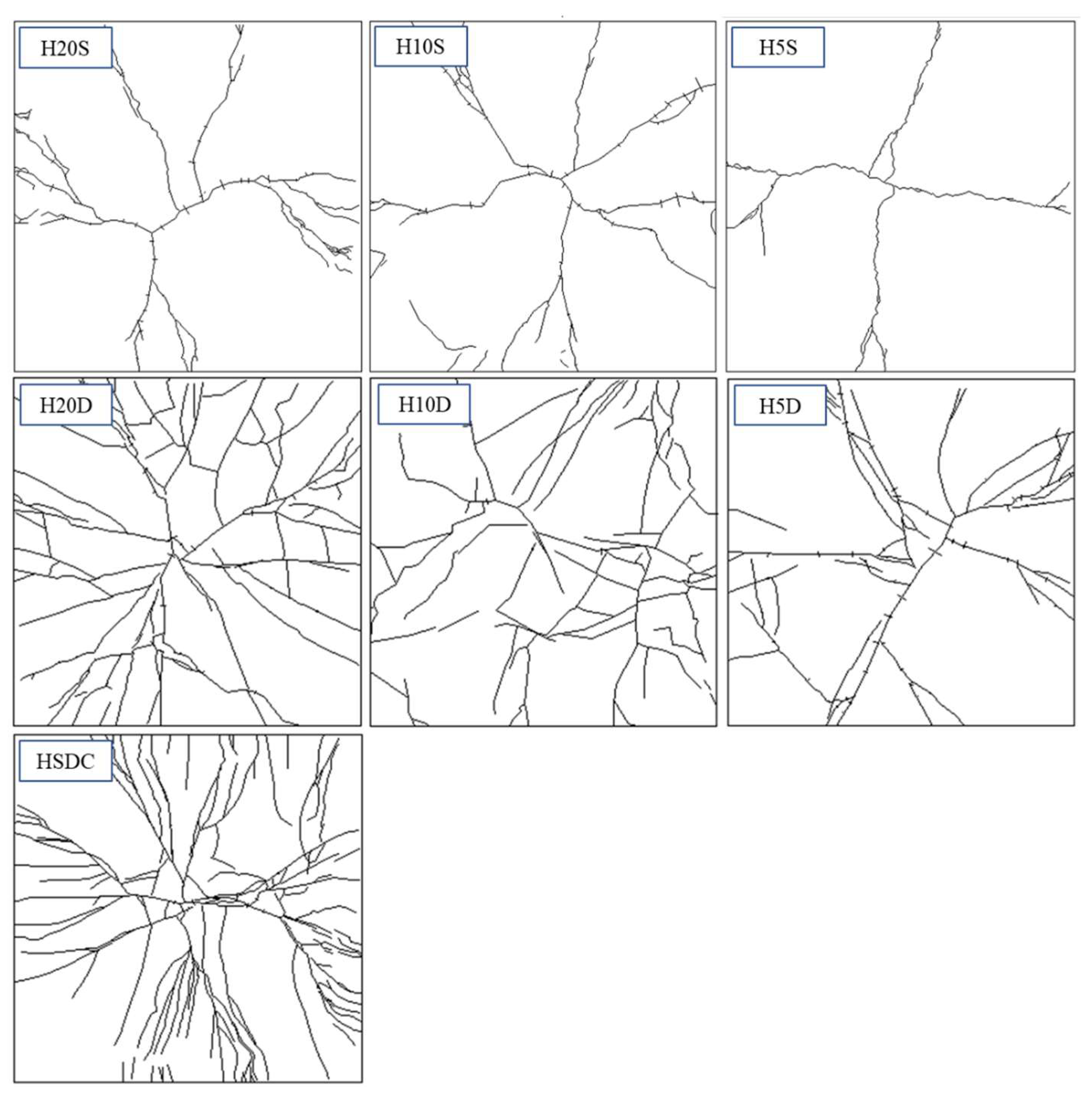

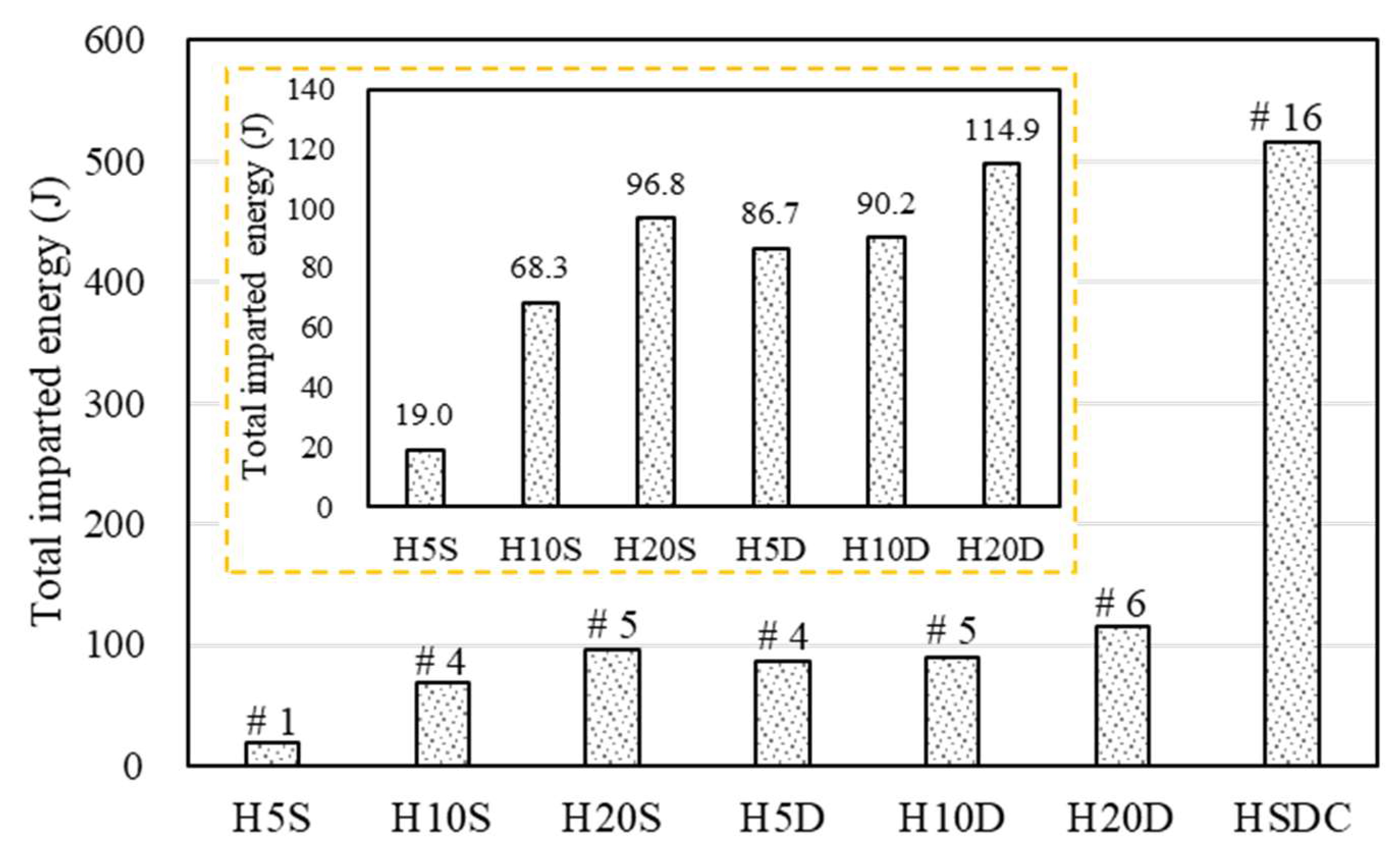

3.2.1. The Results of Drop Weight Impact Test

3.2.2. Shielding Effectiveness after Impact Tests of Strengthened Specimens

4. Conclusions

- The specimens strengthened with HSDC displayed an increase in SE with increasing strengthening thickness, which was 2.4–35.3, 7.0–31.9, and 6.9–43.8 dB, respectively, comparatively higher than specimens without strengthening. For the single- and double-layer HSDC strengthening, a strengthening area ratio greater than 40% produced an SE that was over 20 dB.

- The properties of specimens reinforced with a double layer were greater than those of specimens reinforced with a single layer (such as reaction force, deflection, and cracking resistance). The specimen’s improved impact resistance characteristics corresponded with the strengthening side numbers and thickness, and similar strength trends were achieved for specimens with 20% strengthening area ratios.

- Specimens reinforced by 20 mm of HSDC had the lowest SE decrease ratio when compared to other specimens reinforced by 5 and 10 mm of HSDC, which showed around 7.1 and 24.7%, respectively. This is due to large amounts of spalling in the center of the bottom surface in the impact region in specimens strengthened by 5 and 10 mm, which greatly reduced the effective thickness. Although multiple incidents of damage were displayed and lowered the effective thickness of test specimens, the SE reduction ratio demonstrated equal values in similar damage area ratios of specimens that had uniformly dispersed steel fiber.

Author Contributions

Funding

Conflicts of Interest

References

- Guan, H.; Liu, S.; Duan, Y.; Cheng, J. Cement based electromagnetic shielding and absorbing building materials. Cem. Concr. Compos. 2006, 28, 468–474. [Google Scholar] [CrossRef]

- Shukla, V. Review of electromagnetic interference shielding materials fabricated by iron ingredients. Nanoscale Adv. 2019, 1, 1640–1671. [Google Scholar] [CrossRef]

- Wanasinghe, D.; Aslani, F.; Ma, G.-W.; Habibi, D. Advancements in electromagnetic interference shielding cementitious composites. Constr. Buil. Mater. 2020, 231, 117116. [Google Scholar] [CrossRef]

- Choi, J.-S.; Yuan, T.-F.; Hong, S.-H.; Yoon, Y.-S. Evaluating of Electromagnetic shielding characteristics of reinforced concrete using reinforcing details. J. Korean Soc. Hazard Mitig. 2020, 20, 245–254. [Google Scholar] [CrossRef]

- Yuan, T.-F.; Choi, J.-S.; Kim, S.-K.; Yoon, Y.-S. Assessment of steel slag and steel fiber to control electromagnetic shielding in high-strength concrete. KSCE J. Civ. Eng. 2021, 25, 920–930. [Google Scholar] [CrossRef]

- Yuan, T.-F.; Choi, J.-S.; Hong, S.-H.; Yoon, Y.-S. Enhancing the electromagnetic shielding and impact resistance of a reinforced concrete wall for protective structures. Cem. Concr. Compos. 2021, 122, 104148. [Google Scholar] [CrossRef]

- Mazzoli, A.; Corinaldesi, V.; Donnini, J.; Di Perna, C.; Micheli, D.; Vricella, A.; Pastore, R.; Bastianelli, L.; Moglie, F.; Mariani Priminai, V. Effect of graphene oxide and metallic fibers on the electromagnetic shielding effect of engineered cementitious composites. J. Build. Eng. 2018, 18, 33–39. [Google Scholar] [CrossRef]

- Li, Y.; Yu, M.; Yang, P.; Fu, J. Enhanced microwave absorption property of Fe Nanopaticles encapsulated within reduced graphene oxide with different thicknesses. Ind. Eng. Chem. Res. 2017, 56, 8872–8879. [Google Scholar] [CrossRef]

- Jung, M.-J.; Lee, Y.-S.; Hong, S.-G.; Moon, J.-Y. Carbon nanotubes (CNTs) in ultra-high performance concrete (UHPC): Dispersion, mechanical properties, and electromagnetic interference (EMI) shielding effectiveness (SE). Cem. Concr. Res. 2020, 131, 106017. [Google Scholar] [CrossRef]

- Liu, F.; Lü, X.; Li, Y.-B.; Yang, J.; Pan, Z. Attenuation characteristics on high power microwave penetrating through reinforcement nets. High Power Laser and Part. Beams 2012, 24, 2713–2717. [Google Scholar]

- Liu, F.; Lü, X.; Li, Y.-B.; Yang, J.; Pan, Z. Attenuation characteristics on high power microwave penetrating through reinforced concrete. Chin. J. Radio Sci. 2014, 29, 35–39. [Google Scholar]

- Jung, M.-J.; Lee, Y.-S.; Hong, S.-G. Effect of incident area size on estimation of EMI shielding effectiveness for ultra-high-performance concrete with carbon nanotubes. IEEE Access 2019, 7, 183105–183117. [Google Scholar] [CrossRef]

- Yuan, T.-Y.; Lee, J.-Y.; Min, K.-H.; Yoon, Y.-S. Experimental investigation on mechanical properties of hybrid steel and polyethylene fiber reinforced no-slump high-strength concrete. Int. J. Polym. Sci. 2019, 2019, 4737384. [Google Scholar] [CrossRef] [Green Version]

- Yuan, T.-F.; Lee, J.-Y.; Yoon, Y.-S. Enhancing the tensile capacity of no-slump high-strength high-ductility concrete. Cem. Concr. Compos. 2020, 106, 103458. [Google Scholar] [CrossRef]

- Yuan, T.-F.; Hong, S.-H.; Shin, H.-O.; Yoon, Y.-S. Bond strength and flexural capacity of normal concrete beams strengthened with no-slump high-strength, high-ductility concrete. Materials 2020, 13, 4218. [Google Scholar] [CrossRef]

- MIL-STD-188-125-1, High-Altitude Electro-Magnetic pulse (HEMP) Protection for Ground-Based C4I Facilities Performing Critical, Time Urgent Missions; Department of Defense Interface Standard: Goleta, CA, USA, 1998.

- Quintana, S.; De Blas, J.-M.; Pena, J.; Blanco, J.; Garcia, L.-D.; Pastor, J.-M. Design and operation of a real-scale electromagnetic shielding evaluation system for reinforced composite construction materials. J. Mater. Civ. Eng. 2018, 30, 04018162. [Google Scholar] [CrossRef]

- Lu, H.-D.; Zhu, F.; Li, X.; Tang, Y.-T. Shielding effectiveness of reinforced concrete toward electric arcs in pantograph catenary systems of metro. Chin. J. Radio Sci. 2016, 31, 1209–1215. [Google Scholar]

- Trevor, D.-H.; Frank, J.-V. Behavior of steel fiber-reinforced concrete blabs under impact load. ACI Struct. J. 2014, 111, 1213–12224. [Google Scholar]

- Yoo, D.-Y.; Kang, M.-C.; Choi, H.-J.; Shin, W.-S.; Kim, S.H. Electromagnetic interference shielding of multi-cracked high-performance fiber-reinforced cement composites-Effects of matrix strength and carbon fiber. Constr. Build. Mater. 2020, 261, 119949. [Google Scholar] [CrossRef]

| W/C | W | C | Fine Aggregate | Coase Aggregate | Silica Fume | Silica Filler | Silica Sand | Steel Fiber | Polyethylene Fiber | SP | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| NC | 0.43 | 0.43 | 1.00 | 2.15 | 2.42 | - | - | - | - | - | 0.8% |

| HSDC | 0.172 | 0.215 | 1.00 | - | - | 0.25 | 0.30 | 1.10 | 1.0% | 0.5% | 3.0% |

| Surface Area (cm2/g) | Density (g/cm3) | Chemical Composition (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | |||

| Cement | 3492 | 3.15 | 21.2 | 4.7 | 3.1 | 62.8 | 2.8 | 2.1 | - |

| Silica fume | 200,000 | 2.20 | 96.0 | 0.3 | 0.1 | 0.4 | 0.1 | <0.2 | - |

| Silica sand | 2990 | 2.7 | 99.7 | 0.14 | 0.016 | 0.01 | 0.01 | - | 0.01 |

| Diameter, df (mm) | Length, lf (mm) | Aspect Ratio (lf/df) | Density (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (GPa) | |

|---|---|---|---|---|---|---|

| Steel fiber | 0.2 | 19.5 | 97.5 | 7.8 | 2650 | 200 |

| Variable | Compressive Strength (MPa/CV) | Flexural Strength (MPa/CV) | Tensile Strength (MPa/CV) | Remarks |

|---|---|---|---|---|

| NC | 44.6/0.2 | 25.7/0.4 | 3.9/0.5 | Splitting tensile strength test |

| HSDC | 122.3/0.1 | 22.9/6.5 | 9.7/1.6 | Direct tensile strength test |

| Variable | Thickness | HSDC | ||

|---|---|---|---|---|

| Thickness | Layer | |||

| 1 | D1-HSDC | 100 mm | - | - |

| 2 | D2-HSDC | 200 mm | - | - |

| 3 | D1-H5S | 100 mm | 5 mm | single |

| 4 | D1-H5D | 100 mm | 5 mm | double |

| 5 | D1-H10S | 100 mm | 10 mm | single |

| 6 | D1-H10D | 100 mm | 10 mm | double |

| 7 | D1-H20S | 100 mm | 20 mm | single |

| 8 | D1-H20D | 100 mm | 20 mm | double |

| 9 | D2-H20S | 200 mm | 20 mm | single |

| 10 | D2-H20D | 200 mm | 20 mm | double |

| 11 | D3-H20S | 300 mm | 20 mm | single |

| 12 | D3-H20D | 300 mm | 20 mm | double |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-H.; Choi, J.-S.; Yuan, T.-F.; Yoon, Y.-S. Shielding Effectiveness and Impact Resistance of Concrete Walls Strengthened by High-Strength High-Ductility Concrete. Materials 2021, 14, 7773. https://doi.org/10.3390/ma14247773

Lee J-H, Choi J-S, Yuan T-F, Yoon Y-S. Shielding Effectiveness and Impact Resistance of Concrete Walls Strengthened by High-Strength High-Ductility Concrete. Materials. 2021; 14(24):7773. https://doi.org/10.3390/ma14247773

Chicago/Turabian StyleLee, Jae-Hoon, Jin-Seok Choi, Tian-Feng Yuan, and Young-Soo Yoon. 2021. "Shielding Effectiveness and Impact Resistance of Concrete Walls Strengthened by High-Strength High-Ductility Concrete" Materials 14, no. 24: 7773. https://doi.org/10.3390/ma14247773