Study on Mechanical Properties of Basalt Fiber Shotcrete in High Geothermal Environment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mix Proportions Design and Test Methods

3. Results and Discussion

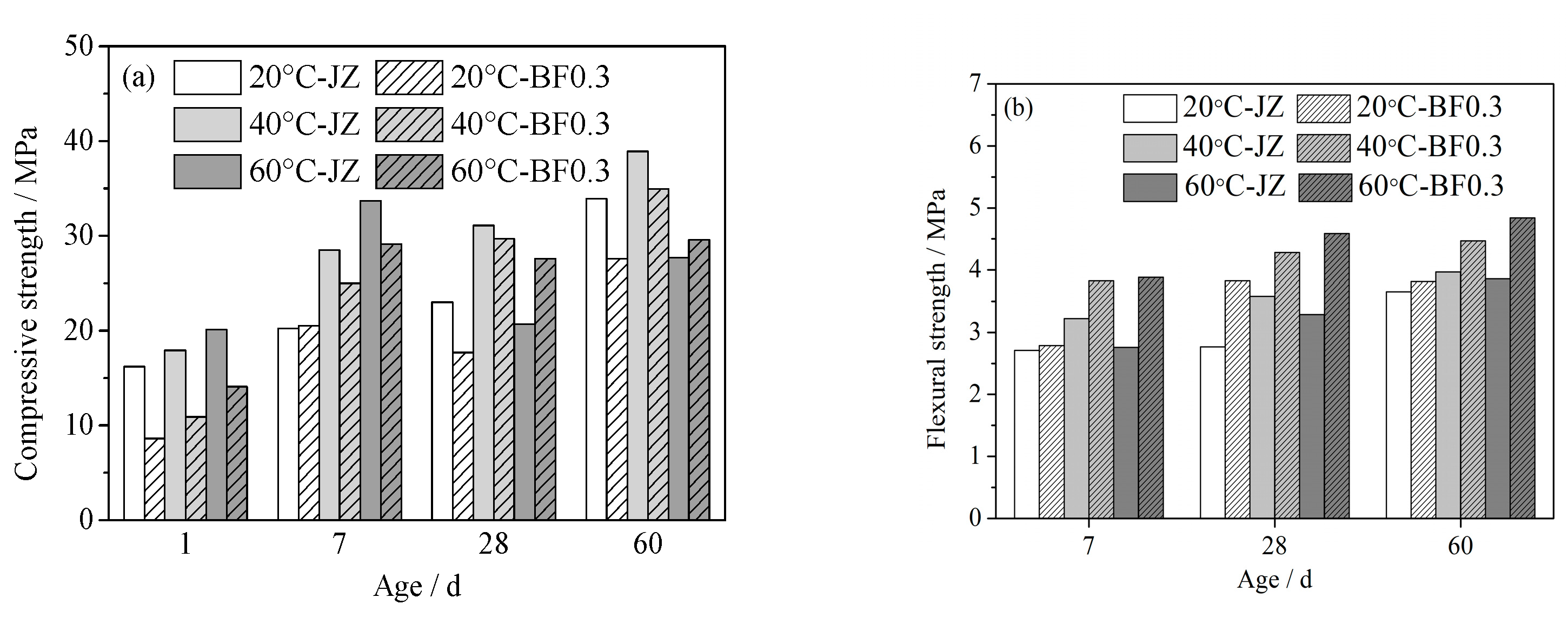

3.1. Compressive and Flexural Strength

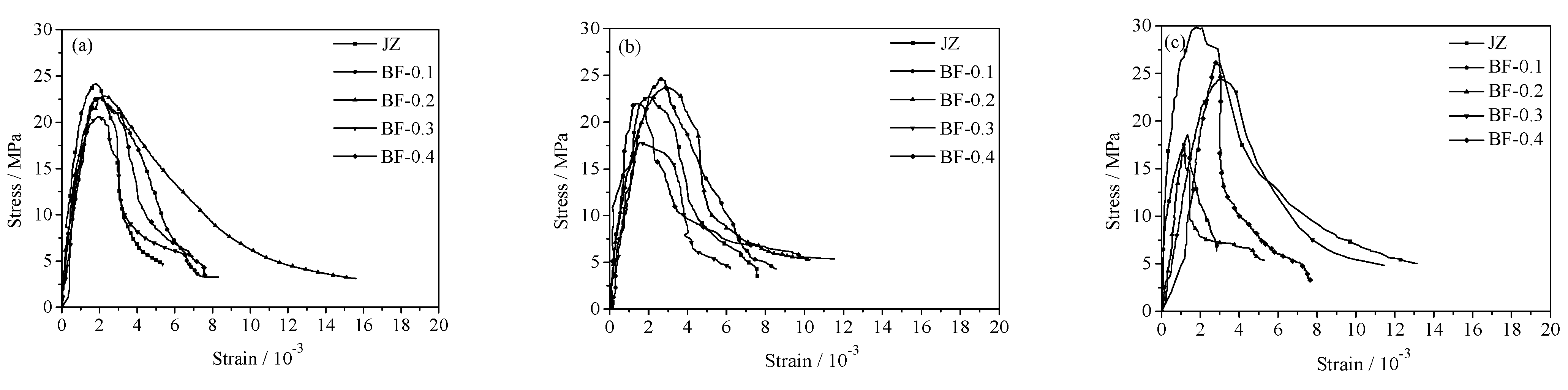

3.2. Uniaxial Compressive Stress-Strain

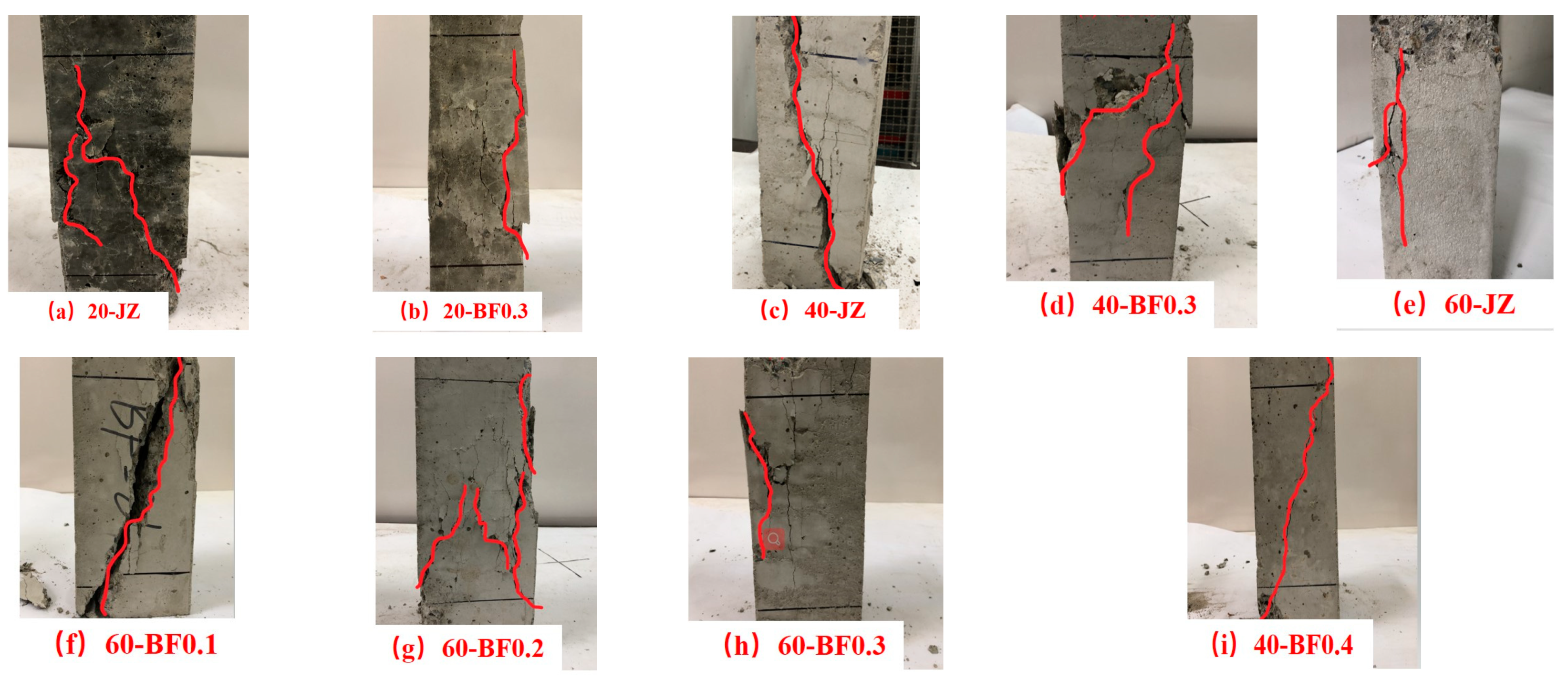

3.2.1. Compression Failure State

3.2.2. Effect of Curing Temperature on Stress-Strain Curve of Shotcrete

3.2.3. Effect of Basalt Fiber on Stress-Strain Curve of Shotcrete

4. Constitutive Model

4.1. Stress-Strain Curve Fitting of Shotcrete at Different Temperatures

4.2. Stress-Strain Curve Fitting of Shotcrete with Different Basalt Fiber Content

4.3. Establishment of Constitutive Equation

5. Conclusions

- (1)

- High temperature curing can improve the early compressive strength of shotcrete, but it is not good for the development of its early flexural strength. After curing for 28 days, both the compressive strength and flexural strength decrease to varying degrees. The addition of fiber can reduce the strength deterioration of shotcrete caused by high temperature environment conservation, and the effect increases first and then decreases with the addition of fiber. The optimum basalt fiber content is 0.3%.

- (2)

- High temperature is attributed to the decrease in the peak stress and strain of shotcrete, and showing a greater brittleness, and the stress-strain curve becomes sharp and steep. Meanwhile, the fiber increases the peak strain of concrete, up to 91.6%, resulting in an increase in the plasticity and ductility.

- (3)

- According to the relationship between peak stress, peak strain, and axial compression, the stress-strain curve parameters a, b and temperature and basalt fiber content of concrete were analyzed, and the constitutive equation of shotcrete in a high geothermal environment is established.

6. Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deng, Z.; Sun, Q. Tunnel engineering of sichuan—Tibet railway. Tunn. Constr. 2017, 37, 1049–1054. [Google Scholar]

- Chen, H.-J.; Yang, T.-Y.; Tang, C.-W. Strength and durability of concrete in hot spring environments. Comput. Concr. 2009, 6, 269–280. [Google Scholar] [CrossRef]

- Tan, K.; Liu, T. Influence of early high temperature curing on compressive strength of concrete. J. Build. Mater. 2006, 473–476. [Google Scholar]

- Niu, D.; Zhang, S.; Wang, Y.; Hong, M.; Li, Z. Effect of temperature on the strength, hydration products and microstructure of shotcrete blended with supplementary cementitious materials. Constr. Build. Mater. 2020, 264, 120234. [Google Scholar] [CrossRef]

- Tang, Y.; Xu, G.; Lian, J.; Su, H.; Qu, C. Effect of temperature and humidity on the adhesion strength and damage mechanism of shotcrete-surrounded rock. Constr. Build. Mater. 2016, 124, 1109–1119. [Google Scholar] [CrossRef]

- Liu, P.; Cui, S.; Li, Z.; Xu, X.; Guo, C. Influence of surrounding rock temperature on mechanical property and pore structure of concrete for shotcrete use in a hot-dry environment of high-temperature geothermal tunnel. Constr. Build. Mater. 2019, 207, 329–337. [Google Scholar] [CrossRef]

- Yin, W. Study on Mechanical Properties of Shotcrete at High Rock Temperature Based on Pore Structure; Hebei University of Engineering: Handan, China, 2021. [Google Scholar]

- Sruthi, J.; Dipti, R.S.; Vasant, M. Experimental investigation of the mechanical properties of basalt fiber-reinforced concrete. Struct. Concr. 2017, 18, 292–302. [Google Scholar]

- Dias, D.P.; Clelio, T. Fracture toughness of geopolymeric concretes reinforced ith basalt fibers. Cem. Concr. Compos. 2005, 27, 49–54. [Google Scholar] [CrossRef]

- Sim, J.; Park, C.; Moon, D.Y. Characteristics of basalt fiber as a strengthening material for oncrete structures. Compos. Part B 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Bazli, M.; Abolfazli, M. Mechanical Properties of Fiber Reinforced Polymers under Elevated Temperatures: An Overview. Polymers 2020, 12, 2600. [Google Scholar] [CrossRef] [PubMed]

- Cui, S.; Liu, P.; Cui, E.; Su, J.; Huang, B. Experimental study on mechanical property and pore structure of concrete for shotcrete use in a hot-dry environment of high geothermal Tunnels. Constr. Build. Mater. 2018, 173, 124–135. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, N.; Zhang, H.; Chen, L.; Yao, X. Experimental study on early split tensile strength of spray layer structure of hydraulic tunnel influenced by temperature difference. J. Hydroelectr. Power 2014, 33, 221–229. [Google Scholar]

- Wang, R.; Chen, G.; Li, T.; Xu, P. Experimental study on mechanical properties of high ground temperature resistant lining concrete. J. Sci. Technol. Eng. 2018, 18, 110–116. [Google Scholar]

- Zhou, P.; Wang, Z.J.; Yang, Y.; Ji, X.F. Experimental study on the performance of basalt fiber shotcrete under thermal environment. Civ. Environ. Eng. 2016, 38, 69–76. [Google Scholar]

- Miao, X.; Lin, J.; Bian, F. Utilization of discarded crop straw to produce cellulose nanofibrils and their assemblies. J. Bioresour. Bioprod. 2020, 5, 26–36. [Google Scholar] [CrossRef]

- Dara, P.K.; Geetha, A.; Mohanty, U.; Raghavankutty, M.; Mathew, S.; Nagarajarao, R.C.; Rangasamy, A. Extraction and Characterization of Myofibrillar Proteins from Different Meat Sources: A Comparative Study. J. Bioresour. Bioprod. 2021, 6, 367–378. [Google Scholar] [CrossRef]

- CECS 13: 2009. Standard Test Method for Fiber Reinforced Concrete; China Planning Press: Beijing, China, 2009. [Google Scholar]

- Wang, M.; Hu, Y.; Wang, Q.; Tian, H.; Liu, D. A study on strength characteristics of concrete under variable temperature curing conditions in ultra-high geothermal tunnels. Constr. Build. Mater. 2019, 229, 116989. [Google Scholar] [CrossRef]

- GB/T 50081-2019. Test Method for Physical and Mechanical Properties of Concrete; China Academy of Building Research: Beijing, China, 2019. [Google Scholar]

- Piao, Z. Experimental Study on Mechanical Properties of Basalt Fiber Reinforced Concrete after High Temperature; Zhengzhou University: Zhengzhou, China, 2016. [Google Scholar]

- Mohamed, O.A.; Al, H.W.; Keshawarz, M. Durability and Mechanical Properties of Concrete Reinforced with Basalt Fiber-Reinforced Polymer (BFRP) Bars: Towards Sustainable Infrastructure. Polymers 2021, 13, 1402. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, S.; Niu, D.; Fu, Q. Quantitative evaluation of the characteristics of air voids and their relationship with the permeability and salt freeze–thaw resistance of hybrid steel-polypropylene fiber–reinforced concrete composites. Cem. Concr. Compos. 2021, 125, 104292. [Google Scholar] [CrossRef]

- Ramesh, B.; Eswari, S. Mechanical behaviour of basalt fibre reinforced concrete: An experimental study. Mater. Today Proc. 2021, 43, 2317–2322. [Google Scholar] [CrossRef]

- Yang, C. Experimental Study on Mechanical Properties and Durability of Hybrid Fiber Reinforced Concrete; Dalian University of Technology: Dalian, China, 2007. [Google Scholar]

- Zhang, Y. Study on Basic Mechanical Properties of Short—Cut Basalt Fiber Concrete; Northeast Forestry University: Harbin, China, 2011. [Google Scholar]

- Zhong, G.; Zhou, Y.; Xiao, Y. Study on uniaxial stress—strain curve of steel—polyvinyl alcohol hybrid fiber concrete. Eng. Mech. 2020, 37, 111–120. [Google Scholar]

- Dong, Y. Experimental Study on Mechanical Properties of Hybrid Fiber Reinforced Concrete after High Temperature; Liaoning University of Technology: Jinzhou, China, 2019. [Google Scholar]

- Guo, Z. Strength and Deformation of Concrete: Test Basis and Constitutive Relation; Tsinghua University Press: Beijing, China, 1997. [Google Scholar]

- Guo, Z.; Shi, X. Principle and Analysis of Reinforced Concrete; Tsinghua University Press: Beijing, China, 1997. [Google Scholar]

- Qian, C.; Xu, Y. Damage Characteristics and Constitutive model of Concrete Structural Materials; Southeast University Press: Nanjing, China, 2014. [Google Scholar]

- Asprone, D.; Cadoni, E.; Iucolano, F.; Prota, A. Analysis of the strain-rate behavior of a basalt fiber reinforced natural hydraulic mortar. Cem. Concr. Compos. 2014, 53, 52–58. [Google Scholar] [CrossRef]

- Gao, D.; Zhao, L.; Chen, G. Compressive stress-strain relationship of fiber and nanosized material reinforced concrete in high temperature. J. Civ. Eng. 2017, 50, 46–58. [Google Scholar]

| Chemical Composition (wt.%) | CaO | SiO2 | Al2O3 | Fe2O3 | Na2O | K2O | MgO | SO3 | TiO2 | Loss on Ignition |

|---|---|---|---|---|---|---|---|---|---|---|

| Value | 61.83 | 19.68 | 4.72 | 3.66 | 0.43 | 1.27 | 1.31 | 0.05 | 2.73 | 2.23 |

| Physical Properties | Initial Setting Time/Min | Final Setting Time/Min | Specific Surface (m2/kg) | Flexural Strength /MPa | Compressive Strength /MPa | ||

|---|---|---|---|---|---|---|---|

| 3 d | 28 d | 3 d | 28 d | ||||

| Value | 135 | 225 | 325 | 3.9 | 7.1 | 19.8 | 44.6 |

| Physical Properties | Particle Size/mm | Bulk Density (g/cm3) | Apparent Density (g/cm3) | Clay Content/% | Crush Value/% | Water Absorption/% | Fineness Modulus |

|---|---|---|---|---|---|---|---|

| Stone | 5–10 | 1.43 | 2.82 | 0.75 | 5 | 1.02 | - |

| Sand | 0–4.75 | 1.48 | 2.63 | 1.0 | - | 1.2 | 2.7 |

| Chemical Composition | Al2O3 | SO42− | Na2O | Al2O3/SO42− | pH (20 °C) |

|---|---|---|---|---|---|

| Value | 11.7 | 25.6 | - | 0.46 | 3.7 |

| Length /mm | Diameter /μm | Density (g/cm3) | Modulus of Elasticity /GPa | Elongation /% | Tensile Strength /MPa |

|---|---|---|---|---|---|

| 6 | 15 | 2.56 | 40 | 3.1 | 2400 |

| Cement | Sand | Gravel | Fiber | Water | Accelerator | Superplasticizer |

|---|---|---|---|---|---|---|

| 400 | 813 | 870 | 0 | 190 | 16 | 4 |

| 400 | 813 | 870 | 0.4 | 190 | 16 | 4 |

| 400 | 813 | 870 | 0.8 | 190 | 16 | 4 |

| 400 | 813 | 870 | 1.2 | 190 | 16 | 4 |

| 400 | 813 | 870 | 1.6 | 190 | 16 | 4 |

| Condition Symbols | σp | εp | ||||

|---|---|---|---|---|---|---|

| 7 d | 28 d | 60 d | 7 d | 28 d | 60 d | |

| 20 °C-JZ | 29.47 | 28.59 | 26.51 | 2.01 | 2.5 | 1.98 |

| 40 °C-JZ | 20.12 | 18.16 | 20.70 | 1.98 | 2.70 | 1.65 |

| 60 °C-JZ | 23.68 | 22.67 | 29.84 | 2.05 | 2.10 | 1.81 |

| Condition Symbols | σp | εp | ||||

|---|---|---|---|---|---|---|

| 7 d | 28 d | 60 d | 7 d | 28 d | 60 d | |

| JZ | 24.14 | 22.67 | 29.84 | 1.80 | 2.10 | 1.70 |

| BF-0.1 | 22.65 | 24.62 | 18.55 | 2.01 | 2.65 | 1.35 |

| BF-0.2 | 22.82 | 23.72 | 17.26 | 2.25 | 3.0 | 1.20 |

| BF-0.3 | 20.58 | 17.81 | 24.43 | 3.45 | 1.55 | 3.04 |

| BF-0.4 | 22.67 | 21.98 | 26.16 | 2.05 | 1.40 | 2.85 |

| Temperature/°C | Mixture | Ascending Section Parameter a | Descending Section Parameter b | ||||

|---|---|---|---|---|---|---|---|

| 7 d | 28 d | 60 d | 7 d | 28 d | 60 d | ||

| 20 | JZ | 0.821 | 2.090 | 0.772 | 0.288 | 2.268 | 1.551 |

| BF-0.3 | 2.173 | 1.580 | 2.723 | 3.459 | 2.604 | 2.113 | |

| 40 | JZ | 0.954 | 2.953 | 1.742 | 5.754 | 2.643 | 2.498 |

| BF-0.3 | 0.961 | 1.757 | 0.923 | 2.260 | 3.545 | 3.714 | |

| 60 | JZ | 2.238 | 2.103 | 2.774 | 3.132 | 2.844 | 1.929 |

| BF-0.3 | 1.872 | 1.306 | 1.275 | 2.350 | 2.148 | 2.383 | |

| Fiber Content/% | Ascending Section Parameter a | Descending Section Parameter b | ||||

|---|---|---|---|---|---|---|

| 7 d | 28 d | 60 d | 7 d | 28 d | 60 d | |

| JZ | 2.238 | 2.103 | 2.174 | 3.132 | 2.844 | 1.929 |

| BF-0.1 | 1.531 | 1.567 | 2.705 | 1.540 | 2.457 | 2.334 |

| BF-0.2 | 2.628 | 2.666 | 0.227 | 2.206 | 3.257 | 2.512 |

| BF-0.3 | 1.872 | 1.306 | 1.275 | 2.350 | 2.148 | 2.383 |

| BF-0.4 | 2.237 | 2.139 | 1.077 | 2.644 | 1.95 | 3.178 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, Y.; Wang, Y.; Zhang, S.; Chen, Y.; Li, Z.; Niu, D. Study on Mechanical Properties of Basalt Fiber Shotcrete in High Geothermal Environment. Materials 2021, 14, 7816. https://doi.org/10.3390/ma14247816

Tong Y, Wang Y, Zhang S, Chen Y, Li Z, Niu D. Study on Mechanical Properties of Basalt Fiber Shotcrete in High Geothermal Environment. Materials. 2021; 14(24):7816. https://doi.org/10.3390/ma14247816

Chicago/Turabian StyleTong, Yueping, Yan Wang, Shaohui Zhang, Yahao Chen, Zhaoguang Li, and Ditao Niu. 2021. "Study on Mechanical Properties of Basalt Fiber Shotcrete in High Geothermal Environment" Materials 14, no. 24: 7816. https://doi.org/10.3390/ma14247816