1. Introduction

Nickel–Titanium, NiTi, is a metallic alloy which allows a tuneable and controlled shape memory effect and superelastic behaviour. This provides some unique features that find application in several industrial fields, such as: thermal and electrical actuators, dampers, biomedical devices, etc. Most of these applications rely on the ability of the material to repeatedly undergo wide reversible straining. Therefore, the fatigue behaviour of NiTi alloys is an important aspect of characterisation for safe design.

When subject to cyclic loading, Nickel–Titanium (NiTi) shape memory alloys exhibit peculiar temperature modulations that are driven by the applied cyclic loads. This implies the presence of reversible thermomechanical heat sources that are activated by the applied stresses. The most influential of such sources is the elastocaloric effect, which accounts for the latent heat of Austenite⇄Martensite (A⇄M) phase transformation (PT). The A→M and M→A PTs respectively determine a release and an absorption of heat, which warms and cools the material at the site of the transformation. When the range of a cyclic load is wide enough to activate a two-way A⇄M PT at each cycle, the result is a modulation of temperature whose amplitude can reach several degrees Celsius.

When the range of cyclic loading is not sufficient to activate this two-way PT within the cycle, the material still exhibits a strong cyclic temperature modulation. This work, then, proposes an investigation on the nature of thermomechanical couplings in NiTi strips under cyclic low-amplitude tensile loading. In particular, the thermomechanical behaviour is monitored at strain amplitudes which do not activate a cyclic A⇄M PT. Indeed, most devices designed to functionally exploit the superelastic behaviour of NiTi are only occasionally strained up to A⇄M PT activation. An example is given by endovascular prostheses, which are collapsed and expanded during implantation, while their routine fatigue loading is carried out at strain variations that do not involve further A⇄M PT [

1]. It is, then, relevant to investigate the NiTi thermomechanical behaviour under such conditions, where the heat source related to the Thermoelastic Effect is expected to become the prominent heat source.

In the last ten years, the investigation of PT and thermomechanical behaviour in superelastic NiTi has significantly advanced thanks to the adoption of full-field techniques for measuring strains and temperature [

2,

3,

4,

5,

6]. Digital Image Correlation (DIC) and Infrared Thermography (IRT) have proven to be particularly useful in revealing the localised features of PT [

7,

8,

9,

10,

11]. A significant majority of fatigue studies so far has then focused on A⇄M PT fatigue, i.e., the case when each loading cycle involves a two-way PT [

12,

13,

14]. In these conditions, fatigue strength is primarily related with the ability of the material to cyclically sustain a back-and-forth transition between the Austenite and Martensite states, which may result in a low-cycle fatigue strength. This case, though, is primarily relevant in applications such as solid-state cooling, or other functional applications specifically relying on the maximum recoverable strain evolution [

15]. Under such high-strain fatigue, the latent heat of transformation is also the major thermomechanical heat source, and its reversible nature is reflected in the modulation of the temperature signal, which is in phase with the loading signal.

Some authors have proposed modelling the transformations going on in the stress/strain hysteresis loop of a cyclically loaded NiTi sample by means of a thermodynamic energy balance [

16,

17]. This can be summarised in a local form of the heat diffusion equation which includes heat source terms specific for shape memory alloys, that account for the latent heat of PT [

16,

18].

Under low-amplitude strain fatigue, assuming adiabatic conditions, neglecting the material intrinsic dissipation and assuming also that no latent heat of transformation is released, the main heat source that remains in this thermodynamic energy balance is associated with the Thermoelastic Effect. This term of the diffusion equation would allow linking the temperature changes with stresses/strains, through the first- or second-order laws of the Thermoelastic Effect. Only a few works have explored the validity and utility of the previous assumptions [

19,

20]. A noteworthy outcome of these studies was that the temperature appears to change in phase with the load, against the predictions of the first order Thermoelastic theory. Similar in-phase responses are observed and reported by others [

2,

21], generally observing a quasi-linear and spatially homogeneous increase of temperature in the sample immediately after the start of tensile loading, up to the A⇄M PT. A few works have also reported a decrease of temperature at the very start of the tensile test, which soon reverses to an increase as the load increases, but well before the initiation of the A→M plateau [

22]. By adopting a higher-order thermoelastic theory, it has been found that a positive-valued derivative of the Young’s modulus with temperature could justify a thermoelastic signal in phase with the external load [

19,

20]. A relatively high and positive

dE/dT was indeed measured experimentally, both in the Austenite and Martensite states, at near room temperature. It has also been observed that some Nitinol grades might activate an intermediate stare between Austenite and Martensite, consisting of an R-type PT [

23]. A stress-activated R-type PT also determines a change in the Young’s modulus

E, which might have an impact on the thermoelastic signal and also on the second harmonic.

The present work investigates the behaviour of a NiTi strip under a cyclic tensile load applied under strain control, with a positive mean strain value and an amplitude smaller than the difference between the two A⇄M transformation plateau stresses. Such a loading condition will generally correspond to a stationary distribution of Austenite or Martensite zones, whose extent depends on the value of the mean strain [

24]. Both DIC and IRT are applied. DIC makes it possible to control the phase distribution during the fatigue loading, while IRT is used to sample the temperature signal during cycling. Since the sampled temperature shows a similar modulation of the applied load, and hence a marked reversible nature, a harmonic analysis is proposed, carried out using Discrete Fourier Transform signal processing.

The proposed investigation of the frequency content and the harmonic features of the temperature signal has the specific purpose of investigating the nature of the heat source feeding such temperature variation. The paper presents an analysis of the first and second harmonics of temperature (i.e., the temperature changes at the load frequency and twice the load frequency), with the purpose of establishing whether the temperature modulation behaviour is fully predicted by the known Thermoelastic Effect theories.

2. NiTi Thermomechanical Modelling

Several authors have modelled the NiTi thermomechanical behaviour within the assumptions and the theory of thermodynamics of irreversible processes for solid systems [

16,

17,

25]. Under quasistatic conditions, the only work done on a solid system can be assumed to be stored as strain energy. Therefore, the local thermodynamic status of the system is determined by a set of state variables: the temperature

T, the strain tensor

εij and other internal state variables. For the case of shape memory alloys, an internal state variable is needed to describe the micro lattice phase status and its changes. Other variables may also be added to describe damage onset. Therefore, all internal variables can be included into a vector

x.

By combining the first and second principles of thermodynamics, introducing the Helmholtz free energy thermodynamic potential,

H, it is possible to obtain the local energy balance in the form of a heat conduction law, as follows [

16,

26]:

where

ρ,

Cε and

k describe the material density, specific heat at constant volume and heat conductivity,

Dm is the intrinsic dissipation and

qs the heat exchange between the body and the surroundings.

When the material undergoes cyclic loading over a sufficiently high frequency threshold, it can be assumed that the transformation is adiabatic, i.e., no internal heat conduction arises and the second term on the left-hand side of Equation (1) is neglected. If the loading amplitude is sufficiently small to be included within a purely elastic material response, insufficient to activate A⇄M PT, then it is possible to assume that

. Moreover, the internal mechanical dissipation can also be assumed to be null and no other internal heat sources are present. Under these assumptions Equation (1) is only left with the thermoelastic coupling term, and becomes [

27]:

Integrating over a finite time, Equation (2) can also be written as:

2.1. Thermoelastic Coupling

The conditions leading to Equation (3) make it possible to establish a stress analysis technique, generally referred to as Thermoelastic Stress Analysis (TSA) [

19], by means of which the temperature harmonic content is filtered from the temperature signal and correlated with stress metrics for structural evaluations.

Further development of Equation (3) requires the evaluation of the derivative of the stress tensor with T. Assuming the generalised Hooke’s elastic law, two different Thermoelastic laws are derived [

27].

The first order thermoelastic law is obtained by assuming that all elastic constants and the coefficient of thermal expansion have a negligible dependence on temperature changes. This holds true for most materials around room temperature, and Equation (3) can be further simplified to become a linear correlation between temperature change and the change of the strain or stress first invariant:

The correlation with the first strain invariant also suggests that the thermoelastic coupling term is related with the local elastic reversible volume change. This is often identified as the Thermoelastic Effect.

A second-order thermoelastic law was derived by Wong et al. [

28,

29], where the dependence of elastic parameters from T is not neglected. This leads to a more complex stress metric that can be summarised as:

where

σI =

σ1 +

σ2 +

σ3 is the first stress invariant and

σI =

σ1,

σ2,

σ3 are the principal stress components. If a one-dimensional stress field is considered where

σI =

σ1 +

σ2 +

σ3,

σ1 =

σ and

σ2 =

σ3 = 0, then Equation (5) simplifies in:

To achieve adiabatic conditions, and to improve the signal to noise ratio, TSA usually applies cyclic loads [

30,

31]. Let us consider the case of a tensile load varying as a sin wave with a frequency

ω i.e.,

σ =

σm + Δ

σ sin(

ωt +

ϕ), and an initial phase

ϕ = 0, then Equations (2) and (6) become:

where:

where

F and

S are the symbols used here for the time varying part of each harmonic term.

F is related to the “first harmonic”, i.e., the harmonic at the frequency

ω, and

S is related to the “second harmonic”, at the frequency 2

ω. Subscripts in

F and

S identify the Thermoelastic Effect formulation, 1 for first order and 2 for second order.

Only a few works have investigated the thermoelastic effect in shape memory alloys [

19,

20,

23]. Cycling under stable Austenite or Martensite phase revealed that the temperature harmonic at the loading frequency,

ω, is in phase with the applied load. This is also confirmed by most quasistatic tests shown in the literature, which generally report a tendency of the material to heat up when the traction load increases and cool down when the traction load is reversed, in both fully Austenite and fully Martensite stages. This behaviour can be justified assuming that the material follows a second-order thermoelastic law, where the sign of the first harmonic in Equation (8) (i.e., the temperature change at

ω) is positive, due to becoming

K1σm > Ko [

19]. This holds true when the value of

dE/dT satisfies:

Summarising:

If dE/dT < 0 → F2 = −sin(ωt) and S2.1 = cos(2ωt)

If dE/dT > 0 but dE/dT < αE2/σm → F2 = −sin(ωt) and S2.2 = −cos(2ωt)

If dE/dT > αE2/σm → F2 = sin(ωt) and S2.2 = −cos(2ωt).

While the above condition (1) is usually followed by most common metals and alloys, the experimental evidence for NiTi is that the temperature harmonic at the frequency ω is in phase with the load and therefore only the third condition is compliant with the observed material behavior, i.e., F2 = sin(ωt) and S2 = −cos(2ωt).

For typical material properties of NiTi alloys, which for the initial fully Austenite stage are α = 11 × 10

−6 °C

−1 and

E around 40 GPa, considering a mean stress

σm between 10 and 400 MPa, to satisfy the inequality in Equation (9),

dE/dT should be higher than 1760–44 MPa/°C. This threshold is commonly exceeded in reported tests (e.g., in [

19] it is reported a measured value of

dE/dT = 2231 MPa/°C, obtained at room temperature

To = 25 °C), with

dE/dT becoming significantly higher when

σm approaches the upper A→M plateau. For a mean stress of 150 MPa and

dE/dT ≈ 2000 MPa/°C, consistent with reported data [

19], the following coefficients arise in Equation (8):

where the coefficient of the second harmonic is about an order of magnitude smaller than that of the first harmonic, but proportional to the square of the stress amplitude. Hence, a value of Δ

σ > 7.75/0.31 = 25 MPa would result in a second harmonic amplitude higher than the first harmonic. Therefore, the nonlinear thermoelastic effect at 2

ω can become significant, contrary to more conventional low-strength ductile materials, where the 2

ω component due to the thermoelastic effect is negligible and the observed second harmonic is often governed by intrinsic dissipation [

32].

2.2. Validation of the Thermomechanical Model

As outlined above, the principal thermomechanical source activated during a low-amplitude fatigue cycling can be reduced to the Thermoelastic Effect, which is compatible with a reversible temperature variation, as is observed from testing. Previous works investigating the nature of the Thermoelastic Effect in NiTi have focused only on retrieving and analysing the first harmonic, i.e., the temperature harmonic at the loading frequency ω. The previous analytical model suggests that the thermoelastic effect is expected to produce a meaningful signature also in the second harmonic 2ω. Therefore, the experimental evaluation proposed in the next sections is mainly aimed at analysing the harmonic content of the temperature signal, and to verify its compliance with the previous analytical framework and if it can be used to extract further information on the thermomechanical response of the material.

The different predictions in terms of temporal shifts of the first and second temperature harmonic response can be summarised and identified as follows:

F1: thermoelastic response at ω according to the first order theory (see Equation (7)).

F2: thermoelastic response at ω according to the second-order theory (Equation (8)) when Equation (9) is satisfied.

S2.1: thermoelastic response at 2ω according to the second-order theory (Equation (8)) when dE/dT < 0.

S2.2: thermoelastic response at 2ω according to the second-order theory (Equation (8)) when Equation (9) is satisfied.

3. Materials and Methods

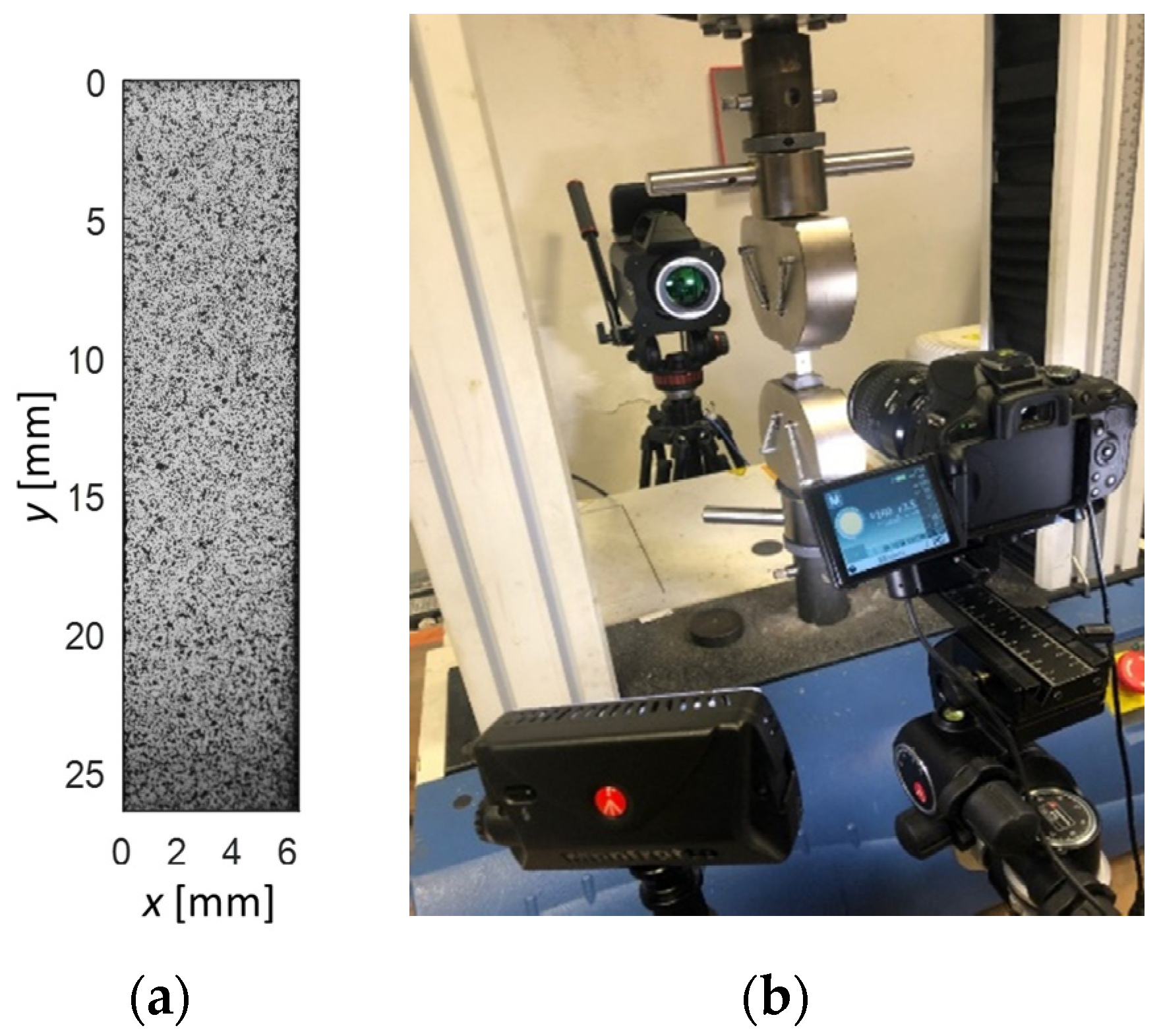

A rectangular strip of NiTi obtained by means of cold rolling, of width equal to 6 mm, gauge length equal to 35 mm and wall thickness equal to 0.2 mm (see

Figure 1), was tested under quasi-static and cyclic loading.

During loading, the strain field and temperature were synchronously monitored by 2D Digital Image Correlation from one face of the sample, and Infrared Thermography on the opposite face of the sample.

Loading was applied on an electro-mechanic Instron 3367 testing machine. Quasi-static loading was applied in displacement control, at a speed of 0.5 mm/min. Cyclic loading was applied by setting a triangular wave shape in the test profiler function of the Instron BlueHill v2.0 software.

3.1. Cyclic Loading and Harmonics Analysis

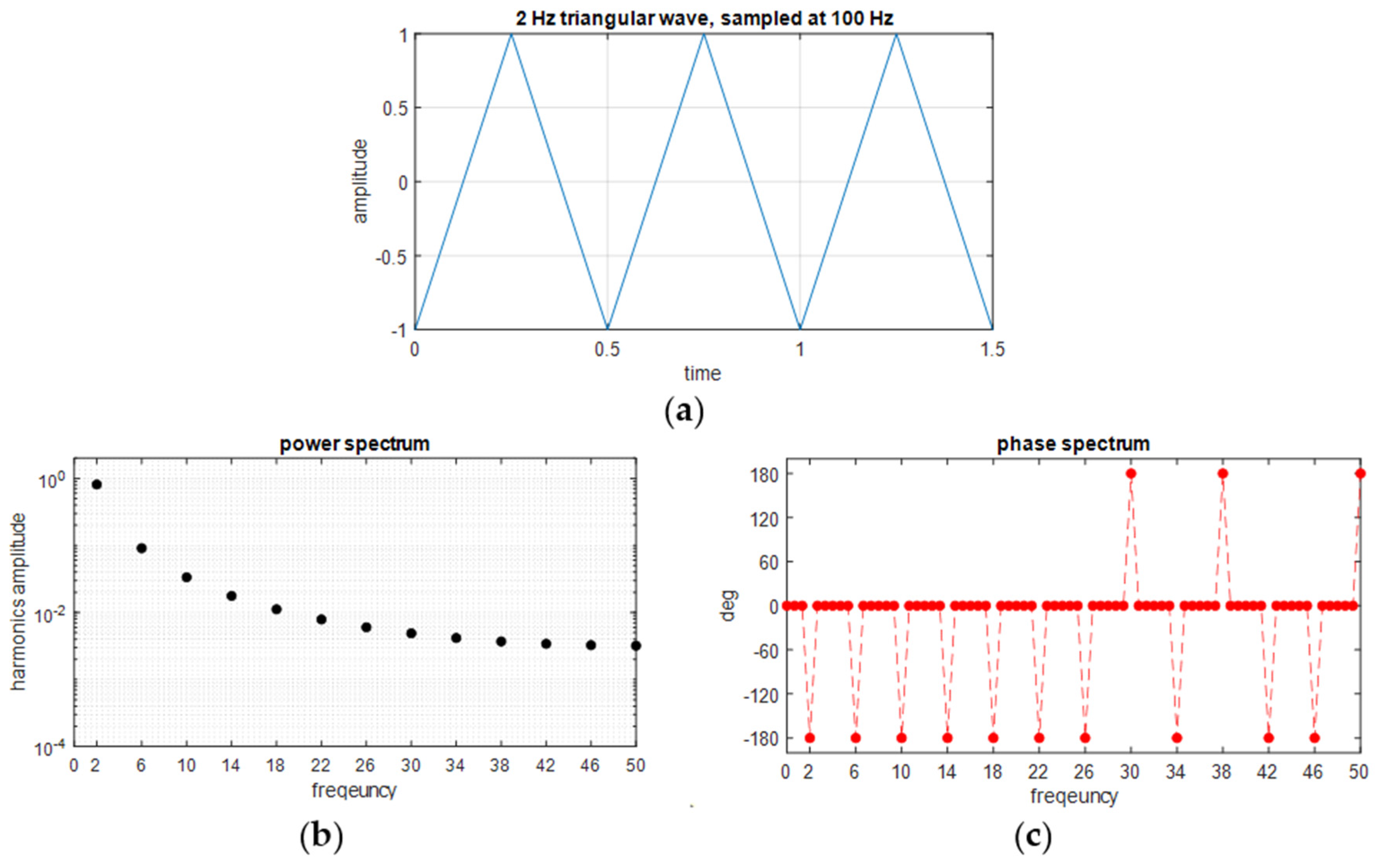

In the present work, cyclic loading is applied by setting a triangular wave modulation of the testing machine crosshead displacement. To evaluate the harmonic content introduced by such loading modulation, the Fourier series of a triangular wave is recalled, considering the time origin at midway of the growing ramp:

where

T is here the fundamental period of the wave and

A its amplitude.

To better process the experimental data, it is useful to shift the time origin by −90°, i.e.,

x =

t +

T/4. Then, the previous relation becomes:

The harmonics of the above series expansion can also be approximated by computing the Discrete Fourier Transform (DFT). This is shown in

Figure 2, where the DFT is computed using the

fft function of MATLAB on a chunk of triangular wave containing an integer number of fundamental periods, to minimise spectral leakage [

31].

From the DFT it is possible to identify the harmonics composing the signal, which are all odd multiples of the fundamental frequency, ω. It is also observed that, based on the chosen initial instant of sampling, all harmonics have a 180° phase shift. This value oscillates between ±180° due to numerical approximations.

3.2. Thermoelastic Source and Phase Modulation

A triangular wave was preferred for this study, as it produces a harmonic spectrum which comprises a fundamental loading harmonic at ω, as well as higher harmonic terms at odd multiple values of ω, i.e., 3, 5, 7, … (2n + 1)ω, with gradually decreasing amplitude. Therefore, the response of the temperature signal at a frequency 2ω is expected to be due to the second-order thermoelastic effect.

As outlined in

Section 2.1, temperature harmonics at

ω and 2

ω can assume different characteristic phase shifts compared to the loading wave.

Figure 3 provides a schematic representation of such phase differences. In this scheme, the amplitudes of all harmonics were normalised to one, since only the phase difference is being evidenced. Furthermore, the initial time is chosen in accordance with the representation of the loading triangular wave reported in

Figure 2. The acquired temperature, load and displacement signals were also truncated so that each acquired signal started at a minimum and contained an even number of periods (in accordance with

Figure 2a). This allows comparing the phase of the first and second harmonic of temperature with the predictions sketched in

Figure 3.

In the present study the MATLAB

fft function is used to compute the DFT of the acquired temperature signal during fatigue loading. The harmonics

Hi computed by the

fft algorithm are trigonometric terms of the type:

For Equation (13) to reproduce the harmonics of

Figure 3, it should then be:

Displacement/Load signal → ϕ = −180°.

F1: Thermoelastic first harmonic (first-order formulation or second-order and Equation (9) not satisfied) → ϕ = 0°.

F2: Thermoelastic first harmonic (second-order formulation, Equations (8) and (9)) → ϕ = −180°.

S2.1: Thermoelastic second harmonic (second-order formulation, Equation (8) and dE/dT < 0) → ϕ = −180°.

S2.2: Thermoelastic second harmonic (second-order formulation, Equations (8) and (9)) → ϕ = 0°.

3.3. Plan of Experiments

In this work three different loading histories are applied to the same sample.

Table 1 reports the nomenclature of these tests, performed in sequence from the QS to the C_up and C_down.

In particular, the load profiles are defined as follows (see also

Figure 4 and

Figure 5):

QS:

C_up and C_down:

ramp from 0 N up to 1.2 mm @ 0.5 mm/min;

C_up: cycling between 1.2 and 1.05 mm @ 0.6 mm/sec for 150 cycles (corresponding to a frequency of the triangular wave of 2 Hz);

ramp from 1.2 up to 2.1 mm @ 0.5 mm/min;

ramp from 2.1 down to 1.2 mm @ 0.5 mm/min;

C_down: cycling between 1.2 and 1.35 @ 0.6 mm/sec for 150 cycles (2 Hz);

ramp from 1.2 mm down to 0.02 mm @ 0.5 mm/min (see also

Figure 4).

The values of load and displacement used to define the C test were chosen based on the results of the previous QS test. This was to make sure that the two cycling stages (up and down) were initiated at a longitudinal average strain placed near the mid upper and lower transformation plateaus. This made it possible to test the sample in presence of both Austenite and Martensite regions [

22,

24]. Additionally, the range of the displacement cycles was chosen so as to avoid any further propagation of the A⇄M PT front during the two cycling windows. A correspondence between the set load and displacement values and the average stress and strain values in the tested sample is reported and commented in

Section 4.1.

Finally, all tests were performed at room temperature, with initial temperatures within the range 20–23 °C.

3.4. DIC Setup

A 2D Digital Image Correlation setup was implemented to monitor the evolution of the strain field. The setup used a reflex photo camera Nikon D5100 equipped with a Macro lens Nikkor AF-S 105 mm Micro f/2.8, a focus rail slider, and a set of LED panels for optimal scene illumination. The sample was painted with a uniform matt white background and random black speckles applied by means of an airbrush gun.

Figure 1a shows the speckled specimen surface. Image sampling was controlled via PC by the software Digicam Control, which allowed a max sampling of 1 picture every 2 s with the time-lapse capture mode. Image correlation was performed using the opens-source software NCORR, operating in MATLAB [

33]. The strain maps presented in this paper were obtained by setting the following correlation parameters: strain radius ranging between 12–20 pixels, subset spacing ranging between 4–8 pixels, strain radius 2–4 subset spacing nodes, while the magnification factor ranged between 0.01–0.016 mm/pixel.

3.5. Infrared Thermography Setup

The temperature field was measured by means of an Infrared camera staring at the face of the sample opposite that stared by the photo-camera (notice that all IR images reported in

Section 4 were flipped left to right to be directly comparable with DIC strain maps). The sample surface was previously painted with a matt black paint to enhance emissivity and reduce reflection. A cooled sensor FLIR X6540sc thermal camera was employed, which allows high thermal resolution and high frame rates (the integration time set in all thermal measurements in this work was 1500 μs). Quasi-static tests were monitored at a frame rate of 1 Hz, while cyclic loadings were sampled at 105 Hz. Data were then pre-processed in Flir Research IR v3.4 and then exported as .mat files for post-processing in MATLAB.

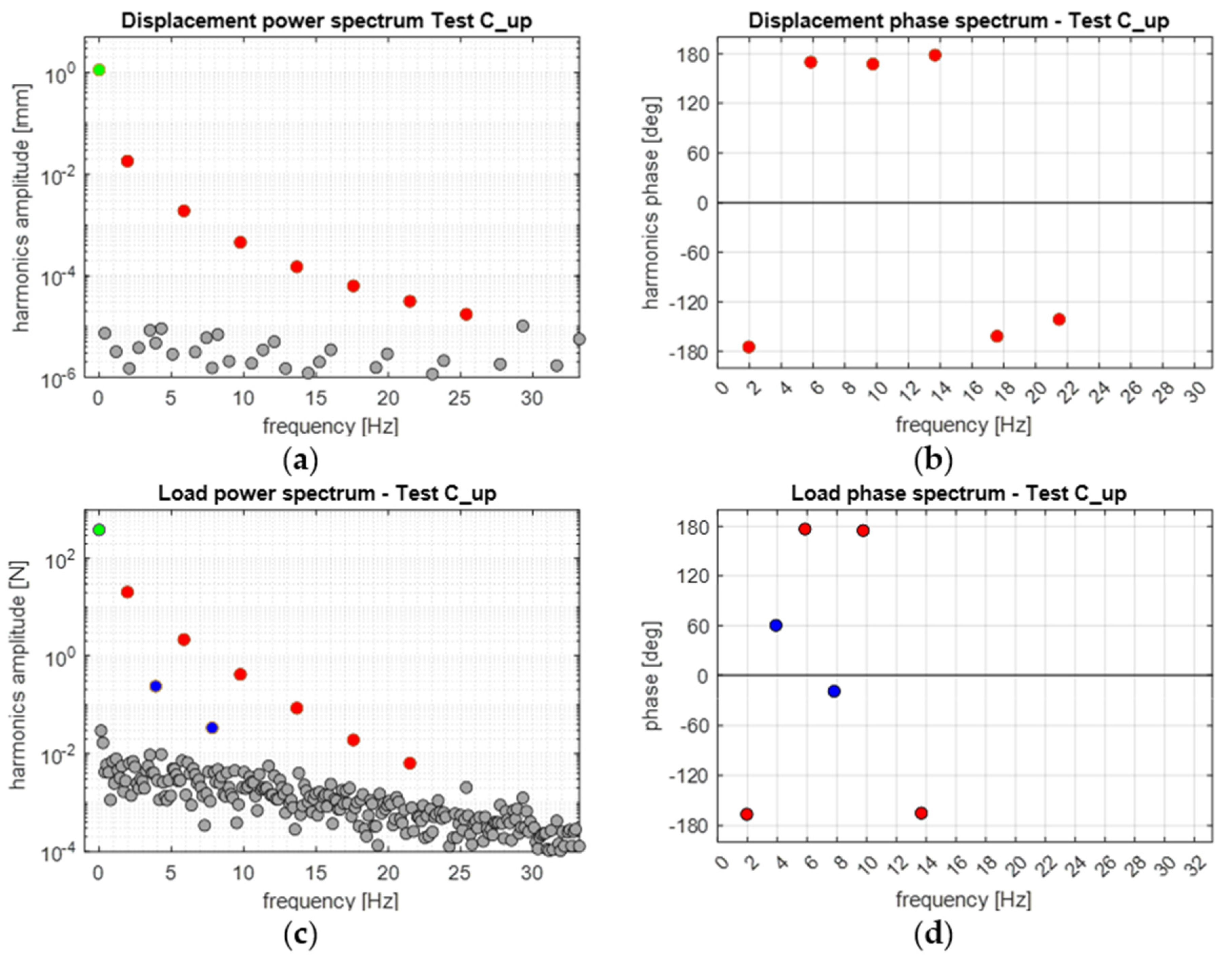

The temperature sequences acquired during cyclic loading were analysed in MATLAB by applying a Discrete Fourier Transform (fft)-based analysis.

The data processing implemented to evaluate the amplitude and phase of the

ω and 2

ω harmonics can be summarised in the following steps [

31].

A time window is selected such to include approximately an integer number of displacement/force and thermogram cycles, starting from a minimum value (or through).

The truncated data series are then imported into MATLAB. The displacement/force/temperature vs. time curves are least square fitted to a three harmonics equation:

where the unknowns are

Ymean,

A1,2,3 and

ϕ1,2,3. The initial fitting is made with an initial guess of

ω that is taken as the main peak of a first DFT spectrum. Then, the optimum

ω is obtained by solving the least square fitting by an iterative optimisation procedure using the MATLAB

patternsearch function.

The previous step yields the optimum value of ω that is then used to optimise the number of frames of the DFT such that a frequency bin is obtained at the value of ω. The lack of spectral leakage in the final DFT spectrum, at ω, 2ω, 3ω and other harmonic peaks, indicates that the optimisation procedure has been successful and the optimal ω has been retrieved.

5. Discussion of Results

In this section, the features of

Figure 11,

Figure 12 and

Figure 13 and

Figure 15,

Figure 16 and

Figure 17 are further commented on, discussing the correlation between the temperature modulation and the expected influence of the Thermoelastic Effect. To better follow the discussion,

Figure 18 is proposed, showing the phase response of only the three harmonics at

ω, 2

ω and 3

ω.

It is undeniable that, under fatigue loading not involving an A⇄M transformation, i.e., under low-amplitude fatigue, the temperature is modulated by reversible thermomechanical heat sources. Moreover, this modulation seems to be strictly correlated with the load applied on the sample. It is also seen that an analysis of the harmonic response of temperature reveals several peculiar features which have the potential to identify the phase of the material (Austenite or Martensite) and the transformation fronts.

It remains to be established whether the mentioned features can be fully explained within the theoretical framework of Thermoelastic Stress Analysis, or if this is insufficient to interpret or model the whole picture.

The resuls in this work show that the temperature harmonic at

ω, 3

ω, and distinctly all other significant harmonics at odd multiples of

ω are always in phase with the corresponding displacement and load harmonics. This is so for both the Austenite and Martensite and at different mean stresses (e.g., for both C_up and C_down tests). This behaviour can only be justified by a second-order thermoelastic effect formulation expressed by the combination of Equation (8) and condition (9), i.e., when

dE/dT is positive and higher than the threshold indicated in Equation (9). By adopting data from the literature (see Equation (10)), though, it should come out that the harmonic amplitude at 2

ω should be of the same order of magnitude of the harmonic at

ω. Results in this work instead found that the 2

ω amplitude is at least two orders of magnitude smaller than the

ω amplitude (see, e.g.,

Figure 12 or

Figure 16). Furthermore, Equation (9) foresees that the harmonic at 2

ω should be a cosine wave with 0° phase if the harmonic at

ω is a cosine wave triggered (i.e., starting) at ±180° (see, e.g.,

Figure 3).

The outcome in terms of phases can be seen in

Figure 18. In this work, Austenite regions have a 2

ω phase that differs from 0° in the C_up test, and Martensite regions also have 2

ω phases different from 0° and consistently equal to ±180°.

In the C_up test, it was curiously observed that the harmonic at 2ω in the Austenite material is opposite in phase to the harmonic at 2ω of the load signal. This is a typical response expected from a first-order thermoelastic theory, which is in any case ruled out by the behaviour of the material at odd harmonics. Additionally, in the C_down test, the Austenite material had a phase value equal to the load, and at 0° as predicted by Equation (9).

The Martensite 2ω phase is instead always against the prediction of the second-order thermoelastic law (Equation (9)) and compliant with the first-order thermoelastic theory. Its 2ω harmonic had a ±180° phase shift at both C_up and C_down.

In general, the DFT on the load signal saw that the load had a significant second harmonic component at 2ω, which was not present in the machine-controlled displacement signal. This load component at 2ω likely arises from a non-linear material response.

In conclusion, there seems to be enough evidence that the Thermoelastic Effect theory and the thermoelastic heat source are not able to fully justify the amplitude and phase of the significant harmonics measured from the Austenite and Martensite regions.

As recalled in the introduction, some authors have tried to investigate the influence on the thermoelastic behaviour of an intermediate R-Type transformation between Austenite and Martensite. In [

23], it was shown that an A→R→M PT can be stress activated, leading to a reduction in the Young’s modulus before reaching the upper plateau of the M PT.

Here it can be observed that an intermediate R-Type transformation can also act as a further reversible thermomechanical heat source, due to the elastocaloric effect associated with this transformation. Some authors have investigated the thermomechanical behaviour of a A⇄R PT [

34,

35,

36]. It is reported that this transformation occurs homogeneously over the sample gauge area, unlike the Lüders-like behaviour of the A⇄M PT. Furthermore, a smaller reversible elastocaloric effect is present which produces a temperature increase in the loading A⇄R path, and a temperature decrease during the unloading R⇄A path. This is also in agreement with the observed in-phase relation between the load and temperature.

As this R-Type intermediate PT seems to deploy its effects in a reversible way and in a uniform and gradual manner, its effect can be modelled via the heat diffusion equation (see Equation (1)) and added as a thermomechanical heat source in the right-hand side of Equation (1). If all other thermomechanical heat sources are neglected and the temperature change occurs under adiabatic conditions, then Equation (1) may be rewritten as:

where

is the thermodynamic force associated with the internal variable

x, which describes the material PT of the R-type [

26]. It can be observed that Equation (15) is formally similar to Equation (2). Therefore, if an early A⇄R PT is present in the range of low-amplitude cycling loading, and it is assumed that

is positive, as the experimental evidence seems to suggest, then a relation formally similar to Equation (7) would be obtained as:

where the temperature change is correlated with the amount of R-phase transformation Δ

x via a positive

K3 coefficient. If the R-Type transformation level, Δ

x, is linearly correlated with the load, then the temperature will still be linearly correlated with the load and will follow the same waveform, as it seems to happen in NiTi under low-amplitude fatigue.

To validate the above assumptions, summarised in Equation (16), further specific tests will be required, which goes beyond the original purposes of this work. Future work is, however, being planned to also explore the role of intermediate R-Type transformations and their influence on the thermoelastic response of the material.

6. Conclusions

A tensile NiTi sample exhibiting a super-elastic behaviour at room temperature was tested under cyclic loading, applied via displacement controlled triangular wave. The applied displacements made it possible to introduce different macro regions of Austenite and Martensite, while the applied cyclic displacement ranges were sufficiently small to avoid further PT and freeze the existing transformation fronts.

Digital Image Correlation was used, making it possible to map the Austenite and Martensite regions, while temperature sampling with an IR camera made it possible to investigate the peculiar temperature modulation.

The frequency domain analysis proposed in this work was demonstrated to be highly informative, as the maps of amplitude and phase of the significant harmonics of temperature carry a signature of the material phase status and of the PT fronts. Future work will investigate how such features are reproduced when a bidimensional stress field is introduced by means of a stress raiser (e.g., holes, notches, cracks, etc.).

The temperature harmonics at the main loading frequency ω and at odd and even multiples of ω were obtained and compared against the theoretical predictions made via the first- and second-order theories of the Thermoelastic Effect. Results show that the measured temperature has a periodic modulation whose waveform seems to correlate well with the waveform of the applied load. Furthermore, the amplitude and phase maps of the harmonics at ω and 3ω show similar features, with the 3ω output just rescaled to lower values. The phase response at 2ω is instead different between the austenite and the martensite regions, and generally not compliant with the predictions of the second-order theory of the Thermoelastic Effect.

Further work is therefore needed to better characterise the nature of the reversible heat sources that determine the modulation of temperature under cyclic low-amplitude loadings of NiTi alloys. Future investigations by the authors will be specifically focused on the analysis of intermediate R-Type PTs, since various experimental and theoretical results show that this could play a significant role as a potential reversible thermomechanical heat source.